ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 781 of 1954

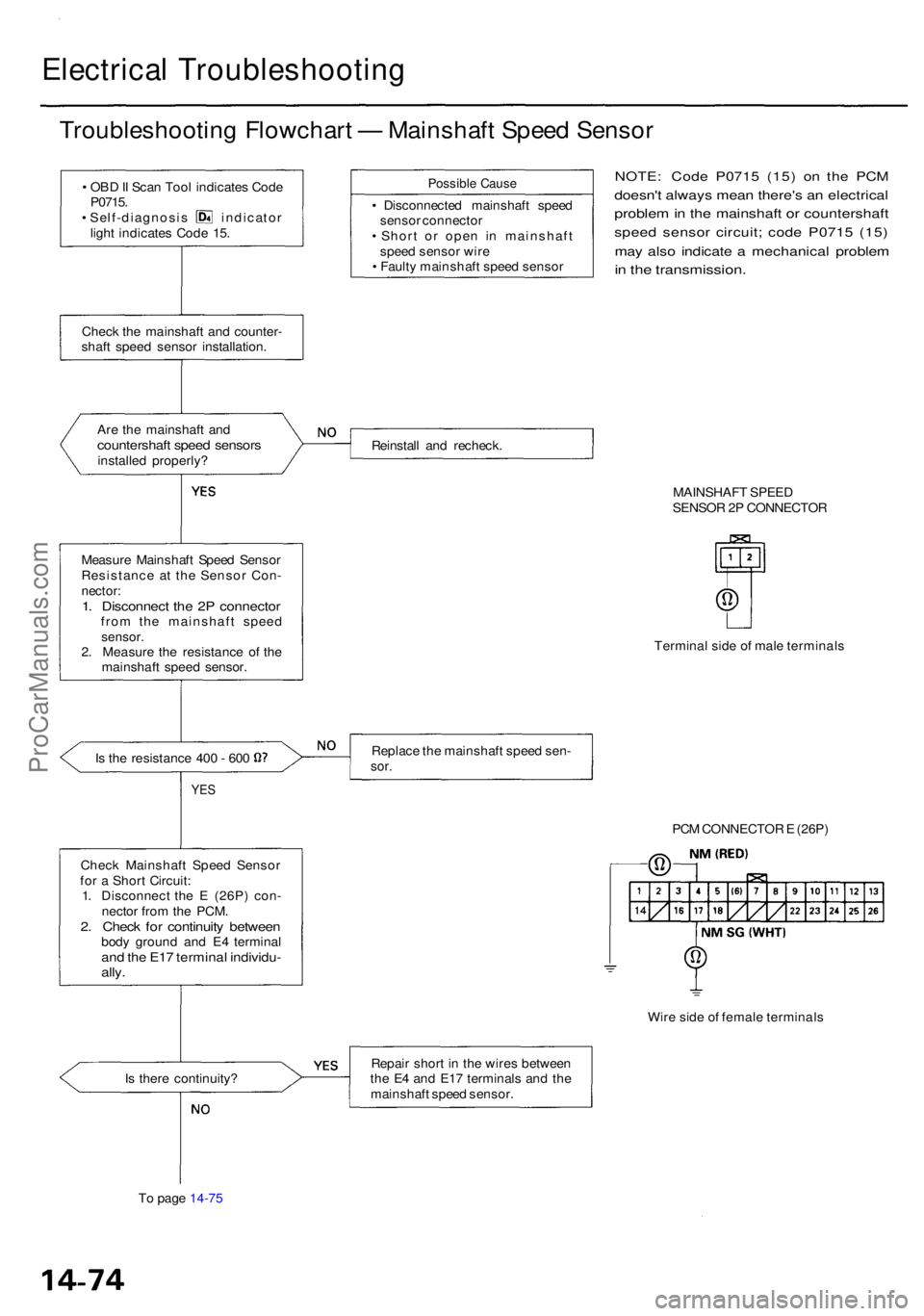

Electrical Troubleshootin g

Troubleshooting Flowchar t — Mainshaf t Spee d Senso r

• OB D II Sca n Too l indicate s Cod e

P0715 .

• Self-diagnosi s indicato r

ligh t indicate s Cod e 15 .

Chec k th e mainshaf t an d counter -

shaf t spee d senso r installation .

Ar e th e mainshaf t an d

countershaf t spee d sensor sinstalled properly ?

Measur e Mainshaf t Spee d Senso r

Resistanc e a t th e Senso r Con -

nector :1. Disconnec t th e 2 P connecto rfrom th e mainshaf t spee dsensor .2. Measur e th e resistanc e o f th e

mainshaf t spee d sensor .

Is th e resistanc e 40 0 - 60 0

YE S

Chec k Mainshaf t Spee d Senso r

fo r a Shor t Circuit :

1 . Disconnec t th e E (26P ) con -

necto r fro m th e PCM .

2. Chec k fo r continuit y betwee nbody groun d an d E 4 termina land th e E1 7 termina l individu -ally.

Possibl e Caus e

• Disconnecte d mainshaf t spee d

senso r connecto r

• Shor t o r ope n i n mainshaf t

spee d senso r wir e

• Fault y mainshaf t spee d senso r

NOTE: Cod e P071 5 (15 ) o n th e PC M

doesn' t alway s mea n there' s a n electrica l

problem in th e mainshaf t o r countershaf t

speed senso r circuit ; cod e P071 5 (15 )

may als o indicat e a mechanica l proble m

in th e transmission .

Reinstall an d recheck .

MAINSHAFT SPEE D

SENSO R 2P CONNECTO R

Termina l sid e o f mal e terminal s

Replac e th e mainshaf t spee d sen -

sor.

Wir e sid e o f femal e terminal s

I s ther e continuity ?

T o pag e 14-7 5 Repai

r shor t i n th e wire s betwee n

th e E 4 an d E1 7 terminal s an d th e

mainshaf t spee d sensor . PC

M CONNECTO R E (26P )

ProCarManuals.com

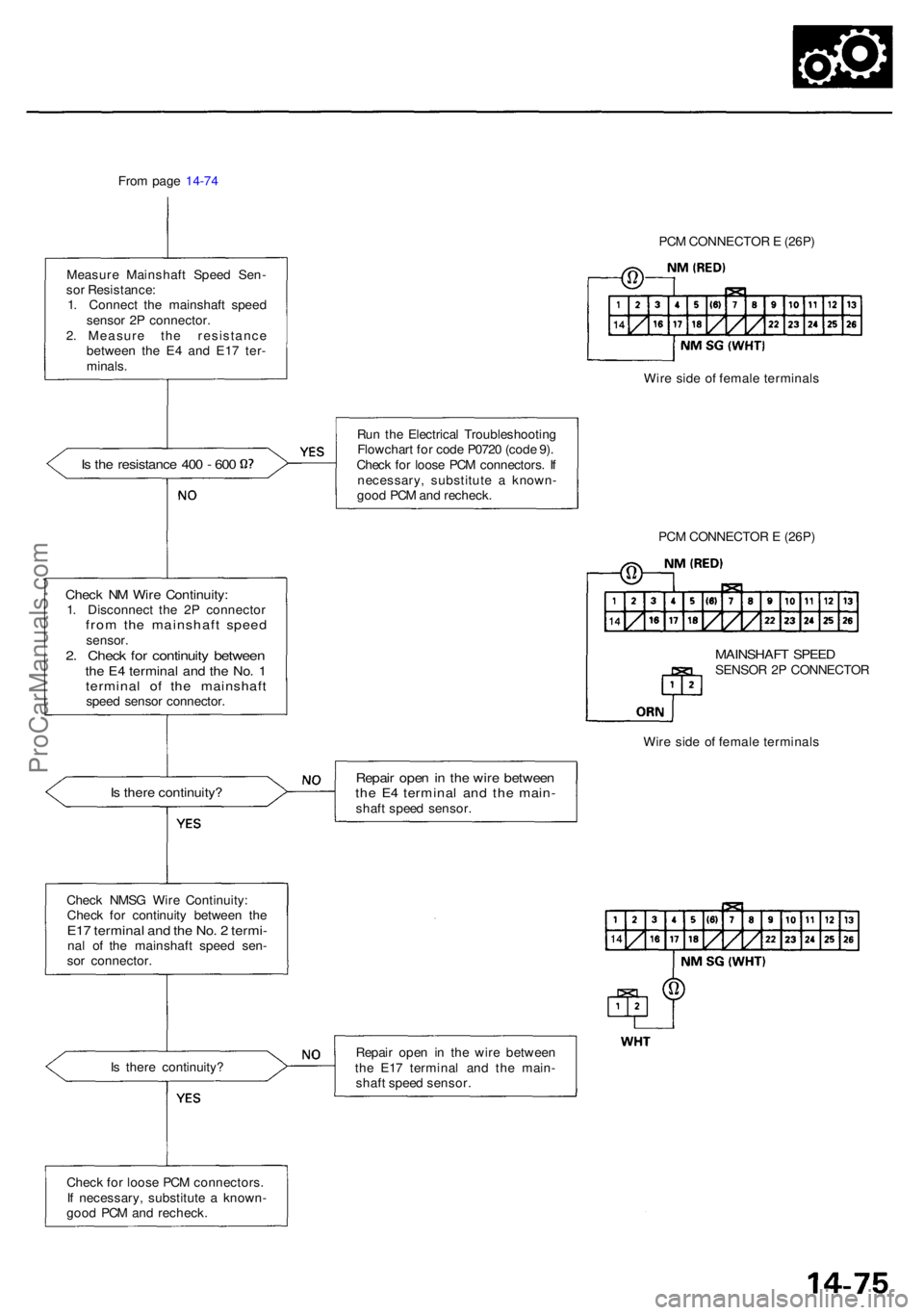

Page 782 of 1954

From pag e 14-7 4

Measur e Mainshaf t Spee d Sen -

so r Resistance :

1 . Connec t th e mainshaf t spee d

senso r 2 P connector .

2 . Measur e th e resistanc e

betwee n th e E 4 an d E1 7 ter -

minals .

Is th e resistanc e 40 0 - 60 0

Chec k N M Wir e Continuity :1. Disconnec t th e 2 P connecto rfrom th e mainshaf t spee dsensor .2. Chec k fo r continuit y betwee nthe E 4 termina l an d th e No . 1termina l o f th e mainshaf tspeed senso r connector .

Is ther e continuity ?

Check NMS G Wir e Continuity :

Chec k fo r continuit y betwee n th e

E17 termina l an d th e No . 2 termi -nal o f th e mainshaf t spee d sen -

so r connector . Wir

e sid e o f femal e terminal s

I s ther e continuity ?

Chec k fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck . Ru

n th e Electrica l Troubleshootin g

Flowchar t fo r cod e P072 0 (cod e 9) .

Chec k fo r loos e PC M connectors . I f

necessary , substitut e a known -

goo d PC M an d recheck .

MAINSHAF T SPEE DSENSO R 2 P CONNECTO R

Wir e sid e o f femal e terminal s

Repair ope n in th e wir e betwee nthe E 4 termina l an d th e main -shaft spee d sensor .

Repai r ope n i n th e wir e betwee n

th e E1 7 termina l an d th e main -

shaf t spee d sensor . PC

M CONNECTO R E (26P )

PC M CONNECTO R E (26P )

ProCarManuals.com

Page 783 of 1954

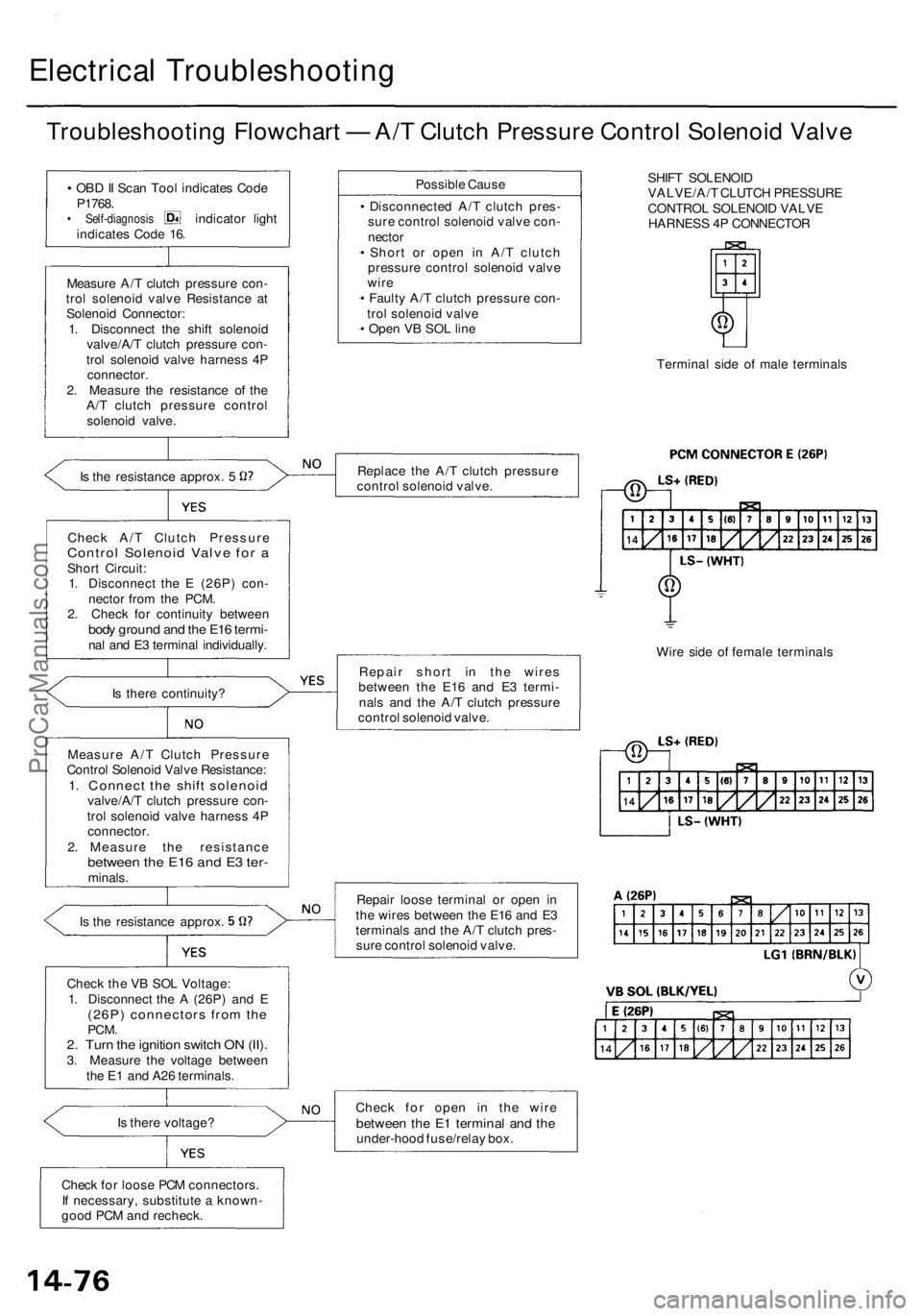

Electrical Troubleshootin g

Troubleshooting Flowchar t — A/ T Clutc h Pressur e Contro l Solenoi d Valv e

• OB D II Sca n Too l indicate s Cod e

P1768 .

• Self-diagnosi s indicator ligh t

indicate s Cod e 16 .

Measur e A/ T clutc h pressur e con -

tro l solenoi d valv e Resistanc e a t

Solenoi d Connector :

1 . Disconnec t th e shif t solenoi d

valve/A/ T clutc h pressur e con -

tro l solenoi d valv e harnes s 4 P

connector .

2 . Measur e th e resistanc e o f th e

A/ T clutc h pressur e contro l

solenoi d valve .

Is th e resistanc e approx . 5

Chec k A/ T Clutc h Pressur e

Control Solenoi d Valv e fo r aShor t Circuit :

1 . Disconnec t th e E (26P ) con -

necto r fro m th e PCM .

2 . Chec k fo r continuit y betwee n

body groun d an d th e E1 6 termi -nal an d E 3 termina l individually .

I s ther e continuity ?

Is th e resistanc e approx .

Chec k th e V B SO L Voltage :

1 . Disconnec t th e A (26P ) an d E

(26P ) connector s fro m th ePCM .2. Tur n th e ignitio n switc h O N (II) .3. Measur e th e voltag e betwee n

th e E 1 an d A2 6 terminals .

I s ther e voltage ?

Chec k fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck . Possibl

e Caus e

• Disconnecte d A/ T clutc h pres -

sur e contro l solenoi d valv e con -

necto r

• Shor t o r ope n i n A/ T clutc h

pressur e contro l solenoi d valv e

wir e

• Fault y A/ T clutc h pressur e con -

tro l solenoi d valv e

• Ope n V B SO L lin e

Replac e th e A/ T clutc h pressur e

contro l solenoi d valve .

Repai r shor t i n th e wire s

betwee n th e E1 6 an d E 3 termi -

nal s an d th e A/ T clutc h pressur e

contro l solenoi d valve .

Repai r loos e termina l o r ope n i n

th e wire s betwee n th e E1 6 an d E 3

terminal s an d th e A/ T clutc h pres -

sur e contro l solenoi d valve .

Chec k fo r ope n i n th e wir e

betwee n th e E 1 termina l an d th eunder-hoo d fuse/rela y box . SHIF

T SOLENOI D

VALVE/A/ T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV E

HARNES S 4 P CONNECTO R

Termina l sid e o f mal e terminal s

Wir e sid e o f femal e terminal s

Measur e A/ T Clutc h Pressur e

Contro l Solenoi d Valv e Resistance :

1. Connec t th e shif t solenoi dvalve/A/T clutc h pressur e con -

tro l solenoi d valv e harnes s 4 P

connector .

2 . Measur e th e resistanc e

between th e E1 6 an d E 3 ter -minals .

ProCarManuals.com

Page 784 of 1954

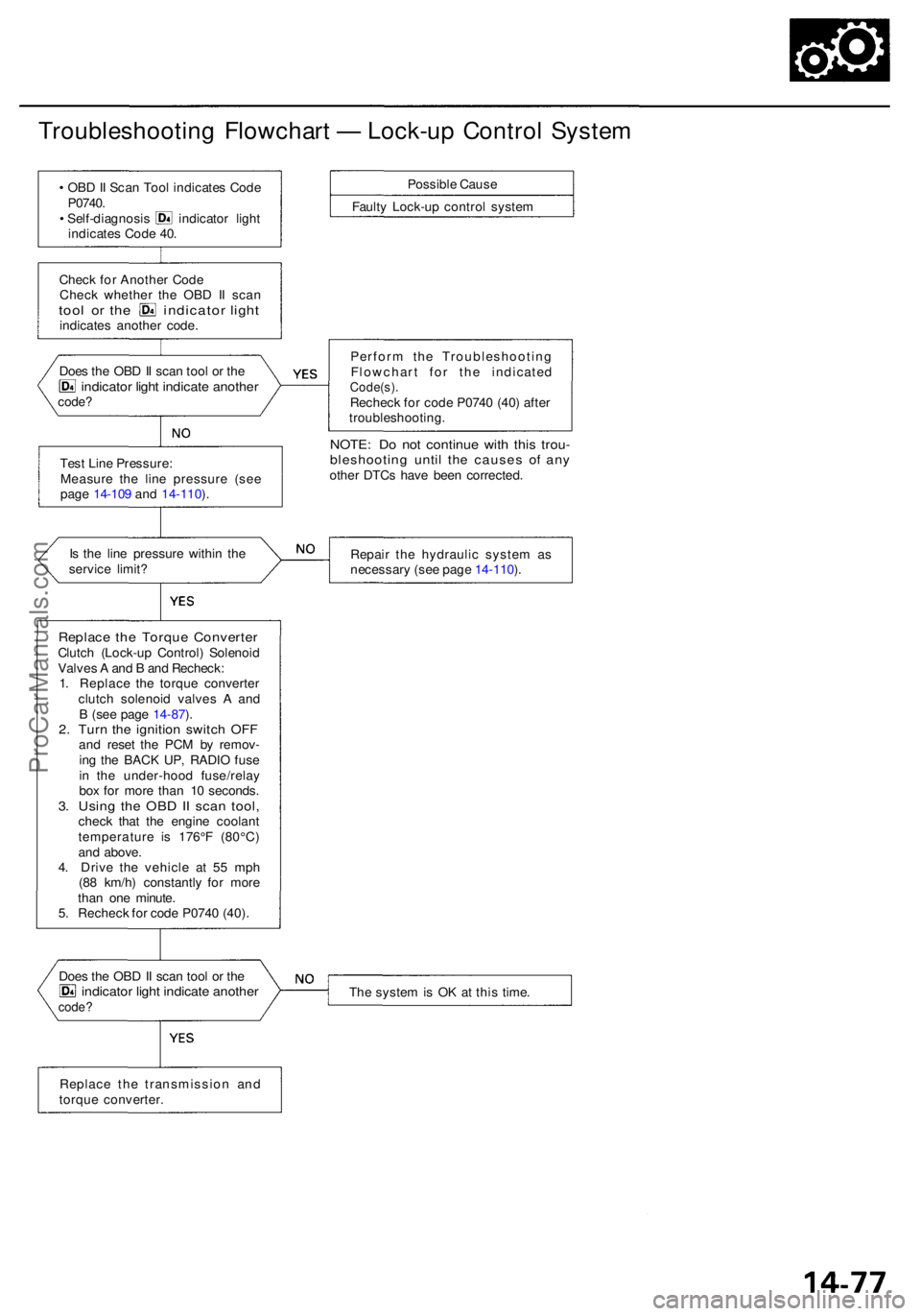

Troubleshooting Flowchar t — Lock-u p Contro l Syste m

• OB D II Sca n Too l indicate s Cod e

P0740 .

• Self-diagnosi s indicato r ligh t

indicate s Cod e 40 .

Chec k fo r Anothe r Cod e

Chec k whethe r th e OB D I I sca n

tool o r th e indicato r ligh tindicate s anothe r code .

Tes t Lin e Pressure :

Measur e th e lin e pressur e (se e

pag e 14-10 9 an d 14-110 ).

I s th e lin e pressur e withi n th e

servic e limit ?

Replac e the Torqu e Converte rClutch (Lock-u p Control ) Solenoi d

Valve s A an d B an d Recheck :

1 . Replac e th e torqu e converte r

clutc h solenoi d valve s A an d

B (se e pag e 14-87 ).

2 . Tur n th e ignitio n switc h OF Fand rese t th e PC M b y remov -

in g th e BAC K UP , RADI O fus e

i n th e under-hoo d fuse/rela y

bo x fo r mor e tha n 1 0 seconds .

3. Usin g th e OB D II sca n tool ,check tha t th e engin e coolan t

temperatur e i s 176° F (80°C )

an d above .

4 . Driv e th e vehicl e a t 5 5 mp h

(8 8 km/h ) constantl y fo r mor e

tha n on e minute .

5 . Rechec k fo r cod e P074 0 (40) .

Doe s th e OB D II sca n too l o r th e

indicato r ligh t indicat e anothe rcode?

Possibl e Caus e

Fault y Lock-u p contro l syste m

Perfor m th e Troubleshootin g

Flowchar t fo r th e indicate d

Code(s).Recheck fo r cod e P074 0 (40 ) afte r

troubleshooting .

NOTE: D o no t continu e wit h thi s trou -bleshootin g unti l th e cause s o f an yothe r DTC s hav e bee n corrected .

Repai r th e hydrauli c syste m a s

necessar y (se e pag e 14-110 ).

Th e syste m is O K a t thi s time .

Doe

s th e OB D II sca n too l o r th e

indicato r ligh t indicat e anothe rcode?

Replac e th e transmissio n an d

torqu e converter .

ProCarManuals.com

Page 785 of 1954

Electrical Troubleshootin g

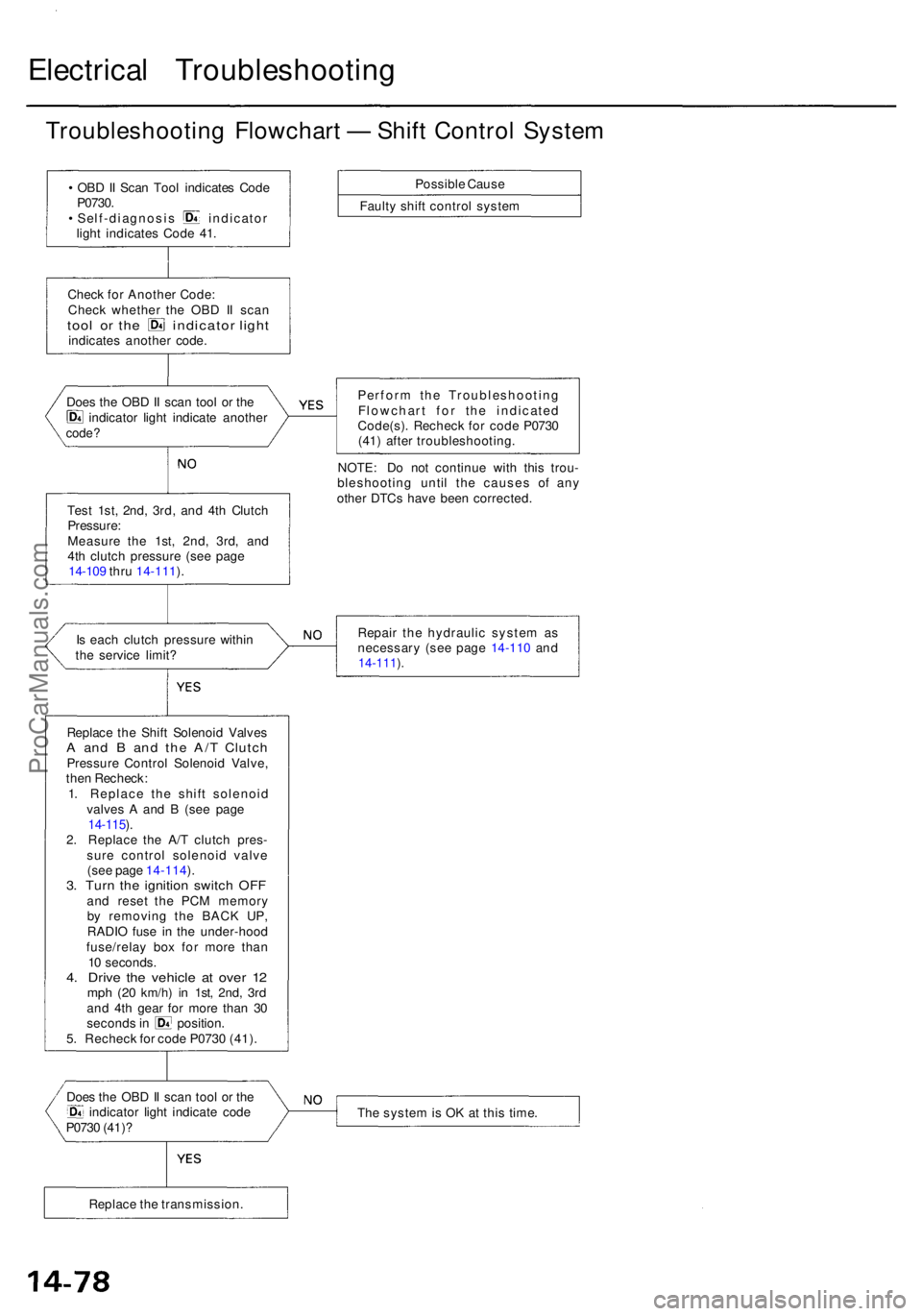

Troubleshooting Flowchar t — Shif t Contro l Syste m

• OB D II Sca n Too l indicate s Cod eP0730 .• Self-diagnosi s indicato r

ligh t indicate s Cod e 41 .

Chec k fo r Anothe r Code :

Chec k whethe r th e OB D I I sca n

tool o r th e indicato r ligh tindicate s anothe r code .

Doe s th e OB D II sca n too l o r th e

indicato r ligh t indicat e anothe rcode?

Test 1st , 2nd , 3rd , an d 4t h Clutc h

Pressure :

Measur e th e 1st , 2nd , 3rd , an d

4t h clutc h pressur e (se e pag e

14-10 9 thr u 14-111 ).

I s eac h clutc h pressur e within

th e servic e limit ?

Replac e th e Shif t Solenoi d Valve s

A an d B an d th e A/ T Clutc hPressur e Contro l Solenoi d Valve ,

the n Recheck :

1 . Replac e th e shif t solenoi d

valve s A an d B (se e pag e

14-115 ).2 . Replac e th e A/ T clutc h pres -

sur e contro l solenoi d valv e

(se e pag e 14-114 ).

3 . Tur n th e ignitio n switc h OF Fand rese t th e PC M memor y

b y removin g th e BAC K UP ,

RADI O fus e i n th e under-hoo d

fuse/rela y bo x fo r mor e tha n

1 0 seconds .

4. Driv e th e vehicl e a t ove r 1 2mp h (2 0 km/h ) in 1st , 2nd , 3rdand 4t h gea r fo r mor e tha n 3 0second s in position .

5 . Rechec k fo r cod e P073 0 (41) .

Doe s th e OB D II sca n too l o r th e

indicato r ligh t indicat e cod e

P073 0 (41) ? Possibl

e Caus e

Fault y shif t contro l syste m

Perfor m th e Troubleshootin g

Flowchar t fo r th e indicate d

Code(s) . Rechec k fo r cod e P073 0

(41 ) afte r troubleshooting .

NOTE : D o no t continu e wit h thi s trou -

bleshootin g unti l th e cause s o f an y

othe r DTC s hav e bee n corrected .

Repai r th e hydrauli c syste m a s

necessar y (se e pag e 14-11 0 an d

14-111 ).

Th e syste m is O K a t thi s time .

Replac e th e transmission .

ProCarManuals.com

Page 786 of 1954

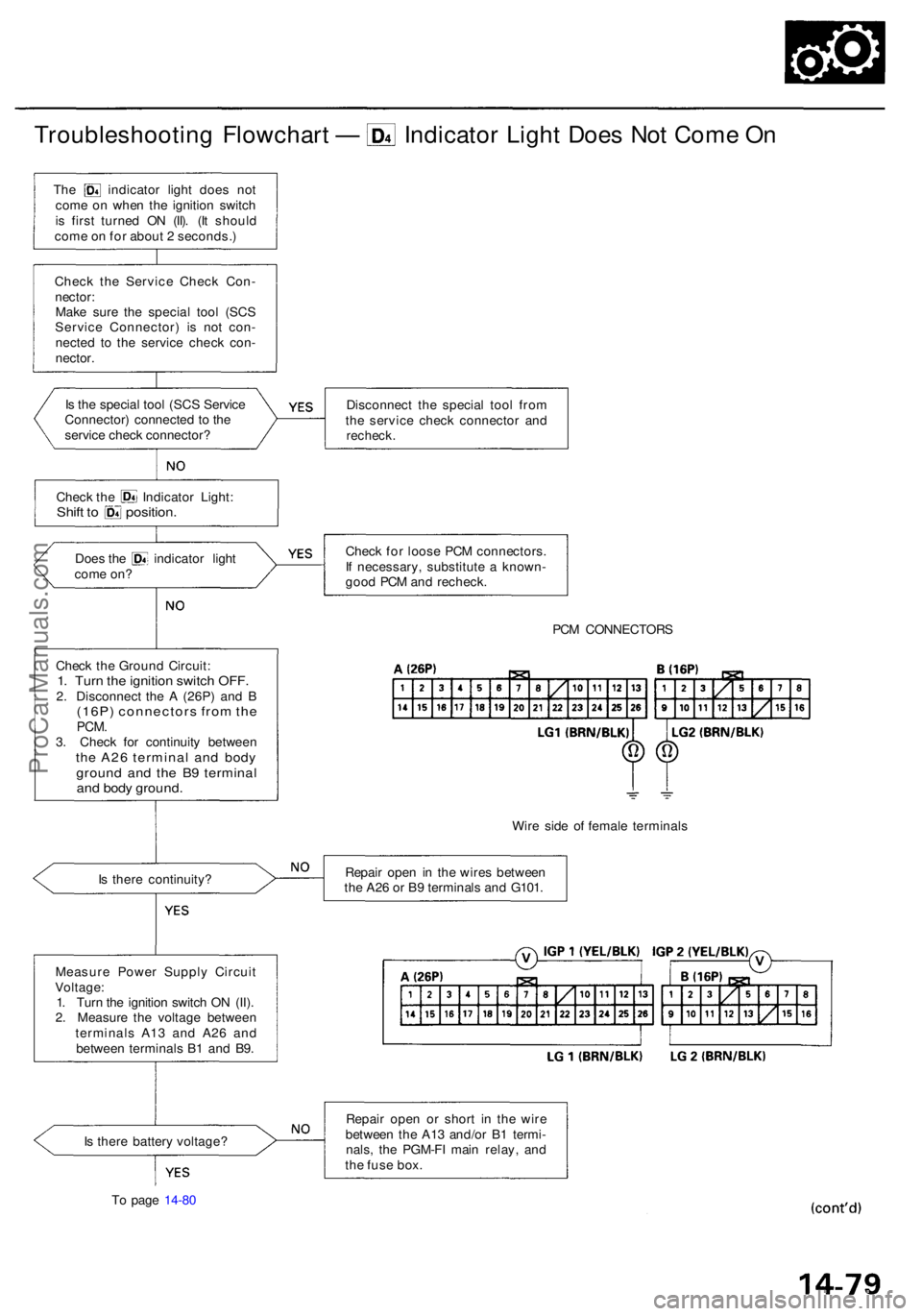

Troubleshooting Flowchar t — Indicato r Ligh t Doe s No t Com e O n

Is th e specia l too l (SC S Servic e

Connector ) connecte d t o th e

servic e chec k connector ?

Check th e Indicato r Light :Shift t o position .

Does th e indicato r ligh t

com e on ?

Chec k th e Groun d Circuit :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e A (26P ) an d B(16P ) connector s fro m th ePCM .3. Chec k fo r continuit y betwee nthe A2 6 termina l an d bod ygroun d an d th e B 9 termina land bod y ground .

Is ther e continuity ?

Measur e Powe r Suppl y Circui t

Voltage :

1 . Tur n th e ignitio n switc h O N (II) .

2 . Measur e th e voltag e betwee n

terminal s A1 3 an d A2 6 an d

betwee n terminal s B 1 an d B9 .

I s ther e batter y voltage ?

T o pag e 14-8 0 Disconnec

t th e specia l too l fro m

th e servic e chec k connecto r an d

recheck .

Check fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck .

PCM CONNECTOR S

Wir e sid e o f femal e terminal s

Repai r ope n i n th e wire s betwee n

th e A2 6 o r B 9 terminal s an d G101 .

Repai r ope n o r shor t i n th e wir e

betwee n th e A1 3 and/o r B 1 termi -

nals , th e PGM-F I mai n relay , an d

th e fus e box .

The indicato r ligh t doe s no t

com e o n whe n th e ignitio n switc h

i s firs t turne d O N (II) . (I t shoul d

com e o n fo r abou t 2 seconds. )

Chec k th e Servic e Chec k Con -

nector :

Mak e sur e th e specia l too l (SC S

Servic e Connector ) i s no t con -

necte d t o th e servic e chec k con -

nector .

ProCarManuals.com

Page 787 of 1954

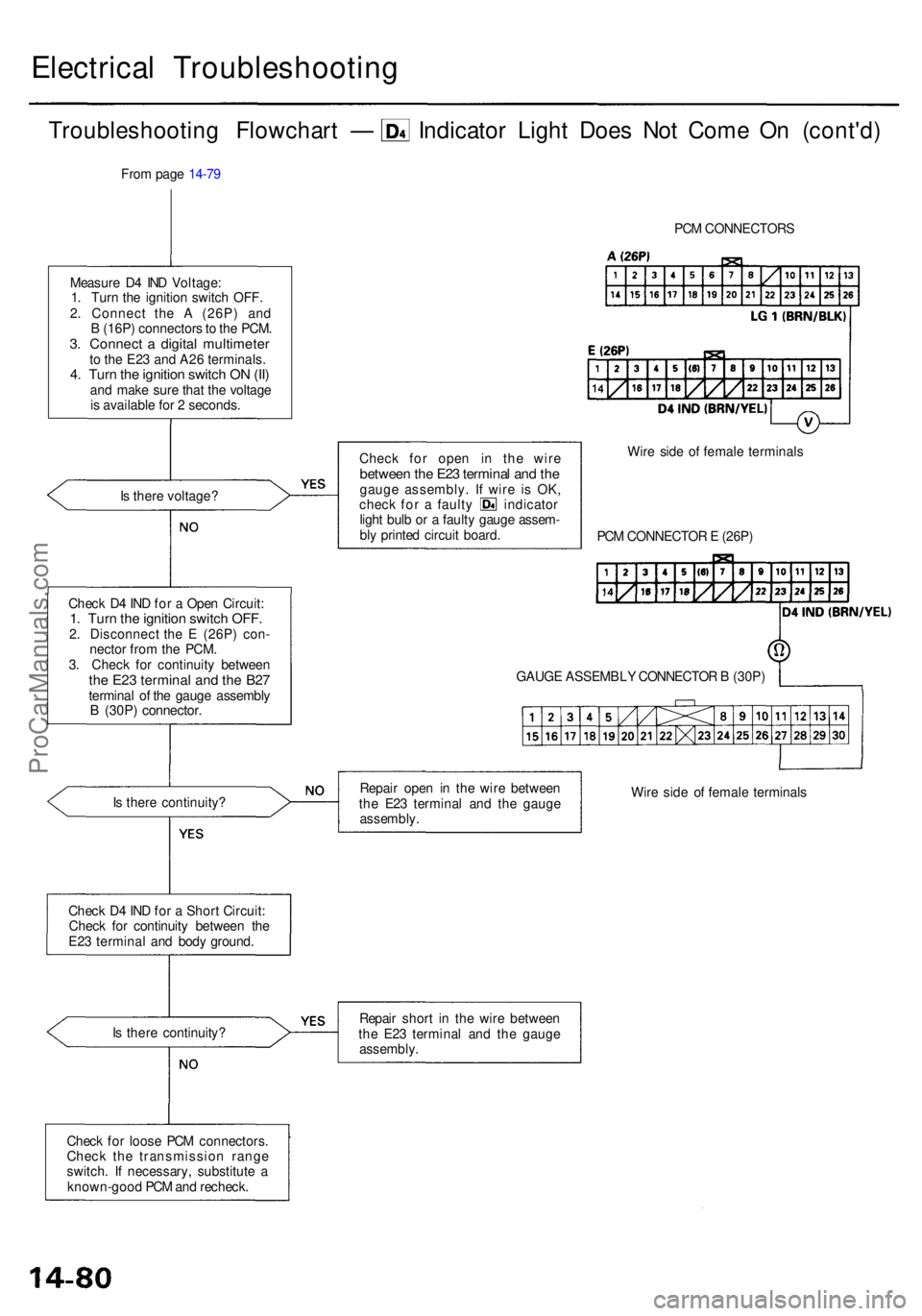

Electrical Troubleshootin g

Troubleshooting Flowchar t — Indicato r Ligh t Doe s No t Com e O n (cont'd )

Measure D 4 IN D Voltage :

1 . Tur n th e ignitio n switc h OFF .

2 . Connec t th e A (26P ) an d

B (16P ) connector s to th e PCM .

3. Connec t a digita l multimete rto th e E2 3 an d A2 6 terminals .4. Tur n th e ignitio n switc h O N (II )an d mak e sur e tha t th e voltag e

i s availabl e fo r 2 seconds .

I s ther e voltage ?

Chec k D 4 IN D fo r a Ope n Circuit :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e E (26P ) con -

necto r fro m th e PCM .

3 . Chec k fo r continuit y betwee n

the E2 3 termina l an d th e B2 7termina l o f th e gaug e assembl yB (30P ) connector .

Is ther e continuity ?

Chec k D 4 IN D fo r a Shor t Circuit :

Chec k fo r continuit y betwee n th e

E2 3 termina l an d bod y ground .

I s ther e continuity ? PC

M CONNECTOR S

Chec k fo r ope n i n th e wir e

betwee n th e E2 3 termina l an d th egaug e assembly . I f wir e i s OK ,chec k fo r a fault y indicato r

ligh t bul b o r a fault y gaug e assem -

bl y printe d circui t board . Wir

e sid e o f femal e terminal s

PC M CONNECTO R E (26P )

GAUG E ASSEMBL Y CONNECTO R B (30P )

Repai r shor t i n th e wir e betwee n

th e E2 3 termina l an d th e gaug e

assembly .

Fro

m pag e 14-7 9

Chec k fo r loos e PC M connectors .

Chec k th e transmissio n rang e

switch . I f necessary , substitut e a

known-goo d PC M an d recheck . Wir

e sid e o f femal e terminal s

Repai

r ope n i n th e wir e betwee n

th e E2 3 termina l an d th e gaug e

assembly .

ProCarManuals.com

Page 788 of 1954

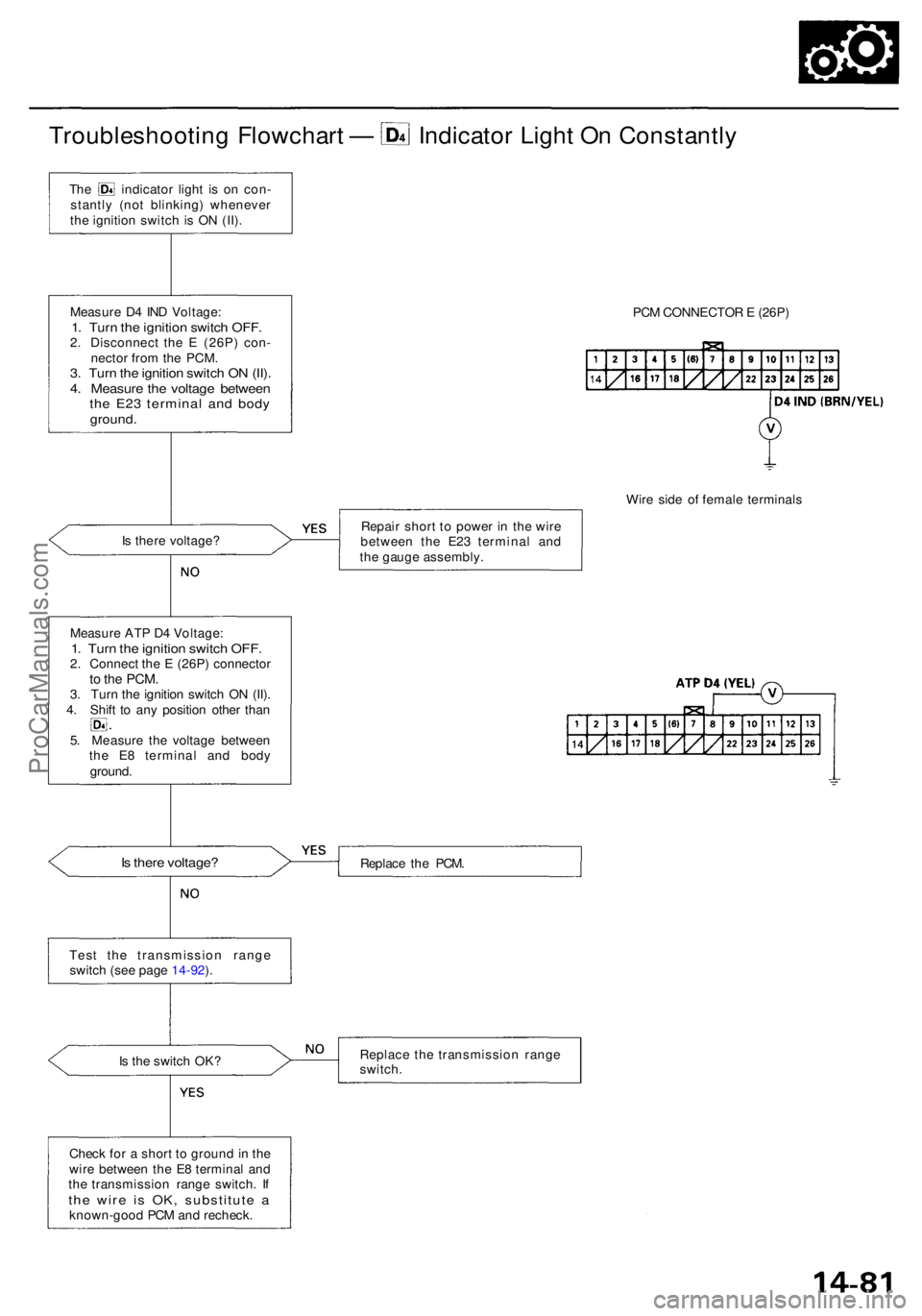

Troubleshooting Flowchar t — Indicato r Ligh t O n Constantl y

The indicato r ligh t i s o n con -

stantl y (no t blinking ) wheneve r

th e ignitio n switc h is O N (II) .

Measur e D 4 IN D Voltage :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e E (26P ) con -

necto r fro m th e PCM .

3. Tur n th e ignitio n switc h O N (II) .4. Measur e th e voltag e betwee nthe E2 3 termina l an d bod yground .

Is ther e voltage ?

Measur e AT P D 4 Voltage :

1. Tur n th e ignitio n switc h OFF .2. Connec t th e E (26P ) connecto rto th e PCM .3. Tur n th e ignitio n switc h O N (II) .4. Shif t t o an y positio n othe r tha n

5 . Measur e th e voltag e betwee n

th e E 8 termina l an d bod y

ground .

Is ther e voltage ?

Test th e transmissio n rang e

switc h (se e pag e 14-92 ).

I s th e switc h OK ?

Chec k fo r a shor t t o groun d in th e

wir e betwee n th e E 8 termina l an d

th e transmissio n rang e switch . I f

th e wir e i s OK , substitut e aknown-goo d PC M an d recheck . PC

M CONNECTO R E (26P )

Wir e sid e o f femal e terminal s

Repai r shor t t o powe r i n th e wir e

betwee n th e E2 3 termina l an d

th e gaug e assembly .

Replac e th e PCM .

Replac e th e transmissio n rang e

switch .

ProCarManuals.com

Page 789 of 1954

Electrical Troubleshootin g

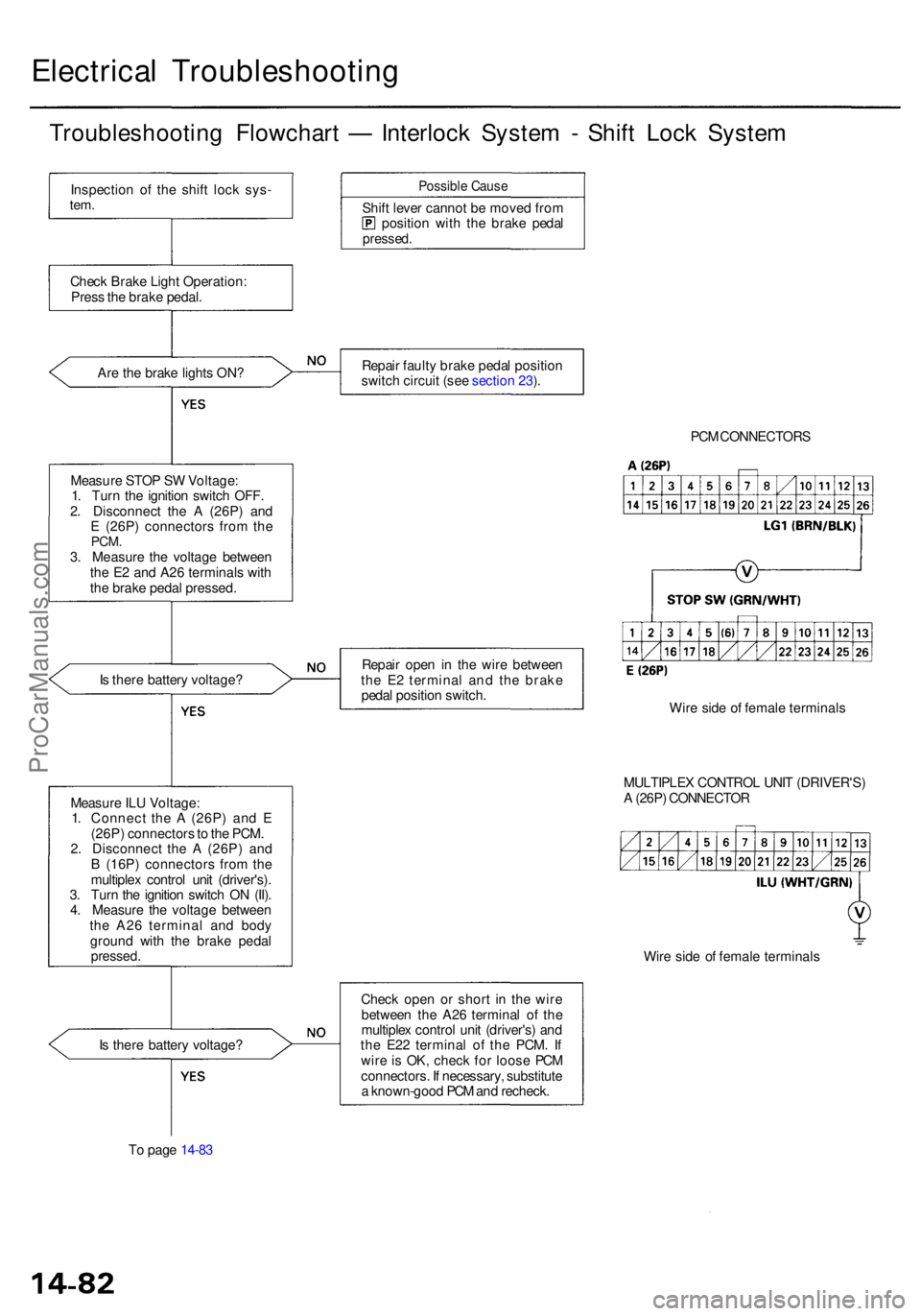

Troubleshooting Flowchar t — Interloc k Syste m - Shif t Loc k Syste m

Inspectio n o f th e shif t loc k sys -tem.

Chec k Brak e Ligh t Operation :

Pres s th e brak e pedal .

Ar e th e brak e light s ON ?

Measur e STO P S W Voltage :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e A (26P ) an d

E (26P ) connector s fro m th e

PCM .3. Measur e th e voltag e betwee n

th e E 2 an d A2 6 terminal s wit h

th e brak e peda l pressed .

I s ther e batter y voltage ?

I s ther e batter y voltage ?

T o pag e 14-8 3

Possibl e Caus e

Shift leve r canno t b e move d fro mpositio n wit h th e brak e peda lpressed .

Repair fault y brak e peda l positio n

switc h circui t (se e sectio n 23 ).

Repai r ope n i n th e wir e betwee n

th e E 2 termina l an d the brak e

peda l positio n switch .

Chec k ope n o r shor t i n th e wir e

betwee n th e A2 6 termina l o f th e

multiple x contro l uni t (driver's ) an d

th e E2 2 termina l o f th e PCM . I f

wir e i s OK , chec k fo r loos e PC M

connectors . I f necessary , substitut e

a known-goo d PC M an d recheck . PC

M CONNECTOR S

Wir e sid e o f femal e terminal s

MULTIPLE X CONTRO L UNI T (DRIVER'S )

A (26P ) CONNECTO R

Wir e sid e o f femal e terminal s

Measur

e IL U Voltage :

1 . Connec t th e A (26P ) an d E

(26P ) connector s to th e PCM .

2 . Disconnec t th e A (26P ) an d

B (16P ) connector s fro m th e

multiple x contro l uni t (driver's) .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e th e voltag e betwee n

th e A2 6 termina l an d bod y

groun d wit h th e brak e peda l

pressed .

ProCarManuals.com

Page 790 of 1954

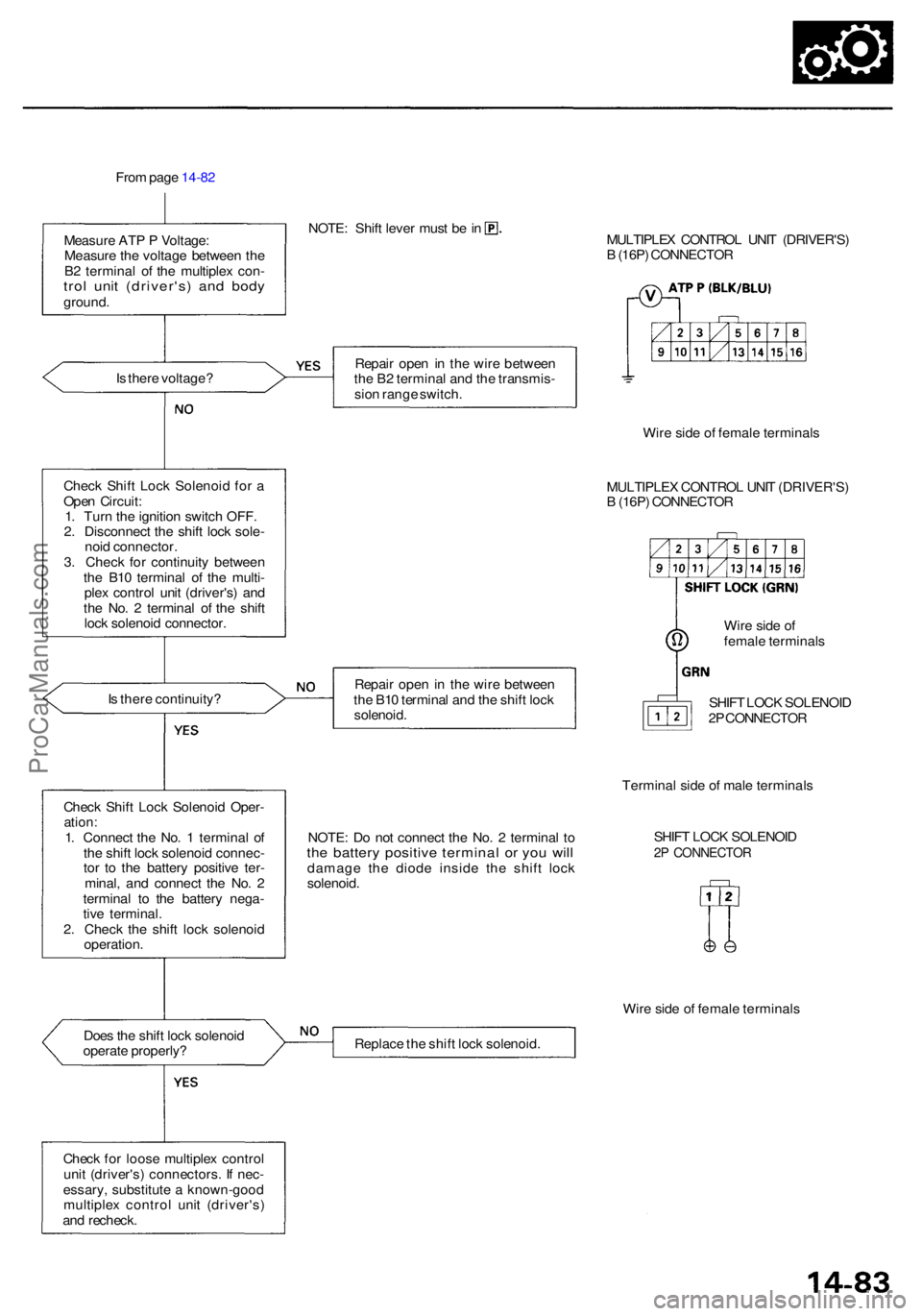

From pag e 14-8 2

Measur e AT P P Voltage :

Measur e th e voltag e betwee n th e

B 2 termina l o f th e multiple x con -

trol uni t (driver's ) an d bod yground .

NOTE: Shif t leve r mus t b e in

MULTIPLEX CONTRO L UNI T (DRIVER'S )

B (16P ) CONNECTO R

I s ther e voltage ?

Chec k Shif t Loc k Solenoi d fo r a

Ope n Circuit :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e shif t loc k sole -

noi d connector .

3 . Chec k fo r continuit y betwee n

th e B1 0 termina l o f th e multi -

ple x contro l uni t (driver's ) an d

th e No . 2 termina l o f th e shif t

loc k solenoi d connector .

I s ther e continuity ?

Doe s th e shif t loc k solenoi d

operat e properly ?

Chec k fo r loos e multiple x contro l

uni t (driver's ) connectors . I f nec -

essary , substitut e a known-goo d

multiple x contro l uni t (driver's )

an d recheck . Repai

r ope n in th e wir e betwee n

th e B 2 termina l an d th e transmis -

sio n rang e switch .

Wire sid e o f femal e terminal s

MULTIPLE X CONTRO L UNI T (DRIVER'S )

B (16P ) CONNECTO R

Wir e sid e o f

femal e terminal s

Repai r ope n in th e wir e betwee n

th e B1 0 termina l an d th e shif t loc k

solenoid .

NOTE: D o no t connec t th e No . 2 termina l t oth e batter y positiv e termina l o r yo u wil ldamag e th e diod e insid e th e shif t loc k

solenoid . SHIF

T LOC K SOLENOI D

2 P CONNECTO R

Termina l sid e o f mal e terminal s

SHIF T LOC K SOLENOI D2P CONNECTO R

Wire sid e o f femal e terminal s

Replac e th e shif t loc k solenoid .

Chec

k Shif t Loc k Solenoi d Oper -

ation:1. Connec t th e No . 1 termina l o f

th e shif t loc k solenoi d connec -

to r t o th e batter y positiv e ter -

minal , an d connec t th e No . 2

termina l t o th e batter y nega -

tiv e terminal .

2 . Chec k th e shif t loc k solenoid

operation .

ProCarManuals.com