ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1521 of 1771

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures and can

result in fire or explosion causing injury or property dam-

age. Never use compressed air to pressure test R-134a

service equipment or vehicle air conditioner systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

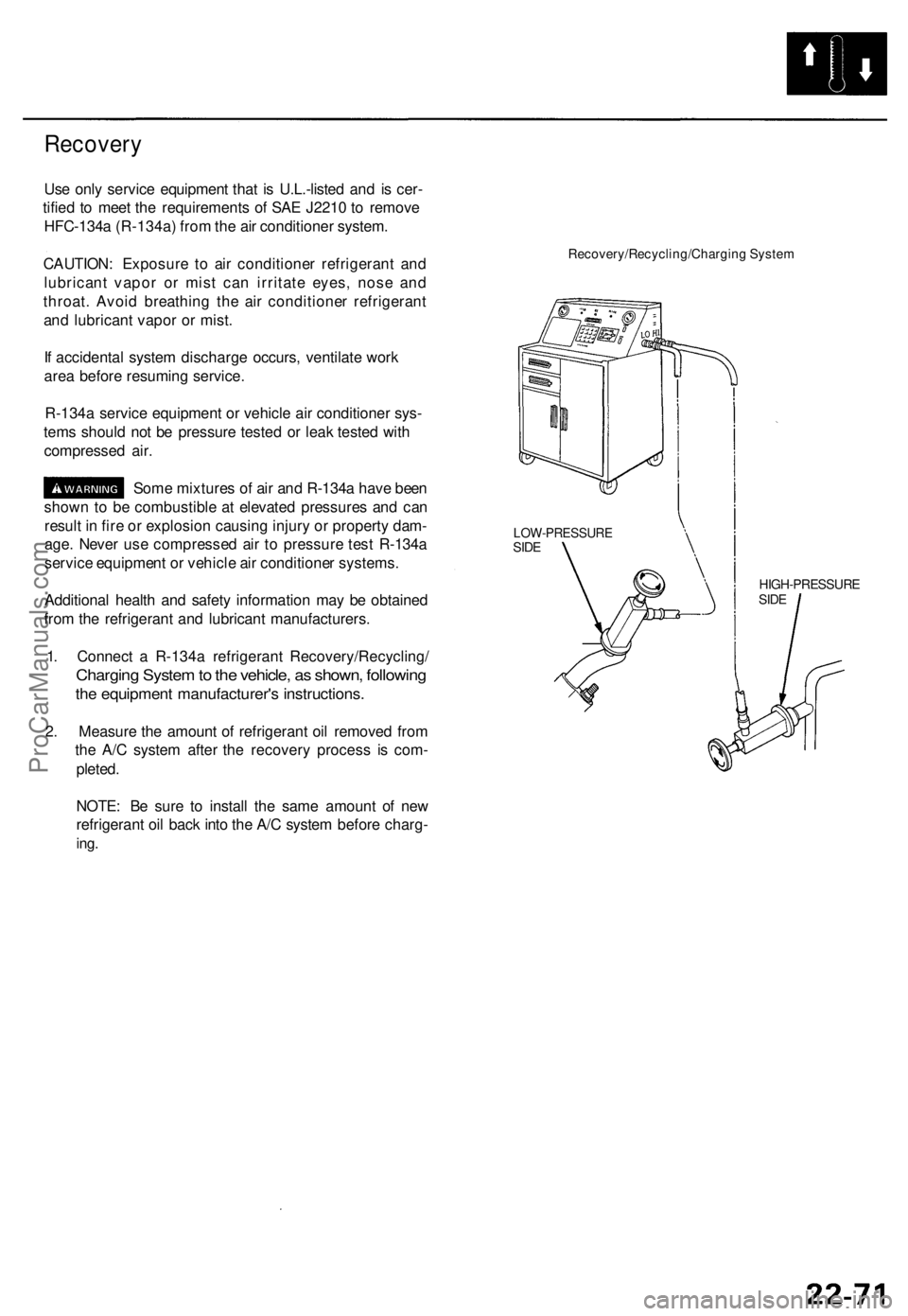

1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, following

the equipment manufacturer's instructions.

2. Measure the amount of refrigerant oil removed from

the A/C system after the recovery process is com-

pleted.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before charg-

ing.

Recovery/Recycling/Charging System

HIGH-PRESSURE

SIDE

LOW-PRESSURE

SIDEProCarManuals.com

Page 1522 of 1771

Compressor

Replacemen t

1. I f th e compresso r i s marginall y operable , ru n th e

engin e a t idl e speed , an d le t th e ai r conditione r

wor k fo r a fe w minutes , the n shu t th e engin e off .

2 . Disconnec t th e negativ e cabl e fro m th e battery .

3 . Recove r th e refrigeran t wit h a Recovery/Recycling /

Chargin g Syste m (se e pag e 22-71 ).

4 . Remov e th e intak e ai r duc t (se e sectio n 5) .

5 . Remov e th e A/ C compresso r bel t (se e pag e 22-78 ).

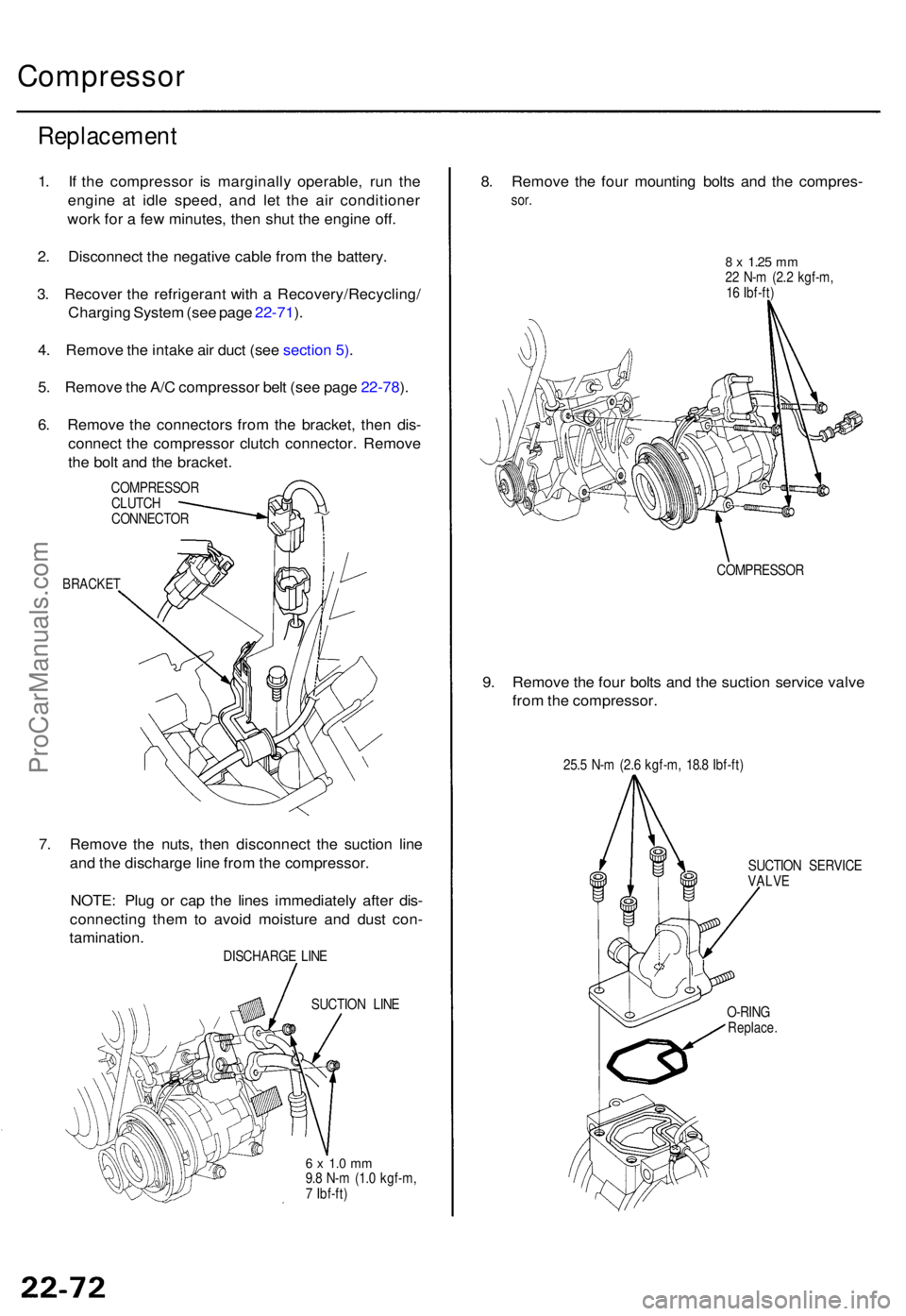

6 . Remov e th e connector s fro m th e bracket , the n dis -

connec t th e compresso r clutc h connector . Remov e

th e bol t an d th e bracket .

COMPRESSO R

CLUTC H

CONNECTO R

BRACKET

7. Remov e th e nuts , the n disconnec t th e suctio n lin e

an d th e discharg e lin e fro m th e compressor .

NOTE : Plu g o r ca p th e line s immediatel y afte r dis -

connectin g the m to avoi d moistur e an d dus t con -

tamination .

DISCHARG E LIN E

SUCTIO N LIN E

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7 Ibf-ft )

8. Remov e th e fou r mountin g bolt s an d th e compres -

sor.

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

COMPRESSO R

9. Remov e th e fou r bolt s an d th e suctio n servic e valv e

fro m th e compressor .

25.5 N- m (2. 6 kgf-m , 18. 8 Ibf-ft )

SUCTIO N SERVIC E

VALV E

O-RIN G

Replace .

ProCarManuals.com

Page 1523 of 1771

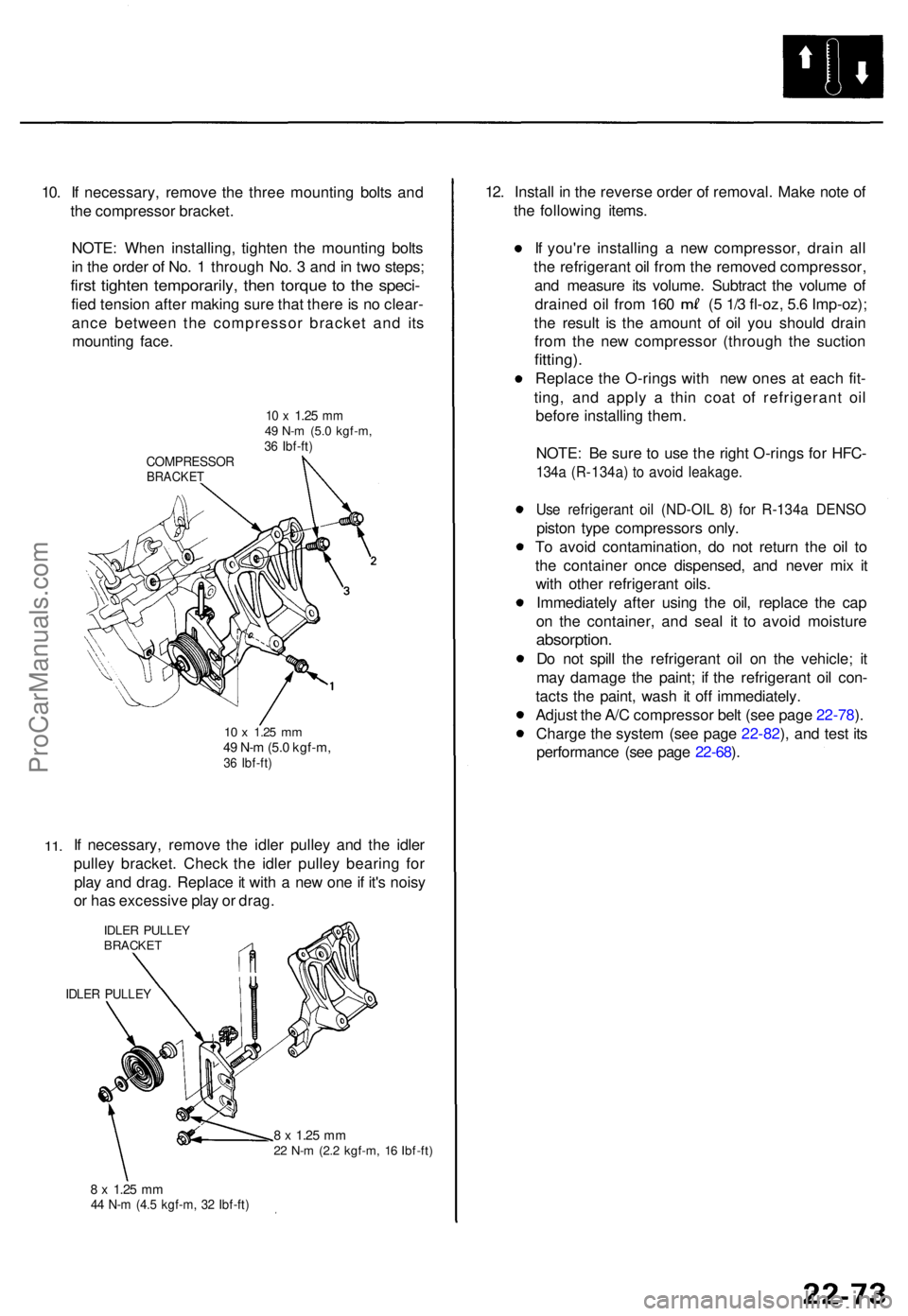

10. I f necessary , remov e th e thre e mountin g bolt s an d

th e compresso r bracket .

NOTE : Whe n installing , tighte n th e mountin g bolt s

i n th e orde r o f No . 1 throug h No . 3 an d in tw o steps ;

first tighte n temporarily , the n torqu e t o th e speci -

fied tensio n afte r makin g sur e tha t ther e is n o clear -

anc e betwee n th e compresso r bracke t an d it s

mountin g face .

10 x 1.2 5 mm49 N- m (5. 0 kgf-m ,36 Ibf-ft )COMPRESSO RBRACKET

11.

10 x 1.2 5 mm49 N- m (5. 0 kgf-m ,36 Ibf-ft )

If necessary , remov e th e idle r pulle y an d th e idle r

pulle y bracket . Chec k th e idle r pulle y bearin g fo r

pla y an d drag . Replac e it wit h a ne w on e if it' s nois y

o r ha s excessiv e pla y o r drag .

IDLER PULLE YBRACKE T

IDLER PULLE Y

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

8 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 2 Ibf-ft )

12. Instal l i n th e revers e orde r o f removal . Mak e not e o f

th e followin g items .

I f you'r e installin g a ne w compressor , drai n al l

th e refrigeran t oi l fro m th e remove d compressor ,

an d measur e it s volume . Subtrac t th e volum e o f

draine d oi l fro m 16 0 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz) ;

th e resul t i s th e amoun t o f oi l yo u shoul d drai n

fro m th e ne w compresso r (throug h th e suctio n

fitting).

Replac e th e O-ring s wit h ne w one s a t eac h fit -

ting , an d appl y a thi n coa t o f refrigeran t oi l

befor e installin g them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r HFC -

134a (R-134a ) t o avoi d leakage .

Use refrigeran t oi l (ND-OI L 8 ) fo r R-134 a DENS O

piston typ e compressor s only .

T o avoi d contamination , d o no t retur n th e oi l t o

th e containe r onc e dispensed , an d neve r mi x i t

wit h othe r refrigeran t oils .

Immediatel y afte r usin g th e oil , replac e th e ca p

o n th e container , an d sea l i t t o avoi d moistur e

absorption .

Do no t spil l th e refrigeran t oi l o n th e vehicle ; i t

ma y damag e th e paint ; i f th e refrigeran t oi l con -

tact s th e paint , was h i t of f immediately .

Adjus t th e A/ C compresso r bel t (se e pag e 22-78 ).

Charg e th e syste m (se e pag e 22-82 ), an d tes t it s

performanc e (se e pag e 22-68 ).

ProCarManuals.com

Page 1524 of 1771

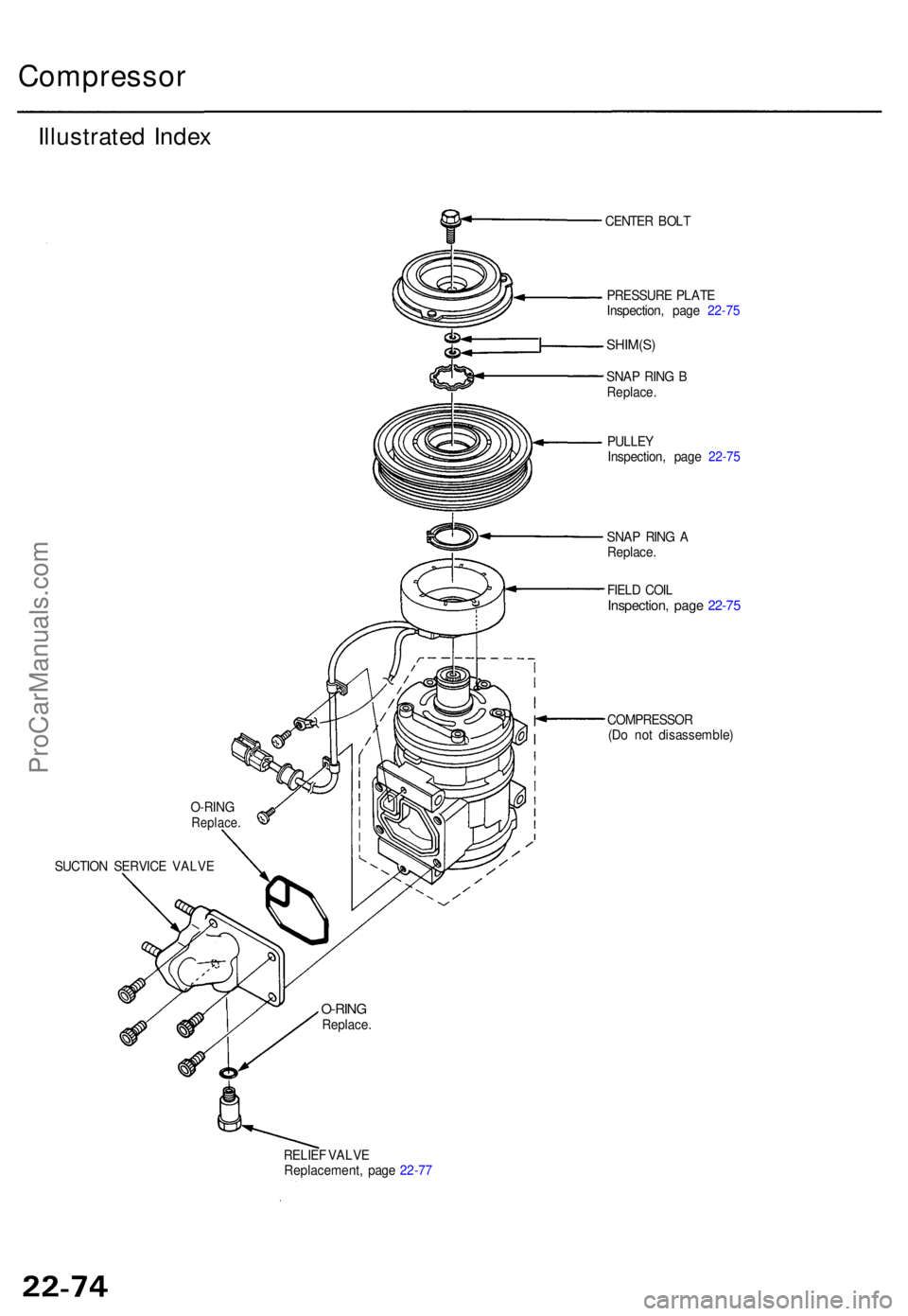

Compressor

Illustrated Inde x

SUCTIO N SERVIC E VALV E CENTE

R BOL T

PRESSUR E PLAT E

Inspection , pag e 22-7 5

SHIM(S )

SNAP RIN G B

Replace .

PULLE Y

Inspection , pag e 22-7 5

SNA P RIN G A

Replace .

FIEL D COI L

Inspection , pag e 22-7 5

COMPRESSO R

(D o no t disassemble )

RELIE F VALV E

Replacement , pag e 22-7 7

O-RIN

G

Replace .

O-RINGReplace .

ProCarManuals.com

Page 1525 of 1771

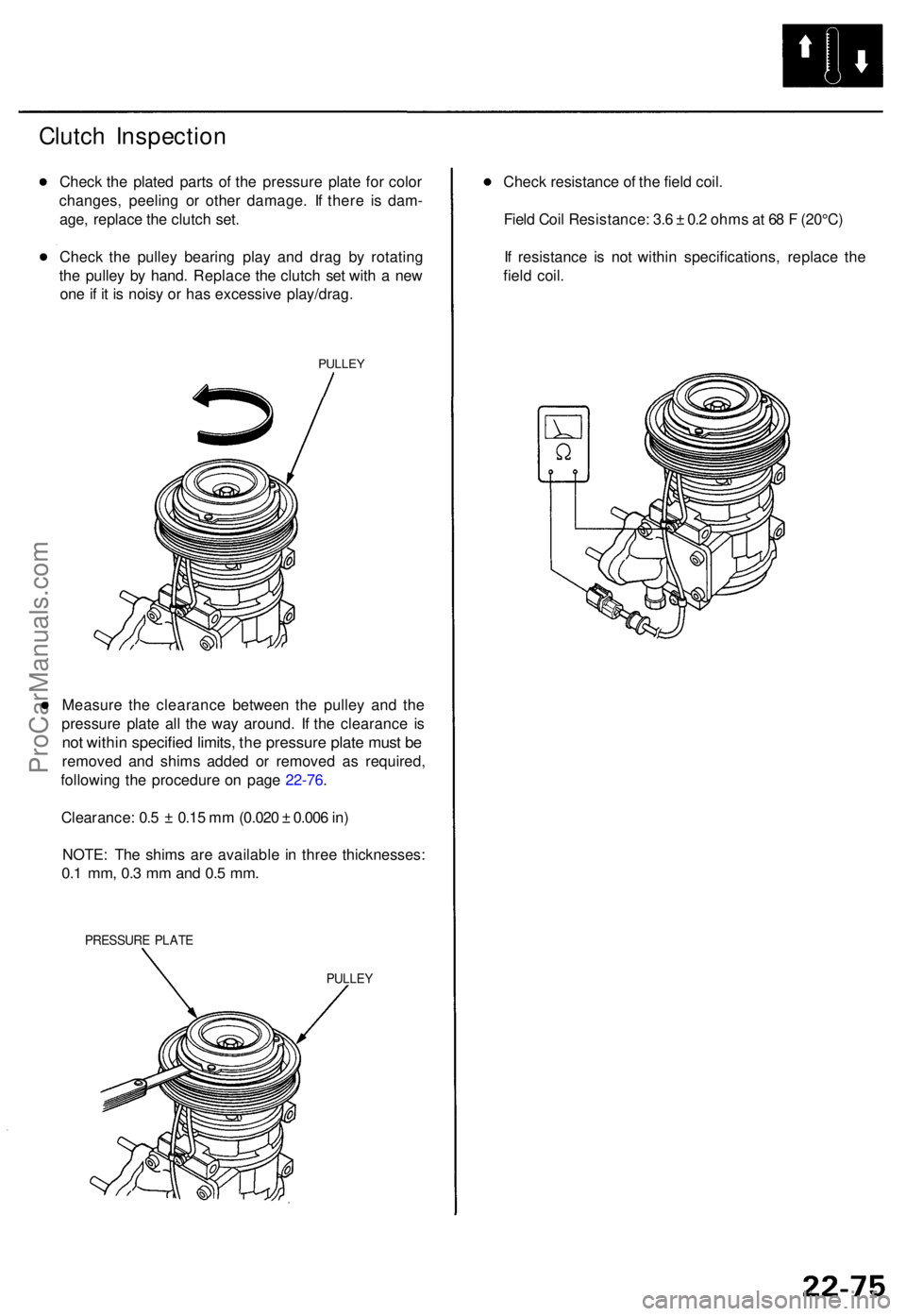

Clutch Inspectio n

Check th e plate d part s o f th e pressur e plat e fo r colo r

changes , peelin g o r othe r damage . I f ther e i s dam -

age , replac e th e clutc h set .

Chec k th e pulle y bearin g pla y an d dra g b y rotatin g

th e pulle y b y hand . Replac e th e clutc h se t wit h a ne w

on e if i t i s nois y o r ha s excessive play/drag.

PULLEY

Measur e th e clearanc e betwee n th e pulle y an d th e

pressur e plat e al l th e wa y around . I f th e clearanc e i s

no t withi n specifie d limits , th e pressur e plat e mus t b e

remove d an d shim s added or remove d a s required ,

followin g th e procedur e o n pag e 22-76 .

Clearance : 0. 5 ± 0.1 5 m m (0.02 0 ± 0.00 6 in )

NOTE : Th e shim s ar e availabl e i n thre e thicknesses :

0.1 mm , 0. 3 m m an d 0. 5 mm .

PRESSUR E PLAT E

PULLE Y

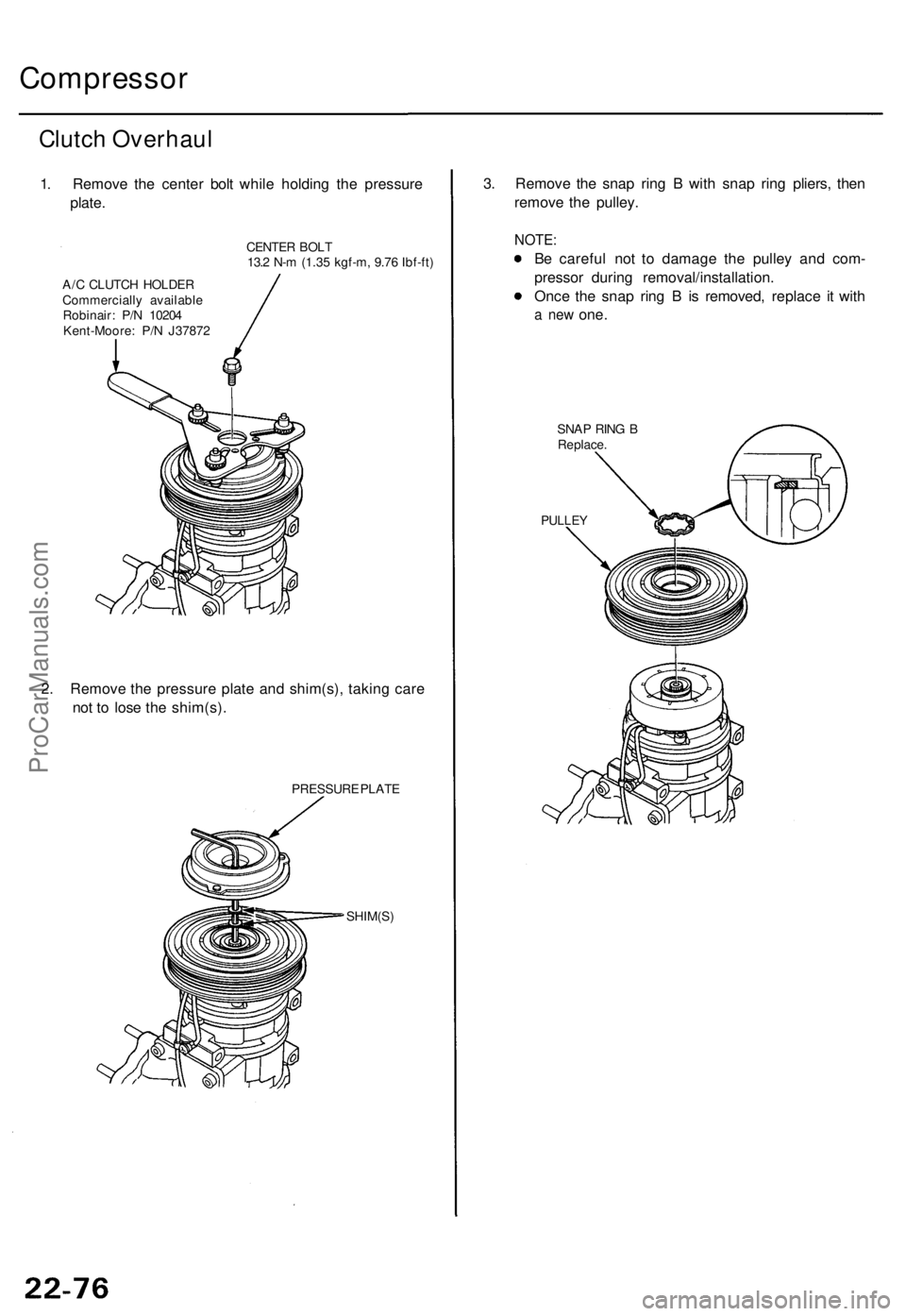

Check resistanc e o f th e fiel d coil .

Fiel d Coi l Resistance : 3. 6 ± 0. 2 ohm s a t 6 8 F (20°C )

I f resistanc e i s no t withi n specifications , replac e th e

fiel d coil .

ProCarManuals.com

Page 1526 of 1771

Compressor

Clutch Overhau l

1. Remov e th e cente r bol t whil e holdin g th e pressur e

plate .

CENTE R BOL T

13. 2 N- m (1.3 5 kgf-m , 9.7 6 Ibf-ft )

A/ C CLUTC H HOLDE R

Commerciall y availabl e

Robinair : P/ N 1020 4

Kent-Moore : P/ N J3787 2

2. Remov e th e pressur e plat e an d shim(s) , takin g car e

no t t o los e th e shim(s) .

PRESSUR E PLAT E

SHIM(S )

3. Remov e th e sna p rin g B wit h sna p rin g pliers , the n

remov e th e pulley .

NOTE:

Be carefu l no t t o damag e th e pulle y an d com -

presso r durin g removal/installation .

Onc e th e sna p rin g B is removed , replac e i t wit h

a ne w one .

SNA P RIN G B

Replace .

PULLEY

ProCarManuals.com

Page 1527 of 1771

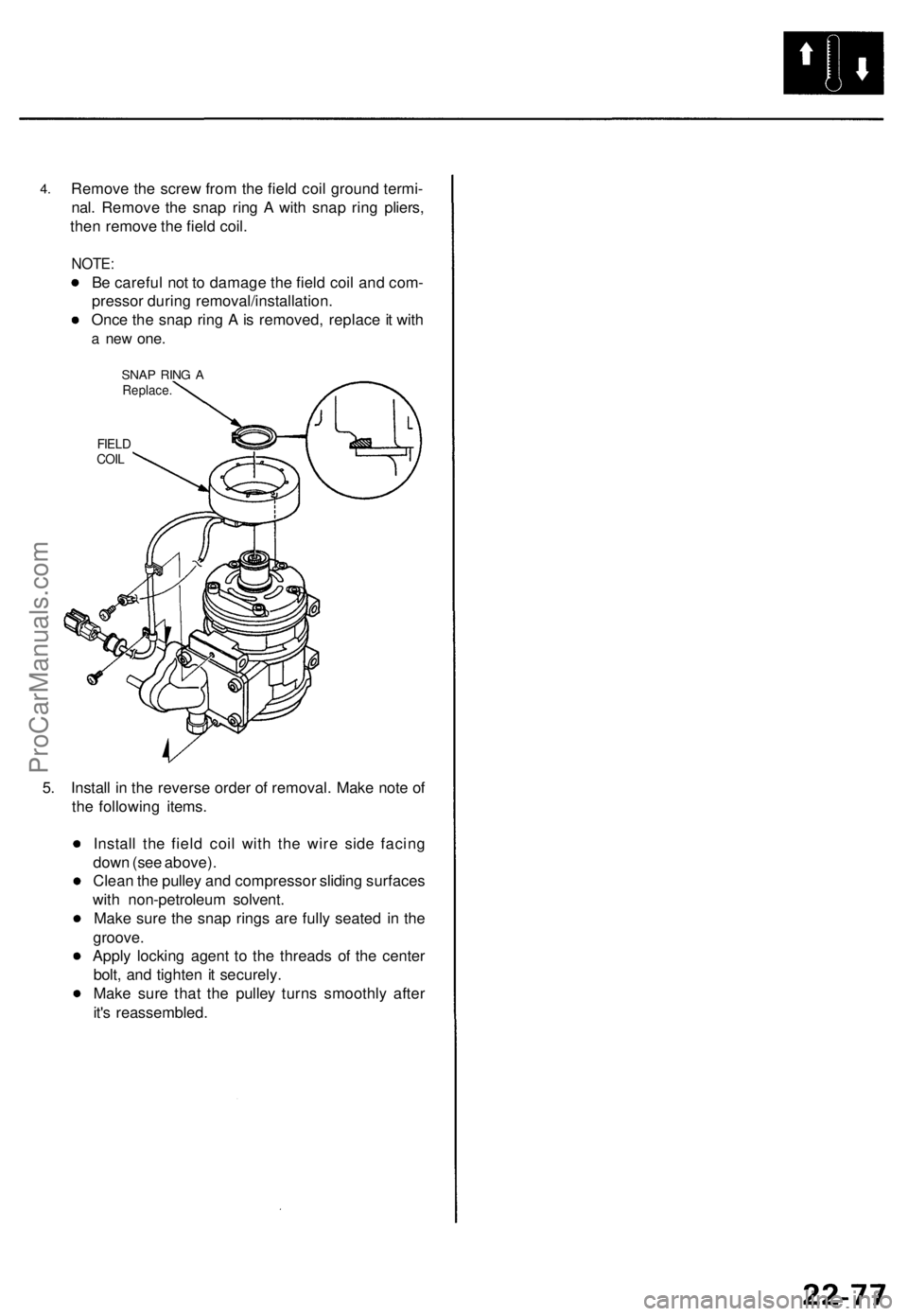

4.

Remove the screw from the field coil ground termi-

nal. Remove the snap ring A with snap ring pliers,

then remove the field coil.

NOTE:

Be careful not to damage the field coil and com-

pressor during removal/installation.

Once the snap ring A is removed, replace it with

a new

one.

SNAP RING A

Replace.

FIELD

COIL

5. Install in the reverse order of removal. Make note of

the following items.

Install the field coil with the wire side facing

down (see above).

Clean the pulley and compressor sliding surfaces

with non-petroleum solvent.

Make sure the snap rings are fully seated in the

groove.

Apply locking agent to the threads of the center

bolt, and tighten it securely.

Make sure that the pulley turns smoothly after

it's reassembled.ProCarManuals.com

Page 1528 of 1771

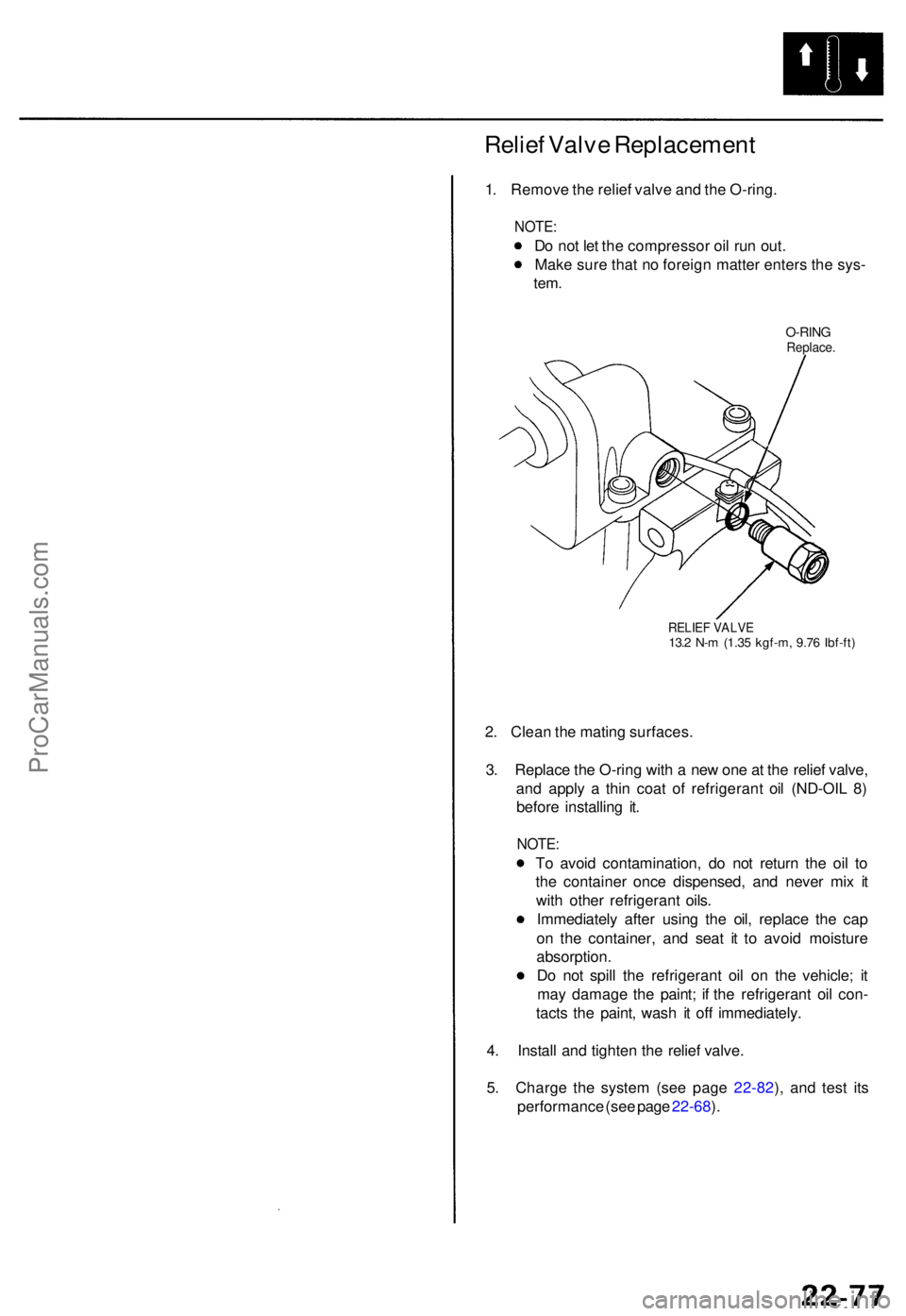

Relief Valv e Replacemen t

1. Remov e th e relie f valv e an d th e O-ring .

NOTE:

Do no t le t th e compresso r oi l ru n out .

Mak e sur e tha t n o foreig n matte r enter s th e sys -

tem.

O-RIN GReplace .

RELIEF VALV E13.2 N- m (1.3 5 kgf-m , 9.7 6 Ibf-ft )

2. Clea n th e matin g surfaces .

3 . Replac e th e O-rin g wit h a ne w on e a t th e relie f valve ,

an d appl y a thi n coa t o f refrigeran t oi l (ND-OI L 8 )

befor e installin g it .

NOTE :

To avoi d contamination , d o no t retur n th e oi l t o

th e containe r onc e dispensed , an d neve r mi x i t

wit h othe r refrigeran t oils .

Immediatel y afte r usin g th e oil , replac e th e cap

o n th e container , an d sea t i t t o avoi d moistur e

absorption .

D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t

ma y damag e th e paint ; i f th e refrigeran t oi l con -

tact s th e paint , was h i t of f immediately .

4 . Instal l an d tighte n th e relie f valve .

5 . Charg e th e syste m (se e pag e 22-82 ), an d tes t it s

performanc e (se e pag e 22-68 ).

ProCarManuals.com

Page 1529 of 1771

A/C Compresso r Bel t

Adjustmen t

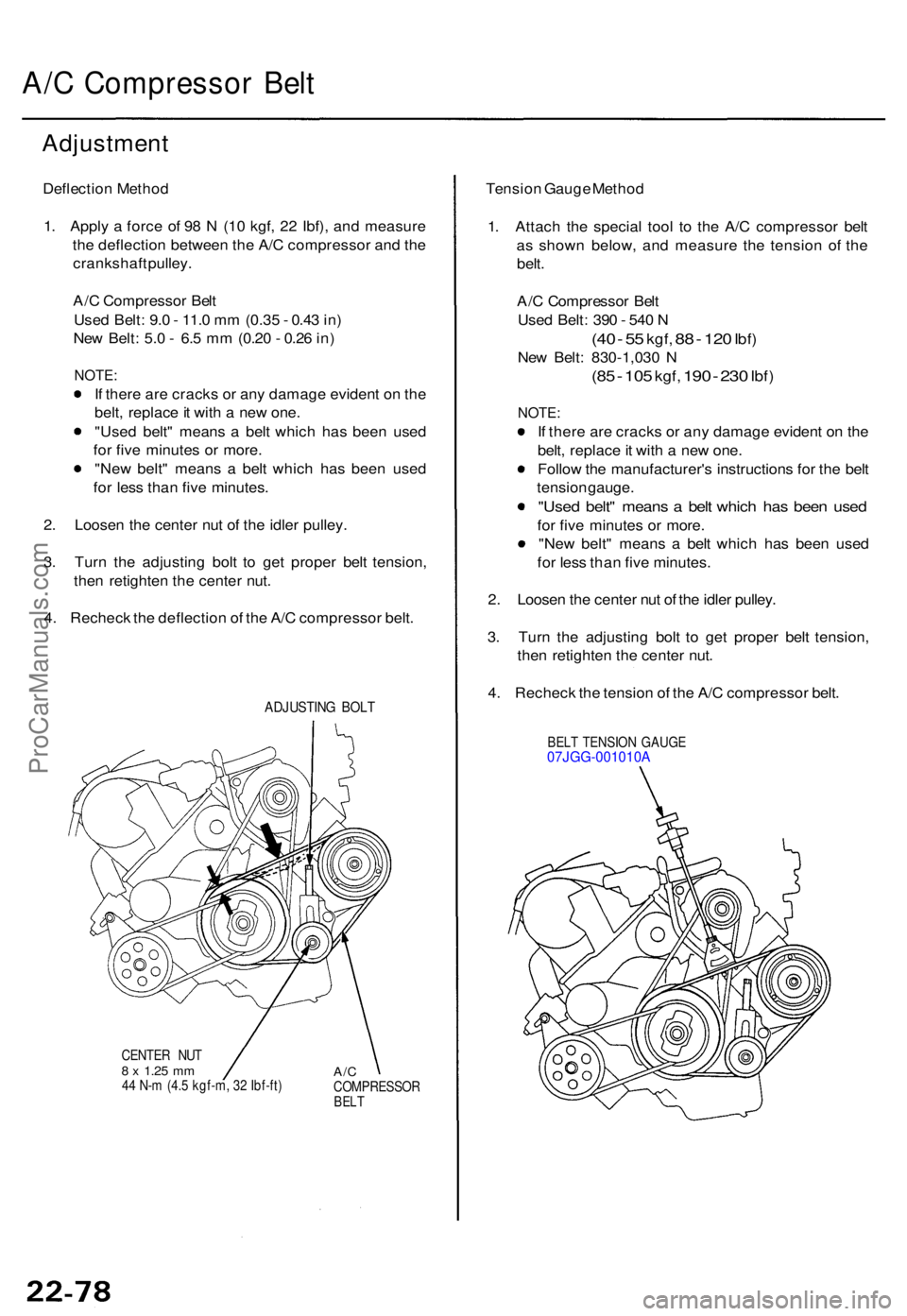

Deflection Metho d

1 . Appl y a forc e o f 9 8 N (1 0 kgf , 2 2 Ibf) , an d measur e

th e deflectio n betwee n th e A/ C compresso r an d th e

crankshaf t pulley .

A/ C Compresso r Bel t

Use d Belt : 9. 0 - 11. 0 m m (0.3 5 - 0.4 3 in )

Ne w Belt : 5. 0 - 6. 5 m m (0.2 0 - 0.2 6 in )

NOTE :

If ther e ar e crack s o r an y damag e eviden t o n th e

belt , replac e it wit h a ne w one .

"Use d belt " mean s a bel t whic h ha s bee n use d

fo r fiv e minute s o r more .

"Ne w belt " mean s a bel t whic h ha s bee n use d

fo r les s tha n fiv e minutes .

2 . Loose n th e cente r nu t o f th e idle r pulley .

3 . Tur n th e adjustin g bol t t o ge t prope r bel t tension ,

the n retighte n th e cente r nut .

4 . Rechec k th e deflectio n o f th e A/ C compresso r belt .

ADJUSTIN G BOL T

CENTE R NU T8 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 2 Ibf-ft )A/CCOMPRESSO RBELT

Tensio n Gaug e Metho d

1 . Attac h th e specia l too l t o th e A/ C compresso r bel t

a s show n below , an d measur e th e tensio n of the

belt .

A/ C Compresso r Bel t

Use d Belt : 39 0 - 54 0 N

(4 0 - 5 5 kgf , 88 - 12 0 Ibf )

New Belt : 830-1,03 0 N

(8 5 - 10 5 kgf , 190 - 230 Ibf )

NOTE :

If ther e ar e crack s o r an y damag e eviden t o n th e

belt , replac e it wit h a ne w one .

Follo w th e manufacturer' s instruction s fo r th e bel t

tensio n gauge .

"Used belt " mean s a bel t whic h ha s bee n use d

for fiv e minute s o r more .

"Ne w belt " mean s a bel t whic h ha s bee n use d

fo r les s tha n fiv e minutes .

2 . Loose n th e cente r nu t o f th e idle r pulley .

3 . Tur n th e adjustin g bol t t o ge t prope r bel t tension ,

the n retighte n th e cente r nut .

4 . Rechec k th e tensio n o f th e A/ C compresso r belt .

BEL T TENSIO N GAUG E07JGG-001010 A

ProCarManuals.com

Page 1530 of 1771

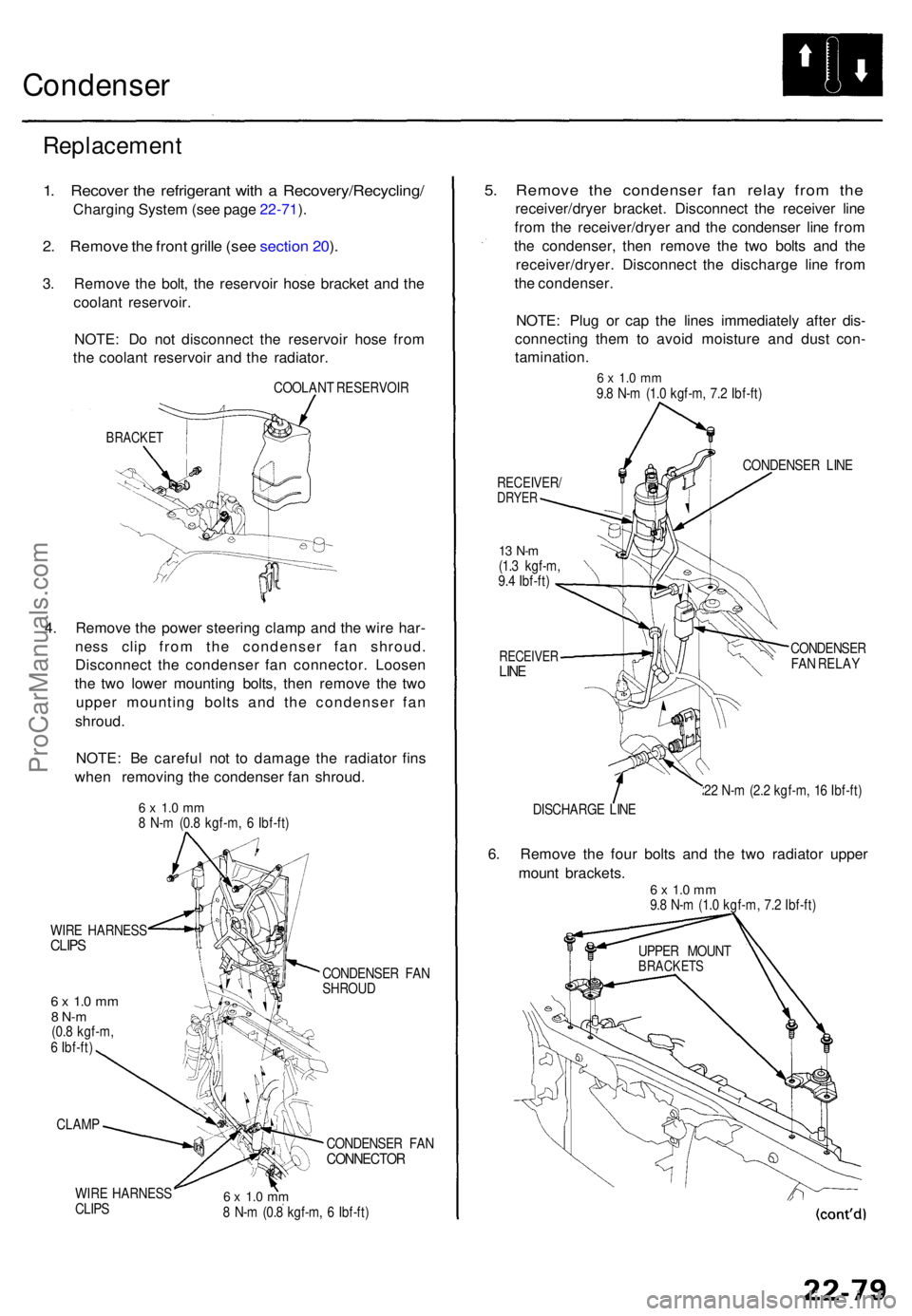

Condenser

Replacemen t

1. Recove r th e refrigeran t wit h a Recovery/Recycling /

Charging Syste m (se e pag e 22-71 ).

2 . Remov e th e fron t grill e (se e sectio n 20 ).

3 . Remov e th e bolt , th e reservoi r hos e bracke t an d th e

coolan t reservoir .

NOTE : D o no t disconnec t th e reservoi r hos e fro m

th e coolan t reservoi r an d th e radiator .

COOLAN T RESERVOI R

BRACKET

4. Remov e th e powe r steerin g clam p an d th e wir e har -

nes s cli p fro m th e condense r fa n shroud .

Disconnec t th e condense r fa n connector . Loose n

th e tw o lowe r mountin g bolts , the n remov e th e tw o

uppe r mountin g bolt s an d th e condense r fa n

shroud .

NOTE : B e carefu l no t t o damag e th e radiato r fin s

whe n removin g th e condense r fa n shroud .

6 x 1. 0 m m8 N- m (0. 8 kgf-m , 6 Ibf-ft )

WIR E HARNES S

CLIPS

6 x 1. 0 m m8 N- m(0.8 kgf-m ,

6 Ibf-ft )

CLAM P

WIR E HARNES S

CLIP S CONDENSE

R FA N

SHROU D

CONDENSE R FA N

CONNECTO R

6 x 1. 0 m m8 N- m (0. 8 kgf-m , 6 Ibf-ft )

5. Remov e th e condense r fa n rela y fro m th e

receiver/drye r bracket . Disconnec t th e receive r lin e

fro m th e receiver/drye r an d th e condense r lin e fro m

th e condenser , the n remov e th e tw o bolt s an d th e

receiver/dryer . Disconnec t th e discharg e lin e fro m

th e condenser .

NOTE : Plu g o r ca p th e line s immediatel y afte r dis -

connectin g the m to avoi d moistur e an d dus t con -

tamination .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

RECEIVER /DRYER

13 N- m(1.3 kgf-m ,

9. 4 Ibf-ft )

RECEIVE RLINE

CONDENSE R LIN E

CONDENSE R

FA N RELA Y

2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

DISCHARG E LIN E

6. Remov e th e fou r bolt s an d th e tw o radiato r uppe r

moun t brackets .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

UPPE R MOUN T

BRACKET S

ProCarManuals.com