CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

PLYMOUTH ACCLAIM 1993

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/56861/w960_56861-0.png

CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Trending: maintenance, battery replacement, interior lights, run flat, wheel bolts, sensor, turn signal bulb

Page 2031 of 2438

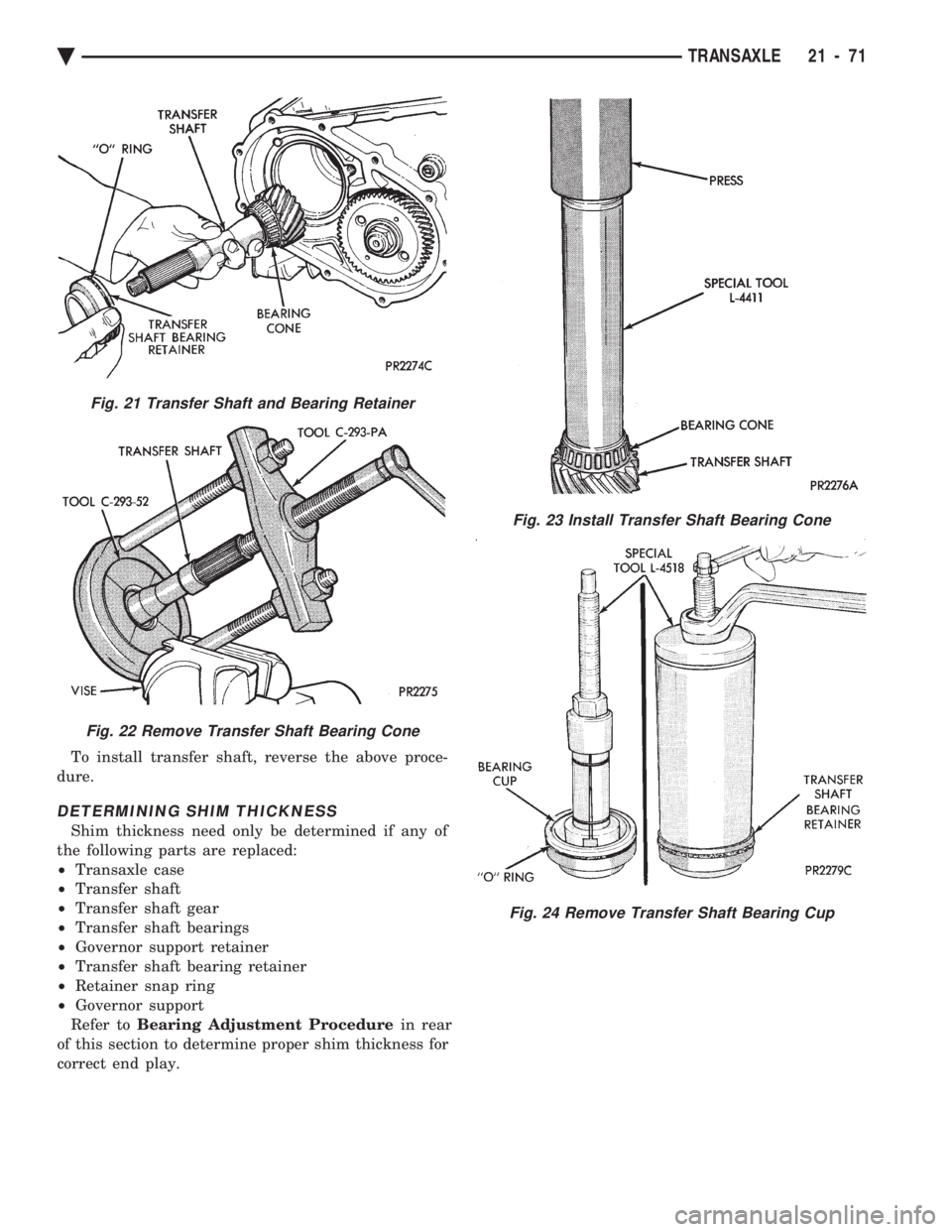

To install transfer shaft, reverse the above proce-

dure.

DETERMINING SHIM THICKNESS

Shim thickness need only be determined if any of

the following parts are replaced:

² Transaxle case

² Transfer shaft

² Transfer shaft gear

² Transfer shaft bearings

² Governor support retainer

² Transfer shaft bearing retainer

² Retainer snap ring

² Governor support

Refer to Bearing Adjustment Procedure in rear

of this section to determine proper shim thickness for

correct end play.

Fig. 23 Install Transfer Shaft Bearing Cone

Fig. 24 Remove Transfer Shaft Bearing Cup

Fig. 21 Transfer Shaft and Bearing Retainer

Fig. 22 Remove Transfer Shaft Bearing Cone

Ä TRANSAXLE 21 - 71

Page 2032 of 2438

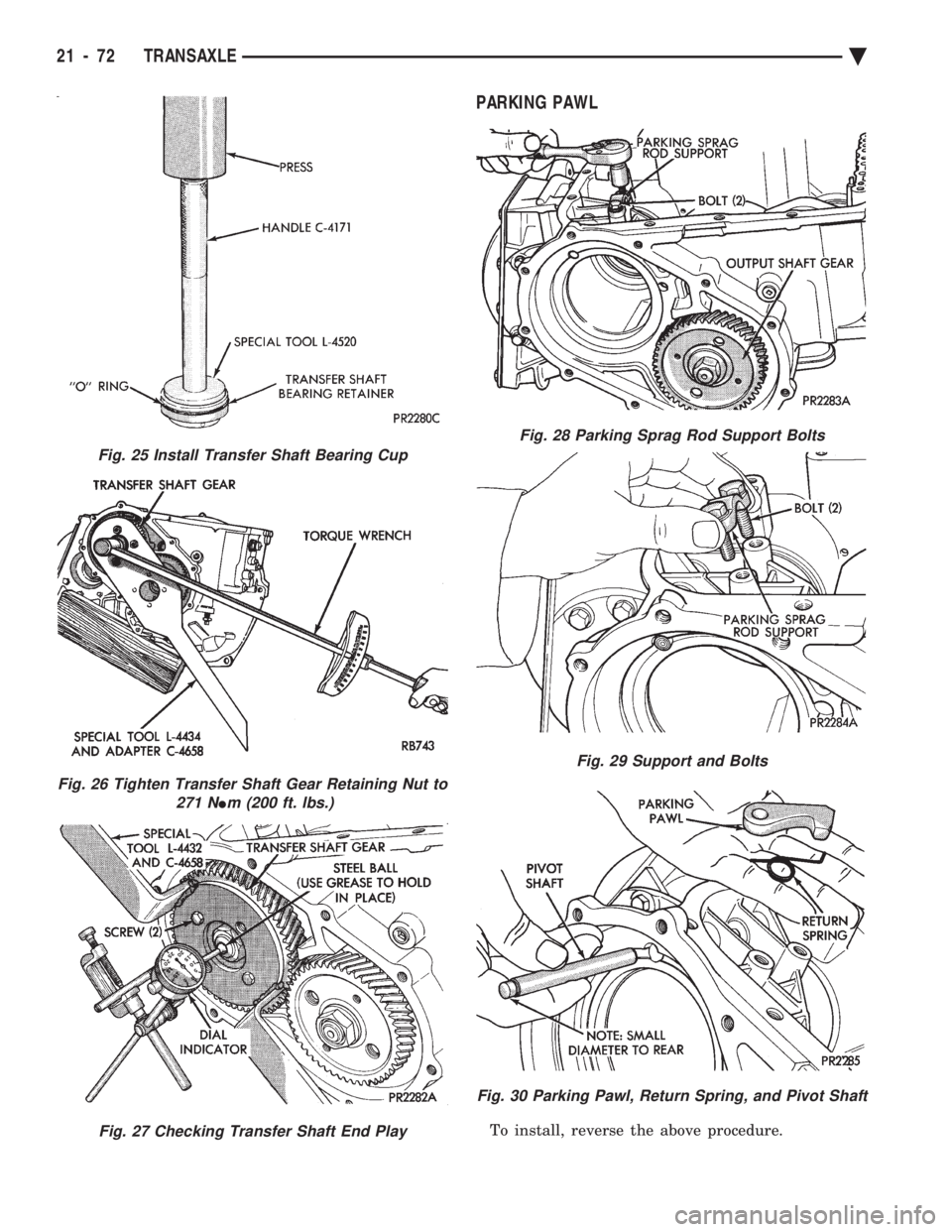

PARKING PAWL

To install, reverse the above procedure.

Fig. 25 Install Transfer Shaft Bearing Cup

Fig. 26 Tighten Transfer Shaft Gear Retaining Nut to 271 N

Im (200 ft. lbs.)

Fig. 27 Checking Transfer Shaft End Play

Fig. 28 Parking Sprag Rod Support Bolts

Fig. 29 Support and Bolts

Fig. 30 Parking Pawl, Return Spring, and Pivot Shaft

21 - 72 TRANSAXLE Ä

Page 2033 of 2438

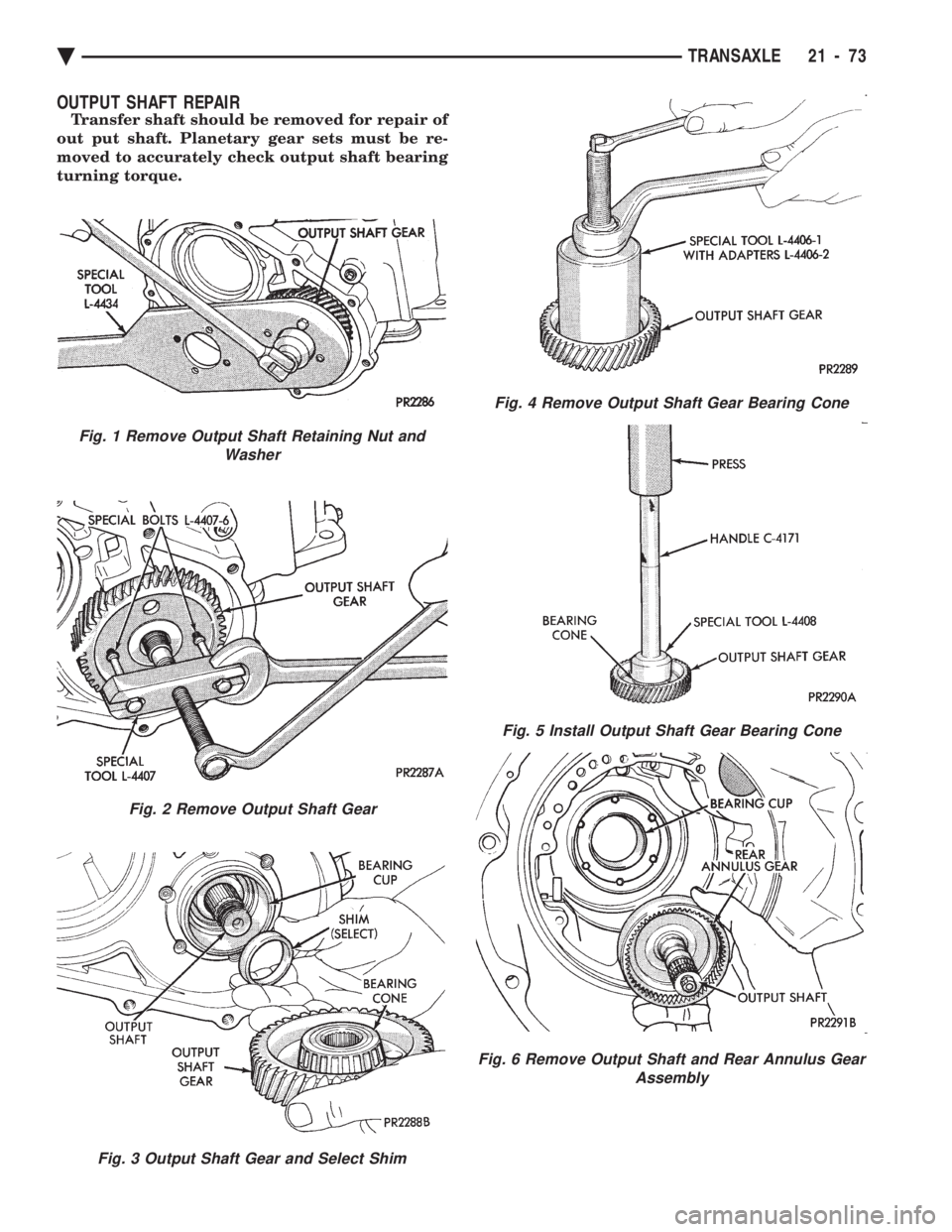

OUTPUT SHAFT REPAIR

Transfer shaft should be removed for repair of

out put shaft. Planetary gear sets must be re-

moved to accurately check output shaft bearing

turning torque.

Fig. 1 Remove Output Shaft Retaining Nut and Washer

Fig. 2 Remove Output Shaft Gear

Fig. 3 Output Shaft Gear and Select Shim

Fig. 4 Remove Output Shaft Gear Bearing Cone

Fig. 5 Install Output Shaft Gear Bearing Cone

Fig. 6 Remove Output Shaft and Rear Annulus Gear Assembly

Ä TRANSAXLE 21 - 73

Page 2034 of 2438

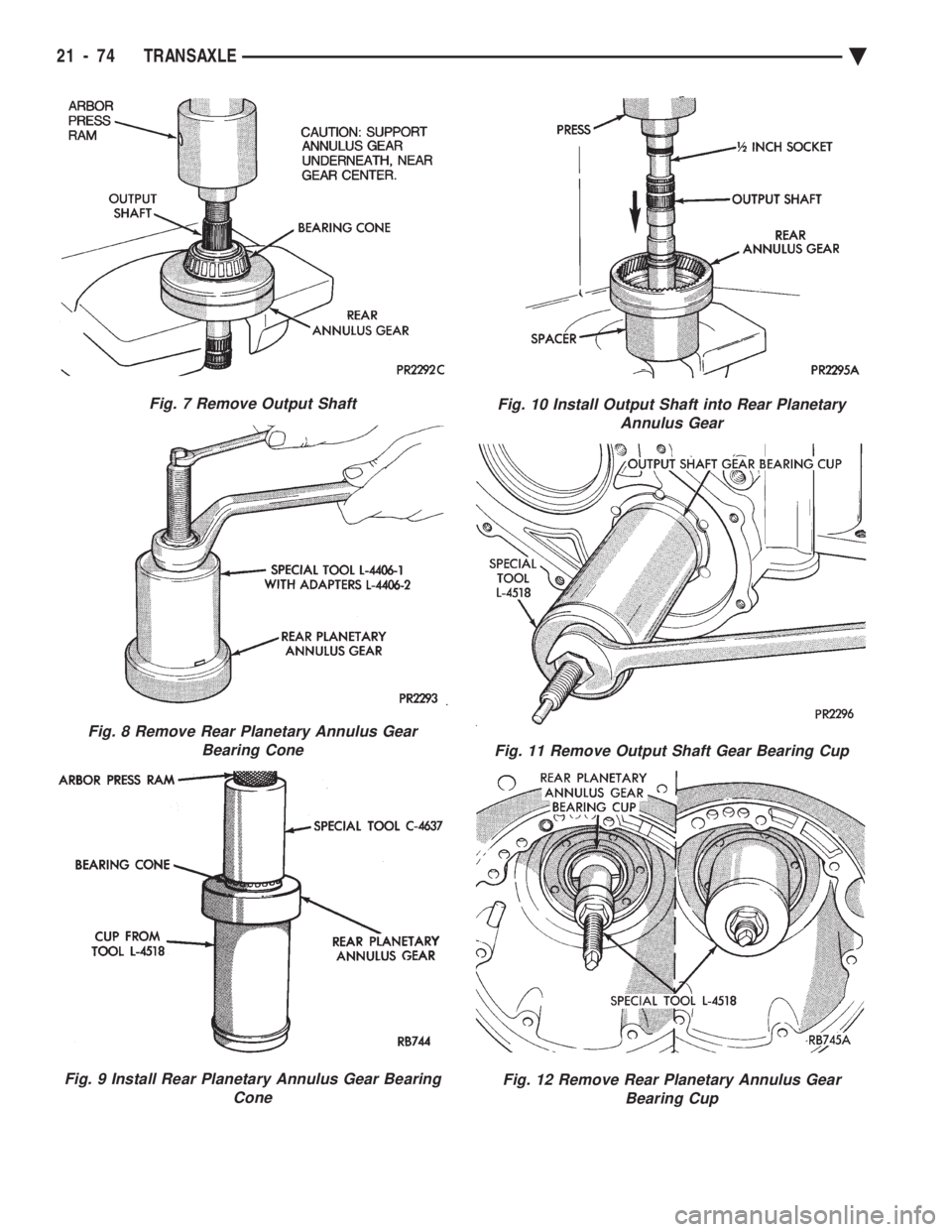

Fig. 7 Remove Output Shaft

Fig. 8 Remove Rear Planetary Annulus Gear Bearing Cone

Fig. 9 Install Rear Planetary Annulus Gear Bearing Cone

Fig. 10 Install Output Shaft into Rear PlanetaryAnnulus Gear

Fig. 11 Remove Output Shaft Gear Bearing Cup

Fig. 12 Remove Rear Planetary Annulus GearBearing Cup

21 - 74 TRANSAXLE Ä

Page 2035 of 2438

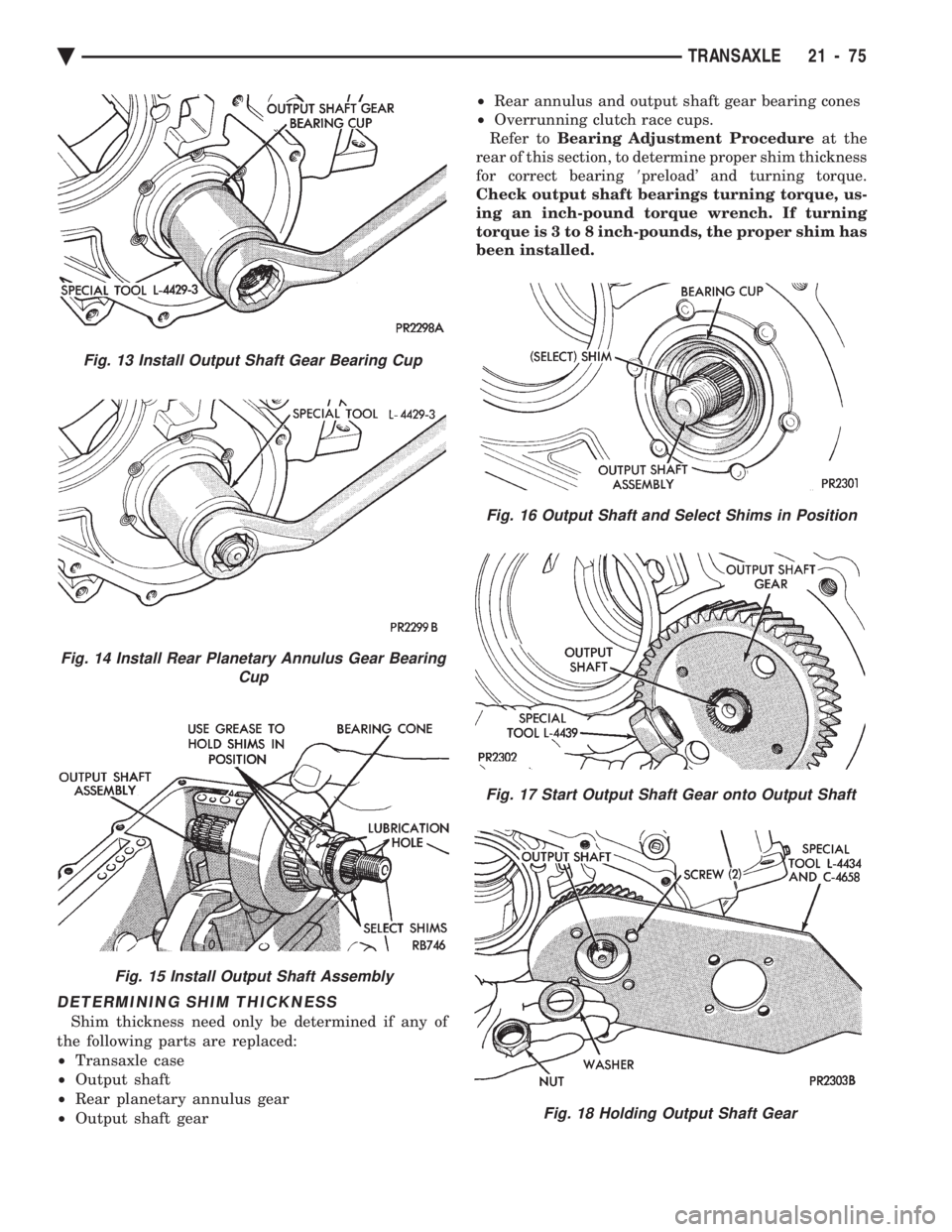

DETERMINING SHIM THICKNESS

Shim thickness need only be determined if any of

the following parts are replaced:

² Transaxle case

² Output shaft

² Rear planetary annulus gear

² Output shaft gear ²

Rear annulus and output shaft gear bearing cones

² Overrunning clutch race cups.

Refer to Bearing Adjustment Procedure at the

rear of this section, to determine proper shim thickness

for correct bearing 8preload' and turning torque.

Check output shaft bearings turning torque, us-

ing an inch-pound torque wrench. If turning

torque is 3 to 8 inch-pounds, the proper shim has

been installed.

Fig. 15 Install Output Shaft Assembly

Fig. 16 Output Shaft and Select Shims in Position

Fig. 17 Start Output Shaft Gear onto Output Shaft

Fig. 18 Holding Output Shaft Gear

Fig. 14 Install Rear Planetary Annulus Gear Bearing Cup

Fig. 13 Install Output Shaft Gear Bearing Cup

Ä TRANSAXLE 21 - 75

Page 2036 of 2438

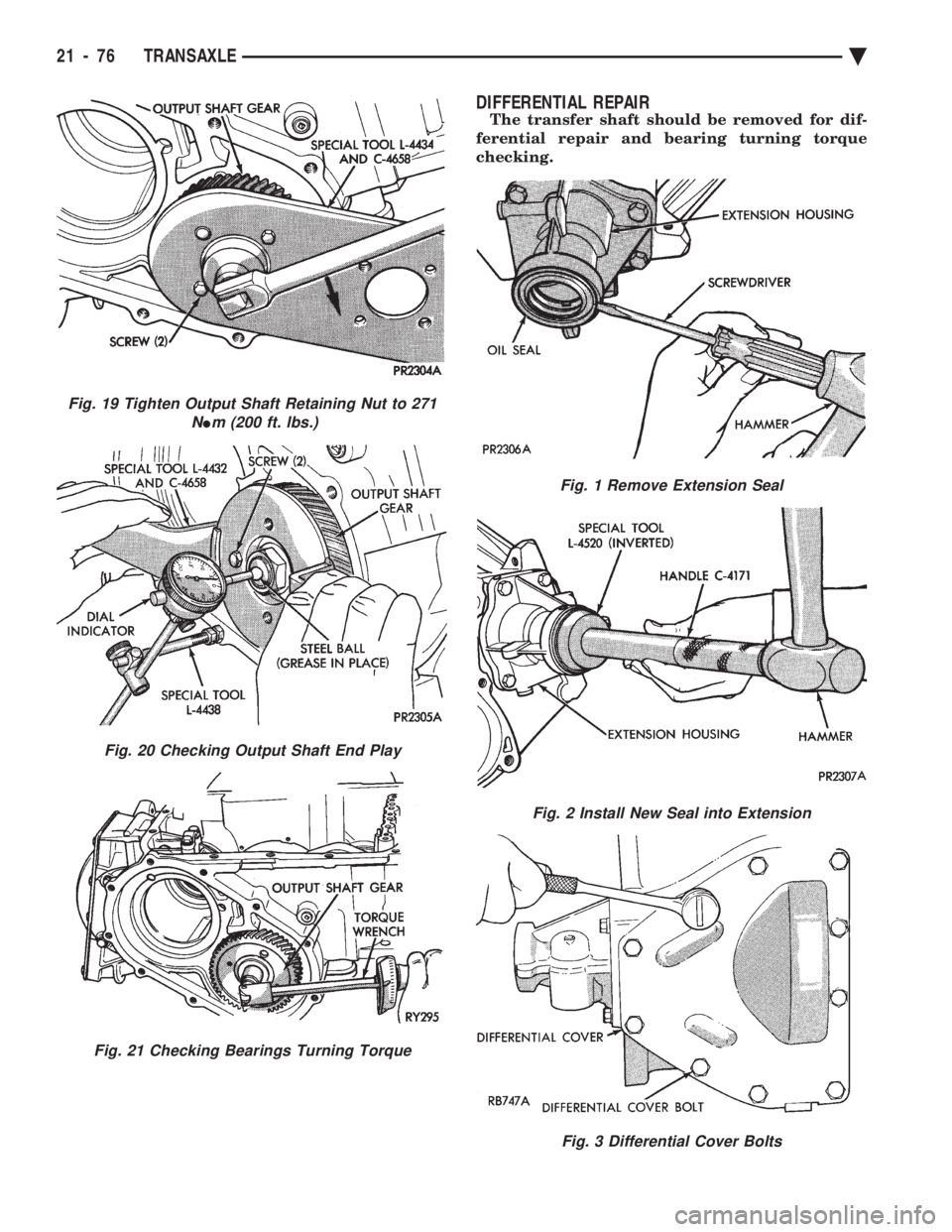

DIFFERENTIAL REPAIR

The transfer shaft should be removed for dif-

ferential repair and bearing turning torque

checking.

Fig. 19 Tighten Output Shaft Retaining Nut to 271 N

Im (200 ft. lbs.)

Fig. 20 Checking Output Shaft End Play

Fig. 21 Checking Bearings Turning Torque

Fig. 1 Remove Extension Seal

Fig. 2 Install New Seal into Extension

Fig. 3 Differential Cover Bolts

21 - 76 TRANSAXLE Ä

Page 2037 of 2438

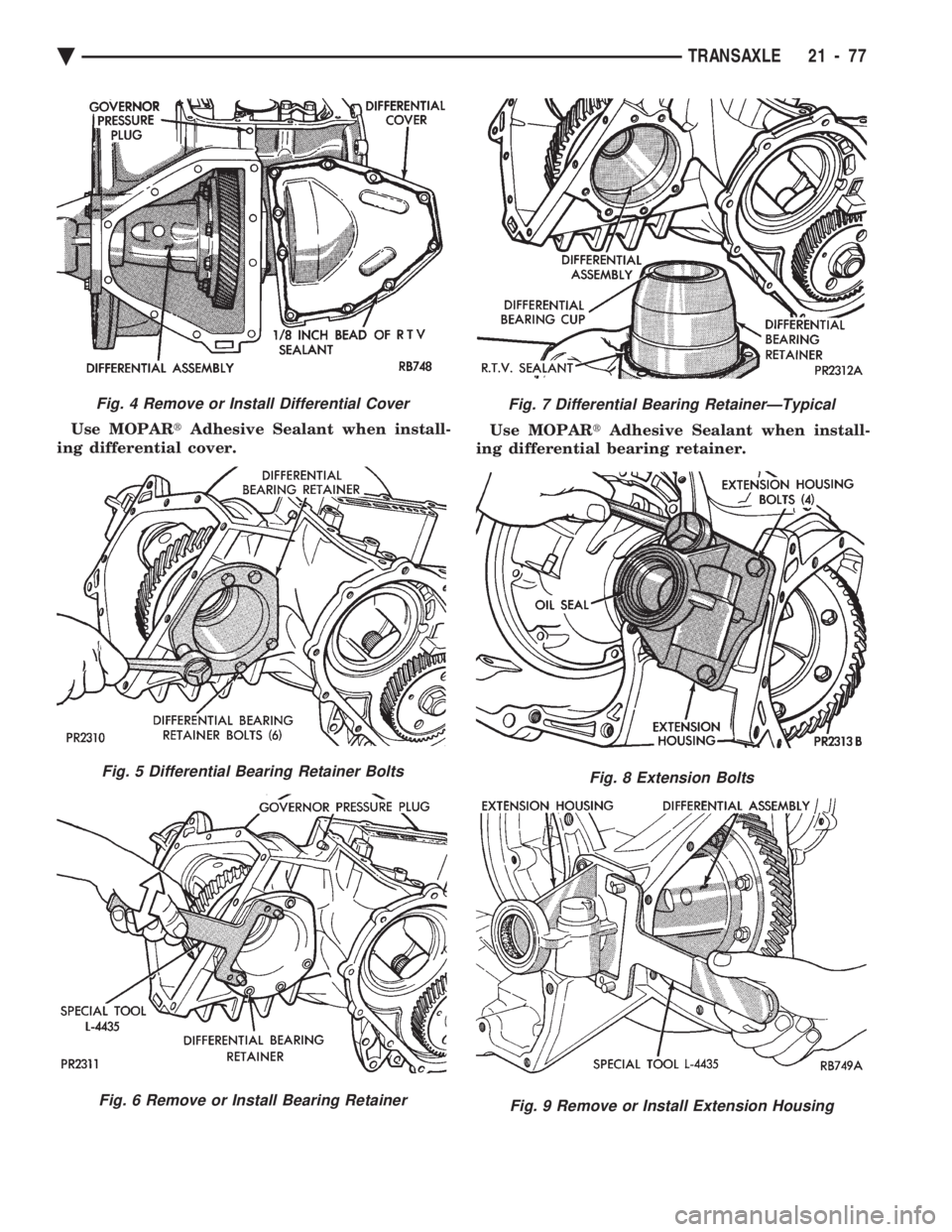

Use MOPAR tAdhesive Sealant when install-

ing differential cover. Use MOPAR

tAdhesive Sealant when install-

ing differential bearing retainer.

Fig. 4 Remove or Install Differential Cover

Fig. 5 Differential Bearing Retainer Bolts

Fig. 6 Remove or Install Bearing Retainer

Fig. 7 Differential Bearing RetainerÐTypical

Fig. 8 Extension Bolts

Fig. 9 Remove or Install Extension Housing

Ä TRANSAXLE 21 - 77

Page 2038 of 2438

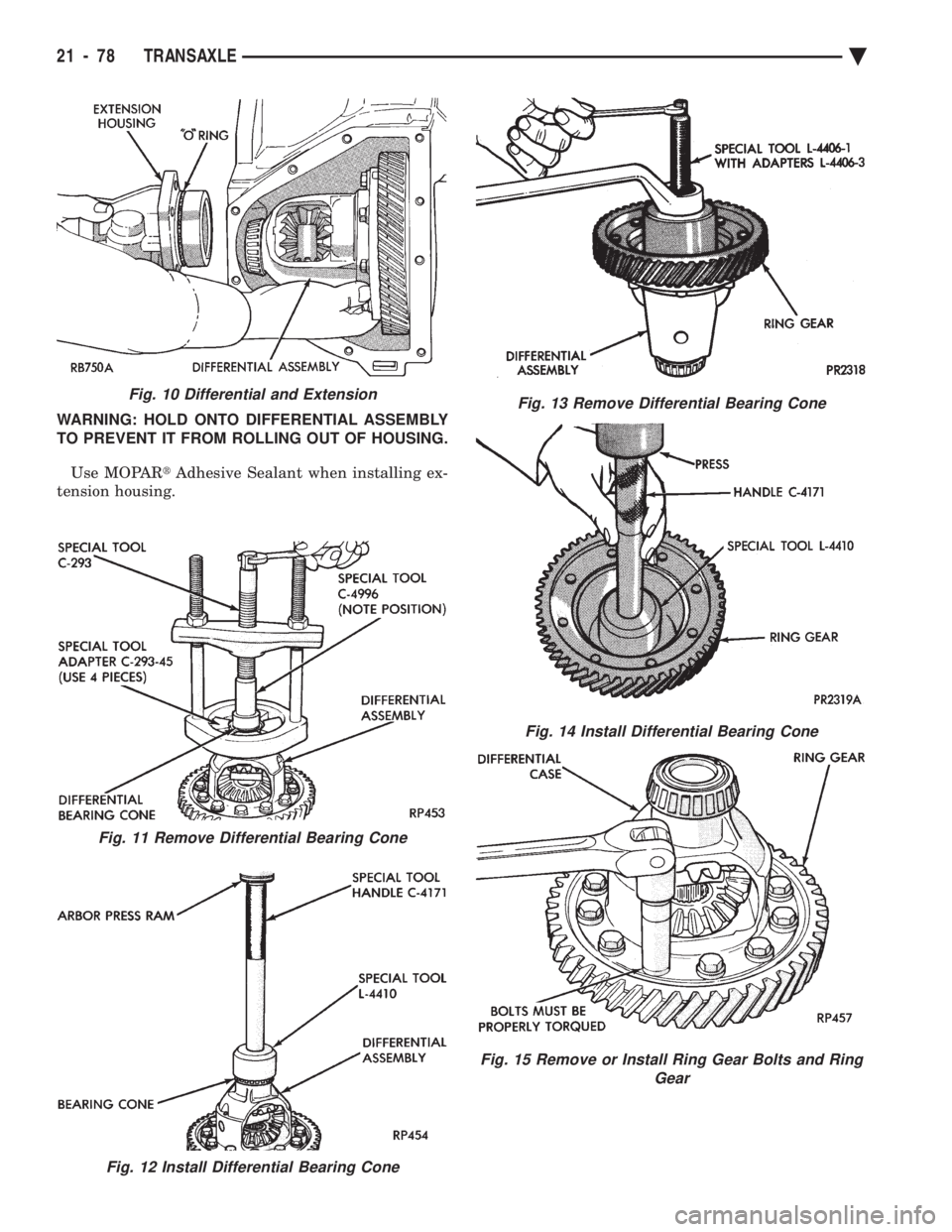

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

Use MOPAR tAdhesive Sealant when installing ex-

tension housing.

Fig. 10 Differential and Extension

Fig. 11 Remove Differential Bearing Cone

Fig. 12 Install Differential Bearing Cone

Fig. 13 Remove Differential Bearing Cone

Fig. 14 Install Differential Bearing Cone

Fig. 15 Remove or Install Ring Gear Bolts and Ring Gear

21 - 78 TRANSAXLE Ä

Page 2039 of 2438

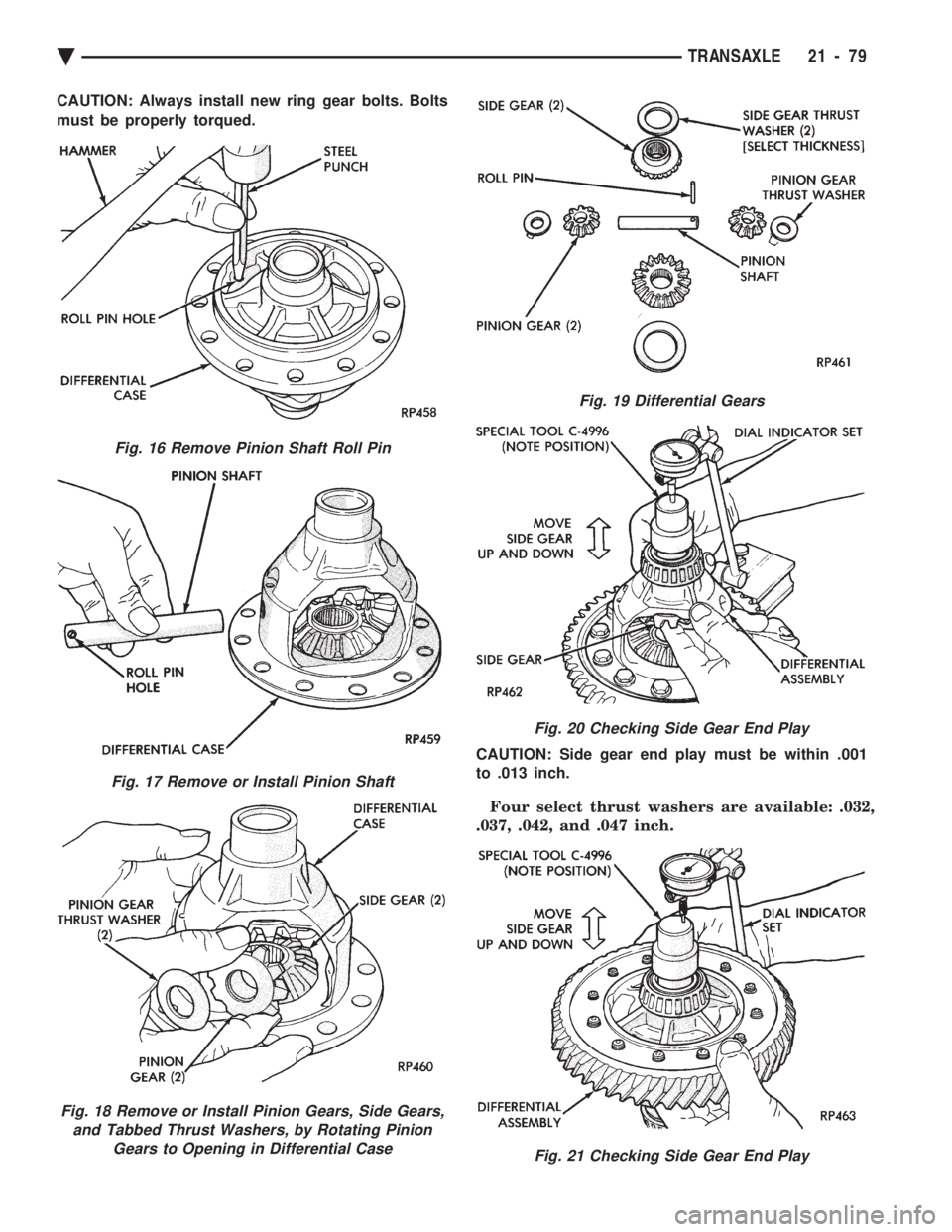

CAUTION: Always install new ring gear bolts. Bolts

must be properly torqued. CAUTION: Side gear end play must be within .001

to .013 inch.

Four select thrust washers are available: .032,

.037, .042, and .047 inch.

Fig. 16 Remove Pinion Shaft Roll Pin

Fig. 17 Remove or Install Pinion Shaft

Fig. 18 Remove or Install Pinion Gears, Side Gears, and Tabbed Thrust Washers, by Rotating Pinion Gears to Opening in Differential Case

Fig. 19 Differential Gears

Fig. 20 Checking Side Gear End Play

Fig. 21 Checking Side Gear End Play

Ä TRANSAXLE 21 - 79

Page 2040 of 2438

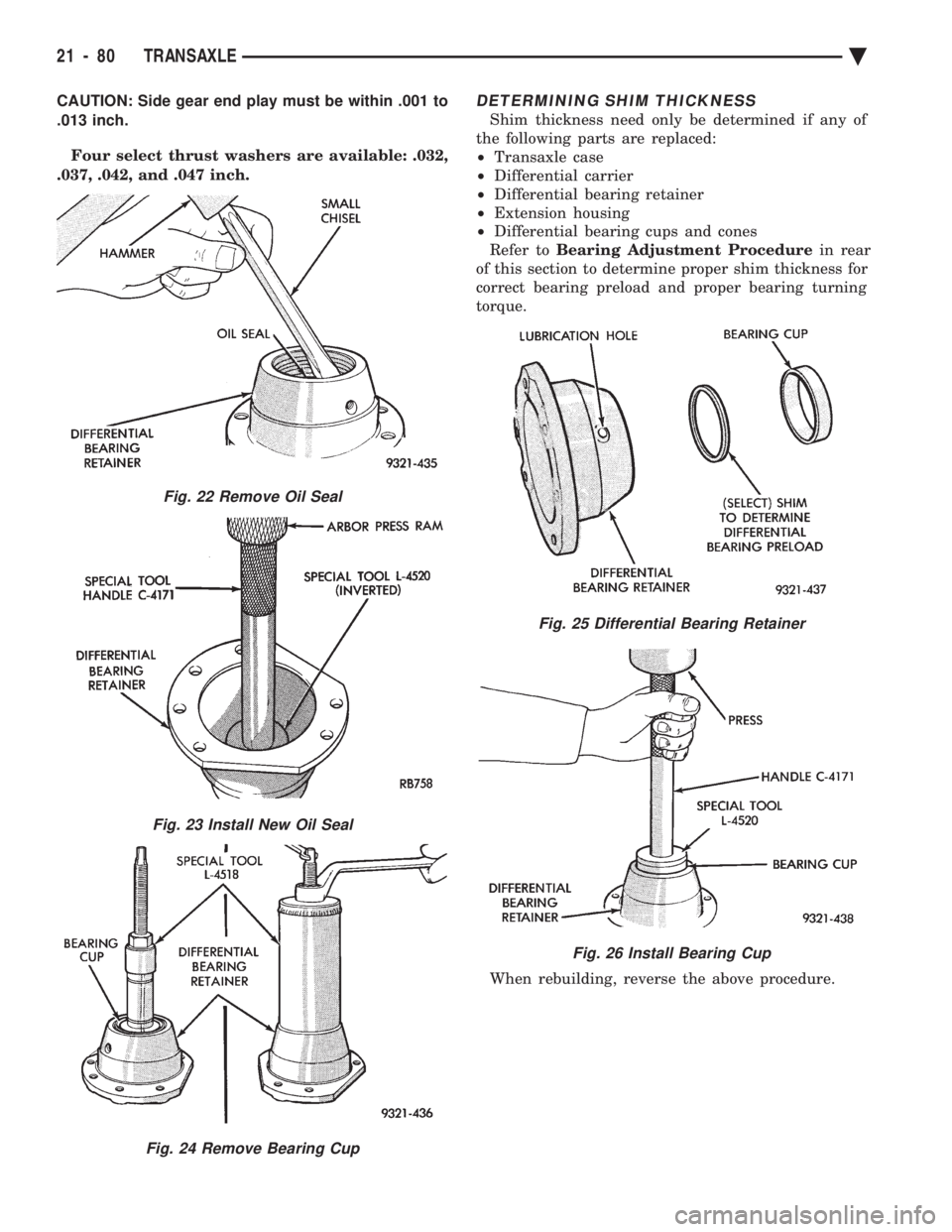

CAUTION: Side gear end play must be within .001 to

.013 inch. Four select thrust washers are available: .032,

.037, .042, and .047 inch.DETERMINING SHIM THICKNESS

Shim thickness need only be determined if any of

the following parts are replaced:

² Transaxle case

² Differential carrier

² Differential bearing retainer

² Extension housing

² Differential bearing cups and cones

Refer to Bearing Adjustment Procedure in rear

of this section to determine proper shim thickness for

correct bearing preload and proper bearing turning

torque.

When rebuilding, reverse the above procedure.

Fig. 25 Differential Bearing Retainer

Fig. 26 Install Bearing Cup

Fig. 22 Remove Oil Seal

Fig. 23 Install New Oil Seal

Fig. 24 Remove Bearing Cup

21 - 80 TRANSAXLE Ä

Trending: fascia, clock setting, engine oil capacity, wiper fluid, air bleeding, oil type, width