CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 511 of 659

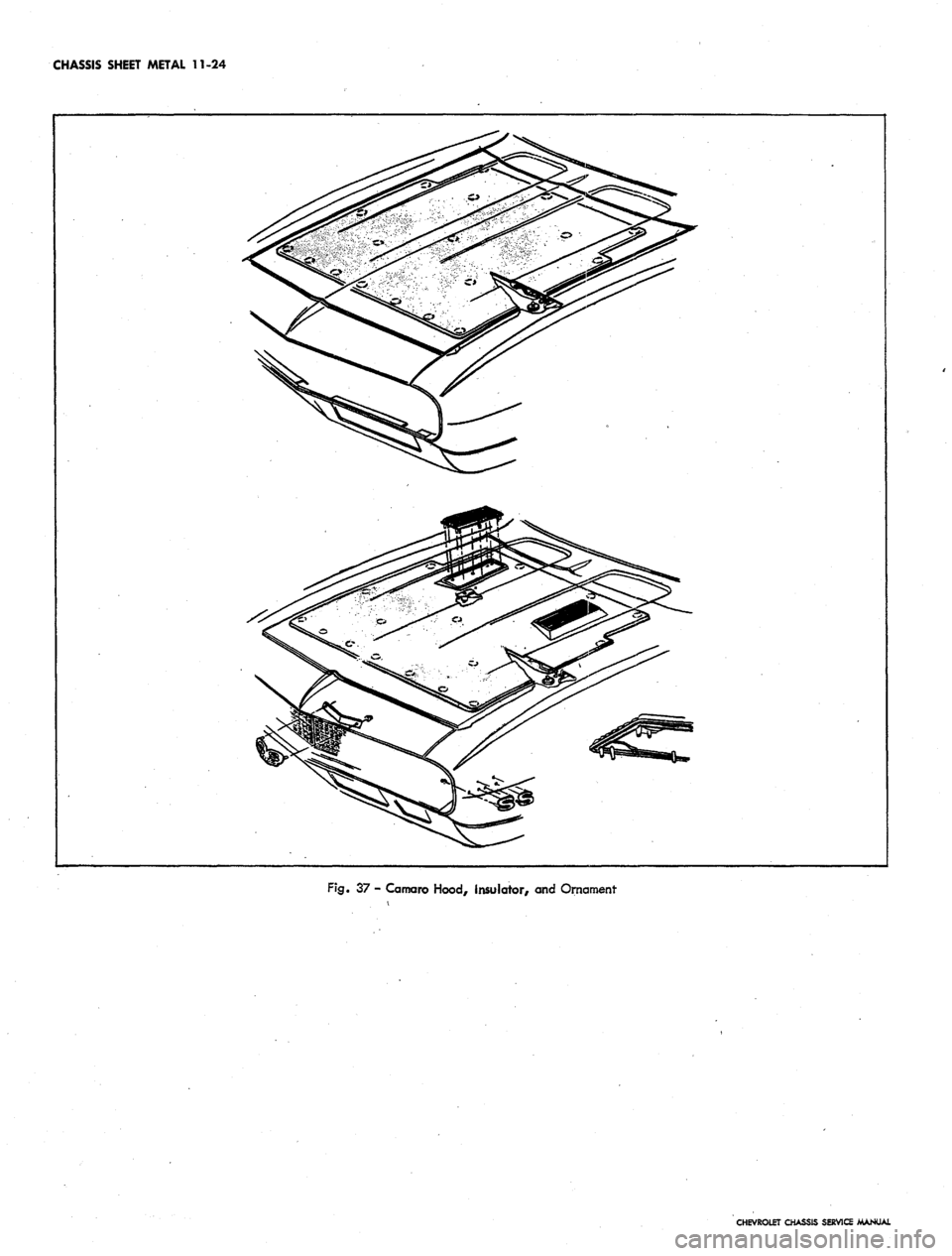

CHASSIS SHEET METAL 11-24

Fig. 37 - Camaro Hood, Insulator, and Ornament

CHEVROLET CHASSIS SERVICE MANUAL

Page 512 of 659

CHASSIS SHEET METAL 11-25

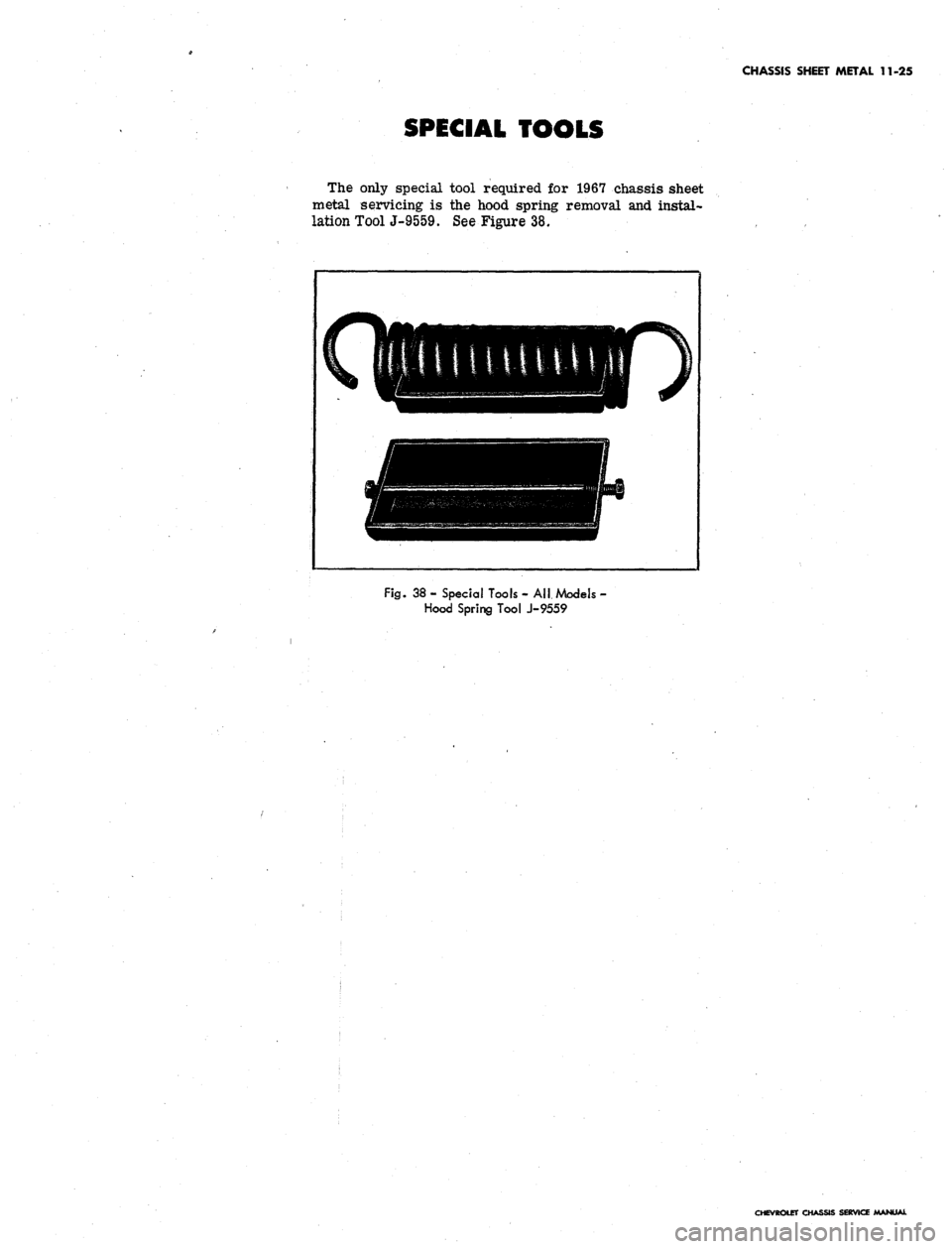

SPECIAL TOOLS

The only special tool required for 1967 chassis sheet

metal servicing is the hood spring removal and instal-

lation ToolJ-9559. See Figure 38.

Fig.

38 - Special Tools - All Models

Hood Spring Tool J-9559

CHEVROLET CHASSIS SERVICE MANUAL

Page 513 of 659

SECTION 12

ELECTRICAL-BODY AND CHASSIS

CONTENTS

OF

THIS

SECTION

Page

Page

System 12-1

Instruments and Gauges 12-21

Directional Signal 12r40

Windshield Wipers and Washers 12-44

Wiring Diagrams 12-56

Special Tools 12-60

LIGHTING SYSTEM

INDEX

Page

General Description

!2-i

Maintenance and Adjustments

•.................. 12-2

Headlamp Adjustment......................

12-3

Headlamp Panel Travel Adjustment.

12-5

Service Operations.

. . .. 12-5

Front Lighting

12-5

Headlamp

. 12_5

Parking Lamp

12-5

Fender Lamp

. 12_^

Headlamp Panel

12-8

Headlamp Panel Motor

^2-9

Rear Lighting

l2-10

Tail, Stop and Directional Lamps

12-10

Page

Backing Lamps

12-14

License Plate Lamp

12-14

Automatic Transmission Quadrant Lamp

12-14

Seat Separator Console Lamps

. 12-15

Lighting Switch

. . 12-15

Wiper Switch.

12-15

Stoplight Switch

12-15

Dimmer Switch

12-15

Backing Lamp Switches

12-15

Neutral Safety Switches

12-17

Parking Brake Alarm Switch

................. 12-19

Instrument Panel Compartment Lamp/Switch

12-19

Cirgarette Lighter

12-19

GENERAL DESCRIPTION

.

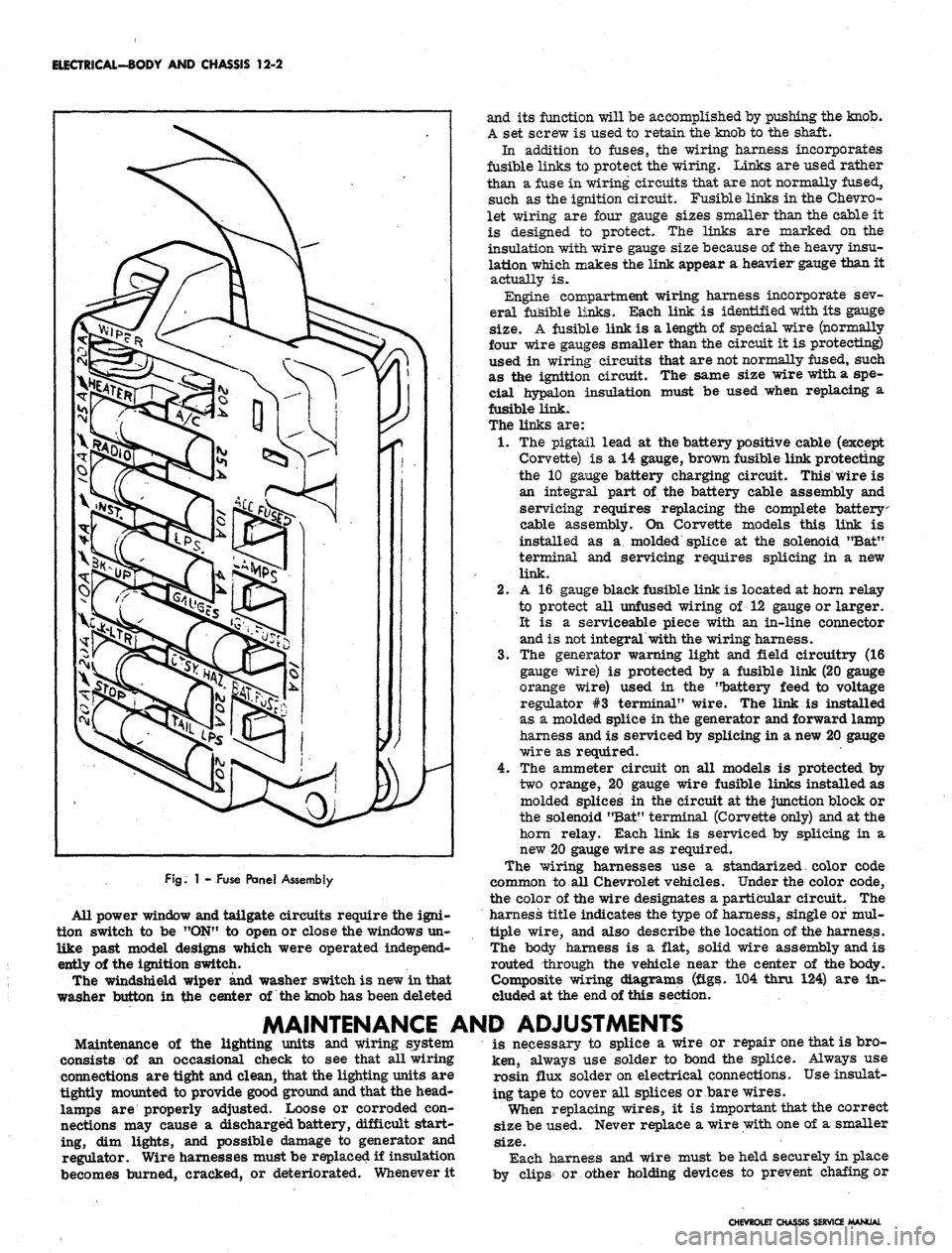

The lighting system includes: the main lighting switch,

stop light, dimmer, and backing lamp switches, head-

lamps, parking lamps, stop, tail and directional lamps,

instrument illumination and indicator lamps, and the

necessary wiring to complete the various circuits. A

fuse panel provides convenient power take offs and fuse

clips for the appropriate circuits (fig. 1).

Chevrolet and Chevelle headlamp installation is all

new in that the headlamps are located in the radiator

support with adjusting screws and springs. Eliminating

the need for having separate headlamp housings. Chev-

rolet and Chevelle headlamp retainers and springs are

interchangeable.

Chevy n headlamp housings are new because of revised

front end styling and Corvette front end lighting is basi-

cally carryover.

Front fender lamps have been added as an option for

Chevrolet models and as standard equipment on Caprice

series.

Camaro models use single headlamps and the Rally

Sport model headlamps are covered by a retractable

section of the grille when lamps are not used. The sec-

tion of the grille covering the headlamps folds back when

lights are required; the headlamps are stationary. The

covering is retracted by a small electric motor mounted

to the headlamp housing. The headlamps are automat-

ically uncovered when the headlight switch is pulled "ON"

for illumination. If at any time the electrical circuit

becomes inoperative, the lamps can be uncovered manu-

ally. The ignition switch must be

"ON"

in order to close

the headlamp doors.

Parking lamp for Chevelle and Chevrolet models are

new due to revised front end sheet metal and bumper

styling. Parking lamps are located in the bumper on

Chevrolet, Chevelle and Chevy n models

Camaro parking lamps are located in the radiator

grille except for the Rally Sport models on which the

parking lamps are in the valance panel. For styling

reasons, the lens is white and an amber glass bulb is

used. All Camaro parking lamps require a separate

ground wire to assure a good ground contact because of

the plastic grille and painted contact surfaces.

The Chevrolet tail, stop, and directional lamps are in

one housing with a three section lens design on Impala

and Caprice sedans. The center lens for Impala series

is the back-up lamp. The center lens on the Caprice is

a tail lamp with the back-up lamps being located in the

rear bumper. Chevrolet station wagons have three indi-

vidual housings with three lenses, the center lamp being

the back-up. Biscayne and Bel-Air sedans have a single

housing and lens for tail, stop, and directional lamp with

a similarly constructed back-up lamp inboard and adja-

cent to it.

Chevelle tail, stop, and directional lamps are a single

lens design that follows through with the rear fender

styling. The back-up lamp is located in r.ear bumper.

Camaro models except Rally Sport have tail lamps

with integral back-up lamps mounted inboard of the rear

fenders between the trunk opening and bumper. The

Rally Sport model has dual tail lamps in the rear housing

and valance mounted back-up lamps.

Corvette, Chevy n, and Corvair tail and directional

signal lights are carryover. The Corvette has new back-

up lamps center mounted above the license plate opening.

CHEVROLET CHASSIS SERVICE

Page 514 of 659

ELECTRICAL-BODY AND CHASSIS 12-2

FJg.

1 - Fuse Panel Assembly

All power window and tailgate circuits require the igni-

tion switch to be "ON" to open or close the windows un-

like past model designs which were operated independ-

ently of the ignition switch.

The windshield wiper and washer switch is new in that

washer button in the center of the knob has been deleted

and its function will be accomplished by pushing the knob.

A set screw is used to retain the knob to the shaft.

In addition to fuses, the wiring harness incorporates

fusible links to protect the wiring. Links are used rather

than a fuse in wiring circuits that are not normally fused,

such as the ignition circuit. Fusible links in the Chevro-

let wiring are four gauge sizes smaller than the cable it

is designed to protect. The links are marked on the

insulation with wire gauge size because of the heavy insu-

lation which makes the link appear a heavier gauge than it

actually is.

Engine compartment wiring harness incorporate sev-

eral fusible links. Each link is identified with its gauge

size.

A fusible link is a length of special wire (normally

four wire gauges smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a spe-

cial hypalon insulation must be used when replacing a

fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gauge, brown fusible link protecting

the 10 gange battery charging circuit. This wire is

an integral part of the battery cable assembly and

servicing requires replacing the complete battery

cable assembly. On Corvette models this link is

installed as a molded splice at the solenoid "Bat"

terminal and servicing requires splicing in a new

link.

2.

A 16 gauge black fusible link is located at horn relay

to protect all unfused wiring of 12 gauge or larger.

It is a serviceable piece with an in-line connector

and is not integral with the wiring harness.

3.

The generator warning light and field circuitry (16

gauge wire) is protected by a fusible link (20 gauge

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed

as a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gauge

wire as required.

4.

The ammeter circuit on all models is protected by

two orange, 20 gauge wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at the

horn relay. Each link is serviced by splicing in a

new 20 gauge wire as required.

The wiring harnesses use a standarized. color code

common to all Chevrolet vehicles. Under the color code,

the color of the wire designates a particular circuit. The

harness title indicates the type of harness, single of mul-

tiple wire, and also describe the location of the harness.

The body harness is a flat, solid wire assembly and is

routed through the vehicle near the center of the body.

Composite wiring diagrams (figs. 104 thru 124) are in-

cluded at the end of this section.

MAINTENANCE AND ADJUSTMENTS

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head-

lamps are properly adjusted. Loose or corroded con-

nections may cause a discharged battery, difficult start-

ing, dim lights, and possible damage to generator and

regulator. Wire harnesses must be replaced if insulation

becomes burned, cracked, or deteriorated. Whenever it

is necessary to splice a wire or repair one that is bro-

ken, always use solder to bond the splice. Always use

rosin flux solder on electrical connections. Use insulat-

ing tape to cover all splices or bare wires.

When replacing wires, it is important that the correct

size be used. Never replace a wire with one of a smaller

size.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

CHEVROLET CHASSIS SERVICE MANUAL

Page 515 of 659

ELECTRICAL-BODY AND CHASSIS 12-3

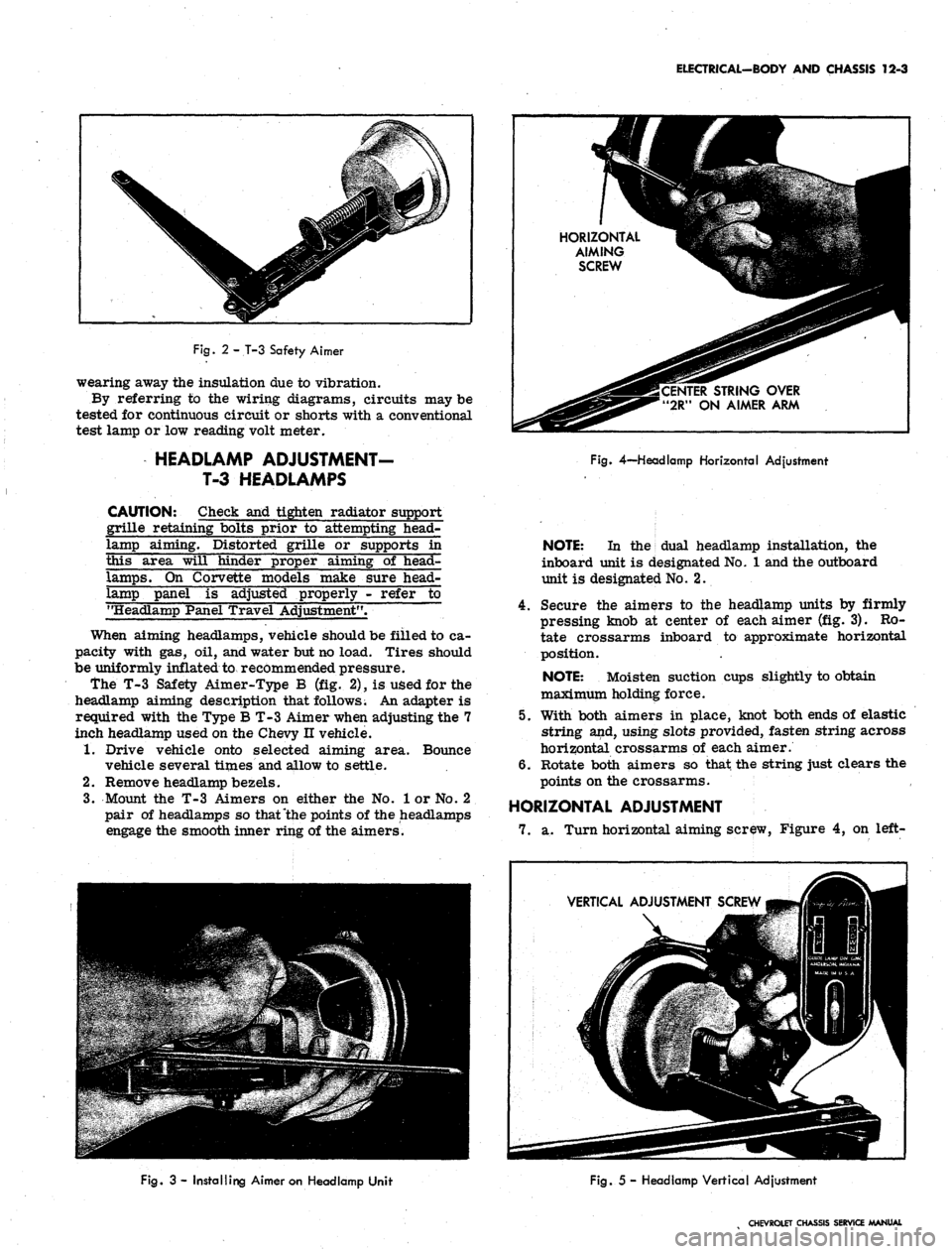

Fig.

2 - T-3 Safety Aimer

wearing away the insulation due to vibration.

By referring to the wiring diagrams, circuits may be

tested for continuous circuit or shorts with a conventional

test lamp or low reading volt meter.

HEADLAMP ADJUSTMENT-

T-3 HEADLAMPS

CAUTION: Check and tighten radiator support

grille retaining bolts prior to attempting head-

lamp aiming. Distorted grille or supports in

this area will hinder proper aiming of head-

lamps. On Corvette models make sure head-

lamp panel is adjusted properly - refer to

"Headlamp Panel Travel Adjustment".

When aiming headlamps, vehicle should be filled to ca-

pacity with gas, oil, and water but no load. Tires should

be uniformly inflated to recommended pressure.

the T-3 Safety Aimer-Type B (fig. 2), is used for the

headlamp aiming description that follows. An adapter is

required with the Type B T-3 Aimer when adjusting the 7

inch headlamp used on the Chevy n vehicle.

1.

Drive vehicle onto selected aiming area. Bounce

vehicle several times and allow to settle.

2.

Remove headlamp bezels.

3.

Mount the T-3 Aimers on either the No. 1 or No. 2

pair of headlamps so that "the points of the headlamps

engage the smooth inner ring of the aimers.

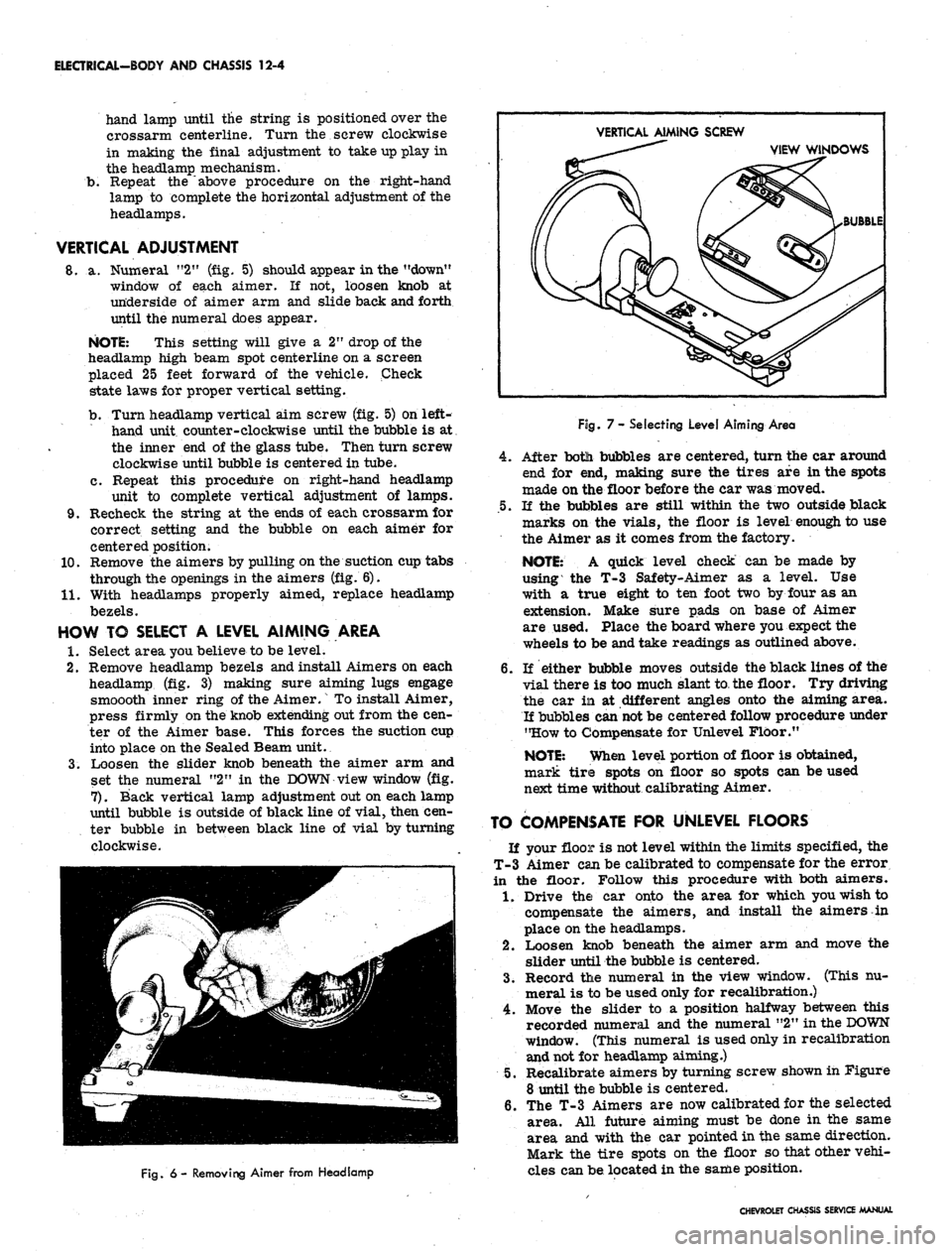

HORIZONTAL

AIMING

SCREW

STRING OVER

"2R" ON AIMER ARM

Fig.

4—-Headlamp Horizontal Adjustment

NOTE:

In the dual headlamp installation, the

inboard unit is designated No. 1 and the outboard

unit is designated No. 2.

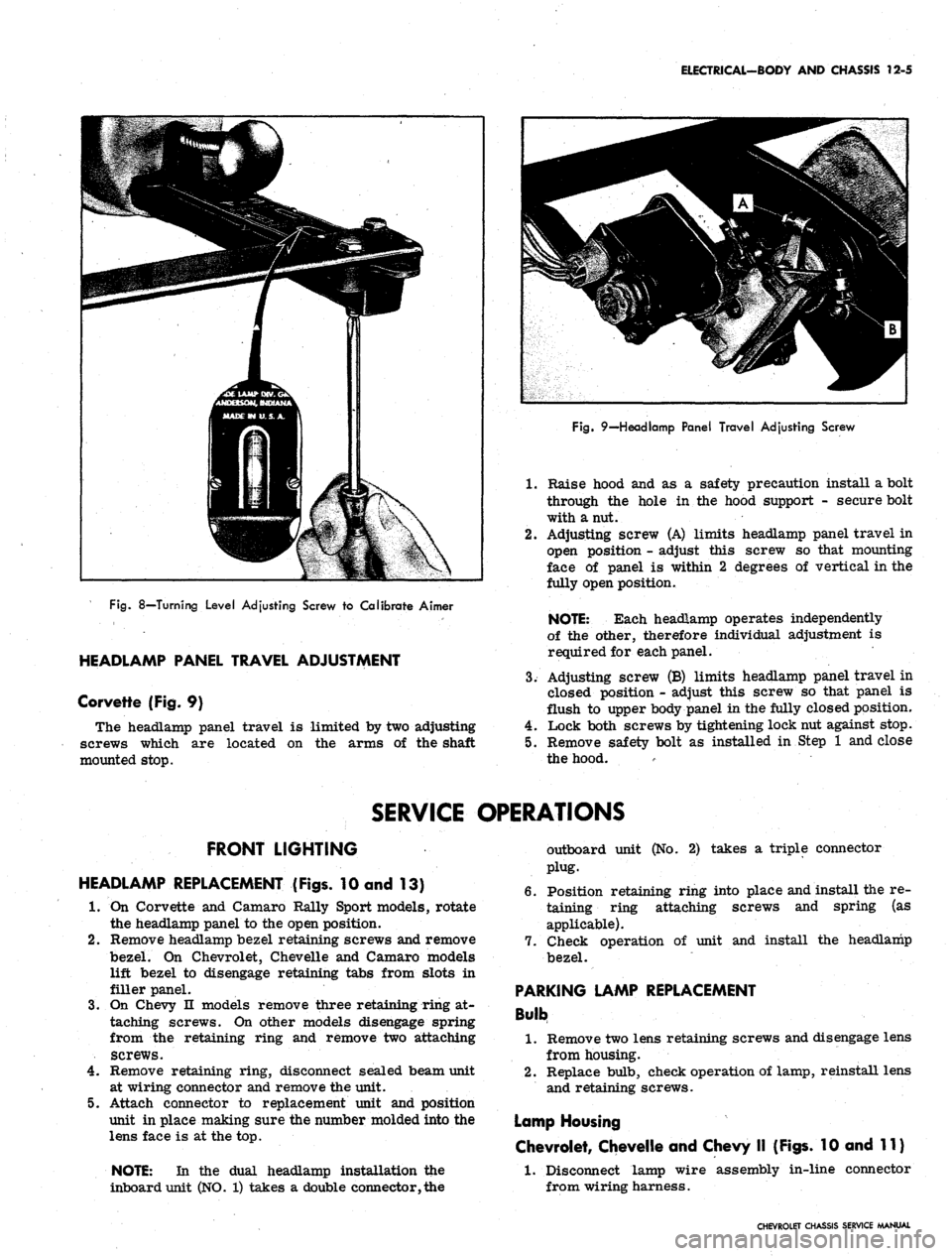

4.

Secure the aimers to the headlamp units by firmly

pressing knob at center of each aimer (fig. 3). Ro-

tate crossarms inboard to approximate horizontal

position.

NOTE:

Moisten suction cups slightly to obtain

maximum holding force.

5. With both aimers in place, knot both ends of elastic

string and, using slots provided, fasten string across

horizontal crossarms of each aimer.

6. Rotate both aimers so that the string just clears the

points on the crossarms.

HORIZONTAL ADJUSTMENT

7. a. Turn horizontal aiming screw, Figure 4, on left-

VERTICAL ADJUSTMENT SCREW

Fig.

3 - Installing Aimer on Headlamp Unit

Fig.

5 - Headlamp Vertical Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 516 of 659

ELECTRICAL-BODY AND CHASSIS 12-4

b.

hand lamp until the string is positioned over the

crossarm centerline. Turn the screw clockwise

in making the final adjustment to take up play in

the headlamp mechanism.

Repeat the above procedure on the right-hand

lamp to complete the horizontal adjustment of the

headlamps.

VERTICAL ADJUSTMENT

8. a. Numeral "2" (fig. 5) should appear in the "down"

window of each aimer. If not, loosen knob at

underside of aimer arm and slide back and forth

until the numeral does appear.

NOTE:

This setting will give a 2" drop of the

headlamp high beam spot centerline on a screen

placed 25 feet forward of the vehicle. Check

state laws for proper vertical setting.

b.

Turn headlamp vertical aim screw (fig. 5) on left-

hand unit counter-clockwise until the bubble is at

the inner end of the glass tube. Then turn screw

clockwise until bubble is centered in tube.

c. Repeat this procedure on right-hand headlamp

unit to complete vertical adjustment of lamps.

9. Recheck the string at the ends of each crossarm for

correct setting and the bubble on each aimer for

centered position.

10.

Remove the aimers by pulling on the suction cup tabs

through the openings in the aimers (fig. 6).

11.

With headlamps properly aimed, replace headlamp

bezels.

HOW TO SELECT A LEVEL AIMING AREA

1.

Select area you believe to be level.

2.

Remove headlamp bezels and install Aimers on each

headlamp (fig. 3) making sure aiming lugs engage

smoooth inner ring of the Aimer.

"

To install Aimer,

press firmly on the knob extending out from the cen-

ter of the Aimer base. This forces the suction cup

into place on the Sealed Beam unit.:

3.

Loosen the slider knob beneath the aimer arm and

set the numeral "2" in the DOWN view window (fig.

7).

Back vertical lamp adjustment out on each lamp

until bubble is outside of black line of vial, then cen-

ter bubble in between black line of vial by turning

clockwise.

VERTICAL AIMING SCREW

VIEW WINDOWS

BUBBLE

Fig.

6 - Removing Aimer from Headlamp

Fog.

7- Selecting Level Aiming Area

4.

After botli bubbles are centered, turn the car around

end for end, making sure the tires are in the spots

made on the floor before the car was moved.

.5.

If the bubbles are still within the two outside black

marks on the vials, the floor is level enough to use

the Aimer as it comes from the factory.

NOTE:

A quick level check can be made by

using the T-3 Safety-Aimer as a level. Use

with a true eight to ten foot two by four as an

extension. Make sure pads on base of Aimer

are used. Place the board where you expect the

wheels to be and take readings as outlined above.

6. If either bubble moves outside the black lines of the

vial there is too much slant to the floor. Try driving

the car in at different angles onto the aiming area.

If bubbles can

not

be centered follow procedure under

"How to Compensate for Unlevel Floor."

NOTE:

When level portion of floor is obtained,

mark tire spots on floor so spots can be used

next time without calibrating Aimer.

TO COMPENSATE FOR UNLEVEL FLOORS

If your floor is not level within the limits specified, the

T-3 Aimer can be calibrated to compensate for the error

in the floor. Follow this procedure with both aimers.

1.

Drive the car onto the area for which you wish to

compensate the aimers, and install the aimers in

place on the headlamps.

2.

Loosen knob beneath the aimer arm and move the

slider until the bubble is centered.

3.

Record the numeral in the view window. (This nu-

meral is to be used only for recalibration.)

4.

Move the slider to a position halfway between this

recorded numeral and the numeral "2" in the

DOWN

window. (This numeral is used only in recalibration

and not for headlamp aiming.)

5.

Recalibrate aimers by turning screw shown in Figure

8 until the bubble is centered.

6. The T-3 Aimers are now calibrated for the selected

area. All future aiming must be done in the same

area and with the car pointed in the same direction.

Mark the tire spots on the floor so that other vehi-

cles can be located in the same position.

CHEVROLET CHASSIS SERVICE MANUAL

Page 517 of 659

ELECTRICAL-BODY AND CHASSIS 12-5

Fig.

8—Turning Level Adjusting Screw to Calibrate Aimer

HEADLAMP PANEL TRAVEL ADJUSTMENT

Corvette (Fig. 9)

The headlamp panel travel is limited by two adjusting

screws which are located on the arms of the shaft

mounted stop.

Fig.

9—Headlamp Panel Travel Adjusting Screw

1.

Raise hood and as a safety precaution install a bolt

through the hole in the hood support - secure bolt

with a nut.

2.

Adjusting screw (A) limits headlamp panel travel in

open position - adjust this screw so that mounting

face of panel is within 2 degrees of vertical in the

fully open position.

NOTE: Each headlamp operates independently

of the other, therefore individual adjustment is

required for each panel.

3.

Adjusting screw (B) limits headlamp panel travel in

closed position - adjust this screw so that panel is

flush to upper body panel in the fully closed position.

4.

Lock both screws by tightening lock nut against stop.

5.

Remove safety bolt as installed in Step 1 and close

the hood.

SERVICE OPERATIONS

FRONT LIGHTING

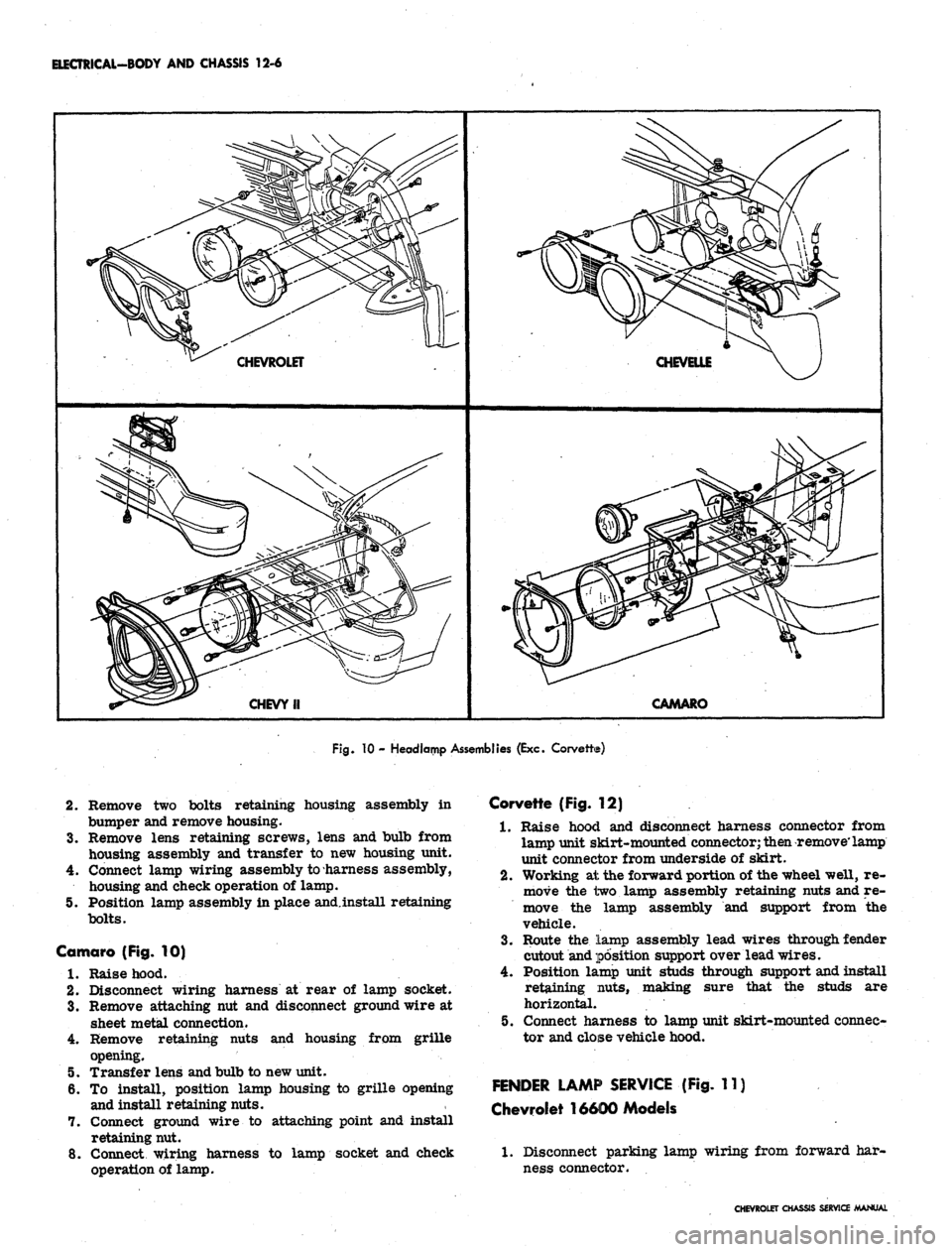

HEADLAMP REPLACEMENT (Figs. 10 and 13)

1.

On Corvette and Camaro Rally Sport models, rotate

the headlamp panel to the open position.

2.

Remove headlamp bezel retaining screws and remove

bezel. On Chevrolet, Chevelle and Camaro models

lift bezel to disengage retaining tabs from slots in

filler panel.

3.

On Chevy n models remove three retaining ring at-

taching screws. On other models disengage spring

from the retaining ring and remove two attaching

screws.

4.

Remove retaining ring, disconnect sealed beam unit

at wiring connector and remove the unit.

5.

Attach connector to replacement unit and position

unit in place making sure the number molded into the

lens face is at the top.

NOTE: In the dual headlamp installation the

inboard unit (NO. 1) takes a double connector, the

outboard unit (No. 2) takes a triple connector

plug.

6. Position retaining ring into place and install the re-

taining ring attaching screws and spring (as

applicable).

7.

Check operation of unit and install the headlamp

bezel.

PARKING LAMP REPLACEMENT

Bulb

1.

Remove two lens retaining screws and disengage lens

from housing.

2.

Replace bulb, check operation of lamp, reinstall lens

and retaining screws.

Lamp Housing

Chevrolet, Chevelle and Chevy II (Figs. 10 and 11)

1.

Disconnect lamp wire assembly in-line connector

from wiring harness.

CHEVROLET CHASSIS SERVICE MANUAL

Page 518 of 659

ELECTRICAL-BODY AND CHASSIS 12-6

\ \

CHEVROLET

CHEVELLE

CHEVY II

CAMARO

Fig.

10 - Headlamp Assemblies (Exc. Corvette)

1.

2.

Remove two bolts retaining housing assembly in Corvette (Fig. 12)

bumper and remove housing.

3.

Remove lens retaining screws, lens and bulb from

housing assembly and transfer to new housing unit.

4.

Connect lamp wiring assembly to harness assembly,

housing and check operation of lamp.

5. Position lamp assembly in place and.install retaining

bolts.

Camaro (Fig. 10)

1.

Raise hood.

2.

Disconnect wiring harness at rear of lamp socket.

3.

Remove attaching nut and disconnect ground wire at

sheet metal connection.

4.

Remove retaining nuts and housing from grille

opening.

5. Transfer lens and bulb to new unit.

6. To install, position lamp housing to grille opening

and install retaining nuts.

7. Connect ground wire to attaching point and install

retaining nut.

8. Connect wiring harness to lamp socket and check

operation of lamp.

Raise hood and disconnect harness connector from

lamp unit skirt-mounted

connector;

then

remove'lamp

unit connector from underside of skirt.

Working at the forward portion of the wheel well, re-

move the two lamp assembly retaining nuts and re-

move the lamp assembly and support from the

vehicle.

Route the lamp assembly lead wires through fender

cutout and position support over lead wires.

Position lamp unit studs through support and install

retaining nuts, making sure that the studs are

horizontal.

Connect harness to lamp unit skirt-mounted connec-

tor and close vehicle hood.

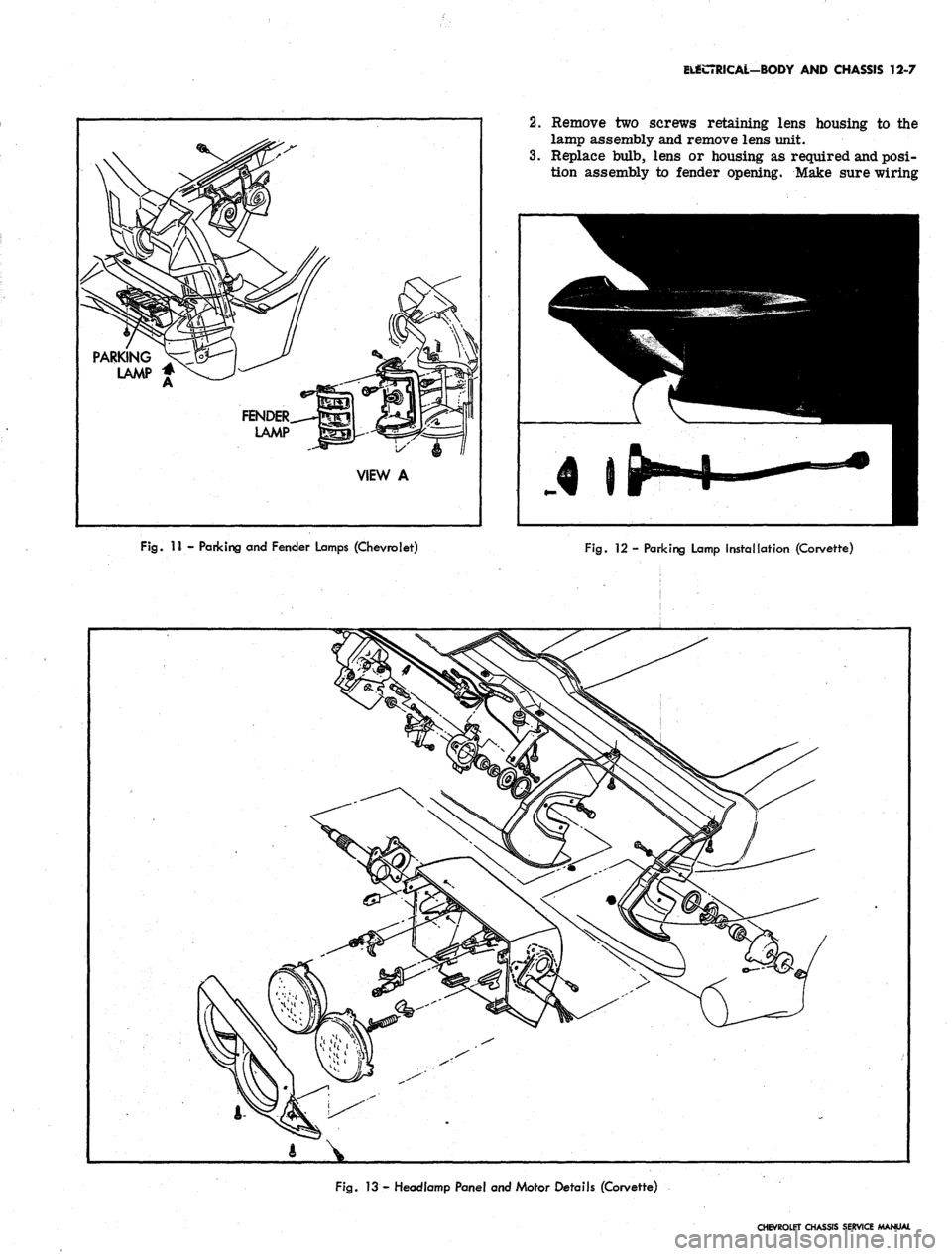

FENDER LAMP SERVICE (Fig. 11)

Chevrolet 16600 Models

1.

Disconnect parking lamp wiring from forward har-

ness connector.

CHEVROLET CHASSIS SERVICE MANUAL

Page 519 of 659

EL«C7RICAL-BODY AND CHASSIS 12-7

PARKING

A

LAMP*

2.

Remove two screws retaining lens housing to the

lamp assembly and remove lens unit.

3.

Replace bulb, lens or housing as required and posi-

tion assembly to fender opening. Make sure wiring

Fig.

11 - Parking and Fender Lamps (Chevrolet)

Fig.

12 - Parking Lamp Installation (Corvette)

Fig.

13 - Headlamp Panel and Motor Details (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 520 of 659

ELECTRICAL-BODY AND CHASSIS 12-8

is inserted through radiator support opening.

Remove two screws retaining lamp assembly to

lower sheet metal.

Remove three screws retaining lamp assembly to

lender.

To replace lamp assembly, reverse removal proce-

dure and check operation of the unit.

is aligned with flat on pivot shaft. Install stop lock

bolt and torque bolt to 45-60 in, lbs. Make sure that

side-to-side panel alignment is not changed when in-

stalling and tightening the stop.

CAUTION: Do not exceed specified torque

when tightening stop lock bolt.

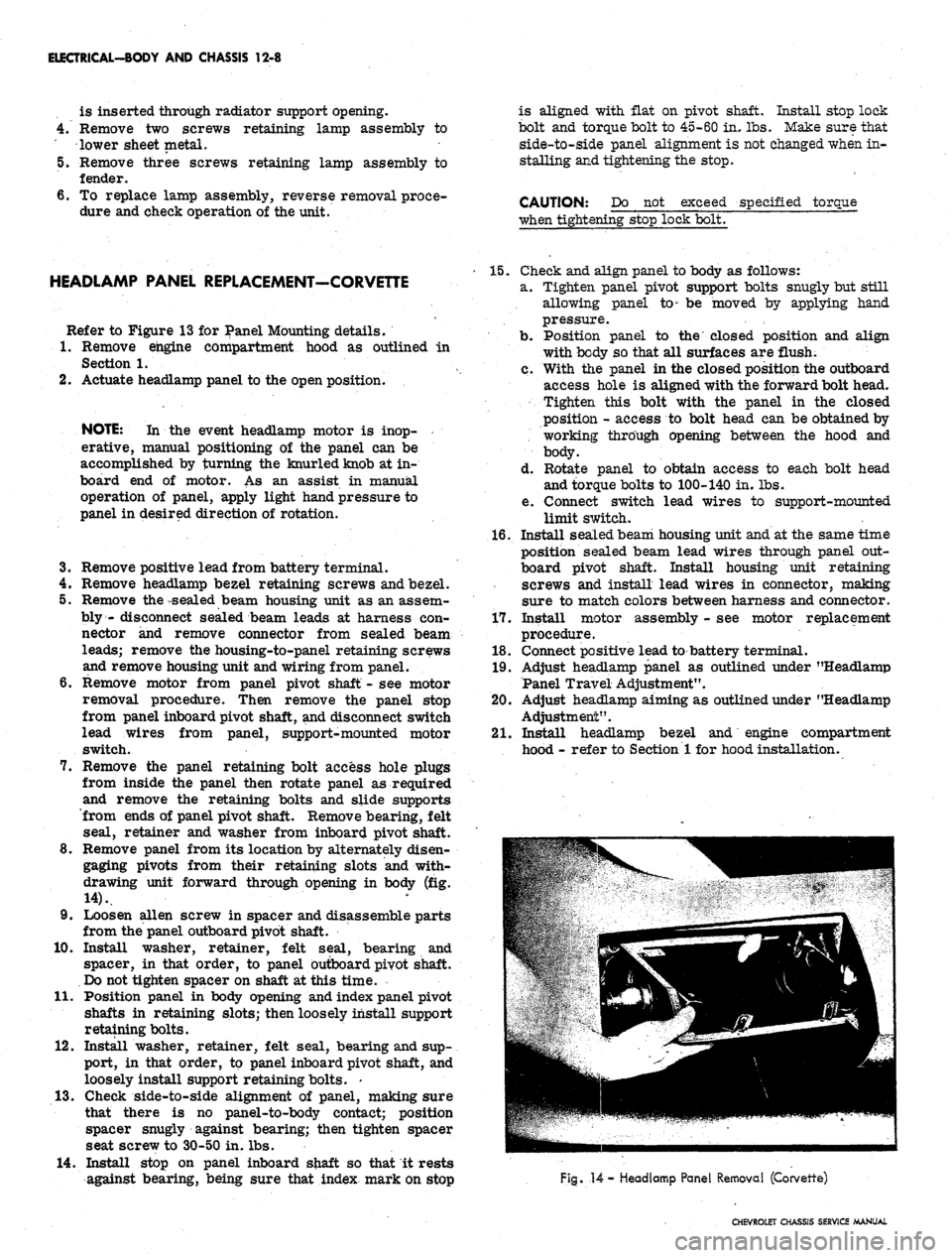

HEADLAMP PANEL REPLACEMENT-CORVETTE

Refer to Figure 13 for Panel Mounting details.

1.

Remove engine compartment hood as outlined in

Section 1.

2.

Actuate headlamp panel to the open position.

NOTE:

In the event headlamp motor is inop-

erative, manual positioning of the panel can be

accomplished by turning the knurled knob at in-

board end of motor. As an assist in manual

operation of panel, apply light hand pressure to

panel in desired direction of rotation.

3.

Remove positive lead from battery terminal.

4.

Remove headlamp bezel retaining screws and bezel.

5. Remove the sealed beam housing unit as an assem-

bly - disconnect sealed beam leads at harness con-

nector and remove connector from sealed beam

leads;

remove the housing-to-panel retaining screws

and remove housing unit and wiring from panel.

6. Remove motor from panel pivot shaft - see motor

removal procedure. Then remove the panel stop

from panel inboard pivot shaft, and disconnect switch

lead wires from panel, support-mounted motor

switch.

7. Remove the panel retaining bolt access hole plugs

from inside the panel then rotate panel as required

and remove the retaining bolts and slide supports

from ends of panel pivot shaft. Remove bearing, felt

seal, retainer and washer from inboard pivot shaft.

8. Remove panel from its location by alternately disen-

gaging pivots from their retaining slots and with-

drawing unit forward through opening in body (fig.

14).

9. Loosen alien screw in spacer and disassemble parts

from the panel outboard pivot shaft.

10.

Install washer, retainer, felt seal, bearing and

spacer, in that order, to panel outboard pivot shaft.

Do not tighten spacer on shaft at this time.

11.

Position panel in body opening and index panel pivot

shafts in retaining slots; then loosely install support

retaining bolts.

12.

Install washer, retainer, felt seal, bearing and sup-

port, in that order, to panel inboard pivot shaft, and

loosely install support retaining bolts. -

13.

Check side-to-side alignment of panel, making sure

that there is no panel-to-body contact; position

spacer snugly against bearing; then tighten spacer

seat screw to 30-50 in. lbs.

14.

Install stop on panel inboard shaft so that it rests

against bearing, being sure that index mark on stop

15.

Check and align panel to body as follows:

a. Tighten panel pivot support bolts snugly but still

allowing panel to" be moved by applying hand

pressure.

b.

Position panel to the closed position and align

with body so that all surfaces are flush.

c. With the panel in the closed position the outboard

access hole is aligned with the forward bolt head.

Tighten this bolt with the panel in the closed

position - access to bolt head can be obtained by

working through opening between the hood and

body.

d. Rotate panel to obtain access to each bolt head

and torque bolts to 100-140 in. lbs.

e. Connect switch lead wires to support-mounted

limit switch.

16.

Install seaLed beam housing unit and at the same time

position sealed beam lead wires through panel out-

board pivot shaft. Install housing unit retaining

screws and install lead wires in connector, making

sure to match colors between harness and connector.

17.

Install motor assembly - see motor replacement

procedure.

18.

Connect positive lead to battery terminal.

19.

Adjust headlamp panel as outlined under "Headlamp

Panel Travel Adjustment".

20.

Adjust headlamp aiming as outlined under "Headlamp

Adjustment".

21.

Install headlamp bezel and engine compartment

hood - refer to Section 1 for hood installation.

Fig.

14

- Headlamp Panel Removal (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL