CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 481 of 659

SECTION 10

WHEELS AND TIRES

INDEX

Page

General Description

10-1

Maintenance

and

Adjustments

.............. 10—1

Tires

10-1

Pressures . 10-1

Inspection 10-1

Wear 10-1

Rotation 10-4

Noise 10-4

Cleaning 10-4

Change (W/Wheels) 10-4

Wheels 10-5

Static Balancing (w/Tire) 10-5

Page

Dynamic Balancing (w/Tire) . 10-5

Run Out (w/o Tire) 10-5

Cleaning 10-5

Service Operations 10-5

Tires 10-5

Removal 10-5

Installation 10-5

Repair 10^6

Wheels . 10-6

Valve Assembly 10-6

Repair (Rim) 10-7

GENERAL DESCRIPTION

WHEELS

Chevrolet, Chevelle, Camaro, Chevy n, and Corvette

are base equipped with welded steel wheels. Five studs

with nuts fasten each wheel to the front hub or rear axle

flange. Disc brake equipped vehicles (except Chevrolet

and Corvette) require special 14 inch diameter wheels

with a revised design for clearance, Chevrolet disc brake

equipped vehicles have 15 in. diameter wheels as do all

Corvettes.

Chevrolet station wagons, Chevelle Super Sport 396,

Corvette and Camaro Super Sport 350 are base equipped

with 6 in. width wheels. All other vehicles have 5 in.

width wheels, except Chevy n 100, 300 and 500 Series

Sedans, which have 4 in. width wheels.

Do not install 6 inch width wheels or snow chains on

Chevrolets equipped with rear fender skirts.

TIRES

The factory installed tires on Chevrolet passenger

cars are selected to provide the best all around tire

performance for all normal operation. They are de-

signed to operate satisfactorily with loads up to and in-

cluding the specified full rated load capacity of the

automobile when inflated as recommended in the Vehicle

Capacity Rating and Recommended Tire Inflation Pres-

sures Table (see Specifications).

Optional Oversize and 8-Ply Rating Tires

{Chevrolet and Chevelle Only)

Oversize or 8-ply rating tires are not necessary on

passenger cars for normal requirements. However, an

extra margin of tire service is available when these

options are used at loads up to and including full rated

load.

Optional oversize 4-ply rating and/or 8-ply rating

tires are available on models as indicated in the Tire

Usage Chart (see Specifications). On some models (ex-

ample—Station Wagon), space limitations do not permit

the use of a larger size tire; hence, the 8-ply rating

tire is an available option.

In either case, these tires are applicable to extended

operation at or near full rated load or for trailer towing

when an extra margin of tire service is desired. How-

ever, use of a larger tire or an 8-ply rating tire should

not be construed as permitting an increase in the full

rated vehicle load (see Specifications).

MAINTENANCE AND ADJUSTMENTS

TIRES

Inflation Pressures

To ensure the proper tire inflation pressure for the

owners particular requirements follow the recommenda-

tions in the Vehicle Capacity Rating and Recommended

Tire Inflation Pressures Table (seeSpecifications). Keep

tires properly inflated, and check inflation pressures

periodically. This will ensure the best tire life and riding

comfort, over the full range of driving conditions.

Inspection

Every few thousand miles and at each lubrication, tires

should be checked for sharp objects or stones in the

tread. H tire is punctured, it should be repaired using

one of several repair kits available through tire manu-

facturers1 outlets.

Wear

Misalignment

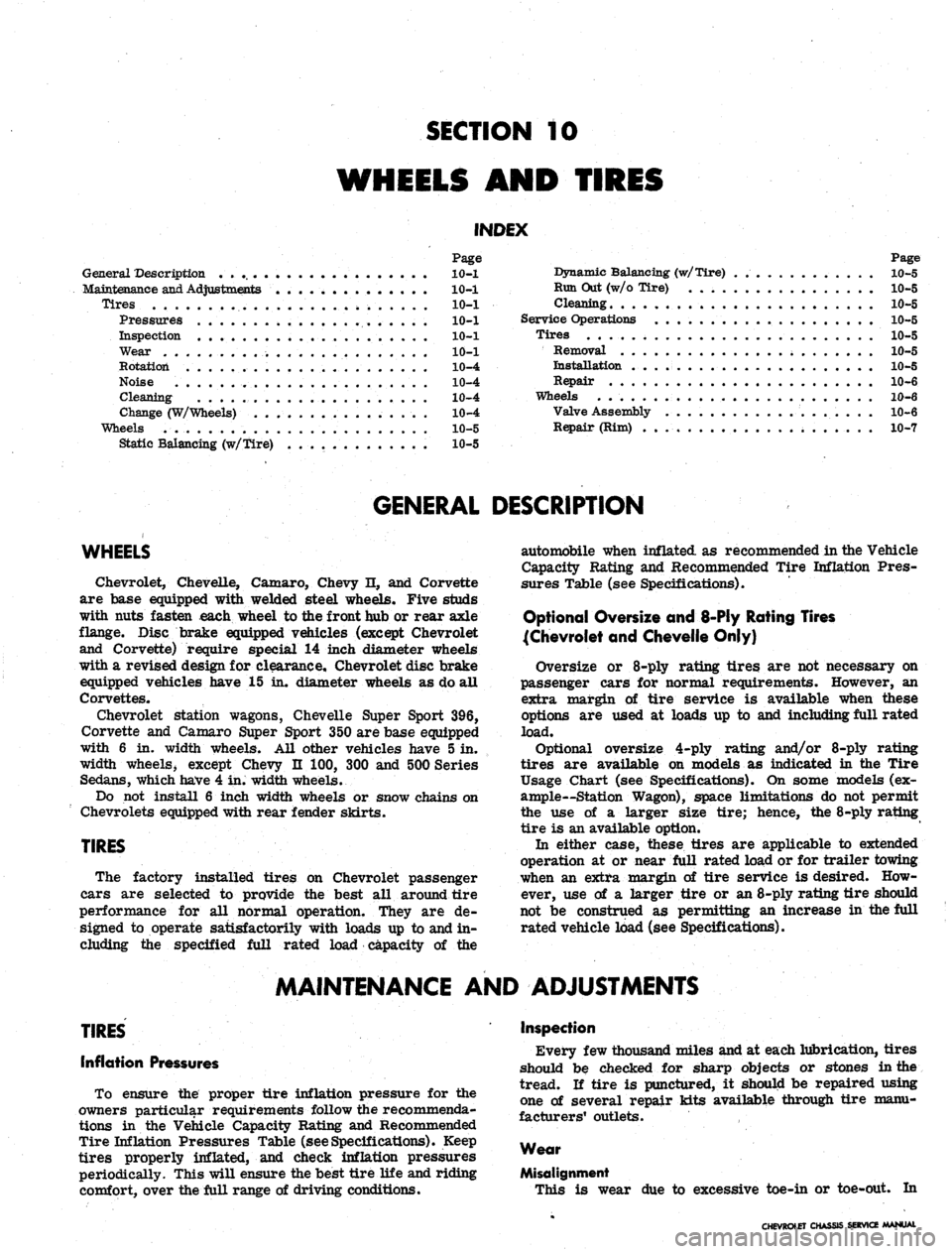

This is wear due to excessive toe-in or toe-out. In

CHEVROLET CHASSIS SERVICE MANUAL

Page 482 of 659

WHEELS AND TIRES 10-2

either case, tires will revolve with a side motion and

scrape the tread rubber off. If misalignment is severe,

the rubber will be scraped off of both tires (or all four

tires if front toe is not correct); if slight, only one will

be affected.

The scraping action against the face of the tire causes

a small feather edge of rubber to appear on

one .side

of

the tread and this feather edge is certain indication of

misalignment (fig. 1). The remedy is. readjusting toe-in

within specifications, or rechecking the entire front end

alignment if necessary.

Heei and Toe

This is a saw-toothed effect where one end of each

tread block is worn more than the other.

The end that wears is the one that first grips the road

when the brakes are applied.

Heel and toe wear is less noticeable onsrear tires than

on front tires, because the propelling action of the rear

wheels creates a force which tends to wear the opposite

end of the tread blocks. The two forces, propelling and

braking, make for more even wear of the rear tires,

whereas only the braking forces act on the front wheels,

and the saw-tooth effect is more noticeable.

A' certain amount of heel and toe wear is normal.

Excessive wear is usually due to high speed driving and

excessive use of brakes. The best remedy, in addition

UNDERINFLATION WEAR

Fig.

1 - Toe In or Toe Out Misalignment Wear

Fig.

2 - Over and Under Inflation Wear

CHEVROLET CHASSIS SERVICE MANUAL

Page 483 of 659

WHEELS AND TIRES 10-3

Fig.

3 - Spof Wear

to cautioning the owner of his driving habits, is to inter-

change tires regularly.

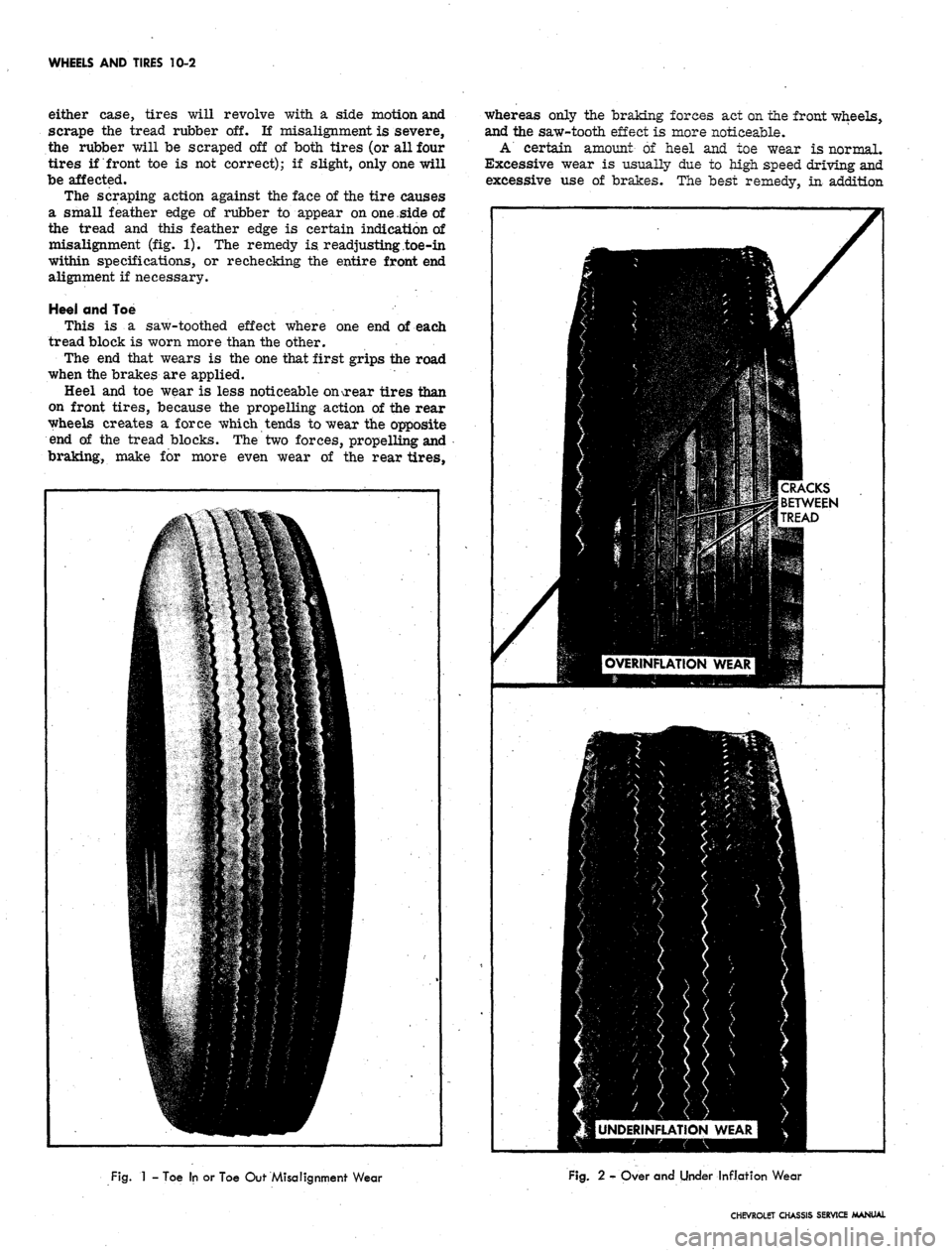

Side

This may be caused by incorrect wheel camber, under-

inflation, high cambered roads or taking corners at too

high a rate of speed.

The first two causes are the most common. Camber

wear can be readily identified because it occurs only on

one side of the treads, whereas underinflation causes

wear on both sides (fig. 2).

There is, of course, no correction for high cambered

roads.

Cornering wear is discussed further on.

Center

This is caused primarily by overinflation pf the tire

(fig. 2). Invisible fabric damage can also be caused by

overinflation.

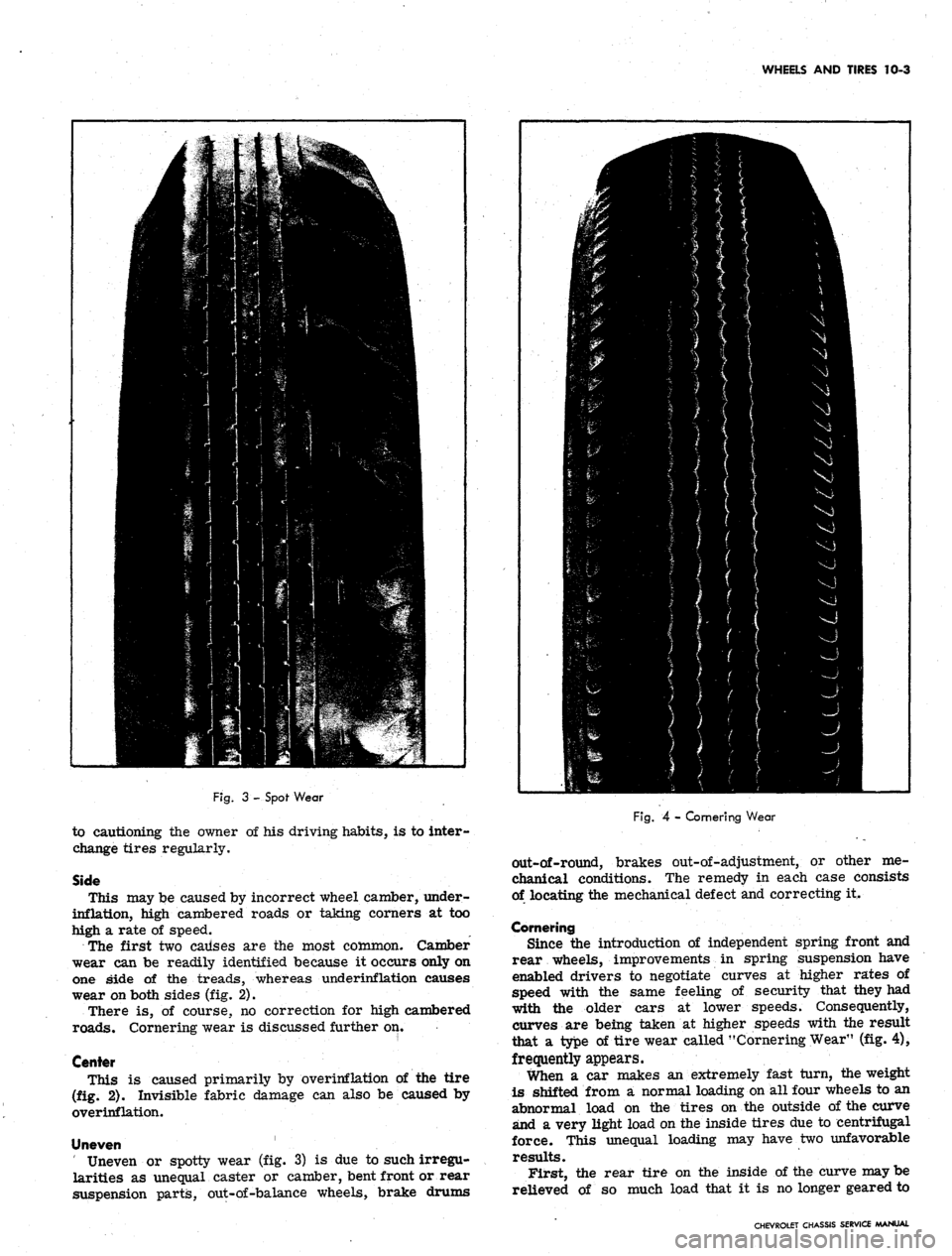

Uneven

Uneven or spotty wear (fig. 3) is due to such irregu-

larities as unequal caster or camber, bent front or rear

suspension parts, out-of-balance wheels, brake drums

Fig.

4 - Cornering Wear

out-of-round, brakes out-of-adjustment, or other me-

chanical conditions. The remedy in each case consists

of locating the mechanical defect and correcting it.

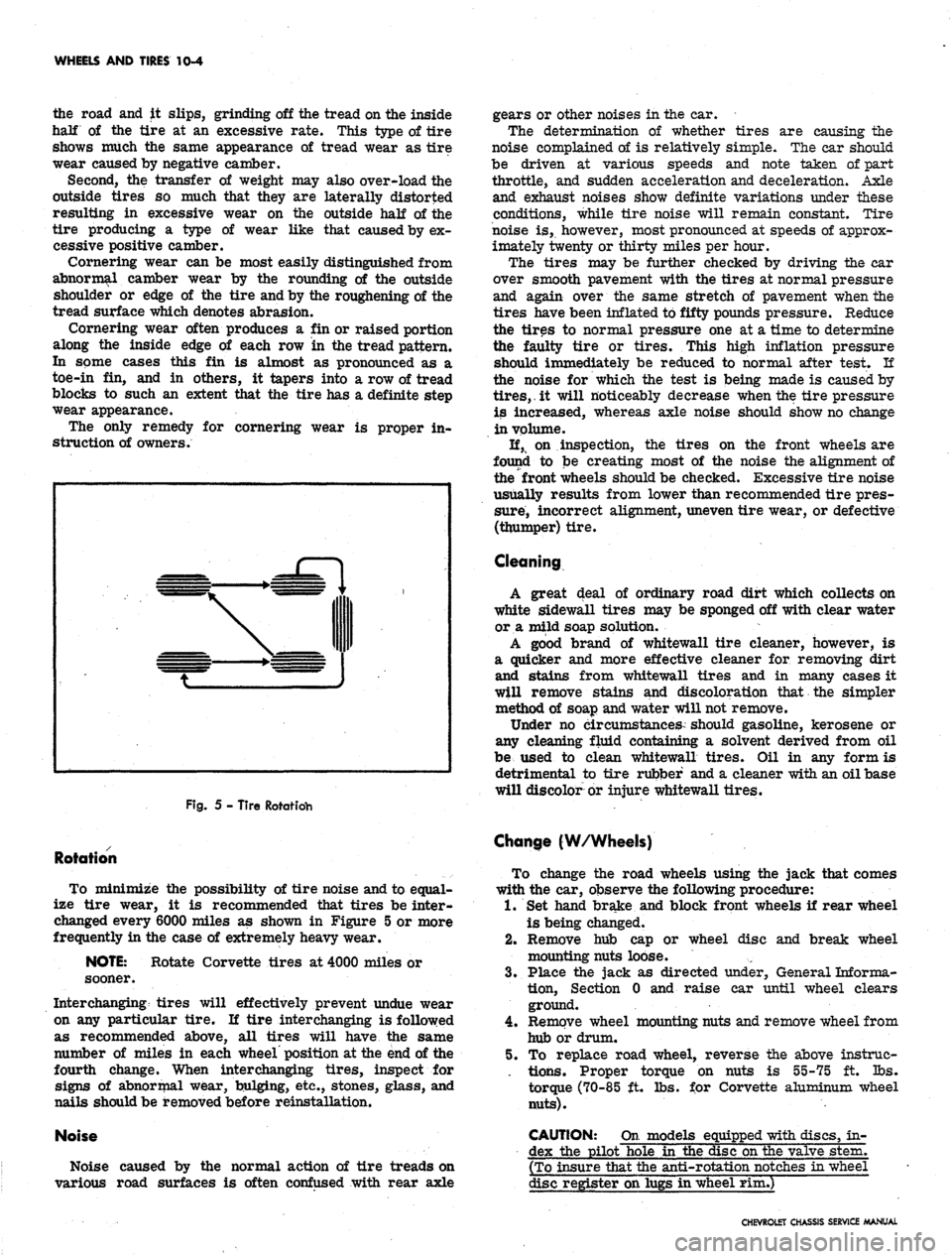

Cornering

Since the introduction of independent spring front and

rear wheels, improvements in spring suspension have

enabled drivers to negotiate curves at higher rates of

speed with the same feeling of security that they had

with the older cars at lower speeds. Consequently,

curves are being taken at higher speeds with the result

that a type of tire wear called "Cornering Wear" (fig. 4),

frequently appears.

When a car makes an extremely fast turn, the weight

is shifted from a normal loading on all four wheels to an

abnormal load on the tires on the outside of the curve

and a very light load on the inside tires due to centrifugal

force. This unequal loading may have two unfavorable

results.

First, the rear tire on the inside of the curve may be

relieved of so much load that it is no longer geared to

CHEVROLET CHASSIS SERVICE MANUAL

Page 484 of 659

WHEELS AND TIRES 10-4

the road and it slips, grinding off the tread on the inside

half of the tire at an excessive rate. This type of tire

shows much the same appearance of tread wear as tire

wear caused by negative camber.

Second, the transfer of weight may also over-load the

outside tires so much that they are laterally distorted

resulting in excessive wear on the outside half of the

tire producing a type of wear like that caused by ex-

cessive positive camber.

Cornering wear can be most easily distinguished from

abnormal camber wear by the rounding of the outside

shoulder or edge of the tire and by the roughening of the

tread surface which denotes abrasion.

Cornering wear often produces a fin or raised portion

along the inside edge of each row in the tread pattern.

In some cases this fin is almost as pronounced as a

toe-in fin, and in others, it tapers into a row of tread

blocks to such an extent that the tire has a definite step

wear appearance.

The only remedy for cornering wear is proper in-

struction of owners.

Fig.

5 - Tire Rotatidh

Rotation

To minimize the possibility of tire noise and to equal-

ize tire wear, it is recommended that tires be inter-

changed every 6000 miles as shown in Figure 5 or more

frequently in the case of extremely heavy wear.

NOTE:

Rotate Corvette tires at 4000 miles or

sooner.

Interchanging tires will effectively prevent undue wear

on any particular tire. II tire interchanging is followed

as recommended above, all tires will have the same

number of miles in each wheel position at the end of the

fourth change. When interchanging tires, inspect for

signs of abnormal wear, bulging, etc., stones, glass, and

nails should be removed before reinstallation.

Noise

Noise caused by the normal action of tire treads on

various road surfaces is often confused with rear axle

gears or other noises in the car.

The determination of whether tires are causing the

noise complained of is relatively simple. The car should

be driven at various speeds and note taken of part

throttle, and sudden acceleration and deceleration. Axle

and exhaust noises show definite variations under these

conditions, while tire noise will remain constant. Tire

noise is, however, most pronounced at speeds of approx-

imately twenty or thirty miles per hour.

The tires may be further checked by driving the ear

over smooth pavement with the tires at normal pressure

and again over the same stretch of pavement when the

tires have been inflated to fifty pounds pressure. Reduce

the tires to normal pressure one at a time to determine

the faulty tire or tires. This high inflation pressure

should immediately be reduced to normal after test. If

the noise for which the test is being made is caused by

tires,.

it will noticeably decrease when the tire pressure

is increased, whereas axle noise should show no change

in volume.

If, on inspection, the tires on the front wheels are

found to be creating most of the noise the alignment of

the front wheels should be checked. Excessive tire noise

usually results from lower than recommended tire pres-

sure, incorrect alignment, uneven tire wear, or defective

(thumper) tire.

Cleaning

A great deal of ordinary road dirt which collects on

white sidewall tires may be sponged off with clear water

or a mild soap solution.

A good brand of whitewall tire cleaner, however, is

a quicker and more effective cleaner for removing dirt

and stains from whitewall tires and in many cases it

will remove stains and discoloration that the simpler

method of soap and water will not remove.

Under no circumstances should gasoline, kerosene or

any cleaning fluid containing a solvent derived from oil

be used to clean whitewall tires. Oil in any form is

detrimental to tire rubber and a cleaner with an oil base

will discolor or injure whitewall tires.

Change (W/Wheels)

To change the road wheels using the jack that comes

with the car, observe the following procedure:

1.

Set hand brake and block front wheels if rear wheel

is being changed.

2.

Remove hub cap or wheel disc and break wheel

mounting nuts loose.

3.

Place the jack as directed tinder, General Informa-

tion,

Section 0 and raise car until wheel clears

ground.

4.

Remove wheel mounting nuts and remove wheel from

hub or drum.

5. To replace road wheel, reverse the above instrue-

. tions. Proper torque on nuts is 55-75 ft. lbs.

torque (70-85 ft. lbs. for Corvette aluminum wheel

nuts).

CAUTION: On models equipped with discs, in-

dex the pilot hole in the disc on the valve stem.

(To insure that the anti-rotation notches in wheel

disc register on lugs in wheel rim.)

CHEVROLET CHASSIS SERVICE MANUAL

Page 485 of 659

WHEELS AND TIRES 10-5

WHEELS

The wheel and tire assembly should be removed from

vehicles equipped with disc brakes to properly perform

balancing operations. This is necessary due to drag of

the spring loaded brake shoes on the disc.

Static Balancing (W/Tire)

Static Balance (still balance) is the equal distribution

of weight of the wheel and tire assembly about the axis

of rotation so that the assembly has no tendency to rotate

by

itself.

Static unbalance causes the pounding action of

the front wheels that is called "tramp".

To correct static unbalance (front and rear): The

quickest and best methods to correct static unbalance

are through the use of wheel balancers which are com-

mercially available. Refer to the Information and in-

structions included with these balaricers.

Dynamic Balancing (W/Tire)

Dynamic Balance (running balance) requires the wheel

to be not only in static balance, but balanced and running

smoothly while turning on an axis which runs through the

centerline of the wheel and tire perpendicular to the axis

of rotation.

The quickest and best methods of testing and correcting

dynamic unbalance are by the use of dynamic wheel

balancers which are commercially available. These bal-

ancers include all necessary information on where and

how the balancing weights should be placed. The follow-

ing information, however, will help in the correction of

dynamic balance.

NOTE:

Before attempting to balance the

wheels, check to be certain that no foreign

matter has been trapped in the wheel ventila-

tion slots or in the accessory wheel discs. This

is especially important if the vehicle has been

run in soft mud and then parked in freezing

weather.

When a wheel that is statically unbalanced is dynam-

ically in balance the dynamic balance can be retained

while correcting "the static balance by installing the cor-

rective weights so that half of the weight required is

placed on the inner edge of the rim and the other half

on the outer edge of the rim.

Dynamic unbalance can be corrected without destroying

static balance by installing weights so half of weight

required for dynamic balance is placed on the rim op-

posite the heavy point, while the other half is placed 180°

away and on the opposite side of the rim.

NOTE:

Vehicles with wire wheel covers should

have the wheels balanced with the wire wheel

covers installed on the wheels.

Run Out (W/OTire)

The wheels should not run out (wobble) more than

1/16" as measured on the side of the rim at the base

of the tire. Excessive run-out is the result of a bent

wheel, an improperly mounted wheel, worn knuckle bear-

ings or steering connections. These parts should be

checked for correct adjustment, proper alignment and

wear whenever excessive run-out is encountered.

The wheels should also run concentric with the steering

knuckle spindle within 1/16 inch as measured on the tire

bead seat of the rim with the tire removed.

Wheel run-out, eccentricity and balance are closely

associated with steering and front wheel alignment.

Further information on these subjects will be found under

"Suspension".

Cleaning Aluminum Wheels

Do not use wire brush or abrasive cleaners when

cleaning wheels. Use only cleaners that will not react

with aluminum.

SERVICE OPERATIONS

TIRES

Removal

Dismounting tubeless tires presents no problems if the

correct procedures are used and the following precau-

tions observed.

1.

Remove the valve cap and valve core. Let out all the

air.

2.

Press the inner side of the tire into the rim well.

Use bead loosening tool or if regular tire irons are

used, take particular care not to injure or tear the

sealing ribs on the bead.

CAUTION: Never use tire irons with sharp

edges or corners.

3.

Using tire irons on the opposite side, remove bead,

taking small "bites" around the rim.

4.

Turn the tire over, and use two tire irons, one be-

tween the rim flange and the bead to pry the rim

upward, the other iron to pry outward between the

bead seat and the bead.

Installation

Extreme care must be exercised to prevent injury to

the sealing bead and circumferential bead when forcing

tire over rim.

1.

Apply a light film of Ruglyde or other suitable rubber

lubricant to sealing bead of tire.

NOTE:

The use of excessive lubrication may

lead to rim slippage and subsequent breaking of

air seal.

2.

Carefully mount the outer bead in usual manner by

using tire irons, taking small "bites" around rim,

being careful not to injure the tire bead.

CAUTION: DO NOT use a hammer, as damage

to the bead will result.

3.

Install the inner bead in the same manner.

NOTE:

If a seal cannot be effected in the fore-

going manner with the rush of air it can be

, accomplished by applying to the circumference

of the tire a tire mounting band or heavy sash

cord and tightening with the use of a tire iron.

On tire mounting machines, bouncing the tire

assembly is not required. The tire should be

CHEVROLET CHASSIS SERVICE MANUAL

Page 486 of 659

WHEELS AND TIRES

10-6

lifted on the rim to force the top tire bead

against the top rim flange. The weight of the

tire will seat the bottom bead.

Repair

When a tire loses all or most of its air pressure,

particularly when driving at high legal speeds on today1 s

super-highways, recommended procedure is to remove it

from the wheel for complete inspection to be sure no

tire damage has occurred. Punctured tires should be

removed from the wheel and permanently repaired from

the inside.

Externally applied plug type repairs should be con-?

sidered temporary and the tire should be permanently

repaired as soon as possible.

Hot Patch Method

It is essential to thoroughly clean and remove all

foreign matter from the hole left by the puncturing-object

without enlarging the injury and then follow the manu-

facturer's instructions for vulcanizing the patch.

Rubber Plug Methods

There are several types of rubber plugs--some are

inserted from the inside of the tire; others are inserted

from the outside of the tire without demounting the tire

from the rim.

When using the plug method be sure to clean and

lubricate the hole with repair cement before inserting

the plug. Your tire supplier has available complete kits

containing materials, tools and detailed instructions for

making repairs with plugs. Follow instructions in the kit

you use.

Cold Patch Method

(Self Vulcanizing Type)

In this method it is essential to thoroughly clean and

remove all foreign matter from the hole left by the

puncturing object without enlarging the injury; also on

the inside of the tire, buff an area large enough for the

patch. Follow the manufacturer1 s instructions for appli-

cation of the special cement and self-vulcanizing cold

patch.

Pressure Gun Method

Several types of pressure guns are available. Consult

your tire supplier for materials and instructions.

Tire Installation Safety Precautions

When tires are mounted on dirty or corroded rims, or

when they are not properly centered on rims, the tire

bead may "bind" on the rim, and refuse to seat. Allowing

pressure to continue to build up within the assembly in

an attempt to seat the tire bead is a DANGEROUS PRAC-

TICE which can result in a broken tire bead, and serious

injury to the serviceman.

1.

Make sure that rim flanges and bead ledge (espe-

cially hump and radius) areas are smooth and clean.

Remove any oxidized rubber, dried soap solution,

rust, heavy paint, etc. with a wire brush, or, in ex-

treme cases, a file.

2.

Lubricate tire beads, rim flanges, and bead ledge

areas with a liberal amount of thin vegetable oil

soap solution, or approved rubber lubricant,

3.

Insure that air pressure build-up during the bead

seating process is not allowed to exceed 40 pounds

pressure. If beads have not seated by the time pres-

sure reaches 40 pounds, assembly should be deflated,

re-positioned on rim, re-lubricated and re-inflated.

4.

Make sure valve core is inserted in valve stem

prior to inflating.

5.

Use an extension gauge with clip on chuck so air

pressure build-up can be closely watched and so

that you can stand well back from the assembly

during the bead seating process.

WHEELS

Valve Assembly

Replace

NOTE: Always use new valve assembly when

replacing.

1.

Cut or drive old valve assembly out of rim.

2.

Clean valve hole and surrounding area on inside of

flange with steel wool.

Fig. 6 - Installing Valve

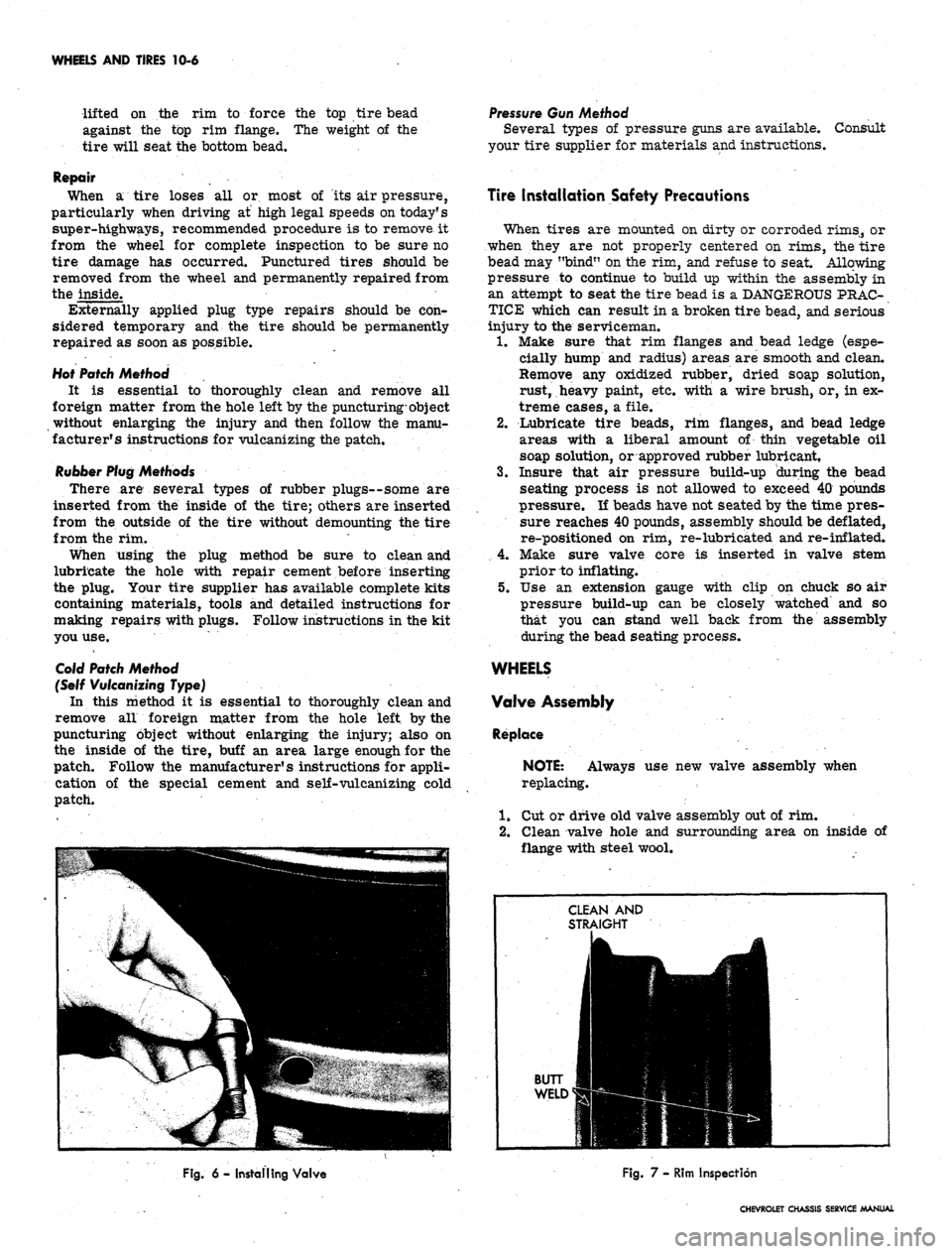

Fig. 7 - Rim Inspection

CHEVROLET CHASSIS SERVICE MANUAL

Page 487 of 659

WHEELS AND TIRES 10-7

3.

Coat O.D. of new valve assembly liberally with the 2. Clean rim flange thoroughly with small piece of

mounting compound. steel wool or sand paper.

4.

Insert assembly through rim from inside (fig. 7). 3. Inspect the butt-weld in the rim flange area to make

Snap into place, using a pair of slip-joint pliers certain there is no groove or high spot (fig. 8).

with one jaw on rim and one jaw on base of valve 4. If air loss occurs at valve it can be corrected by

assembly. replacing valve core or valve assembly.

Rim

Repair

1.

Straighten the rim if it is bent or dented.

CHEVROLET CHASSIS SERVICE MANUAL

Page 488 of 659

SECTION 11

CHASSIS SHEET METAL

CONTENTS OF THIS SECTION

Chevrolet and Chevelle 11-1

Chevy II . . 11.-11

Camaro 11-19

Corvette (See Section IB)

Special Tools 11-25

CHEVROLET AND CHEVELLE

INDEX

Page

General Description 11-1

Maintenance and Adjustments •. il-1

Hood Adjustment 11-1

Hinges 11-1

Bumpers 11-1

Catch Assembly and Lock 11-1

Fenders 11-4

Sheet Metal 11-4

Component Part Replacement 11-4

Battery Tray 11-4

Page

Radiator Support 11-4

Fender Assembly . . 11-4

Skirt 11-4

Trim 11-5

Hood Assembly 11-6

Lock and Catch 11-7

Trim and Insulation 11-7

Cowl Vent Grille 11-7

Rear Wheel Cover 11-7

Simulated Wood Grain Moulding . . . . 11-7

GENERAL DESCRIPTION

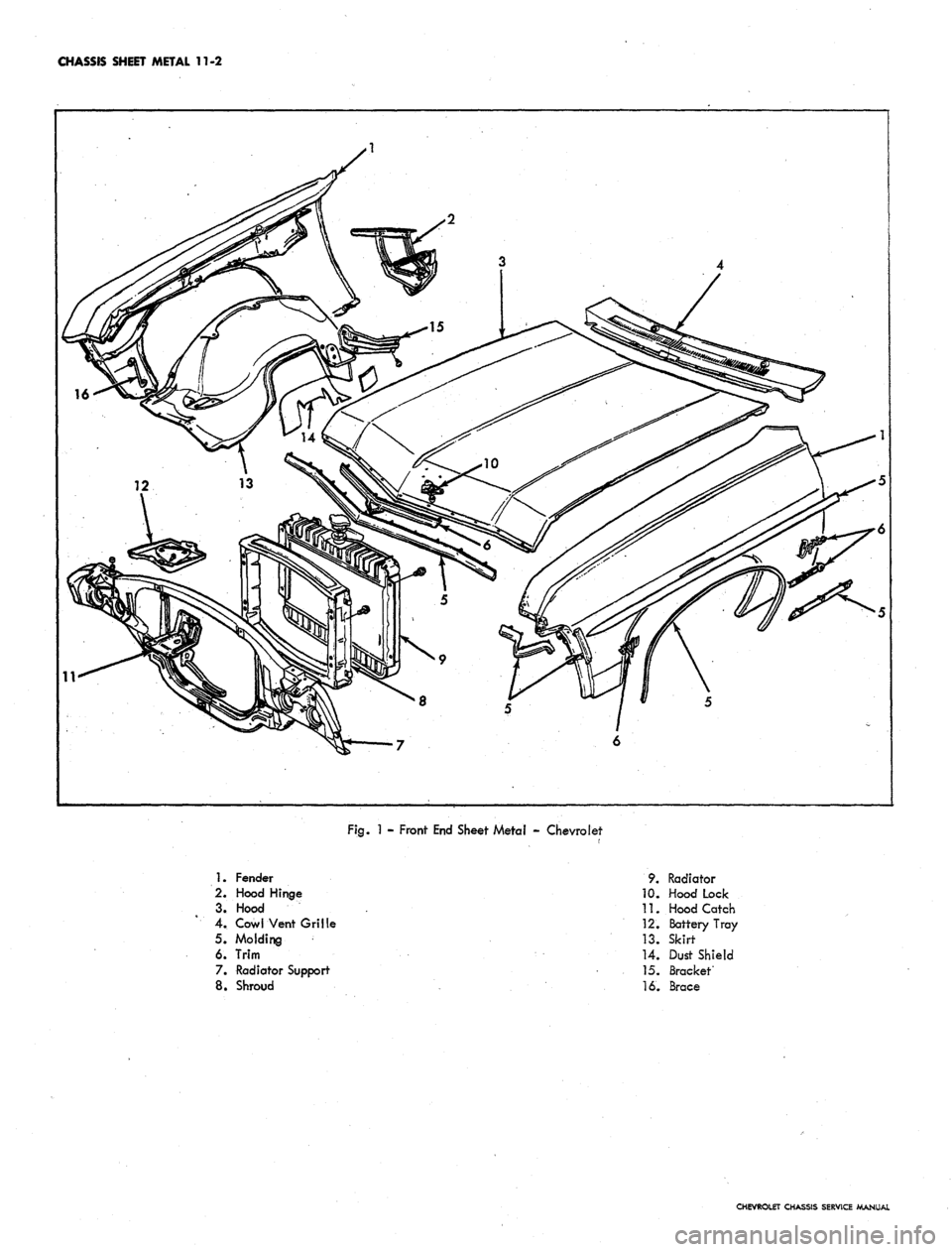

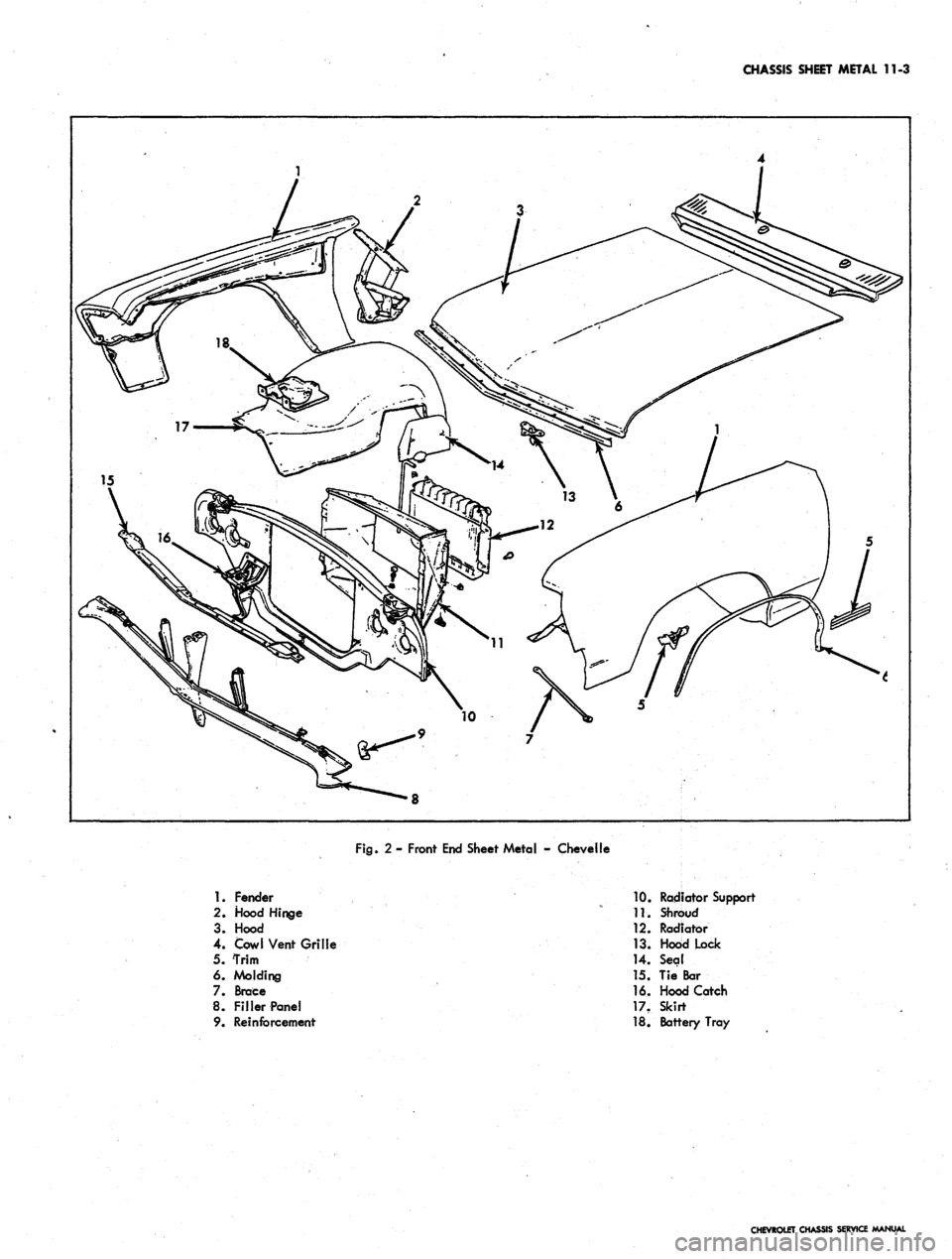

The new front end appearance of the 1967 Chevrolet

and Chevelle passenger cars affects the servicing and

replacement of the chassis sheet metal. Refer to Section

13 for Radiator and Grille service procedures, Section

14 for Bumpers, and Section 1A for Air Conditioning

components. Figures 1 and 2 illustrate the Chevrolet

and Chevelle sheet metal components.

MAINTENANCE AND ADJUSTMENTS

HOOD ADJUSTMENT

The alignment of the hood is controlled by the position

of the hood hinges and the height of the two bumpers lo-

cated one at each side of the radiator support. The ad-

justment at the hood lock must be made after the hinges

and bumpers are properly adjusted. To align the hood

and lock proceed as follows:

HOOD HINGE (Fig. 3)

NOTE:

The body mounted portion of the hood

hinges are slotted to provide up and down move-

ment. The hood mounted end is slotted to pro-

vide forward and rearward movement.

1.

Scribe a line around the entire hinge plate to be re-

positioned.

2.

Loosen the appropriate screws and shift the position

of the hood into correct alignment using the scribe

marks to check amount of movement. Check align-

ment by tightening screws and closing the hood.

HOOD BUMPERS

Adjust hood bumpers so that hood top surface is flush

with the fender and grille top surfaces. Refer to Fig-

ures 4 and 5 for correct sheet metal adjustment dimen-

sions.

HOOD CATCH AND LOCK

The hood catch assembly (fig. 6) mounting holes are

slotted to provide adjustment for the hood lock bolt. Ad-

just the hood lock bolt until hood engages securely when

closed and hood bumpers are slightly compressed.

CHEVROLET CHASSIS SERVICE MANUAL

Page 489 of 659

CHASSIS SHEET METAL 11-2

Fig.

1

- Front End Sheet Metal - Chevrolet

1.

Fender

2.

Hood Hinge

3. Hood

4.

Cowl Vent Grille

5. Molding

6. Trim

7. Radiator Support

8. Shroud

9. Radiator

10.

Hood Lock

11.

Hood Catch

12.

Battery Tray

13.

Skirt

14.

Dust Shield

15.

Bracket'

16.

Brace

CHEVROLET CHASSIS SERVICE MANUAL

Page 490 of 659

CHASSIS SHEET METAL 11-3

Fig.

2 - Front End Sheet Metal - Chevelle

1.

Fender

2.

Hood Hinge

3. Hood

4.

Cowl Vent Grille

5. Trim

6. Molding

7. Brace

8. Filler Panel

9. Reinforcement

10.

Radiator Support

11.

Shroud

12.

Radiator

13.

Hood Lock

14.

Seal

15.

Tie Bar

16.

Hood Catch

17.

Skirt

18.

Battery Tray

CHEVROLET CHASSIS SERVICE MANUAL