ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1201 of 1771

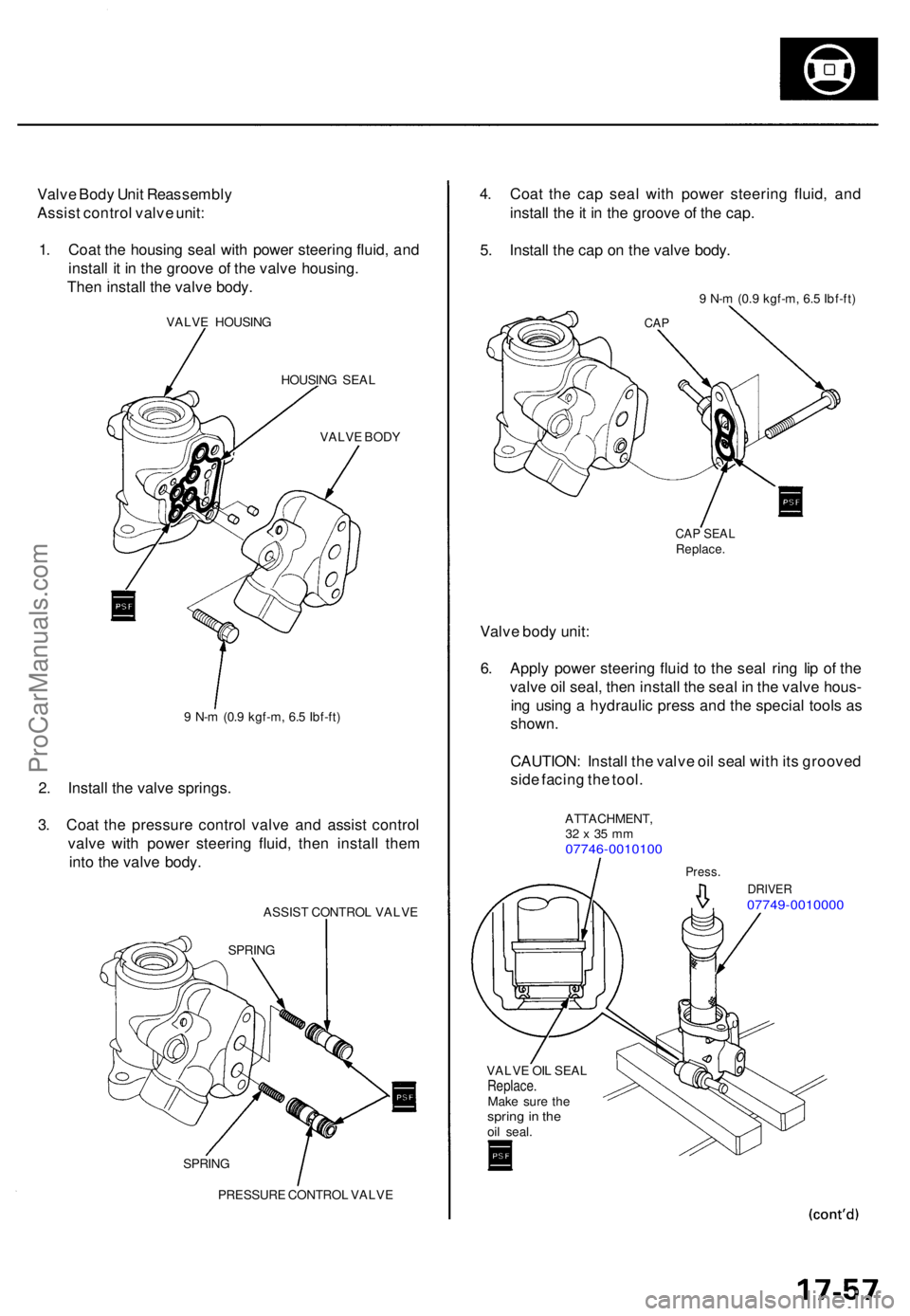

Valve Bod y Uni t Reassembl y

Assis t contro l valv e unit :

1 . Coa t th e housin g sea l wit h powe r steerin g fluid , an d

instal l i t i n th e groov e o f th e valv e housing .

The n instal l th e valv e body .

VALV E HOUSIN G

HOUSIN G SEA L

VALV E BOD Y

9 N- m (0. 9 kgf-m , 6. 5 Ibf-ft )

2. Instal l th e valv e springs .

3 . Coa t th e pressur e contro l valv e an d assis t contro l

valv e wit h powe r steerin g fluid , the n instal l the m

int o th e valv e body .

ASSIS T CONTRO L VALV E

PRESSUR E CONTRO L VALV E

4. Coa t th e ca p sea l wit h powe r steerin g fluid , an d

instal l th e it i n th e groov e o f th e cap .

5 . Instal l th e ca p o n th e valv e body .

9 N- m (0. 9 kgf-m , 6. 5 Ibf-ft )

CAP SEA LReplace .

Valve bod y unit :

6 . Appl y powe r steerin g flui d t o th e sea l rin g li p o f th e

valv e oi l seal , the n instal l th e sea l i n th e valv e hous -

in g usin g a hydrauli c press and th e specia l tool s a s

shown .

CAUTION : Instal l th e valv e oi l sea l wit h it s groove d

sid e facin g th e tool .

ATTACHMENT ,32 x 35 m m07746-001010 0

Press.

DRIVE R07749-001000 0

VALVE OI L SEA LReplace .Make sur e th esprin g in th eoil seal .

CAP

SPRIN G

SPRIN G

ProCarManuals.com

Page 1202 of 1771

Steering Gearbo x

Reassembl y (cont'd )

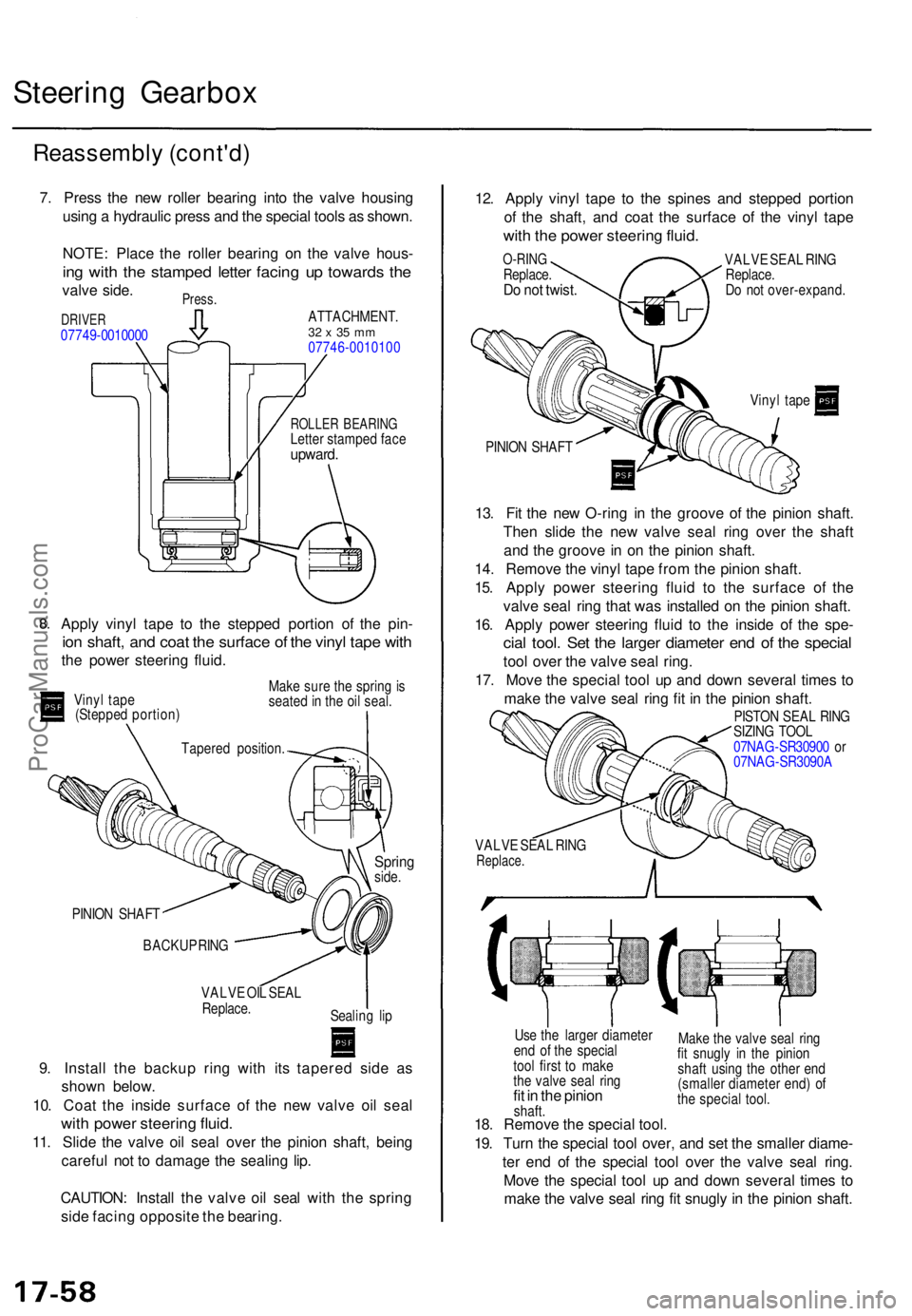

7. Pres s th e ne w rolle r bearin g int o th e valv e housin g

usin g a hydrauli c pres s an d th e specia l tool s a s shown .

NOTE : Plac e th e rolle r bearin g o n th e valv e hous -

ing wit h th e stampe d lette r facin g u p toward s th e

valv e side .Press .

DRIVE R07749-001000 0

ATTACHMENT .32 x 35 m m07746-001010 0

ROLLER BEARIN GLetter stampe d fac eupward .

8.Appl y viny l tap e t o th e steppe d portio n o f th e pin -

ion shaft , an d coa t th e surfac e o f th e viny l tap e wit h

the powe r steerin g fluid .

Vinyl tap e

(Steppe d portion ) Mak

e sur e th e sprin g i s

seate d in th e oi l seal .

Sprin gside.

PINIO N SHAF T

BACKU P RIN G

VALV E OI L SEA L

Replace .

9. Instal l th e backu p rin g wit h it s tapere d sid e a s

show n below .

10 . Coa t th e insid e surfac e of the ne w valv e oi l sea l

with powe r steerin g fluid .

11. Slid e th e valv e oi l sea l ove r th e pinio n shaft , bein g

carefu l no t t o damag e th e sealin g lip .

CAUTION : Instal l th e valv e oi l sea l wit h th e sprin g

sid e facin g opposit e th e bearing . 12

. Appl y viny l tap e t o th e spine s an d steppe d portio n

o f th e shaft , an d coa t th e surfac e o f th e viny l tap e

with th e powe r steerin g fluid .

O-RIN GReplace .Do no t twist .

VALV E SEA L RIN G

Replace .

D o no t over-expand .

Viny l tap e

PINIO N SHAF T

13. Fi t th e ne w O-rin g i n th e groov e o f th e pinio n shaft .

The n slid e th e ne w valv e sea l rin g ove r th e shaf t

an d th e groov e in o n th e pinio n shaft .

14 . Remov e th e vinyl tape fro m th e pinio n shaft .

15 . Appl y powe r steerin g flui d t o th e surfac e of the

valv e sea l rin g tha t wa s installe d o n th e pinio n shaft .

16 . Appl y powe r steerin g flui d t o th e insid e o f th e spe -

cial tool . Se t th e large r diamete r en d o f th e specia l

tool ove r th e valv e sea l ring .

17 . Mov e th e specia l too l u p an d dow n severa l time s t o

mak e th e valv e sea l rin g fi t i n th e pinio n shaft .

Make th e valv e sea l rin g

fi t snugl y i n th e pinio n

shaf t usin g th e othe r en d

(smalle r diamete r end ) o f

th e specia l tool .

Us

e th e large r diamete r

en d o f th e specia l

too l firs t t o mak e

th e valv e sea l rin g

fit i n th e pinio nshaft.18. Remov e th e specia l tool .

19 . Tur n th e specia l too l over , an d se t th e smalle r diame -

te r en d o f th e specia l too l ove r th e valv e sea l ring .

Mov e th e specia l too l u p an d dow n severa l time s t o

mak e th e valv e sea l rin g fi t snugl y in th e pinio n shaft .

Tapere d position .

Sealing li p VALV

E SEA L RIN G

Replace .

PISTON SEA L RIN G

SIZIN G TOO L

07NA G-SR3090 0 o r

07NA G-SR3090 A

ProCarManuals.com

Page 1203 of 1771

20. Appl y powe r steerin g flui d t o th e surfac e o f th e pin -

io n shaft . Assembl e th e sleev e ove r th e pinio n shaf t

b y alignin g th e locatin g pi n o n th e insid e of the

sleev e wit h th e cutou t i n th e shaft . The n instal l th e

ne w circli p securel y i n th e pinio n shaf t groove .

NOTE:

• B e carefu l no t t o damag e th e valv e sea l rin g

whe n insertin g th e sleeve .

• Instal l th e circli p wit h it s radiuse d sid e facin g out .

21 . Appl y powe r steerin g flui d t o th e surfac e o f th e spe -

cia l tool . Se t th e ne w sea l ring s ove r th e specia l too l

fro m th e smalle r diamete r en d o f th e tool , an d

expan d th e sea l rings .

NOTE :

• D o no t over-expan d th e sea l ring . Instal l th e resi n

sea l ring s wit h car e s o as no t t o damag e them .

Afte r installation , b e sur e t o contrac t th e sea l

rings usin g th e specia l too l (sizin g tool) .

• Ther e ar e tw o type s o f sleev e sea l rings : blac k

an d brown . D o no t mi x th e differen t type s of

sleev e sea l ring s a s the y ar e no t compatible .

22 . Se t th e specia l too l i n th e groove s in th e sleeve , an d

se t eac h rin g in eac h groov e securely .

NOTE : Afte r installation , compres s th e sea l ring s

wit h you r finger s temporarily .

SLEEVE

23. Appl y powe r steerin g flui d t o th e sea l ring s o n th e

sleeve , an d t o th e entir e insid e surfac e o f th e spe -

cia l tool .

24 . Inser t th e sleev e int o th e specia l too l slowly .

25 . Mov e th e sleev e eac h directio n severa l time s t o

mak e th e sea l ring s snugl y fi t i n th e sleeve .

NOTE : B e sur e tha t th e sea l ring s ar e no t turne d up .

26. Appl y viny l tap e t o th e pinio n shaft , the n coa t th e

vinyl tape wit h powe r steerin g fluid .

27 . Inser t th e pinio n shaf t int o th e valv e housing .

CAUTION : B e carefu l no t t o damag e th e valv e sea l

rings .

Sealin g li p face .

VALVE OI L SEA L

Replace .

VALVE HOUSIN G

PINIO N SHAF T

SLEEV E SEA L RING SReplace .Be sur e tha t th e

sea l ring s ar e no t

turne d up , whe ninstalled .

28. Remov e th e viny l tap e fro m th e pinio n shaft .

SLEEV E SEA L RIN GReplace .SLEEVE SEA L GUID E07SAG-SW5010 0or07SAG-SW5010 A PISTO

N SEA L RIN G

SIZIN G TOO L

07GA G-S04020 0

or07GA G-SD4020 A

Cutout

.

LOCATION PI NCIRCLI PReplace .

ProCarManuals.com

Page 1204 of 1771

Steering Gearbo x

Reassembl y (cont'd )

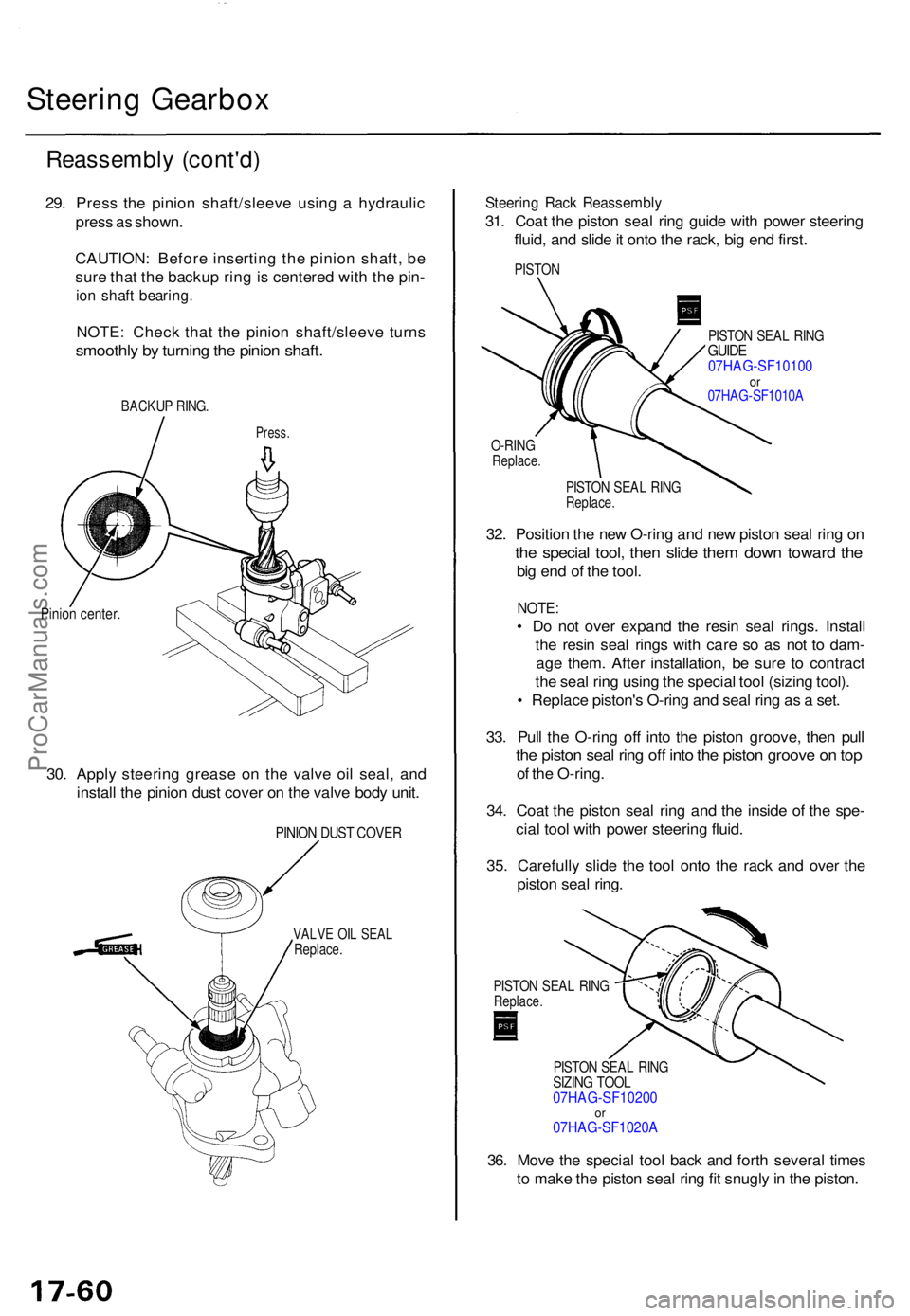

29. Pres s th e pinio n shaft/sleev e usin g a hydrauli c

pres s a s shown .

CAUTION : Befor e insertin g th e pinio n shaft , b e

sur e tha t th e backu p rin g is centere d wit h th e pin -

ion shaf t bearing .

NOTE: Chec k tha t th e pinio n shaft/sleev e turn s

smoothl y b y turnin g th e pinio n shaft .

BACKU P RING .

Press .

Pinion center .

30. Appl y steerin g greas e o n th e valv e oi l seal , an d

instal l th e pinio n dus t cove r o n th e valv e bod y unit .

PINIO N DUS T COVE R

VALVE OI L SEA LReplace .

Steering Rac k Reassembl y

31. Coa t th e pisto n sea l rin g guid e wit h powe r steerin g

fluid , an d slid e it ont o th e rack , bi g en d first .

PISTO N

PISTON SEA L RIN GGUID E07HAG-SF1010 0or07HA G-SF1010 A

O-RINGReplace .

PISTON SEA L RIN GReplace .

32. Positio n th e ne w O-rin g an d ne w pisto n sea l rin g o n

the specia l tool , the n slid e the m dow n towar d th e

big en d o f th e tool .

NOTE :

• D o no t ove r expan d th e resi n sea l rings . Instal l

th e resi n sea l ring s wit h car e s o a s no t t o dam -

ag e them . Afte r installation , b e sur e t o contrac t

th e sea l rin g usin g th e specia l too l (sizin g tool) .

• Replac e piston' s O-rin g an d sea l rin g a s a set .

33 . Pul l th e O-rin g of f int o th e pisto n groove , the n pul l

the pisto n sea l rin g of f int o th e pisto n groov e o n to p

of th e O-ring .

34 . Coa t th e pisto n sea l rin g an d th e insid e o f th e spe -

cia l too l wit h powe r steerin g fluid .

35 . Carefull y slid e th e too l ont o th e rac k an d ove r th e

pisto n sea l ring .

PISTO N SEA L RIN GReplace .

PISTON SEA L RIN GSIZIN G TOO L07HAG-SF1020 0or07HAG-SF1020 A

36. Mov e th e specia l too l bac k an d fort h severa l time s

t o mak e th e pisto n sea l rin g fi t snugl y in th e piston .

ProCarManuals.com

Page 1205 of 1771

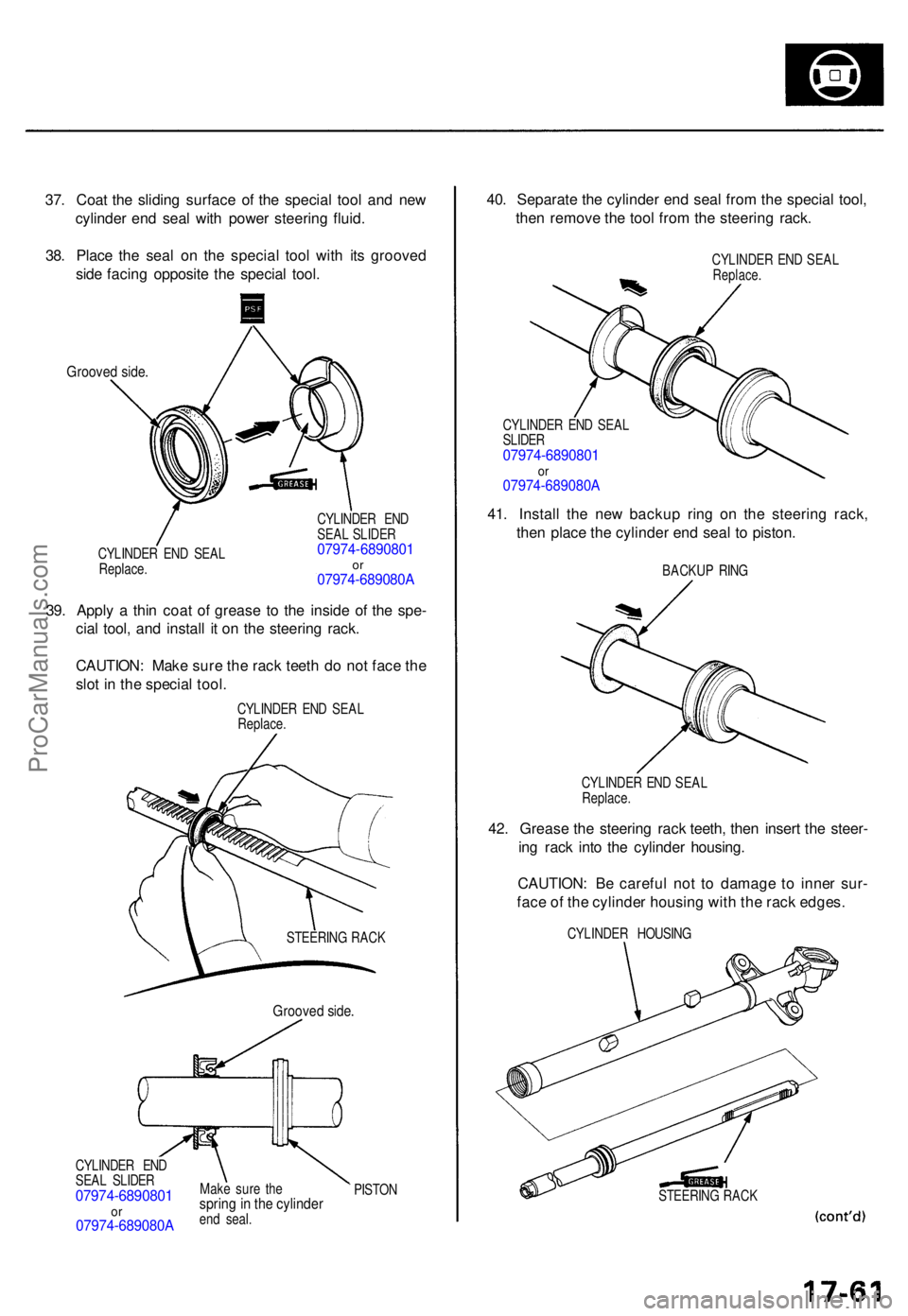

37. Coa t th e slidin g surfac e o f th e specia l too l an d ne w

cylinde r en d sea l wit h powe r steerin g fluid .

38 . Plac e th e sea l o n th e specia l too l wit h it s groove d

sid e facin g opposit e th e specia l tool .

Groove d side .

CYLINDE R EN D SEA L

Replace . CYLINDE

R EN D

SEA L SLIDE R07974-689080 1or07974-689080 A

39. Appl y a thi n coa t o f greas e t o th e insid e o f th e spe -

cia l tool , an d instal l i t o n th e steerin g rack .

CAUTION : Mak e sur e th e rac k teet h d o no t fac e th e

slo t i n th e specia l tool .

CYLINDE R EN D SEA L

Replace .

CYLINDE R EN D

SEA L SLIDE R

07974-689080 1or07974-689080 A

Make sur e th esprin g in th e cylinde rend seal .

40. Separat e th e cylinde r en d sea l fro m th e specia l tool ,

the n remov e th e too l fro m th e steerin g rack .

CYLINDE R EN D SEA LReplace .

CYLINDE R EN D SEA L

SLIDE R

07974-689080 1or07974-689080 A

41. Instal l th e ne w backu p rin g o n th e steerin g rack ,

the n plac e th e cylinde r en d sea l t o piston .

BACKU P RIN G

CYLINDE R EN D SEA L

Replace .

42. Greas e th e steerin g rac k teeth , the n inser t th e steer -

in g rac k int o th e cylinde r housing .

CAUTION : B e carefu l no t t o damag e t o inne r sur -

fac e o f th e cylinde r housin g wit h th e rac k edges .

CYLINDE R HOUSIN G

STEERIN G RAC K

Groove d side .

STEERIN G RAC K

PISTO N

ProCarManuals.com

Page 1206 of 1771

Steering Gearbo x

Reassembl y (cont'd )

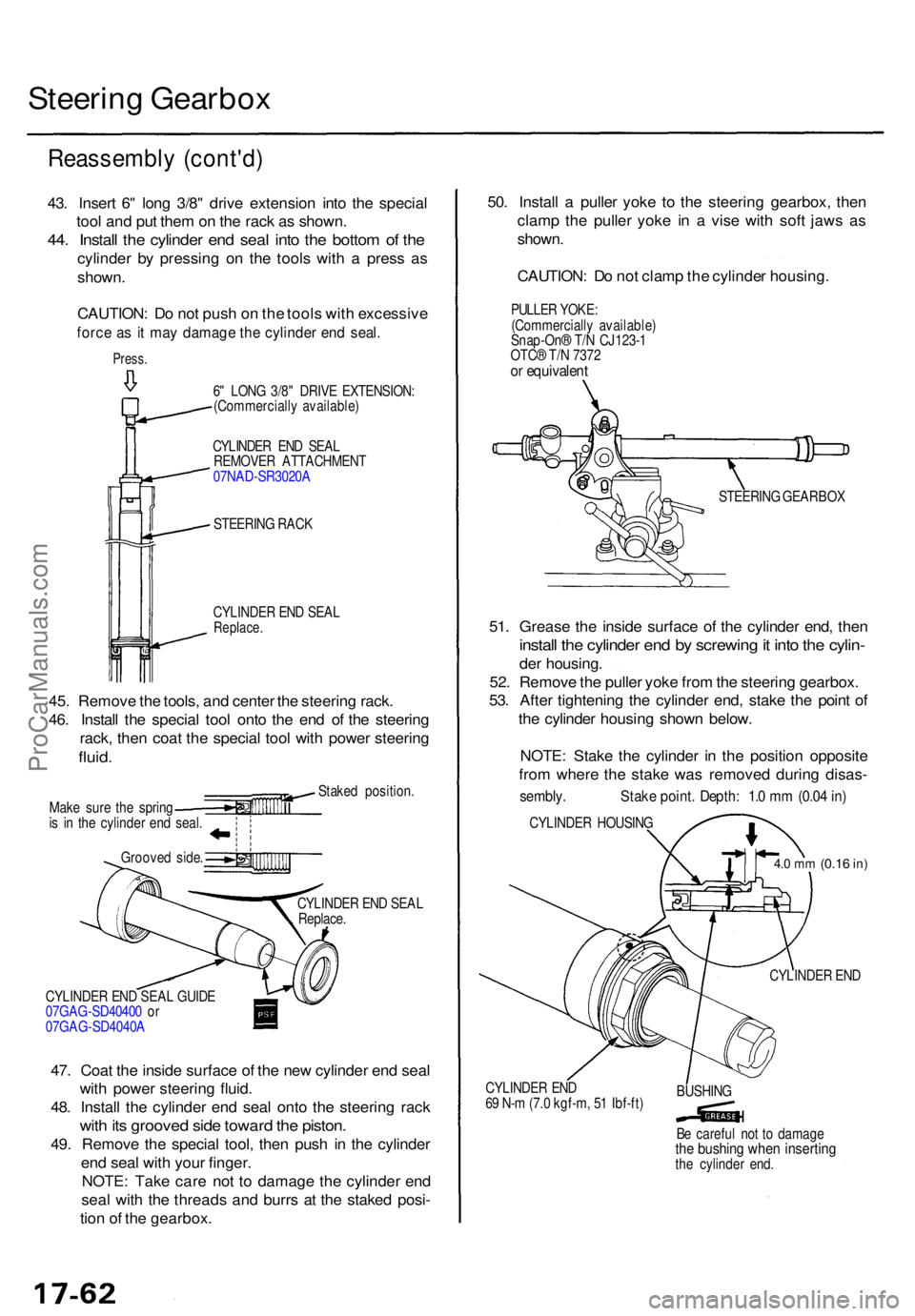

43. Inser t 6 " lon g 3/8 " driv e extensio n int o th e specia l

too l an d pu t the m on th e rac k a s shown .

44. Instal l th e cylinde r en d sea l int o th e botto m o f th e

cylinde r b y pressin g o n th e tool s wit h a pres s a s

shown .

CAUTION : D o no t pus h o n th e tool s wit h excessiv e

force a s i t ma y damag e th e cylinde r en d seal .

Press .

STEERIN G RAC K

CYLINDE R EN D SEA L

Replace .

a

45. Remov e th e tools , an d cente r th e steerin g rack .

46 . Instal l th e specia l too l ont o th e en d o f th e steerin g

rack , the n coa t th e specia l too l wit h powe r steerin g

fluid.

Stake d position .

Mak e sur e th e sprin g

i s i n th e cylinde r en d seal .

Groove d side .

CYLINDER EN D SEA L

Replace .

CYLINDE R EN D SEA L GUID E

07GA G-SD4040 0 o r

07GA G-SD4040 A

47. Coa t th e insid e surfac e o f th e ne w cylinde r en d sea l

wit h powe r steerin g fluid .

48 . Instal l th e cylinde r en d sea l ont o th e steerin g rac k

with it s groove d sid e towar d th e piston .

49. Remov e th e specia l tool , the n pus h i n th e cylinde r

en d sea l wit h you r finger.

NOTE : Tak e car e no t t o damag e th e cylinde r en d

sea l wit h th e thread s an d burr s a t th e stake d posi -

tio n o f th e gearbox . 50

. Instal l a pulle r yok e t o th e steerin g gearbox , the n

clam p th e pulle r yok e i n a vis e wit h sof t jaw s a s

shown .

CAUTION : D o no t clam p th e cylinde r housing .

51 . Greas e th e insid e surfac e o f th e cylinde r end , the n

instal l th e cylinde r en d b y screwin g it int o th e cylin -

der housing .

52 . Remov e th e pulle r yok e fro m th e steerin g gearbox .

53 . Afte r tightenin g th e cylinde r end , stak e th e poin t o f

th e cylinde r housin g show n below .

NOTE : Stak e th e cylinde r i n th e positio n opposit e

fro m wher e th e stak e wa s remove d durin g disas -

sembly . Stak e point . Depth : 1. 0 m m (0.0 4 in )

CYLINDE R HOUSIN G

4.0 m m (0.1 6 in)

CYLINDE R EN D

CYLINDE R EN D

6 9 N- m (7. 0 kgf-m , 5 1 Ibf-ft ) BUSHIN

G

B e carefu l no t t o damag e

the bushin g whe n insertin gthe cylinde r end .

CYLINDE

R EN D SEA L

REMOVE R ATTACHMEN T

07NA D-SR3020 A

6

" LON G 3/8 " DRIV E EXTENSION :

(Commerciall y available ) PULLE

R YOKE :

(Commerciall y available )

Snap-On ® T/ N CJ123- 1

OTC ® T/ N 737 2

or equivalen t

STEERING GEARBO X

ProCarManuals.com

Page 1207 of 1771

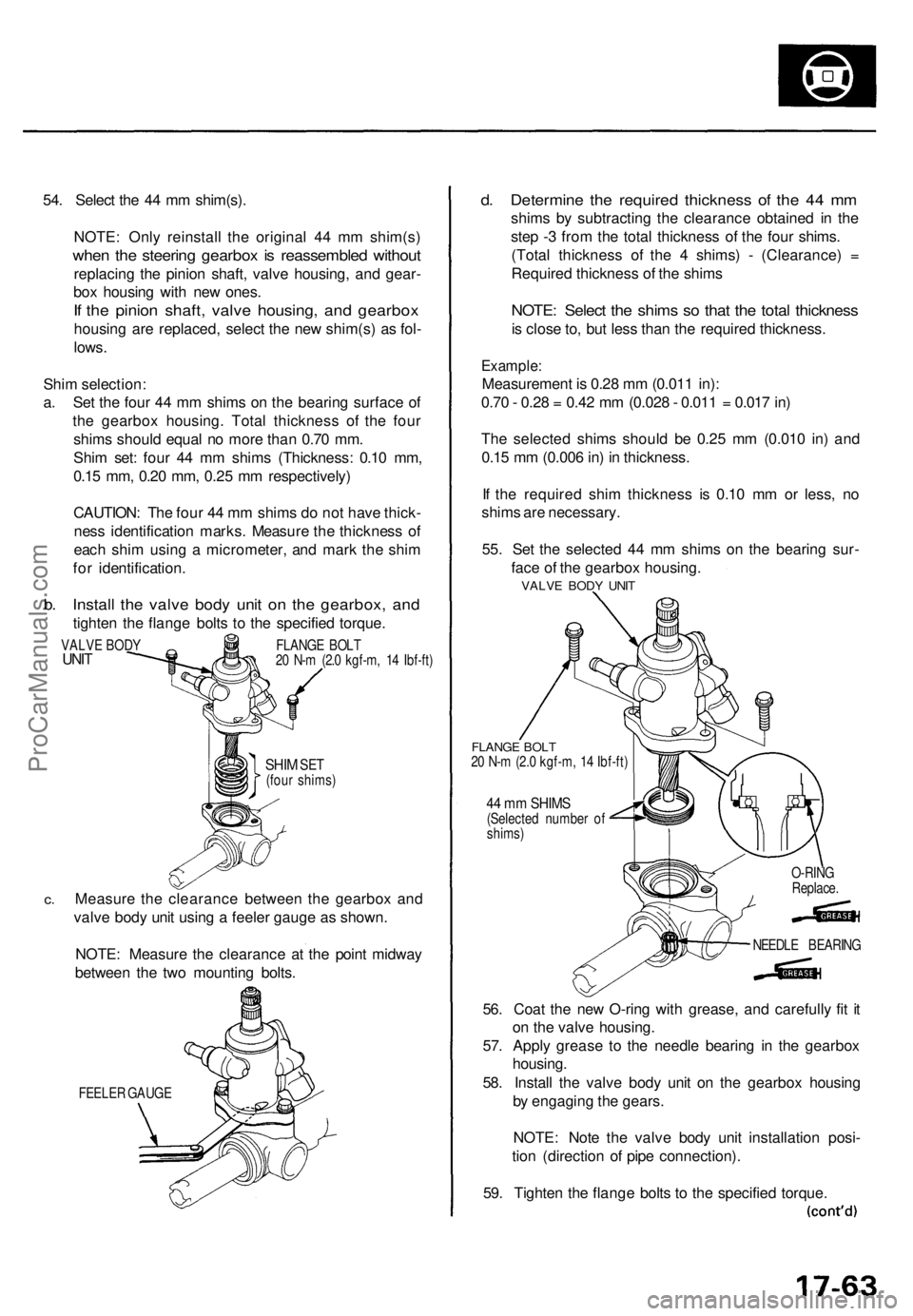

54. Selec t th e 4 4 m m shim(s) .

NOTE : Onl y reinstal l th e origina l 4 4 m m shim(s )

when th e steerin g gearbo x i s reassemble d withou t

replacin g th e pinio n shaft , valv e housing , an d gear -

bo x housin g wit h ne w ones .

If th e pinio n shaft , valv e housing , an d gearbo x

housing ar e replaced , selec t th e ne w shim(s ) a s fol -

lows .

Shi m selection :

a . Se t th e fou r 4 4 m m shim s o n th e bearin g surfac e o f

th e gearbo x housing . Tota l thicknes s o f th e fou r

shim s shoul d equa l n o mor e tha n 0.7 0 mm .

Shi m set : fou r 4 4 m m shim s (Thickness : 0.1 0 mm ,

0.1 5 mm , 0.2 0 mm , 0.2 5 m m respectively )

CAUTION : Th e fou r 4 4 m m shim s d o no t hav e thick -

nes s identificatio n marks . Measur e th e thicknes s o f

eac h shi m usin g a micrometer , an d mar k th e shi m

fo r identification .

b. Instal l th e valv e bod y uni t o n th e gearbox , an d

tighte n th e flang e bolt s t o th e specifie d torque .

SHIM SET(fou r shims )

c.Measur e th e clearanc e betwee n th e gearbo x an d

valv e bod y uni t usin g a feele r gaug e a s shown .

NOTE : Measur e th e clearanc e a t th e poin t midwa y

betwee n th e tw o mountin g bolts .

FEELE R GAUG E

d. Determin e th e require d thicknes s o f th e 4 4 m m

shim s b y subtractin g th e clearanc e obtaine d i n th e

ste p - 3 fro m th e tota l thicknes s o f th e fou r shims .

(Tota l thicknes s o f th e 4 shims ) - (Clearance ) =

Require d thicknes s o f th e shim s

NOTE : Selec t th e shim s s o tha t th e tota l thicknes s

is clos e to , bu t les s tha n th e require d thickness .

Example:

Measuremen t i s 0.2 8 m m (0.01 1 in) :

0.7 0 - 0.2 8 = 0.4 2 m m (0.02 8 - 0.01 1 = 0.01 7 in )

Th e selecte d shim s shoul d b e 0.2 5 m m (0.01 0 in ) an d

0.1 5 m m (0.00 6 in ) i n thickness .

I f th e require d shi m thicknes s i s 0.1 0 m m o r less , n o

shim s ar e necessary .

55 . Se t th e selecte d 4 4 m m shim s o n th e bearin g sur -

fac e o f th e gearbo x housing .

FLANGE BOL T20 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

44 m m SHIM S(Selecte d numbe r o f

shims )

56. Coa t th e ne w O-rin g wit h grease , an d carefull y fi t i t

o n th e valv e housing .

57 . Appl y greas e t o th e needl e bearin g i n th e gearbo x

housing .

58 . Instal l th e valv e bod y uni t o n th e gearbo x housin g

b y engagin g th e gears .

NOTE : Not e th e valv e bod y uni t installatio n posi -

tio n (directio n o f pip e connection) .

59 . Tighte n th e flang e bolt s t o th e specifie d torque .

VALVE BOD YUNITFLANG E BOL T

2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

NEEDLE BEARIN G

O-RIN

G

Replace .

VALVE BOD Y UNI T

ProCarManuals.com

Page 1208 of 1771

Steering Gearbo x

Reassembl y (cont'd )

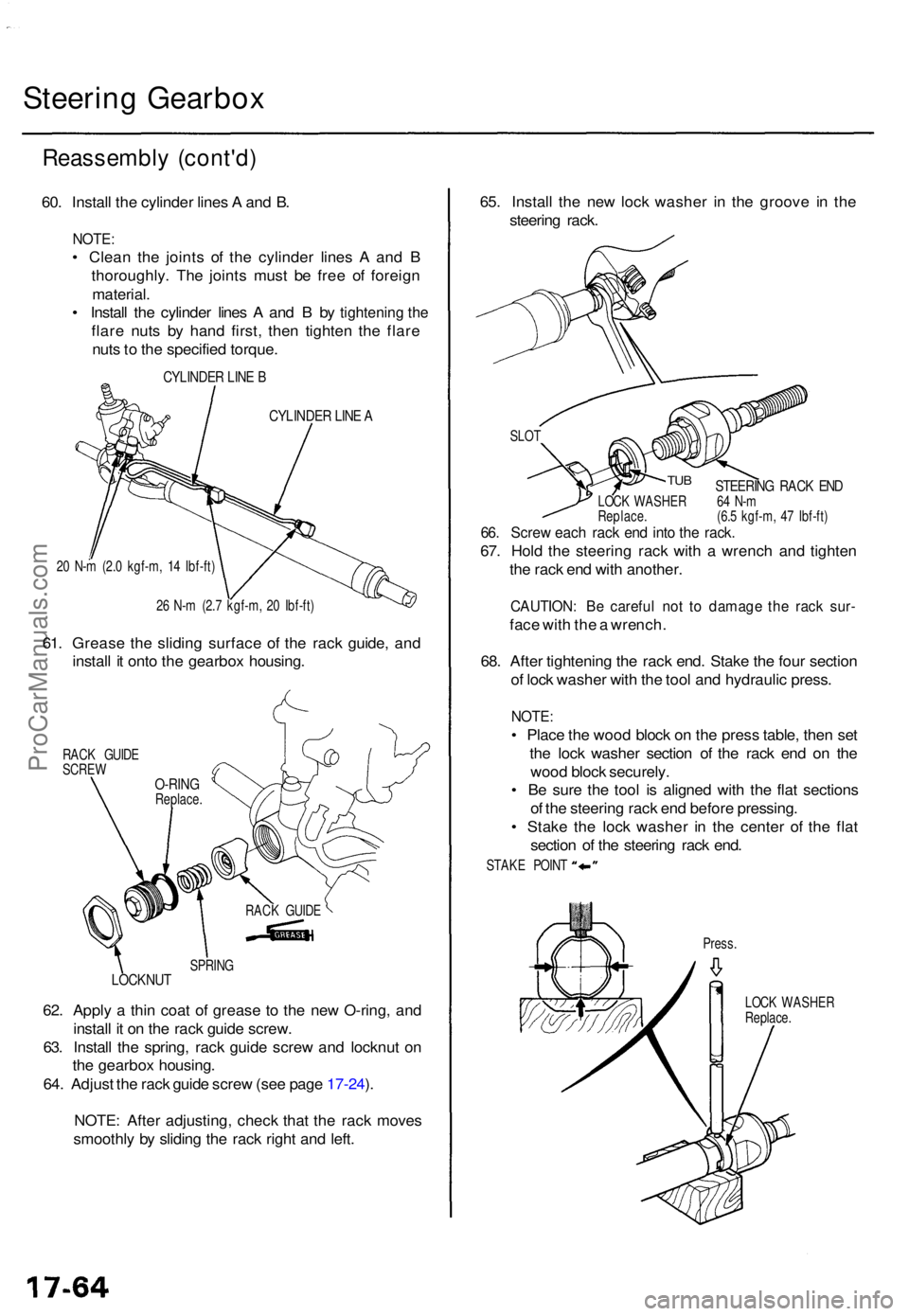

60. Instal l th e cylinde r line s A an d B .

NOTE :

• Clea n th e joint s o f th e cylinde r line s A an d B

thoroughly . Th e joint s mus t b e fre e o f foreig n

material .

• Instal l th e cylinde r line s A an d B by

tightening the

flar e nut s b y han d first , the n tighte n th e flar e

nut s t o th e specifie d torque .

CYLINDE R LIN E B

CYLINDE R LIN E A

20 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

2 6 N- m (2. 7 kgf-m , 2 0 Ibf-ft )

61. Greas e th e slidin g surfac e o f th e rac k guide , an d

instal l i t ont o th e gearbo x housing .

RACK GUID E

SCRE W

SPRING

LOCKNU T

62. Appl y a thi n coa t o f greas e t o th e ne w O-ring , an d

instal l i t o n th e rac k guid e screw .

63 . Instal l th e spring , rac k guid e scre w an d locknu t o n

th e gearbo x housing .

64 . Adjus t th e rac k guid e scre w (se e pag e 17-24 ).

NOTE : Afte r adjusting , chec k tha t th e rac k move s

smoothl y b y slidin g th e rac k righ t an d left . 65

. Instal l th e ne w loc k washe r i n th e groov e i n th e

steerin g rack .

STEERIN G RAC K EN DLOC K WASHE R 6 4 N- m

Replace . (6. 5 kgf-m , 4 7 Ibf-ft )

66. Scre w eac h rac k en d int o th e rack .

67. Hol d th e steerin g rac k wit h a wrenc h an d tighte n

th e rac k en d wit h another .

CAUTION : B e carefu l no t t o damag e th e rac k sur -

face wit h th e a wrench .

68 . Afte r tightenin g th e rac k end . Stak e th e fou r sectio n

o f loc k washe r wit h th e too l an d hydrauli c press .

NOTE:

• Plac e th e woo d bloc k o n th e pres s table , the n se t

th e loc k washe r sectio n o f th e rac k en d o n th e

woo d bloc k securely .

• B e sur e th e too l i s aligne d wit h th e fla t section s

o f th e steerin g rac k en d befor e pressing .

• Stak e th e loc k washe r i n th e cente r o f th e fla t

sectio n o f th e steerin g rac k end .

Press .

LOC K WASHE R

Replace .

RAC

K GUID E

O-RINGReplace .

TUB

SLO T

STAK E POIN T

ProCarManuals.com

Page 1209 of 1771

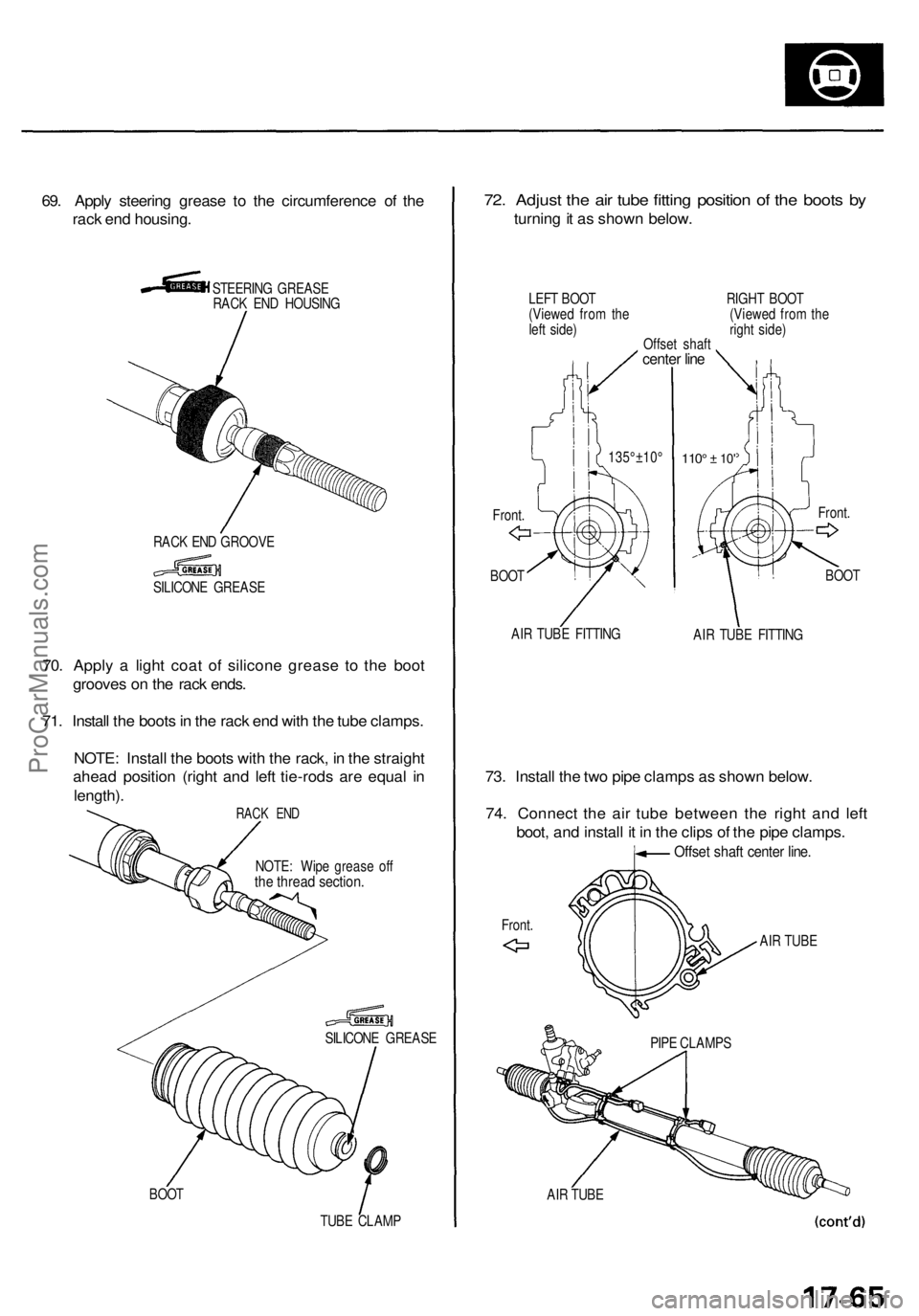

69. Appl y steerin g greas e t o th e circumferenc e o f th e

rac k en d housing .

STEERIN G GREAS E

RAC K EN D HOUSIN G

RAC K EN D GROOV E

SILICON E GREAS E

70. Appl y a ligh t coa t of silicon e greas e t o th e boo t

groove s o n th e rac k ends .

71 . Instal l th e boot s in th e rac k en d wit h th e tub e clamps .

NOTE : Instal l th e boot s wit h th e rack , i n th e straigh t

ahea d positio n (righ t an d lef t tie-rod s ar e equa l i n

length) .

NOTE: Wip e greas e of fthe threa d section .

SILICON E GREAS E

BOO T

TUBE CLAM P

72. Adjus t th e ai r tub e fittin g positio n o f th e boot s b y

turnin g it a s show n below .

LEFT BOO T RIGH T BOO T

(Viewe d fro m th e (Viewe d fro m th e

lef t side ) righ t side )

Offse t shaf t

center lin e

135°±10 °

BOO T110° ± 10 '

BOO T

AI R TUB E FITTIN G

AIR TUB E FITTIN G

73. Instal l th e tw o pip e clamp s a s show n below .

74 . Connec t th e ai r tub e betwee n th e righ t an d lef t

boot , an d instal l i t i n th e clip s o f th e pip e clamps .

Offset shaf t cente r line .

AIR TUB E

AI R TUB E PIP

E CLAMP S

Front

. Front

.

Front .

RACK EN D

ProCarManuals.com

Page 1210 of 1771

Steering Gearbo x

Reassembl y (cont'd )

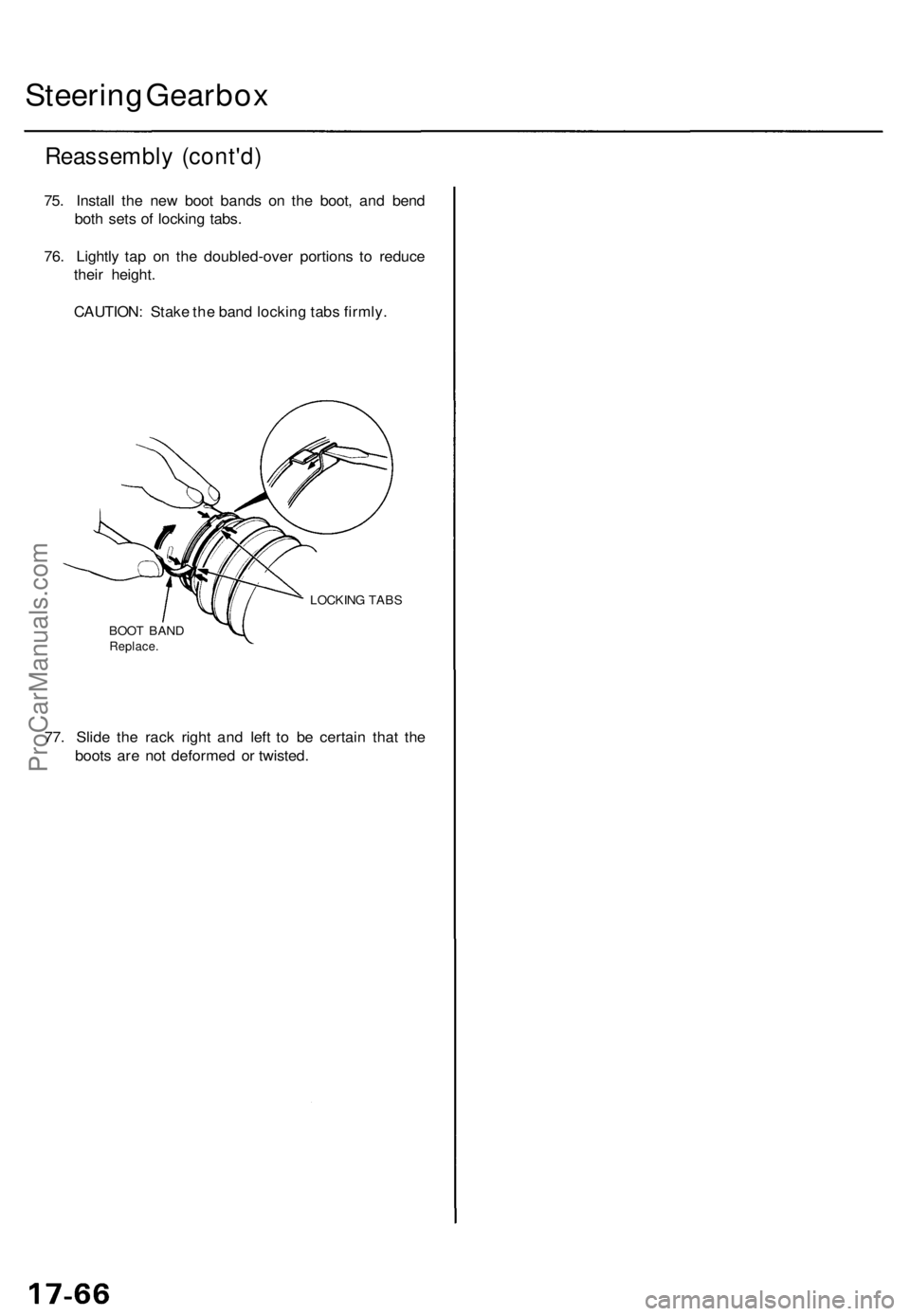

75. Instal l th e ne w boo t band s o n th e boot , an d ben d

bot h set s o f lockin g tabs .

76 . Lightl y ta p o n th e doubled-ove r portion s t o reduc e

thei r height .

CAUTION : Stak e th e ban d lockin g tab s firmly .

LOCKIN G TAB S

BOO T BAN D

Replace .

77. Slid e th e rac k righ t an d lef t t o b e certai n tha t th e

boot s ar e no t deforme d o r twisted .

ProCarManuals.com