engine AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 35 of 72

36

SSP 198/09

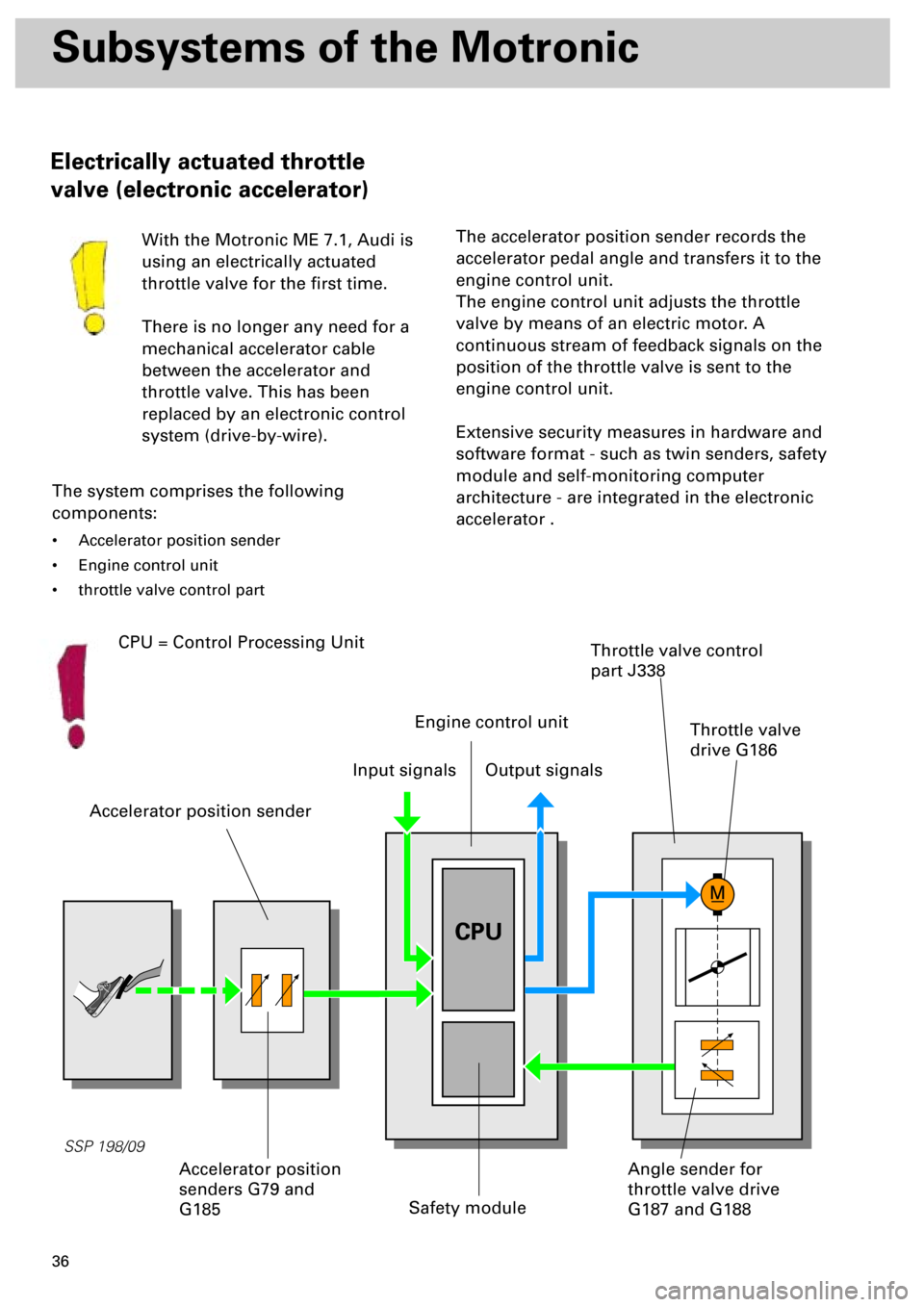

Subsystems of the Motronic

Electrically actuated throttle

valve (electronic accelerator)

With the Motronic ME 7.1, Audi is

using an electrically actuated

throttle valve for the first time.

There is no longer any need for a

mechanical accelerator cable

between the accelerator and

throttle valve. This has been

replaced by an electronic control

system (drive-by-wire).

The system comprises the following

components:

• Accelerator position sender

• Engine control unit

• throttle valve control part

Accelerator position sender

Safety module

Throttle valve control

part J338

The accelerator position sender records the

accelerator pedal angle and transfers it to the

engine control unit.

The engine control unit adjusts the throttle

valve by means of an electric motor. A

continuous stream of feedback signals on the

position of the throttle valve is sent to the

engine control unit.

Extensive security measures in hardware and

software format - such as twin senders, safety

module and self-monitoring computer

architecture - are integrated in the electronic

accelerator .

Input signalsOutput signals

Angle sender for

throttle valve drive

G187 and G188Accelerator position

senders G79 and

G185

Engine control unit

CPU

CPU = Control Processing Unit

Throttle valve

drive G186

Page 36 of 72

37

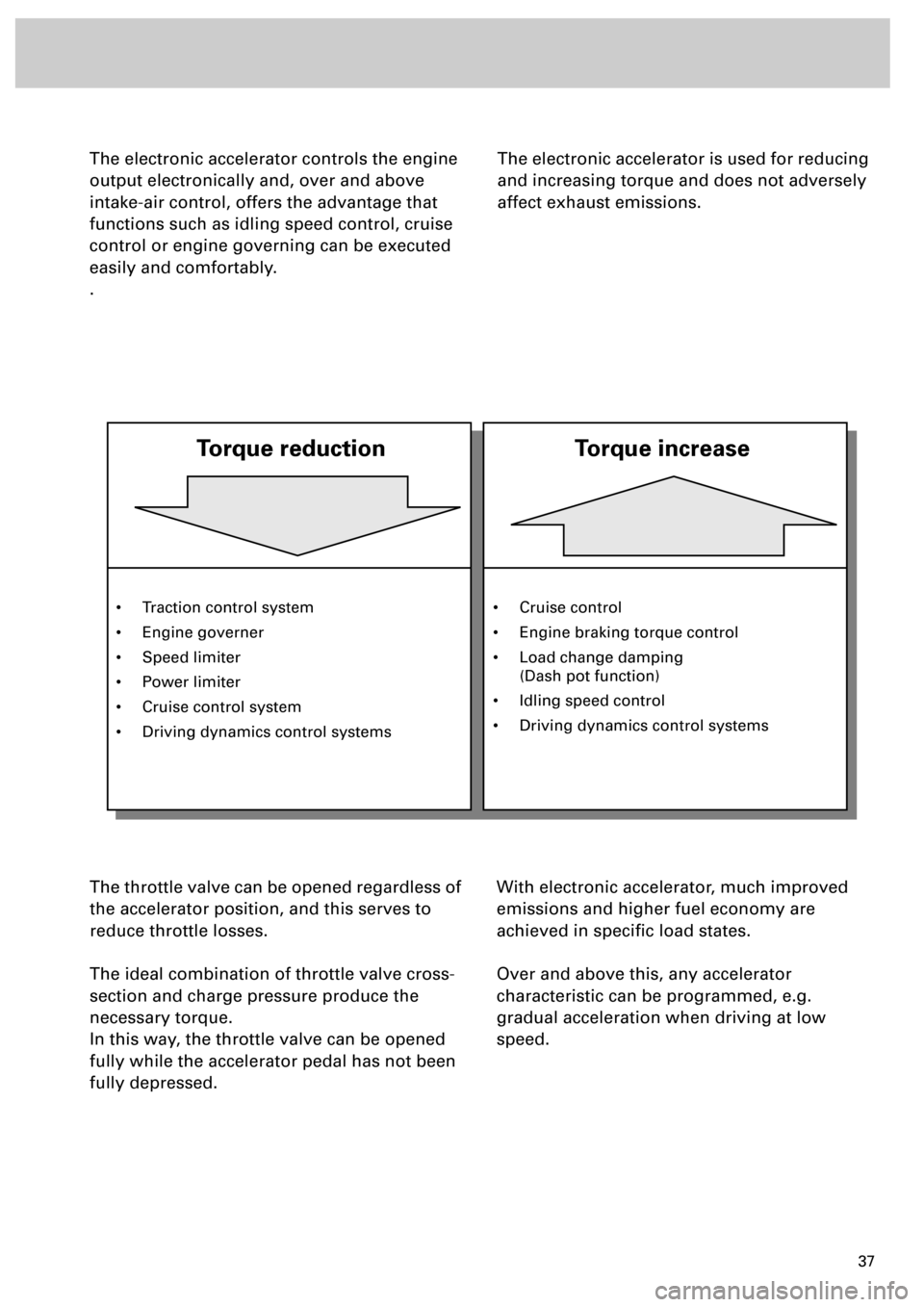

The electronic accelerator controls the engine

output electronically and, over and above

intake-air control, offers the advantage that

functions such as idling speed control, cruise

control or engine governing can be executed

easily and comfortably.

.

The throttle valve can be opened regardless of

the accelerator position, and this serves to

reduce throttle losses.

The ideal combination of throttle valve cross-

section and charge pressure produce the

necessary torque.

In this way, the throttle valve can be opened

fully while the accelerator pedal has not been

fully depressed.With electronic accelerator, much improved

emissions and higher fuel economy are

achieved in specific load states.

Over and above this, any accelerator

characteristic can be programmed, e.g.

gradual acceleration when driving at low

speed.

The electronic accelerator is used for reducing

and increasing torque and does not adversely

affect exhaust emissions.

• Traction control system

• Engine governer

• Speed limiter

• Power limiter

• Cruise control system

• Driving dynamics control systems

Torque reduction

Torque increase

• Cruise control

• Engine braking torque control

• Load change damping

(Dash pot function)

• Idling speed control

• Driving dynamics control systems

Page 37 of 72

38

Subsystems of the Motronic

SSP 198/12

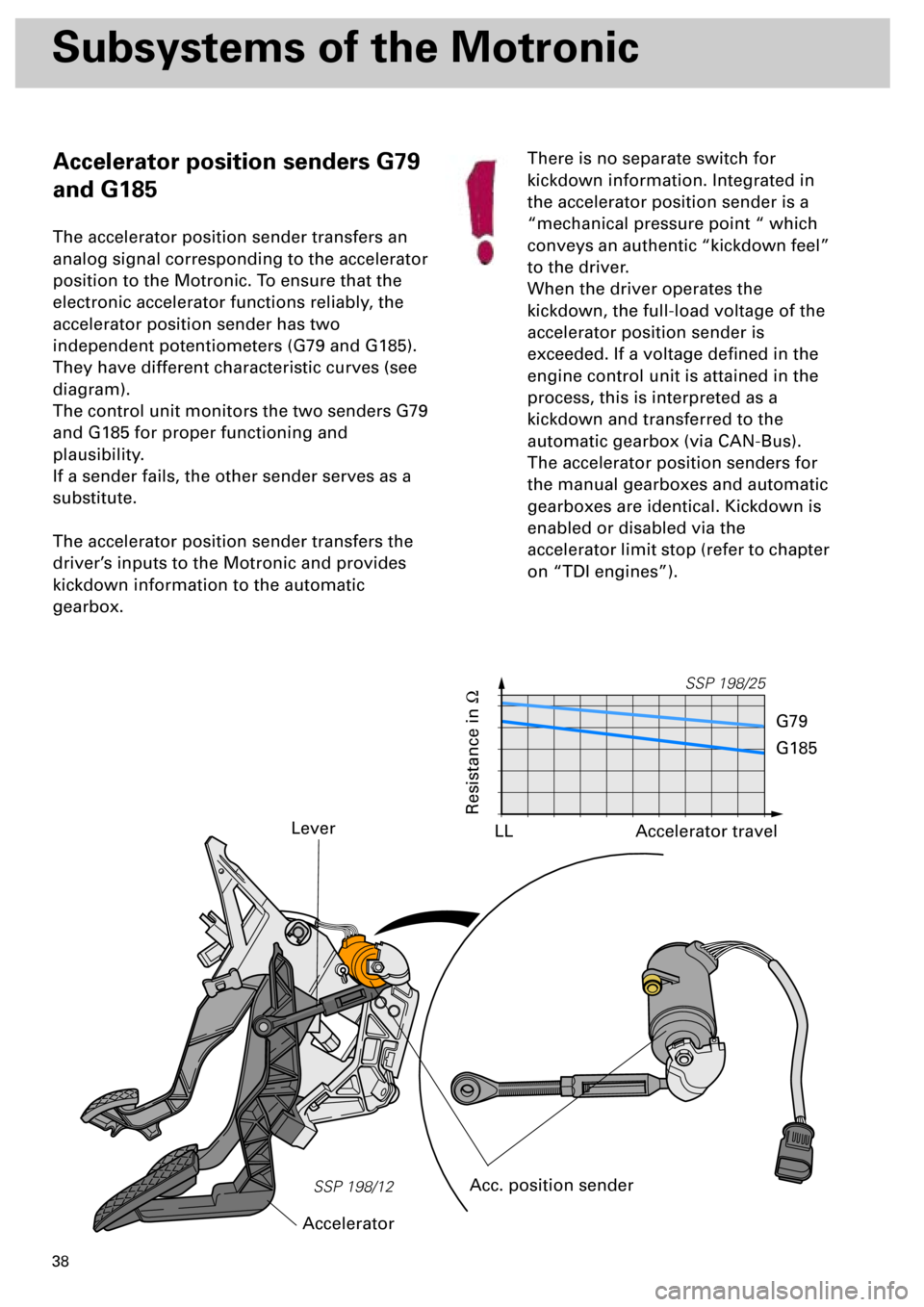

Accelerator position senders G79

and G185

The accelerator position sender transfers an

analog signal corresponding to the accelerator

position to the Motronic. To ensure that the

electronic accelerator functions reliably, the

accelerator position sender has two

independent potentiometers (G79 and G185).

They have different characteristic curves (see

diagram).

The control unit monitors the two senders G79

and G185 for proper functioning and

plausibility.

If a sender fails, the other sender serves as a

substitute.

The accelerator position sender transfers the

driver’s inputs to the Motronic and provides

kickdown information to the automatic

gearbox.

Lever

Acc. position sender

AcceleratorThere is no separate switch for

kickdown information. Integrated in

the accelerator position sender is a

“mechanical pressure point “ which

conveys an authentic “kickdown feel”

to the driver.

When the driver operates the

kickdown, the full-load voltage of the

accelerator position sender is

exceeded. If a voltage defined in the

engine control unit is attained in the

process, this is interpreted as a

kickdown and transferred to the

automatic gearbox (via CAN-Bus).

The accelerator position senders for

the manual gearboxes and automatic

gearboxes are identical. Kickdown is

enabled or disabled via the

accelerator limit stop (refer to chapter

on “TDI engines”).

SSP 198/25

Resistance in

W

Accelerator travel

G79

G185

LL

Page 38 of 72

39

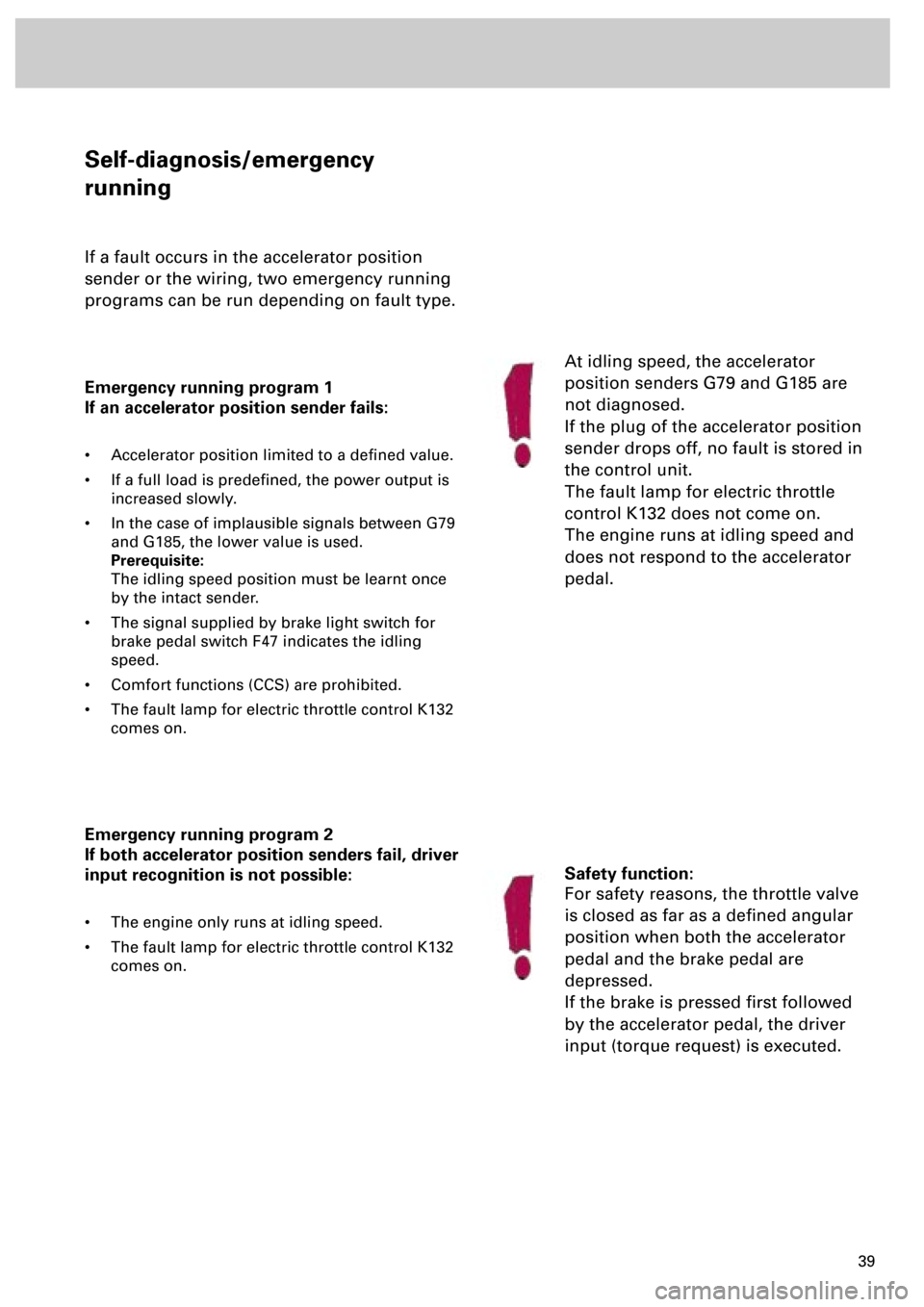

Self-diagnosis/emergency

running

If a fault occurs in the accelerator position

sender or the wiring, two emergency running

programs can be run depending on fault type.

Emergency running program 1

If an accelerator position sender fails:

• Accelerator position limited to a defined value.

• If a full load is predefined, the power output is

increased slowly.

• In the case of implausible signals between G79

and G185, the lower value is used.

Prerequisite:

The idling speed position must be learnt once

by the intact sender.

• The signal supplied by brake light switch for

brake pedal switch F47 indicates the idling

speed.

• Comfort functions (CCS) are prohibited.

• The fault lamp for electric throttle control K132

comes on.

Emergency running program 2

If both accelerator position senders fail, driver

input recognition is not possible:

• The engine only runs at idling speed.

• The fault lamp for electric throttle control K132

comes on.

At idling speed, the accelerator

position senders G79 and G185 are

not diagnosed.

If the plug of the accelerator position

sender drops off, no fault is stored in

the control unit.

The fault lamp for electric throttle

control K132 does not come on.

The engine runs at idling speed and

does not respond to the accelerator

pedal.

Safety function:

For safety reasons, the throttle valve

is closed as far as a defined angular

position when both the accelerator

pedal and the brake pedal are

depressed.

If the brake is pressed first followed

by the accelerator pedal, the driver

input (torque request) is executed.

Page 39 of 72

40

SSP 198/28

Subsystems of the Motronic

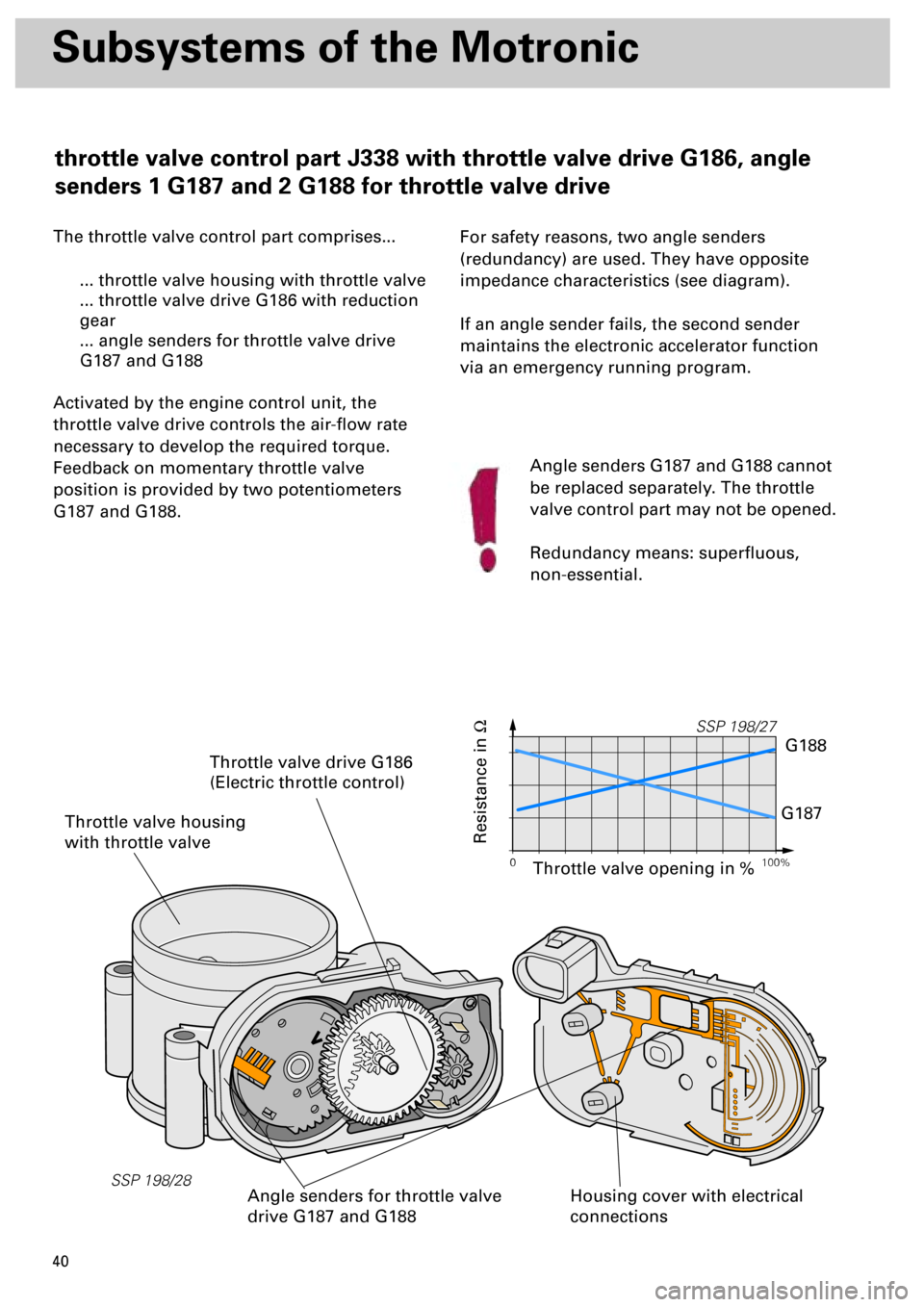

The throttle valve control part comprises...

... throttle valve housing with throttle valve

... throttle valve drive G186 with reduction

gear

... angle senders for throttle valve drive

G187 and G188

Activated by the engine control unit, the

throttle valve drive controls the air-flow rate

necessary to develop the required torque.

Feedback on momentary throttle valve

position is provided by two potentiometers

G187 and G188.

For safety reasons, two angle senders

(redundancy) are used. They have opposite

impedance characteristics (see diagram).

If an angle sender fails, the second sender

maintains the electronic accelerator function

via an emergency running program.

Throttle valve housing

with throttle valve

Housing cover with electrical

connections

Throttle valve drive G186

(Electric throttle control)

Angle senders for throttle valve

drive G187 and G188

Resistance in

W

Angle senders G187 and G188 cannot

be replaced separately. The throttle

valve control part may not be opened.

Redundancy means: superfluous,

non-essential.

0 100%

SSP 198/27

G188

G187

Throttle valve opening in %

throttle valve control part J338 with throttle valve drive G186, angle

senders 1 G187 and 2 G188 for throttle valve drive

Page 40 of 72

41

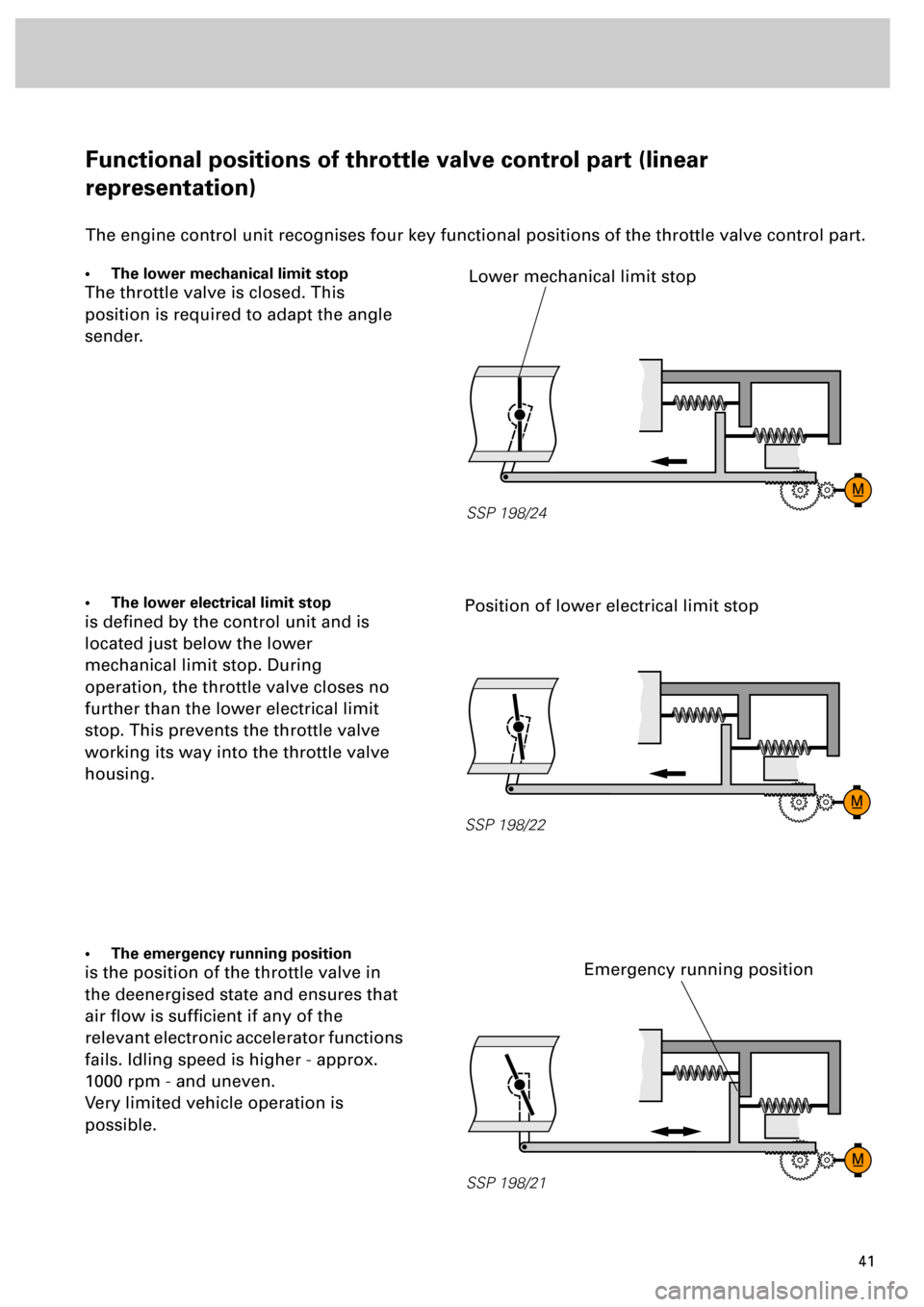

Functional positions of throttle valve control part (linear

representation)

The engine control unit recognises four key functional positions of the throttle valve control part.

• The lower mechanical limit stop

The throttle valve is closed. This

position is required to adapt the angle

sender.

• The lower electrical limit stop

is defined by the control unit and is

located just below the lower

mechanical limit stop. During

operation, the throttle valve closes no

further than the lower electrical limit

stop. This prevents the throttle valve

working its way into the throttle valve

housing.

• The emergency running position

is the position of the throttle valve in

the deenergised state and ensures that

air flow is sufficient if any of the

relevant electronic accelerator functions

fails. Idling speed is higher - approx.

1000 rpm - and uneven.

Very limited vehicle operation is

possible.

SSP 198/21

SSP 198/22

SSP 198/24

Position of lower electrical limit stop

Emergency running position

Lower mechanical limit stop

Page 42 of 72

43

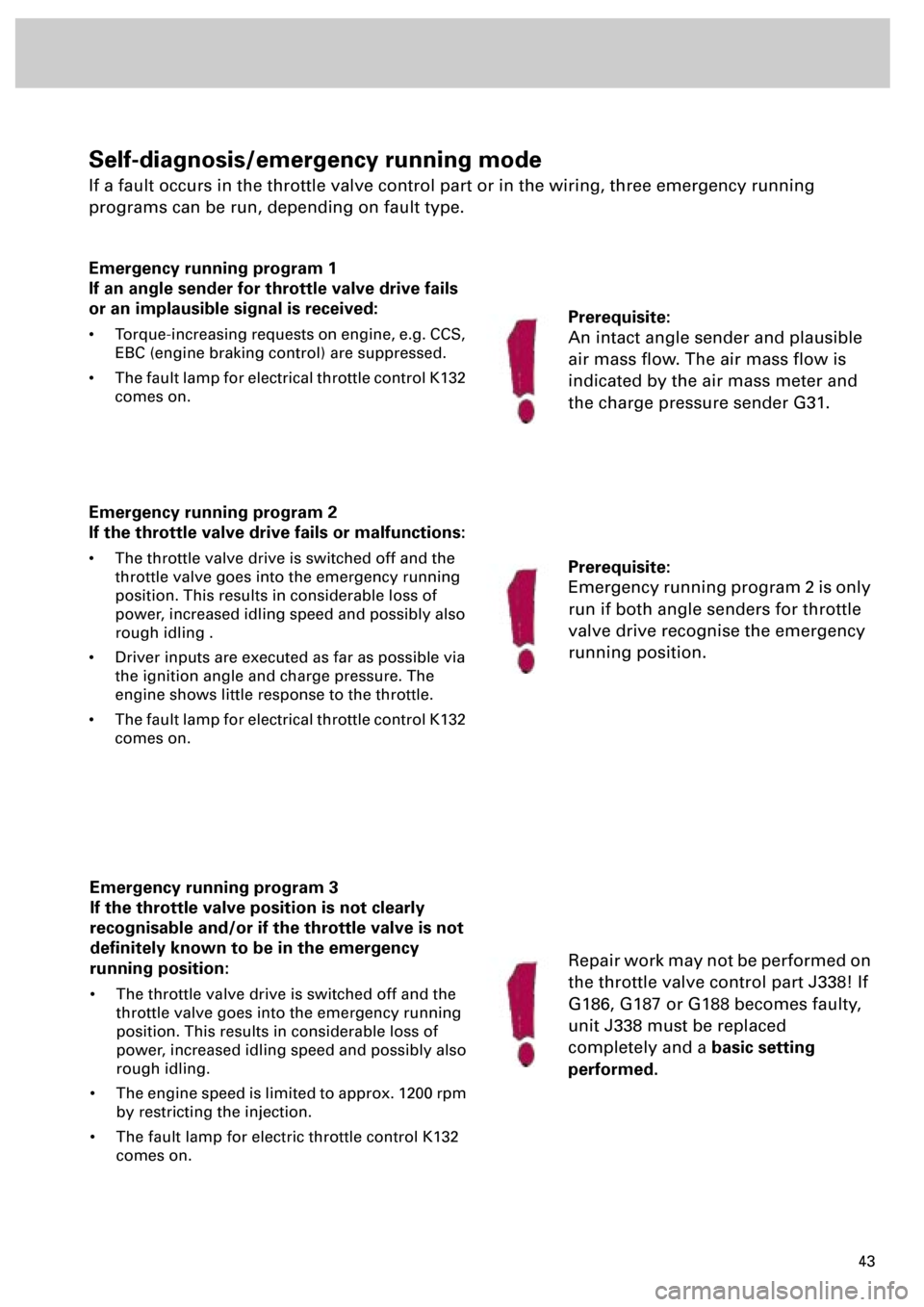

Emergency running program 1

If an angle sender for throttle valve drive fails

or an implausible signal is received:

• Torque-increasing requests on engine, e.g. CCS,

EBC (engine braking control) are suppressed.

• The fault lamp for electrical throttle control K132

comes on.

Prerequisite:

An intact angle sender and plausible

air mass flow. The air mass flow is

indicated by the air mass meter and

the charge pressure sender G31.

Self-diagnosis/emergency running mode

If a fault occurs in the throttle valve control part or in the wiring, three emergency running

programs can be run, depending on fault type.

Emergency running program 2

If the throttle valve drive fails or malfunctions:

• The throttle valve drive is switched off and the

throttle valve goes into the emergency running

position. This results in considerable loss of

power, increased idling speed and possibly also

rough idling .

• Driver inputs are executed as far as possible via

the ignition angle and charge pressure. The

engine shows little response to the throttle.

• The fault lamp for electrical throttle control K132

comes on.

Prerequisite:

Emergency running program 2 is only

run if both angle senders for throttle

valve drive recognise the emergency

running position.

Emergency running program 3

If the throttle valve position is not clearly

recognisable and/or if the throttle valve is not

definitely known to be in the emergency

running position:

• The throttle valve drive is switched off and the

throttle valve goes into the emergency running

position. This results in considerable loss of

power, increased idling speed and possibly also

rough idling.

• The engine speed is limited to approx. 1200 rpm

by restricting the injection.

• The fault lamp for electric throttle control K132

comes on.

Repair work may not be performed on

the throttle valve control part J338! If

G186, G187 or G188 becomes faulty,

unit J338 must be replaced

completely and a

basic setting

performed.

Page 43 of 72

44

Subsystems of the Motronic

120

180

°C 60

90

12

93

6

120

°C 60

12

16

120

100

80

50

30

10140

1234

5

6

7

160

180

200

220

260

Volt8

1/2

1/1

8

0

EPC

EPC

SSP 198/47

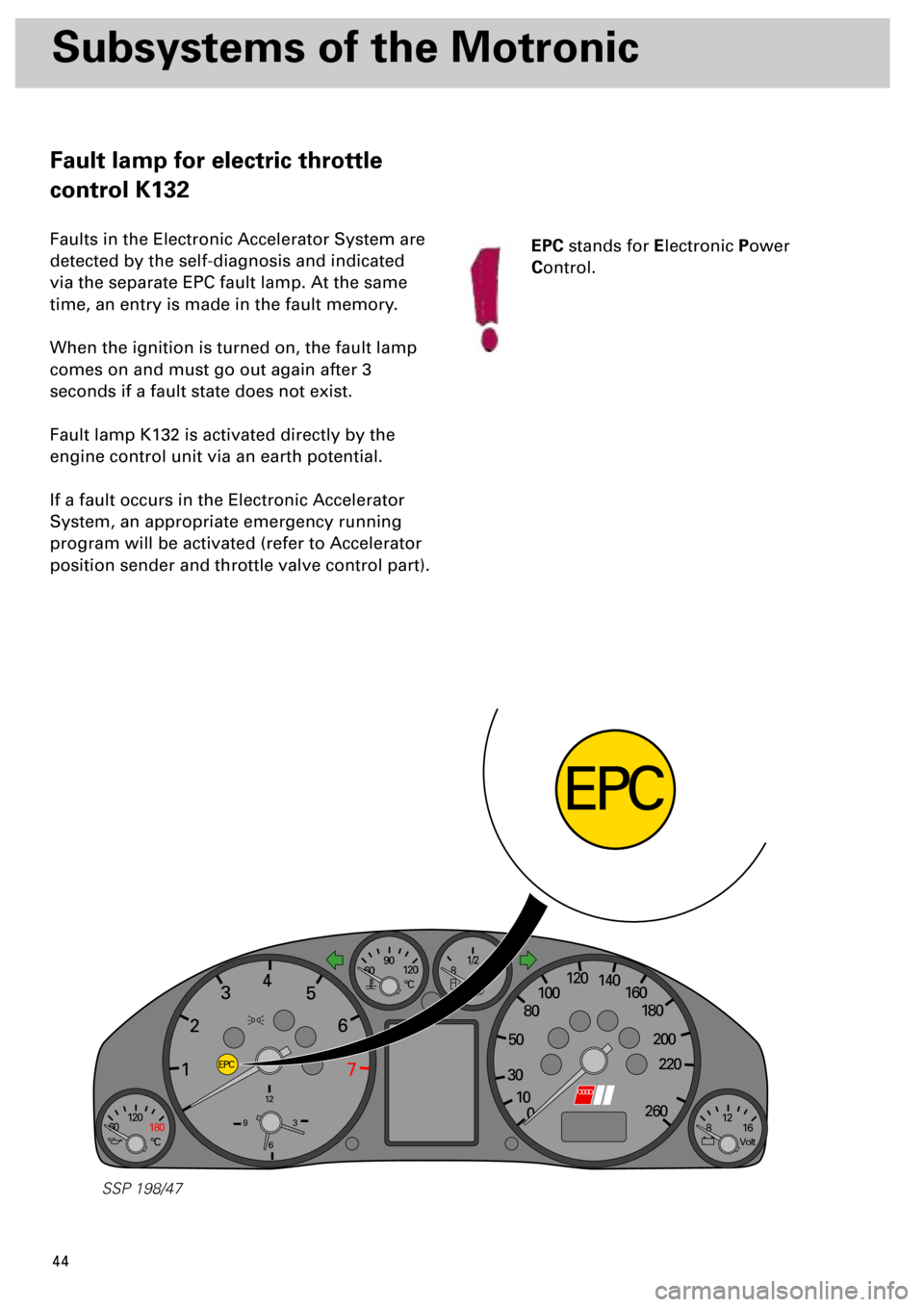

Fault lamp for electric throttle

control K132

Faults in the Electronic Accelerator System are

detected by the self-diagnosis and indicated

via the separate EPC fault lamp. At the same

time, an entry is made in the fault memory.

When the ignition is turned on, the fault lamp

comes on and must go out again after 3

seconds if a fault state does not exist.

Fault lamp K132 is activated directly by the

engine control unit via an earth potential.

If a fault occurs in the Electronic Accelerator

System, an appropriate emergency running

program will be activated (refer to Accelerator

position sender and throttle valve control part).

EPC

stands for

E

lectronic

P

ower

C

ontrol.

Page 45 of 72

46

SSP 198/26

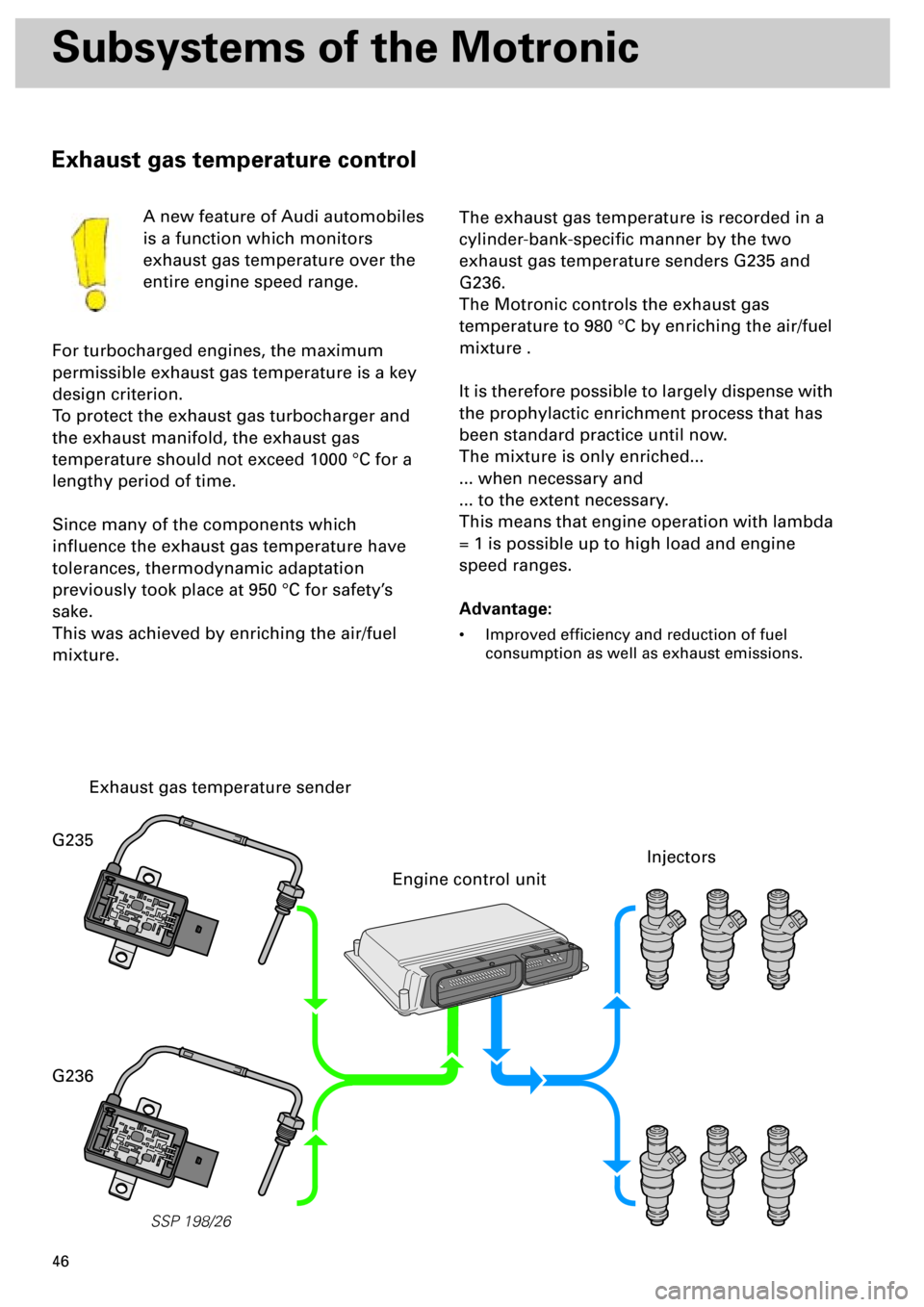

Subsystems of the Motronic

Exhaust gas temperature control

A new feature of Audi automobiles

is a function which monitors

exhaust gas temperature over the

entire engine speed range.

For turbocharged engines, the maximum

permissible exhaust gas temperature is a key

design criterion.

To protect the exhaust gas turbocharger and

the exhaust manifold, the exhaust gas

temperature should not exceed 1000 °C for a

lengthy period of time.

Since many of the components which

influence the exhaust gas temperature have

tolerances, thermodynamic adaptation

previously took place at 950 °C for safety’s

sake.

This was achieved by enriching the air/fuel

mixture.

The exhaust gas temperature is recorded in a

cylinder-bank-specific manner by the two

exhaust gas temperature senders G235 and

G236.

The Motronic controls the exhaust gas

temperature to 980 °C by enriching the air/fuel

mixture .

It is therefore possible to largely dispense with

the prophylactic enrichment process that has

been standard practice until now.

The mixture is only enriched...

... when necessary and

... to the extent necessary.

This means that engine operation with lambda

= 1 is possible up to high load and engine

speed ranges.

Advantage:

• Improved efficiency and reduction of fuel

consumption as well as exhaust emissions.

Exhaust gas temperature sender

Engine control unit

Injectors

G235

G236

Page 46 of 72

47

SSP/198/13

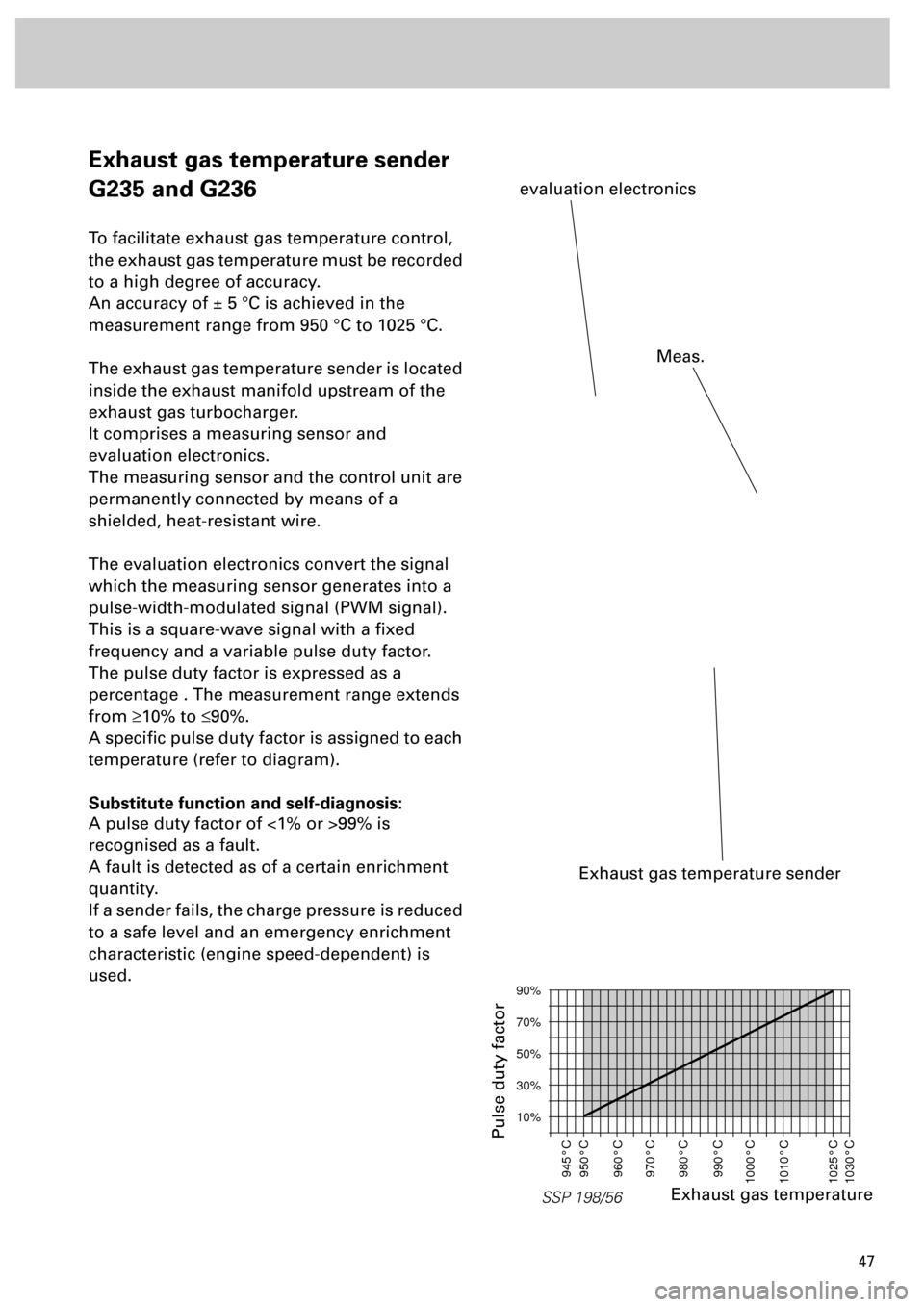

Exhaust gas temperature sender

G235 and G236

To facilitate exhaust gas temperature control,

the exhaust gas temperature must be recorded

to a high degree of accuracy.

An accuracy of ± 5 °C is achieved in the

measurement range from 950 °C to 1025 °C.

The exhaust gas temperature sender is located

inside the exhaust manifold upstream of the

exhaust gas turbocharger.

It comprises a measuring sensor and

evaluation electronics.

The measuring sensor and the control unit are

permanently connected by means of a

shielded, heat-resistant wire.

The evaluation electronics convert the signal

which the measuring sensor generates into a

pulse-width-modulated signal (PWM signal).

This is a square-wave signal with a fixed

frequency and a variable pulse duty factor.

The pulse duty factor is expressed as a

percentage . The measurement range extends

from

³

10% to

£

90%.

A specific pulse duty factor is assigned to each

temperature (refer to diagram).

Substitute function and self-diagnosis:

A pulse duty factor of <1% or >99% is

recognised as a fault.

A fault is detected as of a certain enrichment

quantity.

If a sender fails, the charge pressure is reduced

to a safe level and an emergency enrichment

characteristic (engine speed-dependent) is

used.

Exhaust gas temperature sender

evaluation electronics

SSP 198/56

90%

70%

50%

30%

10%

945°C

950°C

960°C

970°C

980°C

990°C

1000°C

1010°C

1025°C

1030°C

Exhaust gas temperature

Pulse duty factor

Meas.