ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 791 of 1954

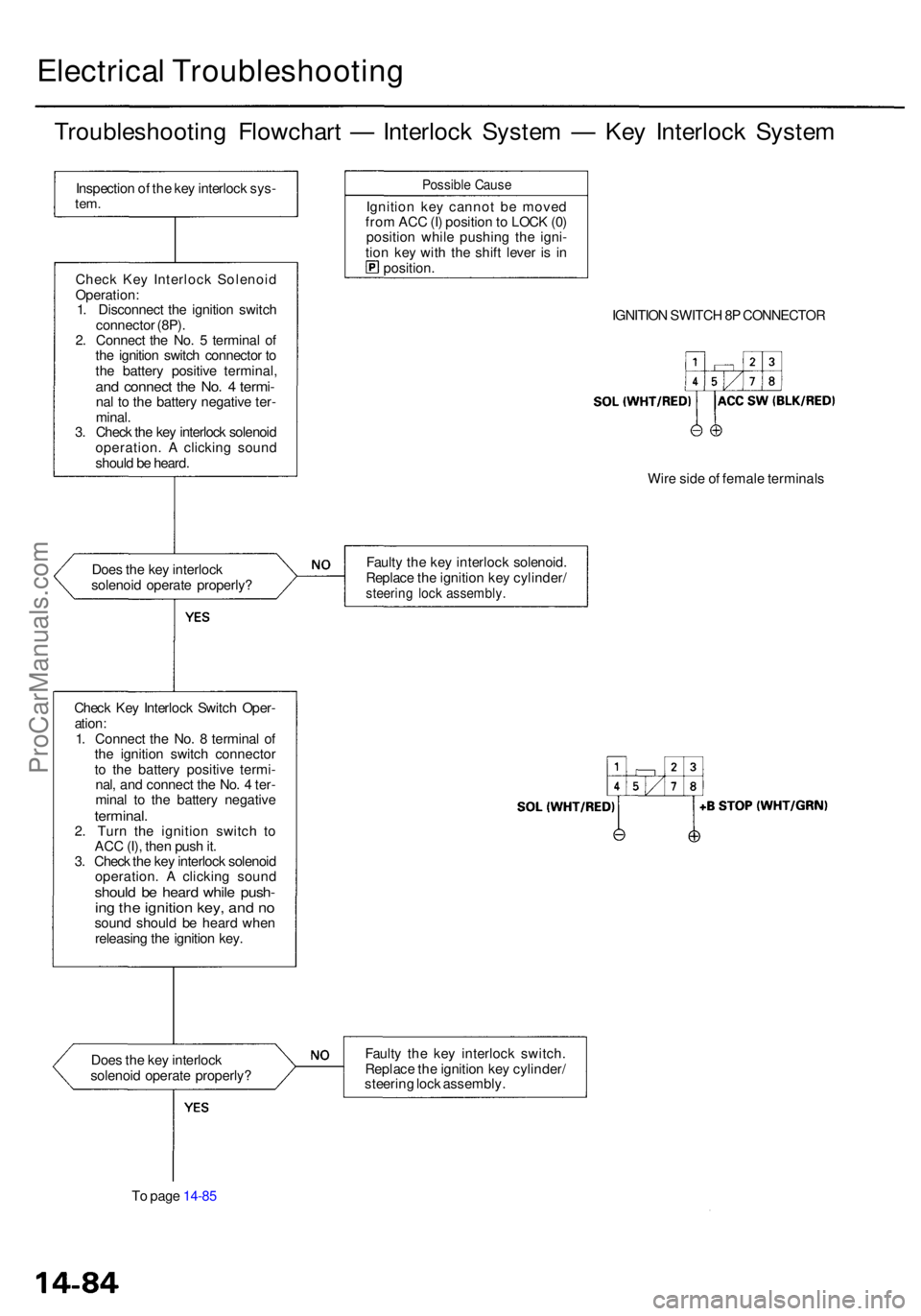

Electrical Troubleshootin g

Troubleshooting Flowchar t — Interloc k Syste m — Ke y Interloc k Syste m

Inspectio n o f th e ke y interloc k sys -tem.

Chec k Ke y Interloc k Solenoi d

Operation :

1 . Disconnec t th e ignitio n switc h

connecto r (8P) .

2 . Connec t th e No . 5 termina l o f

th e ignitio n switc h connecto r t o

th e batter y positiv e terminal ,

and connec t th e No . 4 termi -nal t o th e batter y negativ e ter -

minal .

3 . Chec k th e ke y interloc k solenoi d

operation . A clickin g soun d

shoul d b e heard .

Doe s th e ke y interloc k

solenoi d operat e properly ?

Chec k Ke y Interloc k Switc h Oper -

ation :

1 . Connec t th e No . 8 termina l o f

th e ignitio n switc h connecto r

t o th e batter y positiv e termi -

nal , an d connec t th e No . 4 ter -

mina l t o th e batter y negativ e

terminal.2. Tur n th e ignitio n switc h t o

AC C (I) , the n pus h it .

3 . Chec k th e ke y interloc k solenoi d

operation . A clickin g soun d

should b e hear d whil e push -ing th e ignitio n key , an d n osoun d shoul d b e hear d whe n

releasin g th e ignitio n key .

Doe s th e ke y interloc k

solenoi d operat e properly ?

T o pag e 14-8 5

Possibl e Caus e

Ignitio n ke y canno t b e move d

fro m AC C (I ) positio n to LOC K (0 )

positio n whil e pushin g th e igni -

tio n ke y wit h th e shif t leve r i s in

position .

IGNITION SWITC H 8P CONNECTO R

Wir e sid e o f femal e terminal s

Fault y th e ke y interloc k solenoid .

Replac e th e ignitio n ke y cylinder /

steering loc k assembly .

Faulty th e ke y interloc k switch .

Replac e th e ignitio n ke y cylinder /

steerin g loc k assembly .

ProCarManuals.com

Page 792 of 1954

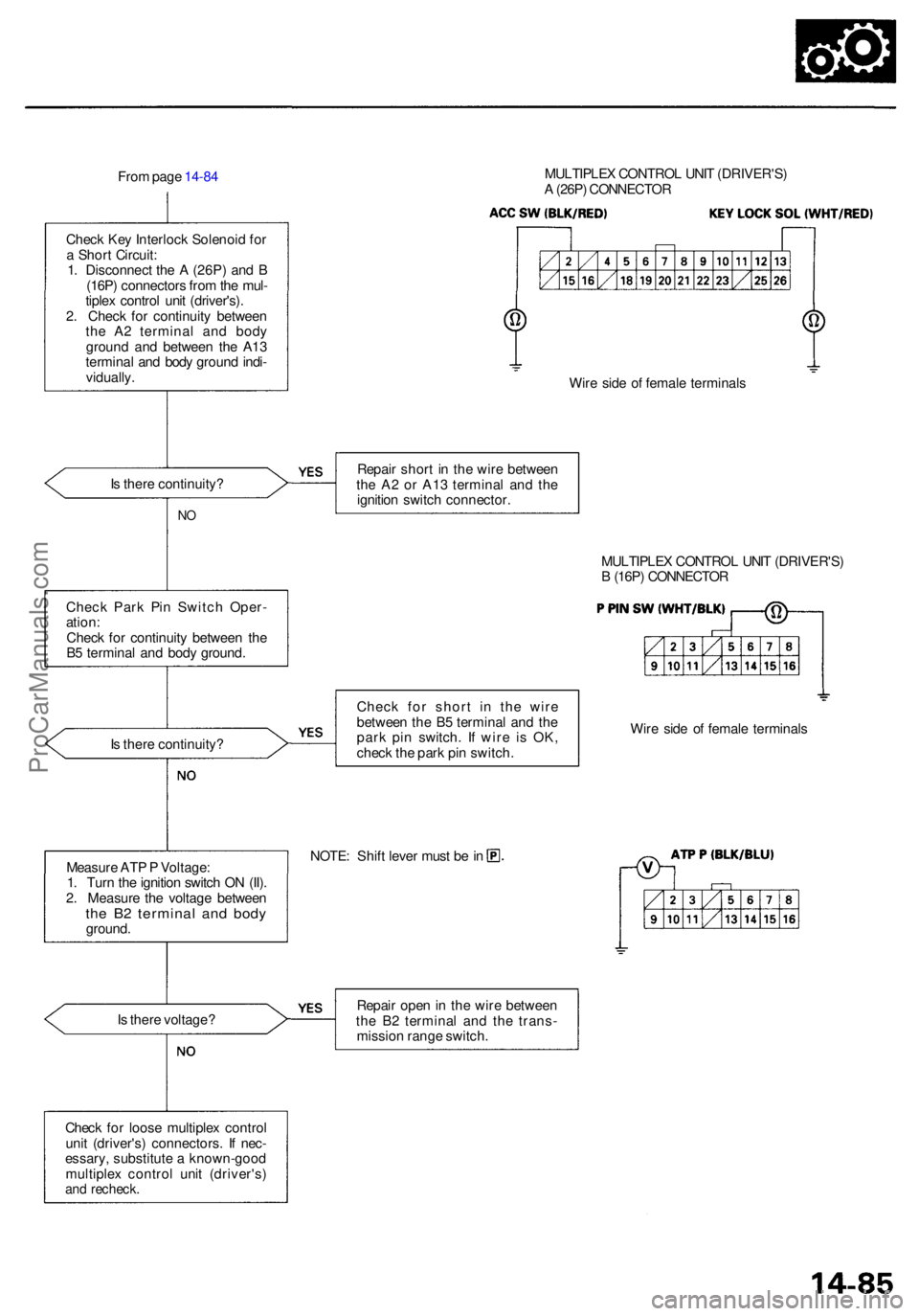

From pag e 14-8 4 MULTIPLE

X CONTRO L UNI T (DRIVER'S )

A (26P ) CONNECTO R

Wir e sid e o f femal e terminal s

I s ther e continuity ?

NO

Repai r shor t i n th e wir e betwee n

th e A 2 o r A1 3 termina l an d th e

ignitio n switc h connector .

MULTIPLEX CONTRO L UNI T (DRIVER'S )

B (16P ) CONNECTO R

I s ther e continuity ? Chec

k fo r shor t i n th e wir e

betwee n th e B 5 termina l an d th e

par k pi n switch . I f wir e i s OK ,

chec k th e par k pi n switch . Wir

e sid e o f femal e terminal s

Measur e AT P P Voltage :

1 . Tur n th e ignitio n switc h O N (II) .

2 . Measur e th e voltag e betwee n

the B 2 termina l an d bod yground .

NOTE: Shif t leve r mus t b e in

I s ther e voltage ? Repai

r ope n in th e wir e betwee n

th e B 2 termina l an d th e trans -

missio n rang e switch .

Chec

k Par k Pi n Switc h Oper -

ation:Chec k fo r continuit y betwee n th e

B 5 termina l an d bod y ground .

Chec k fo r loos e multiple x contro l

uni t (driver's ) connectors . I f nec -

essary , substitut e a known-goo d

multiple x contro l uni t (driver's )

and recheck .

Check Ke y Interloc k Solenoi d fo r

a Shor t Circuit :

1 . Disconnec t th e A (26P ) an d B

(16P ) connector s fro m th e mul -

tiple x contro l uni t (driver's) .

2 . Chec k fo r continuit y betwee n

th e A 2 termina l an d bod y

groun d an d betwee n th e A1 3

termina l an d bod y groun d indi -

vidually .

ProCarManuals.com

Page 793 of 1954

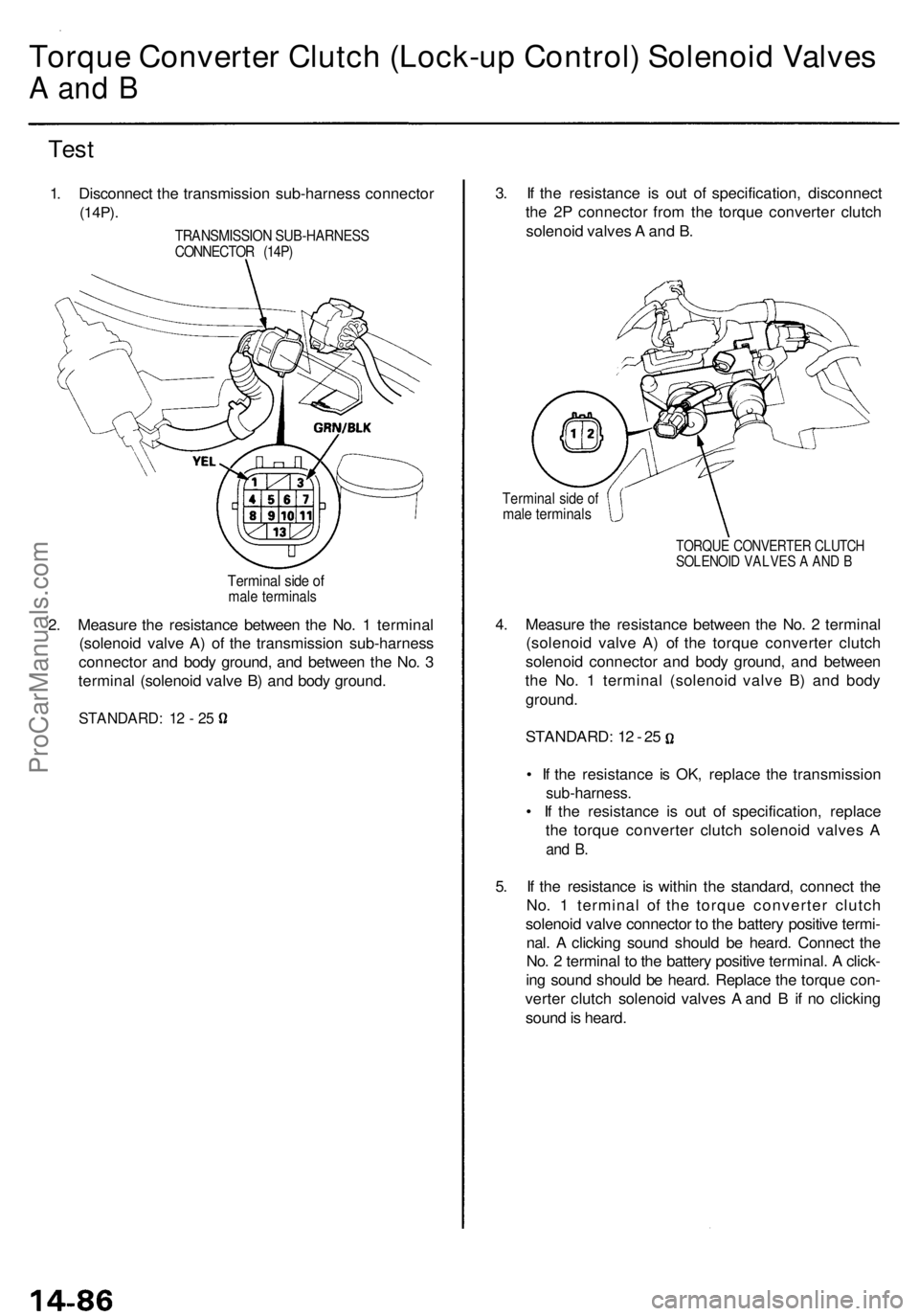

Torque Converter Clutch (Lock-up Control) Solenoid Valves

A an d B

Tes t

1. Disconnec t th e transmissio n sub-harnes s connecto r

(14P).

2. Measur e th e resistanc e betwee n th e No . 1 termina l

(solenoi d valv e A ) o f th e transmissio n sub-harnes s

connecto r an d bod y ground , an d betwee n th e No . 3

termina l (solenoi d valv e B ) an d bod y ground . 3

. I f th e resistanc e i s ou t o f specification , disconnec t

th e 2 P connecto r fro m th e torqu e converte r clutc h

solenoi d valve s A an d B .

Termina l sid e o fmal e terminal s

TORQUE CONVERTE R CLUTC HSOLENOI D VALVE S A AN D B

4. Measur e th e resistanc e betwee n th e No . 2 termina l

(solenoi d valv e A ) o f th e torqu e converte r clutc h

solenoi d connecto r an d bod y ground , an d betwee n

th e No . 1 termina l (solenoi d valv e B ) an d bod y

ground .

STANDARD : 1 2 - 2 5

• I f th e resistanc e i s OK , replac e th e transmissio n

sub-harness.

• I f th e resistance is ou t o f specification , replac e

th e torqu e converte r clutc h solenoi d valve s A

an d B .

5. I f th e resistanc e i s withi n th e standard , connec t th e

No . 1 termina l o f th e torqu e converte r clutc h

solenoi d valv e connecto r t o th e batter y positiv e termi -

nal . A clickin g soun d shoul d b e heard . Connec t th e

No . 2 termina l t o th e batter y positiv e terminal . A click -

in g soun d shoul d b e heard . Replac e th e torqu e con -

verte r clutc h solenoi d valve s A an d B if n o clickin g

soun d is heard .

TRANSMISSIO N SUB-HARNES SCONNECTOR (14P )

Termina l sid e o fmal e terminal s

STANDARD : 1 2 - 2 5

ProCarManuals.com

Page 794 of 1954

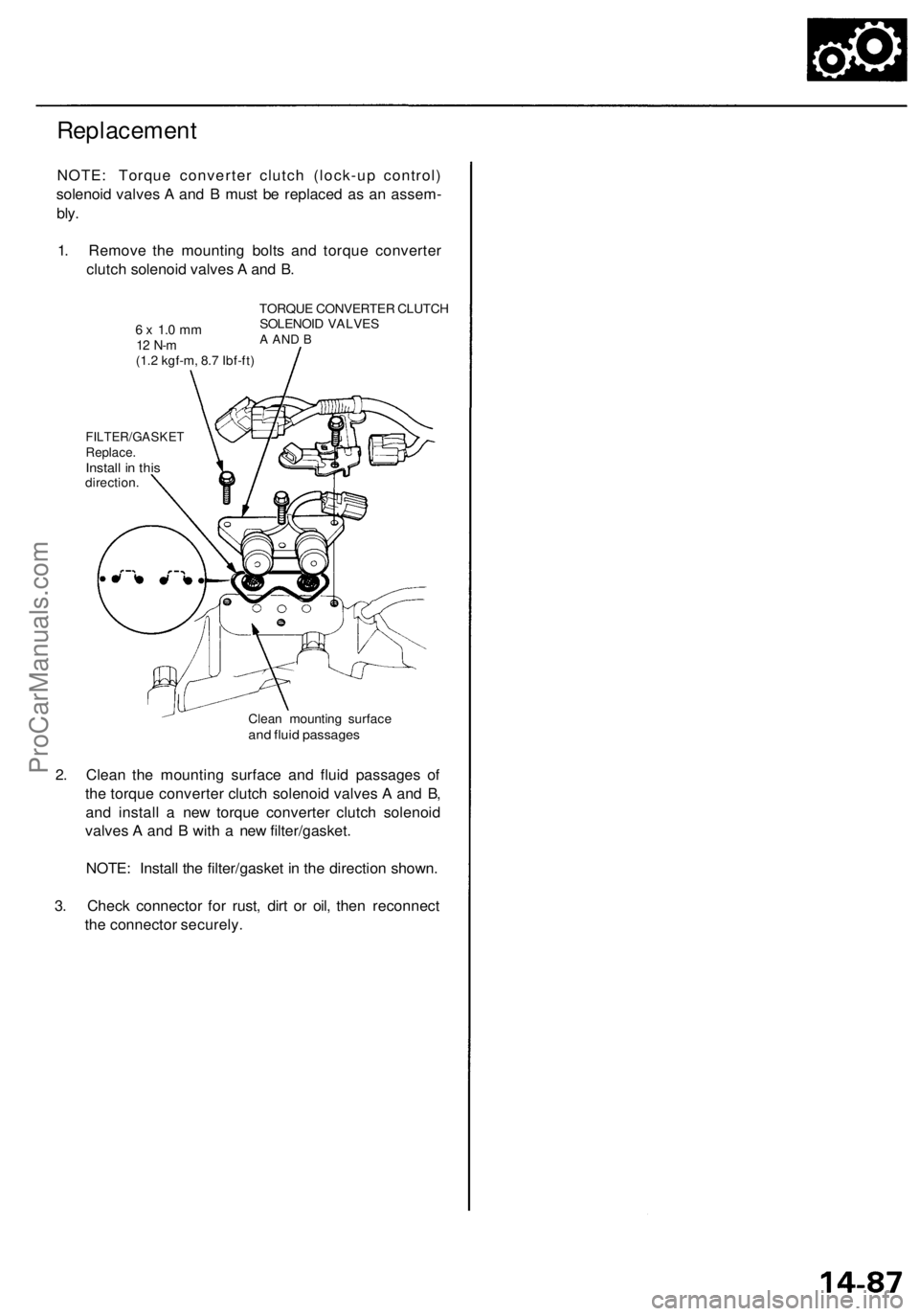

Replacement

NOTE: Torque converter clutch (lock-up control)

solenoid valves A and B must be replaced as an assem-

bly.

1. Remove the mounting bolts and torque converter

clutch solenoid valves A and B.

6 x 1.0 mm

12 N-m

(1.2 kgf-m, 8.7 Ibf-ft)

TORQUE CONVERTER CLUTCH

SOLENOID VALVES

A AND B

FILTER/GASKET

Replace.

Install in this

direction.

Clean mounting surface

and fluid passages

2. Clean the mounting surface and fluid passages of

the torque converter clutch solenoid valves A and B,

and install a new torque converter clutch solenoid

valves A and B with a new filter/gasket.

NOTE: Install the filter/gasket in the direction shown.

3. Check connector for rust, dirt or oil, then reconnect

the connector securely.ProCarManuals.com

Page 795 of 1954

Shift Solenoi d Valve s A an d B

Tes t

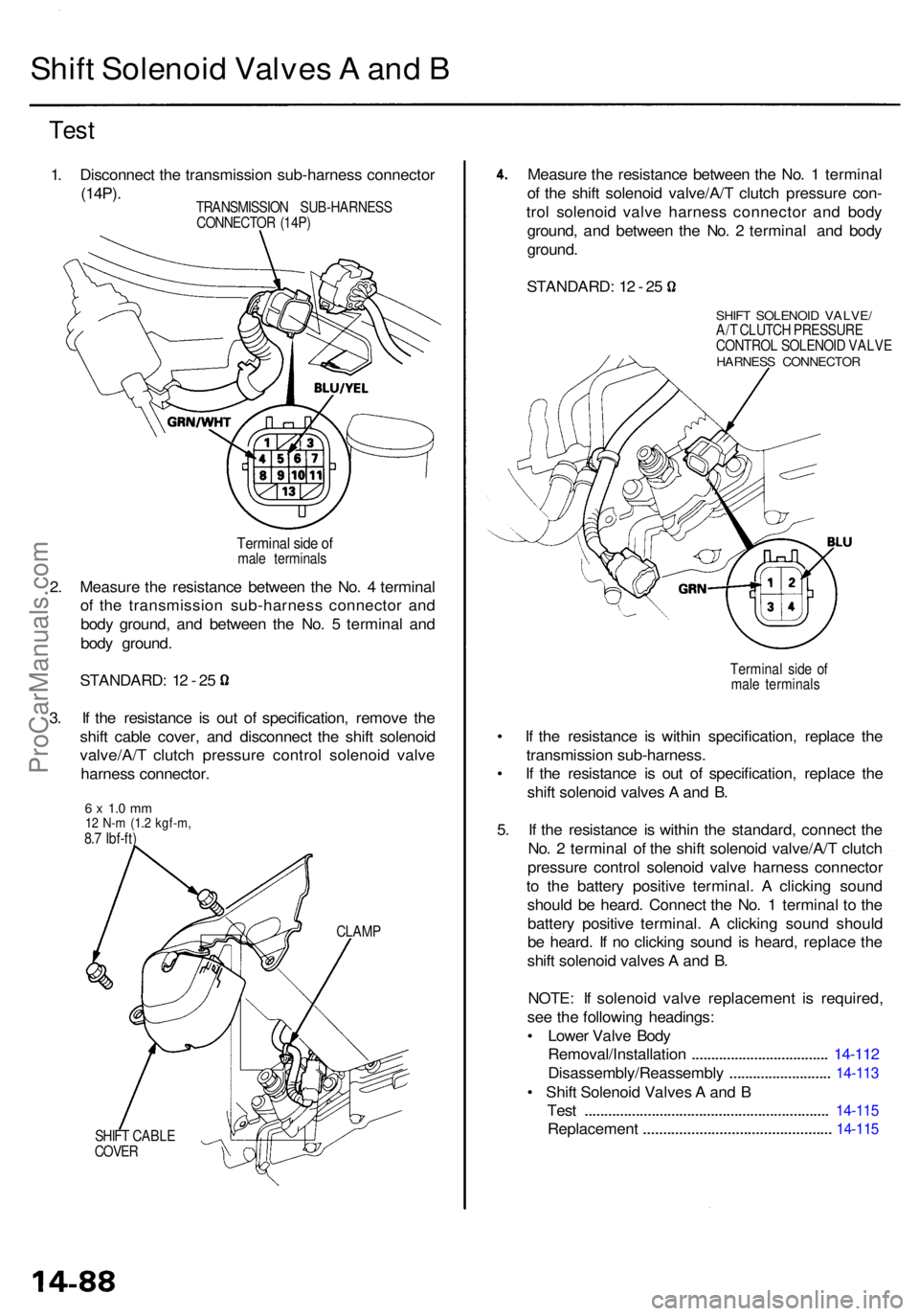

1. Disconnec t th e transmissio n sub-harnes s connecto r

(14P).

2. Measur e th e resistanc e betwee n th e No . 4 termina l

o f th e transmissio n sub-harnes s connecto r an d

bod y ground , an d betwee n th e No . 5 termina l an d

bod y ground .

STANDARD : 1 2 - 2 5

3 . I f th e resistanc e i s ou t o f specification , remov e th e

shif t cabl e cover , an d disconnec t th e shif t solenoi d

valve/A/ T clutc h pressur e contro l solenoi d valv e

harnes s connector .

CLAMP

SHIF T CABL E

COVER

Measur e th e resistanc e betwee n th e No . 1 termina l

o f th e shif t solenoi d valve/A/ T clutc h pressur e con -

tro l solenoi d valv e harnes s connecto r an d bod y

ground , an d betwee n th e No . 2 termina l an d bod y

ground .

STANDARD : 1 2 - 2 5

SHIF T SOLENOI D VALVE /A/T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV E

HARNES S CONNECTO R

Terminal sid e o f

mal e terminal s

• I f th e resistanc e i s withi n specification , replac e th e

transmissio n sub-harness .

• I f th e resistanc e i s ou t o f specification , replac e th e

shif t solenoi d valve s A an d B .

5 . I f th e resistanc e i s withi n th e standard , connec t th e

No . 2 termina l o f th e shif t solenoi d valve/A/ T clutc h

pressur e contro l solenoi d valv e harnes s connecto r

t o th e batter y positiv e terminal . A clickin g soun d

shoul d b e heard . Connec t th e No . 1 termina l t o th e

batter y positiv e terminal . A clickin g soun d shoul d

b e heard . I f n o clickin g soun d i s heard , replac e th e

shif t solenoi d valve s A an d B .

NOTE : I f solenoi d valv e replacemen t i s required ,

se e th e followin g headings :

• Lowe r Valv e Bod y

Removal/Installatio n

................................... 14-11 2

Disassembly/Reassembl y

.......................... 14-11 3

• Shif t Solenoi d Valve s A an d B

Tes t

............................................................. . 14-11 5

Replacemen t .............................................. . 14-11 5

6 x 1. 0 m m12 N-m (1.2 kgf-m,8.7 Ibf-ft ) TRANSMISSIO

N SUB-HARNES S

CONNECTO R (14P )

Termina l sid e o fmal e terminal s

ProCarManuals.com

Page 796 of 1954

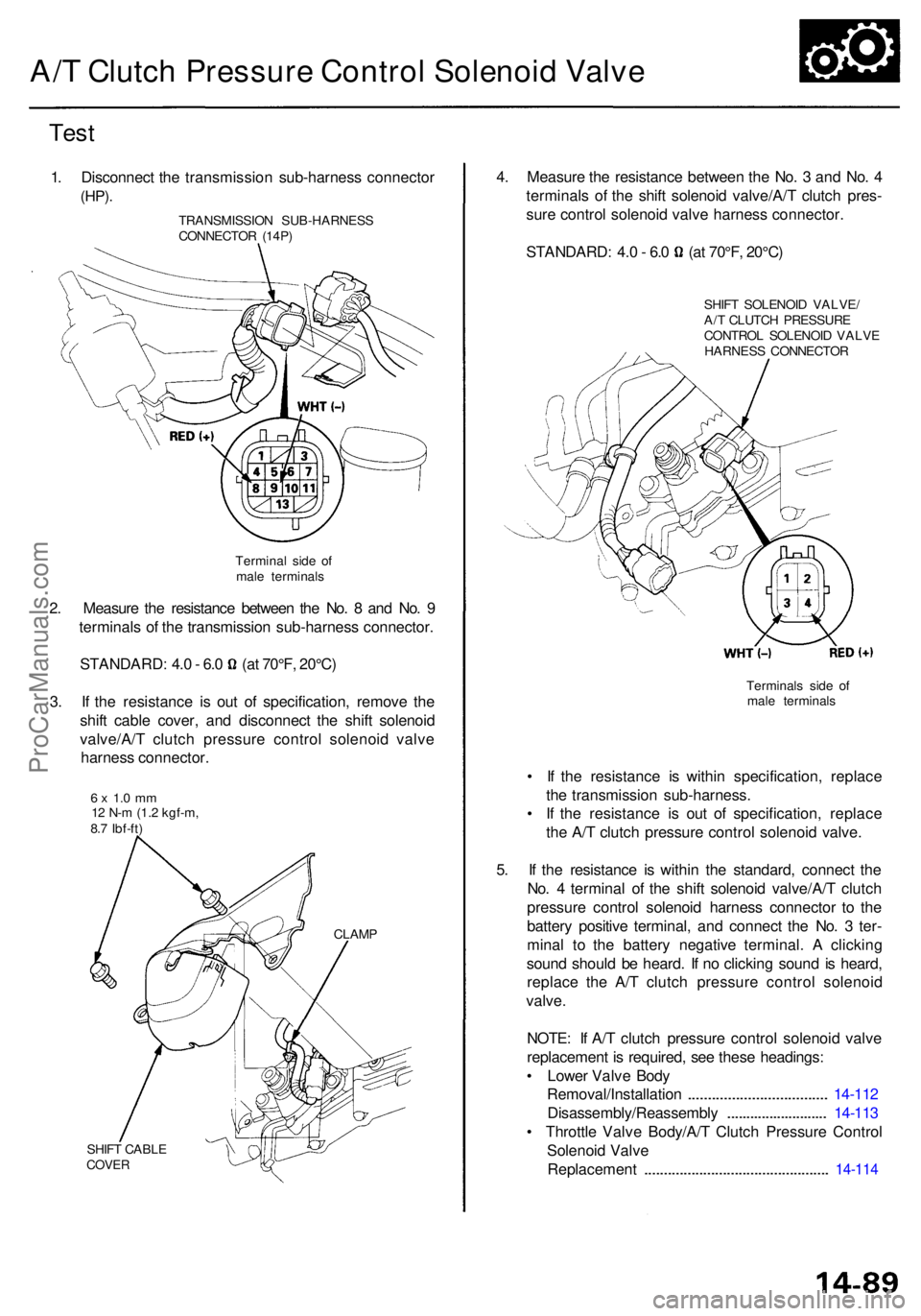

A/T Clutc h Pressur e Contro l Solenoi d Valv e

Test

1. Disconnec t th e transmissio n sub-harnes s connecto r

(HP).

2. Measur e th e resistanc e betwee n th e No . 8 an d No . 9

terminal s o f th e transmissio n sub-harnes s connector .

STANDARD : 4. 0 - 6. 0 (a t 70°F , 20°C )

3 . I f th e resistanc e i s ou t o f specification , remov e th e

shif t cabl e cover , an d disconnec t th e shif t solenoi d

valve/A/ T clutc h pressur e contro l solenoi d valv e

harnes s connector .

CLAMP

SHIF T CABL E

COVER

4. Measur e th e resistanc e betwee n th e No . 3 an d No . 4

terminal s o f th e shif t solenoi d valve/A/ T clutc h pres -

sur e contro l solenoi d valv e harnes s connector .

STANDARD : 4. 0 - 6. 0 (a t 70°F , 20°C )

SHIFT SOLENOI D VALVE /

A/ T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV E

HARNES S CONNECTO R

Terminal s sid e o f

mal e terminal s

• I f th e resistanc e i s withi n specification , replac e

th e transmissio n sub-harness .

• I f th e resistanc e i s ou t o f specification , replac e

th e A/ T clutc h pressur e contro l solenoi d valve .

5 . I f th e resistanc e i s withi n th e standard , connec t th e

No . 4 termina l o f th e shif t solenoi d valve/A/ T clutc h

pressur e contro l solenoi d harnes s connecto r t o th e

batter y positiv e terminal , an d connec t th e No . 3 ter -

mina l t o th e batter y negativ e terminal . A clickin g

soun d shoul d b e heard . I f n o clickin g soun d is heard ,

replac e th e A/ T clutc h pressur e contro l solenoi d

valve .

NOTE : I f A/ T clutc h pressur e contro l solenoi d valv e

replacemen t i s required , se e thes e headings :

• Lowe r Valv e Bod y

Removal/Installatio n

................................... 14-11 2

Disassembly/Reassembl y

.......................... 14-11 3

• Throttl e Valv e Body/A/ T Clutc h Pressur e Contro l

Solenoi d Valv e

Replacemen t

.............................................. . 14-11 4

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) TRANSMISSIO

N SUB-HARNES S

CONNECTO R (14P )

Termina l sid e o f

mal e terminal s

ProCarManuals.com

Page 797 of 1954

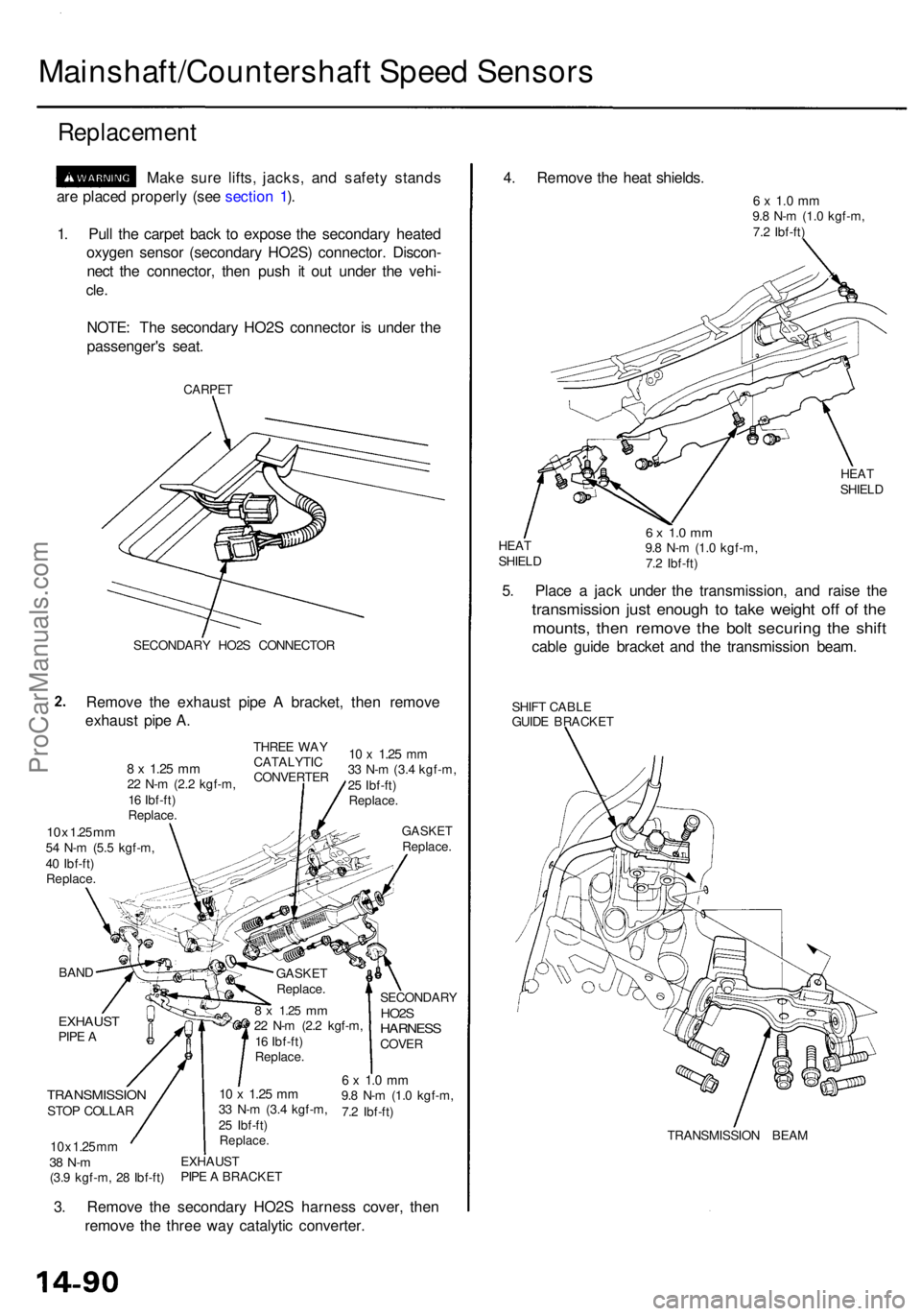

Mainshaft/Countershaft Spee d Sensor s

Replacemen t

Make sur e lifts , jacks , an d safet y stand s

ar e place d properl y (se e sectio n 1 ).

1 . Pul l th e carpe t bac k t o expos e th e secondar y heate d

oxyge n senso r (secondar y HO2S ) connector . Discon -

nec t th e connector , the n pus h i t ou t unde r th e vehi -

cle.

NOTE : Th e secondar y HO2 S connecto r i s unde r th e

passenger' s seat .

SECONDAR Y HO2 S CONNECTO R

Remove th e exhaus t pip e A bracket , the n remov e

exhaus t pip e A .

BAN D

EXHAUS TPIPE A

TRANSMISSIO NSTOP COLLA R THRE

E WA Y

CATALYTI C

CONVERTE R

SECONDAR Y

HO2SHARNES SCOVER

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

3. Remov e th e secondar y HO2 S harnes s cover , the n

remov e th e thre e wa y catalyti c converter . 4

. Remov e th e hea t shields .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

HEATSHIEL D

HEA T

SHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

5. Plac e a jac k unde r th e transmission , an d rais e th e

transmissio n jus t enoug h t o tak e weigh t of f o f th e

mounts , the n remov e th e bol t securin g th e shif t

cable guid e bracke t an d th e transmissio n beam .

SHIFT CABL E

GUID E BRACKE T

TRANSMISSIO N BEA M

CARPE T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

GASKETReplace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Replace .

GASKETReplace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

10 x 1.2 5 m m38 N- m(3.9 kgf-m , 2 8 Ibf-ft )EXHAUS

T

PIP E A BRACKE T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

ProCarManuals.com

Page 798 of 1954

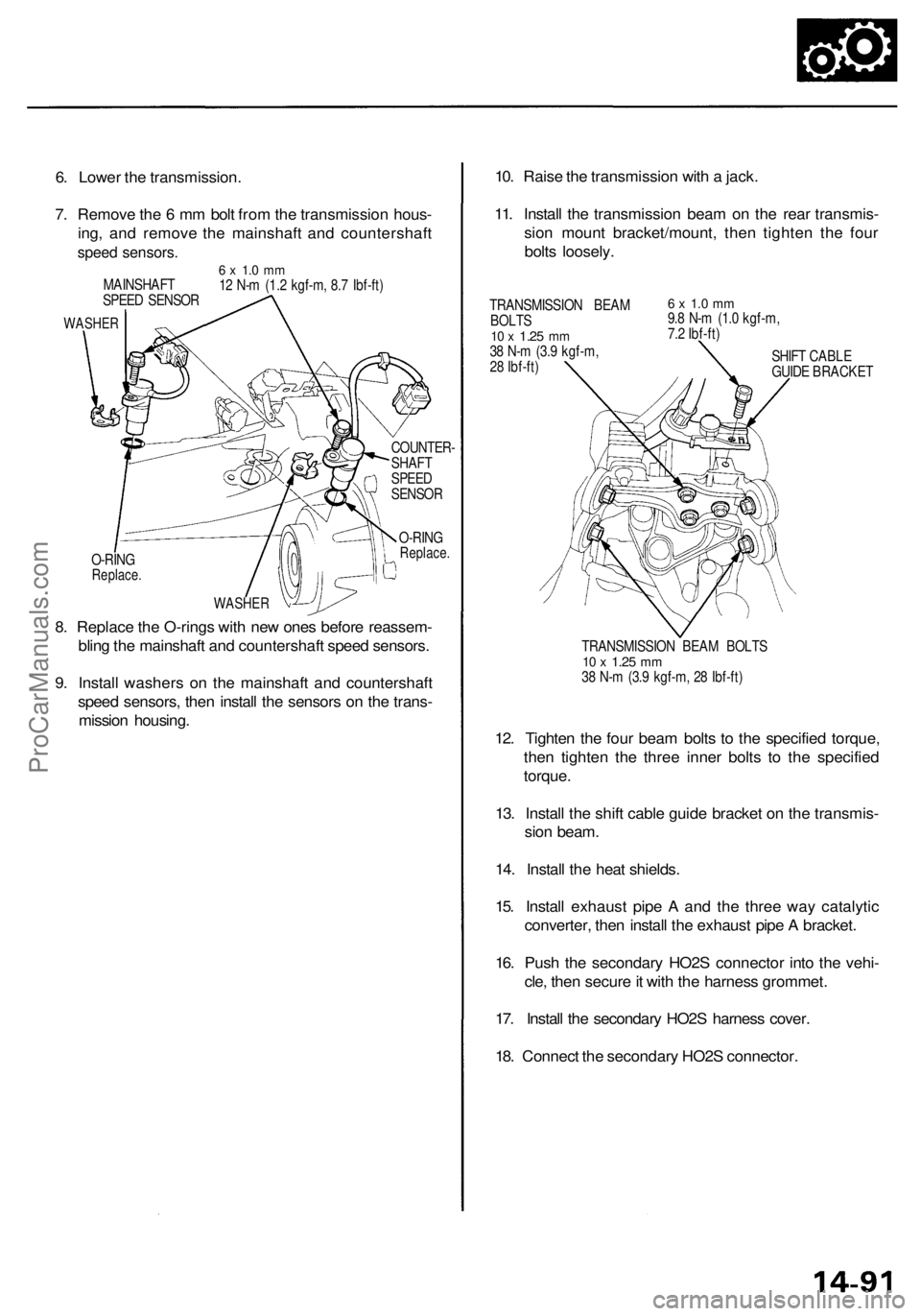

O-RING

Replace.

COUNTER-

SHAFT

SPEED

SENSOR

O-RING

Replace.

8. Replace the O-rings with new ones before reassem-

bling the mainshaft and countershaft speed sensors.

9. Install washers on the mainshaft and countershaft

speed sensors, then install the sensors on the trans-

mission housing.

10. Raise the transmission with a jack.

11. Install the transmission beam on the rear transmis-

sion mount bracket/mount, then tighten the four

bolts loosely.

TRANSMISSION BEAM

BOLTS

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

SHIFT CABLE

GUIDE BRACKET

TRANSMISSION BEAM BOLTS

10 x

1.25

mm

38 N-m (3.9 kgf-m, 28 Ibf-ft)

12. Tighten the four beam bolts to the specified torque,

then tighten the three inner bolts to the specified

torque.

13. Install the shift cable guide bracket on the transmis-

sion beam.

14. Install the heat shields.

15. Install exhaust pipe A and the three way catalytic

converter, then install the exhaust pipe A bracket.

16. Push the secondary HO2S connector into the vehi-

cle, then secure it with the harness grommet.

17. Install the secondary HO2S harness cover.

18. Connect the secondary HO2S connector.

6. Lower the transmission.

7. Remove the 6 mm bolt from the transmission hous-

ing, and remove the mainshaft and countershaft

speed sensors.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

MAINSHAFT

SPEED SENSOR

WASHER

WASHERProCarManuals.com

Page 799 of 1954

Transmission Rang e Switc h (A/ T Gea r Positio n Switch )

Test

Mak e sur e lifts , jacks , an d safet y stand s ar e place d properl y (se e sectio n 1 ).

1 . Rais e th e fron t o f th e vehicle , an d suppor t i t wit h safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s securely .

3 . Pul l th e carpe t bac k t o expos e th e secondar y heate d oxyge n senso r (secondar y HO2S ) connector . Disconnec t th e con -

nector , the n pus h it ou t unde r th e vehicl e (se e pag e 14-90 ).

NOTE : Th e secondar y HO2 S connecto r i s unde r th e passenger' s seat .

4 . Remov e th e exhaus t pip e A bracket , the n remov e exhaus t pip e A .

5 . Remov e th e secondar y HO2 S harnes s cover , the n remov e th e thre e wa y catalyti c converter .

6 . Remov e th e hea t shields .

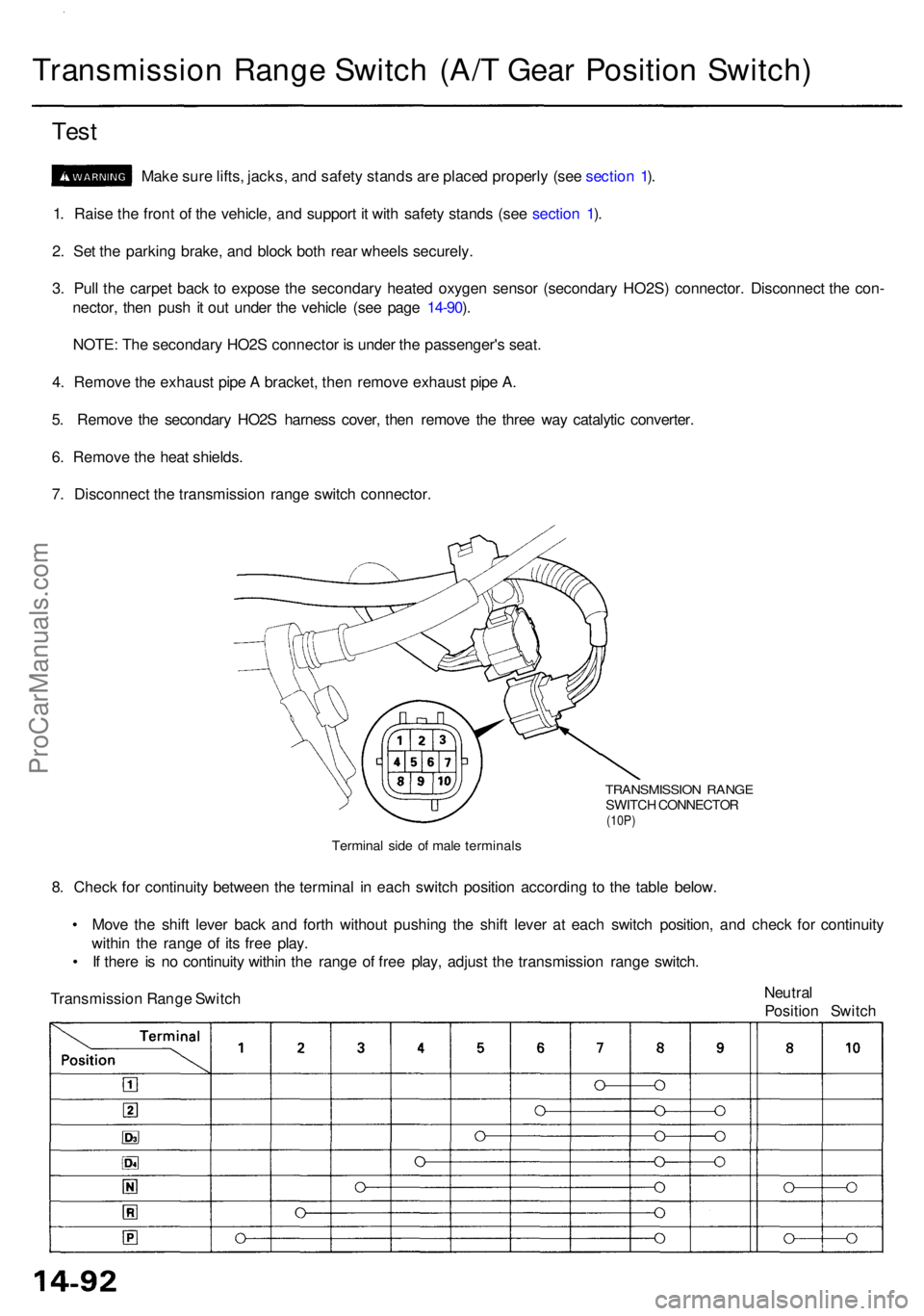

7 . Disconnec t th e transmissio n rang e switc h connector .

TRANSMISSIO N RANG ESWITCH CONNECTO R(10P)

Termina l sid e o f mal e terminal s

8. Chec k fo r continuit y betwee n th e termina l i n eac h switc h positio n accordin g t o th e tabl e below .

• Mov e th e shif t leve r bac k an d fort h withou t pushin g th e shif t leve r a t eac h switc h position , an d chec k fo r continuit y

withi n th e rang e o f it s fre e play .

• I f ther e i s n o continuit y withi n th e rang e o f fre e play , adjus t th e transmissio n rang e switch .

Neutral

Positio n Switc h

Transmissio

n Rang e Switc h

ProCarManuals.com

Page 800 of 1954

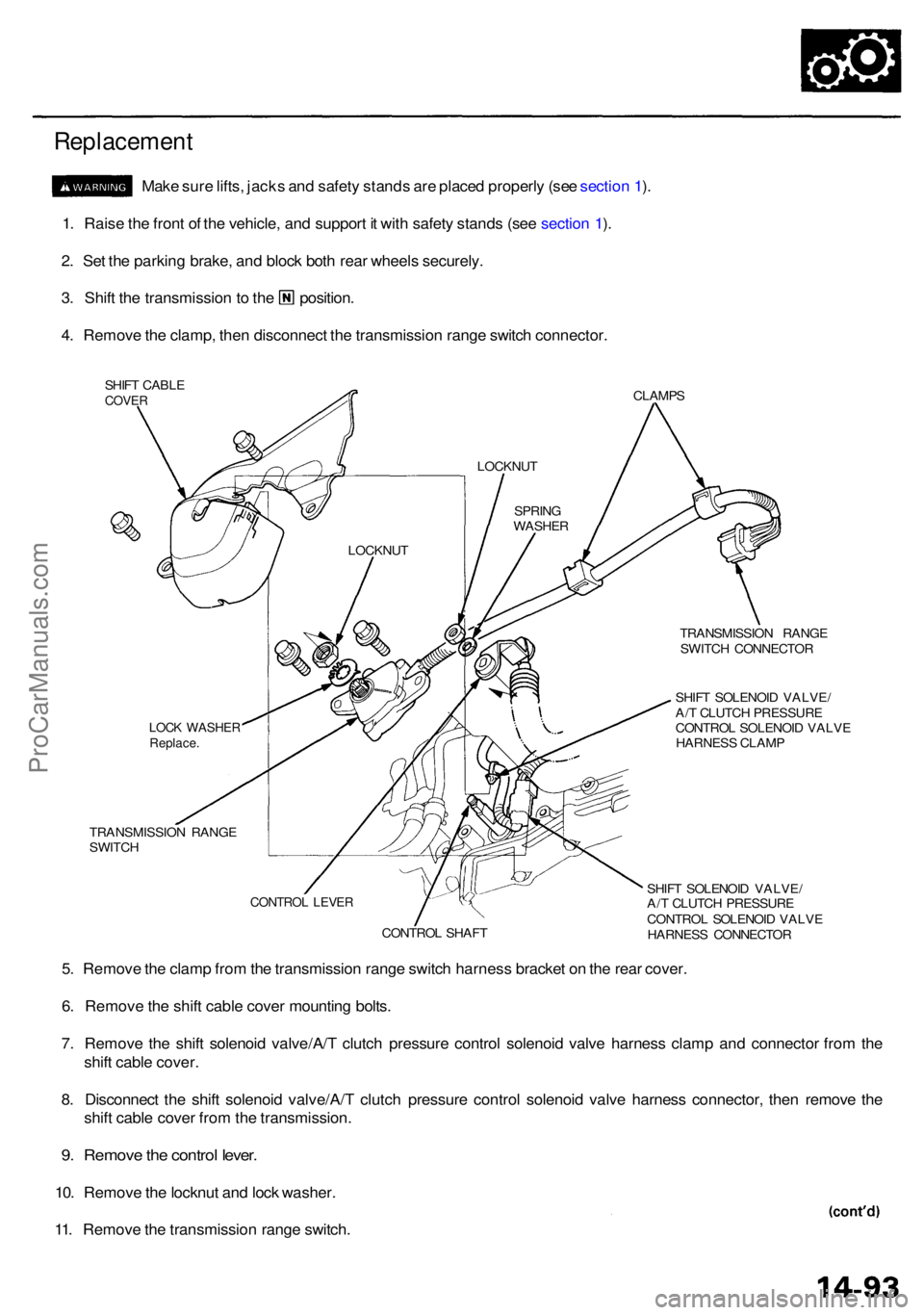

Replacement

Make sur e lifts , jack s an d safet y stand s ar e place d properl y (se e sectio n 1 ).

1 . Rais e th e fron t o f th e vehicle , an d suppor t i t wit h safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s securely .

3. Shif t th e transmissio n to th e position .

4 . Remov e th e clamp , the n disconnec t th e transmissio n rang e switc h connector .

SHIFT CABL ECOVERCLAMP S

TRANSMISSIO N RANG E

SWITC H CONNECTO R

SHIF T SOLENOI D VALVE /

A/ T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV E

HARNES S CLAM P

TRANSMISSIO N RANG E

SWITC H

SHIFT SOLENOI D VALVE /

A/ T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV E

HARNES S CONNECTO R

5. Remov e th e clam p fro m th e transmissio n rang e switc h harnes s bracke t o n th e rea r cover .

6 . Remov e th e shif t cabl e cove r mountin g bolts .

7 . Remov e th e shif t solenoi d valve/A/ T clutc h pressur e contro l solenoi d valv e harnes s clam p an d connecto r fro m th e

shif t cabl e cover .

8 . Disconnec t th e shif t solenoi d valve/A/ T clutc h pressur e contro l solenoi d valv e harnes s connector , the n remov e th e

shif t cabl e cove r fro m th e transmission .

9. Remov e th e contro l lever .

10. Remov e th e locknu t an d loc k washer .

11 . Remov e th e transmissio n rang e switch .

LOCKNU T

LOCK WASHE RReplace.

CONTRO L SHAF T

CONTRO L LEVE R

SPRIN G

WASHE R

LOCKNU

T

ProCarManuals.com