AUDI TT ROADSTER 2014 Owners Manual

Manufacturer: AUDI, Model Year: 2014, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2014Pages: 244, PDF Size: 60.87 MB

Page 211 of 244

A WARNING

If tire pressure is less than 1.3 bar after

driving for 10 minutes, the tire is too se

vere ly damaged . Do not continue to drive .

Seek p rofessional assistance.

@ Tips

After a tire repair, have the sealant bottle

rep laced at a dealership . This restores full

functionality to the Tire Mob ility System .

What should I be

aware of when

changing a tire?

General information

The fo llow ing se ctions wi ll provide yo u wit h

importa nt information on how to change a

tire using the vehicle too l kit .

H oweve r, we recomme nd that you have a

q ua lified servi ce center cha nge the tire and

perform all wo rk associa ted with changing it.

Wheels with cap-covered wheel bolts

Applies to vehicles: with cap-covered wheel bolts

The caps must be removed first from the

wheel bolts before the bol ts can be un

screwed .

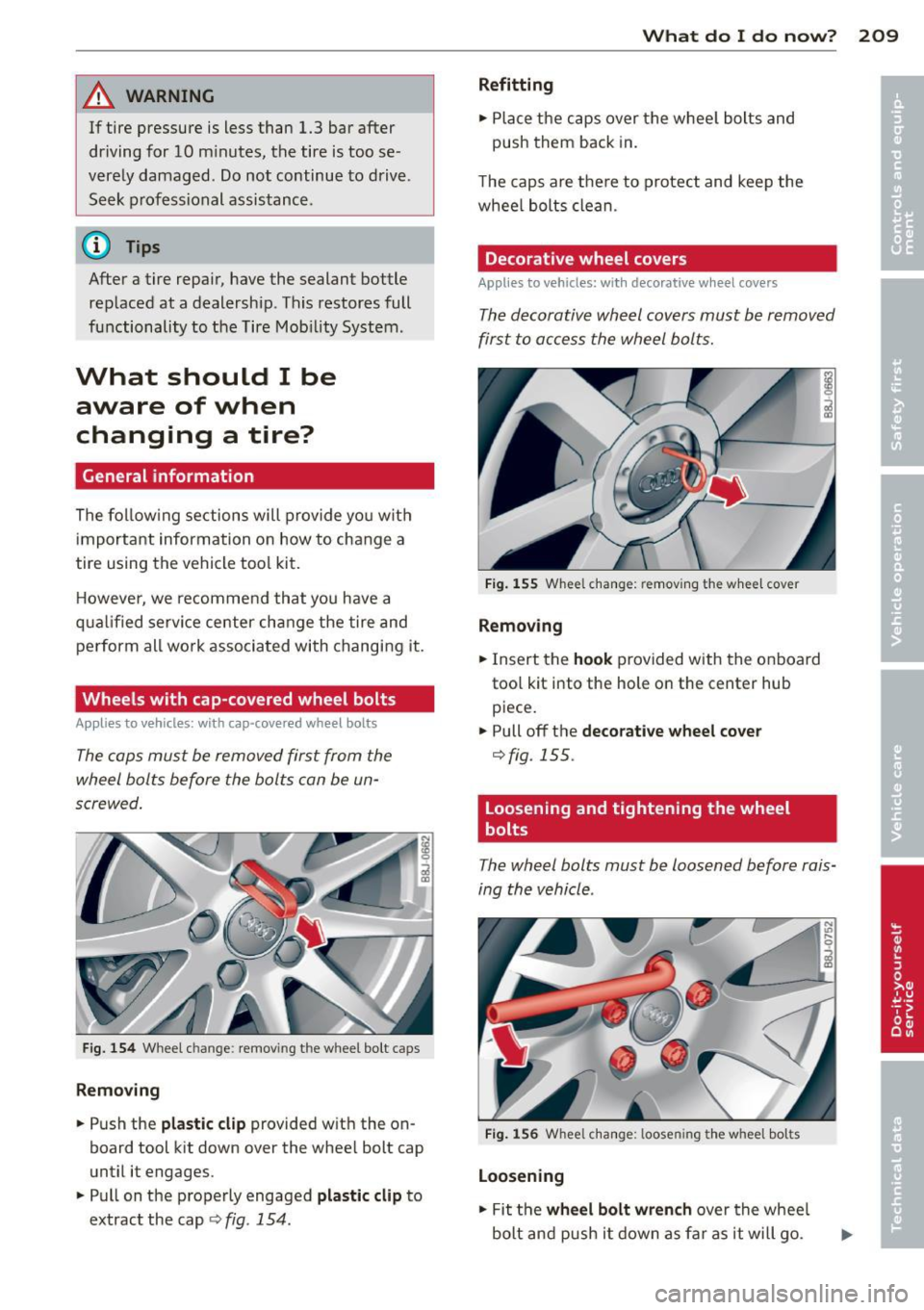

Fig. 154 Wheel c hang e: remov ing the whee l bo lt caps

Rem oving

.,. Push the plastic clip provided w it h the on

board tool kit down over the whee l bolt cap

until it engages .

.,. Pull on the properly engaged

plastic clip to

extract the cap

c> fig . 154.

What do I d o now ? 209

Refitting

.,. Place the caps over t he whee l bolts and

push them back in.

T he caps are t here to protect and keep the

whee l bolts clean .

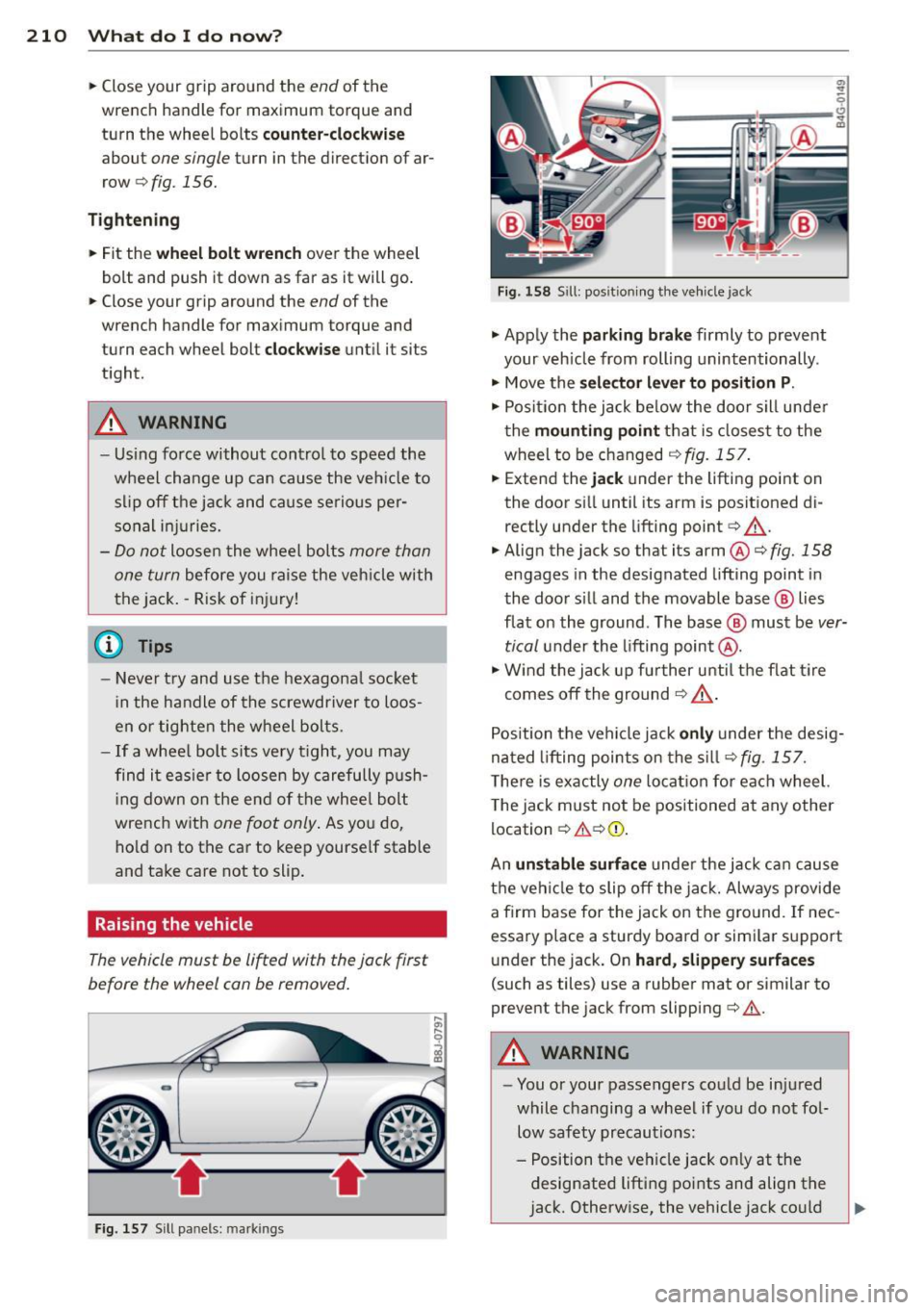

Decorative wheel covers

App lies to vehicles: wi th deco rative w heel covers

Th e decorative whe el covers must be removed

firs t to ac cess the wheel bolt s.

Fi g. 1 55 Wheel change: remov ing the w heel cover

Removing

.,. Insert the hook provided with the on board

too l kit into the hole o n the center hub

piece.

.,. Pull off the

decorative wheel cover

<=>fig. 155.

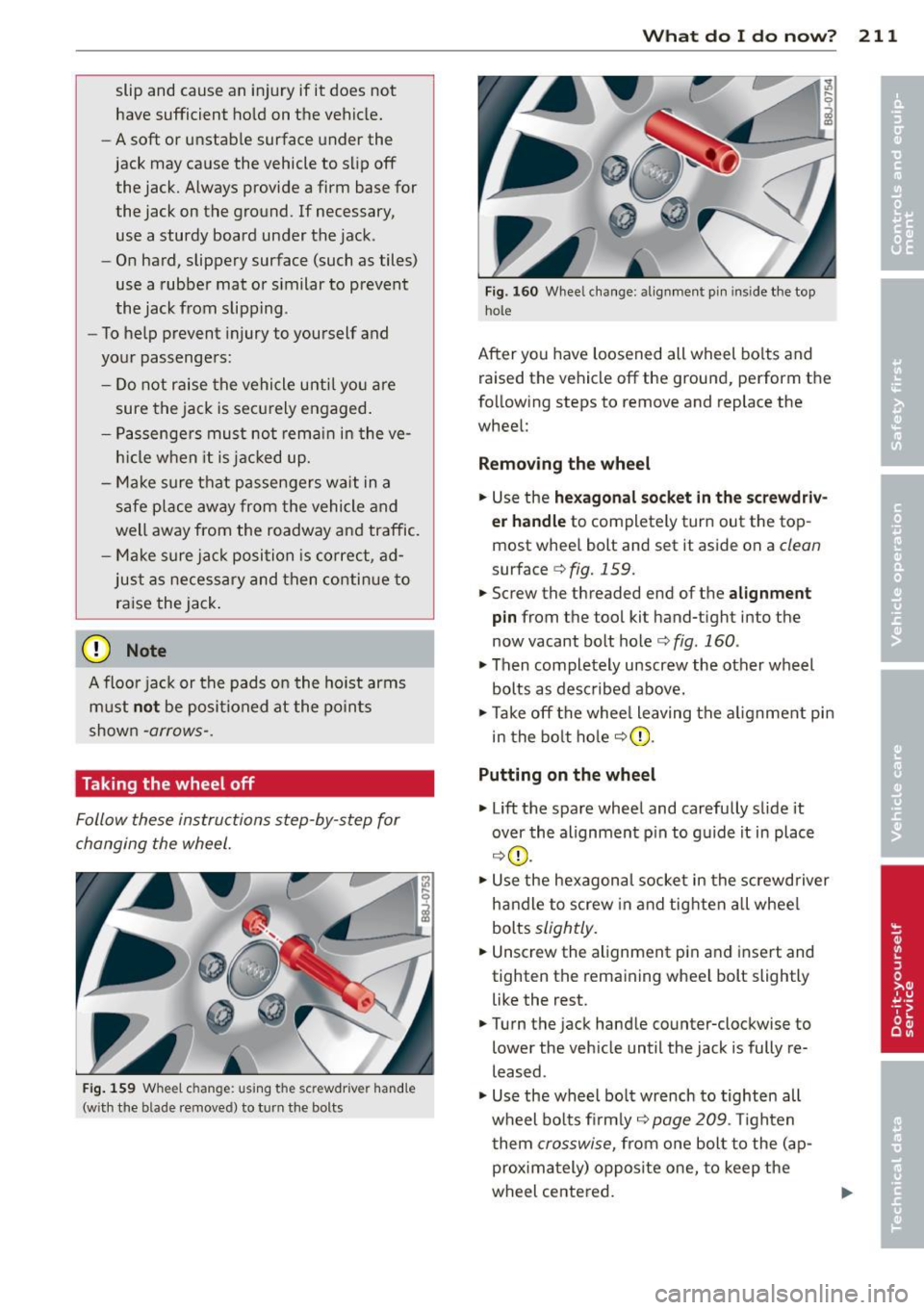

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle .

Fig. 1 56 Wheel cha nge: loosen ing the wheel bolts

Loosening

.,. Fit the wheel bolt wren ch over the whee l

bolt and push i t down as far as it will go .

Page 212 of 244

210 What do I do now?

• Close your grip around the end of the

wrench handle for maximum torque and

turn the wheel bolts

counter-clockwise

about one single turn in the direction of ar

row

¢ fig. 156.

Tightening

• Fit the wheel bolt wrench over the wheel

bolt and push it down as far as it will go .

• Close your grip around the

end of the

wrench handle for maximum torque and

turn each wheel bolt

clockwise until it sits

t ight.

A WARNING

- Us ing force without control to speed the

wheel change up can cause the veh icle to

slip off the jack and cause serious per

sonal inju ries.

-Do not loosen the wheel bolts more than

one turn

before you raise the vehicle with

the jack. -Risk of injury!

- Never t ry and use the hexagonal socket

in the handle of the screwdriver to loos

en or tighten the wheel bolts.

- If a wheel bolt sits very t ight, you may

find i t eas ier to loosen by carefully push

i ng down on the end of the whee l bolt

wrench with

one foot only. As yo u do,

hold on to the car to keep yourself stable

and take care not to slip .

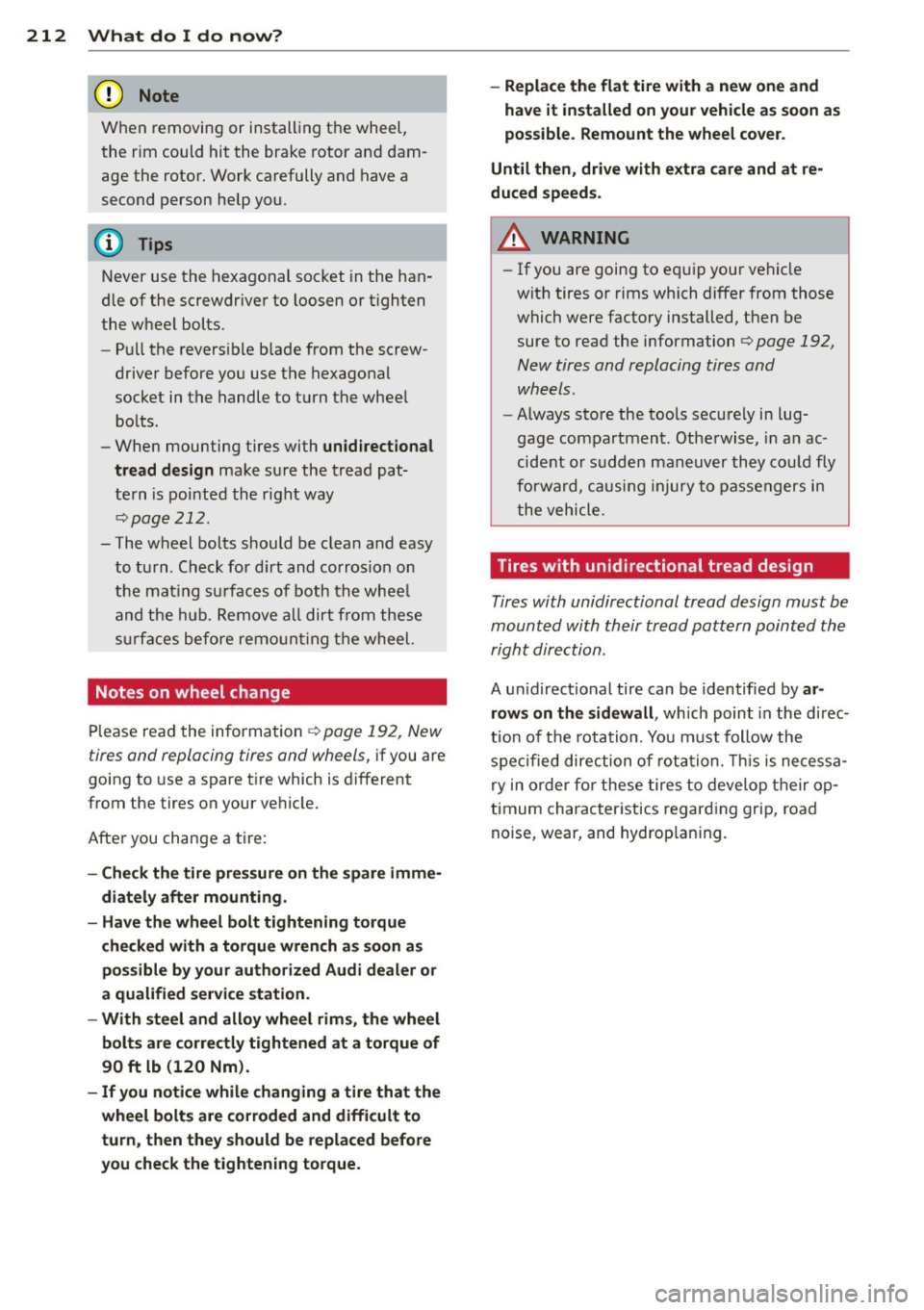

Raising the vehicle

The vehicle must be lifted with the jack first

before the wheel con be removed .

a

Fig. 157 Sill pa nels : m ar kings

Fig. 158 Sill : posit ioning the vehicle jac k

• Apply the parking brake firmly to prevent

your veh icle from roll ing unintentionally.

• Move the

selector lever to position P .

• Position the jack be low the door sill under

t he

mounting point that is closest to the

wheel to be changed ¢

fig. 157.

• Extend the jack under the lifti ng point on

the door s ill until its arm is positioned di

rectly under the lifting point ¢,&. .

• Align the jack so that its arm®¢

fig. 158

engages in the designated lifting point in

the door s ill and the movable base ® lies

flat on the ground . The base @ must be

ver

tical

under the lifting point@.

• Wind the jack up further unti l the flat tire

comes off the ground ¢

.&,.

Position the vehicle jack only under the desig

nated lifting points on the sill

¢fig . 157.

T he re is exactly one locat ion for eac h wheel.

T he jack must not be positioned at any other

location ¢

.&,¢(D .

An unstable surface under the jack can cause

the vehicle to slip off the jack. Always provide

a firm

base for the jack on the ground. If nec

essary p lace a sturdy board or simi lar support

under the jack. On

hard, slippery surfaces

(such as tiles) use a rubber mat or similar to

prevent the jack from slipping ¢

.&,.

A WARNING

--You or your passengers cou ld be injured

while changing a wheel if you do not fol

low safety precautions:

- Position the vehicle jack on ly at the

designated lifting points and align the

jack. Otherwise, the vehicle jack could

Page 213 of 244

slip and cause an injury if it does not

have sufficient hold on the veh icle.

- A soft or unstable surface under the

jack may cause the vehicle to slip off the jack. Always provide a firm base for

the jack on the ground. If necessary, use a sturdy board under the jack .

- On hard, slippery surface (such as tiles)

use a rubber mat or similar to prevent

the jack from slipping .

- To help prevent injury to yourself and

your passengers:

- Do not raise the vehicle u nti l yo u are

sure the jack is sec urely engaged .

- Pa ssenge rs must not remai n in the ve

h icle when it is jacked up.

- Make sure that passengers wait in a

safe pl ace away from the vehicle and

well away from the roadway and traffic.

- Make sure ja ck position is correc t, ad

just as necessary and then continue to

ra ise the jack .

(D Note

A floor jac k or the pads o n the hoist arms

m ust

n ot be po sit ioned at the po ints

shown

-arrows- .

Taking the wheel off

Follow these instructions step-by-step for

changing the wheel.

Fig . 159 W hee l ch ange : us ing th e sc rewdr ive r hand le

(w ith t he blade re m ove d) to turn t he bo lts

What do I d o now ? 211

Fig . 1 60 W hee l cha nge : alignmen t pin inside the top

ho le

After yo u have loosened all wheel bo lts and

raised the vehicle off the ground, perform the

follow ing steps to remove and replace the

whee l:

Remo ving the wheel

.,. Use the he xagonal socket in the scr ewdri v

er handle

to completely turn out the top

most whee l bolt and set it aside on a

clean

surface ¢ fig. 159.

.,. Screw the threaded end of the alignment

pin

from the tool kit hand-tight into the

now vacant bolt hole¢

fig. 160 .

.,. Then completely unscrew the other wheel

bolts as desc ribed above.

.,. Take off the whee l leaving the alignment pin

in the bo lt ho le ¢ (D.

Putting on th e wheel

.,. Lift the spare wheel and carefully slide it

over the alignment p in to guide it in place

Q (D .

.,. Use the hexagona l socket in the screwd river

handle to screw in and tig hten all whee l

bolts

slightly .

.,. Unscrew the alignment p in and insert and

tighten the remaining wheel bolt slightly like the rest .

.,. Turn the jack handle counter-clockwise to

lower the veh icle until the jack is fully re

leased .

.,. Use the whe el bo lt wrench to tighten all

wheel bo lts fi rm ly

Q page 209 . Tighten

t hem

crosswise, from one bolt to the (ap

proxima tely) opposi te one, to keep t he

wheel cente red.

Page 214 of 244

212 What do I do now?

When removing or installing the wheel,

the rim could hit the brake rotor and dam

age the rotor. Work carefully and have a

second person help you.

Never use the hexagonal socket in the han

dle of the screwdriver to loosen or t ighten

the wheel bolts.

- Pull the reversible b lade from the screw

driver before yo u use the hexagonal

socket in the handle to turn the whee l

bo lts.

- When mounting tires with

unid irectional

tread design

make sure the tread pat

tern is pointed the r ight way

~page 212.

- The wheel bolts should be clea n and easy

to tu rn . Check for d irt and corrosion on

the mat ing su rfaces of both th e whee l

and the h ub. Remove a ll dirt from these

su rfaces before remo unti ng the wheel.

Notes on wheel change

Pl ease read the informa tion ~ page 192, New

tires and replacing tires and wheels,

if you are

going to use a spare t ire which is different

from the tires on your vehicle.

After you change a tire :

-Check the tire pressure on the spare imme

diately after mounting .

- Have the wheel bolt tightening torque

che ck e d with a torqu e wrench a s soon as

possible b y your auth orized Audi dealer or

a qualified ser vice station .

- With steel and alloy wheel rims , the wheel

bolts are correctly tightened at a torque of

90 ft lb (1 20 Nm ).

- If y ou notice while changing a tire that the

wheel bolts are co rroded and difficult to

turn , then the y should be repl aced befo re

you check the t ightening torque . -

Repla ce the flat ti re with a new one and

have it installed on your veh icle a s soon as

possible. Remount the wheel cove r.

Until then , dr ive with extra care and at re

duced speed s.

_& WARNING

-

- If you are going to eq uip your vehicle

wit h tires or rims which differ from those

which were factory installed, then be

sure to read the information

9 page 192,

New tires and replacing tires and

wheels.

- Always store the tools secu rely i n lug

gage compartment. Othe rwise, in a n ac

cident or s udden maneuver they cou ld fly

forwa rd, causi ng injury to passengers in

the vehicle.

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed the

right direction.

A un idirectional tire can be identified by ar

rows on the sid ewall ,

which point in the direc

tion of the rota tion. Yo u m ust follow the

specified direction of rota tion. This is ne ces sa

r y in order fo r these tires to develop t heir op

timum character istics regard ing grip, road

noise, wear, and hydrop laning.

Page 215 of 244

Fuses and bulbs

Electrical fuses

Replacing fuses

Fuses that have blown will have metal strips

that have burned through.

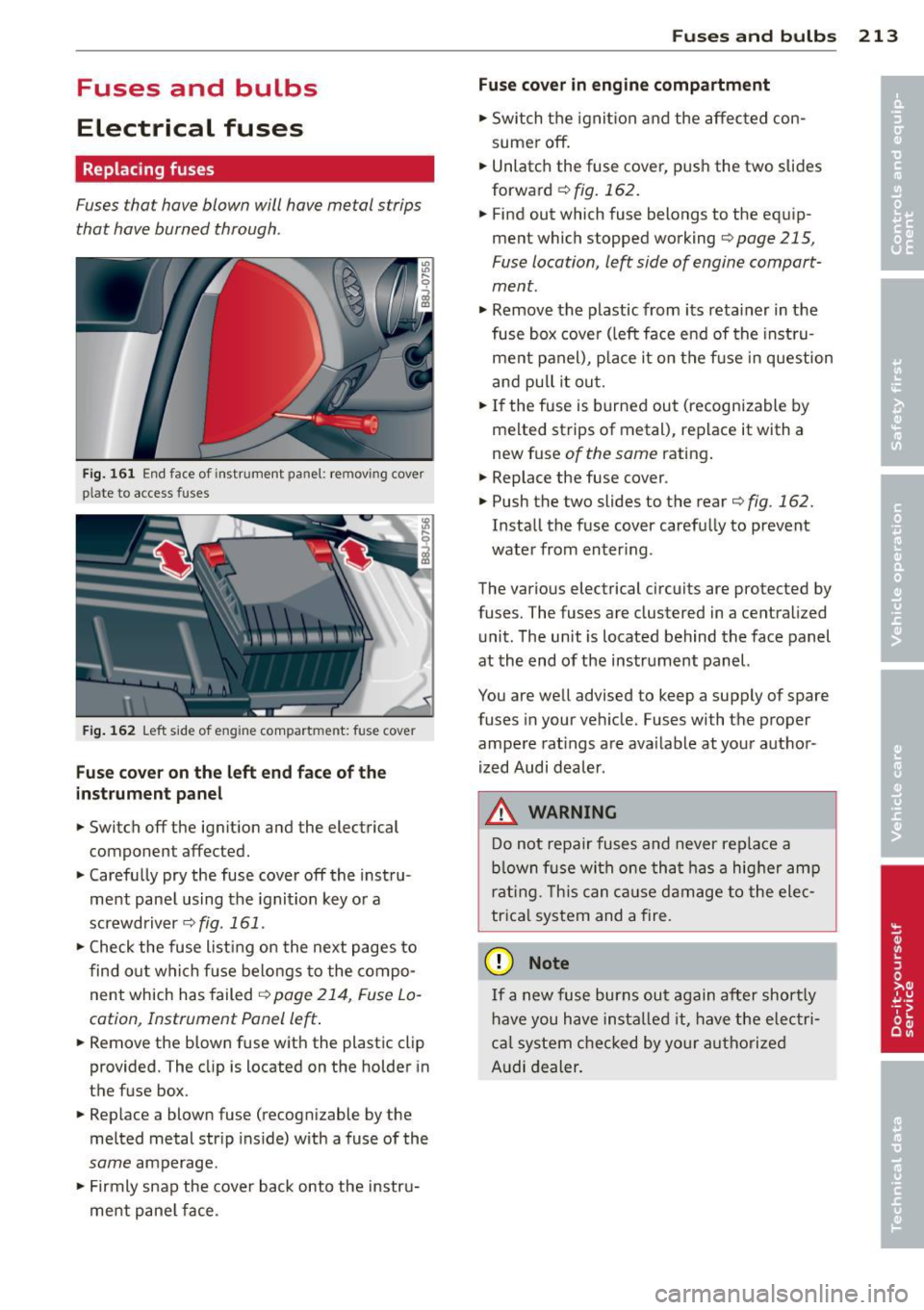

Fig. 161 End face of instrument panel: removing cover

p la te to access fuses

Fig . 162 Left side of eng ine compart ment: fuse cove r

Fuse cover on the left end face of the

instrument panel

.. Switch off the ignition and the electrical

component affected.

.. Carefully pry the fuse cover off the instru

ment panel using the ignition key or a

screwdriver

~ fig. 161 .

.. Check the fuse list ing on the next pages to

find out which f use belongs to the compo

nent which has failed

¢ page 214, Fuse Lo

cation, Instrument Panel left .

.. Remove the blown fuse with the plastic clip

provided. The clip is located on the holder in

t he fuse box .

.. Replace a blown fuse (recognizable by the

melted metal str ip inside) with a fuse of the

same amperage .

.. Firmly snap the cover back onto the instru

ment pane l face .

Fuses and bulbs 213

Fuse cover in engine compartment

.. Switch the ignit ion and the affected con

sumer off .

.. Unlatch the fuse cover, p ush the two slides

forward

~ fig. 162.

.. Fi nd out which fuse belongs to the equip

ment which stopped working

~page 215,

Fuse location, le~ side of engine compart

ment.

.. Remove the plastic from its retainer in the

fuse box cove r (left face end of the instru

ment panel), place it on the f use in question

and pull it out .

.. If the fuse is burned out (recogni zable by

melted strips of metal), replace it with a

new fuse

of the same rating .

.. Replace the fuse cover .

.. Push the two slides to the rear

¢ fig. 162.

Insta ll the fuse cover carefully to prevent

water from enter ing .

The various electrical circuits are protected by

fuses. The fuses are clustered in a centralized

unit. The unit is located behind the face panel

at the end of the instrument panel.

You are well advised to keep a supply of spare

fuses in your vehicle. Fuses with the proper

ampere ratings are available at your author

ized Audi dealer.

A WARNING

-

Do not repair fuses and never replace a

b lown fuse with one that has a higher amp

rating. This can cause damage to the elec

trica l system and a fire.

(D Note

If a new fuse burns out again after short ly

have you have installed it, have the electri

ca l system checked by your authorized

Audi dealer.

Page 216 of 244

214 Fuses and bulbs

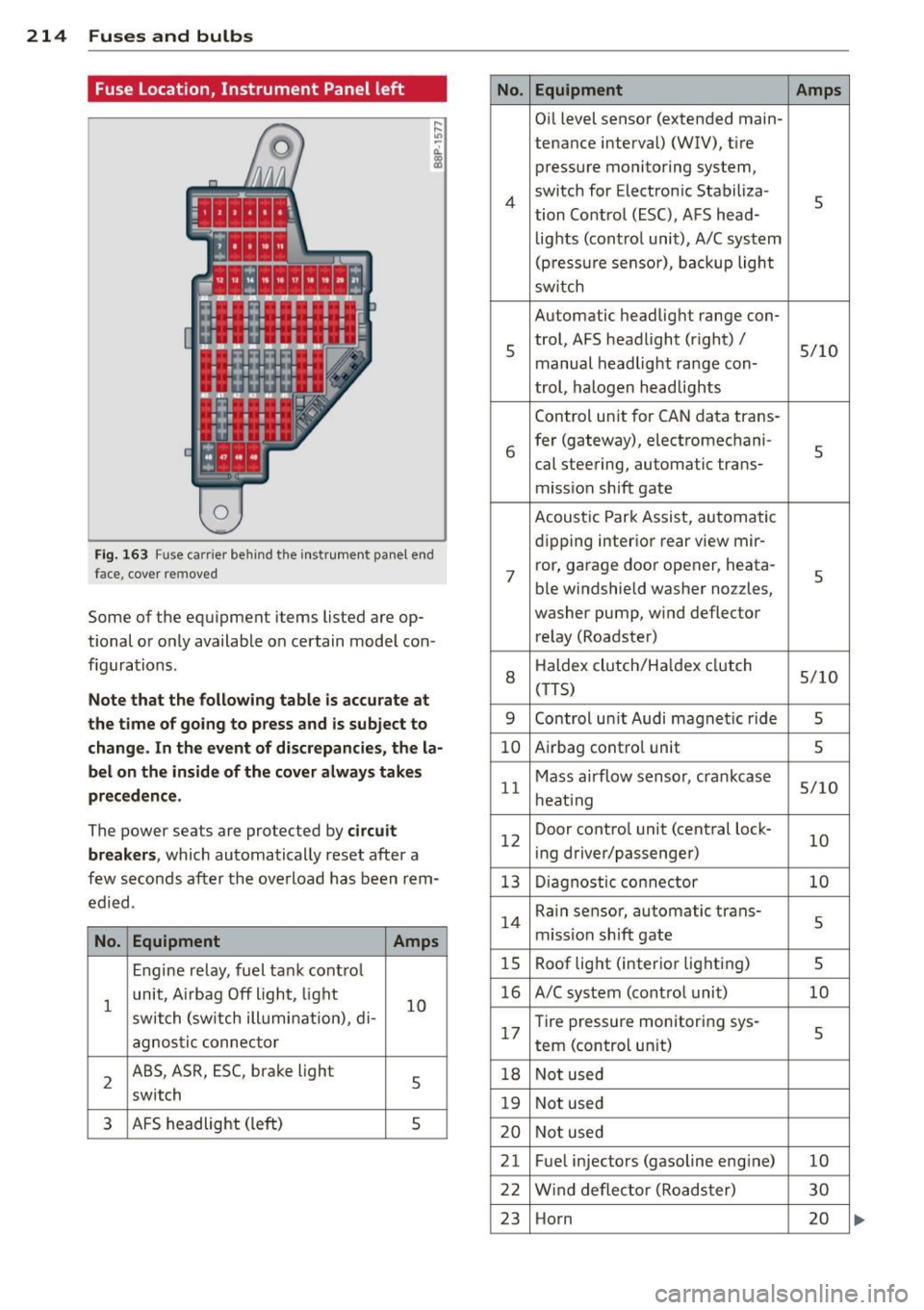

Fuse Location, Instrument Panel left

0

Fi g. 163 Fuse carrier behind the instrument panel end

face, cove r removed

Some of the equipment items listed are op

tional or only available on certain model con

figurations .

Note that the following table is accurate at

the time of going to press and is subject to

change. In the event of discrepancies, the la

bel on the inside of the cover always takes

preceden ce .

The power seats are protected by circuit

breaker s,

which automatically reset after a

few seconds after the overload has been rem

ed ied.

No . Equipment Amps

Engine relay, fuel tank control

1

unit, A irbag Off light, light

10 switch (sw itch illumination), d i-

agnos tic connector

2

ABS, ASR, ESC, brake light

5 switch

3 AFS headlight (left) s

No.

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Equipment Amps

Oil level sensor (extended main-

tena nce interval) (WIV), tire

pressure monitoring system,

switch for Electronic Stabiliza-

s tion Control (ESC), AFS head-

lights (control unit), A/C system

(pressure sensor), backup light

sw itch

Automatic headlight range con-

trol, AFS headlight (right) /

5/10

manual headlight range con-

trol, halogen headlights

Control unit for CAN data trans-

fer (gateway), electromechani-

s cal steering, automatic trans-

mission shift gate

Acoustic Park Assist, automatic

dipping interior rear view mir- ror, garage door opener, heata-

s ble windshield washer nozzles,

washer pump, wind deflector

relay (Roadster)

H aldex clutch/Ha ldex clutch

5/10 (T TS)

Control un it Audi magnetic ride

s

Airbag contro l unit s

Mass airflow sensor, crankcase 5/10

heating

Door control unit (central lock-

10 ing driver/passenger)

Diagnostic connector

10

Rain sensor, automatic trans-

s miss ion shift gate

Roof light (interior lighting)

5

A/C system (control unit) 10

Tire pressure monitoring sys-

5 tern (control un it)

Not used

Not used

Not used

Fuel injectors (gasoline engine)

10

Wind deflector (Roadster) 30

Horn 20

Page 217 of 244

No. Equipment 24 Transmission (control unit)

25 Heater rear window Coupe/

heated rear window Roadster

26 Driver's side power window

27 Passenger's s ide power window

28 Not used

29 Washer pump

30 Cigarette lighter

31 Starter

32 Steering column module

33 Instrument cluster

34 Radio navigation system, radio

35 Audio amplifier

36 Engine (control un it)

37 CAN (Gateway)

38 Cigarette lighter

39 Not used

40 Not used

41 Not used

42 Not used

43 Not used

44 Not used

45 Not used

46 Not used

47 SOARS

tuner, cell phone pack-

age, TV tuner

48 VOA inte rface

49 Not used

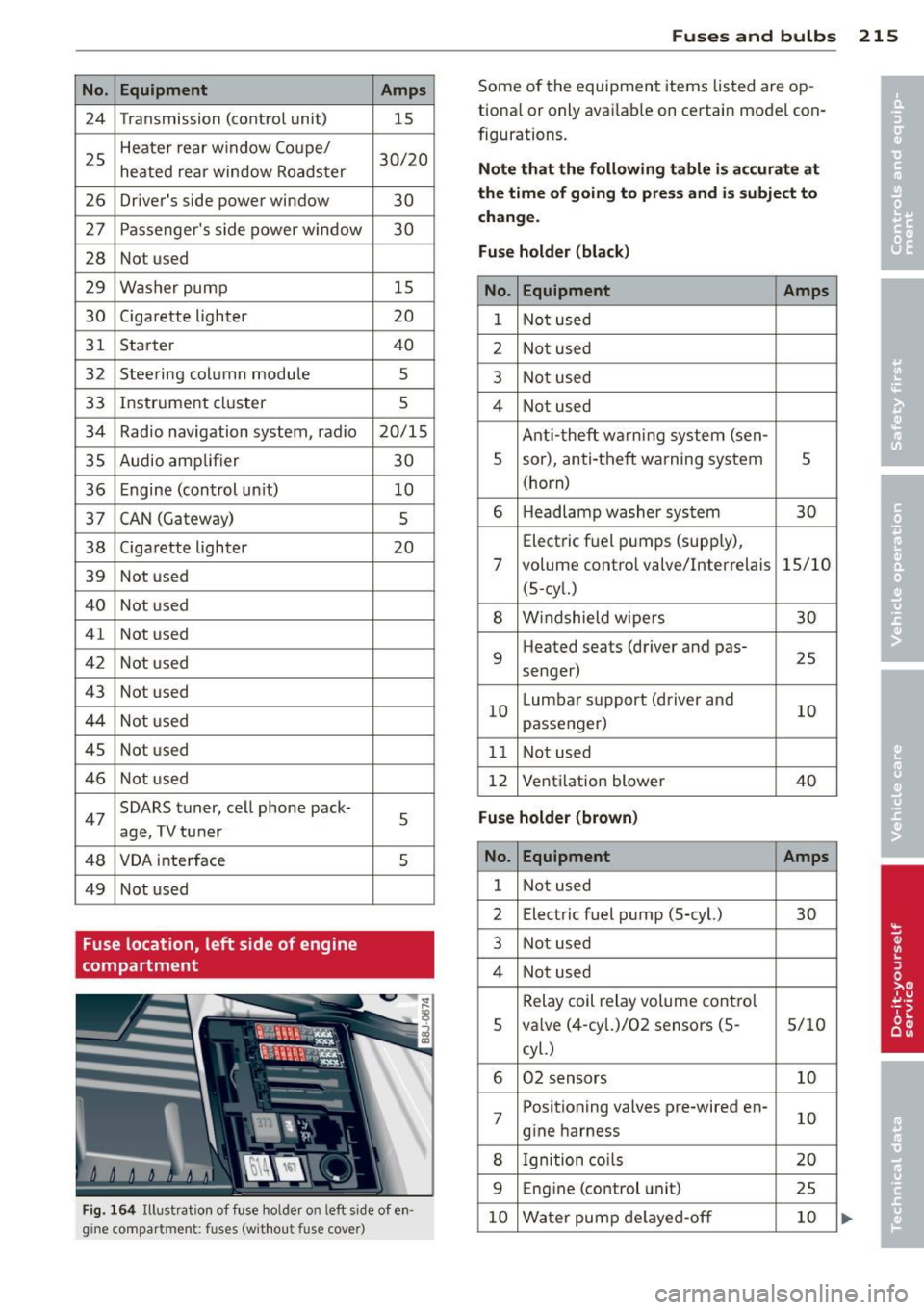

Fuse location, left side of engine

compartment Amps

15

30/20

30

30

15

20

40

5

5

20/15

30 10

5

20

5

5

Fig. 164 Illustrat ion of fuse ho lder on left side of en

gine compart ment: fuses (without fuse cover)

Fuse s and bulb s 215

Some of the equipment items listed are op

tiona l or only avai lab le on certain model con

figurations.

Note th at the foll owing t abl e is ac cur ate at

the time of going t o pre ss and i s subject to

ch ang e.

Fus e holder (bla ck )

No. Equipment Amps

1 Not used

2 Not used

3 Not used

4 Not used

Anti-theft warning system (sen-

5 sor), anti-theft warning system

5

(horn)

6 H

eadlamp washer system

30

Electric f uel pumps (supp ly),

7 volume contro l valve/Interrelais 15/10

(5-cy l.)

8 W indshield w ipers 30

9 Heated

seats (driver and pas-

25

senger)

10 L

umbar support (driver and

10

passenger)

11 Not used

12 Vent

ilation blower

40

Fu se holder (brown )

No. Equipment Amps

1 Not used

2 Electric

fuel pump (5-cyl.)

30

3 Not used

4 Not used

Relay coil relay volume cont ro l

5 va

lve (4-cy l.)/02 sensors (5 -

5/10

cyl.)

6 02 sensors 10

7 Positioning valves pre-wired en-

10

g ine harness

8 Ignition coi ls 20

9 Eng

ine (control unit)

25

10 Water pump de layed-off 10

Page 218 of 244

216 Fuse s a nd bul bs

No. Equipment Amps

11 Feed (brake pedal) 5

12

Activated charcoal fi lter/charge

10 pressure contro l valve

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace burned

out bulbs for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bulb . Th is appl ies especially to the l ight bulbs

in the front of your car which you can only

reach through the engine compartment.

Sheet metal and bulb holders can have sharp

edges that can cause ser ious cuts, and parts

must be co rrectly taken apart and then prop

e rly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been properly resealed.

For your safety, we recommend that you have

your author ized Audi dealer replace any bulbs

for you, since your dealer has the proper tools,

the correct bu lbs and the expertise.

Gas disc harg e la mps (X enon l ig ht s}*:

Due to the high electrical voltage, have the

bulbs replaced by a qualified technician.

Headlights with Xenon light can be identified

by the high voltage sticker.

A WARNING

Contact with high-voltage components of

the electrical system and improper re

placement of gas discharge (Xenon) head

light bulbs can cause serious personal in

jury and death.

- Xenon bulbs are pressurized and can ex

plode when being changed. -

Changing Xenon lamps requires the spe

cial tra ining, instructions and equip

ment.

- Only an authorized Audi dealer or other

qualified workshop should change the

bulbs in gas discharge lamps.

A WARNING

=

There are parts with sharp edges on the

openings and on the bulb holders that can

cause ser ious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified work

shop. Serious personal injury may result

from improperly performed work.

@ Tips

- If you must replace the light bulbs your

self, a lways remember that the eng ine

compartment of any vehicle is a hazard

ous area to work in. A lways read and

heed all WARNINGS

¢page 165, Work

ing in the engine compartment¢.&..

-It is best to ask your authorized Audi

dealer whenever yo u need to change a

bulb .

-

Page 219 of 244

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equipment to

perform these operations.

Starting by pushing or

towing

(D Note

Vehicles with an automatic transmission

cannot be started by pushing or towing .

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumper cables to start the en

g ine.

Jumper cables

Use only jumper cables of sufficiently

largecross section to safely carry the starter

current. Refer to the manufacturer's specifica

tions.

Use only jumper cables which have

insulated

termina l clamps and are properly marked for

distinction :

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black.

_& WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal

injury. Follow the instructions below for

safe handling of your vehicle's battery.

- Always shield you r eyes and avoid lean

ing over the battery whenever possible.

Emergency situations 21 7

-A discharged battery can already freeze

at temperatures just below 32 °F (0 °C).

Before connect ing a jumper cable, the

frozen battery must be thawed com

pletely, otherwise it could explode .

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

water immediately .

- Improper use of a booster battery to

start a vehicle may cause an explosion.

- Vehicle batter ies generate explosive gas

es. Keep sparks, flame and lighted c iga

rettes away from batteries.

- Do not try to jump start any veh icle w ith

a low ac id level in the battery.

- The voltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery. Use of batteries of diff erent voltage

or substantially different "Ah" rat ing

may cause an exp losion and personal in

jury.

- Never charge a frozen battery. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen . The battery case may have

be weakened.

- Use of batter ies of different voltage or

substantially different capacity (Ah) rat

ing may cause an exp losion and injury .

The ca pa city (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

c::;,page 165, Working in the

engine compartment.

(D Note

- App lying a higher voltage booster bat

tery will cause expensive damage to sen

sit ive electronic components, such as

control units, relays, rad io, etc .

- There must be no electrical contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

posit ive(+) terminals are connected. ..,. •

•

Page 220 of 244

218 Emergency situations

@ Tips

The discharged battery must be properly

connected to the vehicle's electrical sys

tem.

Use of jumper cables

Make sure to connect the jumper coble

clomps in exactly the order described below!

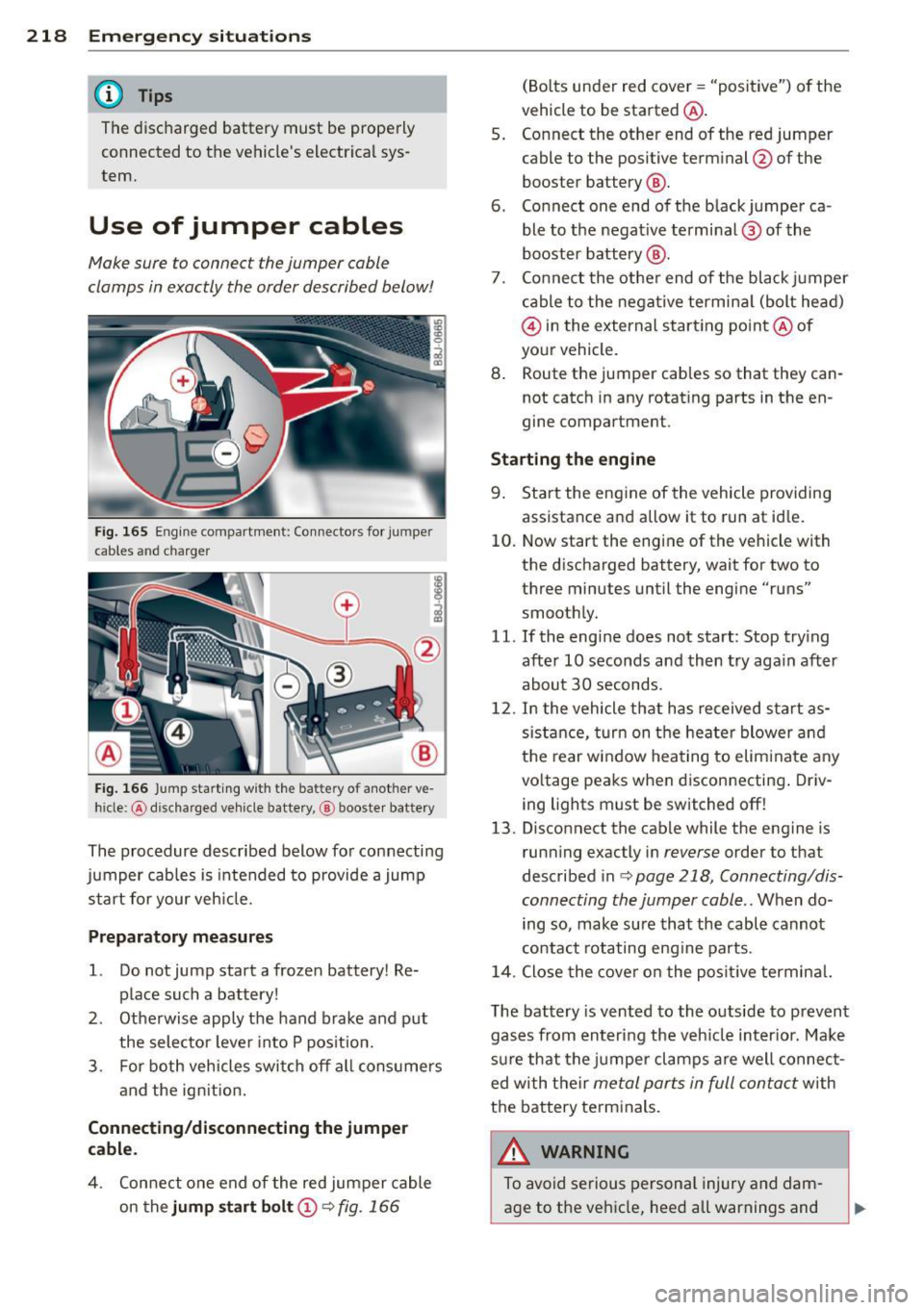

Fig. 165 Engine compart ment: Co nnectors for jumper

cables and charger

Fig. 166 Jump starting with the battery of another ve

hicle: @discharged veh icle batte ry,® booste r battery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your veh icle.

Preparatory measures

1. Do not jump start a frozen battery! Re

place such a battery!

2 . Otherwise apply the hand brake and put

the selector lever into P position.

3. For both vehicles switch off all consumers

and the ign ition.

Connecting/disconnecting the jumper

cable .

4. Connect one end of the red jumper cable

on the

jump start bolt@q fig. 166

(Bolts under red cover = "positive") of the

vehicle to be started @.

5. Connect the other end of the red jumper

cable to the positive terminal @of the

booster battery @.

6. Connect one end of the black jumper ca

ble to the negat ive terminal @of the

booster battery @.

7. Connect the other end of the black jumper

cable to the negative terminal (bolt head)

@ in the external start ing point @ of

your vehicle.

8. Route the jumper cables so that they can

not catch in any rotating parts in the en

gine compartment.

Starting the engine

9. Start the engine of the vehicle providing

assistance and allow it to run at id le .

10. Now start the engine of the vehicle with

the discharged battery, wait for two to

three minutes until the engine "runs"

smoothly.

11. If the eng ine does not start: Stop try ing

after 10 seconds and then try again after

about 30 seconds.

12. In the vehicle that has received start as

sistance, turn on the heater blower and

the rear window heating to elim inate any

vo ltage peaks when disconnecting . Driv

ing lights must be switched off!

13 . Disconnect the cable while the engine is

running exactly in

reverse order to that

described in¢

page 218, Connecting/dis

connecting the jumper coble ..

When do

ing so, make sure that the cable cannot

contact rotating eng ine parts.

14. Close the cover on the positive terminal.

The battery is vented to the outside to prevent

gases from entering the vehicle inter ior. Make

sure that the jumper clamps are well connect

ed with their

metal parts in full contact with

the battery terminals.

A WARNING ~

To avoid serious personal injury and dam-

age to the vehicle, heed all warnings and