CHERY TIGGO 2009 Service Owner's Guide

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 31 of 1903

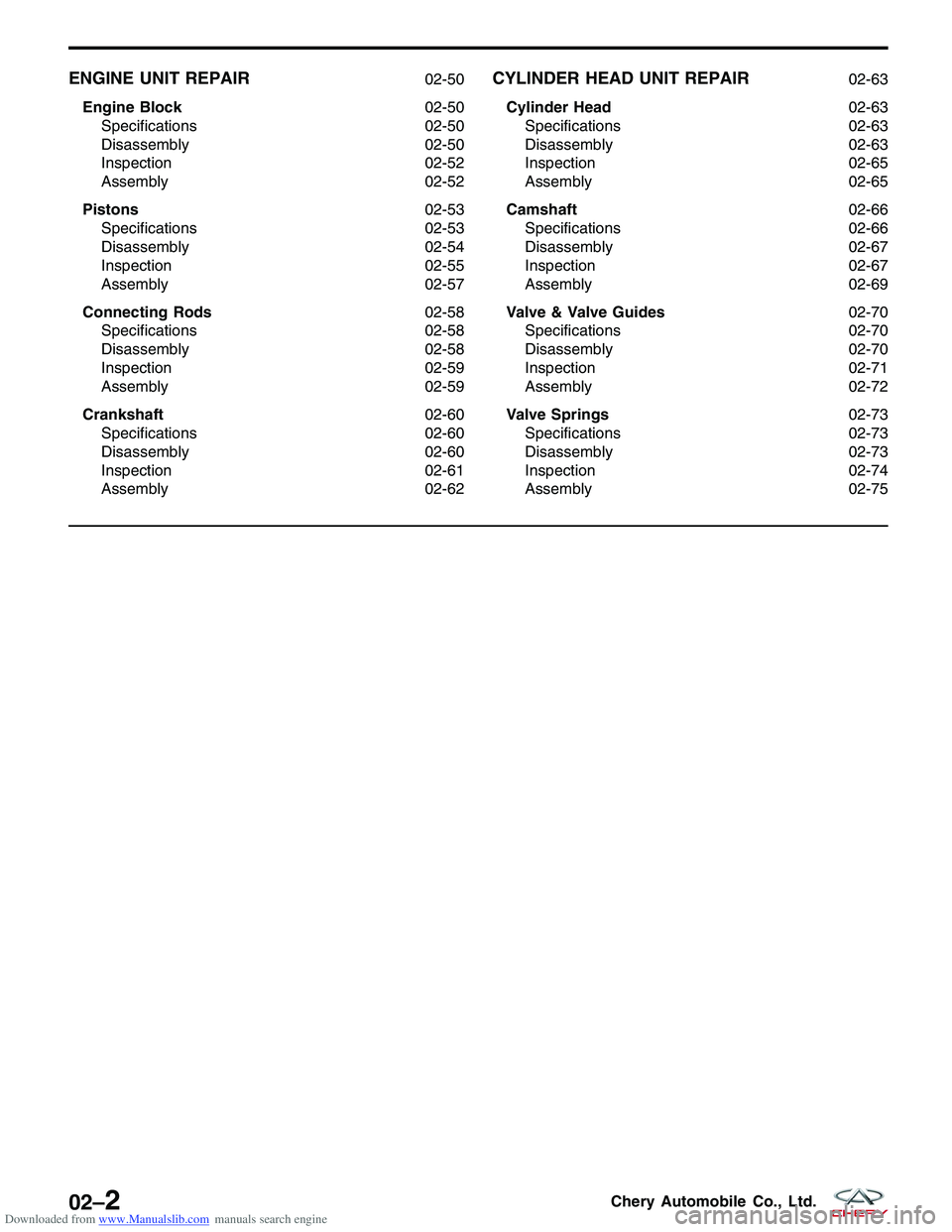

Downloaded from www.Manualslib.com manuals search engine ENGINE UNIT REPAIR02-50

Engine Block 02-50

Specifications 02-50

Disassembly 02-50

Inspection 02-52

Assembly 02-52

Pistons 02-53

Specifications 02-53

Disassembly 02-54

Inspection 02-55

Assembly 02-57

Connecting Rods 02-58

Specifications 02-58

Disassembly 02-58

Inspection 02-59

Assembly 02-59

Crankshaft 02-60

Specifications 02-60

Disassembly 02-60

Inspection 02-61

Assembly 02-62CYLINDER HEAD UNIT REPAIR02-63

Cylinder Head 02-63

Specifications 02-63

Disassembly 02-63

Inspection 02-65

Assembly 02-65

Camshaft 02-66

Specifications 02-66

Disassembly 02-67

Inspection 02-67

Assembly 02-69

Valve & Valve Guides 02-70

Specifications 02-70

Disassembly 02-70

Inspection 02-71

Assembly 02-72

Valve Springs 02-73

Specifications 02-73

Disassembly 02-73

Inspection 02-74

Assembly 02-75

02–2Chery Automobile Co., Ltd.

Page 32 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

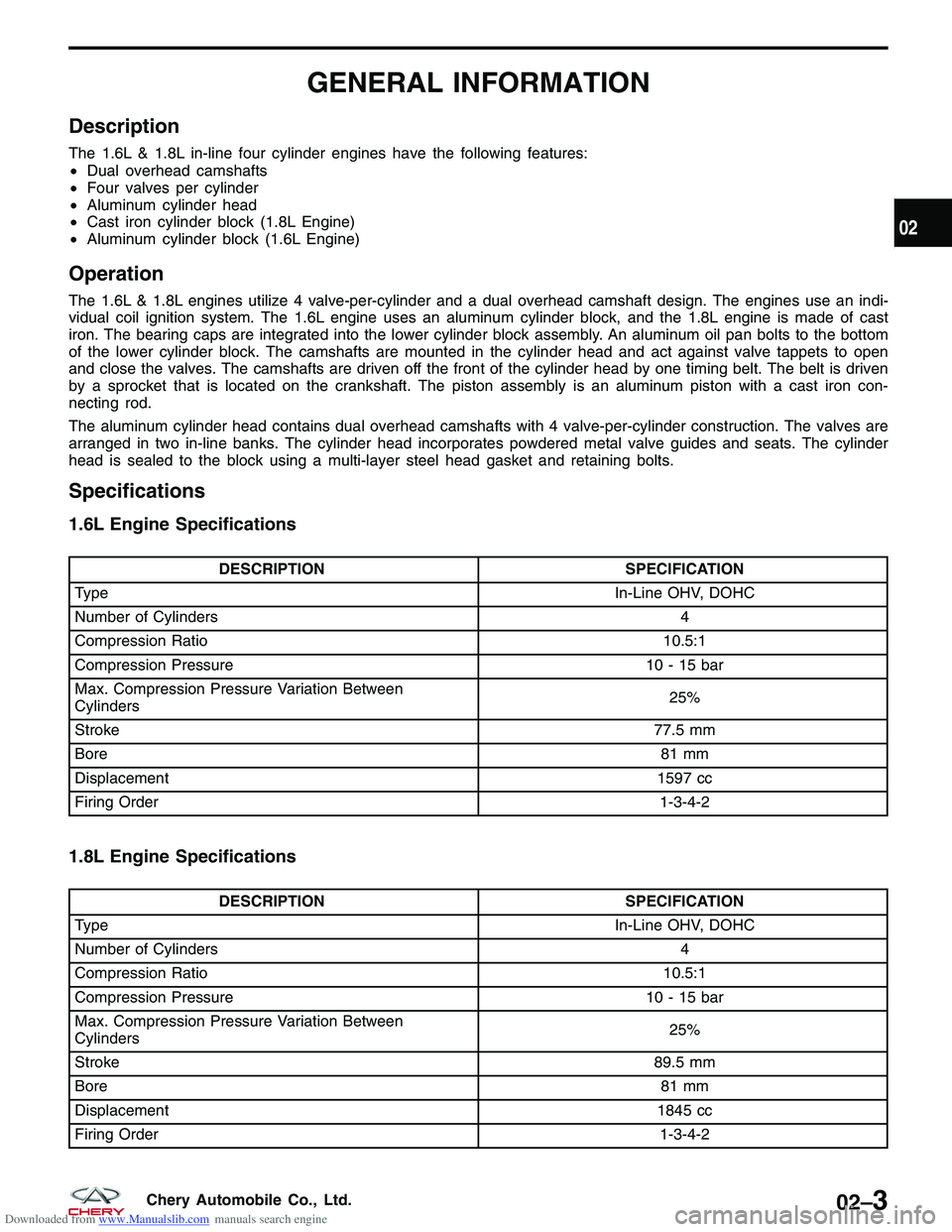

Description

The 1.6L & 1.8L in-line four cylinder engines have the following features:

•Dual overhead camshafts

• Four valves per cylinder

• Aluminum cylinder head

• Cast iron cylinder block (1.8L Engine)

• Aluminum cylinder block (1.6L Engine)

Operation

The 1.6L & 1.8L engines utilize 4 valve-per-cylinder and a dual overhead camshaft design. The engines use an indi-

vidual coil ignition system. The 1.6L engine uses an aluminum cylinder block, and the 1.8L engine is made of cast

iron. The bearing caps are integrated into the lower cylinder block assembly. An aluminum oil pan bolts to the bottom

of the lower cylinder block. The camshafts are mounted in the cylinder head and act against valve tappets to open

and close the valves. The camshafts are driven off the front of the cylinder head by one timing belt. The belt is driven

by a sprocket that is located on the crankshaft. The piston assembly is an aluminum piston with a cast iron con-

necting rod.

The aluminum cylinder head contains dual overhead camshafts with 4 valve-per-cylinder construction. The valves are

arranged in two in-line banks. The cylinder head incorporates powdered metal valve guides and seats. The cylinder

head is sealed to the block using a multi-layer steel head gasket and retaining bolts.

Specifications

1.6L Engine Specifications

DESCRIPTION SPECIFICATION

Type In-Line OHV, DOHC

Number of Cylinders 4

Compression Ratio 10.5:1

Compression Pressure 10 - 15 bar

Max. Compression Pressure Variation Between

Cylinders 25%

Stroke 77.5 mm

Bore 81 mm

Displacement 1597 cc

Firing Order 1-3-4-2

1.8L Engine Specifications

DESCRIPTIONSPECIFICATION

Type In-Line OHV, DOHC

Number of Cylinders 4

Compression Ratio 10.5:1

Compression Pressure 10 - 15 bar

Max. Compression Pressure Variation Between

Cylinders 25%

Stroke 89.5 mm

Bore 81 mm

Displacement 1845 cc

Firing Order 1-3-4-2

02

02–3Chery Automobile Co., Ltd.

Page 33 of 1903

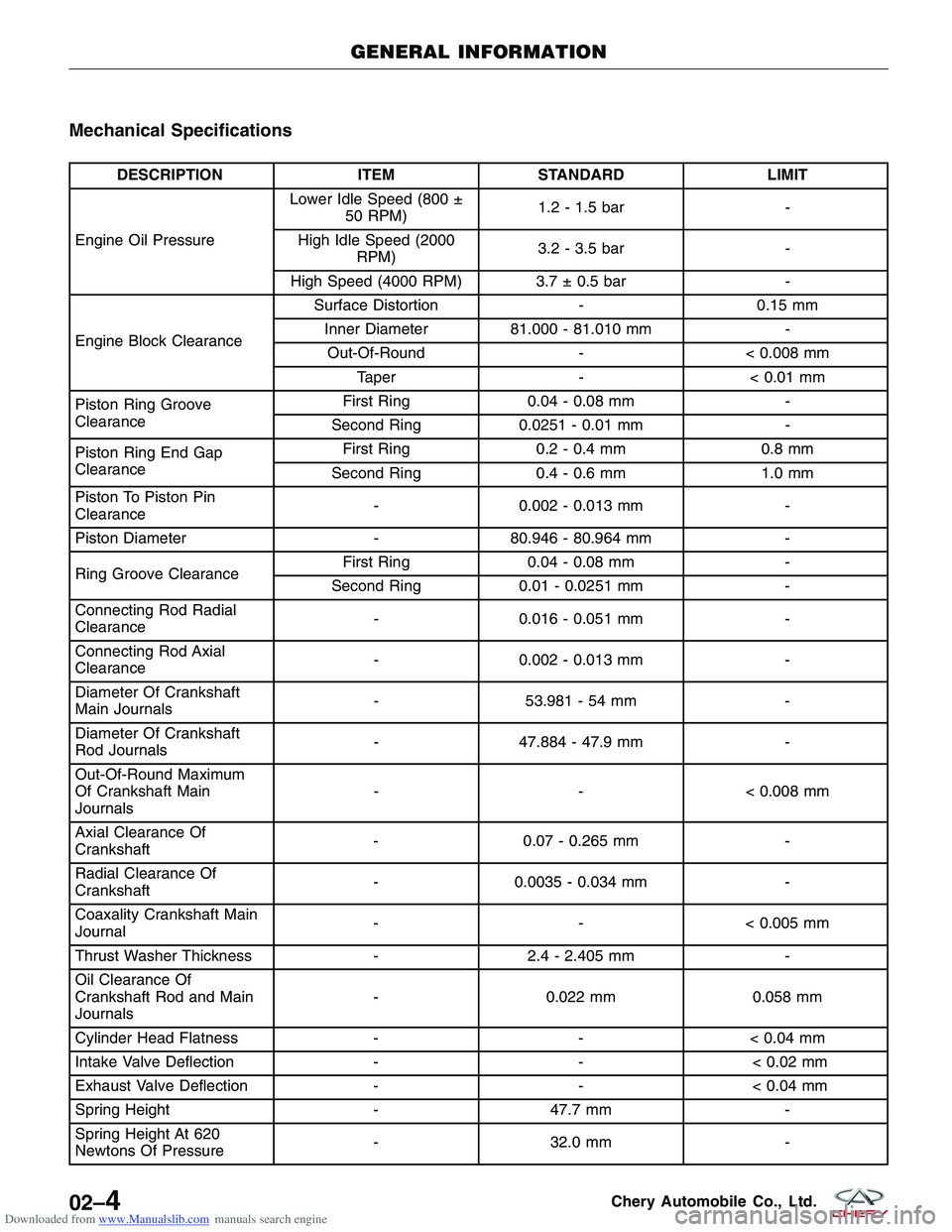

Downloaded from www.Manualslib.com manuals search engine Mechanical Specifications

DESCRIPTIONITEMSTANDARD LIMIT

Engine Oil Pressure Lower Idle Speed (800 ±

50 RPM) 1.2 - 1.5 bar

-

High Idle Speed (2000 RPM) 3.2 - 3.5 bar

-

High Speed (4000 RPM) 3.7 ± 0.5 bar -

Engine Block Clearance Surface Distortion

-0.15 mm

Inner Diameter 81.000 - 81.010 mm -

Out-Of-Round -< 0.008 mm

Taper -< 0.01 mm

Piston Ring Groove

Clearance First Ring

0.04 - 0.08 mm -

Second Ring 0.0251 - 0.01 mm -

Piston Ring End Gap

Clearance First Ring

0.2 - 0.4 mm 0.8 mm

Second Ring 0.4 - 0.6 mm 1.0 mm

Piston To Piston Pin

Clearance -

0.002 - 0.013 mm -

Piston Diameter -80.946 - 80.964 mm -

Ring Groove Clearance First Ring

0.04 - 0.08 mm -

Second Ring 0.01 - 0.0251 mm -

Connecting Rod Radial

Clearance -

0.016 - 0.051 mm -

Connecting Rod Axial

Clearance -

0.002 - 0.013 mm -

Diameter Of Crankshaft

Main Journals -

53.981 - 54 mm -

Diameter Of Crankshaft

Rod Journals -

47.884 - 47.9 mm -

Out-Of-Round Maximum

Of Crankshaft Main

Journals -

-< 0.008 mm

Axial Clearance Of

Crankshaft -

0.07 - 0.265 mm -

Radial Clearance Of

Crankshaft -

0.0035 - 0.034 mm -

Coaxality Crankshaft Main

Journal -

-< 0.005 mm

Thrust Washer Thickness -2.4 - 2.405 mm -

Oil Clearance Of

Crankshaft Rod and Main

Journals -

0.022 mm 0.058 mm

Cylinder Head Flatness --< 0.04 mm

Intake Valve Deflection --< 0.02 mm

Exhaust Valve Deflection --< 0.04 mm

Spring Height -47.7 mm -

Spring Height At 620

Newtons Of Pressure -

32.0 mm -

GENERAL INFORMATION

02–4Chery Automobile Co., Ltd.

Page 34 of 1903

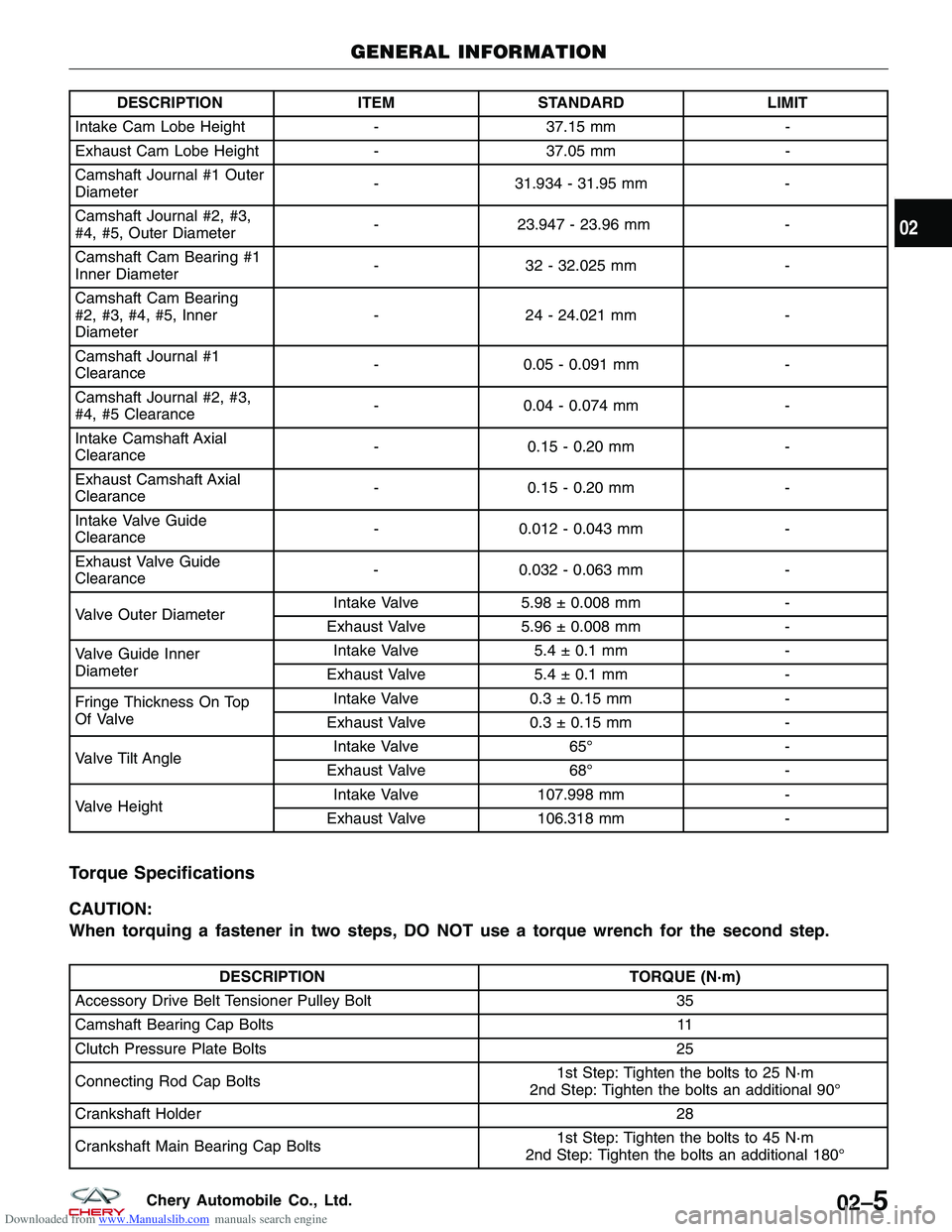

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONITEMSTANDARD LIMIT

Intake Cam Lobe Height -37.15 mm -

Exhaust Cam Lobe Height -37.05 mm -

Camshaft Journal #1 Outer

Diameter -

31.934 - 31.95 mm -

Camshaft Journal #2, #3,

#4, #5, Outer Diameter -

23.947 - 23.96 mm -

Camshaft Cam Bearing #1

Inner Diameter -

32 - 32.025 mm -

Camshaft Cam Bearing

#2, #3, #4, #5, Inner

Diameter -

24 - 24.021 mm -

Camshaft Journal #1

Clearance -

0.05 - 0.091 mm -

Camshaft Journal #2, #3,

#4, #5 Clearance -

0.04 - 0.074 mm -

Intake Camshaft Axial

Clearance -

0.15 - 0.20 mm -

Exhaust Camshaft Axial

Clearance -

0.15 - 0.20 mm -

Intake Valve Guide

Clearance -

0.012 - 0.043 mm -

Exhaust Valve Guide

Clearance -

0.032 - 0.063 mm -

Valve Outer Diameter Intake Valve

5.98 ± 0.008 mm -

Exhaust Valve 5.96 ± 0.008 mm -

Valve Guide Inner

Diameter Intake Valve

5.4 ± 0.1 mm -

Exhaust Valve 5.4 ± 0.1 mm -

Fringe Thickness On Top

Of Valve Intake Valve

0.3 ± 0.15 mm -

Exhaust Valve 0.3 ± 0.15 mm -

Valve Tilt Angle Intake Valve

65°-

Exhaust Valve 68°-

Valve Height Intake Valve

107.998 mm -

Exhaust Valve 106.318 mm -

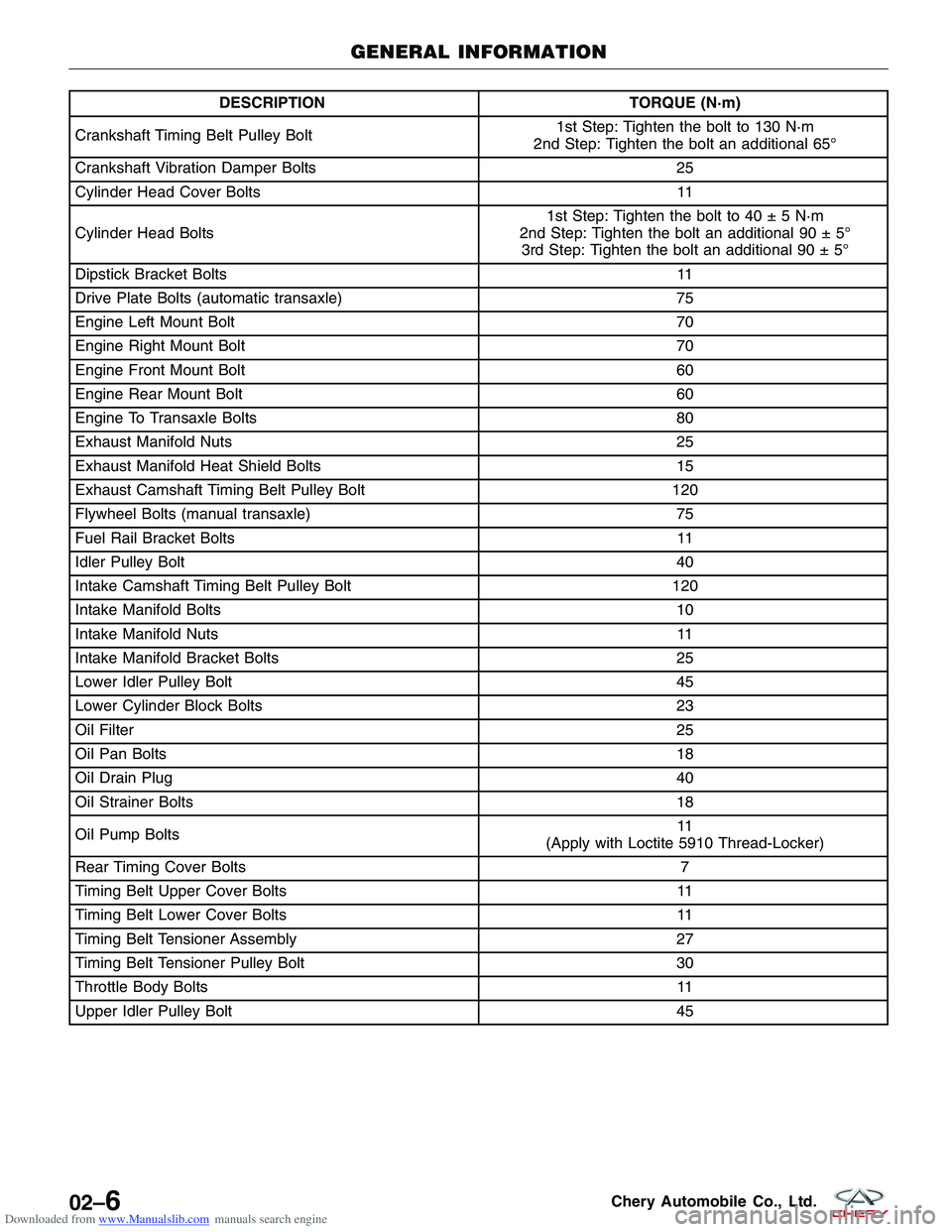

Torque Specifications

CAUTION:

When torquing a fastener in two steps, DO NOT use a torque wrench for the second step.

DESCRIPTION TORQUE (N·m)

Accessory Drive Belt Tensioner Pulley Bolt 35

Camshaft Bearing Cap Bolts 11

Clutch Pressure Plate Bolts 25

Connecting Rod Cap Bolts 1st Step: Tighten the bolts to 25 N·m

2nd Step: Tighten the bolts an additional 90°

Crankshaft Holder 28

Crankshaft Main Bearing Cap Bolts 1st Step: Tighten the bolts to 45 N·m

2nd Step: Tighten the bolts an additional 180°

GENERAL INFORMATION

02

02–5Chery Automobile Co., Ltd.

Page 35 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONTORQUE (N·m)

Crankshaft Timing Belt Pulley Bolt 1st Step: Tighten the bolt to 130 N·m

2nd Step: Tighten the bolt an additional 65°

Crankshaft Vibration Damper Bolts 25

Cylinder Head Cover Bolts 11

Cylinder Head Bolts 1st Step: Tighten the bolt to 40 ± 5 N·m

2nd Step: Tighten the bolt an additional 90 ± 5° 3rd Step: Tighten the bolt an additional 90 ± 5°

Dipstick Bracket Bolts 11

Drive Plate Bolts (automatic transaxle) 75

Engine Left Mount Bolt 70

Engine Right Mount Bolt 70

Engine Front Mount Bolt 60

Engine Rear Mount Bolt 60

Engine To Transaxle Bolts 80

Exhaust Manifold Nuts 25

Exhaust Manifold Heat Shield Bolts 15

Exhaust Camshaft Timing Belt Pulley Bolt 120

Flywheel Bolts (manual transaxle) 75

Fuel Rail Bracket Bolts 11

Idler Pulley Bolt 40

Intake Camshaft Timing Belt Pulley Bolt 120

Intake Manifold Bolts 10

Intake Manifold Nuts 11

Intake Manifold Bracket Bolts 25

Lower Idler Pulley Bolt 45

Lower Cylinder Block Bolts 23

Oil Filter 25

Oil Pan Bolts 18

Oil Drain Plug 40

Oil Strainer Bolts 18

Oil Pump Bolts 11

(Apply with Loctite 5910 Thread-Locker)

Rear Timing Cover Bolts 7

Timing Belt Upper Cover Bolts 11

Timing Belt Lower Cover Bolts 11

Timing Belt Tensioner Assembly 27

Timing Belt Tensioner Pulley Bolt 30

Throttle Body Bolts 11

Upper Idler Pulley Bolt 45

GENERAL INFORMATION

02–6Chery Automobile Co., Ltd.

Page 36 of 1903

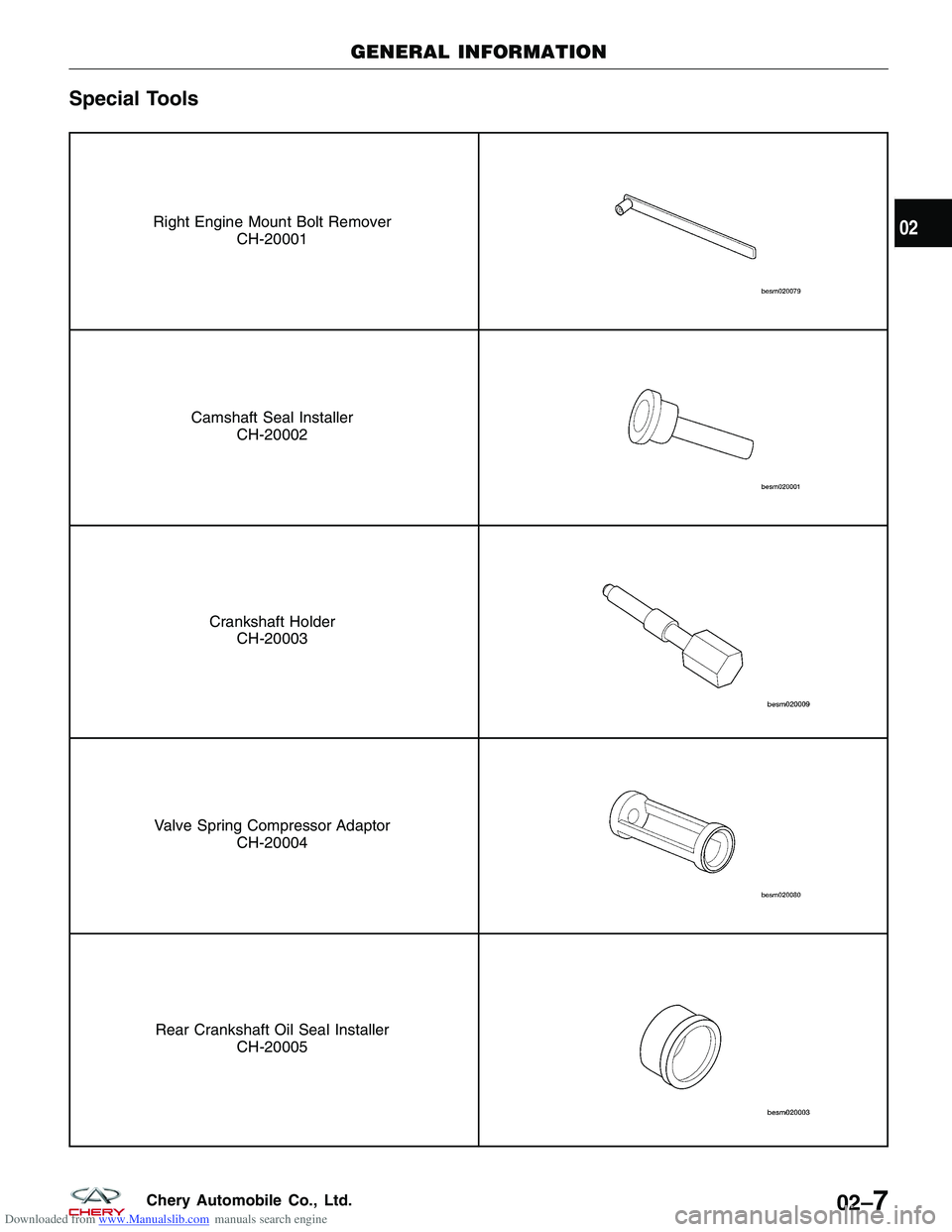

Downloaded from www.Manualslib.com manuals search engine Special Tools

Right Engine Mount Bolt RemoverCH-20001

Camshaft Seal InstallerCH-20002

Crankshaft HolderCH-20003

Valve Spring Compressor Adaptor CH-20004

Rear Crankshaft Oil Seal InstallerCH-20005

GENERAL INFORMATION

02

02–7Chery Automobile Co., Ltd.

Page 37 of 1903

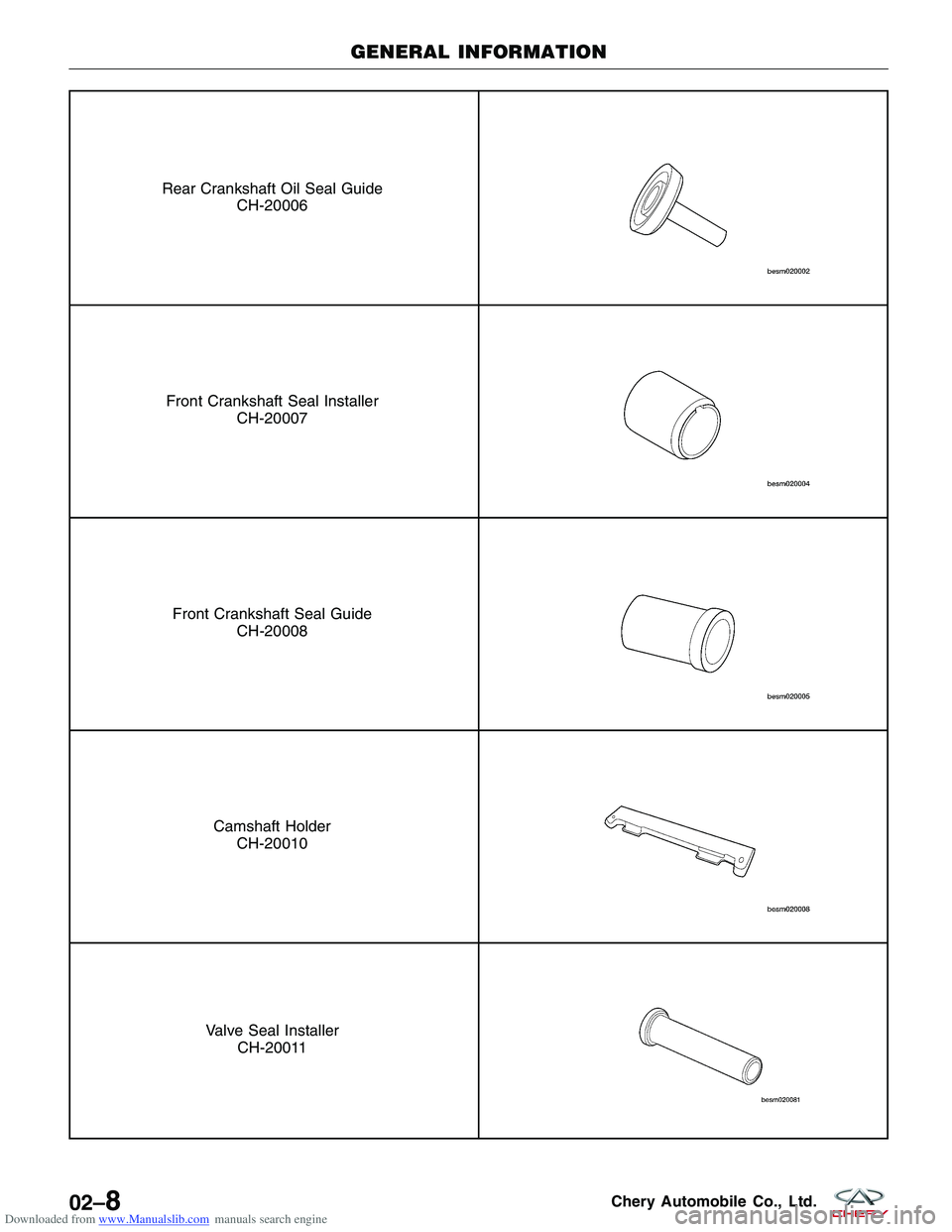

Downloaded from www.Manualslib.com manuals search engine Rear Crankshaft Oil Seal GuideCH-20006

Front Crankshaft Seal InstallerCH-20007

Front Crankshaft Seal GuideCH-20008

Camshaft HolderCH-20010

Valve Seal Installer CH-20011

GENERAL INFORMATION

02–8Chery Automobile Co., Ltd.

Page 38 of 1903

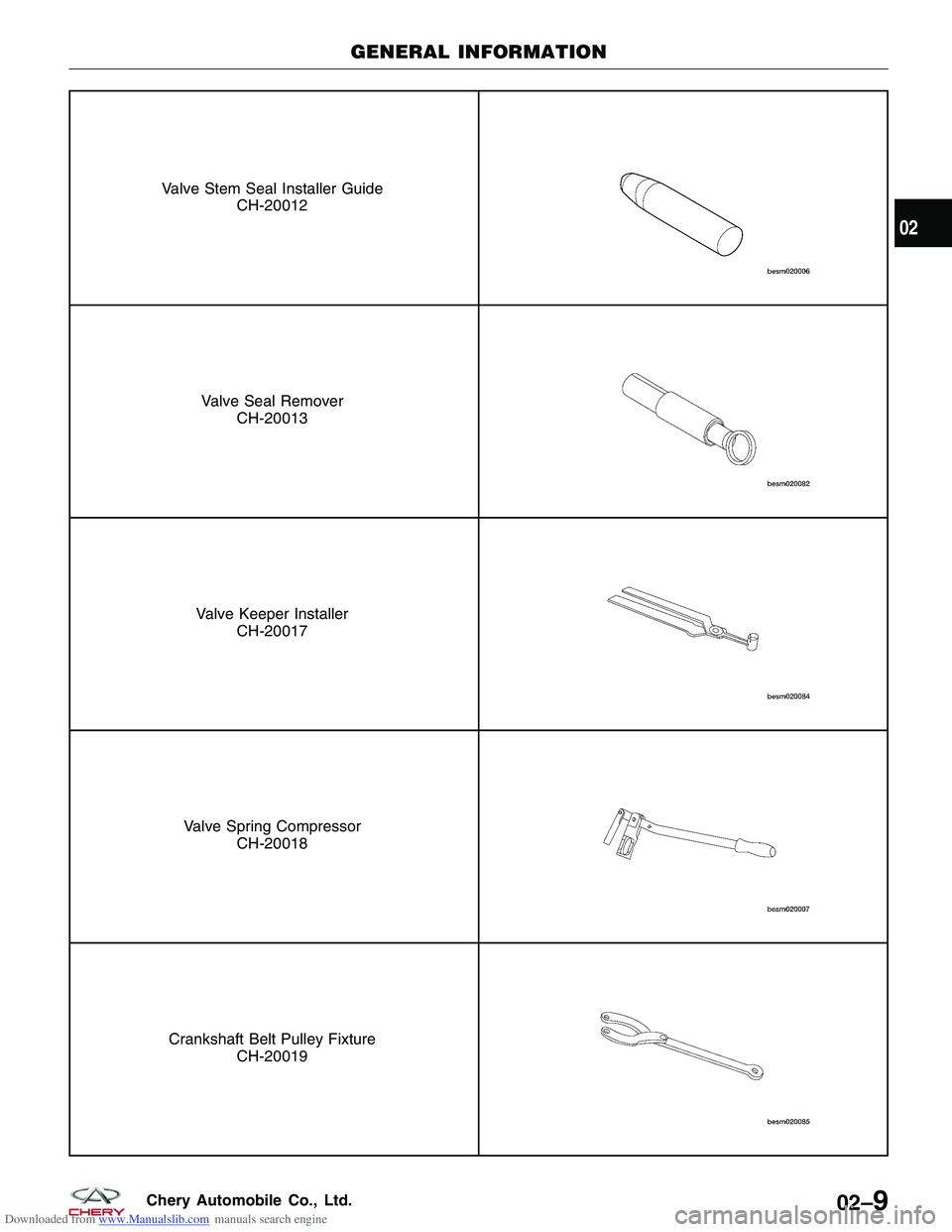

Downloaded from www.Manualslib.com manuals search engine Valve Stem Seal Installer GuideCH-20012

Valve Seal RemoverCH-20013

Valve Keeper Installer CH-20017

Valve Spring Compressor CH-20018

Crankshaft Belt Pulley Fixture CH-20019

GENERAL INFORMATION

02

02–9Chery Automobile Co., Ltd.

Page 39 of 1903

Downloaded from www.Manualslib.com manuals search engine Flywheel FixtureCH-20043

Engine Hoist

Oil Filter Remover CH-10003

Lubrication System

The engine lubrication system operates as follows:

•Oil is drawn into the oil pump through the oil pump strainer tube in the sump of the oil pan.

• Oil is pumped through the oil filter on the cylinder block.

• Oil enters the main oil gallery where it is distributed to the crankshaft main journals and to the cylinder head.

• From the main journals, the oil is routed through cross-drilled passages in the crankshaft to lubricate the con-

necting rod bearings. Controlled leakage through the crankshaft main bearings and connecting rod bearings is

slung radially outward to cool and lubricate the cylinder walls as well as the entire connecting rod, piston and

piston ring assembly.

• The engine lubrication system is a full-flow filtration, pressure feed type. The oil pump body is mounted to the

engine block. The pump inner rotor is driven by the crankshaft.

Engine Oil Pressure Specifications

Lower Idle Speed (800 ± 50 RPM) 1.2 - 1.5 bar

High Idle Speed (2000 RPM) 3.2 - 3.5 bar

High Speed (4000 RPM) 3.7 ± 0.5 bar

GENERAL INFORMATION

02–10Chery Automobile Co., Ltd.

Page 40 of 1903

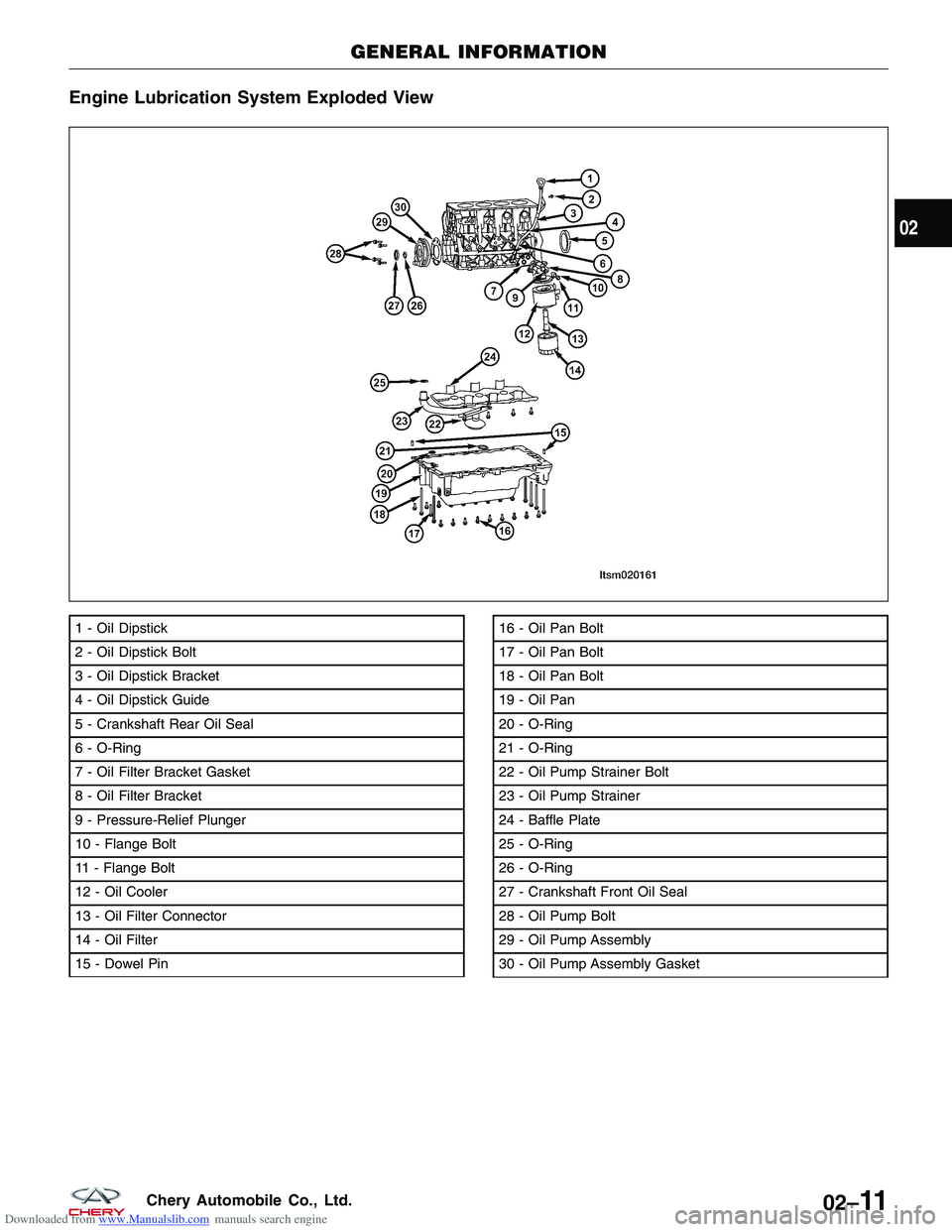

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System Exploded View

1 - Oil Dipstick

2 - Oil Dipstick Bolt

3 - Oil Dipstick Bracket

4 - Oil Dipstick Guide

5 - Crankshaft Rear Oil Seal

6 - O-Ring

7 - Oil Filter Bracket Gasket

8 - Oil Filter Bracket

9 - Pressure-Relief Plunger

10 - Flange Bolt

11 - Flange Bolt

12 - Oil Cooler

13 - Oil Filter Connector

14 - Oil Filter

15 - Dowel Pin16 - Oil Pan Bolt

17 - Oil Pan Bolt

18 - Oil Pan Bolt

19 - Oil Pan

20 - O-Ring

21 - O-Ring

22 - Oil Pump Strainer Bolt

23 - Oil Pump Strainer

24 - Baffle Plate

25 - O-Ring

26 - O-Ring

27 - Crankshaft Front Oil Seal

28 - Oil Pump Bolt

29 - Oil Pump Assembly

30 - Oil Pump Assembly Gasket

GENERAL INFORMATION

LTSM020161

02

02–11Chery Automobile Co., Ltd.