ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 861 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 15 of 43

If the above temporary disablement conditions (inferred ambient temperature and low barometric

pressure) are encountered, the flow test will be su spended and a timer will accumulate. Whenever the

temporary disablement conditions are no longer present the timer will decrement, and the flow test will

operate as normal. However, in extended temporar y disablement conditions if the timer reaches a

calibrated threshold (typically 800 seconds), the EGR flow test is disabled for the remainder of the current

drive cycle, and the EGR monitor I/M readiness bit will be set.

Page 862 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 16 of 43

Electronic Throttle Monitor

Where ETC is used, the system monitor incorporates a complex safety strategy. The main ETC feature is

based around a driver demand torque that is deliver ed as an output shaft torque through the correct

positioning of the throttle plate. The Independent Plausibility Check (IPC) feature performs the primary

monitoring function. This resides within the main microprocessor and is responsible for determining the

driver demand torque and comparing it to an estimate of the actual brake torque delivered. If the generated

torque exceeds the driver demanded torque by a speci fied amount, then the appropriate FMEM action is

taken.

With the IPC feature being on the main processor, an intelligent VQZ watchdog is incorporated on a

separate processor to monitor the performance of the IPC and the main processor. If the VQZ determines

that the IPC function is impaired in any way then it takes the appropriate FMEM action.

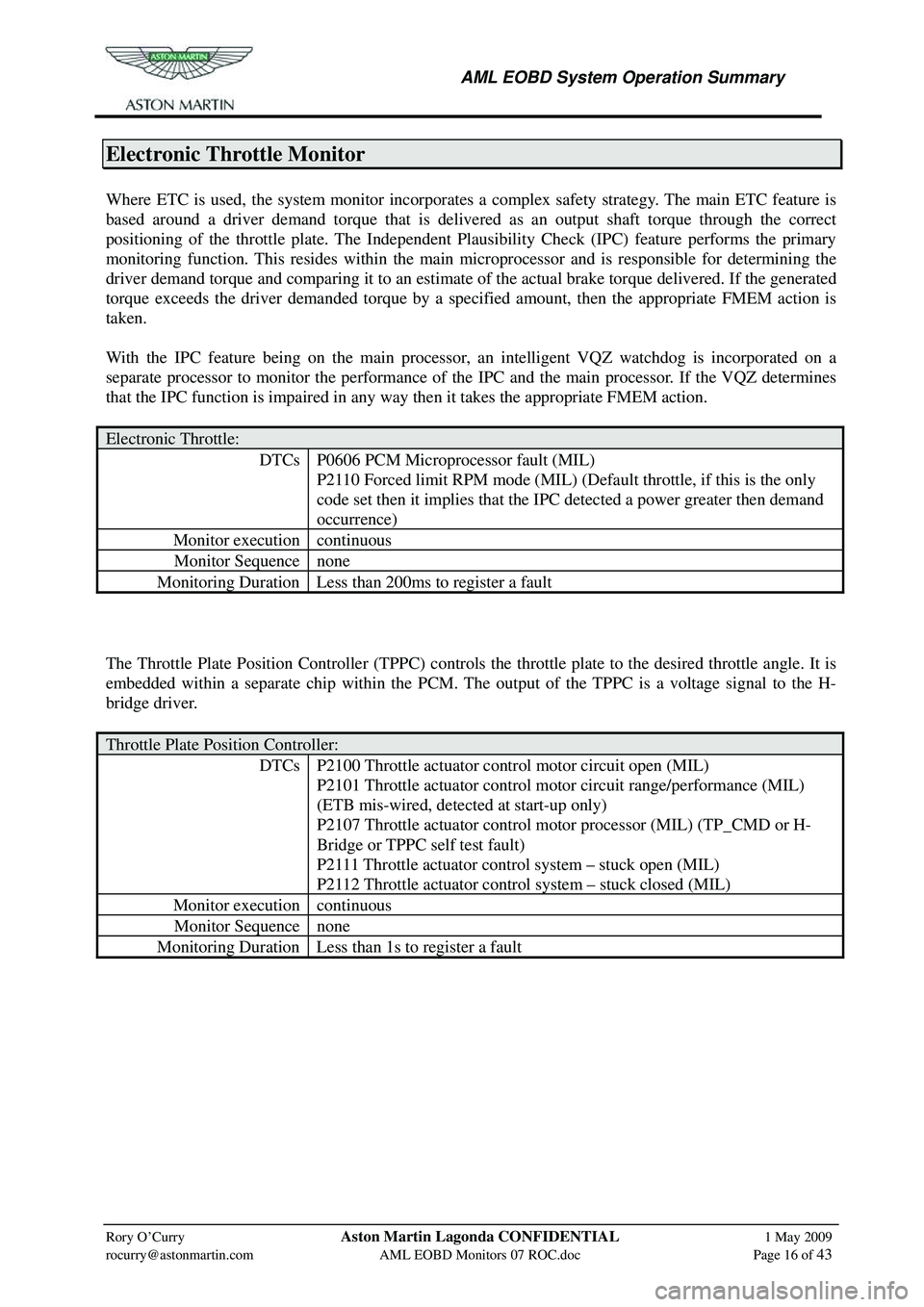

Electronic Throttle:

DTCs P0606 PCM Microprocessor fault (MIL)

P2110 Forced limit RPM mode (MIL) (Default throttle, if this is the only

code set then it implies that the IPC detected a power greater then demand

occurrence)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration Less than 200ms to register a fault

The Throttle Plate Position Controller (TPPC) controls the throttle plate to the desired throttle angle. It is

embedded within a separate chip within the PCM. The output of the TPPC is a voltage signal to the H-

bridge driver.

Throttle Plate Position Controller:

DTCs P2100 Throttle actuator control motor circuit open (MIL)

P2101 Throttle actuator control motor circuit range/performance (MIL)

(ETB mis-wired, detected at start-up only)

P2107 Throttle actuator control motor processor (MIL) (TP_CMD or H-

Bridge or TPPC self test fault)

P2111 Throttle actuator control system – stuck open (MIL)

P2112 Throttle actuator control system – stuck closed (MIL)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration Less than 1s to register a fault

Page 863 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 17 of 43

The system monitor also determines the validity of an y inputs to the electronic throttle control feature by

checking for opens, shorts, out-of-range values and inconsistencies.

Throttle Position Sensors:

DTCs P0121 Throttle position sensor A circ uit range/performance (Closed in bore

out of range fault)

P0122 Throttle position sensor A circuit low input

P0123 Throttle position sensor A circuit high input

P0124 Throttle position sensor A circuit intermittent

P0221 Throttle position sensor B circuit range/performance (Closed in bore

out of range fault)

P0222 Throttle position sensor B circuit low input

P0223 Throttle position sensor B circuit high input

P0224 Throttle position sensor B circuit intermittent

P2135 Throttle position sensor A/B voltage correlation

Monitor execution continuous

Monitor Sequence none

Monitoring Duration Less than 200ms to register a fault

Accelerator Pedal Position Sensors:

DTCs P2121 Pedal position sensor D circuit range/performance

P2122 Pedal position sensor D circuit low input

P2123 Pedal position sensor D circuit high input

P2124 Pedal position sensor D circuit intermittent

P2126 Pedal position sensor E circuit range/performance

P2127 Pedal position sensor E circuit low input

P2128 Pedal position sensor E circuit high input

P2129 Pedal position sensor E circuit intermittent

P2138 Pedal position sensor D/E voltage correlation

Monitor execution continuous

Monitor Sequence none

Monitoring Duration Less than 200ms to register a fault

Brake Pedal Switches:

DTCs P0504 Brake switch A/B correlation (BPS on when BLS is off)

P0571 Brake switch A circuit (BPS failed)

P0703 Brake switch B circuit (BLS failed)

P1572 Brake system input failure (BLS failed then BPS failed)

P1703 Brake switch out of self test range (Set when brake is on for KOEO

test or when brake on or off state is not seen for KOER test)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration Not time dependent

Page 864 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

Dual MAF Diagnostic

Dual MAF Hardware

The V8 uses a common dirty air pick-up, which feeds twin air filters and MAF meters before recombining the two air streams in a junction prior to the throttle.

[email protected] AML EOBD Monitors 07 ROC.doc Page 18 of 43

FilterFilter

Filter Filter

Filter Filter

Filter Filter

MAF

meters

Normal Operation Side Wind or Partial

Blockage Backflow

Total Blockage

MAF meters receive an

equal share of the airflow. One MAF meter receives

an airflow greater than the total engine consumption. One MAF meter

receives airflow equal to the total airflow.

MAF meters receive

unequal airflows. This is due to severe side

wind. Fault judgement is

de

pendant on severity.

This can either be due

to a side wind or a partial blockage. One MAF meter will

measure zero airflow and this needs to be

determined to prevent false circuit faults.

Low engine airflow

conditions are

particularly susceptible to side wind. Fault judgement is

dependant on severity.

Fault judgement is

dependant on severity.

Page 865 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 19 of 43

Dual MAF Diagnostic Overview

The dual MAF diagnostic performs 11 separate tests on the measured MAF values. Each test is designed

to identify specific faults many of which, are only applicable to the dual MAF hardware configuration.

Many of the tests compare the measured MAF values to the estimated MAF (calculated from throttle

position, barometric pressure, act and engine speed). The tests are performed continuously (apart from the

conditions outlined later) and are always completed in the same sequence:

Test1 - Does MAF1+MAF2 = estimated MAF

Test2 - Does MAF1 = ½ estimated MAF

Test3 - Does MAF2 = ½ estimated MAF

Test4 - Is MAF1

Test6 - MAF2 low voltage

Test7 - MAF1 high voltage

Test8 - MAF2 high voltage

Test9 - Is MAF1> estimated MAF

Test10 - Is MAF2> estimated MAF

Test11 - Does MAF1 = MAF2

By pass/fail combinations of the above tests a vari ety of conditions can be detected discretely on each

MAF:

Partly blocked MAF

Fully blocked MAF

Electrical short to ground MAF

Electrical short high MAF

Backflow

Failed in range MAF

Page 866 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

Fault Matrix

ConditionMAF 1 + MAF 2 = EST

MAF 1 = ½ EST

MAF 2 = ½ EST

MAF 1 < MAF 2

MAF 1 low voltage

MAF 2 low voltage

MAF 1 high voltage

MAF 2 high voltage

MAF 1 > EST

MAF 2 > EST

MAF 1 = MAF 2Air Charge P-codes

Normal operating. YY--------f(maf_raw)

None

MAF 1 partly blocked. N-N----f(maf_raw)

P010F, P0100

MAF 1 fully blocked @ low load.

Y-N---- f(maf_raw)

P010F, P0100

MAF 2 partly blocked. -N-N- - -f(maf_raw)

P010F, P010A

MAF 2 fully blocked @ low load. -Y-N---f(maf_raw)

P010F, P010

AMAF 1 shorted to ground.

-Y-N----f(maf_raw)

P0102

MAF 1 shorted to high. -N-Y----f(maf_raw)

P0103

MAF 1 failed in range. -N-N----f(maf_raw)

P0101

MAF 2 shorted to ground. --Y-N---f(maf_raw)

P010C

MAF 2 shorted high. --N-Y---f(maf_raw)

P010D

MAF 2 failed in range. --N-N---f(maf_raw)

P010B

Estimated value wrong. --

Yf(maf_raw)None

MAF 1 and MAF 2 failed in range. --Nf(fmem)

P0101, P010B

Backflow via MAF 1. -

Y-f(fmem)

P0104

MAF 1 short to ground MAF 2 failed in rng. -N-f(fmem)

P0102, P010B

MAF 1 shorted high, MAF 2 failed in rng. -NN

YN---f(fmem)

P0103, P010B

Backflow via MAF 2.Y-- f(fmem)

P010E

MAF 1 failed in rng, MAF2 short to ground. N- -f(fmem)

P0101, P010C

MAF 1 failed in rng, MAF 2 shorted high. NNN

Y---f(fmem)

P0101, P010D

MAF 1 & MAF 2 shorted to ground. -YYNN---f(fmem)

P0102, P010C

MAF 1 & MAF 2 shorted high. -NNYY---f(fmem)

P0103, P010D

Severe backflow via MAF 2.Y-- f(fmem)

P010E

MAF 2 fully blocked @ high load N- -f(fmem)

P010F, P010B

Severe backflow via MAF 1. -

Y-f(fmem)

P0104

MAF 1 fully blocked @ high load. -N-f(fmem)

P010F, P0101

YNNY N

N

NN - NNNN

-

-NYY N

-NYNN

-YNN

Y

N

NY

Y

NN

YN

[email protected] AML EOBD Monitors 07 ROC.doc Page 20 of 43

Page 867 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 21 of 43

Dual MAF Diagnostic Operation:

DTCs P0100 – Mass Air Flow A Circuit

P0101 – Mass Air Flow A Circuit Range/Performance

P0102 – Mass Air Flow A Circuit Low Input

P0103 – Mass Air Flow A Circuit High Input

P0104 – Mass Air Flow A Circuit Intermittent/Erratic

P010A – Mass Air Flow B Circuit

P010B – Mass Air Flow B Circuit Range/Performance

P010C – Mass Air Flow B Circuit Low Input

P010D – Mass Air Flow B Circuit High Input

P010E – Mass Air Flow B Circuit Intermittent/Erratic

P010F – Mass Air Flow Sensors A/B Correlation

Monitor execution Continuous (exceptions below)

Monitor Sequence Continuous (exceptions below)

Sensors/Components OK No Throttle Position Failure

No Vehicle Speed Failure

Monitoring Duration Continuous (exceptions below)

Global Entry Conditions

Entry condition Minimum Maximum

Battery Voltage 11 volts 18 volt

Global Abort Conditions

SAIR monitor running

Abort Conditions for P0100,P0101,P010A,P010B,P010F

Throttle position < 3 degrees & Vehicle Speed > 15mph

Page 868 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

SAIR Monitor

SAIR Hardware

The V8 uses SAIR to enhance the emissions performan ce. The SAIR pump is supplied with clean air from

the ‘Y’ junction prior to the throttle. This air is th en supplied to the exhaust via two vacuum operated

valves, which are controlled from a common electrically operated control valve.

[email protected] AML EOBD Monitors 07 ROC.doc Page 22 of 43

Clean

air pipe

Vacuum

valves

Electric

valve

Air supply

to exhaust

Secondary

Air Pump

Page 869 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 23 of 43

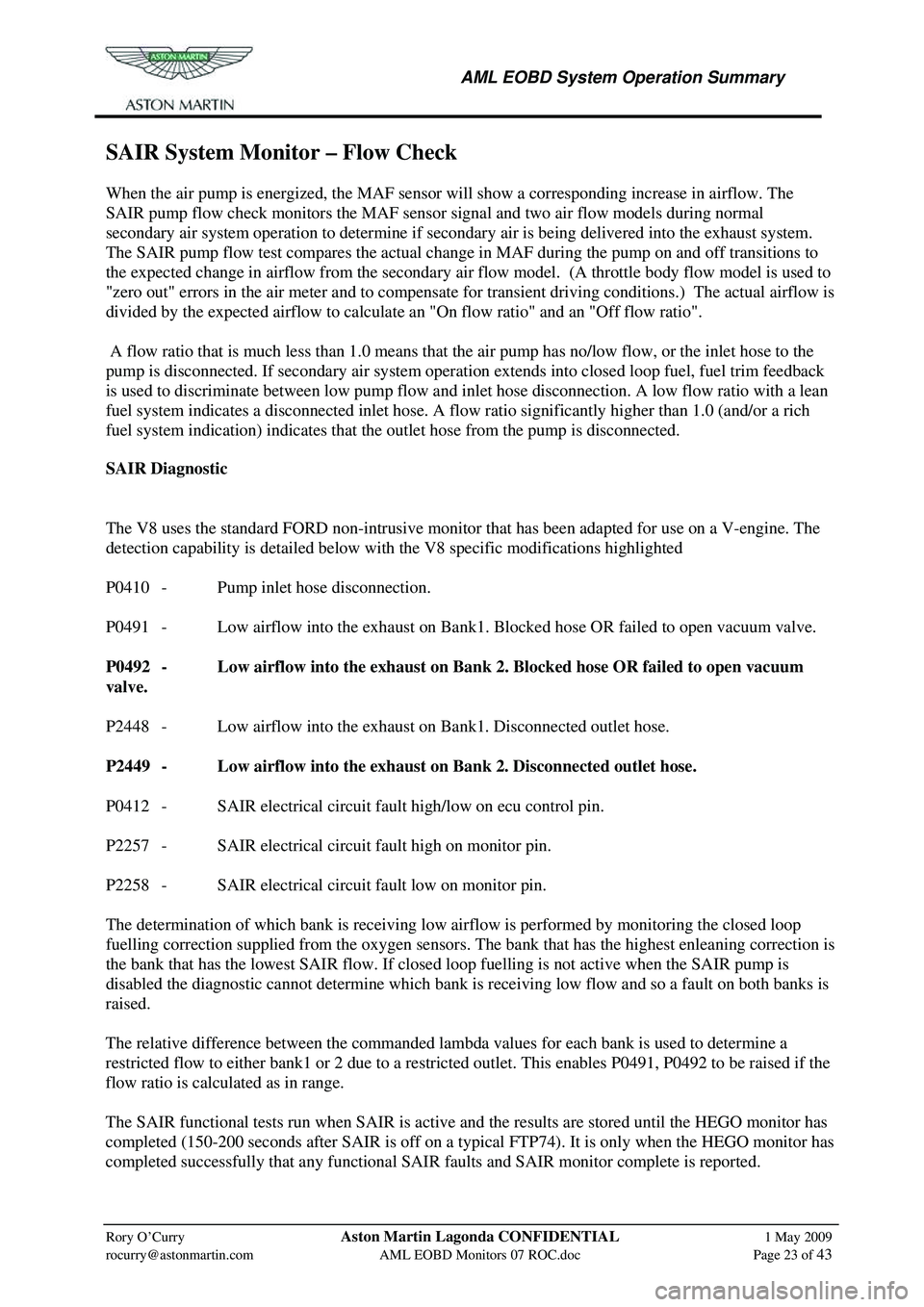

SAIR System Monitor – Flow Check

When the air pump is energized, the MAF sensor will show a corresponding increase in airflow. The

SAIR pump flow check monitors the MAF sensor signal and two air flow models during normal

secondary air system operation to determine if secondary air is being delivered into the exhaust system.

The SAIR pump flow test compares the actual change in MAF during the pump on and off transitions to

the expected change in airflow from the secondary air fl ow model. (A throttle body flow model is used to

"zero out" errors in the air meter and to compensate fo r transient driving conditions.) The actual airflow is

divided by the expected airflow to calculate an "On flow ratio" and an "Off flow ratio".

A flow ratio that is much less than 1.0 means that the air pump has no/low flow, or the inlet hose to the

pump is disconnected. If secondary air system operation ex tends into closed loop fuel, fuel trim feedback

is used to discriminate between low pump flow and in let hose disconnection. A low flow ratio with a lean

fuel system indicates a disconnected inlet hose. A flow ratio significantly higher than 1.0 (and/or a rich

fuel system indication) indicates that th e outlet hose from the pump is disconnected.

SAIR Diagnostic

The V8 uses the standard FORD non-intrusive monitor that has been adapted for use on a V-engine. The

detection capability is detailed below with the V8 specific modifications highlighted

P0410 - Pump inlet hose disconnection.

P0491 - Low airflow into the exhaust on Bank1. Blocked hose OR failed to open vacuum valve.

P0492 - Low airflow into the exhaust on Bank 2. Blocked hose OR failed to open vacuum

valve.

P2448 - Low airflow into the exhaust on Bank1. Disconnected outlet hose.

P2449 - Low airflow into the exhaust on Bank 2. Disconnected outlet hose.

P0412 - SAIR electrical circuit fault high/low on ecu control pin.

P2257 - SAIR electrical circuit fault high on monitor pin.

P2258 - SAIR electrical circuit fault low on monitor pin.

The determination of which bank is receiving low ai rflow is performed by monitoring the closed loop

fuelling correction supplied from the oxygen sensors. The bank that has the highest enleaning correction is

the bank that has the lowest SAIR flow. If closed loop fuelling is not active when the SAIR pump is

disabled the diagnostic cannot determ ine which bank is receiving low flow and so a fault on both banks is

raised.

The relative difference between the commanded lambda values for each bank is used to determine a

restricted flow to either bank1 or 2 due to a restricted outlet. This enables P0491, P0492 to be raised if the

flow ratio is calculated as in range.

The SAIR functional tests run when SAIR is active and the results are stored until the HEGO monitor has

completed (150-200 seconds after SAIR is off on a typical FTP74). It is only when the HEGO monitor has

completed successfully that any functional SAIR fa ults and SAIR monitor complete is reported.

Page 870 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 24 of 43

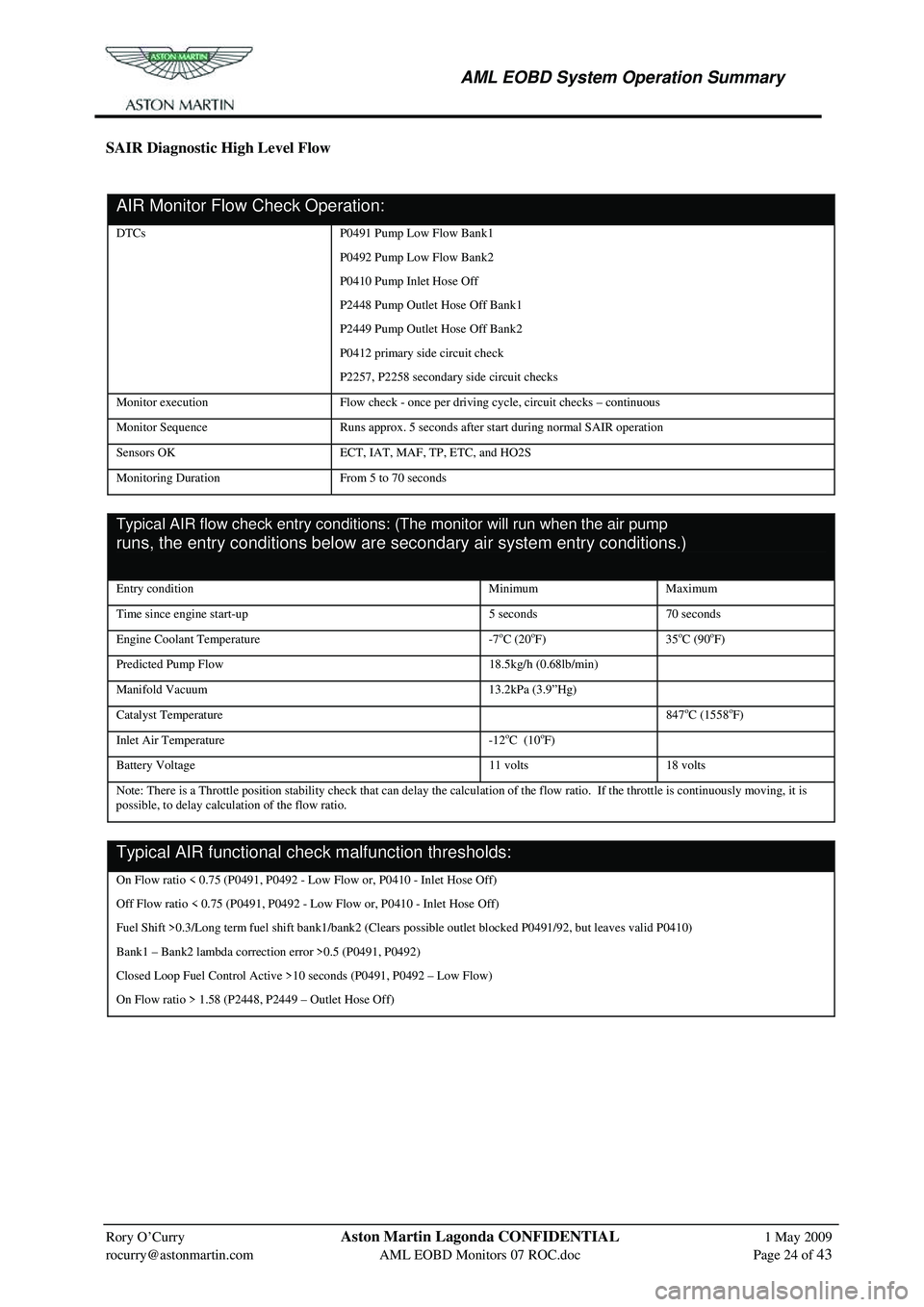

SAIR Diagnostic High Level Flow

AIR Monitor Flow Check Operation: onitor Flow Check Operation:

DTCs P0491 Pump Low Flow Bank1

P0492 Pump Low Flow Bank2

P0410 Pump Inlet Hose Off

P2448 Pump Outlet Hose Off Bank1

P2449 Pump Outlet Hose Off Bank2

P0412 primary side circuit check

P2257, P2258 secondary side circuit checks

Monitor execution Flow check - once per driving cycle, circuit checks – continuous

Monitor Sequence Runs approx. 5 seconds after start during normal SAIR operation

Sensors OK ECT, IAT, MAF, TP, ETC, and HO2S

Monitoring Duration From 5 to 70 seconds

Typical AIR flow check entry conditions: (The monitor will run when the air pump

runs, the entry conditions below are secondary air system entry conditions.) re secondary air

system entry conditions.)

Entry condition Minimum Maximum

Time since engine start-up 5 seconds 70 seconds

Engine Coolant Temperature -7oC (20oF) 35oC (90oF)

Predicted Pump Flow 18.5kg/h (0.68lb/min)

Manifold Vacuum 13.2kPa (3.9”Hg)

Catalyst Temperature 847oC (1558oF)

Inlet Air Temperature -12oC (10oF)

Battery Voltage 11 volts 18 volts

Note: There is a Throttle position stability ch eck that can delay the calculation of the flow ratio. If the throttle is continuously moving, it is

possible, to delay calculation of the flow ratio.

Typical AIR functional check malfunction thresholds:heck malfunction thresholds:

On Flow ratio < 0.75 (P0491, P0492 - Low Flow or, P0410 - Inlet Hose Off)

Off Flow ratio < 0.75 (P0491, P0492 - Lo w Flow or, P0410 - Inlet Hose Off)

Fuel Shift >0.3/Long term fuel shift bank1/bank2 (Clears possible outlet blocked P0491/92, but leaves valid P0410)

Bank1 – Bank2 lambda correcti on error >0.5 (P0491, P0492)

Closed Loop Fuel Control Active >10 seconds (P0491, P0492 – Low Flow)

On Flow ratio > 1.58 (P2448, P2449 – Outlet Hose Off)