ACURA RL KA9 1996 Service Repair Manual

RL KA9 1996

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56992/w960_56992-0.png

ACURA RL KA9 1996 Service Repair Manual

Trending: oil pressure, engine oil, fog light, air condition, fuel cap, airbag disable, turn signal

Page 851 of 1954

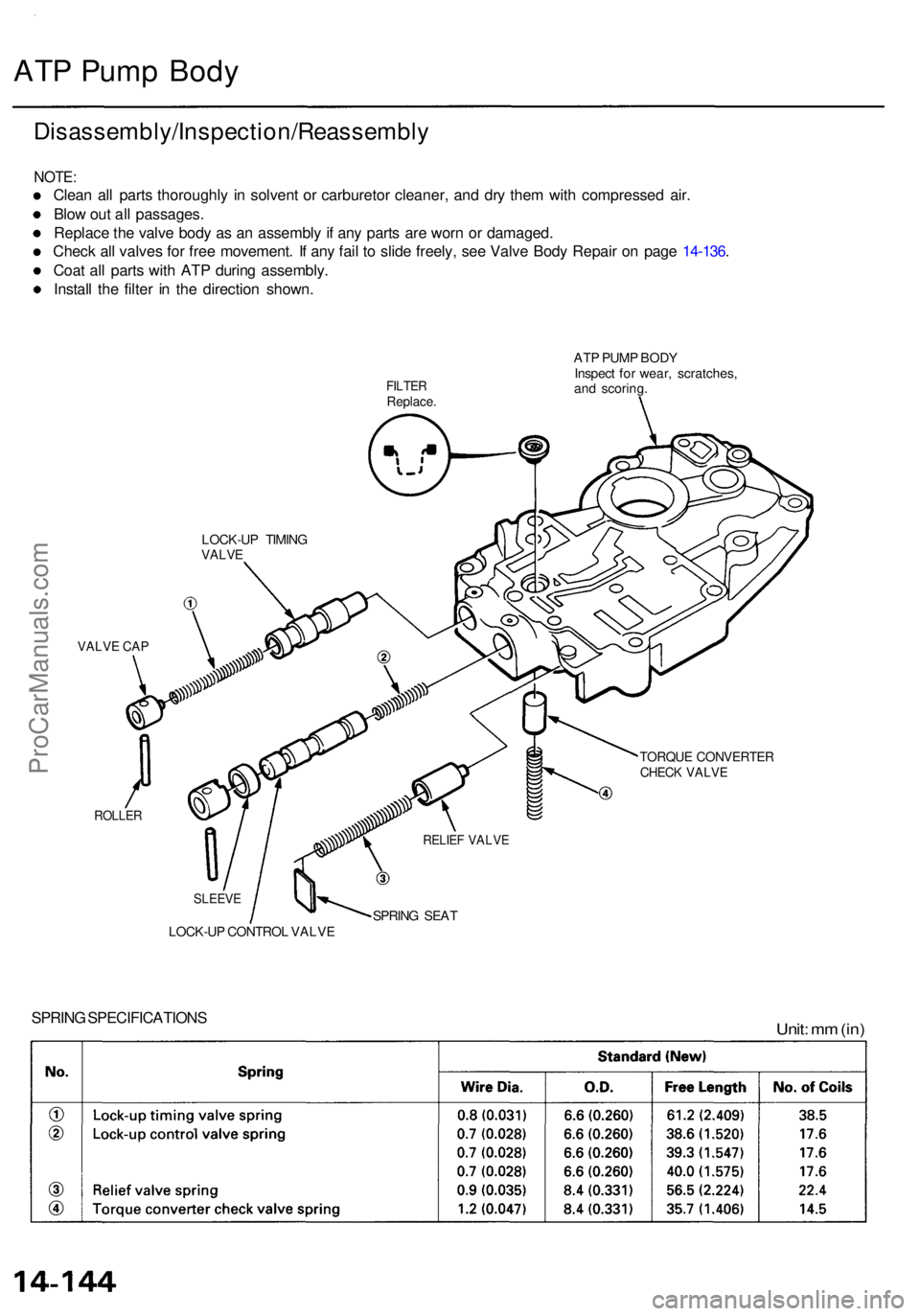

ATP Pum p Bod y

Disassembly/Inspection/Reassembl y

NOTE:

Clean al l part s thoroughl y i n solven t o r carbureto r cleaner , an d dr y the m wit h compresse d air .

Blo w ou t al l passages .

Replac e th e valv e bod y a s a n assembl y i f an y part s ar e wor n o r damaged .

Chec k al l valve s fo r fre e movement . I f an y fai l t o slid e freely , se e Valv e Bod y Repai r o n pag e 14-136 .

Coa t al l part s wit h ATP durin g assembly .

Instal l th e filte r i n th e directio n shown .

FILTERReplace .

ATP PUM P BOD Y

Inspec t fo r wear , scratches ,

an d scoring .

LOCK-U P TIMIN G

VALVE

VALV E CA P

ROLLE R

TORQU E CONVERTE RCHECK VALV E

SLEEV E

SPRING SEA T

LOCK-U P CONTRO L VALV E

SPRIN G SPECIFICATION SUnit: m m (in )

RELIE F VALV E

ProCarManuals.com

Page 852 of 1954

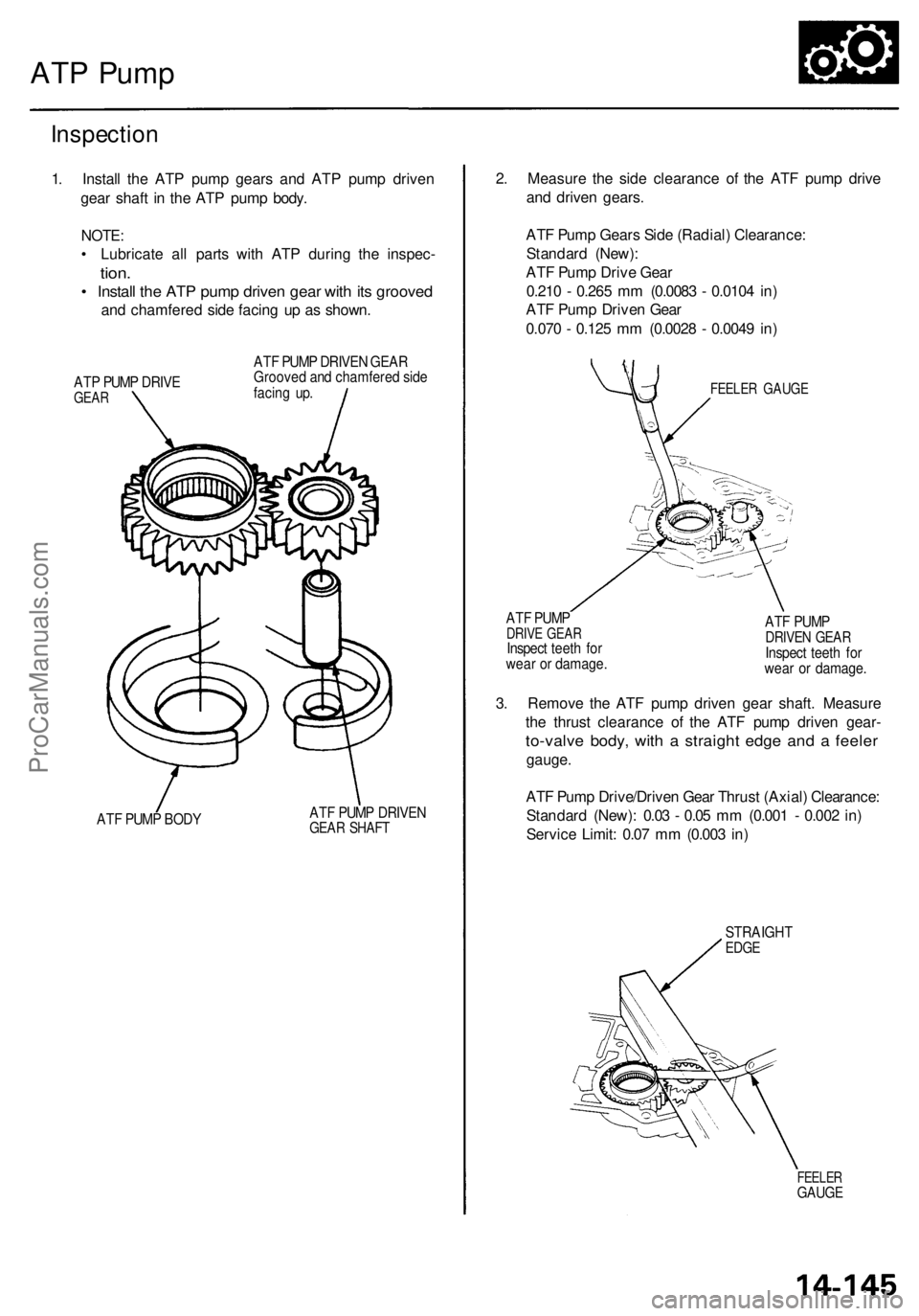

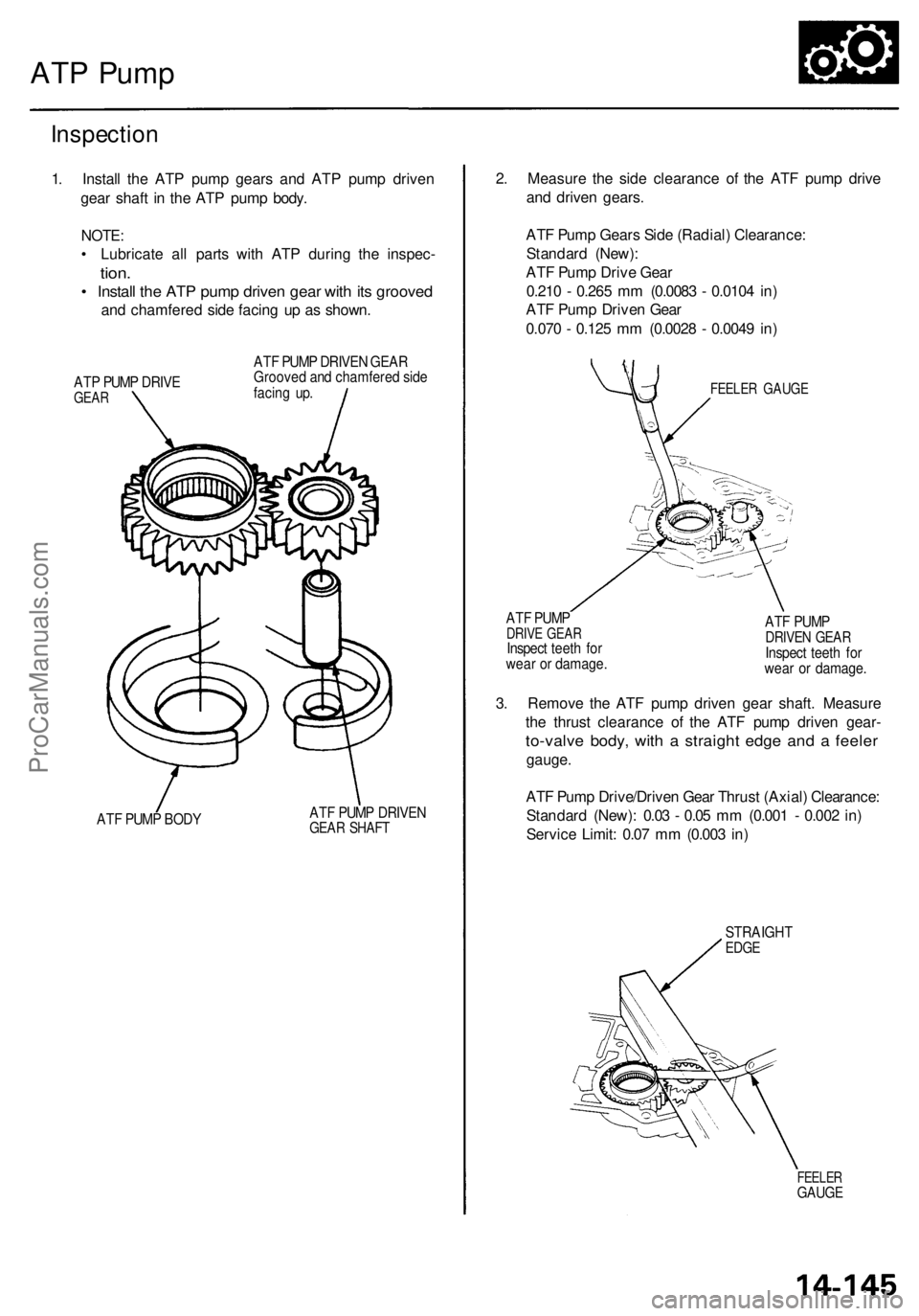

ATP Pump

Inspection

1. Install the ATP pump gears and ATP pump driven

gear shaft in the ATP pump body.

NOTE:

• Lubricate all parts with ATP during the inspec-

tion.

• Install the ATP pump driven gear with its grooved

and chamfered side facing up as shown.

ATP PUMP DRIVE

GEAR

ATF PUMP DRIVEN GEAR

Grooved and chamfered side

facing up.

ATF PUMP BODY

ATF PUMP DRIVEN

GEAR SHAFT

2. Measure the side clearance of the ATF pump drive

and driven gears.

ATF Pump Gears Side (Radial) Clearance:

Standard (New):

ATF Pump Drive Gear

0.210 - 0.265 mm (0.0083 - 0.0104 in)

ATF Pump Driven Gear

0.070 - 0.125 mm (0.0028 - 0.0049 in)

FEELER GAUGE

ATF PUMP

DRIVE GEAR

Inspect teeth for

wear or damage.

ATF PUMP

DRIVEN GEAR

Inspect teeth for

wear or damage.

3. Remove the ATF pump driven gear shaft. Measure

the thrust clearance of the ATF pump driven gear-

to-valve body, with a straight edge and a feeler

gauge.

ATF Pump Drive/Driven Gear Thrust (Axial) Clearance:

Standard (New): 0.03 - 0.05 mm (0.001 - 0.002 in)

Service Limit: 0.07 mm (0.003 in)

STRAIGHT

EDGE

FEELER

GAUGEProCarManuals.com

Page 853 of 1954

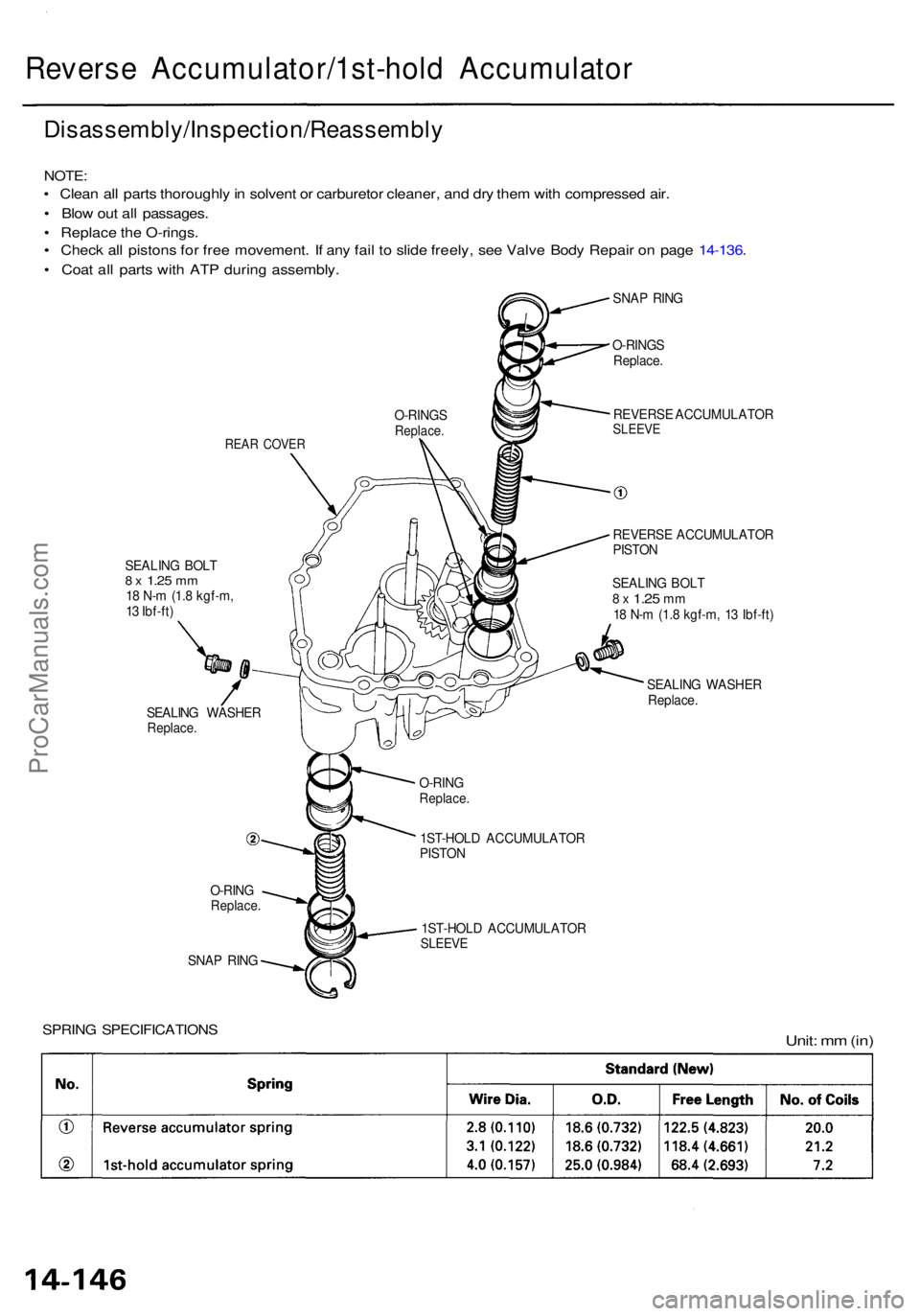

Reverse Accumulator/ 1st-hol d Accumulato r

Disassembly/Inspection/Reassembl y

NOTE:

• Clea n al l part s thoroughl y in solven t o r carbureto r cleaner , an d dr y the m wit h compresse d air .

• Blo w ou t al l passages .

• Replac e th e O-rings .

• Chec k al l piston s fo r fre e movement . I f an y fai l t o slid e freely , se e Valv e Bod y Repai r o n pag e 14-136 .

• Coa t al l part s wit h AT P durin g assembly .

SNAP RIN G

O-RING S

Replace .

REAR COVE R

SEALIN G BOL T8 x 1.2 5 mm18 N- m (1. 8 kgf-m ,

1 3 Ibf-ft )

SEALIN G WASHE R

Replace.

O-RINGReplace .

SNAP RIN G 1ST-HOL

D ACCUMULATO R

PISTO N

1ST-HOL D ACCUMULATO R

SLEEVE

REVERS E ACCUMULATO RSLEEVE

REVERS E ACCUMULATO R

PISTO N

SEALIN G BOL T

8 x 1.2 5 mm18 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

SEALIN G WASHE R

Replace .

SPRING SPECIFICATION SUnit: m m (in )

O-RING SReplace .

O-RINGReplace .

ProCarManuals.com

Page 854 of 1954

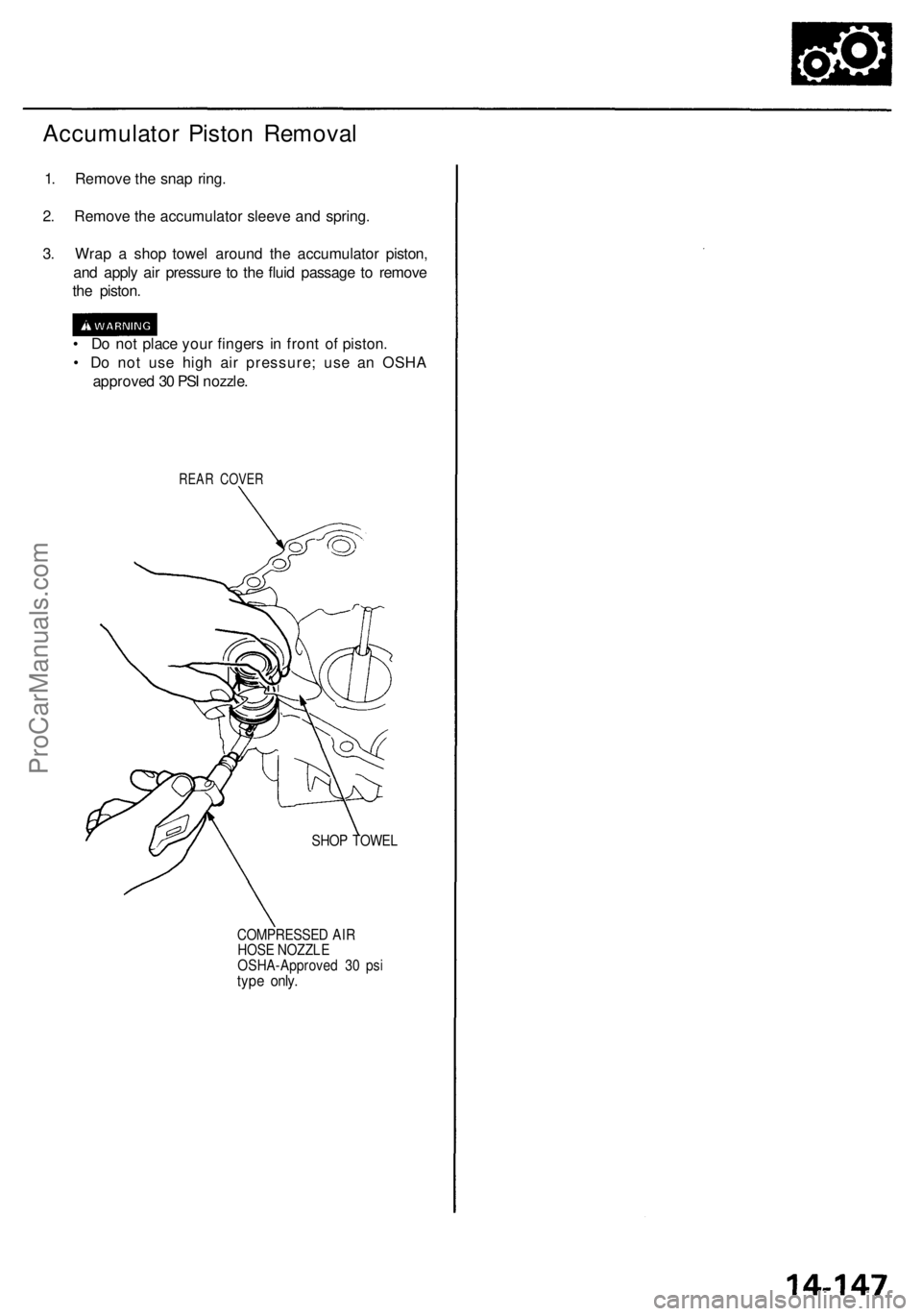

Accumulator Piston Removal

1. Remove the snap ring.

2. Remove the accumulator sleeve and spring.

3. Wrap a shop towel around the accumulator piston,

and apply air pressure to the fluid passage to remove

the piston.

• Do not place your fingers in front of piston.

• Do not use high air pressure; use an OSHA

approved 30 PSI nozzle.

REAR COVER

SHOP TOWEL

COMPRESSED AIR

HOSE NOZZLE

OSHA-Approved 30 psi

type only.ProCarManuals.com

Page 855 of 1954

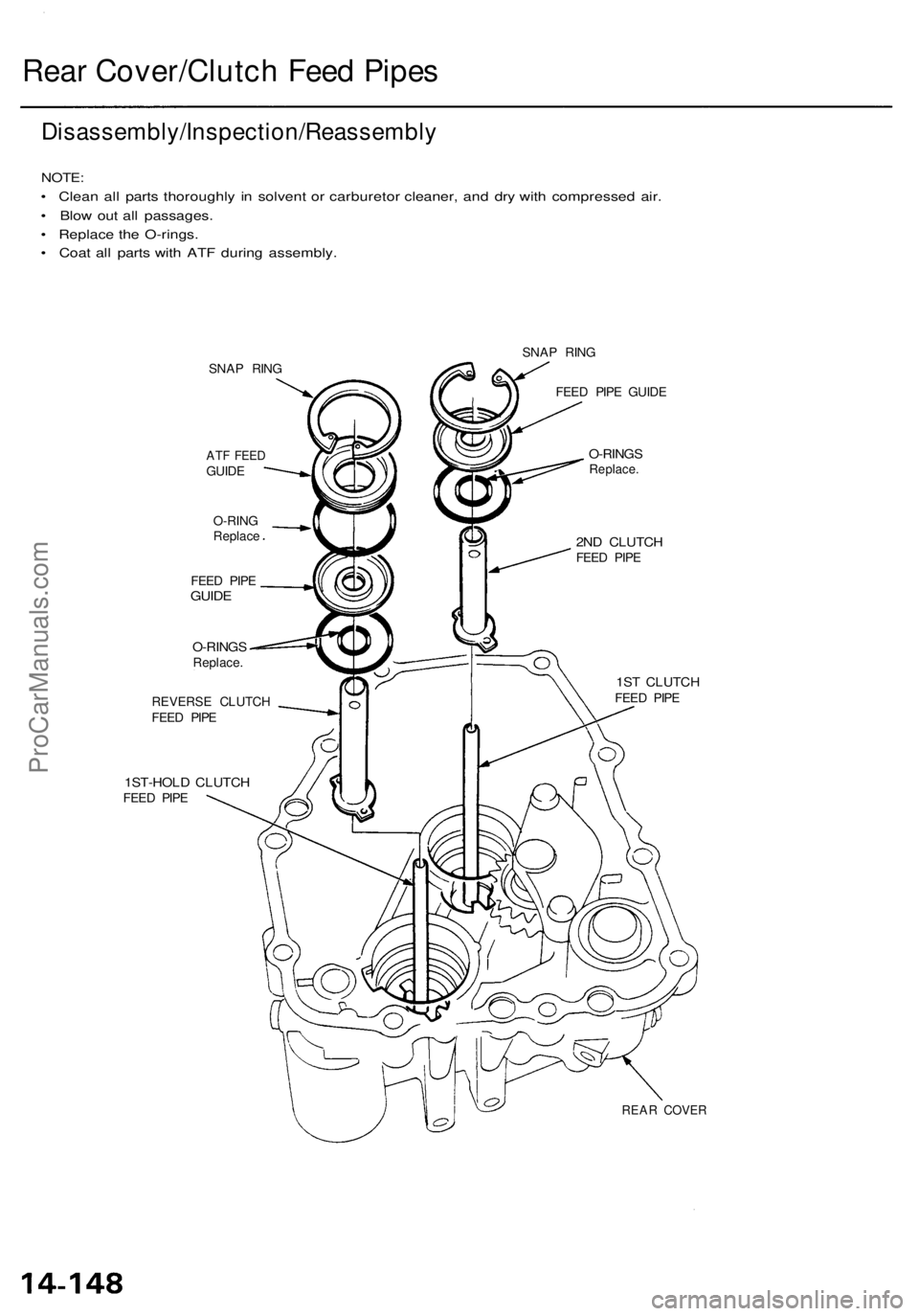

Rear Cover/Clutch Feed Pipes

Disassembly/Inspection/Reassembly

NOTE:

• Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.

• Blow out all passages.

• Replace the O-rings.

• Coat all parts with ATF during assembly.

SNAP RING

ATF FEED

GUIDE

O-RING

Replace

FEED PIPE

GUIDE

1ST-HOLD CLUTCH

FEED PIPE

SNAP RING

FEED PIPE GUIDE

O-RINGS

Replace.

2ND CLUTCH

FEED PIPE

1ST CLUTCH

FEED PIPE

REAR COVER

REVERSE CLUTCH

FEED PIPE

O-RINGS

Replace.ProCarManuals.com

Page 856 of 1954

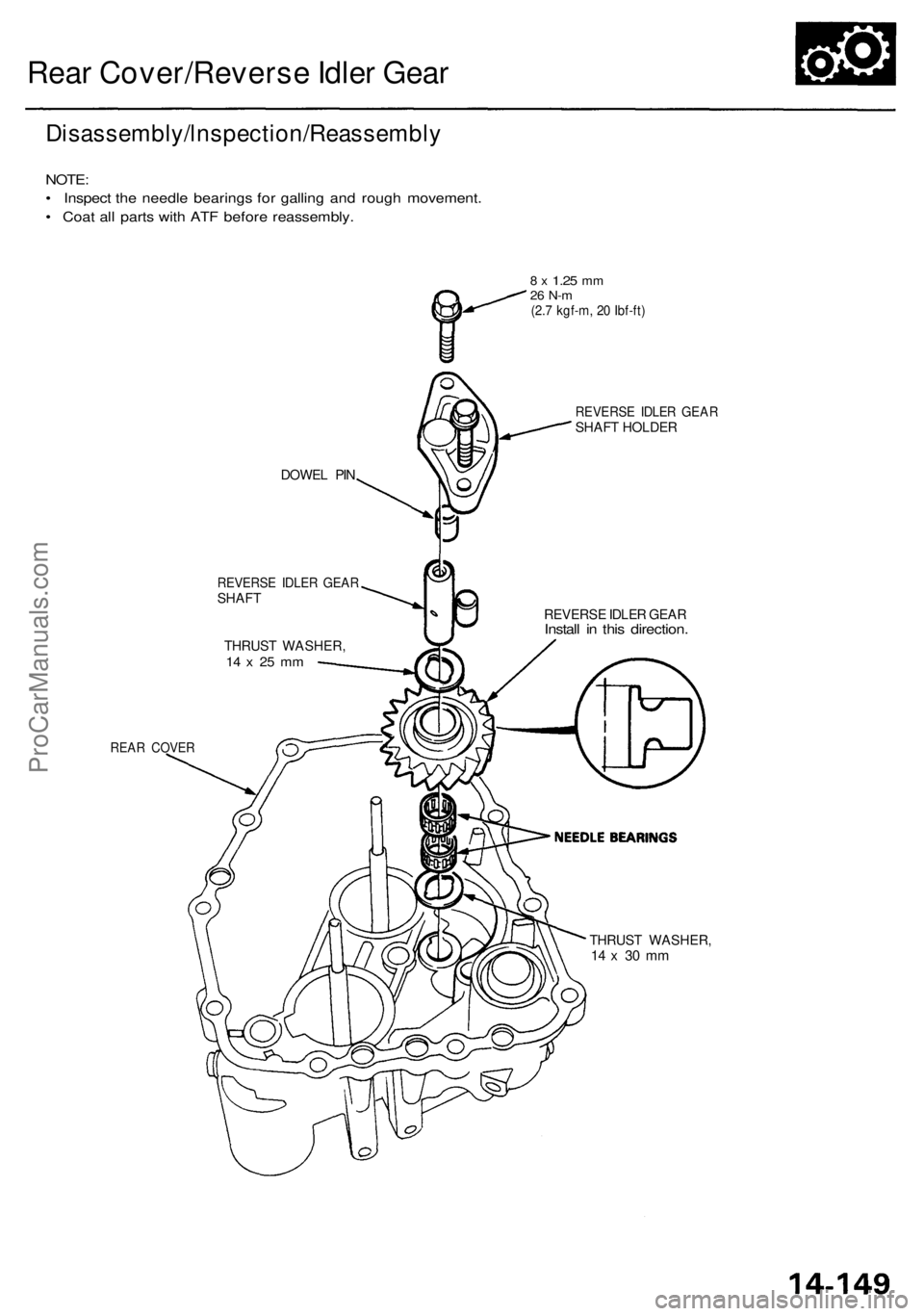

Rear Cover/Reverse Idler Gear

Disassembly/lnspection/Reassembly

NOTE:

• Inspect the needle bearings for galling and rough movement.

• Coat all parts with ATF before reassembly.

DOWEL PIN

REVERSE IDLER GEAR

SHAFT

THRUST WASHER,

14 x 25 mm

REAR COVER

8 x

1.25

mm

26 N-m

(2.7 kgf-m, 20 Ibf-ft)

REVERSE IDLER GEAR

SHAFT HOLDER

REVERSE IDLER GEAR

Install in this direction.

THRUST WASHER,

14 x 30 mmProCarManuals.com

Page 857 of 1954

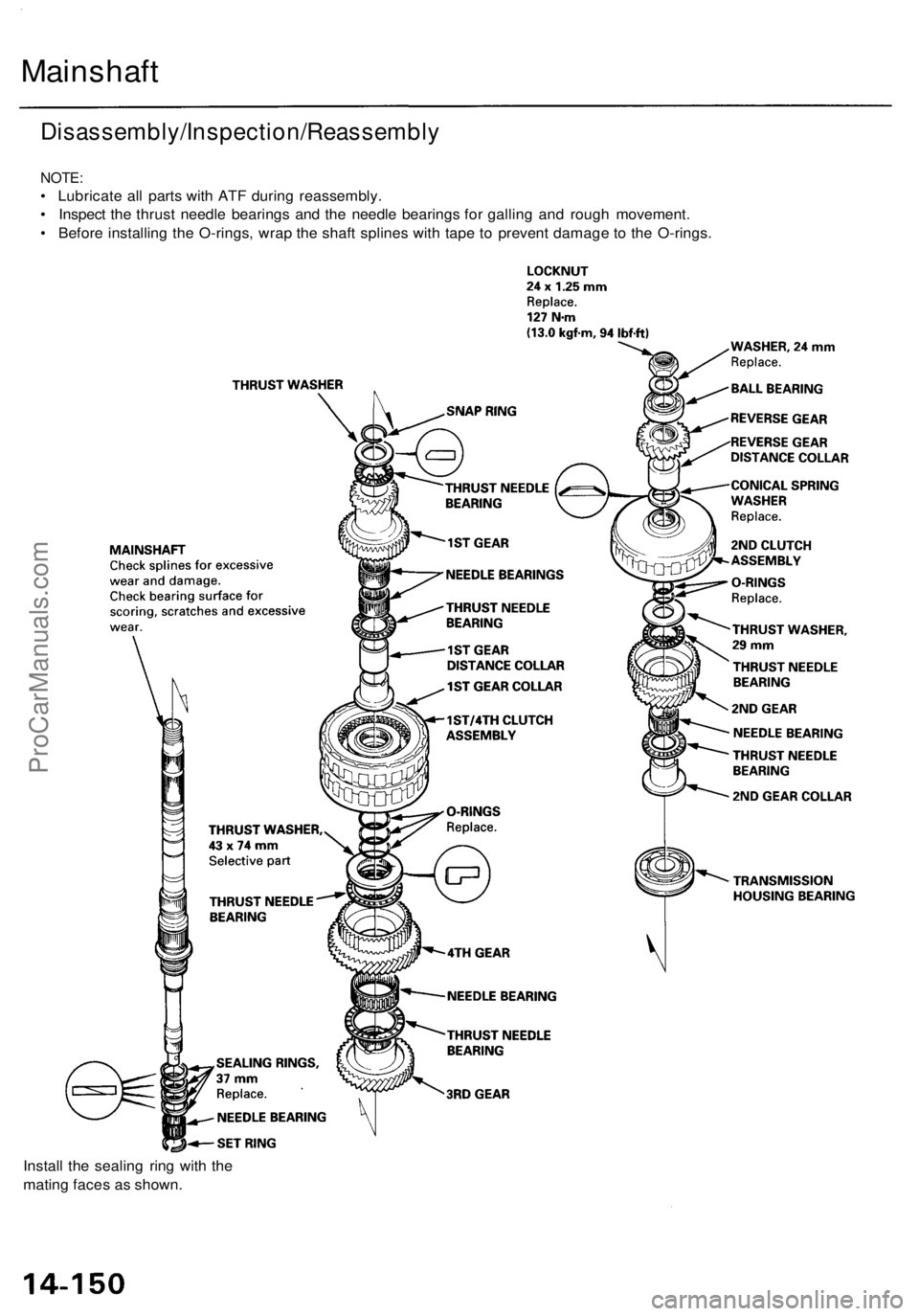

Mainshaft

Disassembly/Inspection/Reassembly

NOTE:

• Lubricate all parts with ATF during reassembly.

• Inspect the thrust needle bearings and the needle bearings for galling and rough movement.

• Before installing the O-rings, wrap the shaft splines with tape to prevent damage to the O-rings.

Install the sealing ring with the

mating faces as shown.ProCarManuals.com

Page 858 of 1954

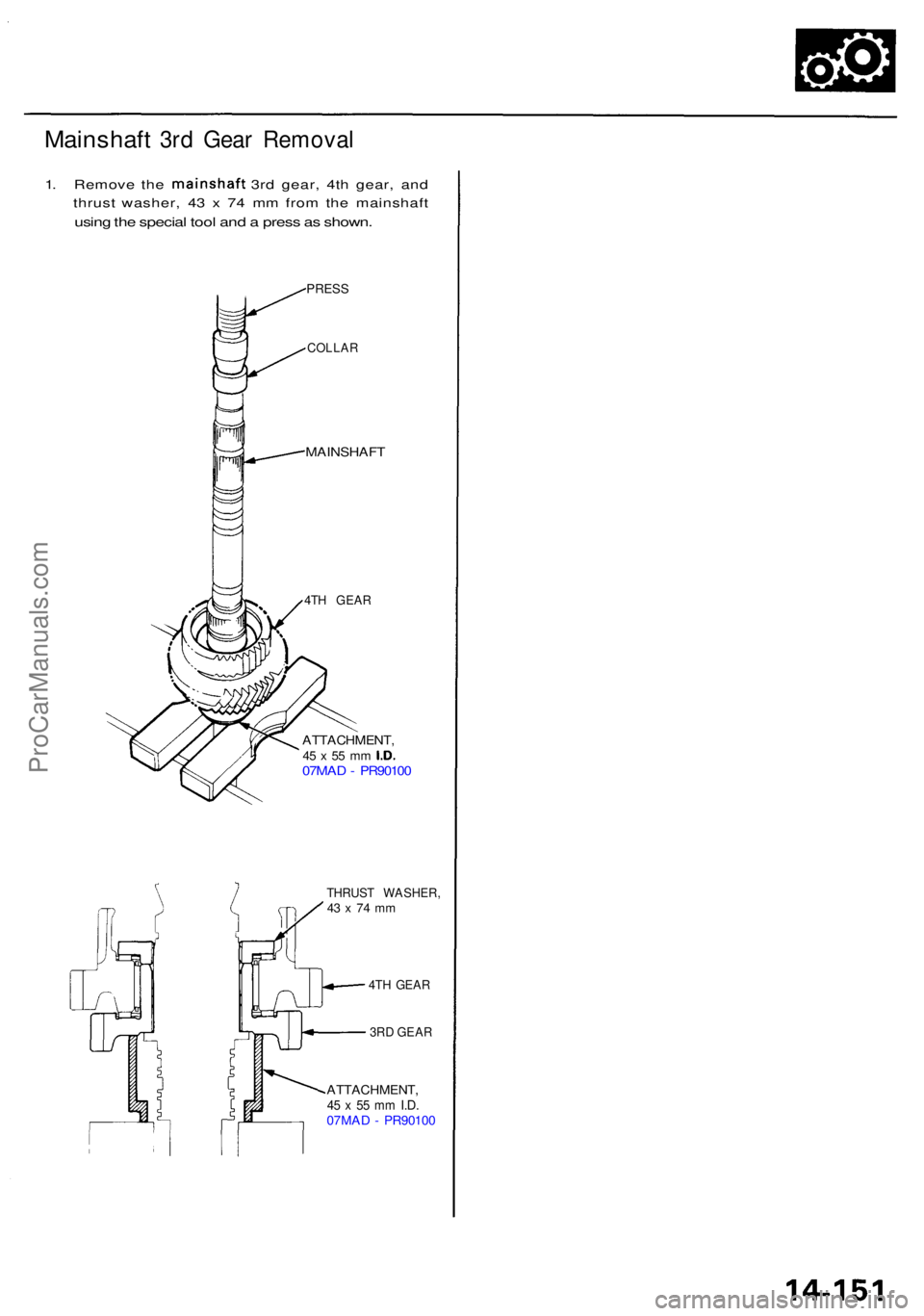

Mainshaft 3rd Gea r Remova l

1. Remov e th e mainshaf t 3rd gear , 4t h gear , an d

thrus t washer , 4 3 x 7 4 m m fro m th e mainshaf t

using th e specia l too l an d a pres s a s shown .

PRESS

COLLA R

MAINSHAF T

4TH GEA R

ATTACHMENT ,45 x 55 m m I.D .07MA D - PR9010 0

THRUST WASHER ,43 x 74 m m

4TH GEA R

3R D GEA R

ATTACHMENT ,45 x 55 m m I.D .07MA D - PR9010 0

ProCarManuals.com

Page 859 of 1954

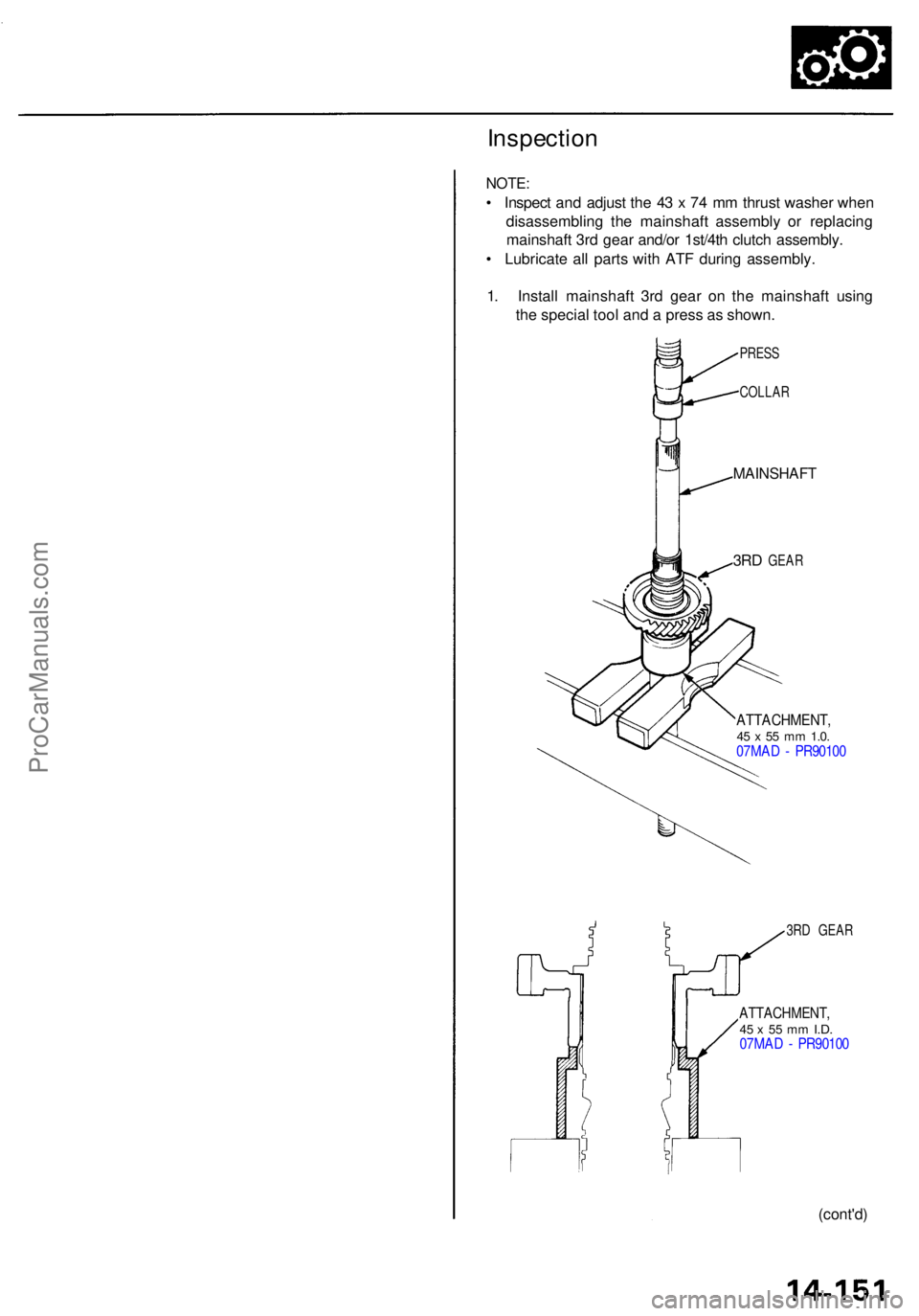

Inspection

NOTE:

• Inspec t an d adjus t th e 4 3 x 7 4 m m thrus t washe r whe n

disassemblin g th e

mainshaf t assembly o r replacin g

mainshaft 3rd gea r and/o r 1st/4th clutch assembly .

• Lubricat e al l part s wit h AT F durin g assembly .

1 . Instal l mainshaf t 3r d gea r o n th e mainshaf t usin g

th e specia l too l an d a pres s a s shown .

PRESS

COLLA R

MAINSHAF T

3RD GEA R

ATTACHMENT ,45 x 55 m m 1.0 .07MA D - PR9010 0

3RD GEA R

ATTACHMENT ,45 x 5 5 m m I.D .07MA D - PR9010 0

(cont'd)

ProCarManuals.com

Page 860 of 1954

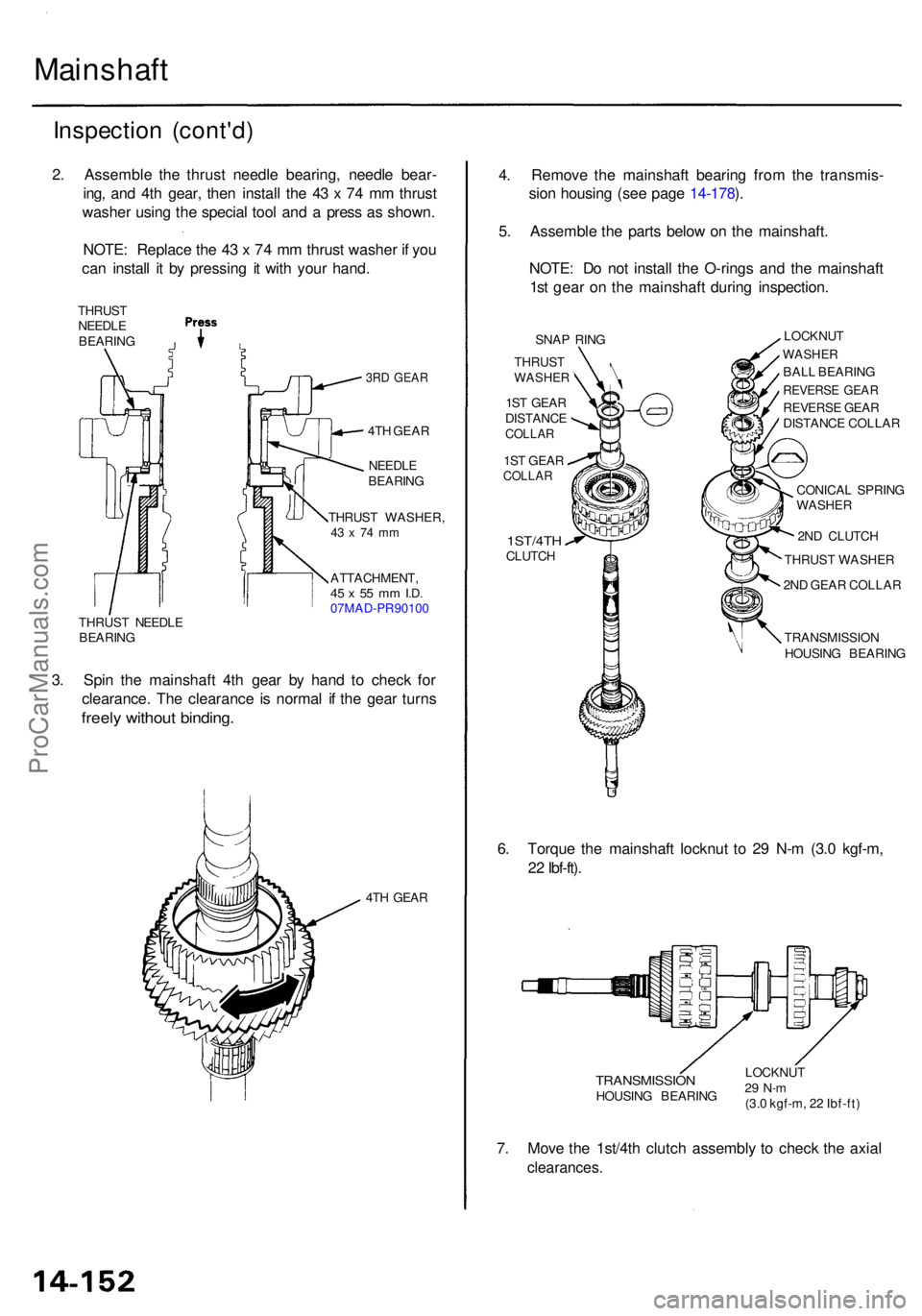

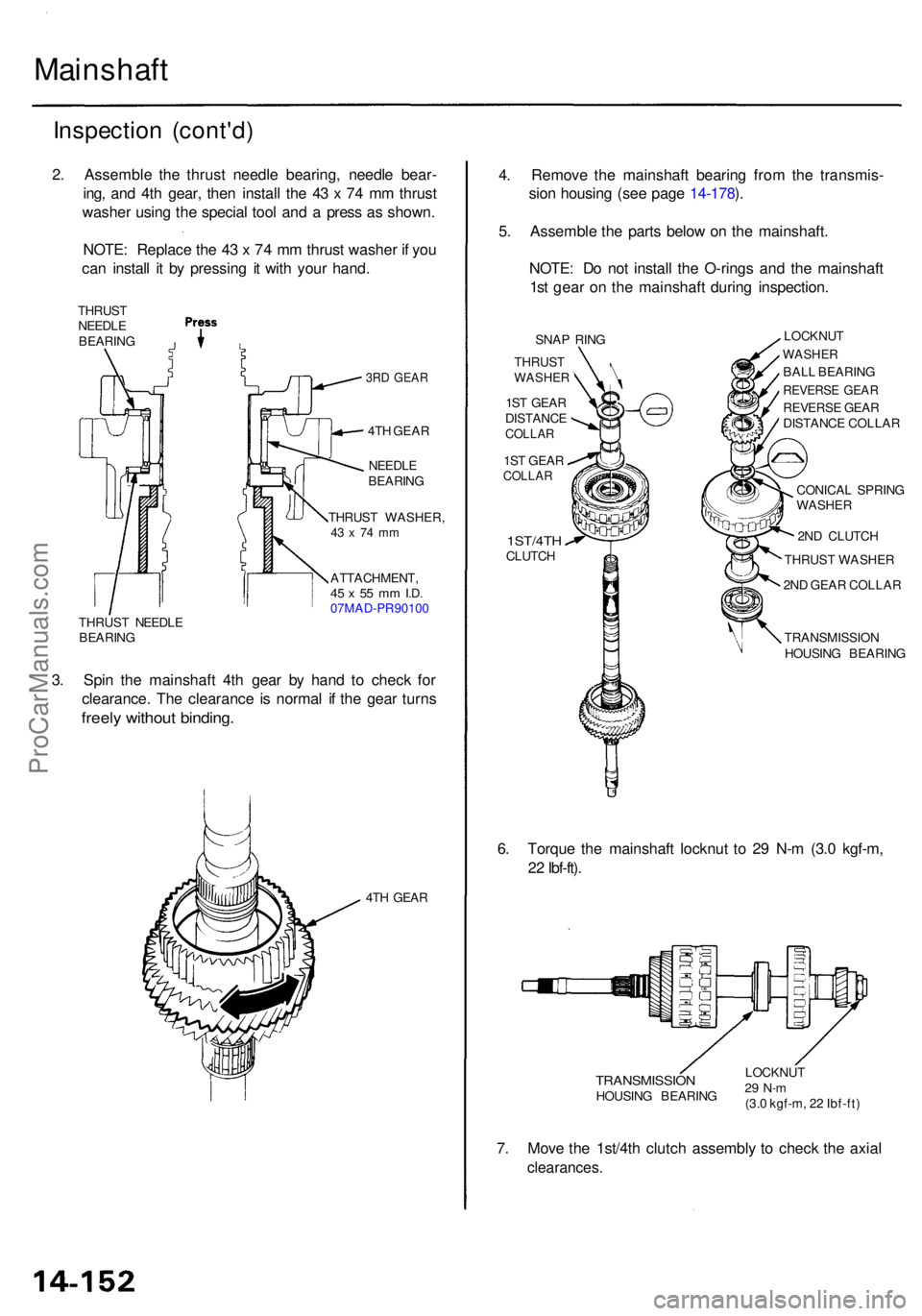

Mainshaft

Inspection (cont'd )

2. Assembl e th e thrus t needl e bearing , needl e bear -

ing , an d 4t h gear , the n instal l th e 4 3 x 7 4 m m thrus t

washe r usin g th e specia l too l an d a pres s a s shown .

NOTE : Replac e th e 4 3 x 7 4 m m thrus t washe r i f yo u

ca n instal l i t b y pressin g i t wit h you r hand .

THRUS T

NEEDL E

BEARIN G

3RD GEA R

4TH GEA R

NEEDL E

BEARIN G

THRUS T WASHER ,

43 x 74 m m

ATTACHMENT ,45 x 55 m m I.D .07MAD-PR9010 0THRUST NEEDL E

BEARIN G

3. Spi n th e mainshaf t 4t h gea r b y han d t o chec k fo r

clearance . Th e clearanc e i s norma l i f th e gea r turn s

freely withou t binding .

4TH GEA R

4. Remov e th e mainshaf t bearin g fro m th e transmis -

sio n housin g (se e pag e 14-178 ).

5 . Assembl e th e part s belo w o n th e mainshaft .

NOTE : D o no t instal l th e O-ring s an d th e mainshaf t

1s t gea r o n th e mainshaf t durin g inspection .

1ST/4THCLUTCH LOCKNU

T

WASHER

BALL BEARIN G

REVERS E GEA R

REVERS E GEA R

DISTANC E COLLA R

CONICA L SPRIN G

WASHE R

2ND GEA R COLLA R

TRANSMISSIO N

HOUSIN G BEARIN G

6. Torqu e th e mainshaf t locknu t t o 2 9 N- m (3. 0 kgf-m ,

2 2 Ibf-ft) .

TRANSMISSIO NHOUSING BEARIN GLOCKNU

T29 N- m(3.0 kgf-m , 2 2 Ibf-ft )

7. Mov e th e 1st/4t h clutc h assembl y t o chec k th e axia l

clearances .

SNAP RIN G

THRUS T

WASHE R

1ST GEA R

DISTANC E

COLLAR

1ST GEA RCOLLA R

THRUS T WASHE R

2N

D CLUTC H

ProCarManuals.com

Trending: oil capacity, seats, fuel tank removal, oil, tire pressure, height, ESP