air condition DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 156 of 548

3

way

connector

ck

Air

@

Manometer

Carbon

canister

Emission

Control

System

400

mmH20

15

75

inH20

Check

valve

Fuel

filler

cap

r

EC091A

Fig

EC

I09

Checking

Evaporative

Emiuion

Control

Syatem

FUEL

CHECK

VALVE

I

Blow

air

through

connector

on

fuel

tank

side

A

considerable

resistance

should

be

felt

at

the

mouth

and

a

portion

of

air

flow

be

directed

toward

the

engine

2

Blow

air

through

connector

on

engine

side

Air

flow

should

be

smoothly

direct

ed

toward

fuel

tank

3

If

fuel

check

valve

is

suspected

of

not

being

properly

functioning

in

steps

I

and

2

above

replace

Engine

side

Fuel

tank

side

Q

Evaporative

fuel

flow

Fresh

air

flow

EC090A

Fig

EC

110

Checking

Fuel

Check

Valve

CARBON

CANISTER

PURGE

CONTROL

VALVE

Check

for

fuel

vapor

leakage

in

the

distributor

vacuum

line

at

diaphragm

of

carbon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

I

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

vacuum

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET349

Fig

EC

lll

Checking

Carbon

Canister

Purge

Control

Valve

EC37

3

If

there

is

a

leak

remove

top

cover

from

purge

control

valve

and

check

for

dislocated

or

cracked

dia

phragm

If

necessary

replace

dia

phragrrt

kit

which

is

made

up

of

a

retainer

diaphragm

and

spring

i

ii

1

Cover

2

Diaphragm

3

Retainer

4

Diaphragm

spring

ET350

Fig

EC

112

Carbon

Canister

Purge

Control

Valve

FUEL

TANK

VACUUM

RELIEF

VALVE

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

unit

O

ET500

Fig

EC

1l3

Fuel

Filler

Cap

Page 178 of 548

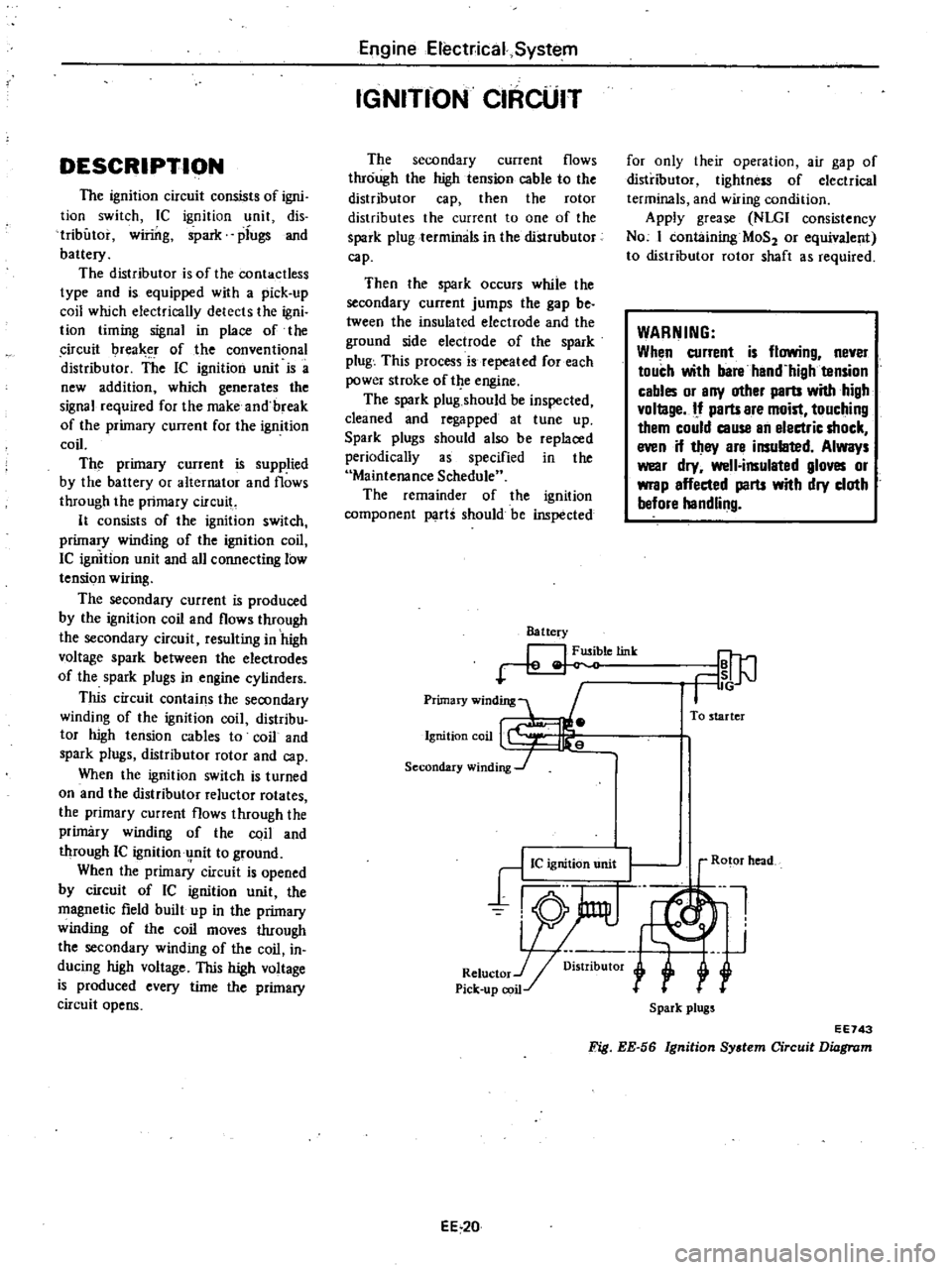

DESCRIPTION

The

ignition

circuit

consists

of

igni

tion

switch

Ie

ignition

unit

dis

tributor

winng

ipark

plugs

and

battery

The

distributor

is

of

the

contactless

type

and

is

equipped

with

a

pick

up

coil

which

electrically

detects

the

igni

tion

timing

signal

in

place

of

the

ircuit

I

rea

r

of

the

conventional

distributor

The

IC

ignition

unit

is

a

new

addition

which

generates

the

signal

required

for

the

make

and

break

of

the

primary

current

for

the

ignition

coil

The

primary

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

primary

winding

of

the

ignition

coil

IC

ignition

unit

and

all

connecting

low

tension

wiring

The

secondary

current

is

produced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

resulting

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

secondary

winding

of

the

ignition

coil

distribu

tor

high

tension

cables

to

coil

and

spark

plugs

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

reluctor

rotates

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

IC

ignitionu

nit

to

ground

When

the

primary

circuit

is

opened

by

circuit

of

IC

ignition

unit

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

in

ducing

high

voltage

This

high

voltage

is

produced

every

time

the

primary

circuit

opens

EngineElect

ical

System

IGNITfON

CIRCUIT

The

secondary

current

flows

through

the

high

tension

cable

to

the

distributor

cap

then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distrubutor

cap

Then

the

spark

occurs

while

the

secondary

current

jumps

the

gap

be

tween

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

t

e

engine

The

spark

plug

should

be

inspected

cleaned

and

regapped

at

tune

up

Spark

plugs

should

also

be

replaced

periodically

as

specified

in

the

Maintenance

Schedule

The

remainder

of

the

ignition

component

parti

should

be

inspected

Battery

letink

Primary

winding

1

Ignition

coil

Secondary

winding

J

for

only

their

operation

air

gap

of

distributor

tightness

of

electrical

terminals

and

wiring

condition

Apply

grease

NLGI

consistency

No

I

containing

MaS

or

equivalent

to

distributor

rotor

shaft

as

required

WARNING

When

current

is

flowing

never

touch

with

bare

hand

high

tension

cables

or

any

other

parts

with

high

vollage

If

parts

are

moist

touching

them

could

cause

an

electric

shock

even

if

they

are

insulated

Always

wear

dry

well

insulated

gloves

or

wrap

affected

parts

with

dry

cloth

before

handling

To

starter

EE

20

Ro

or

head

Ul

J

r

Spark

plugs

EE743

Fig

EE

56

Ignition

System

Circuit

Diagram

Page 181 of 548

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

should

be

in

spected

periodically

as

specified

in

the

Main

teoanee

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

from

time

to

time

If

cap

is

cracked

or

is

leaking

replace

wi

th

a

new

one

ADVANCE

MECHANISMS

SpecHlcatlons

Refer

to

Service

Data

and

Specifica

tions

for

distributor

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

followin

B

items

and

correct

the

mal

function

as

required

I

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

If

necessary

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controUer

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

halls

or

if

necessary

replace

breaker

plate

as

an

assembly

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

mecha

nical

parts

use

distributor

tester

to

check

its

characteristics

If

nothing

is

wrong

with

its

charac

teristics

conceivable

causes

are

faulty

or

abnormal

wear

of

driving

part

or

others

So

do

not

disassemble

it

In

the

event

of

improper

character

istics

check

closely

rotor

shaft

assem

bly

governor

weight

and

shaft

If

any

of

the

above

parts

are

mal

functioning

replace

the

parts

Engine

Electrical

System

DISASSEMBLY

AND

ASSEMBLY

DISASSEMBLY

I

Take

off

cap

and

remove

rotor

head

2

Remove

Ie

ignition

unit

Refer

to

IC

Ignition

Unit

for

removal

and

in

stallation

3

Remove

stator

and

magnet

by

removing

stator

securing

screws

4

Remove

vacuum

controller

by

removing

securing

screws

EE746

Fig

EE

59

Removing

Vacuum

Controller

5

Using

two

pry

bars

or

suitable

puller

pry

reluctor

from

shaft

CAUTION

When

removing

reluctor

be

careful

not

10

distort

or

damage

the

teeth

6

Remove

roll

pin

7

Remove

pick

up

coil

assembly

8

Remove

breaker

plate

setscrews

and

remove

breaker

plate

assembly

EE703

Fig

EE

60

Removing

Breaker

Plate

Setscrews

9

Punch

knock

pin

out

and

remove

pinion

EE

23

EE704

Fig

EE

61

Removing

Knock

Pin

10

Remove

rotor

shaft

and

drive

shaft

assembly

EE705

Fig

EE

62

Removing

Rotor

Shaft

and

Drive

Shaft

Assembly

11

Mark

rotor

shaft

and

drive

shaft

Remove

packing

from

the

top

of

rotor

shaft

and

unscrew

rotor

shaft

setscrew

Remove

rotor

shaft

EE706

Fig

EE

63

Removing

Rotor

Shaft

12

Mark

one

of

the

governor

springs

and

its

bracket

Also

mark

one

of

the

governor

weights

and

its

pivot

pins

13

Carerully

unhook

and

remove

governor

springs

14

Remove

governor

weights

A

r

ply

grease

to

guvernor

weights

after

disassembling

Page 187 of 548

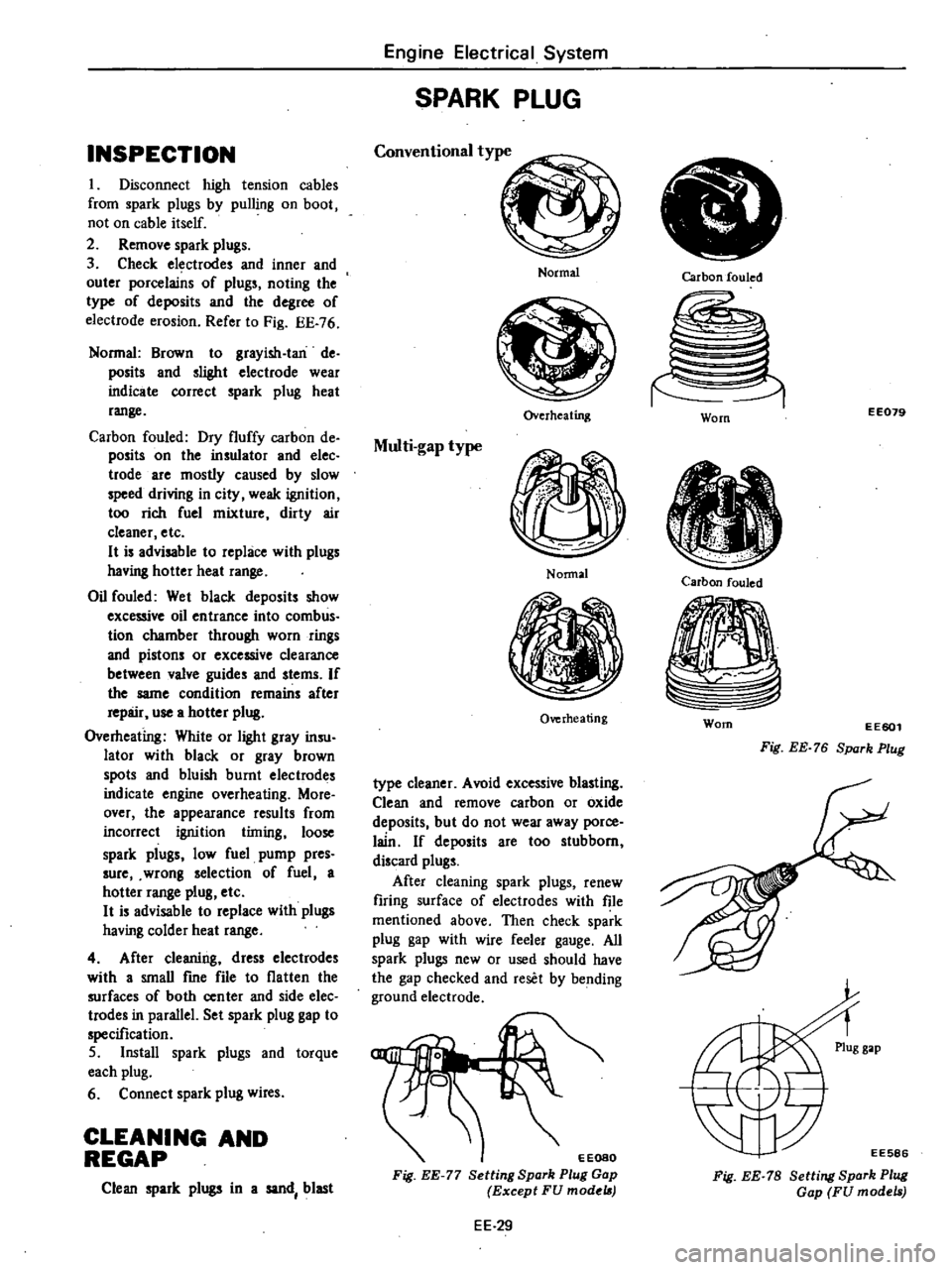

INSPECTION

I

Disconnect

high

tension

cables

from

spark

plugs

by

pulling

on

boot

not

on

cable

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Fig

EE

76

Normal

Brown

to

grayish

Ian

de

posits

and

slighl

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

de

posits

on

the

insulator

and

elec

trode

are

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

entrance

into

comb

us

tion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insu

lator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

range

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

4

After

cleaning

dress

electrodes

with

a

smaU

fme

file

to

flatten

the

surfaces

of

both

center

and

side

elec

trodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

Engine

Electrical

System

SPARK

PLUG

Conventional

type

Normal

Overheating

Multi

gap

type

Nonnal

Overheating

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porce

lain

If

deposits

are

too

stubborn

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

file

mentioned

above

Then

check

spark

plug

gap

with

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOSO

Fig

EE

77

Setting

Spark

Plug

Gap

Except

FU

model

EE

29

Carbon

fouled

EE079

Worn

Carbon

fouled

Worn

EE601

Fig

EE

76

Spark

Plug

EE586

Fig

EE

78

Setting

Spark

Plug

Gap

FU

models

Page 193 of 548

Engine

Electrical

System

II

STARTING

MOTOR

Condition

Starting

motor

will

not

operate

Noisy

starting

motor

Starting

motor

cranks

lowly

Starting

motor

cranks

slowly

Starting

motor

operate

but

does

not

crank

engine

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Probable

cause

Discharged

battery

Damaged

solenoid

witch

Loose

connections

of

terminal

Damaged

field

coil

Damaged

brushes

Damaged

bearing

Damaged

annature

Loose

securing

bolt

Worn

pinion

gear

Poor

lubrication

Worn

commutator

Worn

brushes

Discharged

battery

Loose

connection

of

terminal

Worn

brushes

Locked

brushes

Loose

connections

of

terminal

Damaged

field

coil

Damaged

brushes

Damaged

bearing

Damaged

armature

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

splenoid

switch

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Damaged

sOlenoid

switch

Damaged

gear

teeth

EE

35

Corrective

action

Charge

or

repiace

battery

Repair

or

replace

solenoid

switch

Clean

and

tighten

terminal

Replace

yoke

Replace

brushes

Replace

bearing

Replace

armature

Tighten

Replace

Add

oil

Replace

Replace

Charge

Clean

and

tighten

Replace

Inspect

brush

pring

tension

or

repair

brush

holder

Clean

and

tighten

terminal

Replace

yoke

Replace

brushe

Replace

bearing

Replace

armature

Clean

and

repair

Repalce

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

Page 194 of 548

Engine

Electrical

System

III

ALTERNATOR

Including

voltage

regulator

Condition

No

output

Excessive

output

Low

output

Noisy

alternator

Probable

cause

Sticking

brushes

Dirty

brushes

and

slip

rings

Loose

connections

or

broken

leads

Open

stator

winding

Open

rotor

winding

Open

diodes

Shorted

diodes

Shorted

rotor

Shorted

stator

Ground

BAT

terminal

Broken

fan

belt

Voltage

regulator

breakdown

Poor

connection

of

alternator

S

terminal

Open

diode

Loose

or

worn

fan

belt

Slicking

brushes

Low

brush

spring

tension

Voltage

regulator

breakdown

Dirty

slip

ring

Partial

hort

ground

or

open

in

stator

winding

Partially

shorted

or

grounded

rotor

winding

Open

or

damaged

diode

Loose

mounting

Loose

drive

pulley

Broken

ball

bearing

Improperly

seated

brushes

EE

36

Corrective

action

Correct

or

replace

bru

hes

and

brush

springs

Clean

Retigliten

or

older

connection

Replace

leads

if

necessary

Repair

or

replace

stator

Replace

rotor

Replace

Replace

Replace

rotor

Replace

Replace

insulator

Replace

Check

regulator

operation

and

repair

or

replace

a

required

Correct

Replace

Retighten

or

replace

Correct

or

replace

brushes

and

springs

if

necessary

Replace

brush

spring

Check

regulator

operation

and

repair

or

replace

as

required

Clean

Replace

tator

Replace

rotor

Replace

diode

Retighten

bolts

Retighten

Replace

Seat

correctly

Page 195 of 548

Engine

Electrical

System

IV

IGNITION

CIRCUIT

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

distributor

starting

engine

and

ob

serving

oondition

of

spark

that

occurs

between

high

tension

cable

and

engine

block

After

checking

this

repair

as

necessary

tery

and

anti

dieseliilg

wlenoid

valve

connector

to

cuI

off

supply

of

fuel

10

engine

Then

observe

the

condition

of

sparks

while

starter

motor

is

in

operation

Note

Turn

ignilion

switch

off

and

disconnect

ground

cable

from

bat

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Open

pick

up

coil

Replace

Air

gap

wider

than

specification

Adjust

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Faulty

insulation

Replace

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

Spark

length

Spark

plugs

Spark

plug

gap

too

wide

Correct

or

replace

More

than

6

mm

Too

much

carbon

Clean

or

replace

0

24

in

Broken

neck

of

insulator

Replace

Expiration

of

plug

life

Replace

Distributor

Air

gap

too

wide

Correct

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

EE

37

Page 196 of 548

2

Engine

rotates

but

does

not

run

smoothly

This

may

be

caused

by

the

ignition

Condition

Location

Engine

misses

Distributor

Ignition

coil

High

tension

cable

Spark

plugs

IC

ignition

unit

Engine

causes

knocking

very

often

Distributor

Spark

plugs

Engine

does

not

deliver

enough

power

Distributor

Spark

plugs

Engine

Electrical

System

system

or

other

engine

conditions

not

related

to

ignition

system

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

Probable

cause

Foreign

matter

onpicl

up

coil

Improper

air

gap

Leak

of

electricity

at

cap

and

rotor

head

Breakage

of

pick

up

coil

lead

wire

Worn

or

shaky

breaker

plate

Worn

or

shaky

distributor

driVing

shaft

Layer

short

circuit

or

inferior

quality

coil

Deterioration

of

insulation

with

cense

quenlleak

of

electricity

Fouled

Leak

of

electricity

at

upper

porcelain

insulator

Spark

plug

gap

too

narrow

Faulty

IC

ignition

unit

Breakage

of

circuit

Detached

connection

Improper

ignition

timing

too

advanced

Coming

off

or

breakage

of

governor

spring

Worn

pin

or

hole

of

governor

Burnt

too

much

Improper

ignition

timing

too

retarded

Improper

functioning

governor

Foreign

particles

stuck

in

air

gap

Fouled

EE

38

Corrective

action

Clean

Correct

Repair

or

replace

Replace

Replace

assembly

Replace

aSsembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

or

replace

Replace

Replace

Repair

Correct

Correct

or

replace

Replace

Replace

Correct

Replace

assembly

Clean

Clean

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder

Page 201 of 548

INSTALLATION

Install

in

the

reverse

order

of

re

moval

observing

the

following

Note

When

inslal1ing

be

sure

to

check

thaI

electrical

harnesses

are

connected

ly

1

When

installing

first

secure

rear

engine

mounting

member

to

body

2

Refer

to

applicable

section

when

installing

and

adjusting

any

parts

Adjust

clutch

pedal

free

travel

Re

fer

to

Clutch

Pedal

Free

Travel

Section

CL

for

installation

and

adjustment

Adjust

accelerator

control

system

Refer

to

Engine

Control

System

Section

FE

for

adjustment

For

installation

of

air

conditioner

compressor

and

belt

adjustment

Refer

to

Idler

Pulley

and

Com

pressor

Drive

Belt

for

adjustment

of

belt

tension

3

When

installing

exhaust

front

tube

on

exhaust

manifold

be

sure

to

use

new

gasket

4

When

installing

hood

following

engine

installation

be

sure

that

it

is

properly

centered

and

that

hood

lock

operates

securely

Refer

to

Hood

See

tion

BF

for

adjustment

Engine

Removal

Installation

ENGINE

MOUNTING

INSULATOR

FRONT

INSULATOR

Removal

Disconnect

battery

ground

cable

2

Suspend

engine

with

wire

or

chain

3

Remove

front

engine

mounting

insulator

lower

and

upper

nuts

on

both

sides

4

Make

sure

that

wire

or

chain

used

to

suspend

engine

is

positioned

prqper

ly

so

that

no

load

is

applied

to

insulators

and

remove

nuts

complete

ly

5

Lift

up

engine

and

separate

in

sulators

from

engine

mounting

rack

ets

Inspection

If

there

is

damage

deterioration

or

separation

of

bounded

surface

re

place

Installation

Install

front

insulators

in

reverse

sequence

of

removal

noting

the

fol

lowing

1

Do

not

confuse

right

and

left

insulators

R

right

side

or

L

left

side

identification

mark

is

stamp

ed

on

each

insulator

2

Install

front

insulator

so

that

ER

5

position

pin

is

projected

upward

3

Tighten

the

bolts

and

nut

correct

ly

and

securely

See

Fig

ER

I

REAR

INSULATOR

Removal

l

Support

transmission

weight

with

ajack

2

Remove

nuts

securing

rear

engine

mounting

insulator

to

mounting

mem

ber

3

Remove

bolts

connecting

rear

en

gine

mounting

insulator

to

transmis

sion

reaf

extension

housing

4

Jack

up

the

transmission

a

little

and

remove

insulator

Inspection

If

there

is

damage

deterioration

or

separation

of

mating

surface

replace

Installation

Install

rear

engine

mounting

mem

ber

and

insulator

in

reverse

order

of

removal

noting

the

following

I

Install

insulator

in

place

so

that

direction

of

mounted

insulator

is

same

as

that

in

Fig

ER

2

Tighten

nuts

and

bolts

correctly

and

securely

As

for

tightening

torque

see

Fig

ER

l