ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 151 of 947

Convertible Roof (01.17)

Body System (01.00)

May 2007 Workshop Manual 1-12-13

Convertible Top ECU - Renew

Removal

1. Remove wheel arch liner rear RH (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

2. Remove bolts (x4) securing ECU mounting plate and release from body (see Figure 1).

3. Disconnect multiplugs (x3) from ECU (see Figure 2).

4 . R e m o v e E C U f r o m m o u n t i n g p l a t e ( n u t s x 2 ) .

Installation

1. Install ECU to mounting plate.

2. Connect multiplugs (x3) to ECU. 3. Position mounting plate to body and install securing

bolts.

4. Remove wheel arch liner rear RH (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

Hydraulic Pump - Renew

Removal

1. Operate roof to halfway position with tonneau open and support roof when hydraulic pressure drops with

suitable straps and support tonneau cover with suitable

prop (see Figure 1).

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 152 of 947

Convertible Roof (01.17)

Body System (01.00)1-12-14 Workshop Manual May 2007

2. Remove trim clip and releas e tonneau lining stiffening

rod (see Figure 2).

3. Release velcro and move tonneau well liner aside to expose lower cylinder fixing and motor casing.

4. Release cylinder lower retaining clip and disconnect tonneau cylinder from body (see Figure 3). 5. Remove cylinder pivot bracket from body (bolts x3) (see

Figure 4).

6. Release pump and casing from under tonneau body side (see Figure 5).

Figure 2

Figure 3

Figure 4

Figure 5

Page 153 of 947

Convertible Roof (01.17)

Body System (01.00)

May 2007 Workshop Manual 1-12-15

7. Release velcro around pump casing and remove casing (see Figure 6).

8. Disconnect pump multiplug (see Figure 7). 9. Disconnect pump multiplug (see Figure 8).

10. Remove end cover (locating tabs x2).

11. Disconnect pump lucar conne

ctors (x2) (see Figure 9).

Figure 6

Figure 7

Figure 8

Figure 9

Page 154 of 947

Convertible Roof (01.17)

Body System (01.00)1-12-16 Workshop Manual May 2007

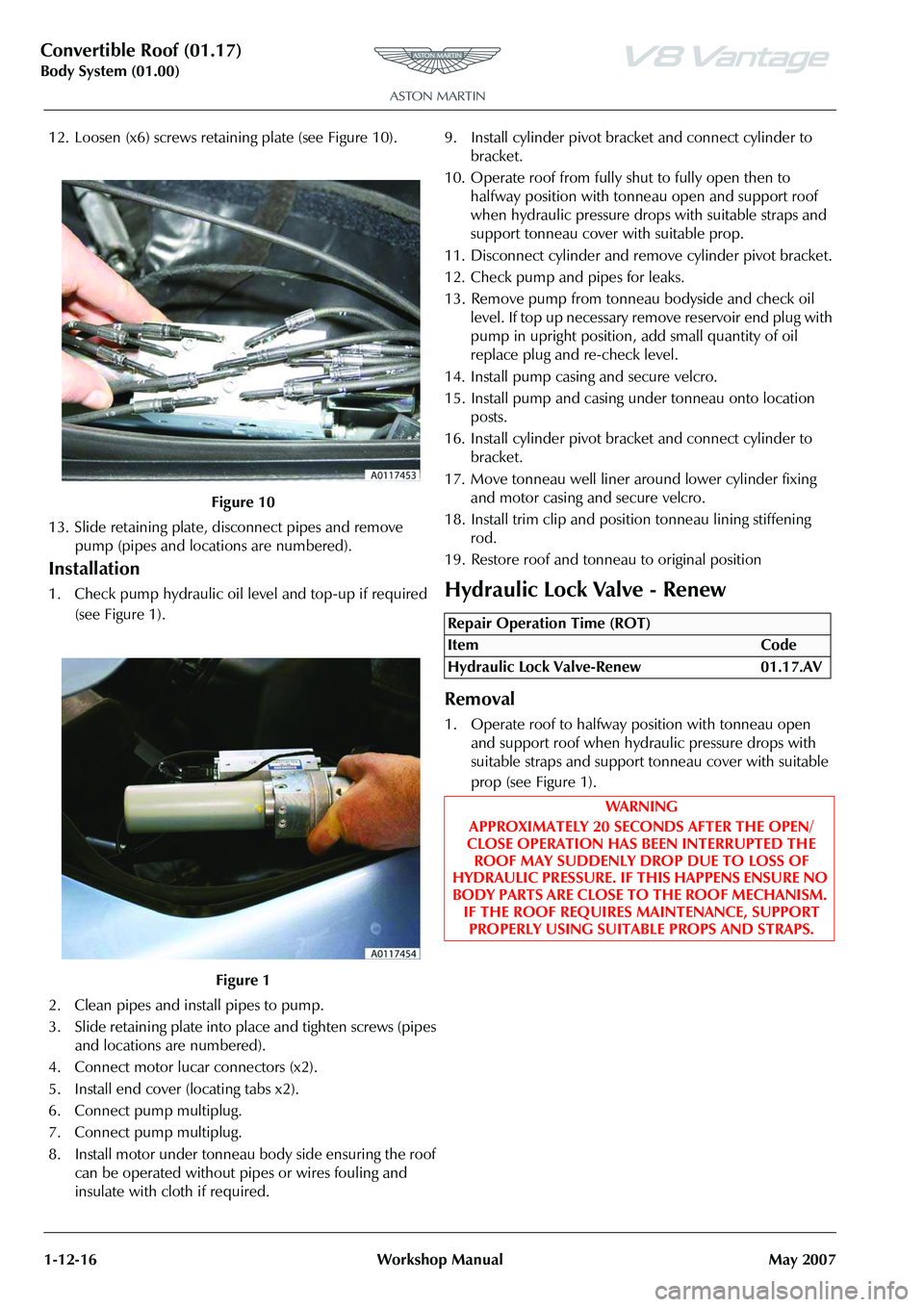

12. Loosen (x6) screws retain ing plate (see Figure 10).

13. Slide retaining plate, disconnect pipes and remove pump (pipes and locations are numbered).

Installation

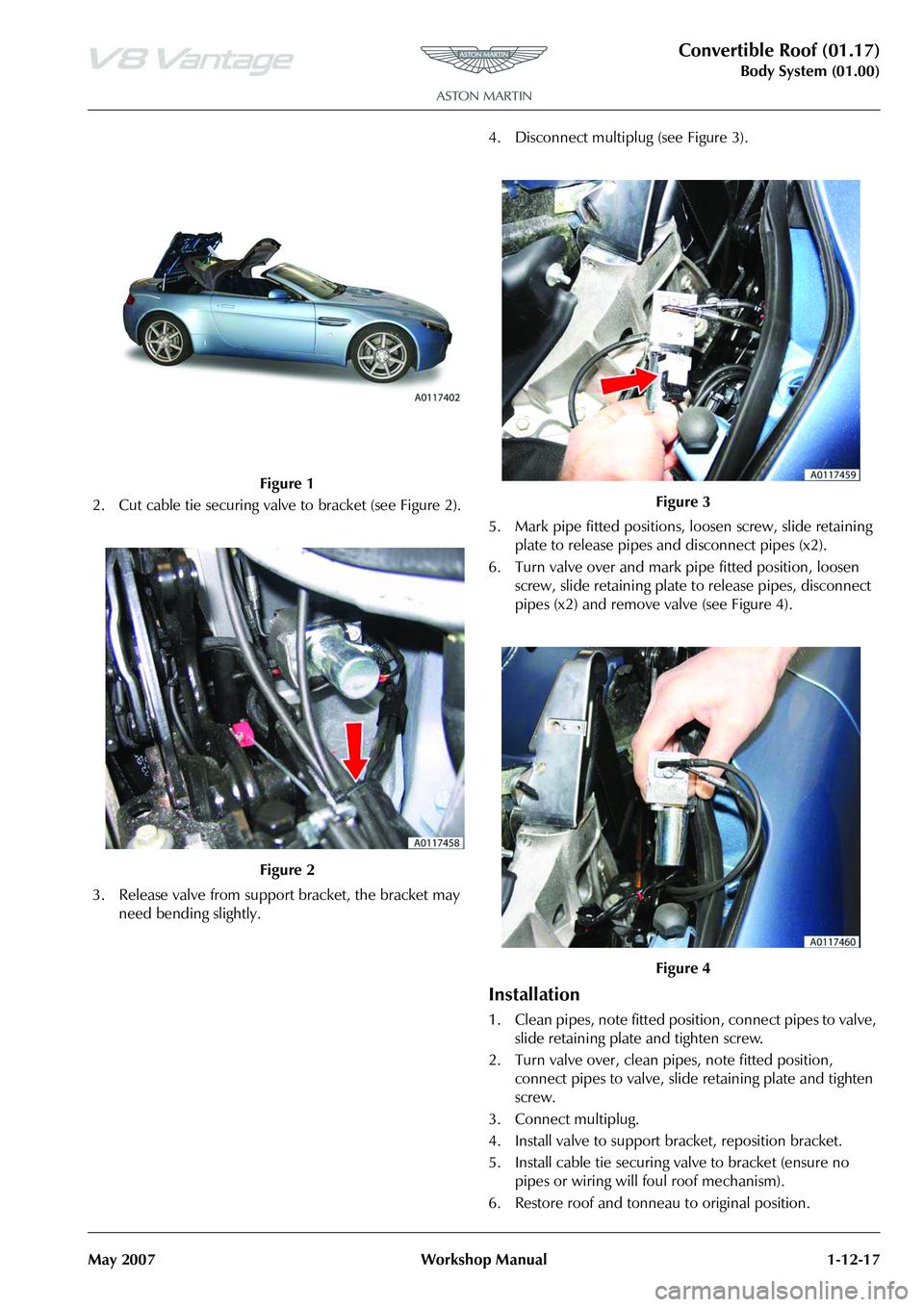

1. Check pump hydraulic oil le vel and top-up if required

(see Figure 1).

2. Clean pipes and install pipes to pump.

3. Slide retaining plate into place and tighten screws (pipes and locations are numbered).

4. Connect motor lucar connectors (x2).

5. Install end cover (locating tabs x2).

6. Connect pump multiplug.

7. Connect pump multiplug.

8. Install motor under tonneau body side ensuring the roof can be operated without pipes or wires fouling and

insulate with cloth if required. 9. Install cylinder pivot bracket and connect cylinder to

bracket.

10. Operate roof from fully shut to fully open then to halfway position with tonneau open and support roof

when hydraulic pressure drop s with suitable straps and

support tonneau cover with suitable prop.

11. Disconnect cylinder and remove cylinder pivot bracket.

12. Check pump and pipes for leaks.

13. Remove pump from tonneau bodyside and check oil level. If top up necessary remove reservoir end plug with

pump in upright position, add small quantity of oil

replace plug and re-check level.

14. Install pump casing and secure velcro.

15. Install pump and casing under tonneau onto location posts.

16. Install cylinder pivot bracket and connect cylinder to bracket.

17. Move tonneau well liner arou nd lower cylinder fixing

and motor casing and secure velcro.

18. Install trim clip and positi on tonneau lining stiffening

rod.

19. Restore roof and tonneau to original positionHydraulic Lock Valve - Renew

Removal

1. Operate roof to halfway position with tonneau open and support roof when hydraulic pressure drops with

suitable straps and support tonneau cover with suitable

prop (see Figure 1).

Figure 10

Figure 1

Repair Operation Time (ROT)

ItemCode

Hydraulic Lock Valve-Renew 01.17.AV

WAR NI NG

APPROXIMATELY 20 SECONDS AFTER THE OPEN/

CLOSE OPERATION HAS BEEN INTERRUPTED THE ROOF MAY SUDDENLY DROP DUE TO LOSS OF

HYDRAULIC PRESSURE. IF THIS HAPPENS ENSURE NO

BODY PARTS ARE CLOSE TO THE ROOF MECHANISM. IF THE ROOF REQUIRES MAINTENANCE, SUPPORT

PROPERLY USING SUITABLE PROPS AND STRAPS.

Page 155 of 947

Convertible Roof (01.17)

Body System (01.00)

May 2007 Workshop Manual 1-12-17

2. Cut cable tie securing valve to bracket (see Figure 2).

3. Release valve from support bracket, the bracket may need bending slightly. 4. Disconnect multiplug (see Figure 3).

5. Mark pipe fitted positions, loosen screw, slide retaining

plate to release pipes and disconnect pipes (x2).

6. Turn valve over and mark pipe fitted position, loosen screw, slide retaining plate to release pipes, disconnect

pipes (x2) and remove valve (see Figure 4).

Installation

1. Clean pipes, note fitted posi tion, connect pipes to valve,

slide retaining plate and tighten screw.

2. Turn valve over, clean pipes, note fitted position, connect pipes to valve, slide retaining plate and tighten

screw.

3. Connect multiplug.

4. Install valve to support br acket, reposition bracket.

5. Install cable tie securing valve to bracket (ensure no pipes or wiring will foul roof mechanism).

6. Restore roof and tonneau to original position.

Figure 1

Figure 2

Figure 3

Figure 4

Page 156 of 947

Convertible Roof (01.17)

Body System (01.00)1-12-18 Workshop Manual May 2007

RH/LH Front Cantrail Seal - Spare Part -

Renew

Removal

1. Remove header trim (see Workshop Manual procedure 01.05.BB Panel Assembly - Header - Renew).

2. Mark position of nuts (x2) to aid installation.

3. Remove nuts (x2) secu ring seal holder to hood

mechanism and remove seal from holder.

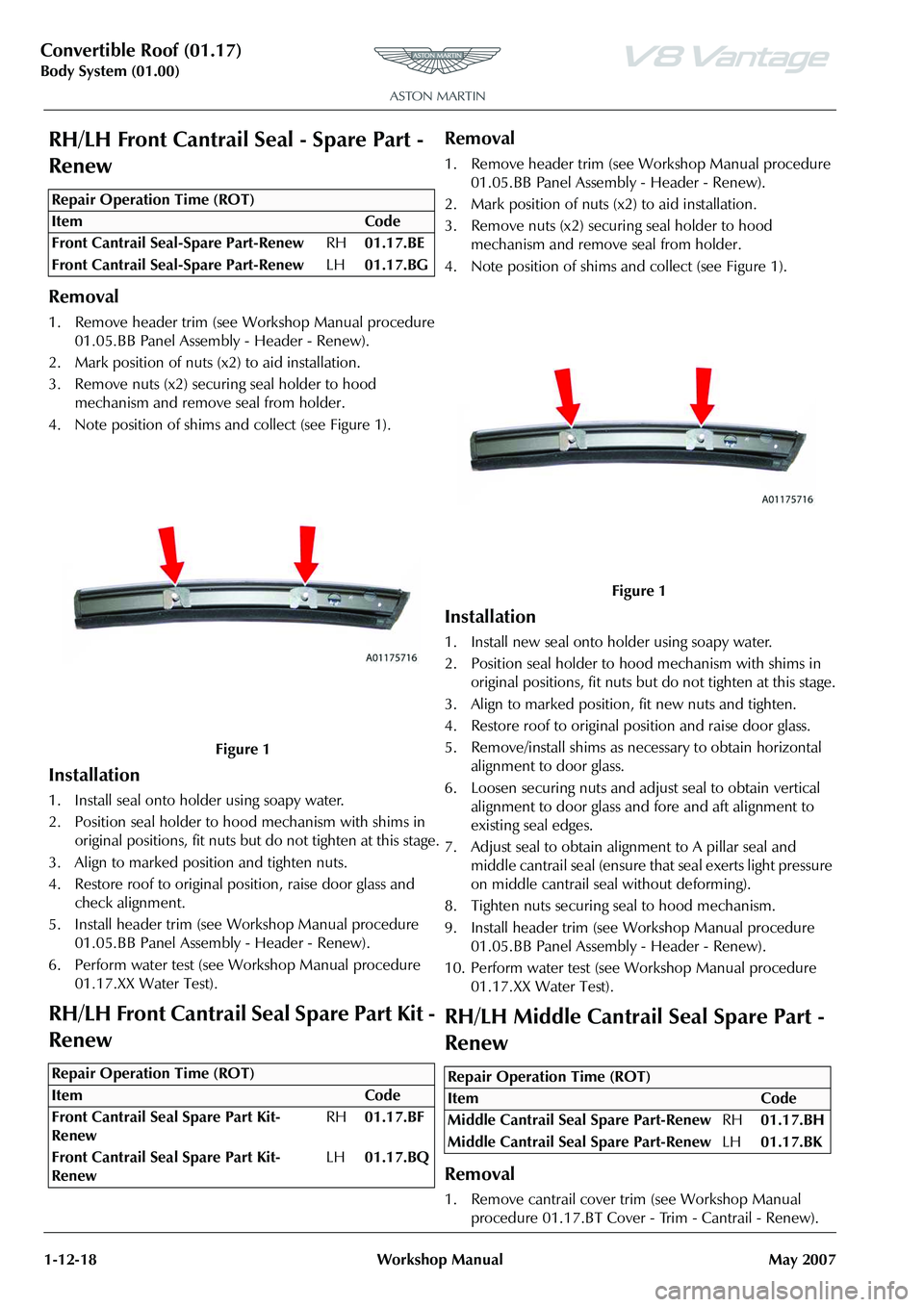

4. Note position of shims and collect (see Figure 1).

Installation

1. Install seal onto holder using soapy water.

2. Position seal holder to hood mechanism with shims in original positions, fit nuts but do not tighten at this stage.

3. Align to marked position and tighten nuts.

4. Restore roof to original position, raise door glass and check alignment.

5. Install header trim (see Workshop Manual procedure 01.05.BB Panel Assembly - Header - Renew).

6. Perform water test (see Workshop Manual procedure

01.17.XX Water Test).

RH/LH Front Cantrail Seal Spare Part Kit -

Renew

Removal

1. Remove header trim (see Workshop Manual procedure 01.05.BB Panel Assembly - Header - Renew).

2. Mark position of nuts (x2) to aid installation.

3. Remove nuts (x2) secu ring seal holder to hood

mechanism and remove seal from holder.

4. Note position of shims and collect (see Figure 1).

Installation

1. Install new seal onto holder using soapy water.

2. Position seal holder to hood mechanism with shims in

original positions, fit nuts but do not tighten at this stage.

3. Align to marked position, fit new nuts and tighten.

4. Restore roof to original position and raise door glass.

5. Remove/install shims as necessary to obtain horizontal alignment to door glass.

6. Loosen securing nuts and adju st seal to obtain vertical

alignment to door glass and fore and aft alignment to

existing seal edges.

7. Adjust seal to obtain alignment to A pillar seal and middle cantrail seal (ensure that seal exerts light pressure

on middle cantrail seal without deforming).

8. Tighten nuts securing seal to hood mechanism.

9. Install header trim (see Workshop Manual procedure 01.05.BB Panel Assembly - Header - Renew).

10. Perform water test (see Workshop Manual procedure 01.17.XX Water Test).

RH/LH Middle Cantrail Seal Spare Part -

Renew

Removal

1. Remove cantrail cover trim (see Workshop Manual procedure 01.17.BT Cover - Trim - Cantrail - Renew).

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Figure 1

Repair Operation Time (ROT)

ItemCode

Middle Cantrail Se al Spare Part-Renew RH01.17.BH

Middle Cantrail Se al Spare Part-Renew LH01.17.BK

Page 157 of 947

Convertible Roof (01.17)

Body System (01.00)

May 2007 Workshop Manual 1-12-19

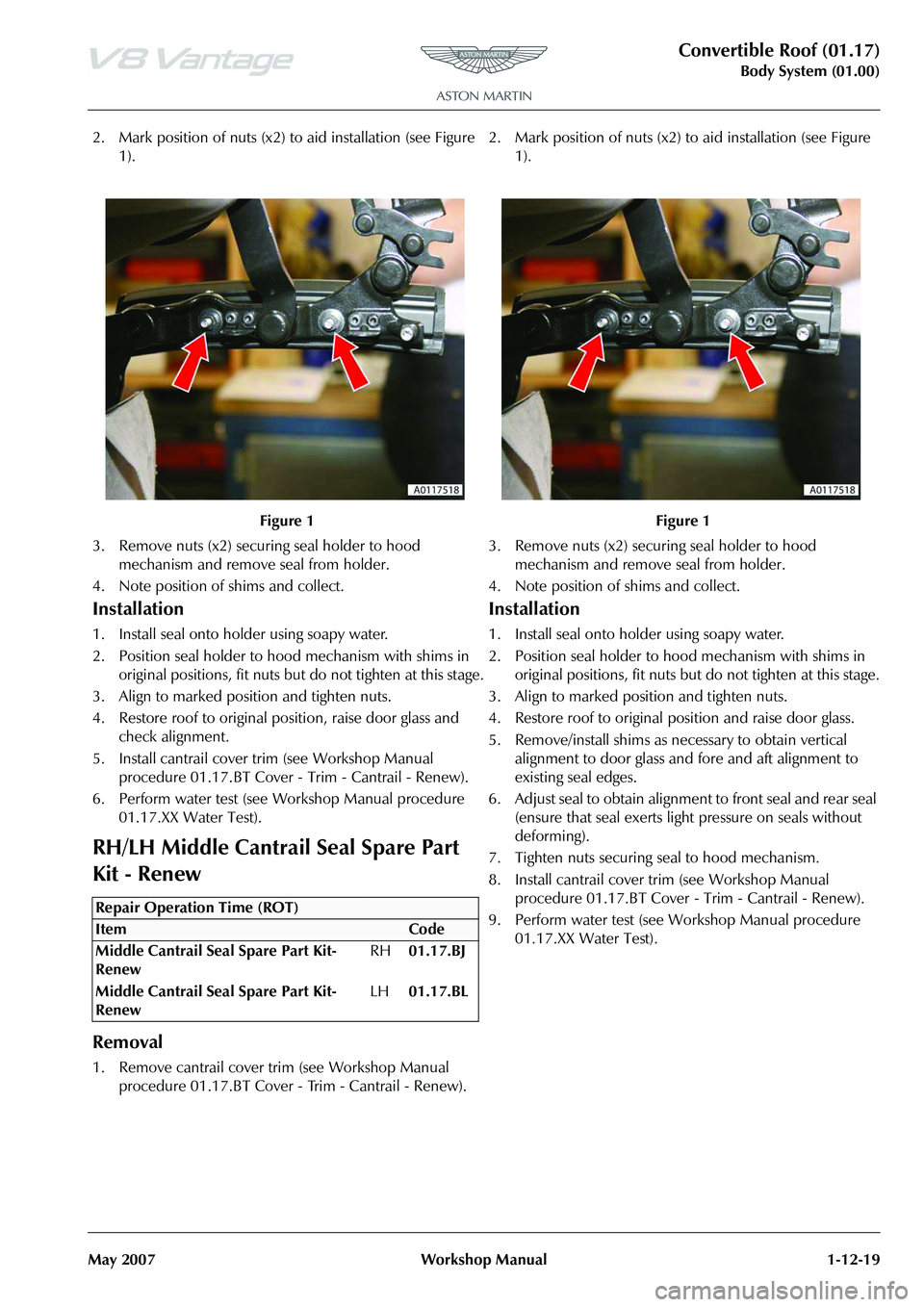

2. Mark position of nuts (x2) to aid installation (see Figure

1).

3. Remove nuts (x2) securing seal holder to hood mechanism and remove seal from holder.

4. Note position of shims and collect.

Installation

1. Install seal onto holder using soapy water.

2. Position seal holder to hood mechanism with shims in original positions, fit nuts but do not tighten at this stage.

3. Align to marked position and tighten nuts.

4. Restore roof to original position, raise door glass and check alignment.

5. Install cantrail cover tr im (see Workshop Manual

procedure 01.17.BT Cover - Trim - Cantrail - Renew).

6. Perform water test (see Workshop Manual procedure 01.17.XX Water Test).

RH/LH Middle Cantrail Seal Spare Part

Kit - Renew

Removal

1. Remove cantrail cover trim (see Workshop Manual procedure 01.17.BT Cover - Trim - Cantrail - Renew). 2. Mark position of nuts (x2) to aid installation (see Figure

1).

3. Remove nuts (x2) securing seal holder to hood mechanism and remove seal from holder.

4. Note position of shims and collect.

Installation

1. Install seal onto holder using soapy water.

2. Position seal holder to hood mechanism with shims in original positions, fit nuts bu t do not tighten at this stage.

3. Align to marked position and tighten nuts.

4. Restore roof to original position and raise door glass.

5. Remove/install shims as nece ssary to obtain vertical

alignment to door glass and fore and aft alignment to

existing seal edges.

6. Adjust seal to obtain alignment to front seal and rear seal (ensure that seal exerts light pressure on seals without

deforming).

7. Tighten nuts securing seal to hood mechanism.

8. Install cantrail cover trim (see Workshop Manual procedure 01.17.BT Cover - Trim - Cantrail - Renew).

9. Perform water test (see Workshop Manual procedure 01.17.XX Water Test).

Figure 1

Repair Operation Time (ROT)

Figure 1

Page 158 of 947

Convertible Roof (01.17)

Body System (01.00)1-12-20 Workshop Manual May 2007

Rear Seal Spare Part Assembly Kit -

Renew

Removal

1. Operate roof to halfway position (support roof when hydraulic pressure drops with suitable straps) (see Figure

1).

2. Remove 2 screws securing seal retaining brackets to rear seal assembly, remove brackets (see Figure 2).

3. Remove remaining 26 screws securing rear seal assembly to tension bow, rest seal assembly on tonneau

(note fitted position of tension springs).

4. Remove RH cant rail trims (see Workshop Manual procedure 01.17.BT Cover - Trim - Cantrail - Renew). 5. Remove LH cant rail trims (see Workshop Manual

procedure 01.17.BT Cover - Trim - Cantrail - Renew).

6. Mark position of B-post trim bolts.

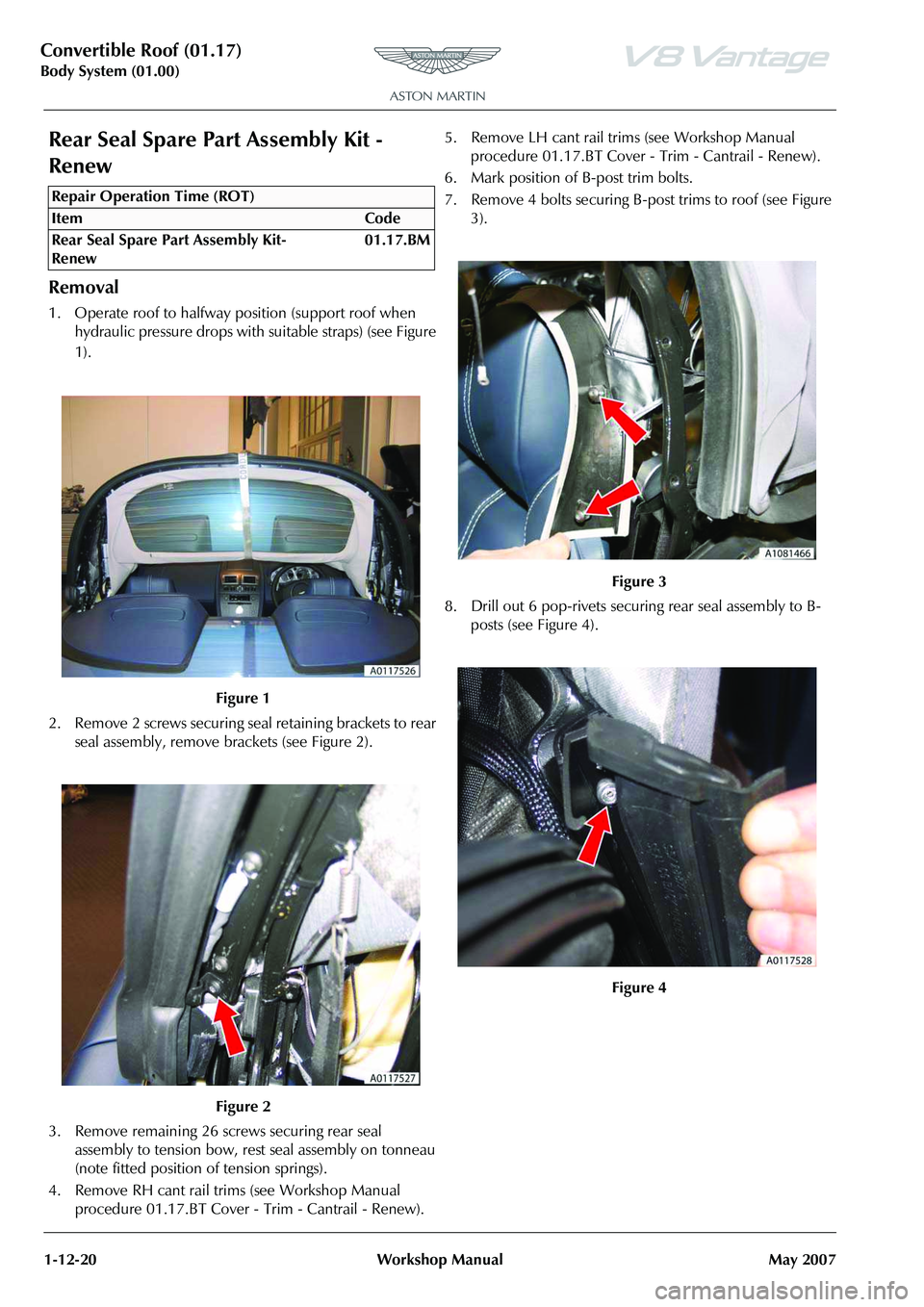

7. Remove 4 bolts securing B-post trims to roof (see Figure 3).

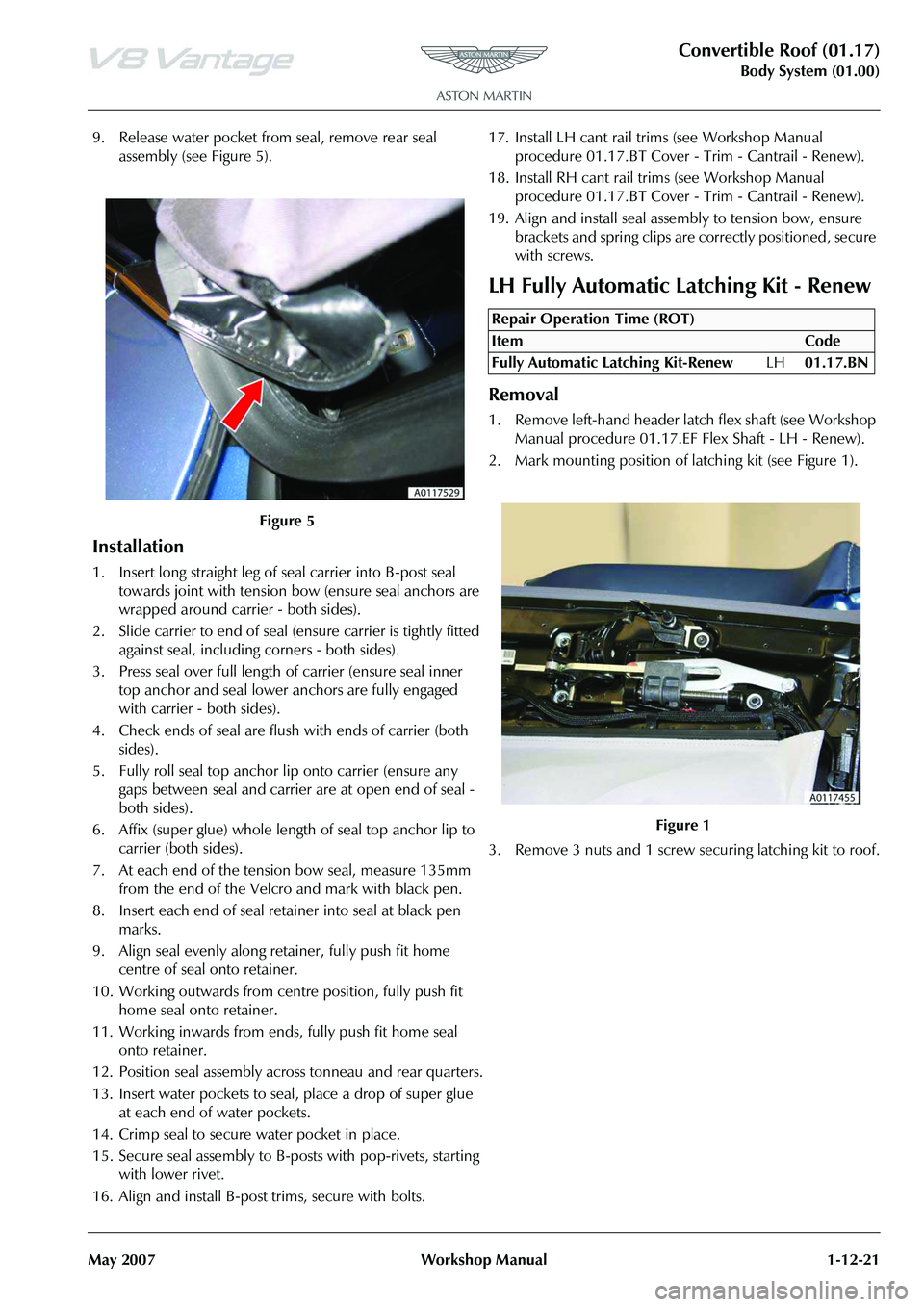

8. Drill out 6 pop-rivets securi ng rear seal assembly to B-

posts (see Figure 4).

Repair Operation Time (ROT)

Figure 3

Figure 4

Page 159 of 947

Convertible Roof (01.17)

Body System (01.00)

May 2007 Workshop Manual 1-12-21

9. Release water pocket from seal, remove rear seal assembly (see Figure 5).

Installation

1. Insert long straight leg of seal carrier into B-post seal

towards joint with tension bo w (ensure seal anchors are

wrapped around carrier - both sides).

2. Slide carrier to end of seal (ensure carrier is tightly fitted

against seal, including corners - both sides).

3. Press seal over full length of carrier (ensure seal inner

top anchor and seal lower anchors are fully engaged

with carrier - both sides).

4. Check ends of seal are flush with ends of carrier (both sides).

5. Fully roll seal top anchor lip onto carrier (ensure any gaps between seal and carrier are at open end of seal -

both sides).

6. Affix (super glue) whole length of seal top anchor lip to carrier (both sides).

7. At each end of the tension bow seal, measure 135mm from the end of the Velcro and mark with black pen.

8. Insert each end of seal retainer into seal at black pen marks.

9. Align seal evenly along retainer, fully push fit home centre of seal onto retainer.

10. Working outwards from cent re position, fully push fit

home seal onto retainer.

11. Working inwards from ends, fully push fit home seal onto retainer.

12. Position seal assembly across tonneau and rear quarters.

13. Insert water pockets to seal, place a drop of super glue at each end of water pockets.

14. Crimp seal to secure water pocket in place.

15. Secure seal assembly to B-posts with pop-rivets, starting with lower rivet.

16. Align and install B-post trims, secure with bolts. 17. Install LH cant rail tr

ims (see Workshop Manual

procedure 01.17.BT Cover - Trim - Cantrail - Renew).

18. Install RH cant rail trims (see Workshop Manual procedure 01.17.BT Cover - Trim - Cantrail - Renew).

19. Align and install seal asse mbly to tension bow, ensure

brackets and spring clips are correctly positioned, secure

with screws.

LH Fully Automatic Latching Kit - Renew

Removal

1. Remove left-hand header latch flex shaft (see Workshop Manual procedure 01.17.EF Flex Shaft - LH - Renew).

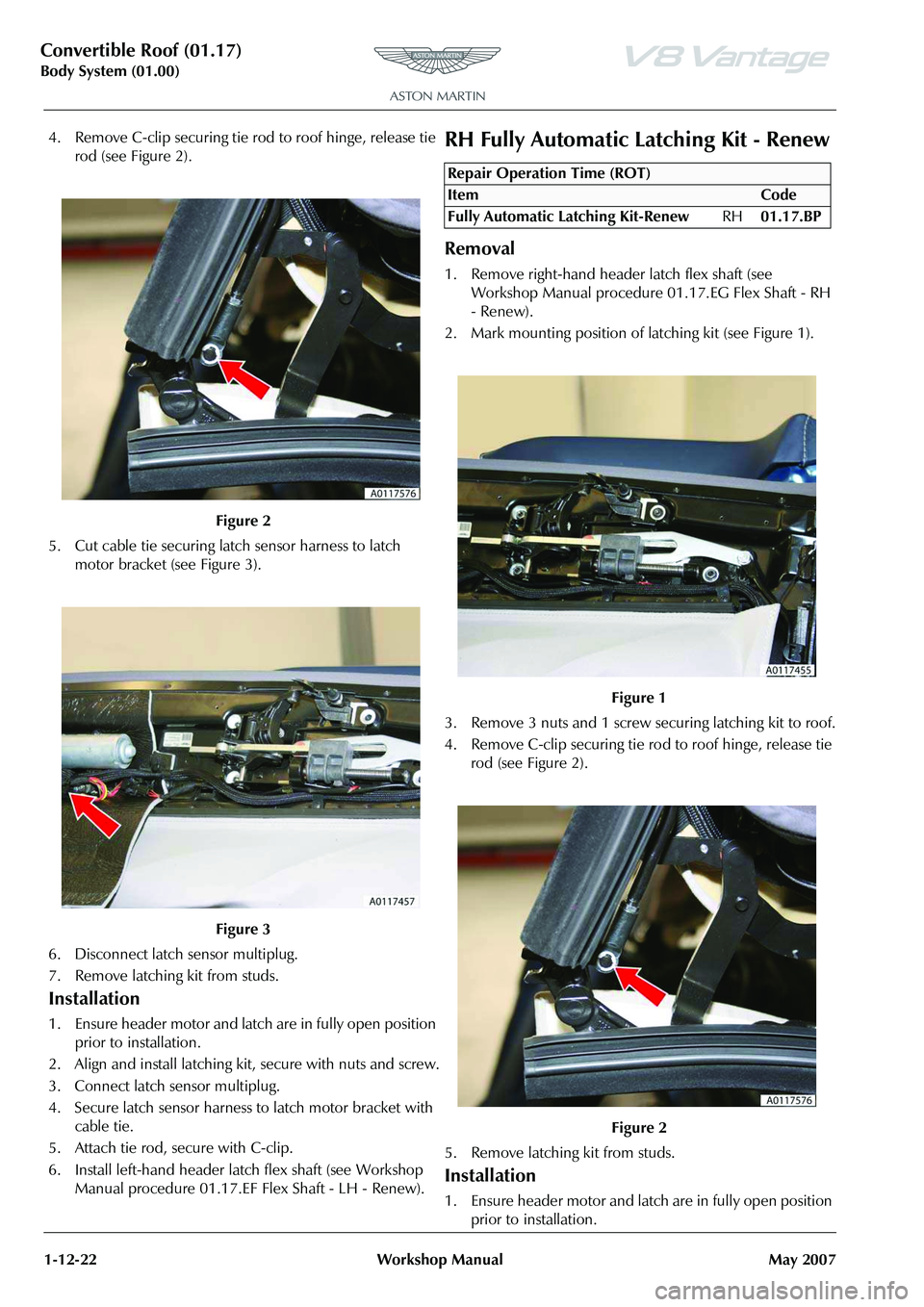

2. Mark mounting position of latching kit (see Figure 1).

3. Remove 3 nuts and 1 screw securing latching kit to roof.

Figure 5

Repair Operation Time (ROT)

Page 160 of 947

Convertible Roof (01.17)

Body System (01.00)1-12-22 Workshop Manual May 2007

4. Remove C-clip securing tie rod to roof hinge, release tie rod (see Figure 2).

5. Cut cable tie securing latch sensor harness to latch motor bracket (see Figure 3).

6. Disconnect latch sensor multiplug.

7. Remove latching kit from studs.

Installation

1. Ensure header motor and latch are in fully open position prior to installation.

2. Align and install latching kit, secure with nuts and screw.

3. Connect latch sensor multiplug.

4. Secure latch sensor harness to latch motor bracket with

cable tie.

5. Attach tie rod, secure with C-clip.

6. Install left-hand header latch flex shaft (see Workshop Manual procedure 01.17.EF Flex Shaft - LH - Renew).

RH Fully Automatic Latching Kit - Renew

Removal

1. Remove right-hand header latch flex shaft (see Workshop Manual procedure 01.17.EG Flex Shaft - RH

- Renew).

2. Mark mounting position of latching kit (see Figure 1).

3. Remove 3 nuts and 1 screw securing latching kit to roof.

4. Remove C-clip securing tie ro d to roof hinge, release tie

rod (see Figure 2).

5. Remove latching kit from studs.

Installation

1. Ensure header motor and latc h are in fully open position

prior to installation.

Figure 2

Figure 3

Repair Operation Time (ROT)

ItemCode

Fully Automatic Latching Kit-Renew RH01.17.BP

Figure 1

Figure 2