ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 821 of 1954

Throttle Valv e Body/A/ T Clutc h Pressur e Contro l

Solenoi d Valv e

Test

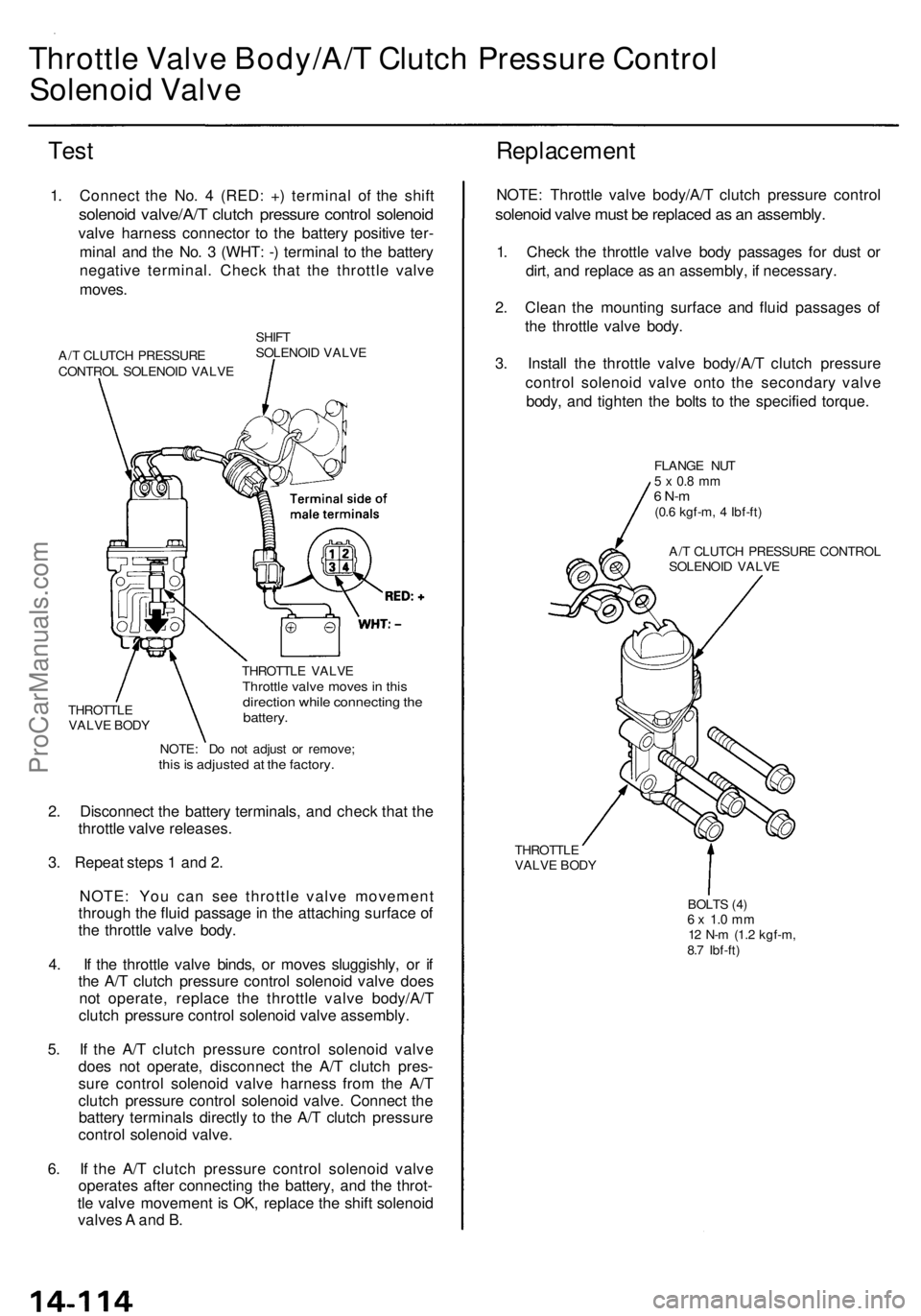

1. Connec t th e No . 4 (RED : + ) termina l of the shif t

solenoi d valve/A/ T clutc h pressur e contro l solenoi d

valve harnes s connecto r t o th e batter y positiv e ter -

mina l an d th e No . 3 (WHT : - ) termina l t o th e batter y

negativ e terminal . Chec k tha t th e throttl e valv e

moves .

Replacemen t

A/T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV ESHIF

T

SOLENOI D VALV E

THROTTL E

VALV E BOD Y THROTTL

E VALV E

Throttle valv e move s in thi sdirectio n whil e connectin g th ebattery .

NOTE: D o no t adjus t o r remove ;this is adjuste d a t th e factory .

2. Disconnec t th e batter y terminals , an d chec k tha t th e

throttl e valv e releases .

3 . Repea t step s 1 an d 2 .

NOTE : Yo u ca n se e throttl e valv e movemen t

throug h th e flui d passag e in th e attachin g surfac e o f

th e throttl e valv e body .

4 . I f th e throttl e valv e binds , o r move s sluggishly , o r i f

th e A/ T clutc h pressur e contro l solenoi d valv e doe s

no t operate , replac e th e throttl e valv e body/A/ T

clutc h pressur e contro l solenoi d valv e assembly .

5 . I f th e A/ T clutc h pressur e contro l solenoi d valv e

doe s no t operate , disconnec t th e A/ T clutc h pres -

sur e contro l solenoi d valv e harnes s fro m th e A/ T

clutc h pressur e contro l solenoi d valve . Connec t th e

batter y terminal s directl y t o th e A/ T clutc h pressur e

contro l solenoi d valve .

6 . I f th e A/ T clutc h pressur e contro l solenoi d valv e

operate s afte r connectin g th e battery , an d th e throt -

tl e valv e movemen t i s OK , replac e th e shif t solenoi d

valve s A an d B . NOTE

: Throttl e valv e body/A/ T clutc h pressur e contro l

solenoid valv e mus t b e replace d a s a n assembly .

1. Chec k th e throttl e valv e bod y passage s fo r dus t o r

dirt , an d replac e a s a n assembly , i f necessary .

2 . Clea n th e mountin g surfac e an d flui d passage s o f

th e throttl e valv e body .

3 . Instal l th e throttl e valv e body/A/ T clutc h pressur e

contro l solenoi d valv e ont o th e secondar y valv e

body , an d tighte n th e bolt s t o th e specifie d torque .

FLANG E NU T5 x 0. 8 m m6 N- m(0.6 kgf-m , 4 Ibf-ft )

THROTTL E

VALV E BOD Y

BOLTS (4 )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

A/

T CLUTC H PRESSUR E CONTRO L

SOLENOI D VALV E

ProCarManuals.com

Page 822 of 1954

Shift Solenoid Valves A and B

Test

Replacement

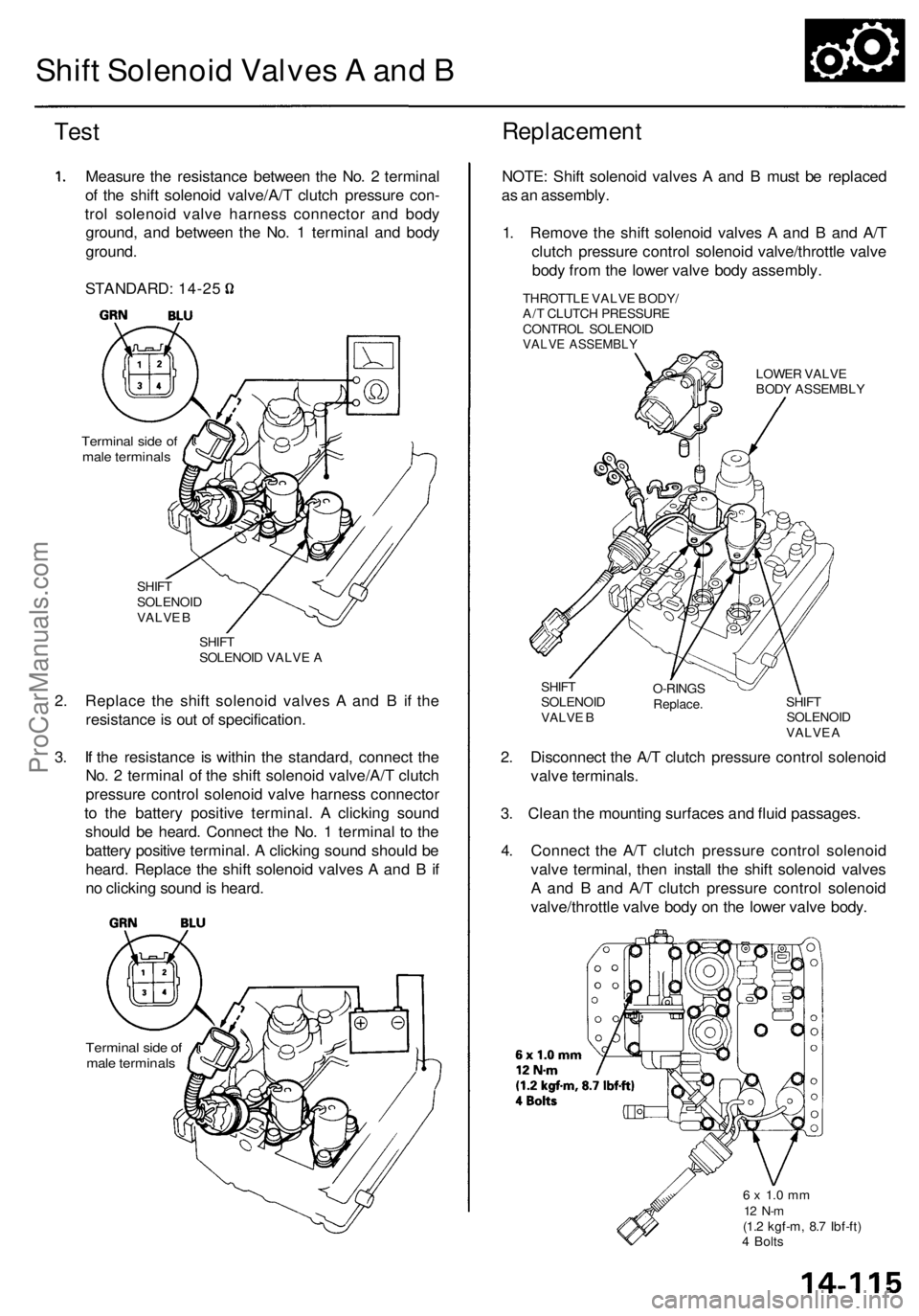

Measure the resistance between the No. 2 terminal

of the shift solenoid valve/A/T clutch pressure con-

trol solenoid valve harness connector and body

ground, and between the No. 1 terminal and body

ground.

Terminal side of

male terminals

SHIFT

SOLENOID

VALVE B

SHIFT

SOLENOID VALVE A

2. Replace the shift solenoid valves A and B if the

resistance is out of specification.

3. If the resistance is within the standard, connect the

No. 2 terminal of the shift solenoid valve/A/T clutch

pressure control solenoid valve harness connector

to the battery positive terminal. A clicking sound

should be heard. Connect the No. 1 terminal to the

battery positive terminal. A clicking sound should be

heard. Replace the shift solenoid valves A and B if

no clicking sound is heard.

Terminal side of

male terminals

NOTE: Shift solenoid valves A and B must be replaced

as an assembly.

1. Remove the shift solenoid valves A and B and A/T

clutch pressure control solenoid valve/throttle valve

body from the lower valve body assembly.

THROTTLE VALVE BODY/

A/T CLUTCH PRESSURE

CONTROL SOLENOID

VALVE ASSEMBLY

LOWER VALVE

BODY ASSEMBLY

SHIFT

SOLENOID

VALVE B

O-RINGS

Replace.

SHIFT

SOLENOID

VALVE A

2. Disconnect the A/T clutch pressure control solenoid

valve terminals.

3. Clean the mounting surfaces and fluid passages.

4. Connect the A/T clutch pressure control solenoid

valve terminal, then install the shift solenoid valves

A and B and A/T clutch pressure control solenoid

valve/throttle valve body on the lower valve body.

6 x 1.0 mm

12 N-m

(1.2 kgf-m, 8.7 Ibf-ft)

4 Bolts

STANDARD: 14-25ProCarManuals.com

Page 823 of 1954

Transmission

Removal

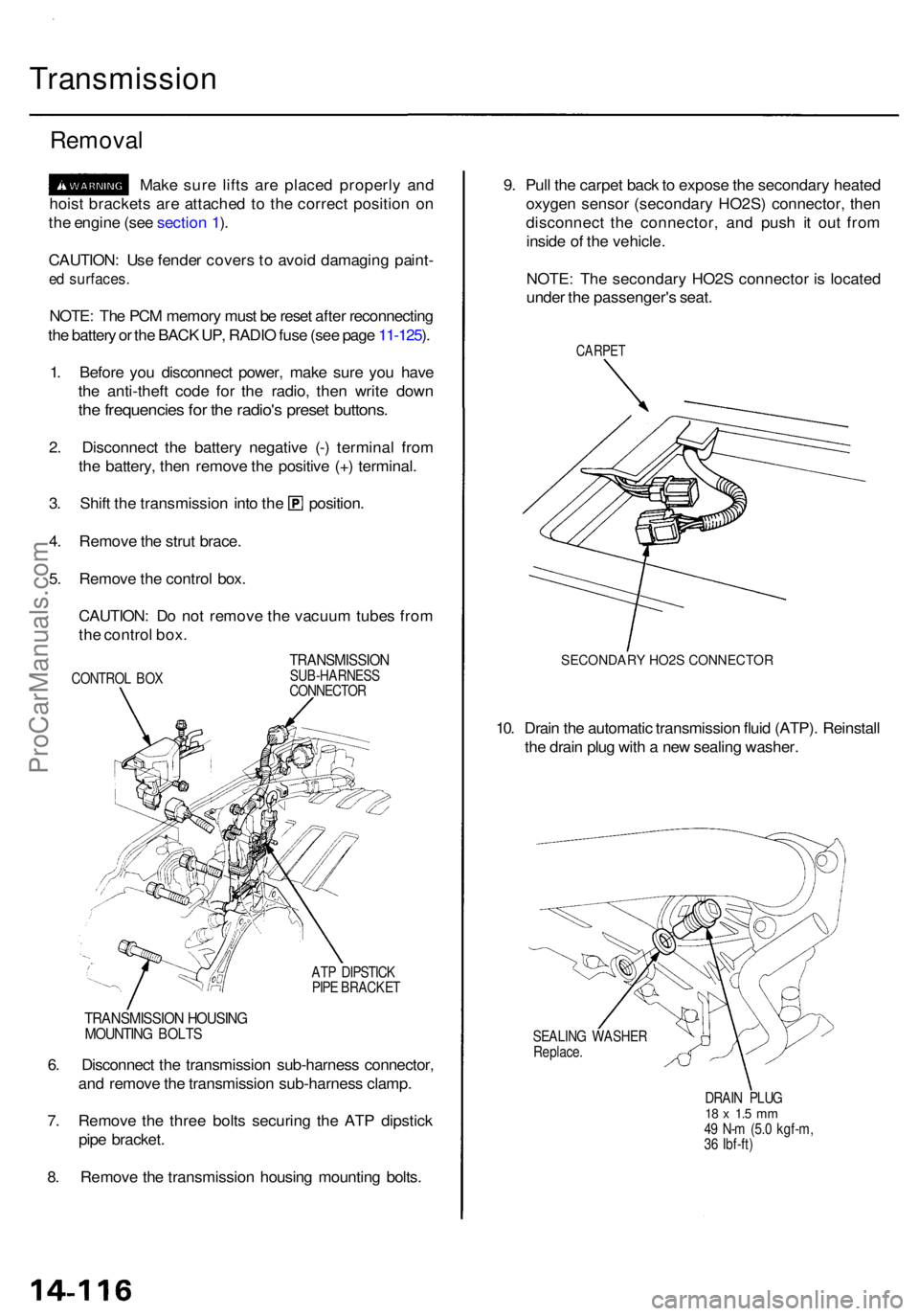

Make sur e lift s ar e place d properl y an d

hois t bracket s ar e attache d t o th e correc t positio n o n

th e engin e (se e sectio n 1 ).

CAUTION : Us e fende r cover s t o avoi d damagin g paint -

ed surfaces .

NOTE: Th e PC M memor y mus t b e rese t afte r reconnectin g

th e batter y o r th e BAC K UP , RADI O fus e (se e pag e 11-125 ).

1 . Befor e yo u disconnec t power , mak e sur e yo u hav e

th e anti-thef t cod e fo r th e radio , the n writ e dow n

the frequencie s fo r th e radio' s prese t buttons .

2. Disconnec t th e batter y negativ e (- ) termina l fro m

th e battery , the n remov e th e positiv e (+ ) terminal .

3. Shif t th e transmissio n int o th e position .

4 . Remov e th e stru t brace .

5 . Remov e th e contro l box .

CAUTION : D o no t remov e th e vacuu m tube s fro m

th e contro l box .

CONTRO L BO X

TRANSMISSIO NSUB-HARNESS

CONNECTO R

AT P DIPSTIC K

PIP E BRACKE T

9. Pul l th e carpe t bac k to expos e th e secondar y heate d

oxyge n senso r (secondar y HO2S ) connector, then

disconnec t th e connector , an d pus h i t ou t fro m

insid e o f th e vehicle .

NOTE : Th e secondar y HO2 S connecto r i s locate d

unde r th e passenger' s seat .

CARPE T

SECONDARY HO2S CONNECTOR

10. Drai n th e automati c transmissio n flui d (ATP) . Reinstal l

th e drai n plu g wit h a ne w sealin g washer .

SEALIN G WASHE R

Replace .

DRAIN PLU G

18 x 1. 5 m m49 N- m (5. 0 kgf-m ,

3 6 Ibf-ft )

6. Disconnec t th e transmissio n sub-harnes s connector ,

an d remov e th e transmissio n sub-harnes s clamp .

7 . Remov e th e thre e bolt s securin g th e AT P dipstic k

pip e bracket .

8 . Remov e th e transmissio n housin g mountin g bolts .

TRANSMISSIO N HOUSIN GMOUNTIN G BOLT S

ProCarManuals.com

Page 824 of 1954

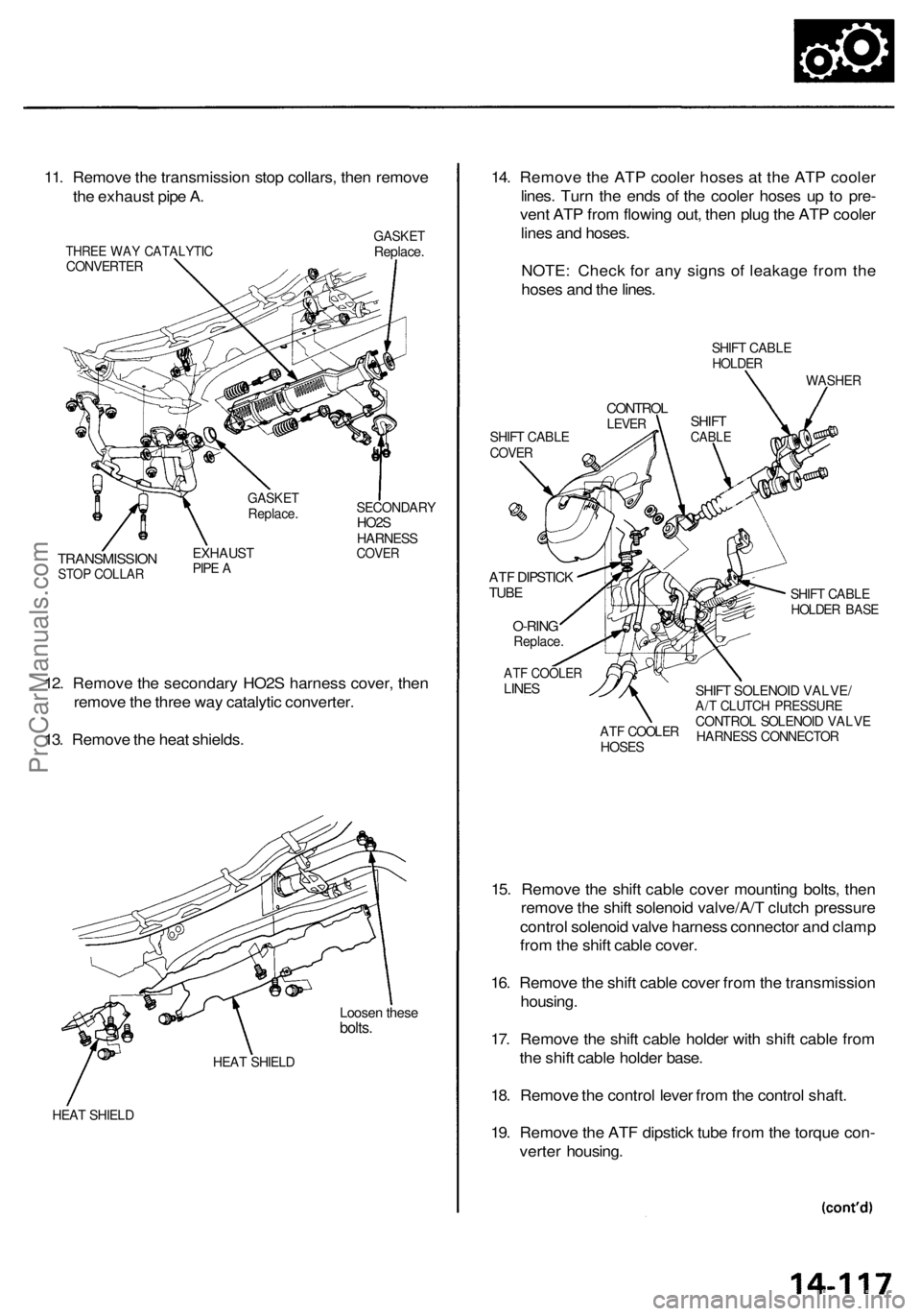

11. Remove the transmission stop collars, then remove

the exhaust pipe A.

THREE WAY CATALYTIC

CONVERTER

GASKET

Replace.

TRANSMISSION

STOP COLLAR

EXHAUST

PIPE A

SECONDARY

HO2S

HARNESS

COVER

12. Remove the secondary HO2S harness cover, then

remove the three way catalytic converter.

13. Remove the heat shields.

Loosen these

bolts.

HEAT SHIELD

HEAT SHIELD

14. Remove the ATP cooler hoses at the ATP cooler

lines. Turn the ends of the cooler hoses up to pre-

vent ATP from flowing out, then plug the ATP cooler

lines and hoses.

NOTE: Check for any signs of leakage from the

hoses and the lines.

SHIFT CABLE

HOLDER

WASHER

SHIFT CABLE

COVER

ATF DIPSTICK

TUBE

O-RING

Replace.

SHIFT CABLE

HOLDER BASE

15. Remove the shift cable cover mounting bolts, then

remove the shift solenoid valve/A/T clutch pressure

control solenoid valve harness connector and clamp

from the shift cable cover.

16. Remove the shift cable cover from the transmission

housing.

17. Remove the shift cable holder with shift cable from

the shift cable holder base.

18. Remove the control lever from the control shaft.

19. Remove the ATF dipstick tube from the torque con-

verter housing.

GASKET

Replace.

ATF COOLER

LINES

ATF COOLER

HOSES

SHIFT SOLENOID VALVE/

A/T CLUTCH PRESSURE

CONTROL SOLENOID VALVE

HARNESS CONNECTOR

CONTROL

LEVER

SHIFT

CABLEProCarManuals.com

Page 825 of 1954

Transmission

Removal (cont'd )

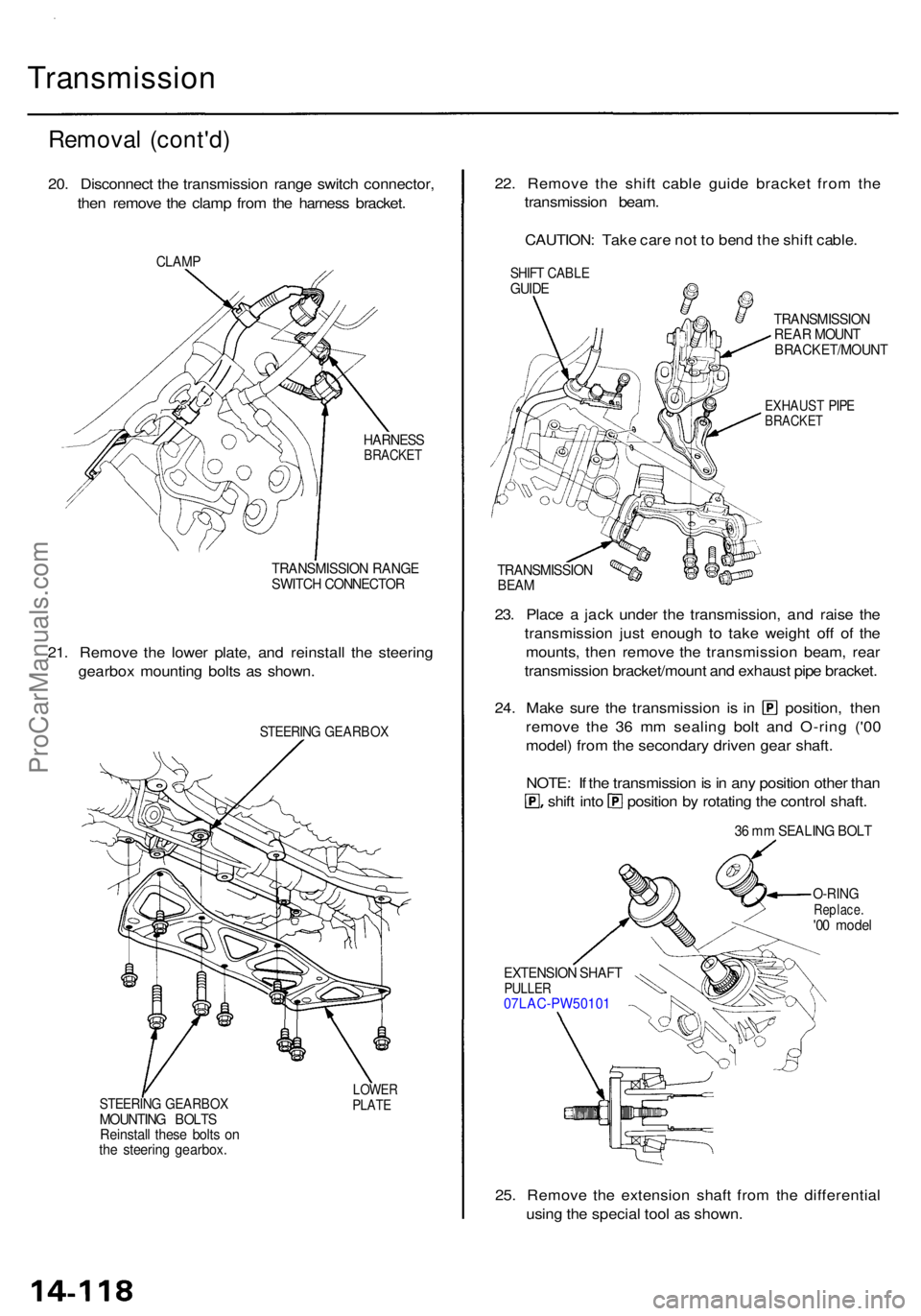

20. Disconnec t th e transmissio n rang e switc h connector ,

the n remov e th e clam p fro m th e harnes s bracket .

CLAMP

HARNES SBRACKE T

TRANSMISSIO N RANG E

SWITC H CONNECTO R

21. Remov e th e lowe r plate , an d reinstal l th e steerin g

gearbo x mountin g bolt s a s shown .

STEERIN G GEARBO X

STEERING GEARBO XMOUNTING BOLT S

Reinstal l thes e bolt s o n

th e steerin g gearbox .

LOWERPLATE

22. Remov e th e shif t cabl e guid e bracke t fro m th e

transmissio n beam .

CAUTION : Tak e car e no t t o ben d th e shif t cable .

TRANSMISSIO N

REA R MOUN T

BRACKET/MOUN T

EXHAUST PIP EBRACKE T

TRANSMISSIO NBEAM

23. Plac e a jac k unde r th e transmission , an d rais e th e

transmissio n jus t enoug h t o tak e weigh t of f o f th e

mounts , the n remov e th e transmissio n beam , rea r

transmissio n bracket/moun t an d exhaus t pip e bracket .

24. Mak e sur e th e transmissio n i s i n position , the n

remov e th e 3 6 m m sealin g bol t an d O-rin g ('0 0

model ) fro m th e secondar y drive n gea r shaft .

NOTE : I f th e transmissio n is in an y positio n othe r tha n

shift int o positio n b y rotatin g th e contro l shaft .

36 m m SEALIN G BOL T

O-RIN GReplace .'00 mode l

EXTENSIO N SHAF T

PULLE R07LAC-PW5010 1

25. Remov e th e extensio n shaf t fro m th e differentia l

usin g th e specia l too l a s shown .

SHIFT CABL EGUIDE

ProCarManuals.com

Page 826 of 1954

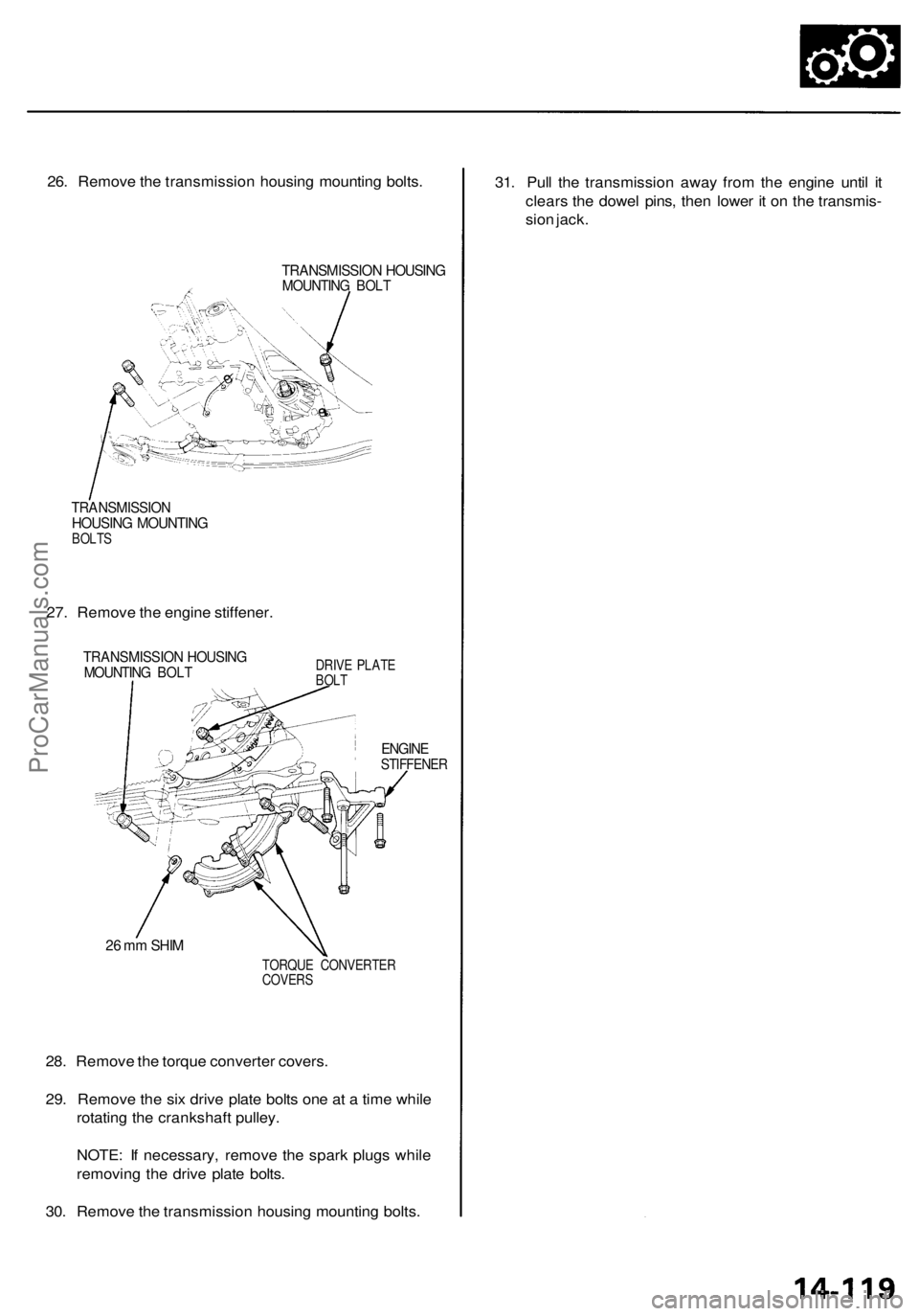

26. Remove the transmission housing mounting bolts.

TRANSMISSION HOUSING

MOUNTING BOLT

TRANSMISSION

HOUSING MOUNTING

BOLTS

27. Remove the engine stiffener.

TRANSMISSION HOUSING

MOUNTING BOLT

DRIVE PLATE

BOLT

ENGINE

STIFFENER

26 mm SHIM

TORQUE CONVERTER

COVERS

28. Remove the torque converter covers.

29. Remove the six drive plate bolts one at a time while

rotating the crankshaft pulley.

NOTE: If necessary, remove the spark plugs while

removing the drive plate bolts.

30. Remove the transmission housing mounting bolts.

31. Pull the transmission away from the engine until it

clears the dowel pins, then lower it on the transmis-

sion jack.ProCarManuals.com

Page 827 of 1954

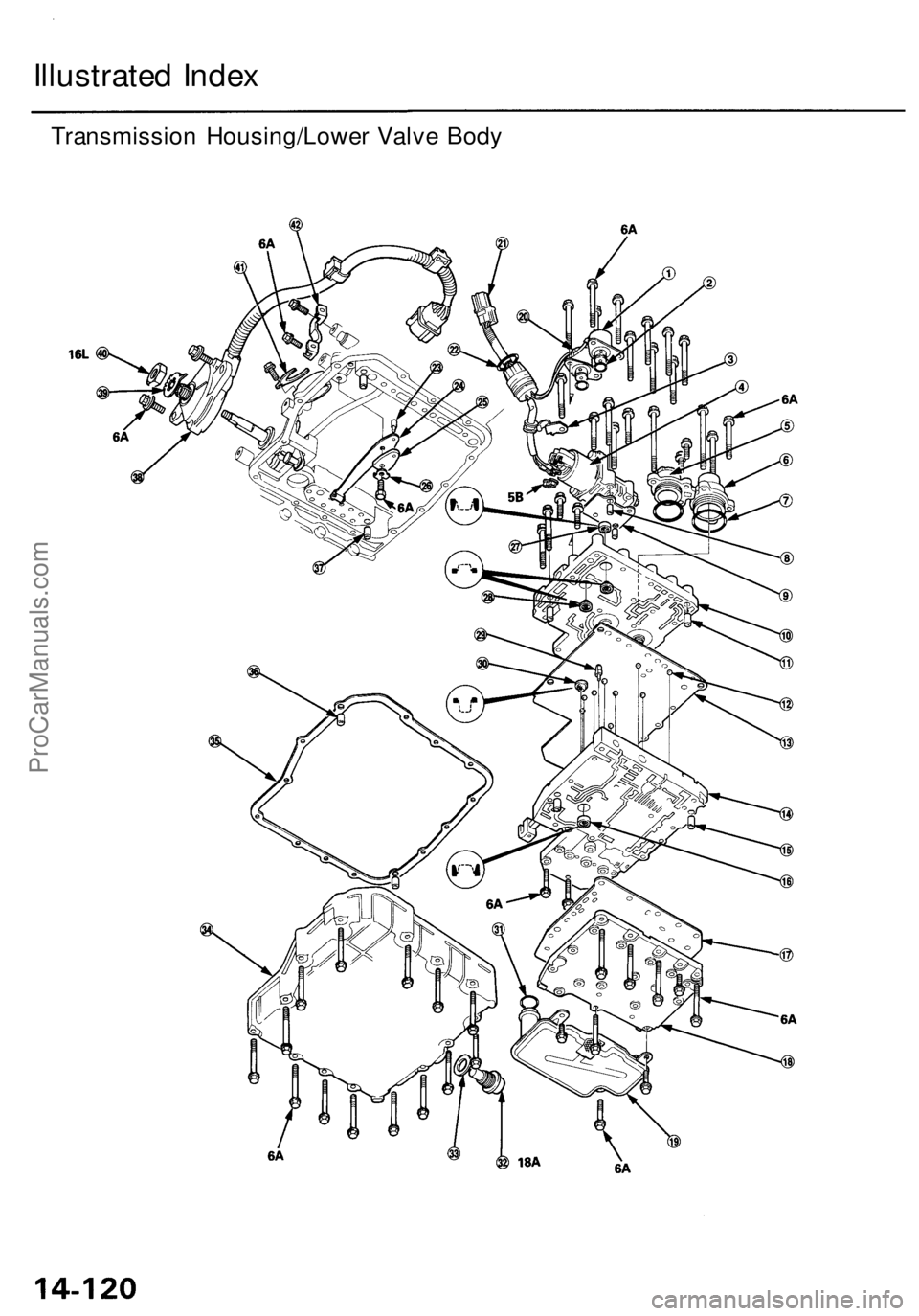

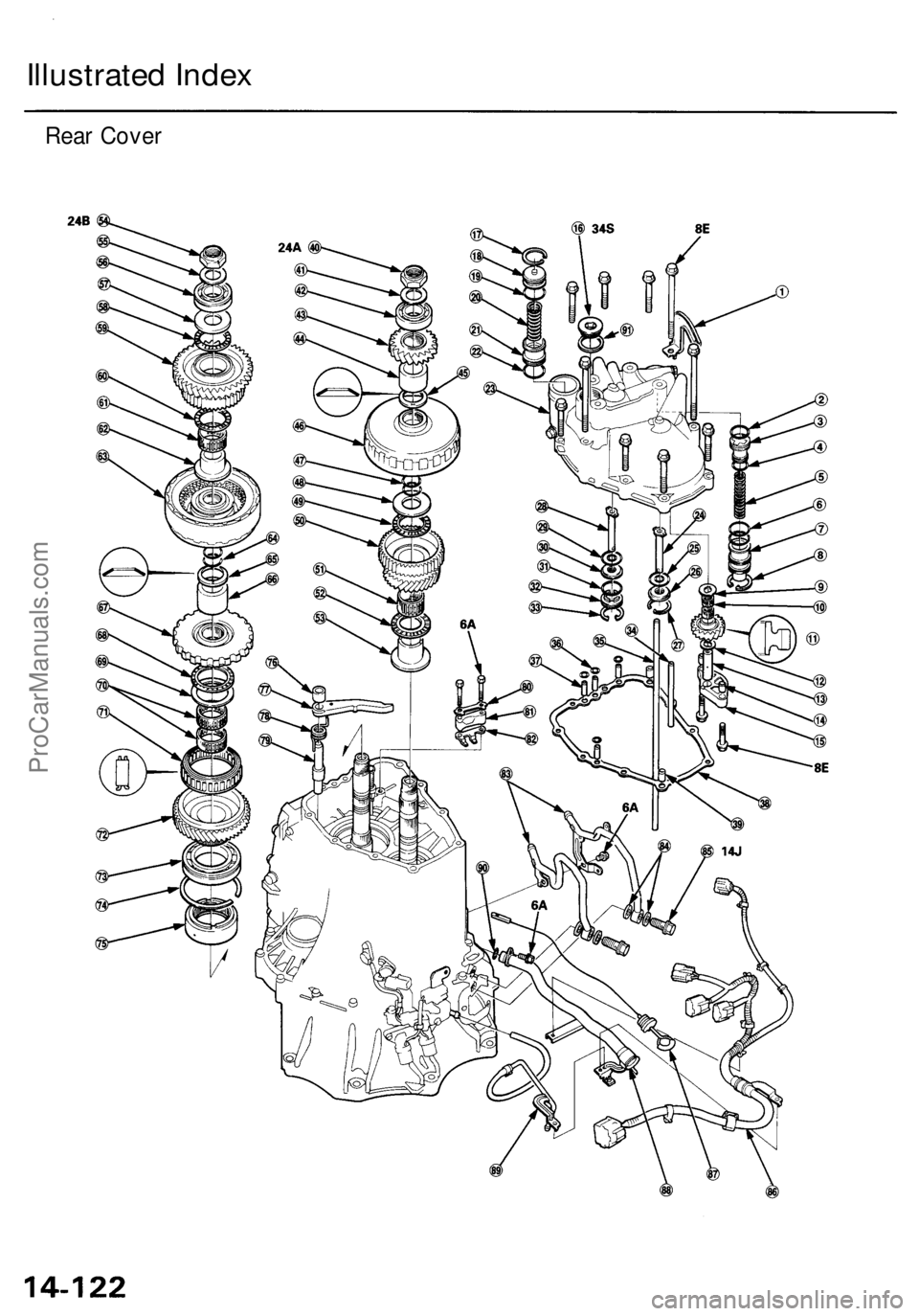

Illustrated Index

Transmission Housing/Lower Valve BodyProCarManuals.com

Page 828 of 1954

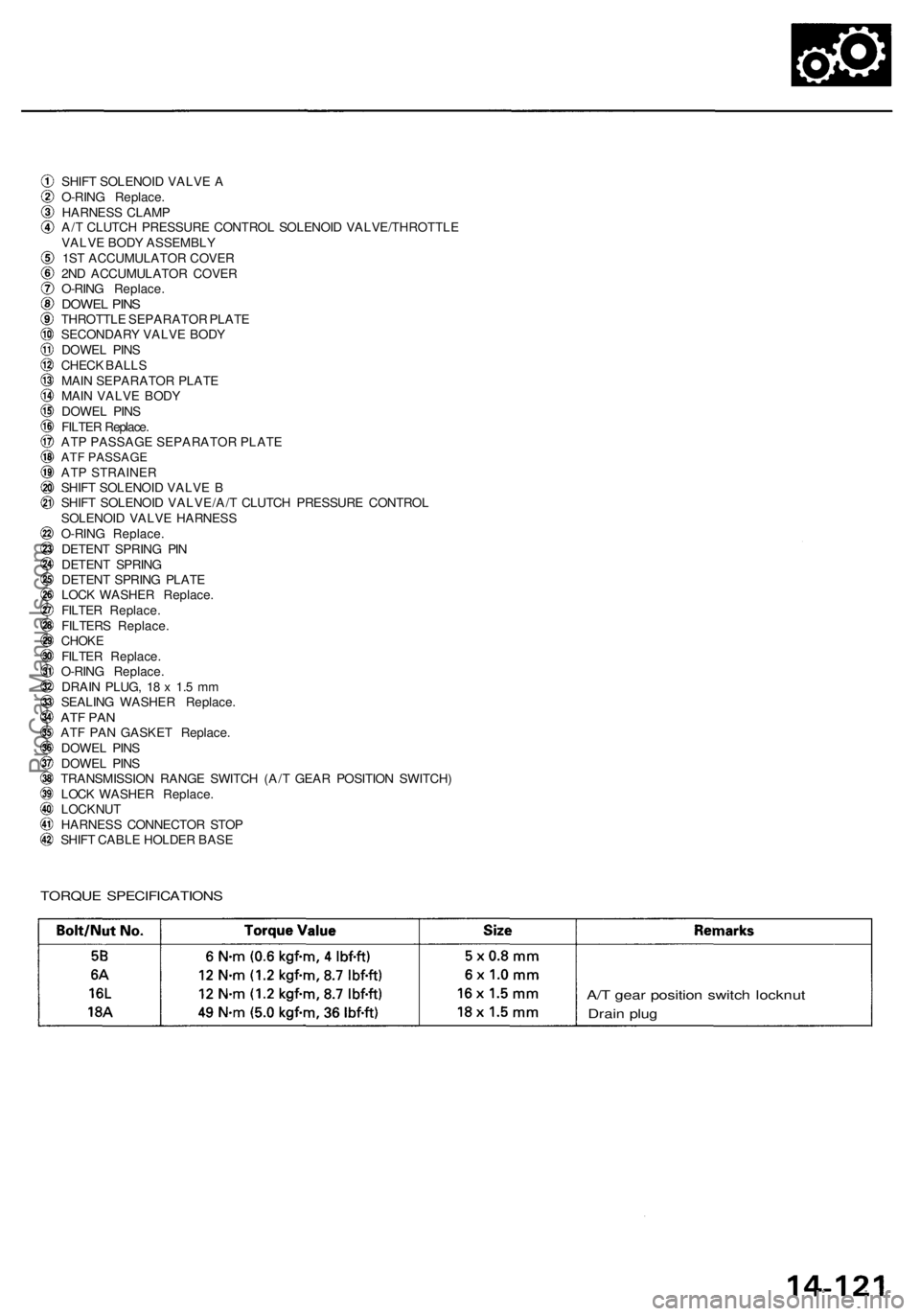

SHIFT SOLENOI D VALV E A

O-RIN G Replace .

HARNES S CLAM P

A/ T CLUTC H PRESSUR E CONTRO L SOLENOI D VALVE/THROTTL E

VALV E BOD Y ASSEMBL Y

1S T ACCUMULATO R COVE R

2N D ACCUMULATO R COVE R

O-RIN G Replace .

DOWEL PIN STHROTTL E SEPARATO R PLAT E

SECONDAR Y VALV E BOD Y

DOWE L PIN S

CHEC K BALL S

MAI N SEPARATO R PLAT E

MAI N VALV E BOD Y

DOWE L PIN S

FILTE R Replace.

ATP PASSAGE SEPARATOR PLATE

ATF PASSAGEATP STRAINER

SHIF T SOLENOI D VALV E B

SHIF T SOLENOI D VALVE/A/ T CLUTC H PRESSUR E CONTRO L

SOLENOI D VALV E HARNES S

O-RIN G Replace .

DETEN T SPRIN G PI N

DETEN T SPRIN G

DETEN T SPRIN G PLAT E

LOC K WASHE R Replace .

FILTE R Replace .

FILTER S Replace .

CHOKEFILTER Replace .

O-RIN G Replace .

DRAI N PLUG , 1 8 x 1. 5 m m

SEALIN G WASHE R Replace .

ATF PA NATF PA N GASKE T Replace .

DOWE L PIN S

DOWE L PIN S

TRANSMISSIO N RANG E SWITC H (A/ T GEA R POSITIO N SWITCH )

LOC K WASHE R Replace .

LOCKNU T

HARNES S CONNECTO R STO P

SHIF T CABL E HOLDE R BAS E

TORQU E SPECIFICATION S

A/T gea r positio n switc h locknu t

Drain plu g

ProCarManuals.com

Page 829 of 1954

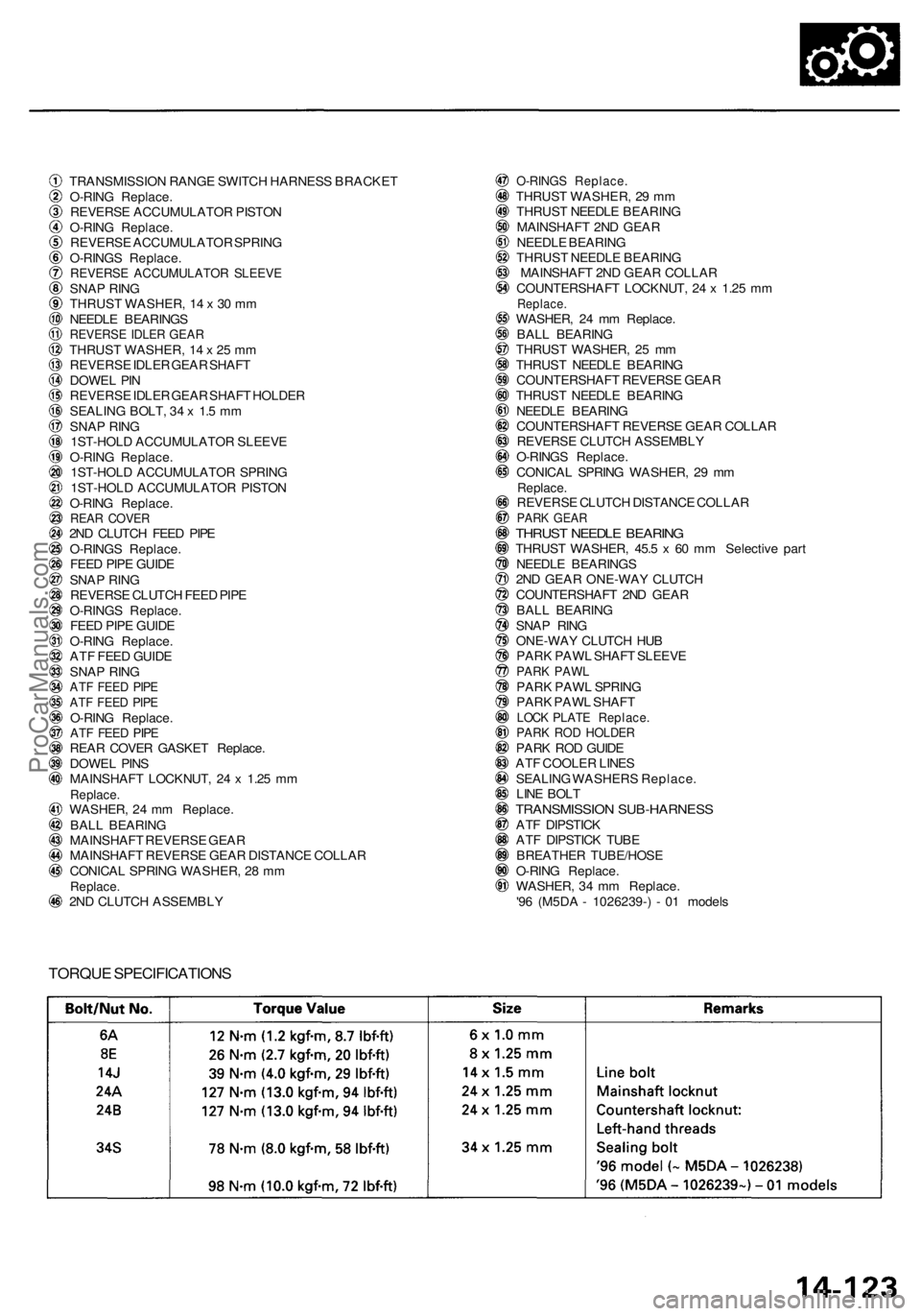

Illustrated Index

Rear CoverProCarManuals.com

Page 830 of 1954

TRANSMISSION RANG E SWITC H HARNES S BRACKE T

O-RIN G Replace .

REVERS E ACCUMULATO R PISTO N

O-RIN G Replace .

REVERS E ACCUMULATO R SPRIN G

O-RING S Replace .

REVERSE ACCUMULATO R SLEEV ESNAP RIN G

THRUS T WASHER , 1 4 x 30 m m

NEEDL E BEARING S

REVERSE IDLE R GEA RTHRUS T WASHER , 1 4 x 25 m m

REVERS E IDLE R GEA R SHAF T

DOWE L PI N

REVERS E IDLE R GEA R SHAF T HOLDE R

SEALIN G BOLT , 3 4 x 1. 5 m m

SNA P RIN G

1ST-HOL D ACCUMULATO R SLEEV E

O-RIN G Replace .

1ST-HOL D ACCUMULATO R SPRIN G

1ST-HOL D ACCUMULATO R PISTO N

O-RIN G Replace .

REAR COVE R2ND CLUTC H FEE D PIP E

O-RING S Replace .

FEE D PIP E GUID E

SNA P RIN G

REVERS E CLUTC H FEE D PIP E

O-RING S Replace .

FEE D PIP E GUID E

O-RIN G Replace .

AT F FEE D GUID E

SNA P RIN G

ATF FEE D PIP EATF FEE D PIP EO-RIN G Replace .ATF FEE D PIP EREA R COVE R GASKE T Replace .

DOWE L PIN S

MAINSHAF T LOCKNUT , 2 4 x 1.2 5 m m

Replace .WASHER , 2 4 m m Replace .

BAL L BEARIN G

MAINSHAF T REVERS E GEA R

MAINSHAF T REVERS E GEA R DISTANC E COLLA R

CONICA L SPRIN G WASHER , 2 8 m m

Replace .2ND CLUTC H ASSEMBL Y

O-RINGS Replace .THRUST WASHER , 2 9 m m

THRUS T NEEDL E BEARIN G

MAINSHAF T 2N D GEA R

NEEDL E BEARIN G

THRUS T NEEDL E BEARIN G

MAINSHAF T 2N D GEA R COLLA R

COUNTERSHAF T LOCKNUT , 2 4 x 1.2 5 m m

Replace .WASHER , 2 4 m m Replace .

BAL L BEARIN G

THRUS T WASHER , 2 5 m m

THRUS T NEEDL E BEARIN G

COUNTERSHAF T REVERS E GEA R

THRUS T NEEDL E BEARIN G

NEEDL E BEARIN G

COUNTERSHAF T REVERS E GEA R COLLA R

REVERS E CLUTC H ASSEMBL Y

O-RING S Replace .

CONICA L SPRIN G WASHER , 2 9 m m

Replace .REVERS E CLUTC H DISTANC E COLLA RPARK GEA RTHRUS T NEEDL E BEARIN GTHRUST WASHER , 45. 5 x 60 m m Selectiv e par t

NEEDL E BEARING S

2N D GEA R ONE-WA Y CLUTC H

COUNTERSHAF T 2N D GEA R

BAL L BEARIN G

SNA P RIN G

ONE-WA Y CLUTC H HU B

PAR K PAW L SHAF T SLEEV E

PARK PAW LPARK PAW L SPRIN G

PAR K PAW L SHAF T

LOCK PLAT E Replace .PARK RO D HOLDE RPARK RO D GUID E

AT F COOLE R LINE S

SEALIN G WASHER S Replace .

LIN E BOL T

TRANSMISSIO N SUB-HARNES SATF DIPSTIC K

AT F DIPSTIC K TUB E

BREATHE R TUBE/HOS E

O-RIN G Replace .

WASHER , 3 4 m m Replace .

'9 6 (M5D A - 1026239- ) - 0 1 model s

TORQU E SPECIFICATION S

ProCarManuals.com