ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1531 of 1771

Condenser

Replacemen t (cont'd )

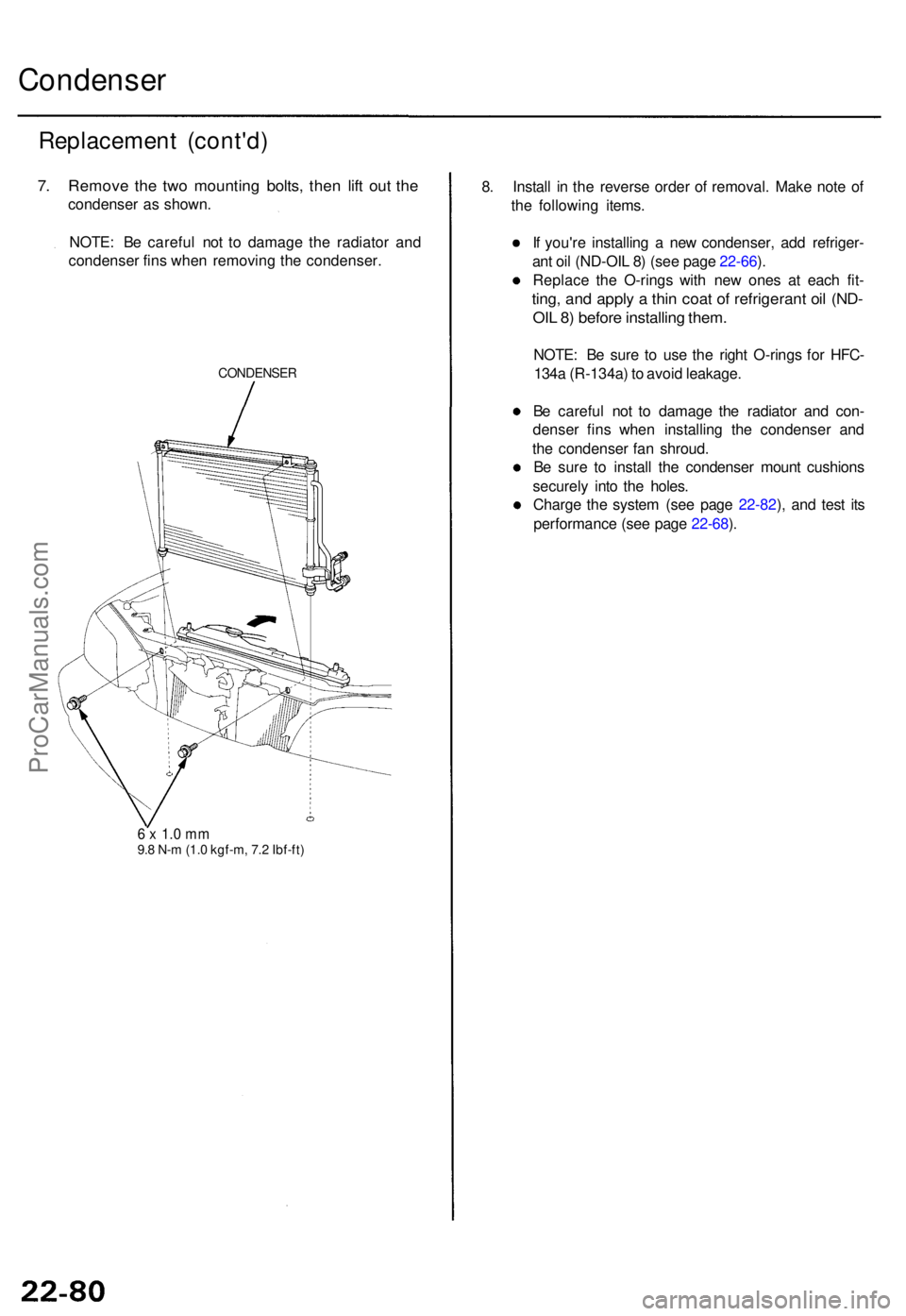

7. Remov e th e tw o mountin g bolts , the n lif t ou t th e

condense r a s shown .

NOTE : B e carefu l no t t o damag e th e radiato r an d

condense r fin s whe n removin g th e condenser .

CONDENSE R

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

8. Instal l i n th e revers e orde r o f removal . Mak e not e o f

th e followin g items .

I f you'r e installin g a ne w condenser , ad d refriger -

an t oi l (ND-OI L 8 ) (se e pag e 22-66 ).

Replac e th e O-ring s wit h ne w one s a t eac h fit -

ting , an d appl y a thi n coa t o f refrigeran t oi l (ND -

OI L 8 ) befor e installin g them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r HFC -

134 a (R-134a ) t o avoi d leakage .

B e carefu l no t t o damag e th e radiato r an d con -

dense r fin s whe n installin g th e condense r an d

th e condense r fa n shroud .

B e sur e t o instal l th e condense r moun t cushion s

securel y int o th e holes .

Charg e th e syste m (se e pag e 22-82 ), an d tes t it s

performanc e (se e pag e 22-68 ).

ProCarManuals.com

Page 1532 of 1771

A/C System Service

Evacuation

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and throat.

Avoid breathing the air conditioner refrigerant and lubri-

cant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures and can

result in fire or explosion causing injury or property

damage. Never use compressed air to pressure test R-

134a service equipment or vehicle air conditioner sys-

tems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. When an A/C System has been opened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. (If the system has been

open for several days, the receiver/dryer should be

replaced, and the system should be evacuated for

several hours.)

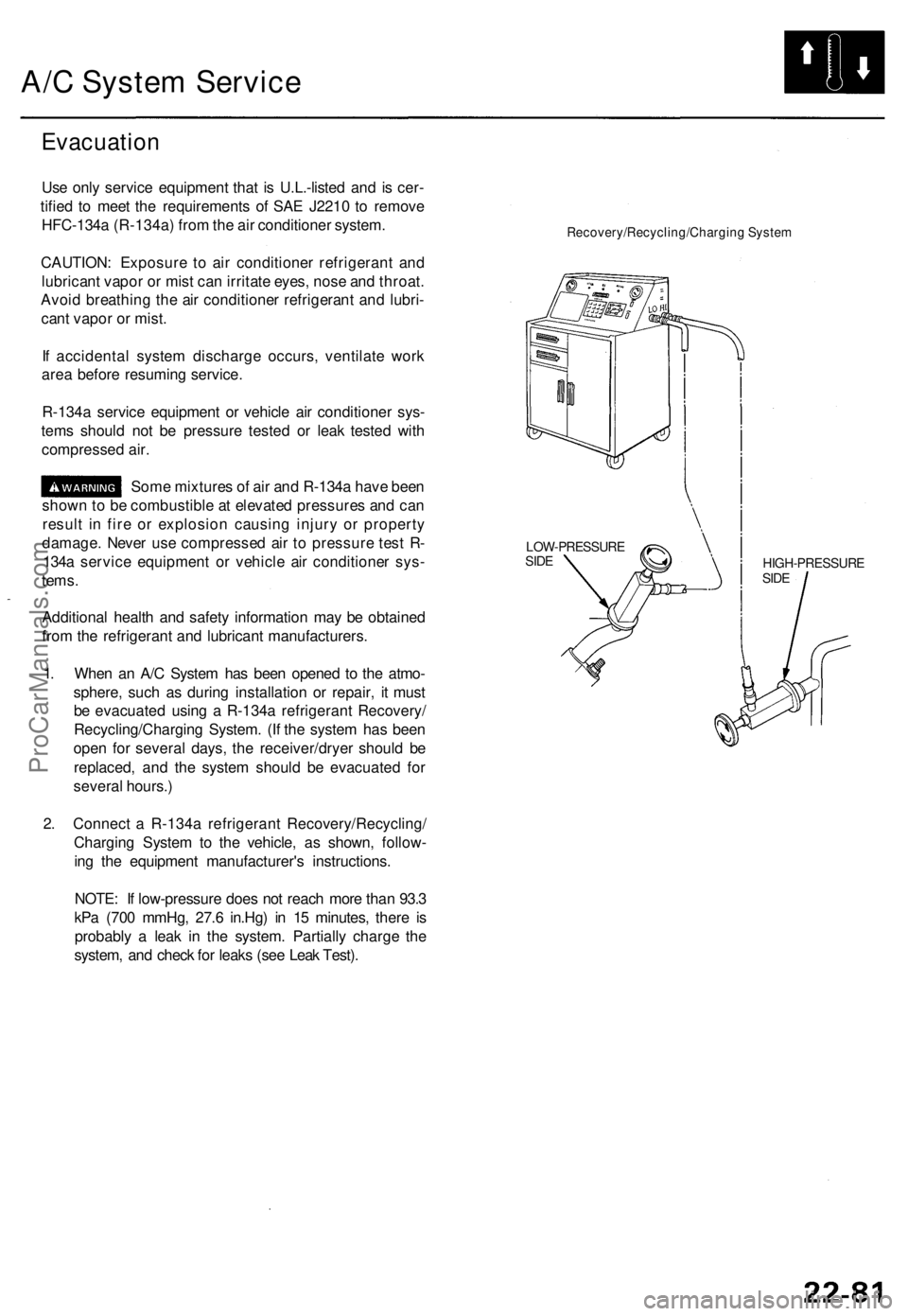

2. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE: If low-pressure does not reach more than 93.3

kPa (700 mmHg, 27.6 in.Hg) in 15 minutes, there is

probably a leak in the system. Partially charge the

system, and check for leaks (see Leak Test).

Recovery/Recycling/Charging System

HIGH-PRESSURE

SIDE

LOW-PRESSURE

SIDEProCarManuals.com

Page 1533 of 1771

A/C Syste m Servic e

Chargin g

Use onl y servic e equipmen t tha t i s U.L.-liste d an d i s cer -

tified to mee t th e requirement s o f SA E J221 0 to remov e

HFC-134 a (R-134a ) fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d

lubricant vapor o r mis t ca n irritat e eyes , nos e an d

throat . Avoi d breathin g th e ai r conditione r refrigeran t

an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service . Additiona l healt h an d

safet y informatio n ma y b e obtaine d fro m th e refrigeran t

an d lubrican t manufacturers .

Refrigerant capacity : 75 0 g (26.5 oz )

CAUTION : D o no t overcharg e th e system ; th e compresso r

will b e damaged .

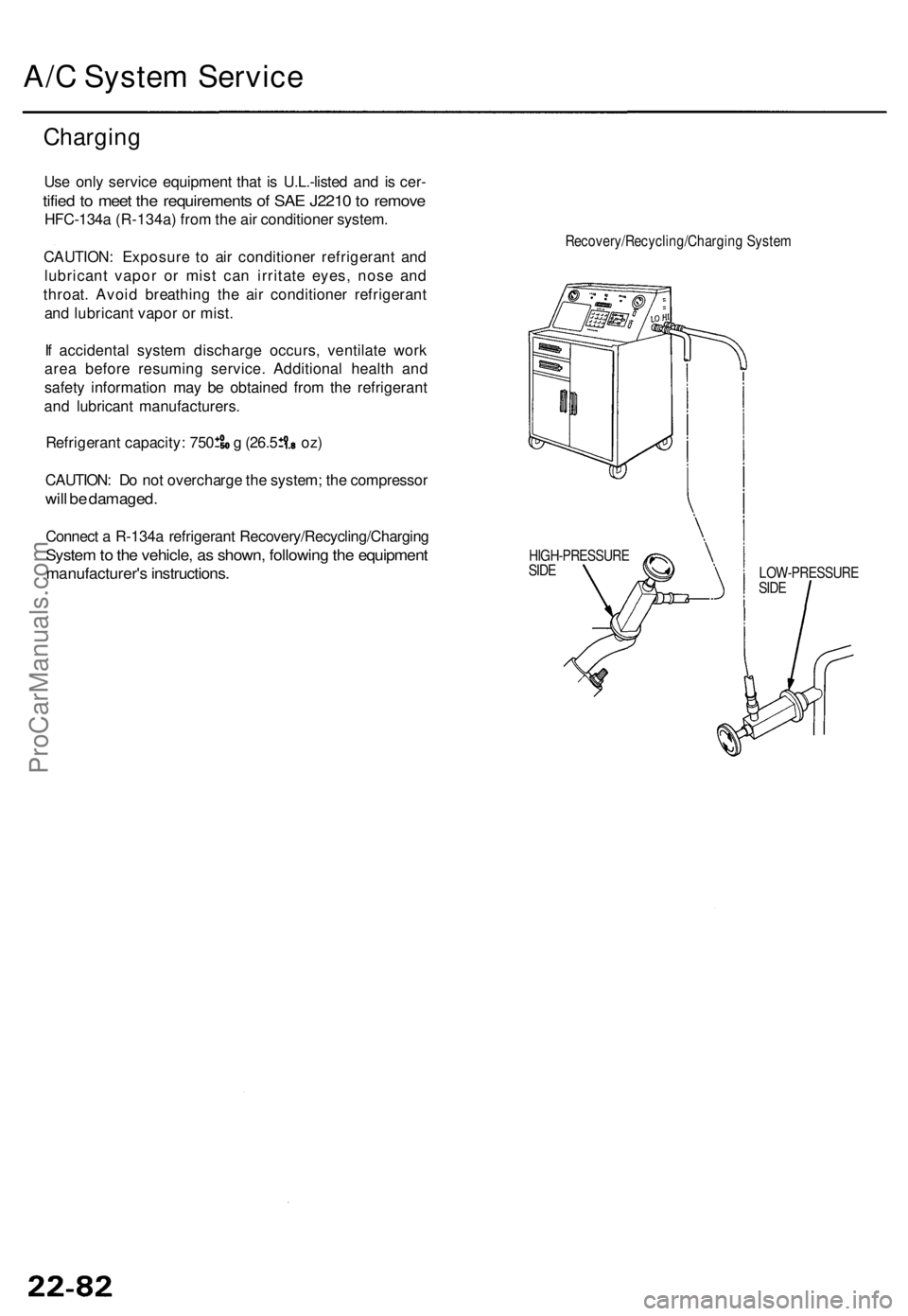

Connect a R-134 a refrigeran t Recovery/Recycling/Chargin g

System to th e vehicle , a s shown , followin g th e equipmen t

manufacturer' s instructions .

Recovery/Recycling/Chargin g Syste m

LOW-PRESSUR ESIDE

HIGH-PRESSUR ESIDE

ProCarManuals.com

Page 1534 of 1771

Leak Tes t

Use onl y servic e equipmen t tha t i s U.L.-liste d an d i s cer -

tified to mee t th e requirement s o f SA E J221 0 to remov e

HFC-134 a (R-134a ) fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d

lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat .

Avoi d breathin g th e ai r conditione r refrigeran t an d lubri -

can t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r sys -

tem s shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e

bee n show n t o b e combustibl e a t elevate d pressure s

an d ca n resul t i n fir e o r explosio n causin g injur y o r

propert y damage . Neve r us e compresse d ai r t o pressur e

tes t R-134 a servic e equipmen t o r vehicl e ai r conditione r

systems.

Additiona l healt h an d safet y informatio n ma y b e obtaine d

fro m th e refrigeran t an d lubrican t manufacturers .

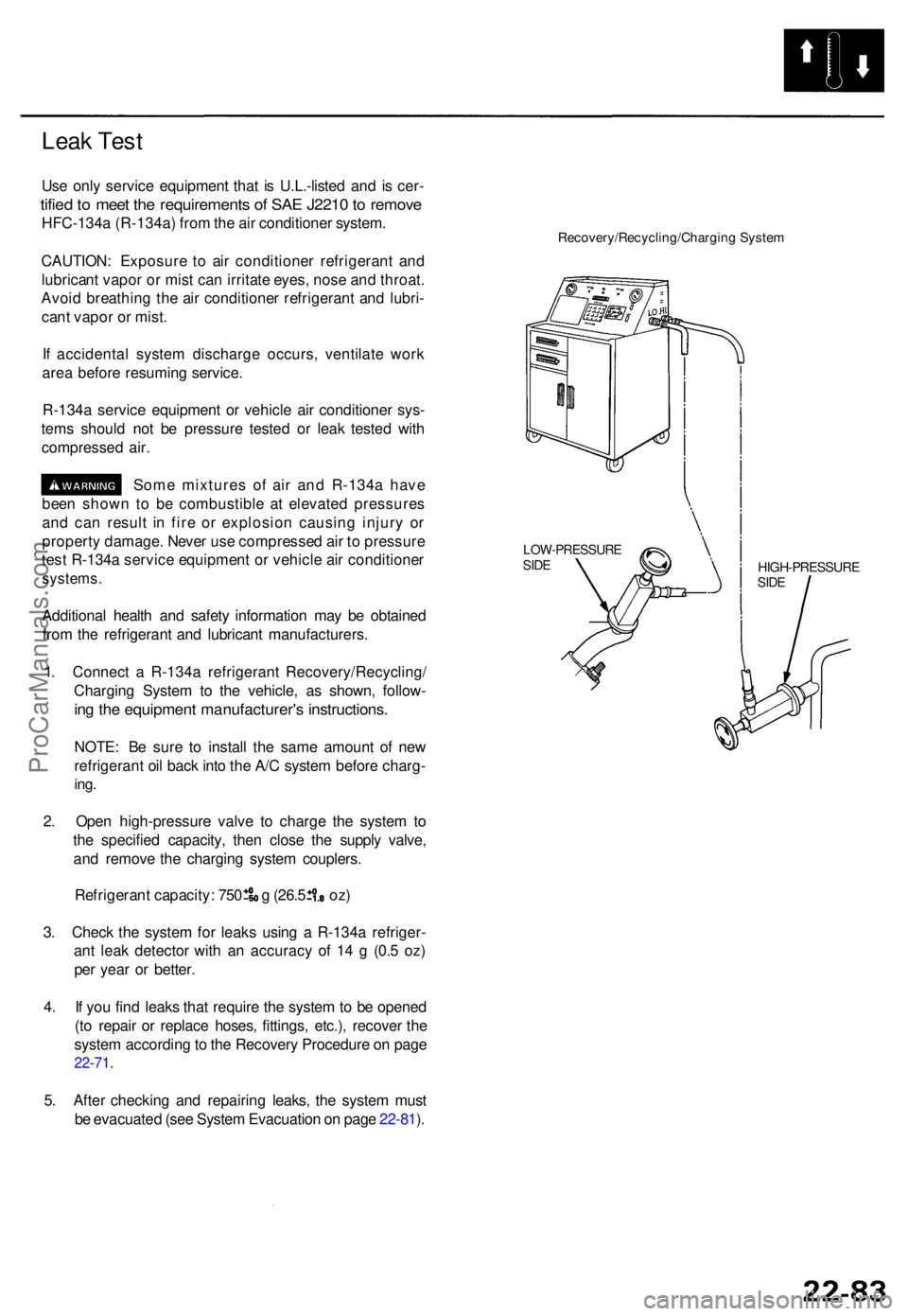

1 . Connec t a R-134 a refrigeran t Recovery/Recycling /

Chargin g Syste m to th e vehicle , a s shown , follow -

ing th e equipmen t manufacturer' s instructions .

NOTE: B e sur e t o instal l th e sam e amoun t o f ne w

refrigeran t oi l bac k int o th e A/ C syste m befor e charg -

ing.

2. Ope n high-pressur e valv e t o charg e th e syste m to

th e specifie d capacity , the n clos e th e suppl y valve ,

an d remov e th e chargin g syste m couplers .

Refrigeran t capacity : 75 0 g (26.5 oz )

3 . Chec k th e syste m fo r leak s usin g a R-134 a refriger -

an t lea k detecto r wit h a n accurac y o f 1 4 g (0. 5 oz )

pe r yea r o r better .

4 . I f yo u fin d leak s tha t requir e th e syste m to b e opene d

(t o repai r o r replac e hoses , fittings , etc.) , recove r th e

syste m accordin g to th e Recover y Procedur e o n pag e

22-71 .

Recovery/Recycling/Chargin g Syste m

HIGH-PRESSUR ESIDE

5. Afte r checkin g an d repairin g leaks , th e syste m mus t

b e evacuate d (se e Syste m Evacuatio n o n pag e 22-81 ).

LOW-PRESSUR ESIDE

ProCarManuals.com

Page 1535 of 1771

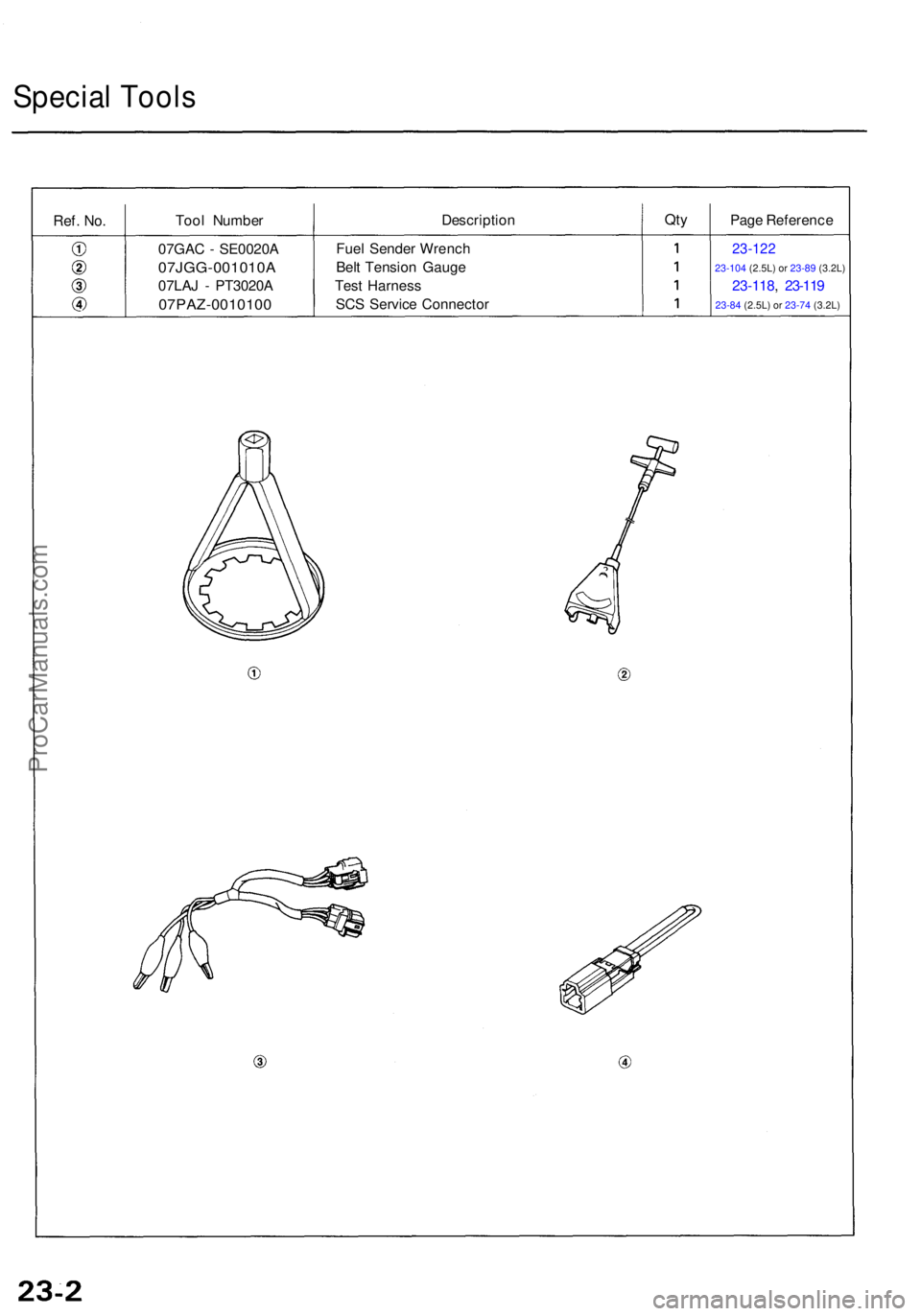

Special Tool s

Ref. No.Too l Numbe r Descriptio

nQtyPag e Referenc e

07GA C - SE0020 A

07JGG-001010 A

07LAJ - PT3020 A

07PAZ-001010 0

Fuel Sende r Wrenc h

Bel t Tensio n Gaug e

Tes t Harnes s

SC S Servic e Connecto r23-122

23-104 (2.5L) or 23-89 (3.2L)

23-118 , 23-11 9

23-84 (2.5L) or 23-74 (3.2L)

ProCarManuals.com

Page 1536 of 1771

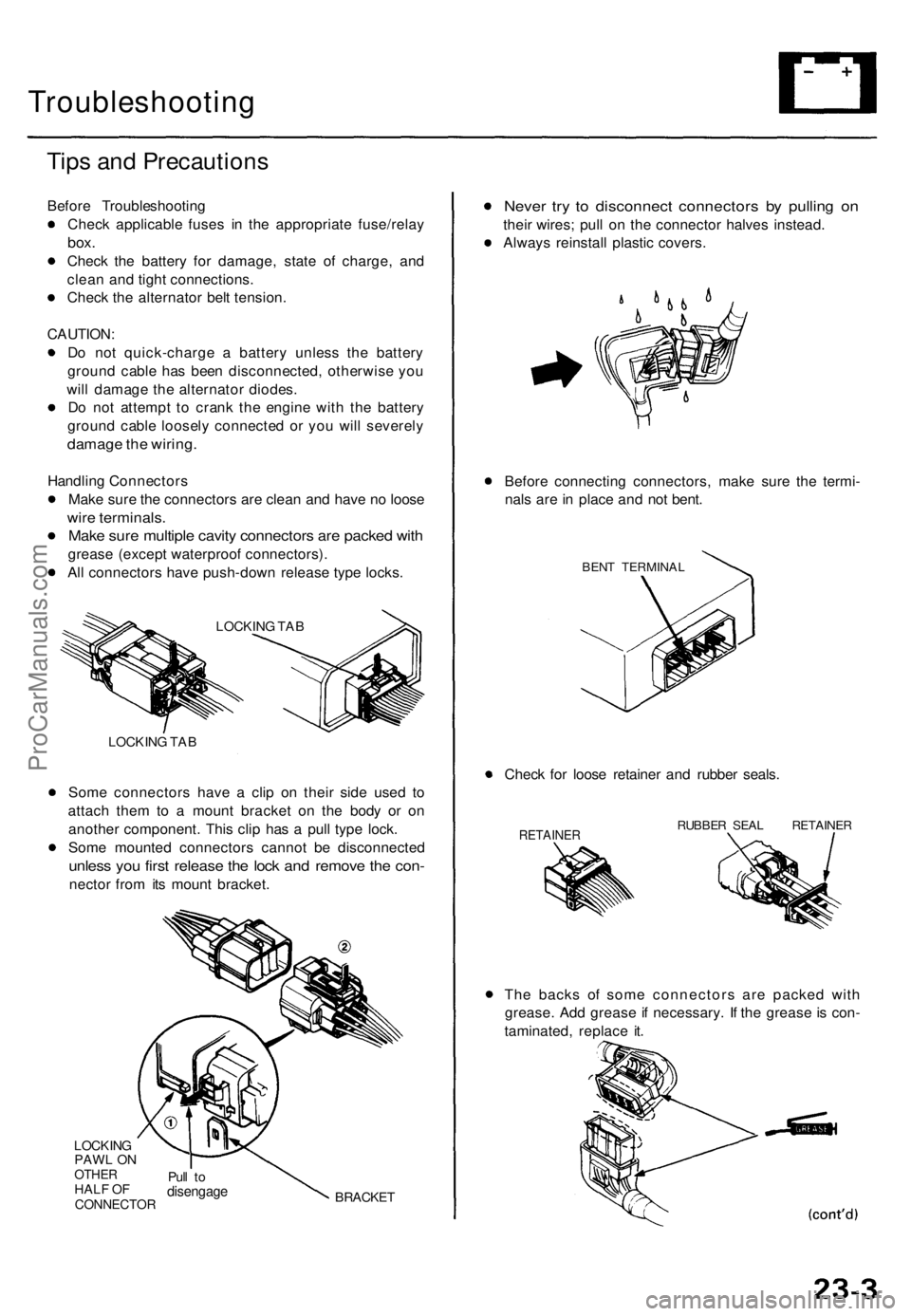

Troubleshooting

Tips and Precautions

Before Troubleshooting

Check applicable fuses in the appropriate fuse/relay

box.

Check the battery for damage, state of charge, and

clean and tight connections.

Check the alternator belt tension.

CAUTION:

Do not quick-charge a battery unless the battery

ground cable has been disconnected, otherwise you

will damage the alternator diodes.

Do not attempt to crank the engine with the battery

ground cable loosely connected or you will severely

damage the wiring.

Handling Connectors

Make sure the connectors are clean and have no loose

wire terminals.

Make sure multiple cavity connectors are packed with

grease (except waterproof connectors).

All connectors have push-down release type locks.

LOCKING TAB

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKING

PAWL ON

OTHER

HALF OF

CONNECTOR

Pull to

disengage

BRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead.

Always reinstall plastic covers.

Before connecting connectors, make sure the termi-

nals are in place and not bent.

BENT TERMINAL

Check for loose retainer and rubber seals.

RETAINER

RUBBER SEAL RETAINER

The backs of some connectors are packed with

grease. Add grease if necessary. If the grease is con-

taminated, replace it.

LOCKING TABProCarManuals.com

Page 1537 of 1771

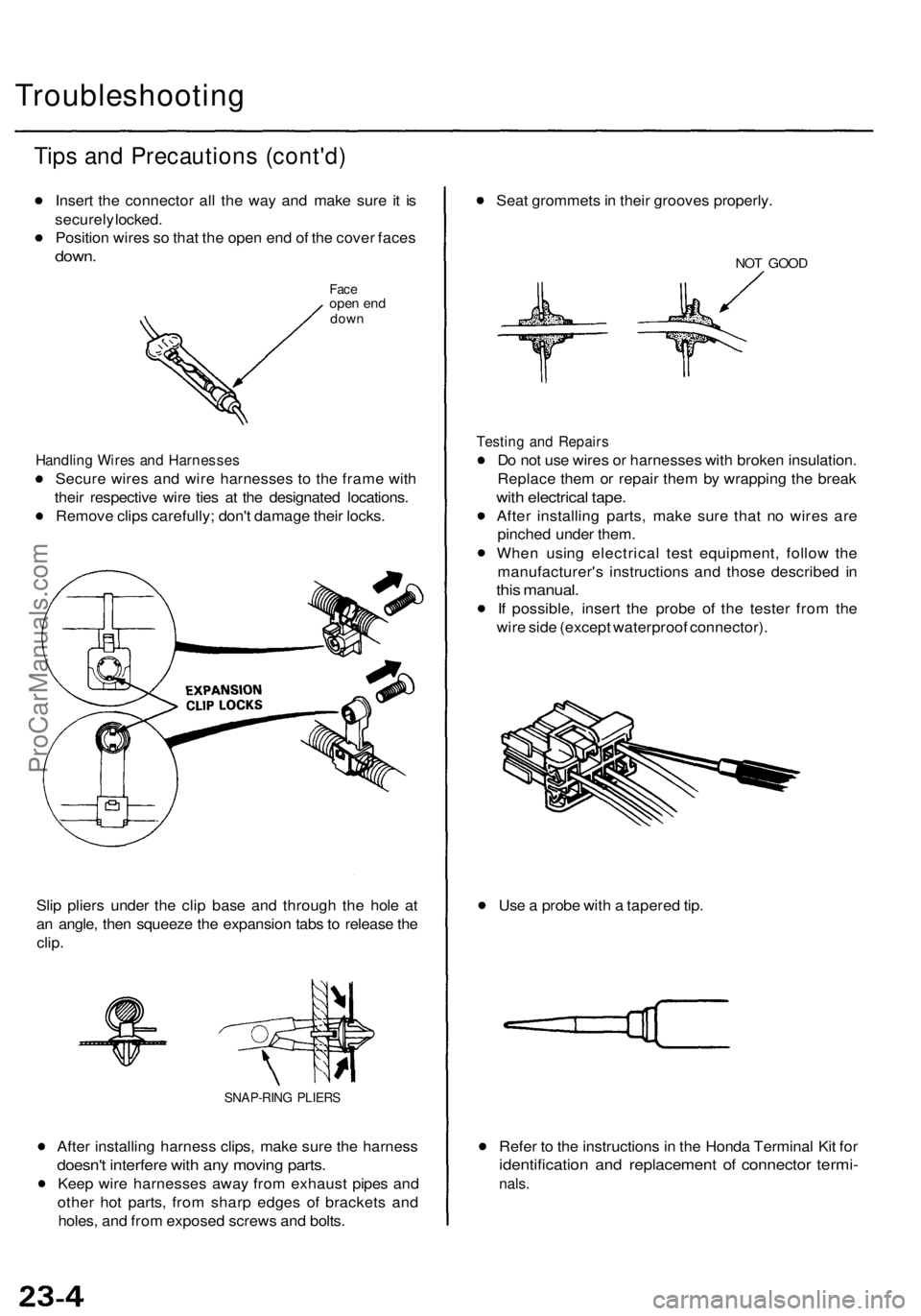

Troubleshooting

Tips and Precautions (cont'd)

Insert the connector all the way and make sure it is

securely locked.

Position wires so that the open end of the cover faces

down.

Face

open end

down

Handling Wires and Harnesses

Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clip.

SNAP-RING PLIERS

After installing harness clips, make sure the harness

doesn't interfere with any moving parts.

Keep wire harnesses away from exhaust pipes and

other hot parts, from sharp edges of brackets and

holes, and from exposed screws and bolts.

Seat grommets in their grooves properly.

NOT GOOD

Testing and Repairs

Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electrical tape.

After installing parts, make sure that no wires are

pinched under them.

When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

If possible, insert the probe of the tester from the

wire side (except waterproof connector).

Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nals.ProCarManuals.com

Page 1538 of 1771

Five-step Troubleshooting

1. Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

2. Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. If several

circuits fail at the same time, the fuse or ground is a

likely cause.

Based on the symptoms and your understanding of

the circuit operation, identify one or more possible

causes of the problem.

3. Isolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep in mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

5. Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. If the problem was a blown fuse, be sure to

test all of the circuits on the fuse. Make sure no new

problems turn up and the original problem does not

recur.

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

WHT .............................White

YEL ............................... Yellow

BLK .............................. Black

BLU

..............................

Blue

GRN ............................. Green

RED

..............................

Red

ORN ............................. Orange

PNK.............................. Pink

BRN .............................. Brown

GRY.............................. Gray

PUR .............................. Purple

LT BLU ......................... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

NOTE: Different wires with the same color in the same

system have been given number suffixes to distinguish

them (for example, YEL1 and YEL2 are not the same).ProCarManuals.com

Page 1539 of 1771

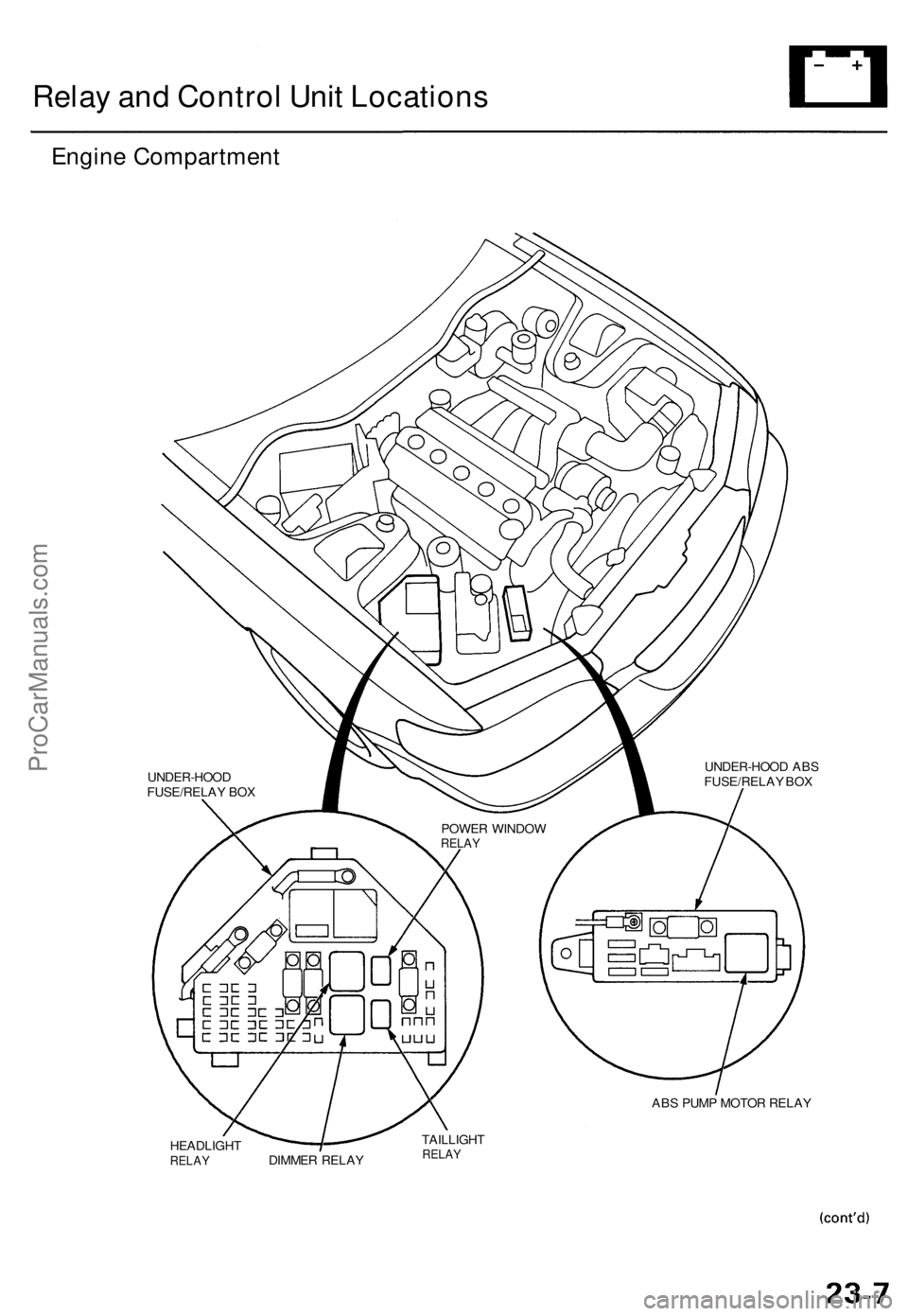

Relay and Control Unit Locations

Engine Compartment

UNDER-HOOD ABS

FUSE/RELAY BOX

ABS PUMP MOTOR RELAY

HEADLIGHT

RELAY

DIMMER RELAY

TAILLIGHT

RELAY

POWER WINDOW

RELAY

UNDER-HOOD

FUSE/RELAY BOXProCarManuals.com

Page 1540 of 1771

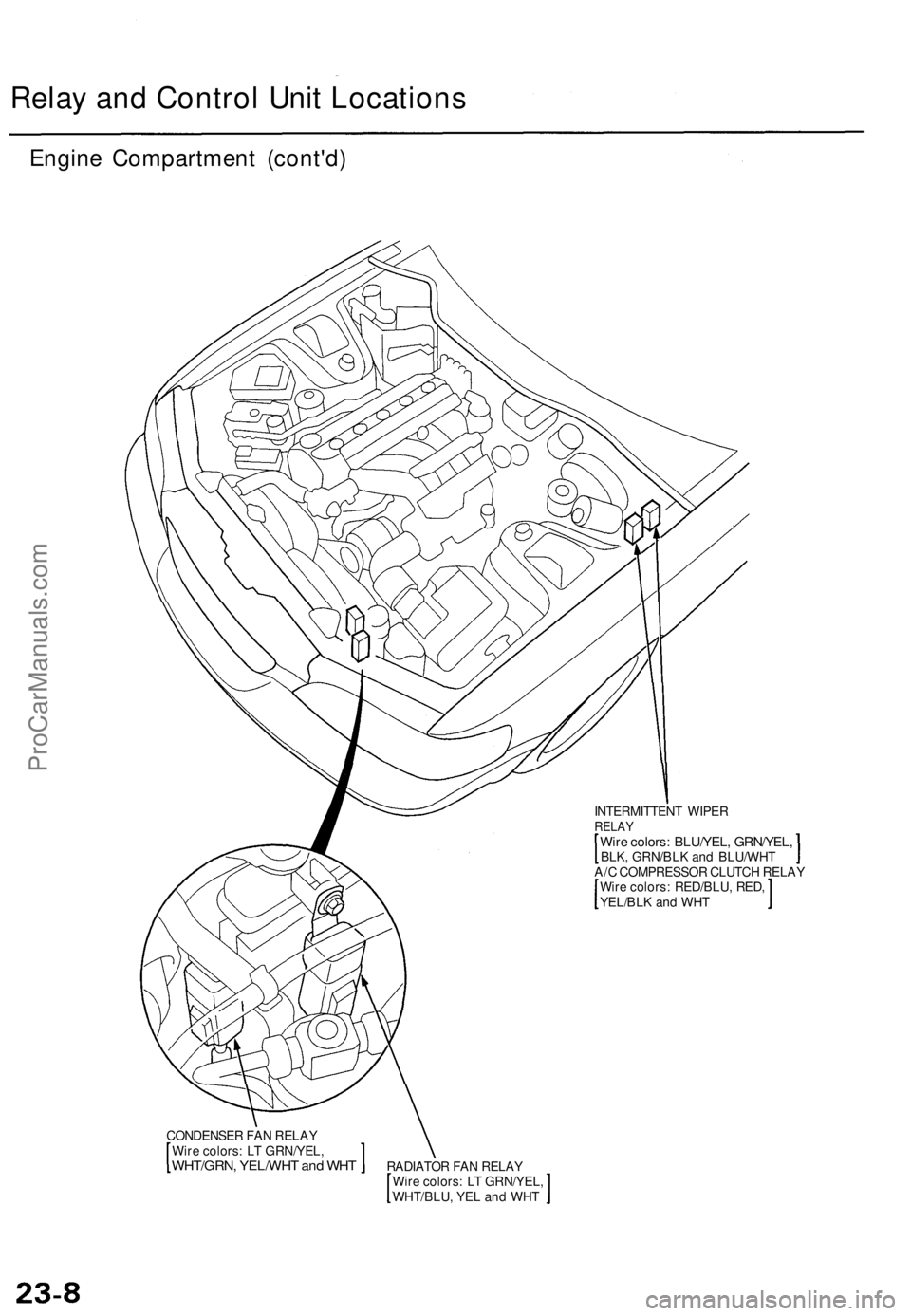

Relay and Control Unit Locations

Engine Compartment (cont'd)

INTERMITTENT WIPER

RELAY

Wire colors: BLU/YEL, GRN/YEL,

BLK, GRN/BLK and BLU/WHT

A/C COMPRESSOR CLUTCH RELAY

Wire colors: RED/BLU, RED,

YEL/BLK and WHT

CONDENSER FAN RELAY

Wire colors: LT GRN/YEL,

WHT/GRN, YEL/WHT and WHT

RADIATOR FAN RELAY

Wire colors: LT GRN/YEL,

WHT/BLU, YEL and WHTProCarManuals.com