CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 381 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 381

It is not necessary to remove the radi

ator hose from the thermostat housing.

4. Remove the two retaining bolts from the thermostat housing and remove

the thermostat.

To install: 5. Using a new gasket, install the thermostat and housing.

6. Tighten the bolts to 21 ft lbs. (28 Nm).

7. Fill and bleed t he cooling system.

INTAKE MANIFOLD

REMOVAL & INSTALLATION

When servicing all vehicles, be absolutel y sure to mark vacuum hoses and

wiring so that these items may be properly reconnected during installation. Also,

when disconnecting fitting lines (fuel lines, power brake vacuum lines,

transmission and engine cooler lines, etc.), always use two flare nut (or line)

wrenches. Hold the wrench on the large fitti ng with pressure on the wrench as if

you were tightening the fitting (clockw ise), THEN loosen and disconnect the

smaller fitting from the larger fitting. If this is not done, damage to the line will

result. Always relieve fuel system pressure before disconnecting lines.

CAUTION - When draining the coolant, keep in mind that cats and dogs are

attracted by the ethylene gl ycol antifreeze, and are quite likely to drink any that

is left in an uncovered container or in puddles on the ground. This will prove

fatal in sufficient quantity. Always drai n the coolant into a sealable container.

Coolant should be reused unless it is contaminated or several years old.

2.5L ENGINE

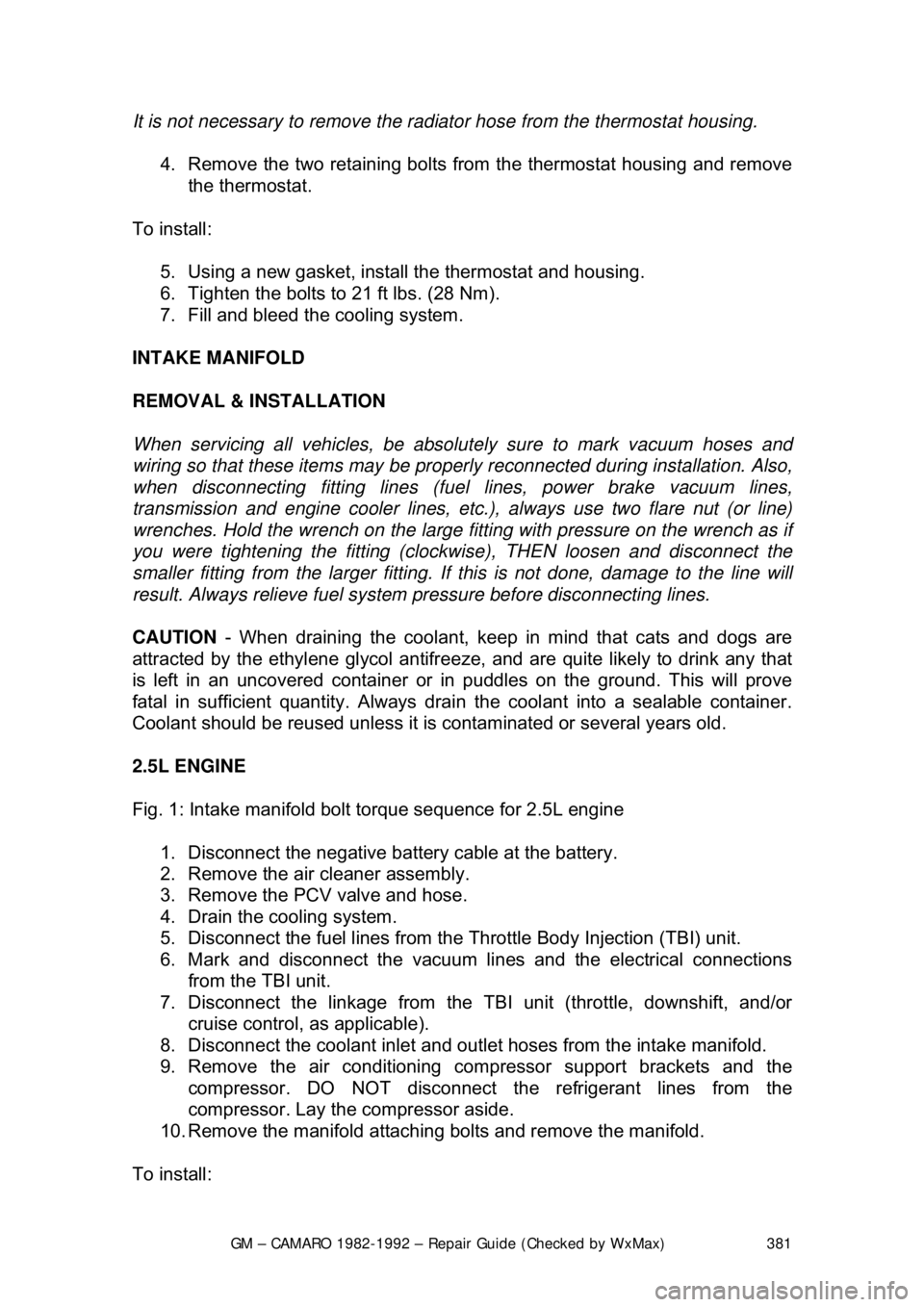

Fig. 1: Intake manifold bol t torque sequence for 2.5L engine

1. Disconnect the negative batte ry cable at the battery.

2. Remove the air cleaner assembly.

3. Remove the PCV valve and hose.

4. Drain the cooling system.

5. Disconnect the fuel lines from the Throttle Body Injection (TBI) unit.

6. Mark and disconnect the vacuum li nes and the electrical connections

from the TBI unit.

7. Disconnect the linkage from the TBI unit (throttle, downshift, and/or

cruise control, as applicable).

8. Disconnect the coolant inlet and outlet hoses from the intake manifold.

9. Remove the air conditioning co mpressor support brackets and the

compressor. DO NOT disconnect the refrigerant lines from the

compressor. Lay the compressor aside.

10. Remove the manifold attachi ng bolts and remove the manifold.

To install:

Page 382 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 382

11. Position the manifold into place and install manifold attaching bolts.

Torque manifold bolts to specificat ion (see illustration for tightening

sequence and torque specifications).

12. Install the air conditioning comp ressor and compressor support brackets,

if so equipped.

13. Connect the coolant inlet and outlet hoses to the intake manifold.

14. Connect the linkage to the TBI unit (throttle, downshift, and/or cruise

control, as applicable).

15. Connect the vacuum lines and the elec trical connections to the TBI unit.

16. Connect the fuel lines to the Th rottle Body Injection (TBI) unit.

17. Install the PCV valve and hose.

18. Install the air cleaner assembly.

19. Connect the negative battery cable at the battery.

20. Fill the cooling system.

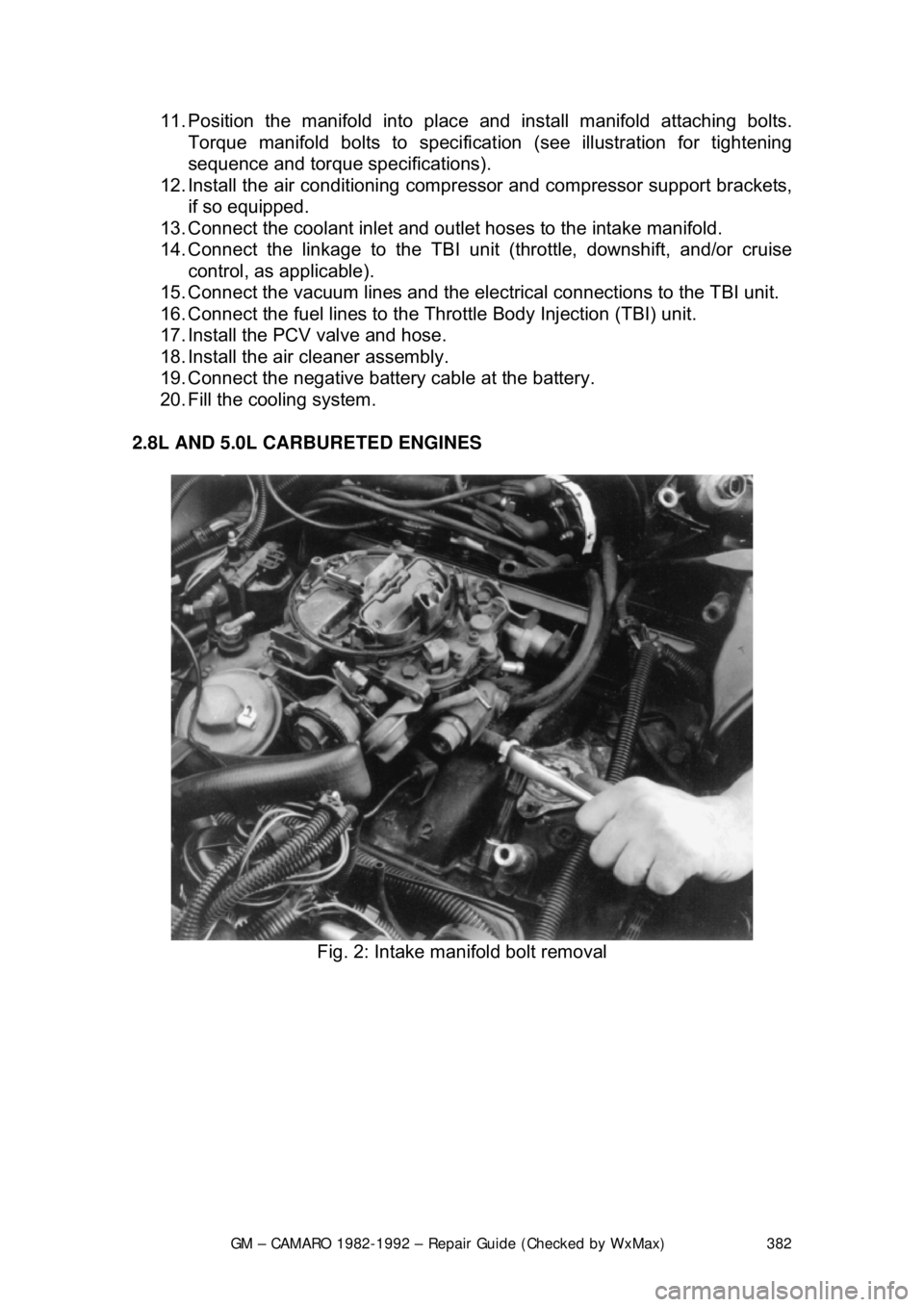

2.8L AND 5.0L CARBURETED ENGINES

Fig. 2: Intake manifold bolt removal

Page 383 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 383

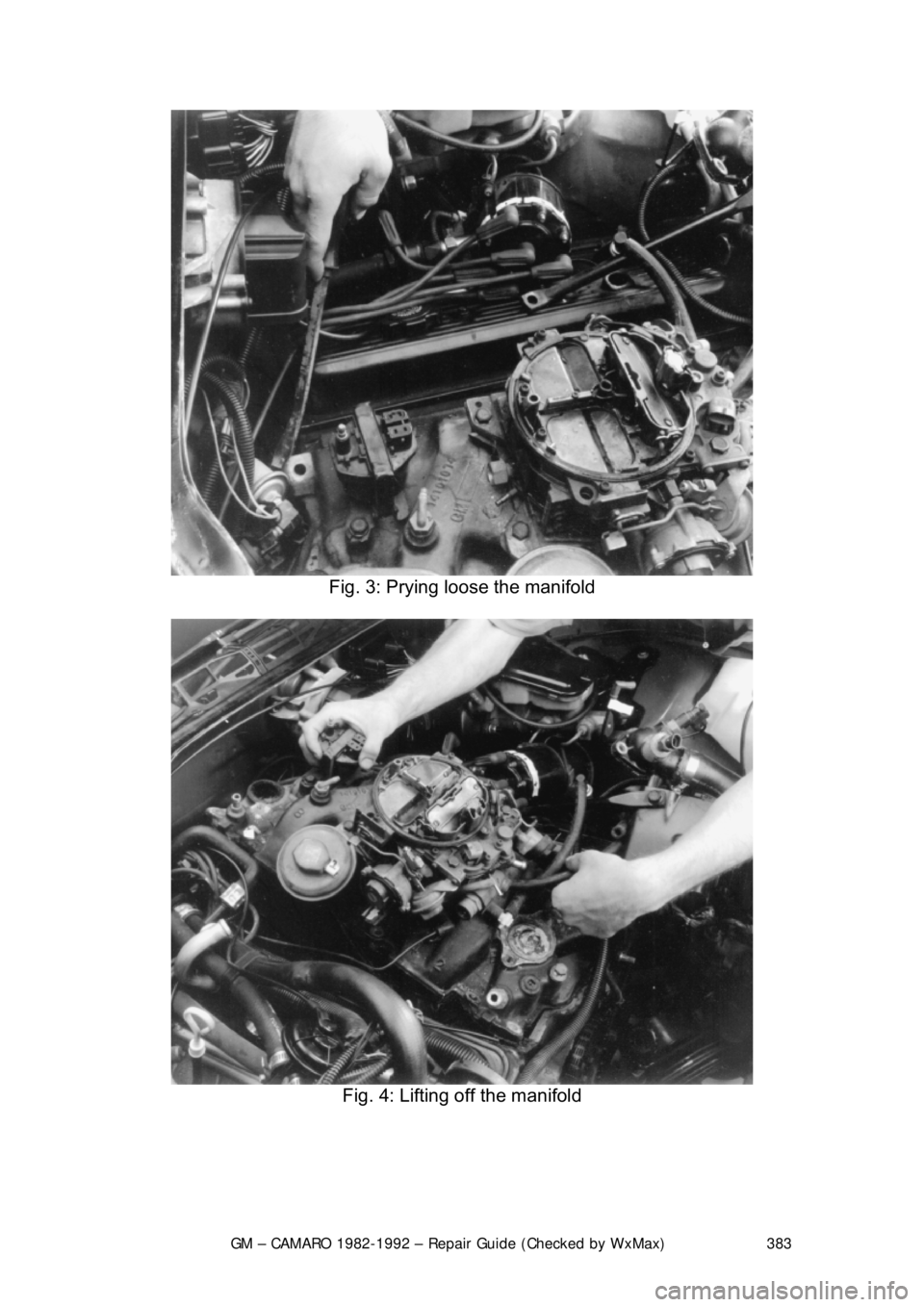

Fig. 3: Prying loose the manifold

Fig. 4: Lifting off the manifold

Page 384 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 384

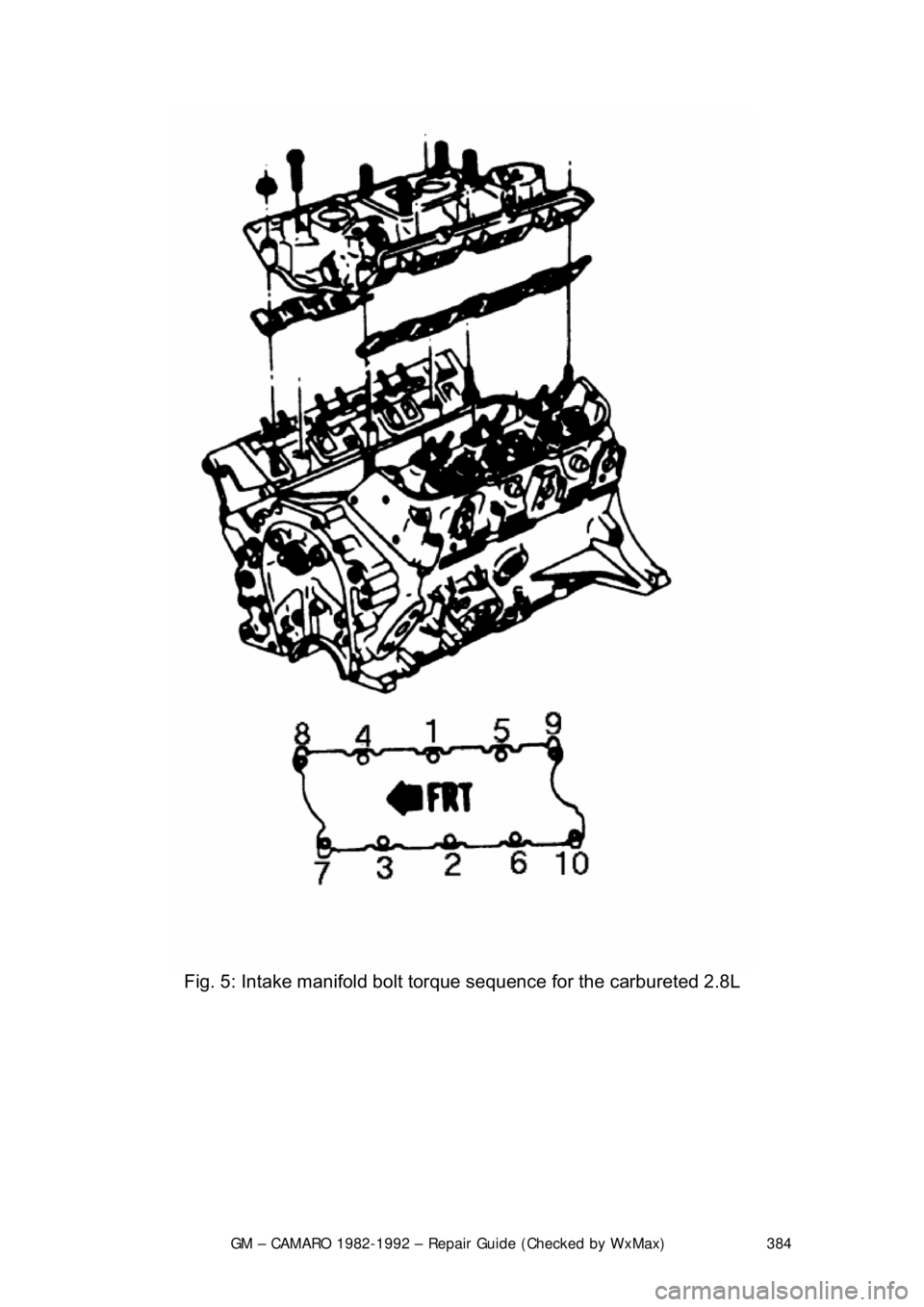

Fig. 5: Intake manifold bolt to rque sequence for the carbureted 2.8L

Page 385 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 385

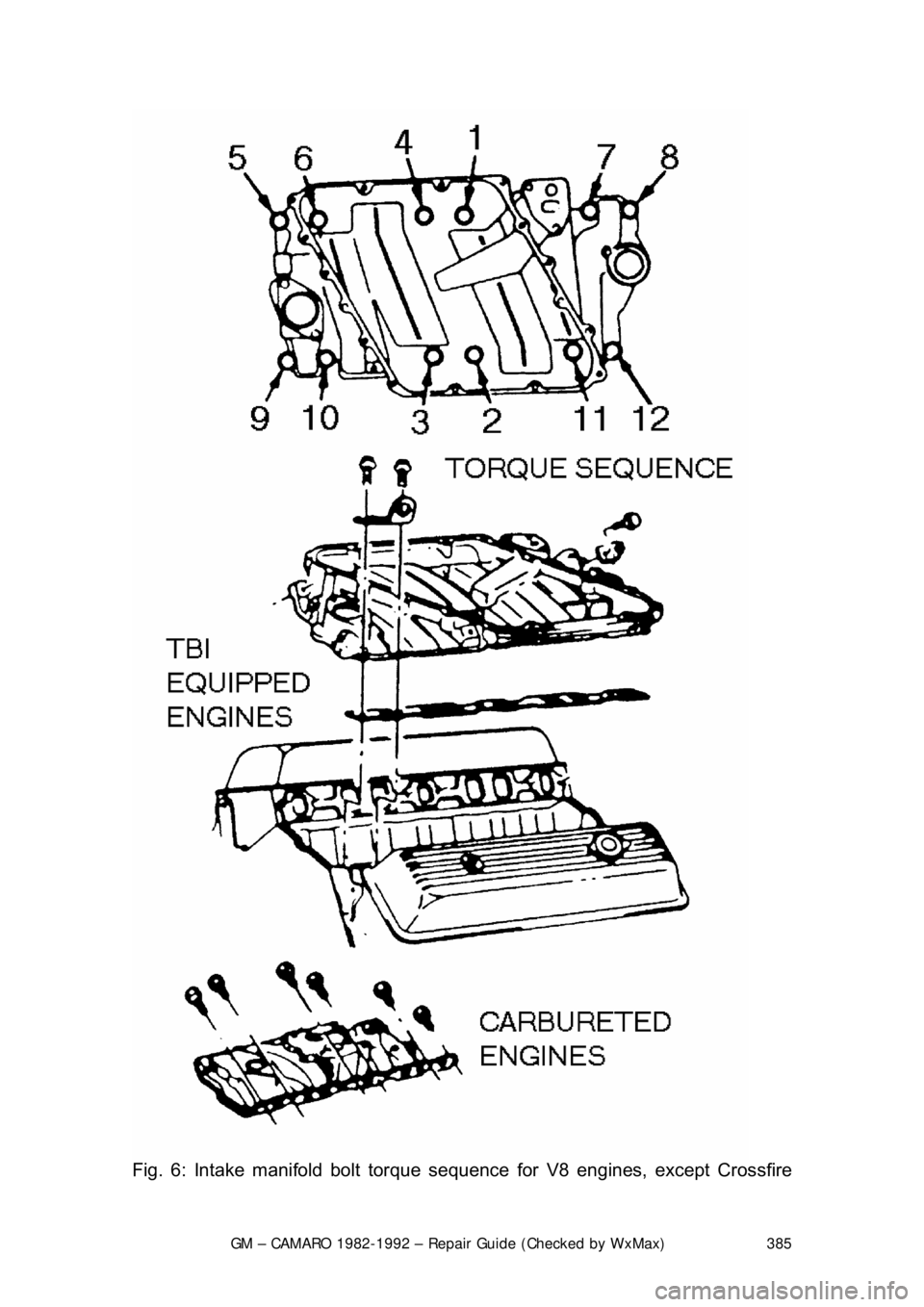

Fig. 6: Intake manifold bolt torque sequ ence for V8 engines, except Crossfire

Page 386 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 386

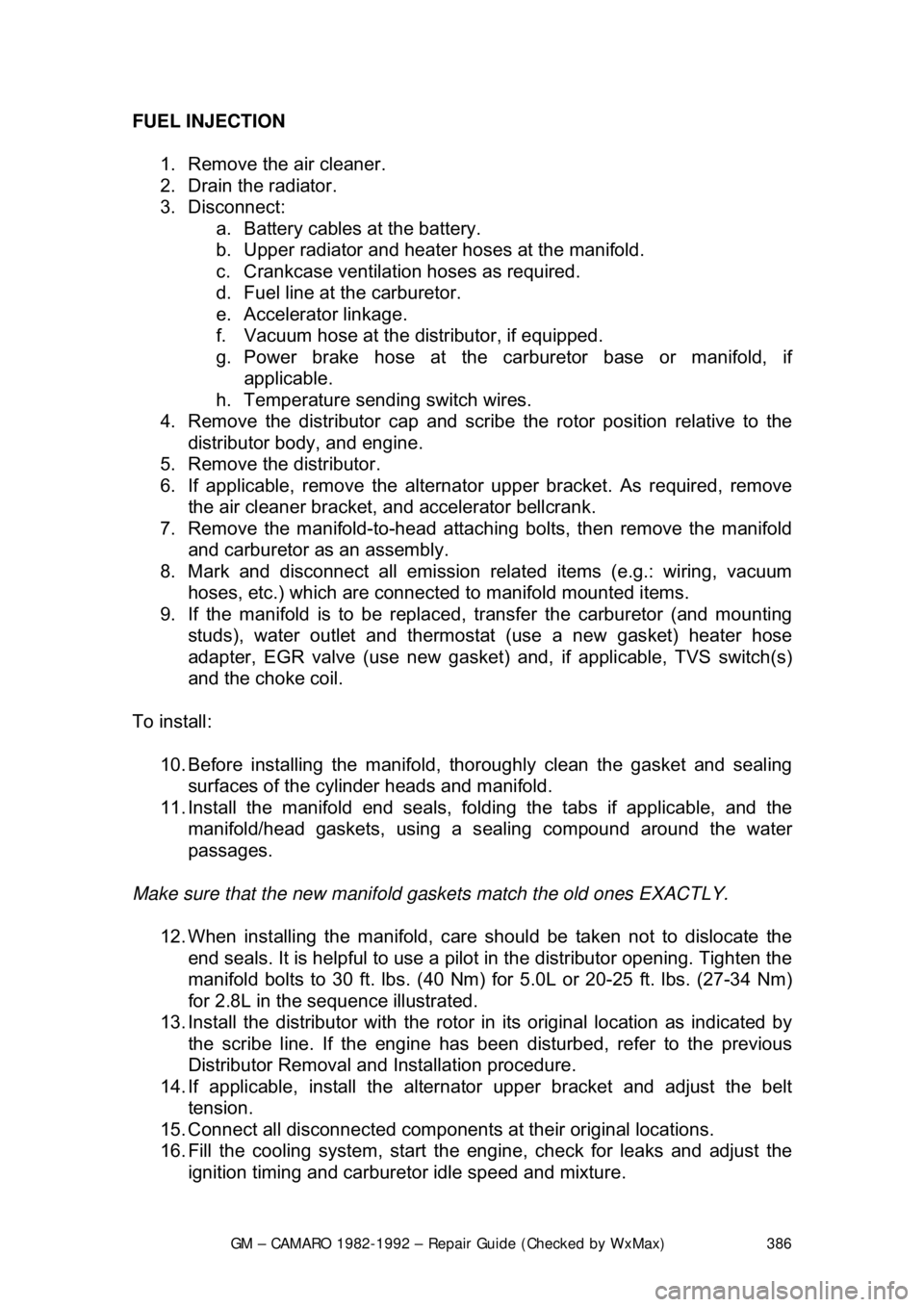

FUEL INJECTION

1. Remove the air cleaner.

2. Drain the radiator.

3. Disconnect: a. Battery cables at the battery.

b. Upper radiator and heater hoses at the manifold.

c. Crankcase ventilation hoses as required.

d. Fuel line at the carburetor.

e. Accelerator linkage.

f. Vacuum hose at the distributor, if equipped.

g. Power brake hose at the car buretor base or manifold, if

applicable.

h. Temperature sending switch wires.

4. Remove the distributor cap and scribe the rotor position relative to the

distributor body, and engine.

5. Remove the distributor.

6. If applicable, remove the alternator upper bracket. As required, remove

the air cleaner bracket, and accelerator bellcrank.

7. Remove the manifold-to-head attachi ng bolts, then remove the manifold

and carburetor as an assembly.

8. Mark and disconnect all emission re lated items (e.g.: wiring, vacuum

hoses, etc.) which are connected to manifold mounted items.

9. If the manifold is to be replaced , transfer the carburetor (and mounting

studs), water outlet and thermostat (use a new gasket) heater hose

adapter, EGR valve (use new gasket) and, if applicable, TVS switch(s)

and the choke coil.

To install: 10. Before installing the manifold, thoroughly clean the gasket and sealing

surfaces of the cylinder heads and manifold.

11. Install the manifold end seals, folding the tabs if applicable, and the

manifold/head gaskets, using a s ealing compound around the water

passages.

Make sure that the new manifold gaskets match the old ones EXACTLY.

12. When installing the manifold, care should be taken not to dislocate the

end seals. It is helpful to use a pilo t in the distributor opening. Tighten the

manifold bolts to 30 ft. lbs. (40 Nm) for 5.0L or 20-25 ft. lbs. (27-34 Nm)

for 2.8L in the sequence illustrated.

13. Install the distributor with the rotor in its original location as indicated by

the scribe line. If the engi ne has been disturbed, refer to the previous

Distributor Removal and Installation procedure.

14. If applicable, install the alter nator upper bracket and adjust the belt

tension.

15. Connect all disconnected components at their original locations.

16. Fill the cooling system, start the engine, check for leaks and adjust the

ignition timing and carburetor idle speed and mixture.

Page 387 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 387

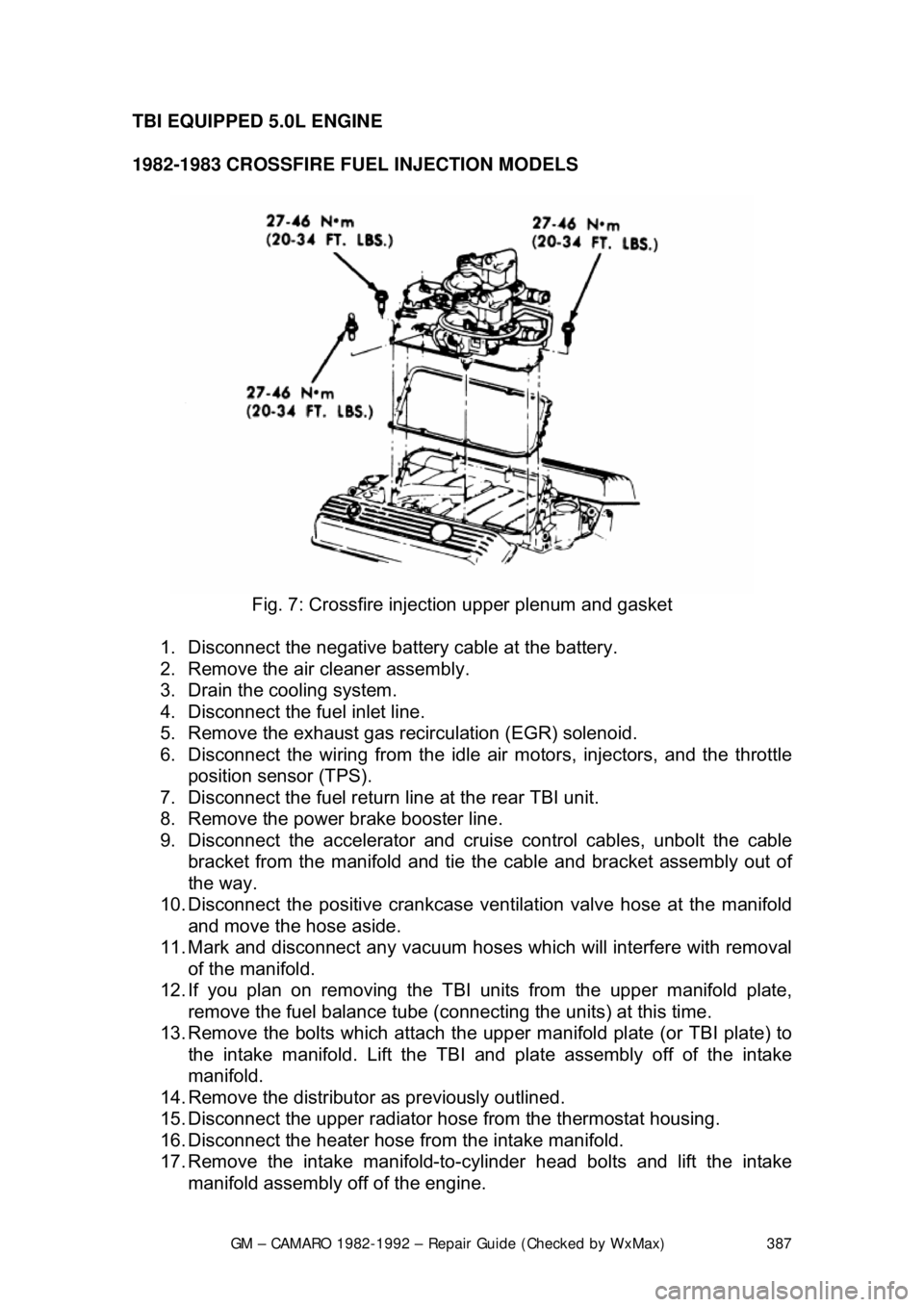

TBI EQUIPPED 5.0L ENGINE

1982-1983 CROSSFIRE FUEL INJECTION MODELS

Fig. 7: Crossfire inje ction upper plenum and gasket

1. Disconnect the negative batte ry cable at the battery.

2. Remove the air cleaner assembly.

3. Drain the cooling system.

4. Disconnect the fuel inlet line.

5. Remove the exhaust gas re circulation (EGR) solenoid.

6. Disconnect the wiring fr om the idle air motors, injectors, and the throttle

position sensor (TPS).

7. Disconnect the fuel return line at the rear TBI unit.

8. Remove the power brake booster line.

9. Disconnect the accelerator and crui se control cables, unbolt the cable

bracket from the manifold and tie t he cable and bracket assembly out of

the way.

10. Disconnect the positive crankcase vent ilation valve hose at the manifold

and move the hose aside.

11. Mark and disconnect any vacuum hoses which will interfere with removal of the manifold.

12. If you plan on removing the TBI units from the upper manifold plate, remove the fuel balance tube (connec ting the units) at this time.

13. Remove the bolts which attach the upp er manifold plate (or TBI plate) to

the intake manifold. Lift the TBI and plate assembly off of the intake

manifold.

14. Remove the distributor as previously outlined.

15. Disconnect the upper radiator hos e from the thermostat housing.

16. Disconnect the heater hose fr om the intake manifold.

17. Remove the intake manifold-to- cylinder head bolts and lift the intake

manifold assembly off of the engine.

Page 388 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 388

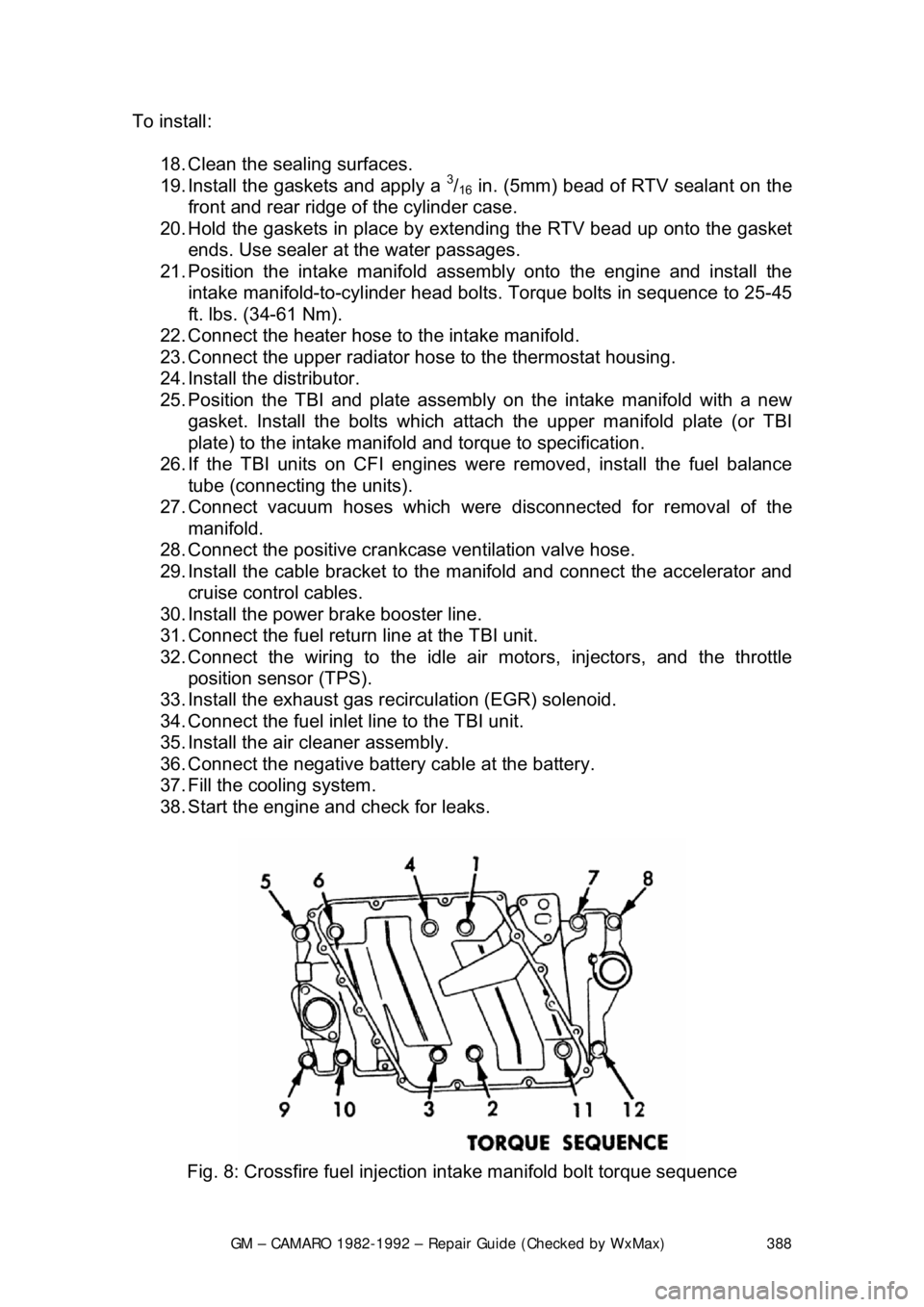

To install:

18. Clean the sealing surfaces.

19. Install the gaskets and apply a

3/16 in. (5mm) bead of RTV sealant on the

front and rear ridge of the cylinder case.

20. Hold the gaskets in place by ex tending the RTV bead up onto the gasket

ends. Use sealer at the water passages.

21. Position the intake manifold as sembly onto the engine and install the

intake manifold-to-cylinder head bolts. Torque bolts in sequence to 25-45

ft. lbs. (34-61 Nm).

22. Connect the heater hose to the intake manifold.

23. Connect the upper radiator hose to the thermostat housing.

24. Install the distributor.

25. Position the TBI and plate assembly on the intake manifold with a new

gasket. Install the bolts which attach the upper manifold plate (or TBI

plate) to the intake manifold and torque to specification.

26. If the TBI units on CFI engines were removed, install the fuel balance

tube (connecting the units).

27. Connect vacuum hoses which were disconnected for removal of the manifold.

28. Connect the positive crankcase ventilation valve hose.

29. Install the cable bracket to the m anifold and connect the accelerator and

cruise control cables.

30. Install the power brake booster line.

31. Connect the fuel return line at the TBI unit.

32. Connect the wiring to the idle air motors, injectors, and the throttle

position sensor (TPS).

33. Install the exhaust gas re circulation (EGR) solenoid.

34. Connect the fuel inlet line to the TBI unit.

35. Install the air cleaner assembly.

36. Connect the negative battery cable at the battery.

37. Fill the cooling system.

38. Start the engine and check for leaks.

Fig. 8: Crossfire fuel injection intake manifold bolt torque sequence

Page 389 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 389

1988-1992 MODELS

1. Disconnect the negative battery cable.

2. Drain the cooling system.

3. Remove the air cleaner.

4. Remove the throttle body.

5. Label and unplug all vacuum hose and electrical connections on the manifold.

6. Disconnect the upper radiator hose from the manifold.

7. Mark the distributor position and remove it.

8. Remove the EGR valve, if necessary.

9. Remove the intake manifold bolts and studs.

10. Remove the manifold and discard the gaskets.

To install: 11. Make sure the sealing surfaces are clean.

12. Install the gaskets and apply a

3/16 in. (5mm) bead of RTV sealant on the

front and rear ridge of the cylinder block.

13. Hold the gaskets in place by ex tending the RTV bead up onto the gasket

ends. Use sealer at the water passages.

14. Install the intake manifold.

Sealing of the intake mani fold to the "V" of the engine is obtained by employing

an intermediate torque specification to a ll the attaching bolts, alternately, in the

proper sequence. This step is used to rock the manifold into place before

applying the final torque figur e. Failure to follow this two-step procedure can

result in possible leaks.

15. Install the intake manifold attach ing bolts. Tighten them, using the proper

sequence, to 89 in lbs. (10 Nm).

16. Final torque the bolts, using the proper sequence, to 35 ft lbs. (47 Nm\

).

17. Install the EGR valve.

18. Install the distributor.

19. Connect the upper radiator hose to the thermostat housing.

20. Install the throttle body.

21. Engage all electrical and hose connections.

22. Fill the cooling system.

23. Connect the negative battery cable.

24. Install the air cleaner.

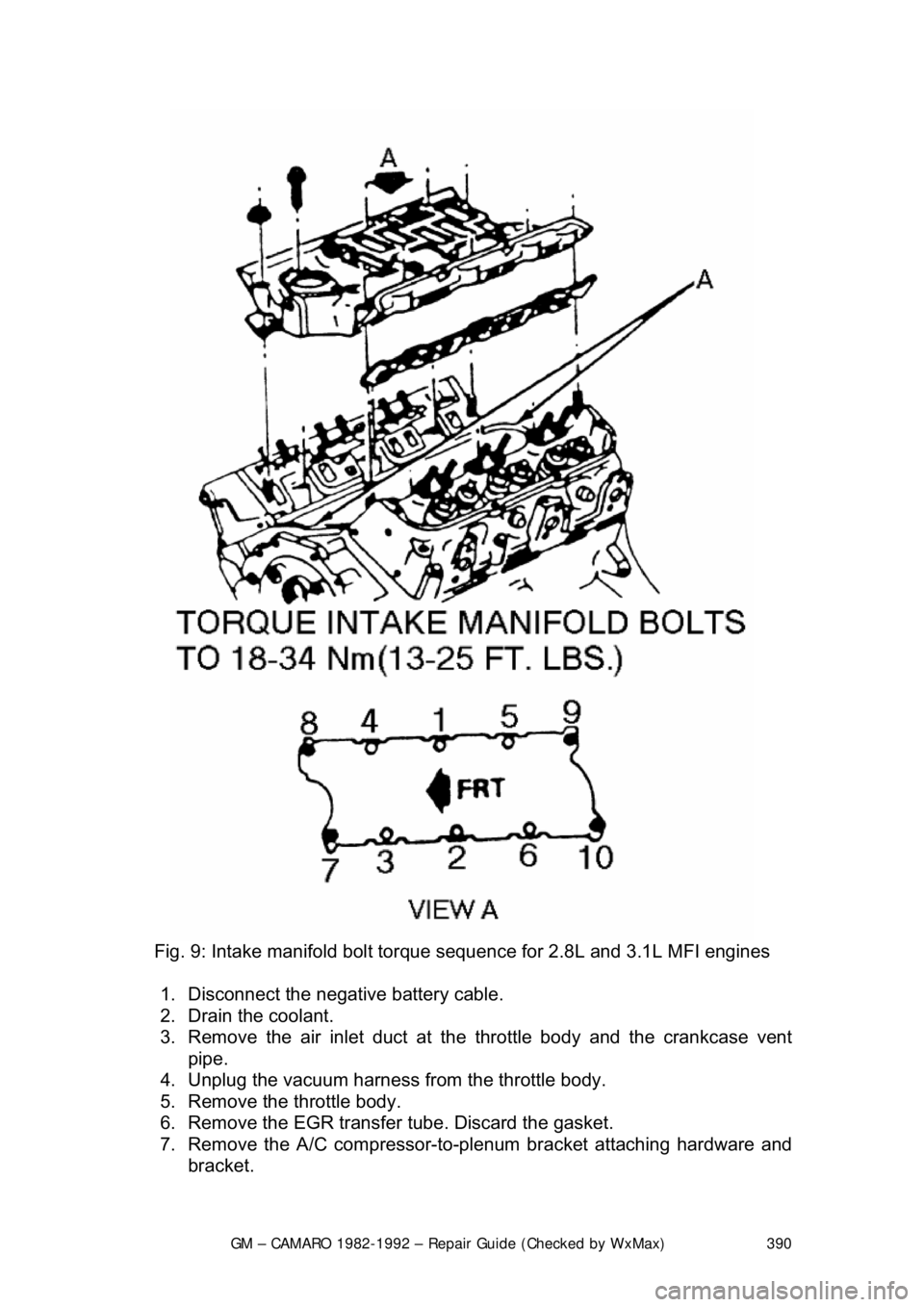

1985-1992 MFI ENGINES

2.8L AND 3.1L ENGINES

Page 390 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 390

Fig. 9: Intake manifold bolt tor que sequence for 2.8L and 3.1L MFI engines

1. Disconnect the negative battery cable.

2. Drain the coolant.

3. Remove the air inlet duct at t he throttle body and the crankcase vent

pipe.

4. Unplug the vacuum harness from the throttle body.

5. Remove the throttle body.

6. Remove the EGR transfer tube. Discard the gasket.

7. Remove the A/C compressor-to-plenum bracket attaching hardware and

bracket.