ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1561 of 1771

Starting System

Armature Inspection and Test

1.

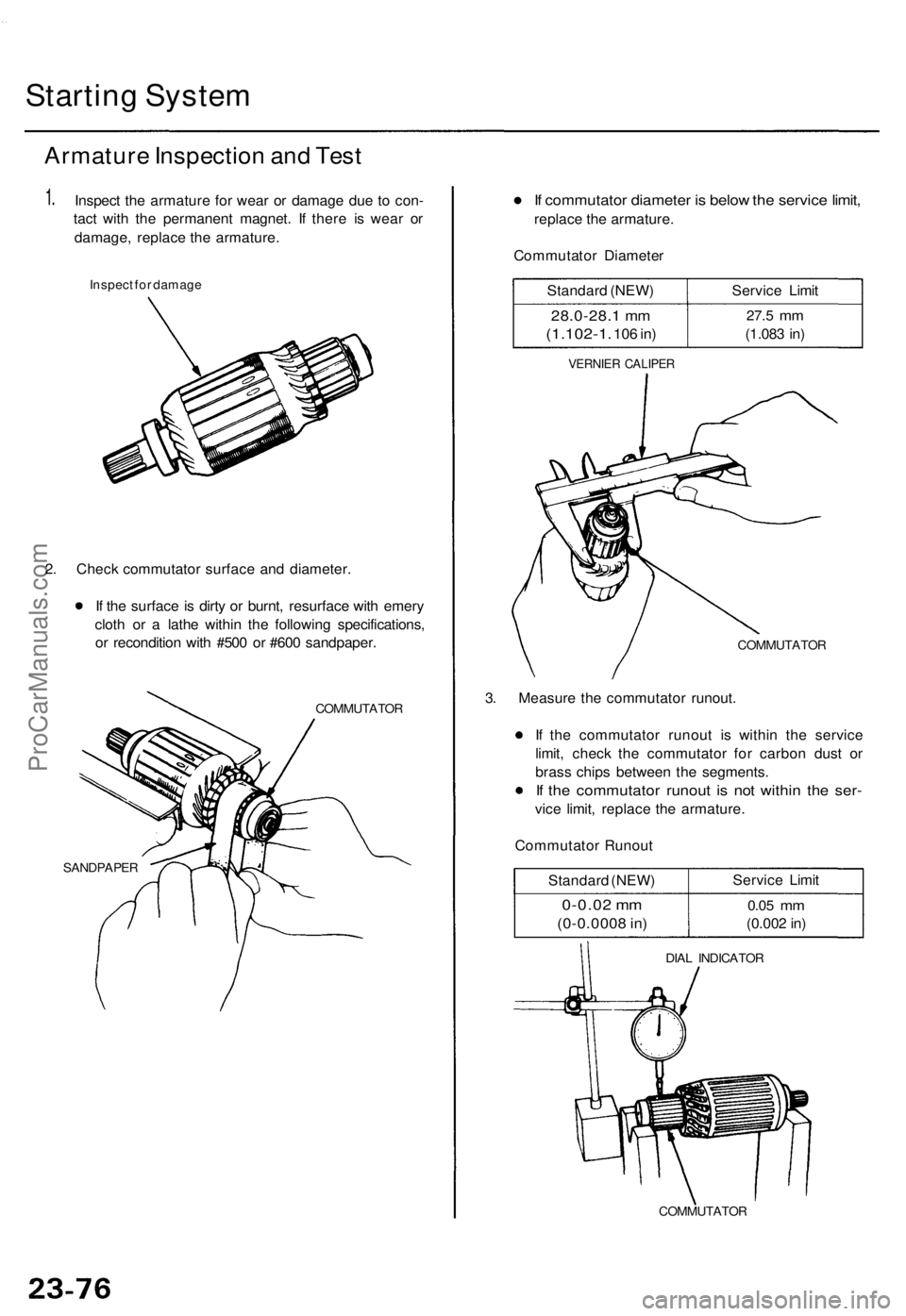

Inspect the armature for wear or damage due to con-

tact with the permanent magnet. If there is wear or

damage, replace the armature.

Inspect for damage

2. Check commutator surface and diameter.

If the surface is dirty or burnt, resurface with emery

cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper.

COMMUTATOR

SANDPAPER

If commutator diameter is below the service limit,

replace the armature.

Commutator Diameter

Standard (NEW)

28.0-28.1 mm

(1.102-1.

106 in)

Service Limit

27.5

mm

(1.083 in)

VERNIER CALIPER

COMMUTATOR

3. Measure the commutator runout.

If the commutator runout is within the service

limit, check the commutator for carbon dust or

brass chips between the segments.

If the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

Standard (NEW)

0-0.02 mm

(0-0.0008 in)

Service Limit

0.05

mm

(0.002 in)

DIAL INDICATOR

COMMUTATORProCarManuals.com

Page 1562 of 1771

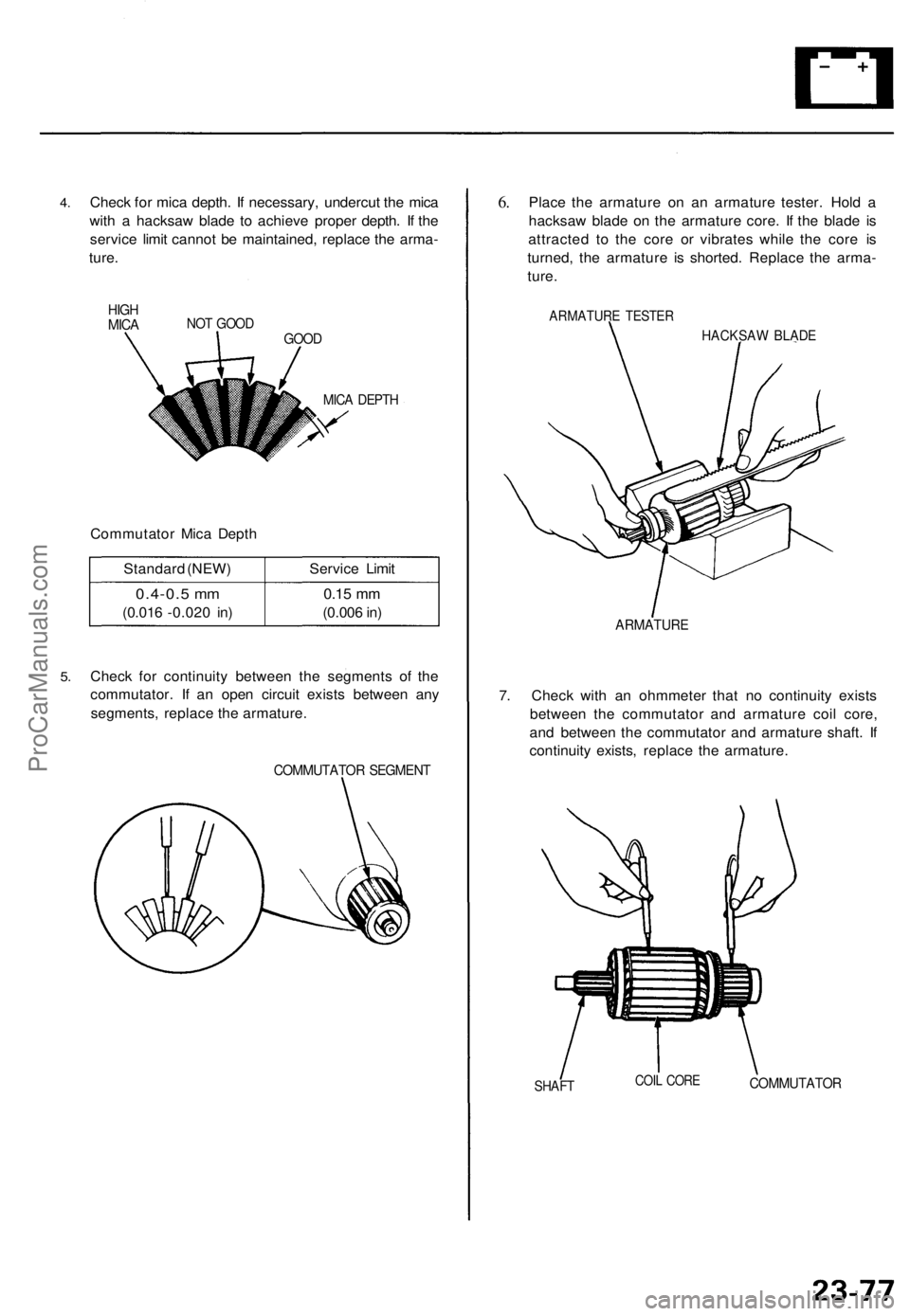

4.

Check for mica depth. If necessary, undercut the mica

with a hacksaw blade to achieve proper depth. If the

service limit cannot be maintained, replace the arma-

ture.

HIGH

MICA

NOT GOOD

GOOD

MICA DEPTH

Commutator Mica Depth

Standard (NEW)

0.4-0.5 mm

(0.016 -0.020 in)

Service Limit

0.15

mm

(0.006 in)

5.

Check for continuity between the segments of the

commutator. If an open circuit exists between any

segments, replace the armature.

COMMUTATOR SEGMENT

6.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. If the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Replace the arma-

ture.

ARMATURE TESTER

HACKSAW BLADE

ARMATURE

7. Check with an ohmmeter that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. If

continuity exists, replace the armature.

SHAFT

COIL CORE

COMMUTATORProCarManuals.com

Page 1563 of 1771

Starting Syste m

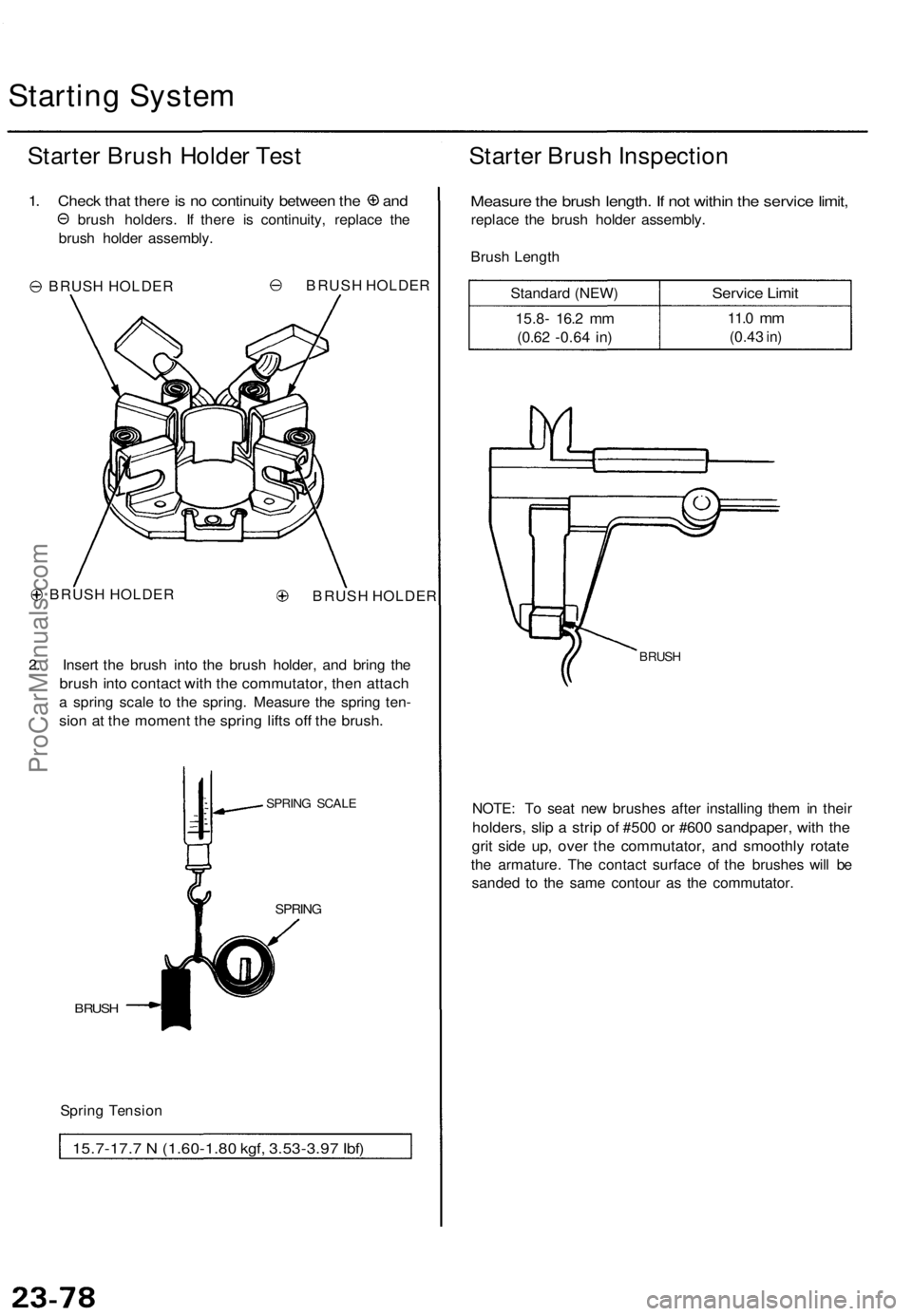

Starter Brus h Holde r Tes t

1. Chec k tha t ther e is n o continuit y betwee n th e an d

brush holders . I f ther e i s continuity , replac e th e

brus h holde r assembly .

BRUS H HOLDE R BRUS

H HOLDE R

BRUS H HOLDE R

BRUSH HOLDE R

2 . Inser t th e brus h int o th e brus h holder , an d brin g th e

brus h int o contac t wit h th e commutator , the n attac h

a sprin g scal e t o th e spring . Measur e th e sprin g ten -

sion a t th e momen t th e sprin g lift s of f th e brush .

SPRIN G SCAL E

BRUSH

SPRIN G

Spring Tensio n

15.7-17. 7 N (1.60-1.8 0 kgf , 3.53-3.9 7 Ibf )

Starte r Brus h Inspectio n

Measure th e brus h length . I f no t withi n th e servic e limit ,

replac e th e brus h holde r assembly .

Brus h Lengt h

Standar d (NEW )

15.8- 16. 2 mm

(0.6 2 -0.6 4 in)

Servic e Limi t

11.0 mm

(0.4 3 in)

BRUS H

NOTE : T o sea t ne w brushe s afte r installin g the m in thei r

holders , sli p a stri p of #50 0 o r #60 0 sandpaper , wit h th e

grit sid e up , ove r th e commutator , an d smoothl y rotat e

the armature . Th e contac t surfac e o f th e brushe s wil l b e

sande d t o th e sam e contou r a s th e commutator .

ProCarManuals.com

Page 1564 of 1771

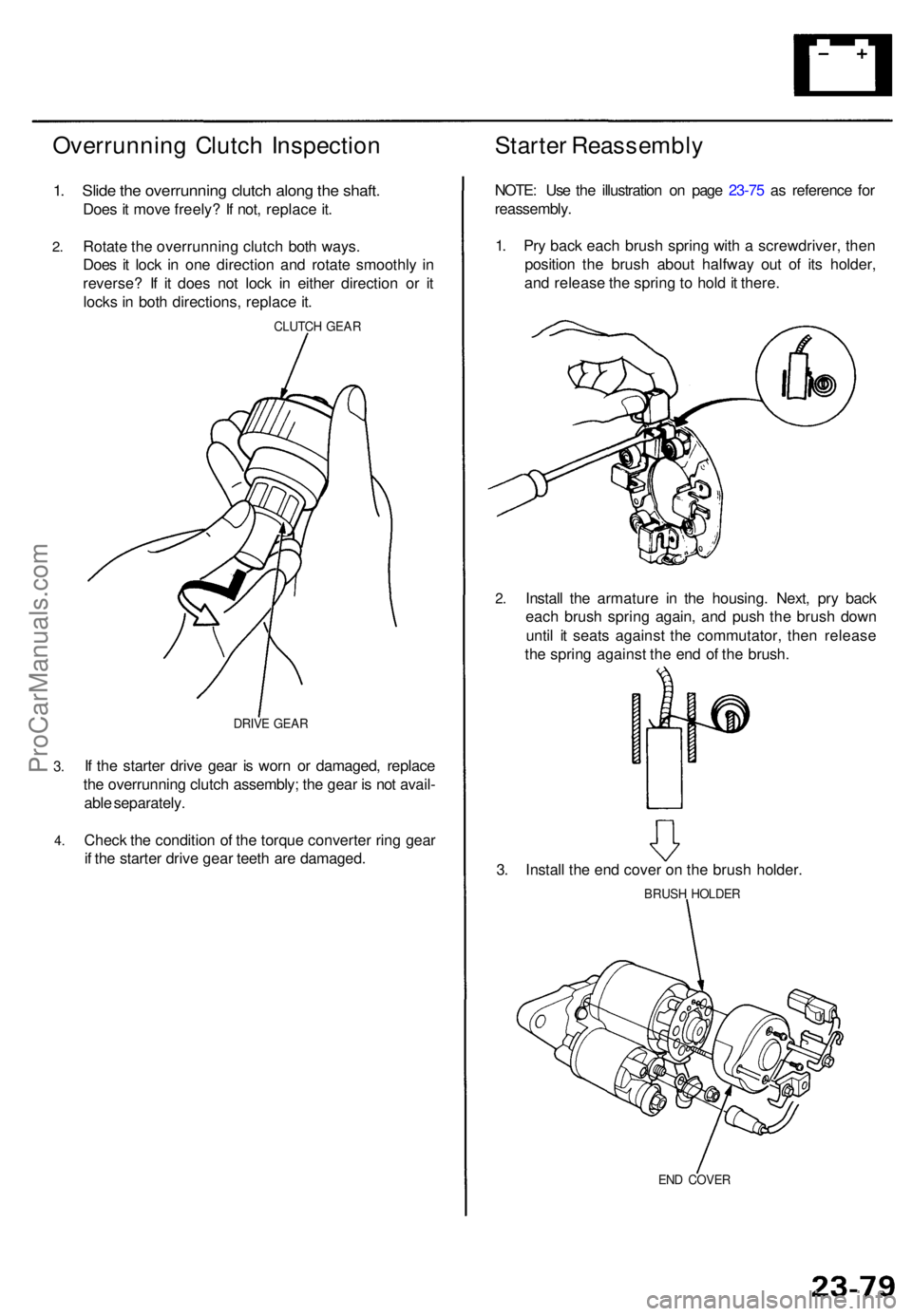

Overrunning Clutc h Inspectio n

1. Slid e th e overrunnin g clutc h alon g th e shaft .

Does i t mov e freely ? I f not , replac e it .

Starte r Reassembl y

2.Rotat e th e overrunnin g clutc h bot h ways .

Doe s i t loc k i n on e directio n an d rotat e smoothly in

reverse ? I f i t doe s no t loc k i n eithe r directio n o r i t

lock s in bot h directions , replac e it .

CLUTC H GEA R

3.

4 .

DRIV E GEA R

If th e starte r driv e gea r i s wor n o r damaged , replac e

th e overrunnin g clutc h assembly ; th e gea r i s no t avail -

abl e separately .

Chec k th e conditio n o f th e torqu e converte r rin g gea r

i f th e starte r driv e gea r teet h ar e damaged . NOTE

: Us e th e illustratio n o n pag e 23-7 5 a s referenc e fo r

reassembly .

1 . Pr y bac k eac h brus h sprin g wit h a screwdriver , the n

positio n th e brus h abou t halfwa y ou t o f it s holder ,

an d releas e th e sprin g t o hol d it there .

2.Instal l th e armatur e i n th e housing . Next , pr y bac k

eac h brus h sprin g again , an d pus h th e brus h dow n

unti l i t seat s agains t th e commutator , the n releas e

th e sprin g agains t th e en d o f th e brush .

3 . Instal l th e en d cove r o n th e brus h holder .

BRUSH HOLDE R

END COVE R

ProCarManuals.com

Page 1565 of 1771

Starting System

Performance Test

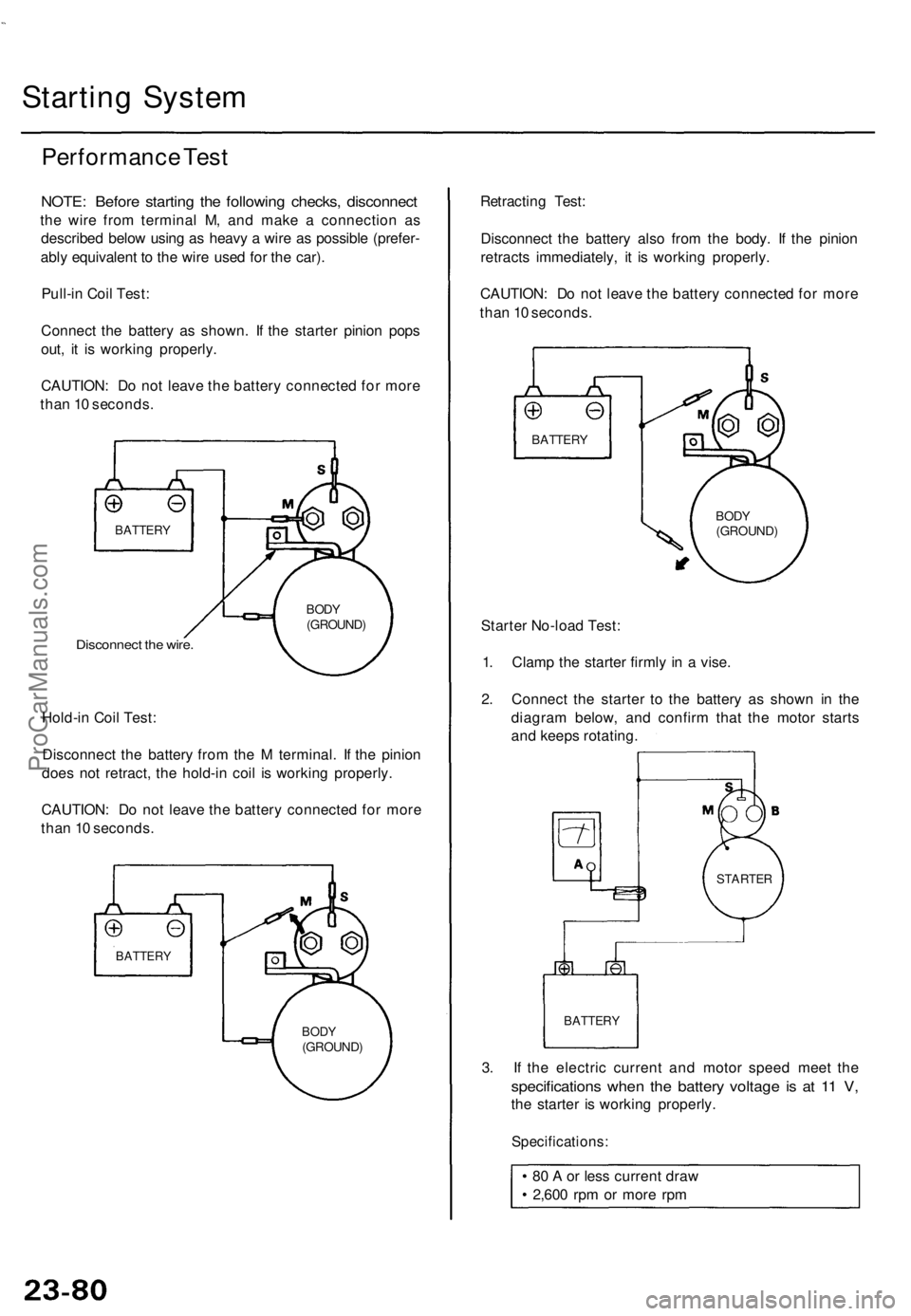

NOTE: Before starting the following checks, disconnect

the wire from terminal M, and make a connection as

described below using as heavy a wire as possible (prefer-

ably equivalent to the wire used for the car).

Pull-in Coil Test:

Connect the battery as shown. If the starter pinion pops

out, it is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

Disconnect the wire.

Hold-in Coil Test:

Disconnect the battery from the M terminal. If the pinion

does not retract, the hold-in coil is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

Retracting Test:

Disconnect the battery also from the body. If the pinion

retracts immediately, it is working properly.

CAUTION: Do not leave the battery connected for more

than 10 seconds.

Starter No-load Test:

1. Clamp the starter firmly in a vise.

2. Connect the starter to the battery as shown in the

diagram below, and confirm that the motor starts

and keeps rotating.

3. If the electric current and motor speed meet the

specifications when the battery voltage is at 11 V,

the starter is working properly.

Specifications:

80 A or less current draw

2,600 rpm or more rpm

BATTERY

BODY

(GROUND)

BATTERY

STARTER

BODY

(GROUND)

BATTERY

BODY

(GROUND)

BATTERYProCarManuals.com

Page 1566 of 1771

Ignition Syste m

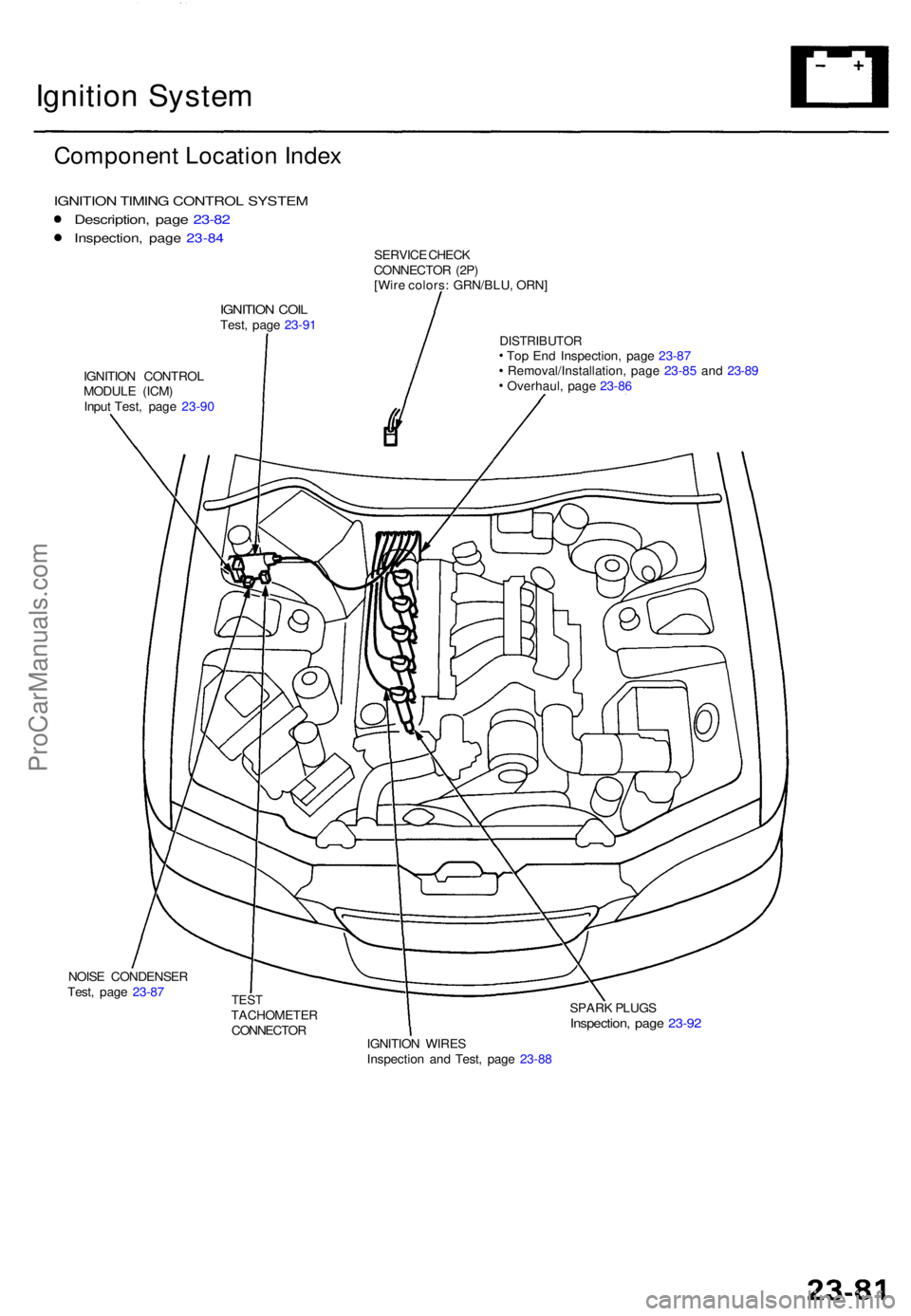

Componen t Locatio n Inde x

IGNITIO N TIMIN G CONTRO L SYSTE M

Description , pag e 23-8 2

Inspection , pag e 23-8 4

IGNITIO N COI LTest , pag e 23-9 1 SERVIC

E CHEC K

CONNECTO R (2P )

[Wir e colors : GRN/BLU , ORN ]

IGNITIO N CONTRO L

MODUL E (ICM )

Inpu t Test , pag e 23-9 0DISTRIBUTO RTop En d Inspection , pag e 23-8 7

Removal/Installation , pag e 23-8 5 an d 23-8 9

Overhaul , pag e 23-8 6

NOIS E CONDENSE R

Test , pag e 23-8 7

TESTTACHOMETE R

CONNECTO R SPAR

K PLUG SInspection , pag e 23-9 2

IGNITIO N WIRE S

Inspectio n an d Test , pag e 23-8 8

ProCarManuals.com

Page 1567 of 1771

Ignition Syste m

Descriptio n

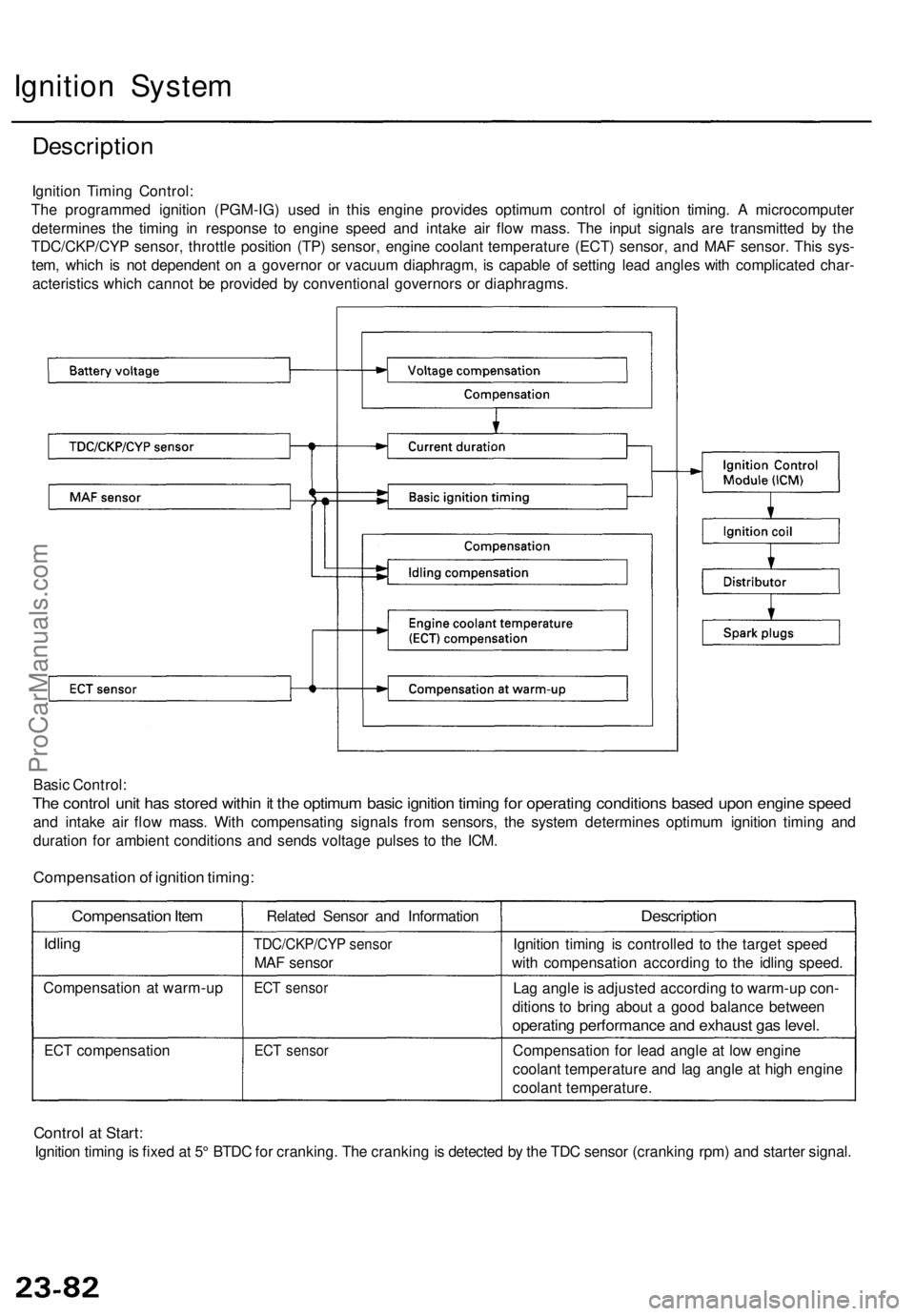

Ignition Timin g Control :

Th e programme d ignitio n (PGM-IG ) use d i n thi s engin e provide s optimu m contro l o f ignitio n timing . A microcompute r

determine s th e timin g i n respons e t o engin e spee d an d intak e ai r flo w mass . Th e inpu t signal s ar e transmitte d b y th e

TDC/CKP/CY P sensor , throttl e positio n (TP ) sensor , engine coolant temperatur e (ECT ) sensor , an d MA F sensor . Thi s sys -

tem , whic h i s no t dependen t o n a governo r o r vacuu m diaphragm , i s capabl e o f settin g lea d angle s wit h complicate d char -

acteristic s whic h canno t b e provide d b y conventiona l governor s o r diaphragms .

Basi c Control :

The contro l uni t ha s store d withi n it th e optimu m basi c ignitio n timin g fo r operatin g condition s base d upo n engin e spee d

and intak e ai r flo w mass . Wit h compensatin g signal s fro m sensors , th e syste m determine s optimu m ignitio n timin g an d

duratio n fo r ambien t condition s an d send s voltag e pulse s t o th e ICM .

Compensatio n of ignitio n timing :

Compensatio n Ite m

Idlin g

Compensatio n a t warm-u p

ECT compensatio n Relate

d Senso r an d Informatio n

TDC/CKP/CY P senso r

MAF senso r

ECT senso r

ECT senso r

Descriptio n

Ignition timin g i s controlle d t o th e targe t spee d

wit h compensatio n accordin g t o th e idlin g speed .

La g angl e is adjuste d accordin g t o warm-u p con -

dition s t o brin g abou t a goo d balanc e betwee n

operating performanc e an d exhaus t ga s level .

Compensatio n fo r lea d angl e a t lo w engin e

coolan t temperatur e an d la g angl e a t hig h engin e

coolan t temperature .

Control a t Start :

Ignitio n timin g is fixe d a t 5 ° BTD C fo r cranking . Th e crankin g is detecte d b y th e TD C senso r (crankin g rpm ) an d starte r signal .

ProCarManuals.com

Page 1568 of 1771

Ignition Syste m

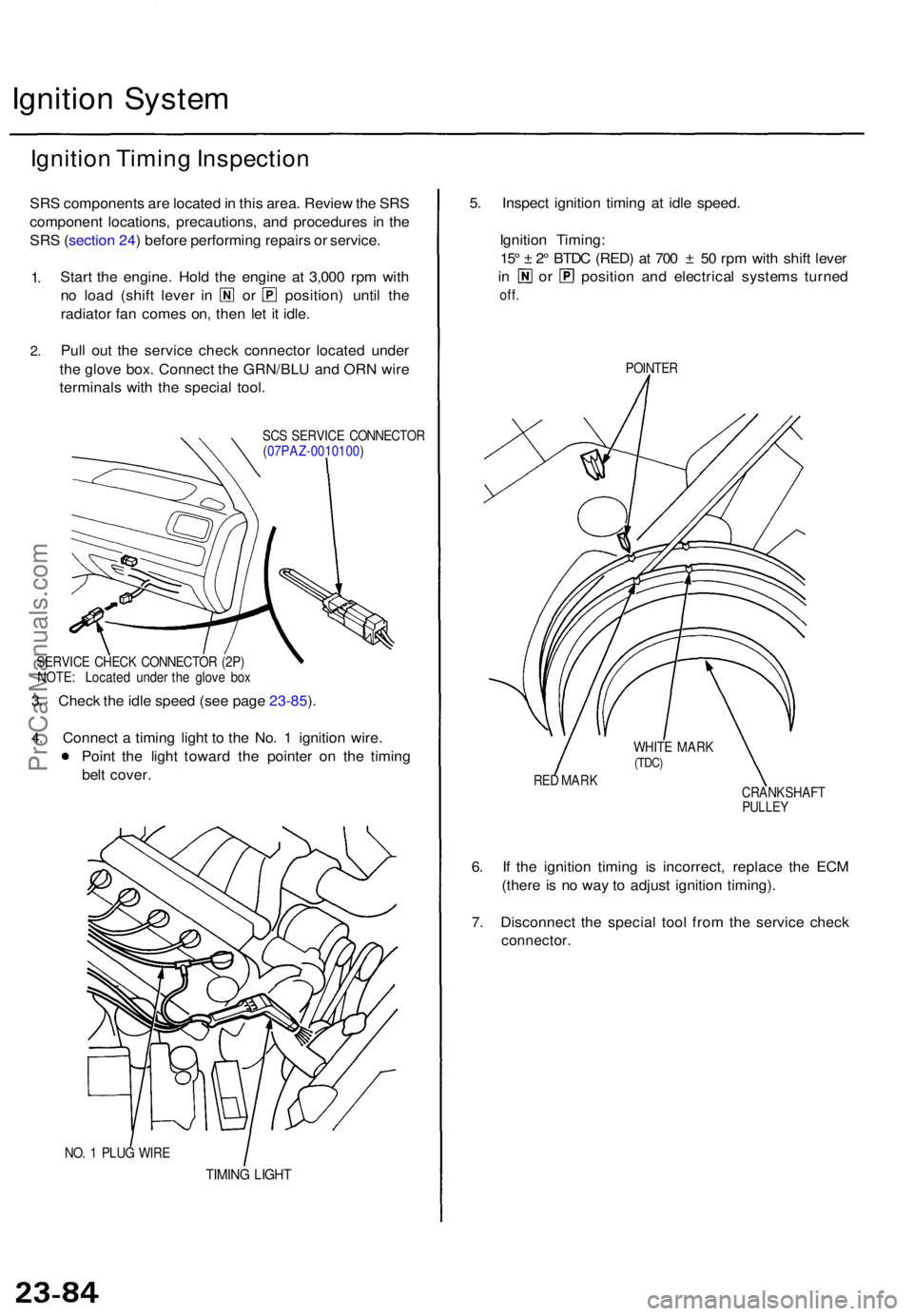

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1.

2 .

Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (shif t leve r i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

Pul l ou t th e servic e chec k connecto r locate d unde r

th e glov e box . Connec t th e GRN/BL U an d OR N wir e

terminal s wit h th e specia l tool .

SCS SERVIC E CONNECTO R

( 07PAZ-0010100 )

SERVIC E CHEC K CONNECTO R (2P)

NOTE : Locate d unde r th e glov e bo x

3. Chec k th e idl e spee d (se e pag e 23-85 ).

4 . Connec t a timin g ligh t t o th e No . 1 ignitio n wire .

Poin t th e ligh t towar d th e pointe r o n th e timin g

bel t cover .

NO. 1 PLU G WIR E

TIMIN G LIGH T

5. Inspec t ignitio n timin g a t idl e speed .

Ignitio n Timing :

15 ° ± 2° BTD C (RED ) a t 70 0 ± 50 rp m wit h shif t leve r

in o r positio n an d electrica l system s turne d

off.

POINTE R

RE D MAR K

CRANKSHAFT

PULLEY

6. I f th e ignitio n timin g i s incorrect , replac e th e EC M

(ther e is n o wa y t o adjus t ignitio n timing) .

7 . Disconnec t th e specia l too l fro m th e servic e chec k

connector .

WHITE MAR K(TDC)

ProCarManuals.com

Page 1569 of 1771

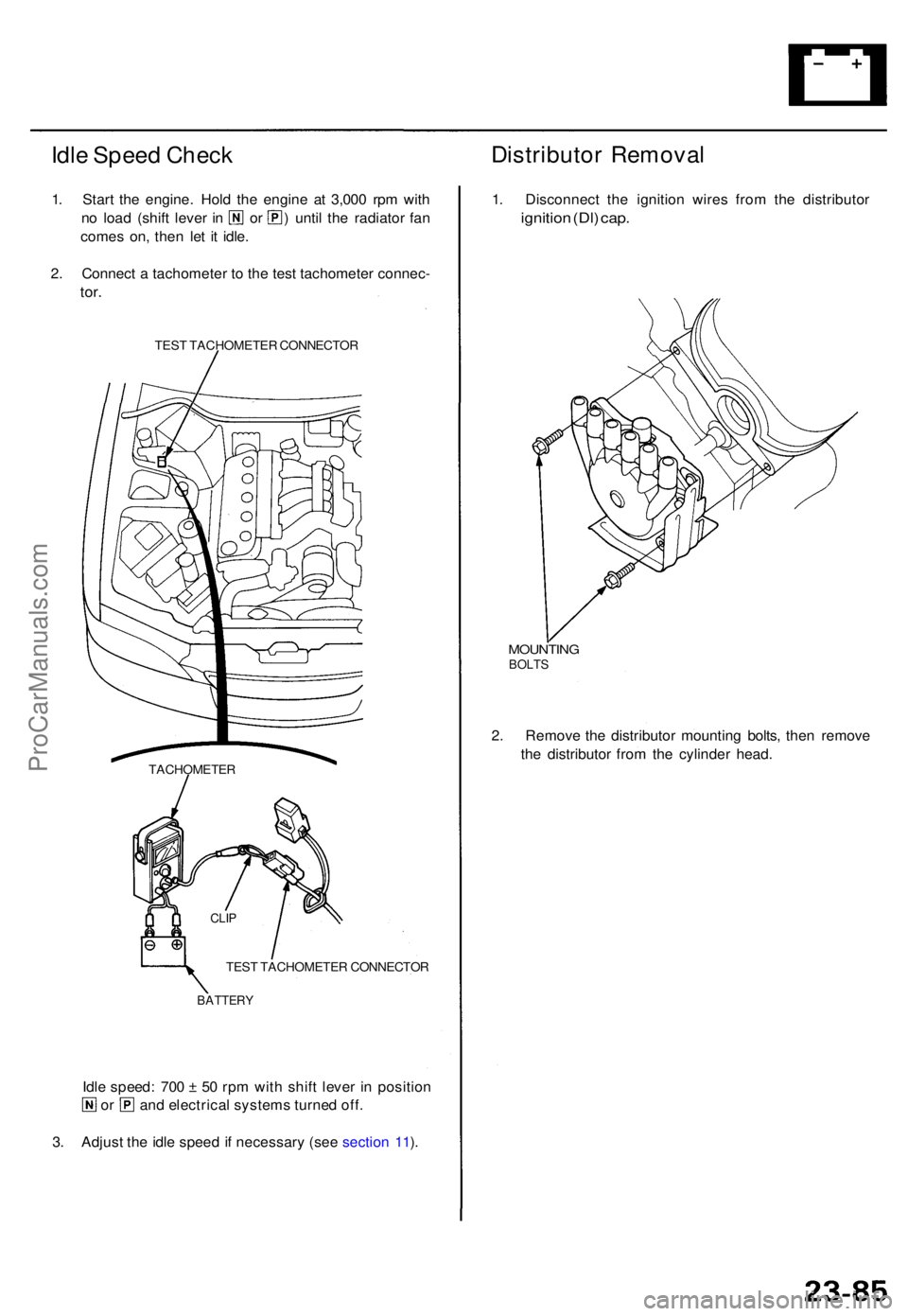

Idle Spee d Chec k

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (shif t leve r i n o r ) unti l th e radiato r fa n

come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r connec -

tor.

TES T TACHOMETE R CONNECTO R

TES T TACHOMETE R CONNECTO R

BATTERY

Idle speed : 70 0 ± 5 0 rp m wit h shif t leve r i n positio n

or an d electrica l system s turne d off .

3 . Adjus t th e idl e spee d if necessar y (se e sectio n 11 ).

Distributo r Remova l

1. Disconnec t th e ignitio n wire s fro m th e distributo r

ignition (Dl ) cap .

MOUNTIN GBOLTS

2. Remov e th e distributo r mountin g bolts , the n remov e

th e distributo r fro m th e cylinde r head .

CLIP

TACHOMETE R

ProCarManuals.com

Page 1570 of 1771

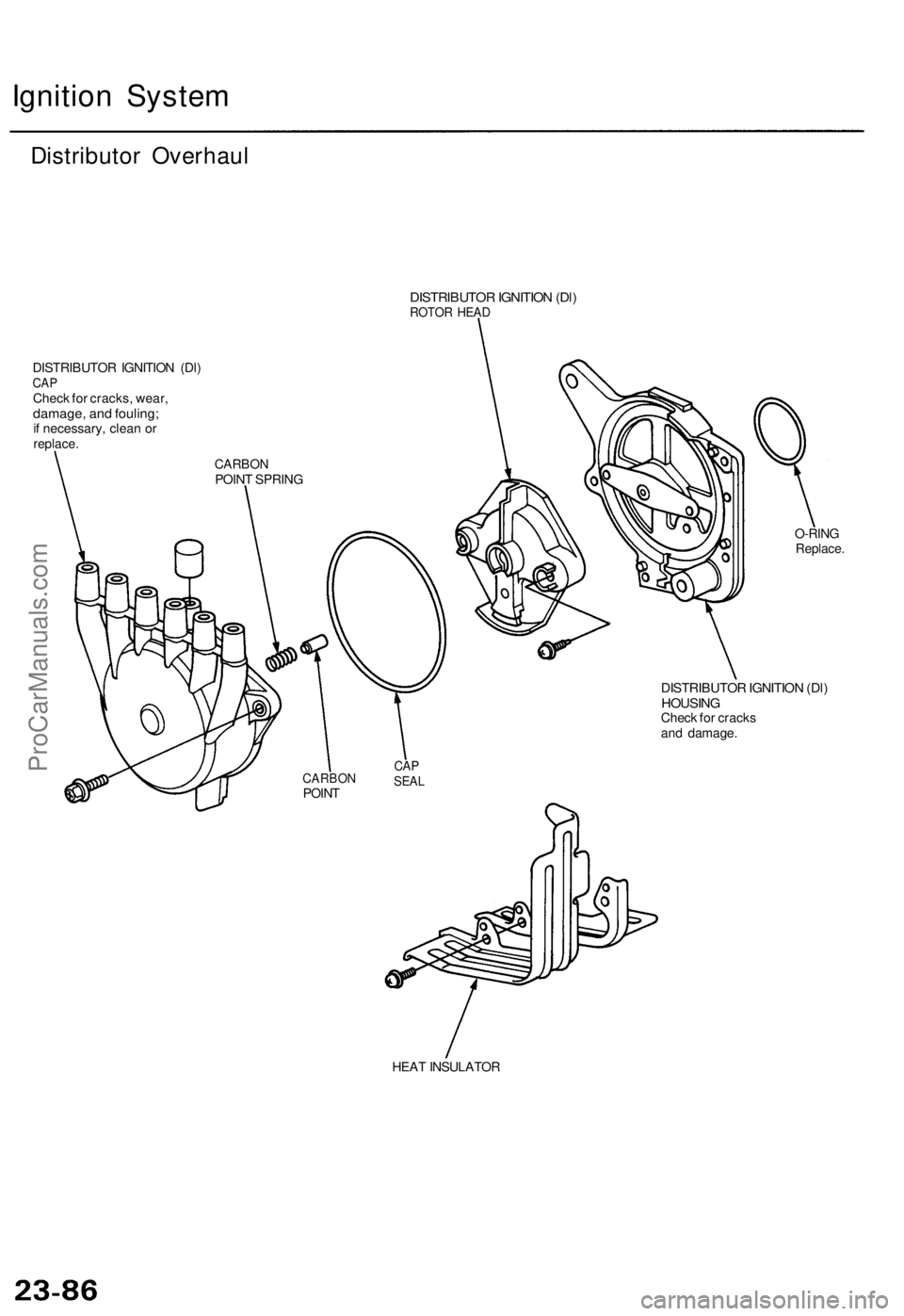

Ignition System

Distributor Overhaul

DISTRIBUTOR IGNITION (Dl)

CAP

Check for cracks, wear,

damage, and fouling;

if necessary, clean or

replace.

DISTRIBUTOR IGNITION (Dl)

ROTOR HEAD

O-RING

Replace.

DISTRIBUTOR IGNITION (Dl)

HOUSING

Check for cracks

and damage.

CARBON

POINT

CAP

SEAL

HEAT INSULATOR

CARBON

POINT SPRINGProCarManuals.com