lock DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 207 of 548

are

clean

and

free

from

foreign

matter

Cearance

between

cylinder

bore

and

piston

Leu

than

0

15

mm

0

0059

in

ASSEMBLY

Assemble

clutch

master

cylinder

in

the

reverse

order

of

disassembly

Ob

serve

the

following

I

Dip

piston

cup

in

brake

fluid

before

installing

Make

sure

that

it

is

correctly

faced

in

position

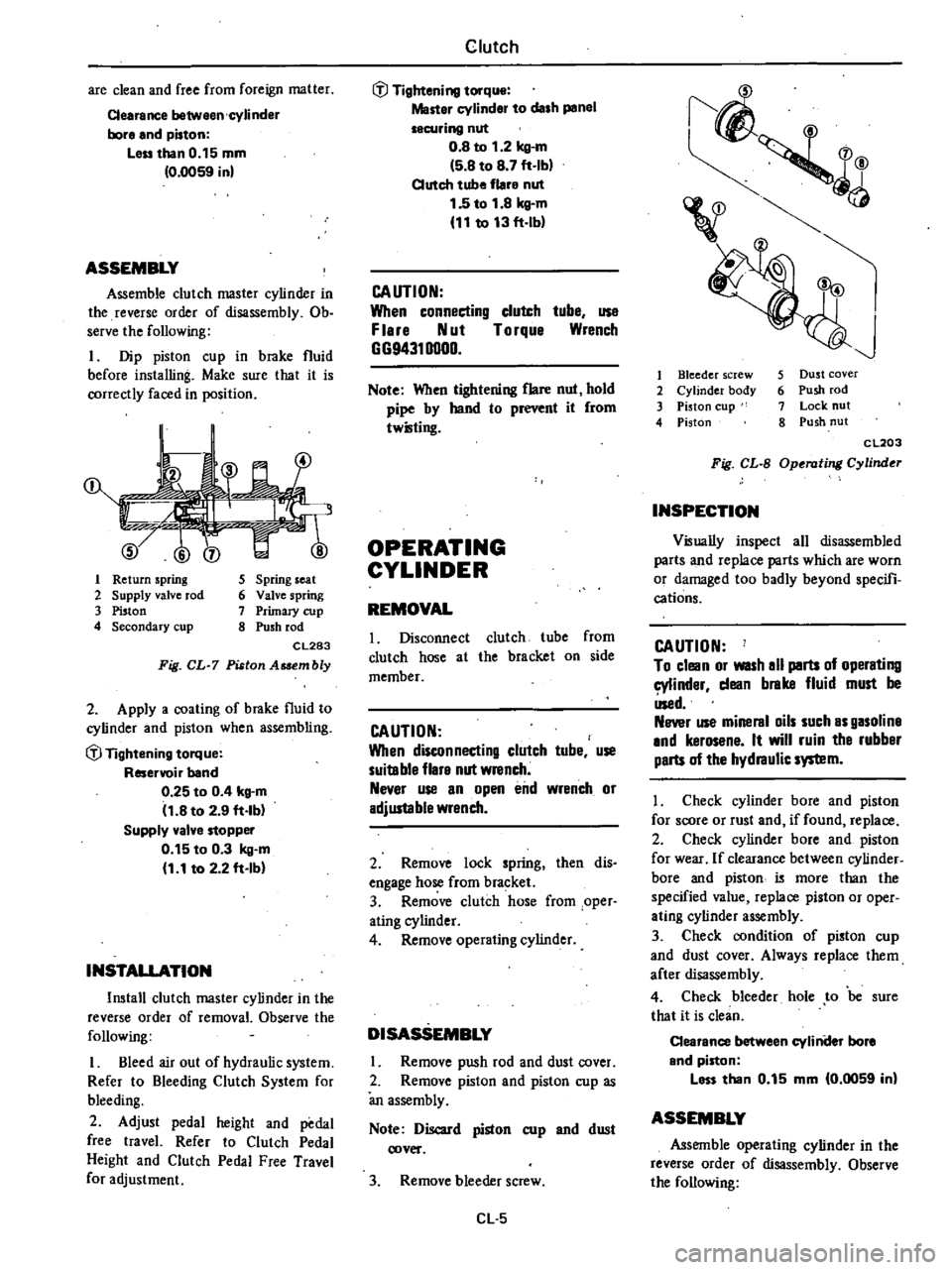

1

Return

spring

2

Supply

valve

rod

3

Piston

4

Secondary

cup

5

Spring

seat

6

Valve

spring

7

Primary

cup

8

Push

rod

CL283

Fig

CL

7

Piston

Asaembly

2

Apply

a

coating

of

brake

fluid

to

cylinder

and

piston

when

assembling

if

Tightening

torque

Reservoir

band

0

25

to

0

4

kg

m

11

8

to

2

9

ft

lb

Supply

valve

stopper

0

15

to

0

3

kg

m

1

1

to

2

2

ft

Ib

INSTALLATION

Install

clutch

master

cylinder

in

the

reverse

order

of

removal

Observe

the

following

I

Bleed

air

out

of

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

2

Adjust

pedal

height

and

pedal

free

travel

Refer

to

Clutch

Pedal

Height

and

Clutch

Pedal

Free

Travel

for

adjustment

Clutch

if

Tightening

torque

Master

cylinder

to

dash

panel

securing

nut

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Clutch

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

CAUTION

When

connecting

clutch

tube

use

F

lere

Nut

Torque

Wrench

GG94310000

Note

When

tightening

flare

nut

hold

pipe

by

hand

to

r

it

from

twilling

OPERATING

CYLINDER

REMOVAL

I

Disconnect

clutch

tube

from

clutch

hose

at

the

bracket

on

side

member

CAUTION

When

disconnecting

clutch

tube

use

suitable

flare

nut

wrench

Never

use

an

open

end

wrench

or

adjustable

wrench

2

Remove

lock

spring

then

dis

engage

hose

from

bracket

3

Remove

clutch

hose

from

oper

ating

cylinder

4

Remove

operating

cylinder

DISASSEMBLY

Remove

push

rod

and

dust

cover

2

Remove

piston

and

piston

cup

as

an

assembly

Note

Discard

piston

cup

and

dust

cover

3

Remove

bleeder

screw

Cl

5

1

4

v

I

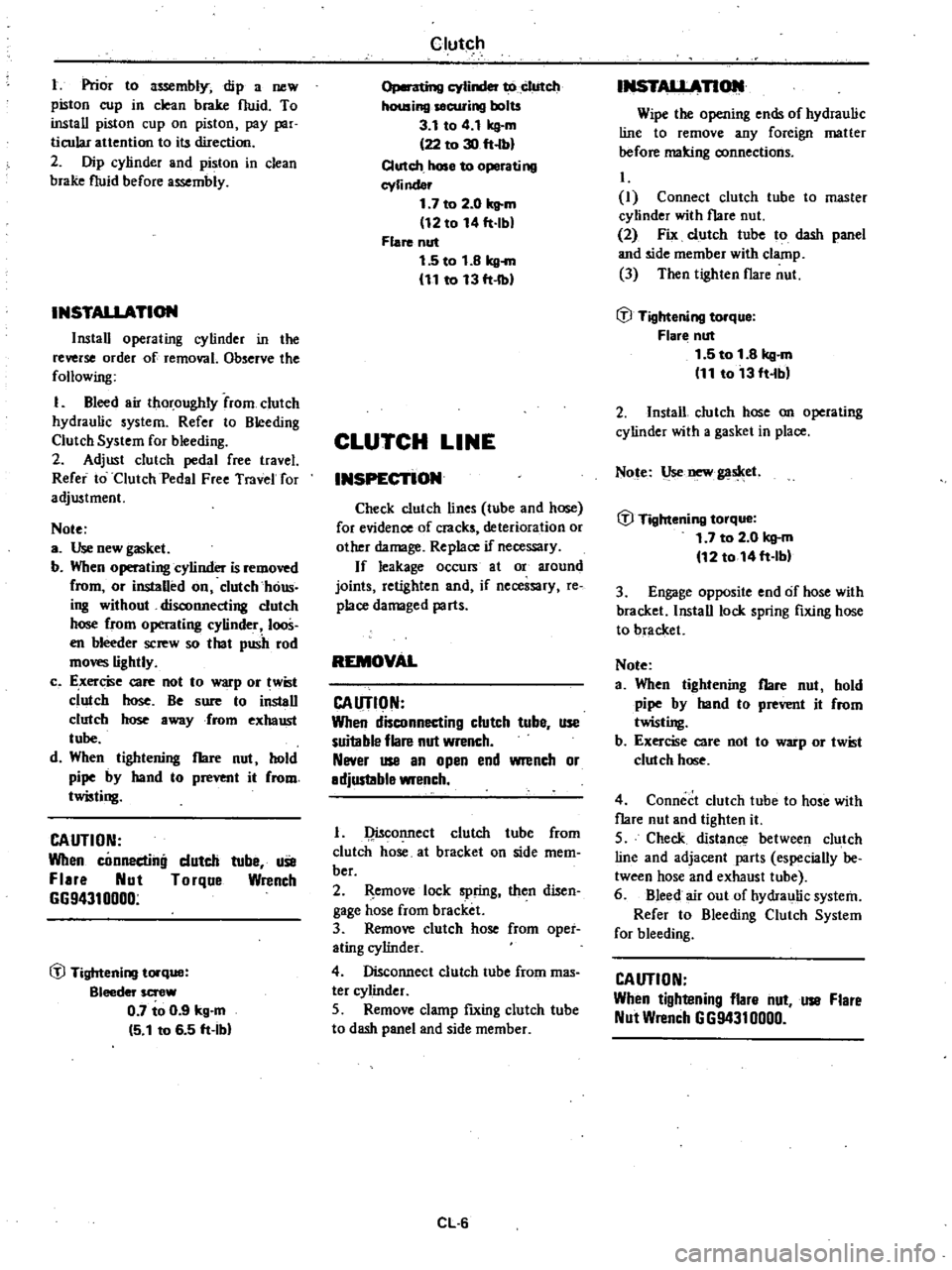

Bleeder

screw

2

Cylinder

body

3

Piston

cup

4

Piston

5

Dust

cover

6

Push

rod

7

Lock

nut

8

Push

nut

CL203

Fig

CL

B

Operating

Cylinder

INSPECTION

Visually

inspect

all

disassembled

parts

and

replace

parts

which

are

worn

or

damaged

too

badly

beyond

specifi

cations

CAUTION

To

clean

or

WISh

all

parts

of

operating

cylinder

dean

brake

fluid

must

be

Used

Never

use

mineral

oils

such

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydraulic

system

I

Check

cylinder

bore

and

piston

for

score

or

rust

and

if

found

replace

2

Check

cylinder

bore

and

piston

for

wear

If

clearance

between

cylinder

bore

and

piston

i5

more

than

the

specified

value

replace

piston

or

oper

ating

cylinder

assembly

3

Check

condition

of

piston

cup

and

dust

cover

Always

replace

them

after

disassembly

4

Check

bleeder

hole

to

be

sure

that

it

is

clean

Clearance

between

cyliniler

bore

and

piston

less

than

0

15

mm

0

0059

in

ASSEMBLY

Assemble

operating

cylinder

in

the

reverse

order

of

disassembly

Observe

the

following

Page 208 of 548

t

Prior

to

lWembly

dip

a

new

piston

cup

in

clean

brake

fluid

To

install

piston

cup

on

piston

pay

par

ticular

auention

to

its

direction

2

Dip

cylinder

and

piston

in

clean

brake

fluid

before

assembly

INSTALLATION

Install

operating

cylinder

in

the

reverse

order

of

removal

Observe

the

following

1

Bleed

air

thoroughly

from

clutch

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

2

Adjust

clutch

pedal

free

travel

Refer

to

Clutch

Pedal

Free

Travel

for

adjustment

Note

a

Use

new

gasket

b

When

operating

cylinder

is

removed

from

or

instaUed

on

clutch

haus

ing

without

disconnecting

clutch

hose

from

operating

cylinder

loos

en

bleeder

screw

so

that

push

rod

mo

lightly

c

E

xer

e

care

not

to

p

or

wist

clutch

hose

Be

sure

to

install

clutch

hose

away

from

exhaust

tube

d

When

tightening

flare

nut

hold

pipe

by

hand

to

prevent

it

from

twisting

CAUTION

When

connecting

dutch

tuhe

uSe

Flare

Nut

Torque

Wrench

G694310000

@

Tightening

torque

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

Ihl

Clutch

o

cylinder

to

clutch

housing

securing

bolts

3

1

to

4

1

kg

m

22

to

30

ft

lbl

Clutch

hose

to

operating

cyli

nder

1

7

to

2

0

kg

m

12

to

14

ft

lbl

Flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

Ibl

CLUTCH

LINE

INSPECTION

Check

clutch

lines

tube

and

hose

for

evidence

of

cracks

deterioration

or

other

damage

Replace

if

necessary

If

leakage

occurs

at

or

around

joints

retighten

and

if

necessary

re

place

damaged

parts

REMOVAL

CAUTION

When

disconnecting

clutch

tube

use

suitable

flare

nut

wrench

Never

use

an

open

end

wrench

or

adjustable

wrench

1

Qisconnect

clutch

tube

from

clutch

hose

at

bracket

on

side

mem

ber

2

emove

lock

spring

then

disen

gage

hose

from

bracket

3

Remove

clutch

hose

from

oper

ating

cylinder

4

Disconnect

clutch

tube

from

mas

ter

cylinder

5

Remove

clamp

fIxing

clutch

tube

to

dash

panel

and

side

member

CL

6

INSTALLAnOlll

Wipe

the

opening

ends

of

hydraulic

line

to

remove

any

foreign

matter

before

malting

connections

I

Connect

clutch

tuhe

to

master

cylinder

with

flare

nut

2

Fix

clutch

tube

to

dash

panel

and

side

member

with

clamp

3

Then

tighten

flare

nut

@

Tightening

torque

Flar

nut

1

5

to

1

8

kg

m

11

to

13

ft

Ibl

2

InstaU

clutch

hose

on

operating

cylinder

with

a

gasket

in

place

Note

Use

new

gaslcet

@

Tightening

torque

1

7

to

2

0

kg

m

12

to

14ft

lbl

3

Engage

opposite

end

of

hose

with

bracket

InstaU

lock

spring

fIxing

hose

to

bracket

Note

a

When

tightening

flare

nut

hold

pipe

by

hand

to

prevent

it

from

twisting

b

Exercise

care

not

to

warp

or

twist

clu1ch

hose

4

Connect

clutch

tube

to

hose

with

flare

nut

and

tighten

it

5

Check

distance

between

clutch

line

and

adjacent

parts

especially

be

tween

hose

and

exhaust

tube

6

Bleed

air

out

of

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

CAUTION

When

tightening

flare

nut

use

Flare

Nut

Wrench

G

G9431

0000

Page 213 of 548

Clutch

Clutch

cover

Diaphragm

spring

height

mm

in

Unevenness

of

diaphragm

spnng

toe

height

mm

in

29

0

to

31

0

1

142

to

1

220

Less

than

O

5

0

020

TIGHTENING

TORQUE

Pedal

stopper

lock

nut

Master

cylinder

push

rod

lock

nut

Operating

cylinder

push

rod

lock

nut

Operating

cylinder

bleeder

screw

Master

cylinder

to

dash

panel

securing

nut

kg

m

ft

lb

Clutch

tube

flare

nut

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

b

0

8

to

1

2

5

8

to

8

7

0

8

to

1

2

5

8

to

8

7

0

8

to

1

2

5

8

to

8

7

0

7

to

0

9

5

1

to

6

5

0

8

to

1

2

5

8

to

8

7

1

5

to

1

8

11

to

13

Operating

cylinder

to

clutch

housing

securing

bolt

Qutch

hose

to

operating

cylinder

Qutch

cover

bolt

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

3

1

to

4

1

22

to

30

17

to

2

0

12

to

14

1

6

to

2

1

12

to

15

CL

11

Page 219 of 548

I

ht

2nd

fork

r

2

3rd

top

fork

rod

3

Reverse

fork

rod

4

Retaining

pin

5

I

t

2nd

shift

fork

6

3rd

top

shift

fork

7

Checking

ball

plug

8

Check

ban

spring

9

Check

ball

10

Interlock

plunger

11

S

topper

ring

12

Shift

rod

A

bracket

13

Reverse

shift

fork

14

Lock

pin

15

Striking

lever

Manual

Transmission

16

Striking

rod

17

Return

spring

plug

18

Reverse

check

spring

19

Return

pring

20

Plunger

21

D

ring

22

Stopper

pin

bolt

23

Striking

guide

assembly

24

Striking

guide

oil

seal

REMOVAL

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

m

TM781

Fig

MT

4

Removing

Control

Lever

@

@

25

Control

lever

bushing

26

Expansion

plug

27

Control

pin

bushing

28

Control

arm

pin

29

Control

lever

o

Tightening

torque

kg

m

ft

lb

@

0

5

to

0

8

3

6

tn

5

8

@

1

3

to

1

7

9

to

12

Fig

MT

3

F4W60L

Tra11lmiBSion

Shift

Control

Components

TM094A

4

Jack

up

the

car

and

support

its

weight

on

safety

stands

Use

a

hy

draulic

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

5

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

removey

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PO

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

MT

3

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

00

not

place

the

jack

under

the

oil

pan

drain

plug

11

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

V

Page 221 of 548

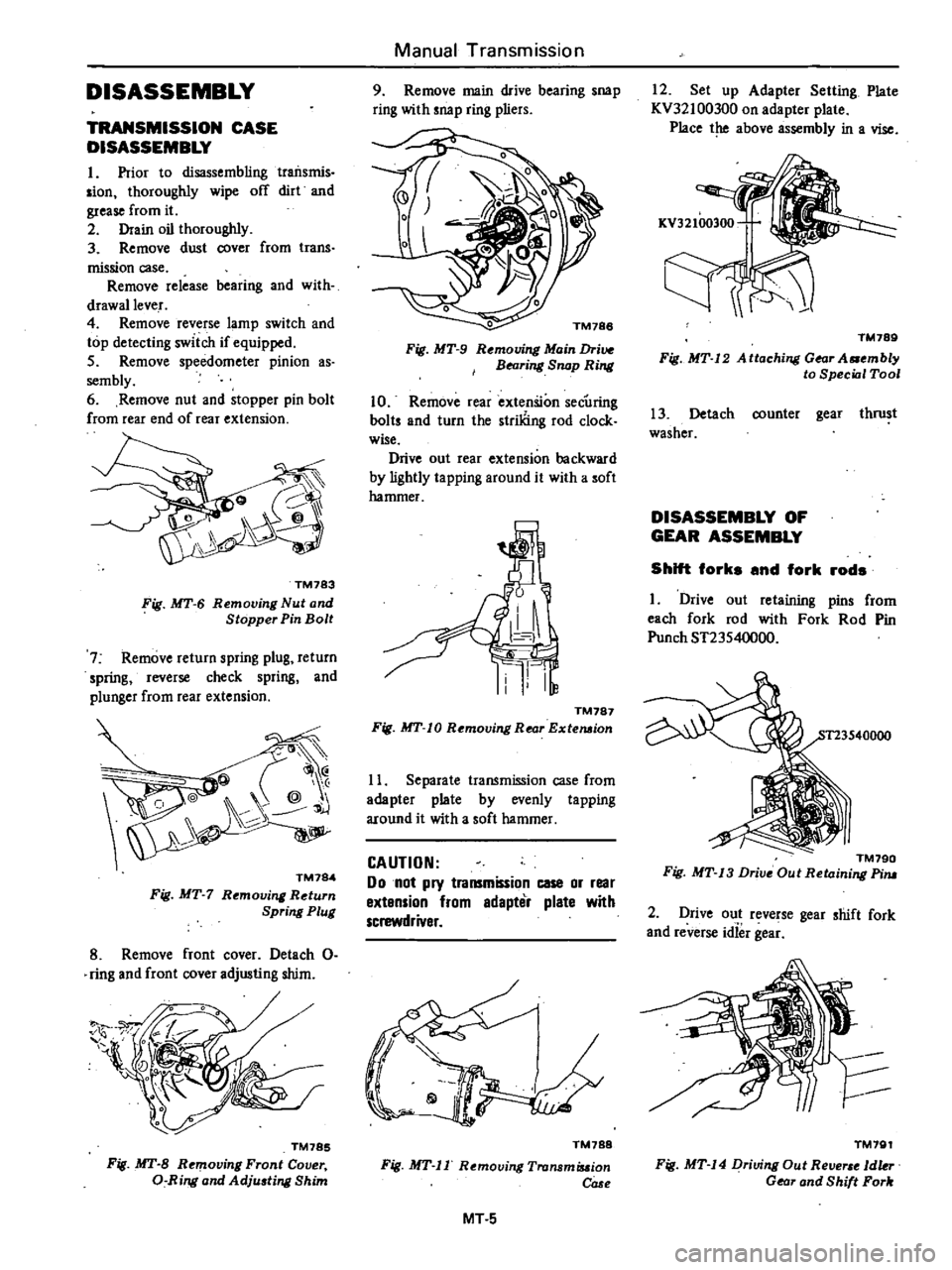

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

I

Prior

to

disassembling

traiIsmis

sian

thoroughly

wipe

off

dirt

and

grease

from

it

2

Drain

oil

thoroughly

3

Remove

dust

cover

from

trans

mission

case

Remove

release

bearing

and

with

drawallever

4

Remove

reverse

lamp

switch

and

top

detecting

switch

if

equipped

5

Remove

speedometer

pinion

as

sembly

6

Remove

nut

and

stopper

pin

bolt

from

rear

end

of

rear

extension

TM783

Fig

MT

6

Removing

Nut

and

Stopper

Pin

Bolt

7

Remove

return

spring

plug

return

spring

reverse

check

spring

and

plunger

from

rear

extension

@

@

j

TM784

Fig

MT

7

Rt

moving

Return

Spring

Plug

8

Remove

front

cover

Detach

0

ring

and

front

cover

adjusting

shim

TM785

Fig

MT

B

Removing

Front

Cover

a

Ring

and

Adju

ting

Shim

Manual

Transmission

9

Remove

main

drive

bearing

snap

ring

with

snap

ring

pliers

o

TM188

Fig

MT

9

Rt

mouing

Main

Drive

BNring

Snap

Ring

10

Remove

rear

extenSion

secUring

baits

and

turn

the

striliing

rod

clock

wise

Drive

out

rear

extension

backward

by

lightly

ta

pping

around

it

with

a

soft

hammer

TM787

Fig

MT

10

Removing

Rear

Extemion

11

Separate

transmission

case

from

adapter

plate

by

evenly

tapping

around

it

with

a

soft

hammer

CAUTION

Do

not

pry

transmission

case

or

rear

extension

from

edapter

plate

with

screwdriver

TM788

Fig

MT

II

Removing

Tronsmiuion

COSf

MT

5

12

Set

up

Adapter

Setting

Plate

KV32100300

on

adapter

plate

Place

the

above

assembly

in

a

vise

TM789

Fig

MT

12

A

ttaching

Gear

A

mbly

to

Special

Tool

13

Detach

counter

gear

thrust

washer

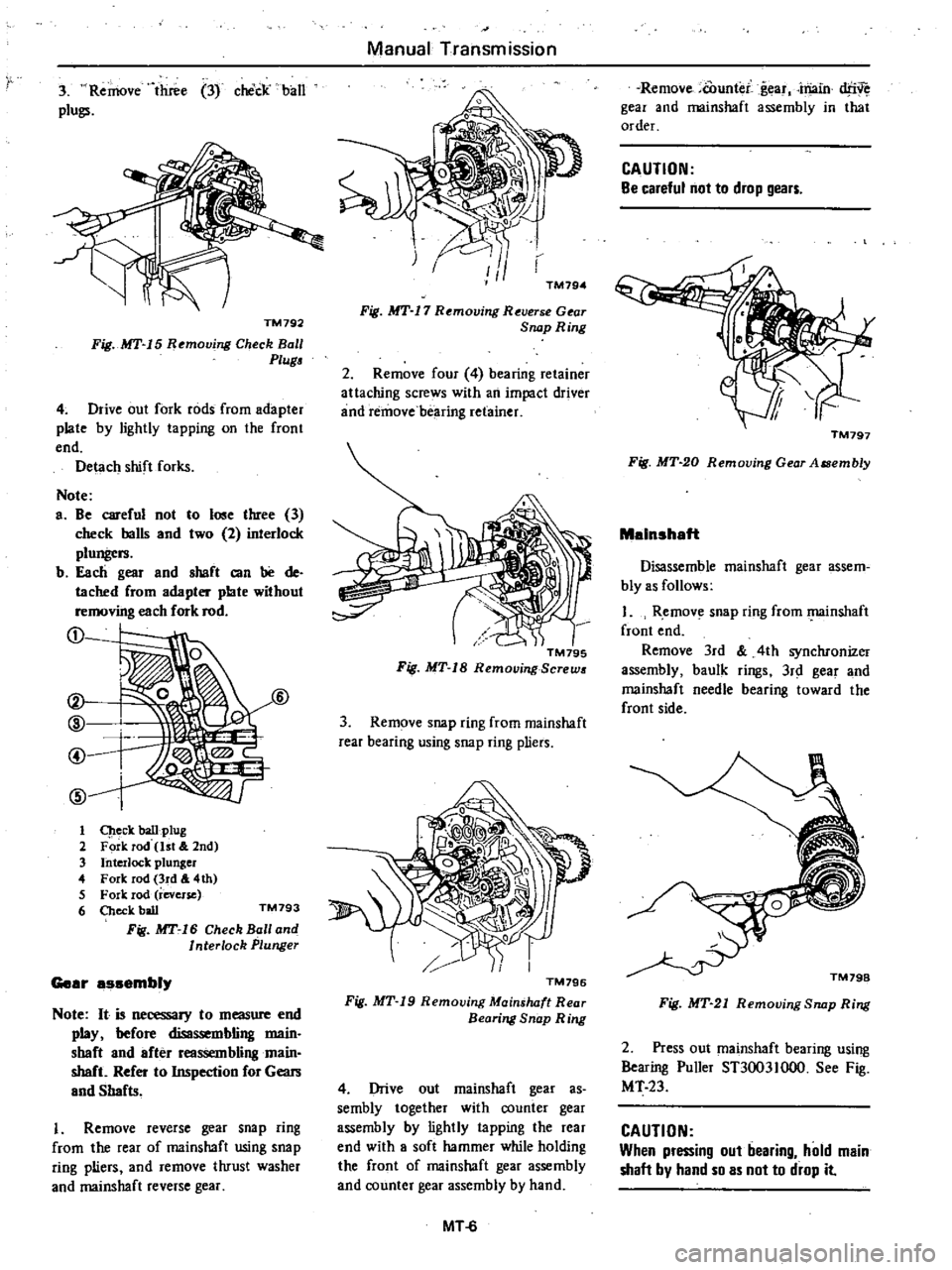

DISASSEMBLY

OF

GEAR

ASSEMBLY

Shift

forks

and

fork

rods

I

Drive

out

retaining

pins

from

each

fork

rod

with

Fork

Rod

Pin

Punch

ST23540000

TM790

Fig

MT

13

Drive

Out

Retaining

Pim

2

Drive

out

reverse

gear

shift

fork

and

reverse

idief

gea

TM791

Fig

MT

14

Driving

Out

Re

1dkr

Gear

and

Shift

Fork

Page 222 of 548

3

Remove

three

3

chick

ball

plugs

TM792

Fig

MT

15

Removing

Check

Ball

Plug

4

Drive

out

fork

rods

from

adapter

plate

by

lightly

tapping

on

the

front

end

Detach

shift

forks

Note

a

Be

careful

not

to

lose

three

3

check

balls

and

two

2

interlock

pluDgl

rs

b

Each

gear

and

sbaft

can

be

de

tached

from

adapter

plate

without

removing

each

fork

rod

D

t

@

@

6

@

1

q

eck

ball

ptug

2

Fork

Tod

1st

2nd

3

InterJock

plunger

4

Fork

rod

3rd

4th

5

Fork

rod

reverse

6

Check

ball

TM793

Fig

MT

16

Check

Ball

and

Interlock

Plunger

Gear

assembly

Note

It

is

necessary

to

measure

end

play

before

disassembling

main

sbaft

and

after

reassembling

main

shaft

Refer

to

Inspection

for

Gears

and

Shafts

1

Remove

reverse

gear

snap

ring

from

the

rear

of

mainshaft

using

snap

ring

pliers

and

remove

thrust

washer

and

mainshaft

reverse

gear

Manual

Transmission

TM794

Fig

MT

17

R

molJing

Reuerse

Gear

SfUJpRing

2

Remove

four

4

bearing

retainer

attaching

screws

with

an

impact

driver

and

remove

bearing

retainer

TM79S

Fif

MT

18

RemouingBcrews

3

Remove

snap

ring

from

mainshaft

rear

bearing

using

snap

ring

pliers

TM796

Fig

MT

19

Removing

Mainshaft

Rear

Bearing

Snap

Ring

4

Drive

out

mainshaft

gear

as

sembly

together

with

counter

gear

assembly

by

lightly

tapping

the

rea

end

with

a

soft

hammer

while

holding

the

front

of

mainshaft

gear

assembly

and

counter

gear

assembly

by

hand

MT

6

Remove

counter

g

ar

main

dfN

gear

and

mainshaft

assembly

in

that

order

CAUTION

Be

careful

not

to

drop

gears

TM797

Fig

MT

20

Removing

Gear

AlSembly

Malnshaft

Disassemble

mainsltaft

gear

assem

bly

as

follows

1

R

emove

snap

ring

from

l

l

Iinshaft

front

end

Remove

3rd

4th

synchronizer

assembly

baulk

rings

3r

gear

and

mainshaft

needle

bearing

toward

the

front

side

Fig

MT

21

Removing

Snap

Ring

2

Press

out

mainsltaft

bearing

using

Bearing

Puller

ST3003Iooo

See

Fig

MT

23

CAUTION

When

pressing

out

bearing

hold

main

shaft

by

hand

so

as

not

to

drop

it

Page 225 of 548

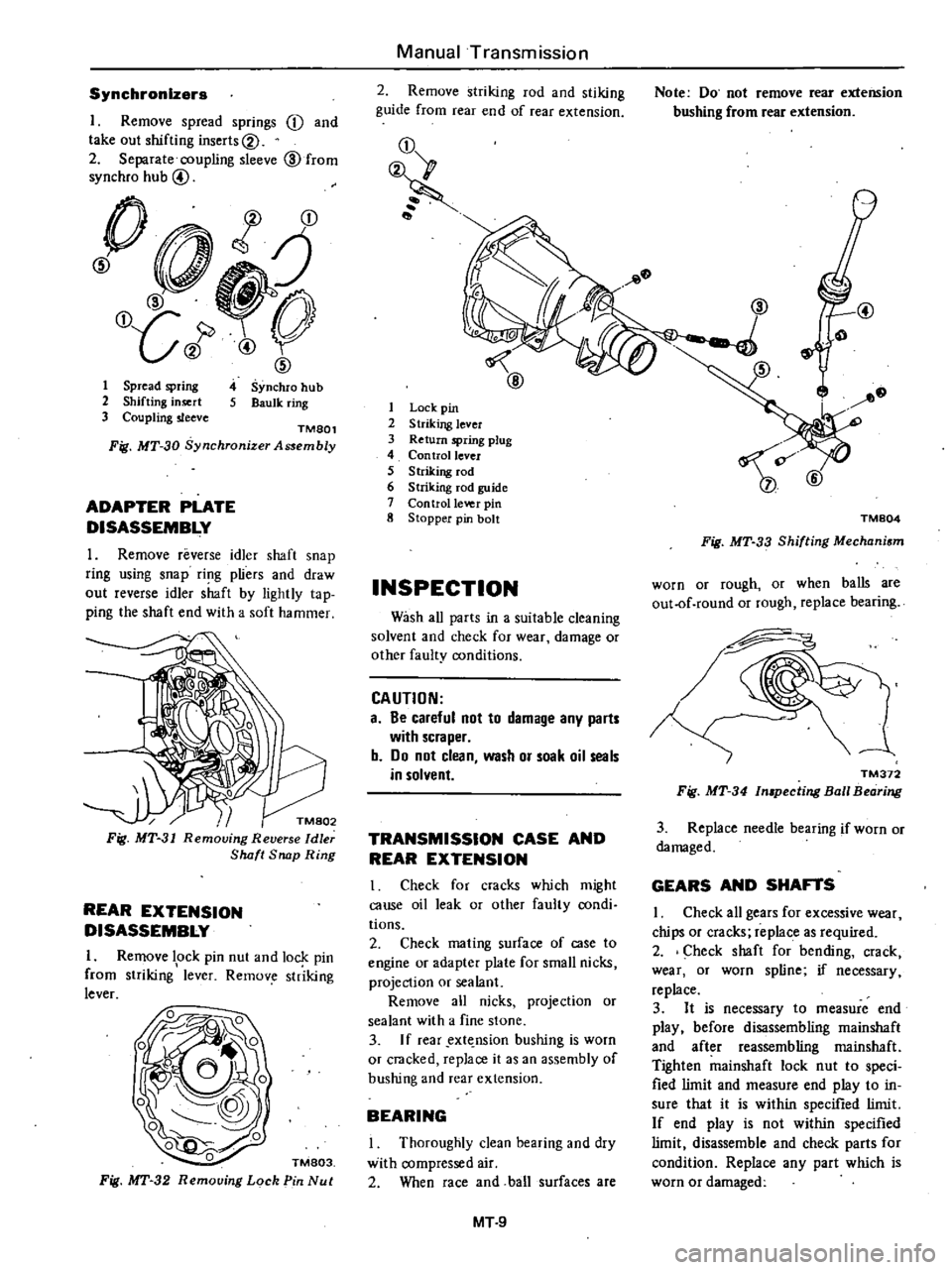

Synchronizers

I

Remove

spread

springs

j

and

take

out

shifting

inserts@

2

Separate

coupling

sleeve

@

from

synchro

hub

@

0

t

j

@

O

LJ

J

1

ID

4

Synchro

hub

S

Baulk

ring

1

Spread

spring

2

Shifting

insert

3

Coupling

sleeve

TMSOl

Fig

MT

30

Synchronjzer

Assembly

ADAPTER

PLATE

DISASSEMBLY

1

Remove

reverse

idler

shaft

snap

ring

using

snap

ri

1g

pliers

and

draw

out

reverse

idler

shaft

by

lightly

tap

ping

the

shaft

end

with

a

soft

hammer

k

Fig

MT

31

Removing

Reverse

Idler

Shaft

Snap

Ring

REAR

EXTENSION

DISASSEMBLY

I

Remove

lock

pin

nut

and

lock

pin

from

striking

1

lever

Remov

str

iking

lever

TM803

Fig

MT

32

Removing

Lock

Pin

Nut

Manual

Transmission

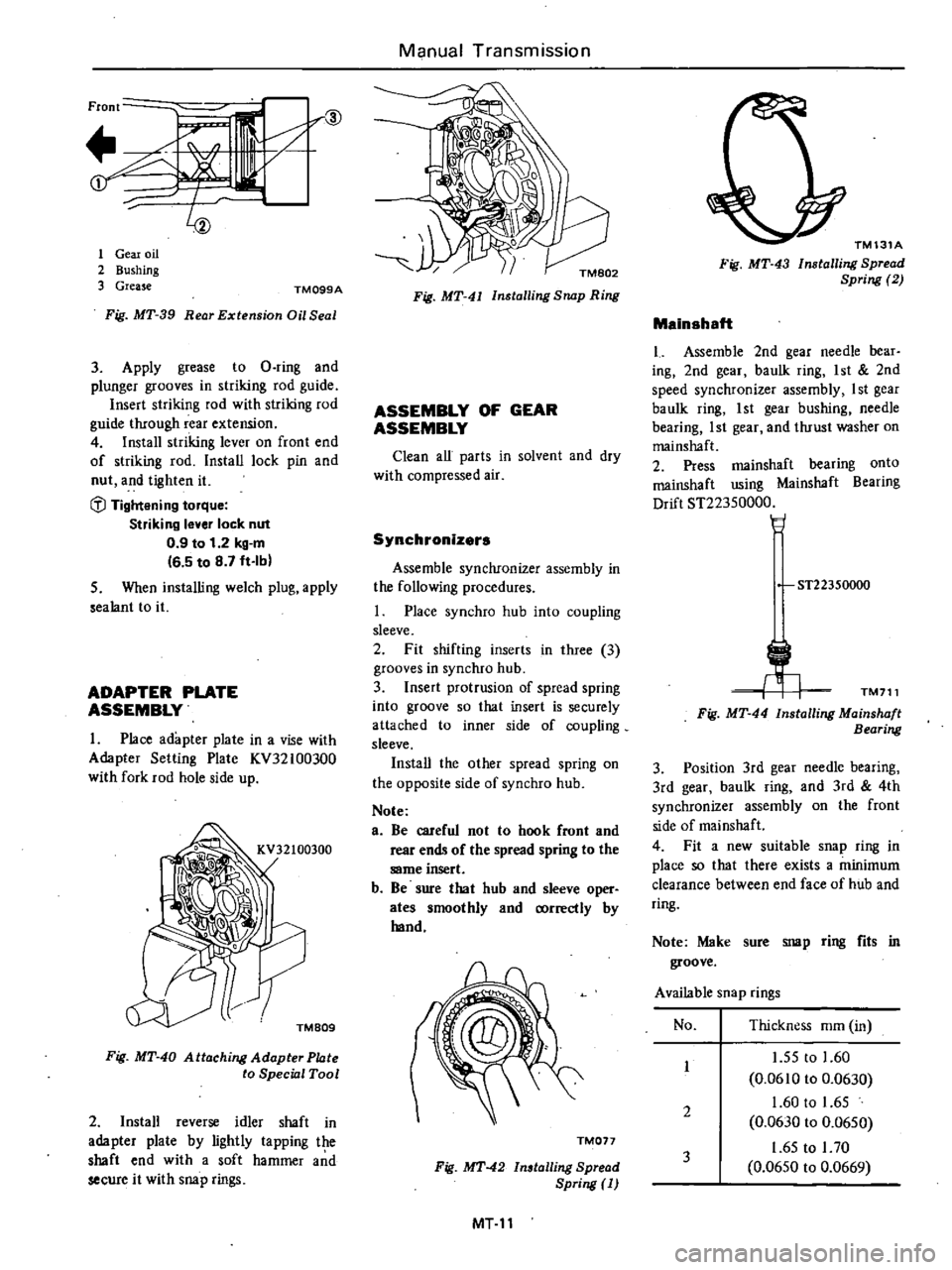

2

Remove

striking

rod

and

stiking

guide

from

rear

end

of

rear

extension

j

1

Lock

pin

2

Striking

lever

3

Return

spring

plug

4

Con

trollevcr

5

Striking

rod

6

Striking

fod

guide

7

Control

Ie

o

eI

pin

8

Stopper

pin

bolt

INSPECTION

Wash

all

parts

in

a

suitable

cleaning

solvent

and

check

for

wear

damage

or

other

faulty

conditions

CAUTION

a

Be

careful

not

to

damage

any

parts

with

scraper

b

Do

not

clean

wash

or

soak

oil

seals

in

solvent

TRANSMISSION

CASE

AND

REAR

EXTENSION

I

Check

for

cracks

which

might

cause

oil

leak

or

other

faulty

condi

tions

2

Check

mating

surface

of

case

to

engine

or

adapter

plate

for

small

nicks

projection

or

sealant

Remove

all

nicks

projection

or

sealant

with

a

fine

stone

3

If

rear

ext

nsion

bushing

is

worn

or

cracked

replace

it

as

an

assembly

of

bushing

and

rear

extension

BEARING

Thoroughly

clean

bearing

and

dry

with

compressed

air

2

When

race

and

ball

surfaces

are

MT

9

Note

Do

not

remove

rear

extension

bushing

from

rear

extension

@

TM804

Fig

MT

33

Shifting

Mechanism

worn

or

rough

or

when

balls

are

out

of

round

or

rough

replace

bearing

TM372

Fig

MT

34

In

pecting

Ball

Bearing

3

Replace

needle

bearing

if

worn

or

damaged

GEARS

AND

SHAFTS

I

Check

all

gears

for

excessive

wear

chips

or

cracks

replace

as

required

2

Check

shaft

for

bending

crack

wear

or

worn

spline

if

necessary

replace

3

It

is

necessary

to

measure

end

play

before

disassembling

mainshaft

and

after

reassembling

rnainshaft

Tighten

mainshaft

lock

nut

to

speci

fied

limit

and

measure

end

play

to

in

sure

that

it

is

within

specified

limit

If

end

play

is

not

within

specified

limit

disassemble

and

check

parts

for

condition

Replace

any

part

which

is

worn

or

damaged

Page 227 of 548

Front

if

r@

t

1

1

Gear

oil

2

Bushing

3

Grease

TM099A

Fig

MT

39

Rear

Extension

Oil

Seal

3

Apply

grease

to

D

ring

and

plunger

grooves

in

striking

rod

guide

Insert

striking

rod

with

striking

rod

guide

through

rear

extension

4

Install

striking

lever

on

front

end

of

striking

rod

Install

lock

pin

and

nut

and

tighten

it

fl

Tightening

torque

Striking

lever

lock

nut

0

9

to

1

2

kg

m

16

5

to

8

7

ft

Ib

5

When

installing

welch

plug

apply

sealant

to

it

ADAPTER

PLATE

ASSEMBLY

1

Place

adapter

plate

in

a

vise

with

Adaptet

Selling

Plate

KV32100300

with

fork

rod

hole

side

up

TMB09

Fig

MT

40

Attaching

Adapter

Phlte

to

Special

Tool

2

Install

reverse

idler

shaft

in

adapter

plate

by

lightly

tapping

the

shaft

end

with

a

soft

hammer

a

d

secure

it

with

snap

rings

Manual

Transmission

Fig

MT

4J

Installing

Snap

Ring

ASSEMBLY

OF

GEAR

ASSEMBLY

Clean

all

parts

in

solvent

and

dry

with

compressed

air

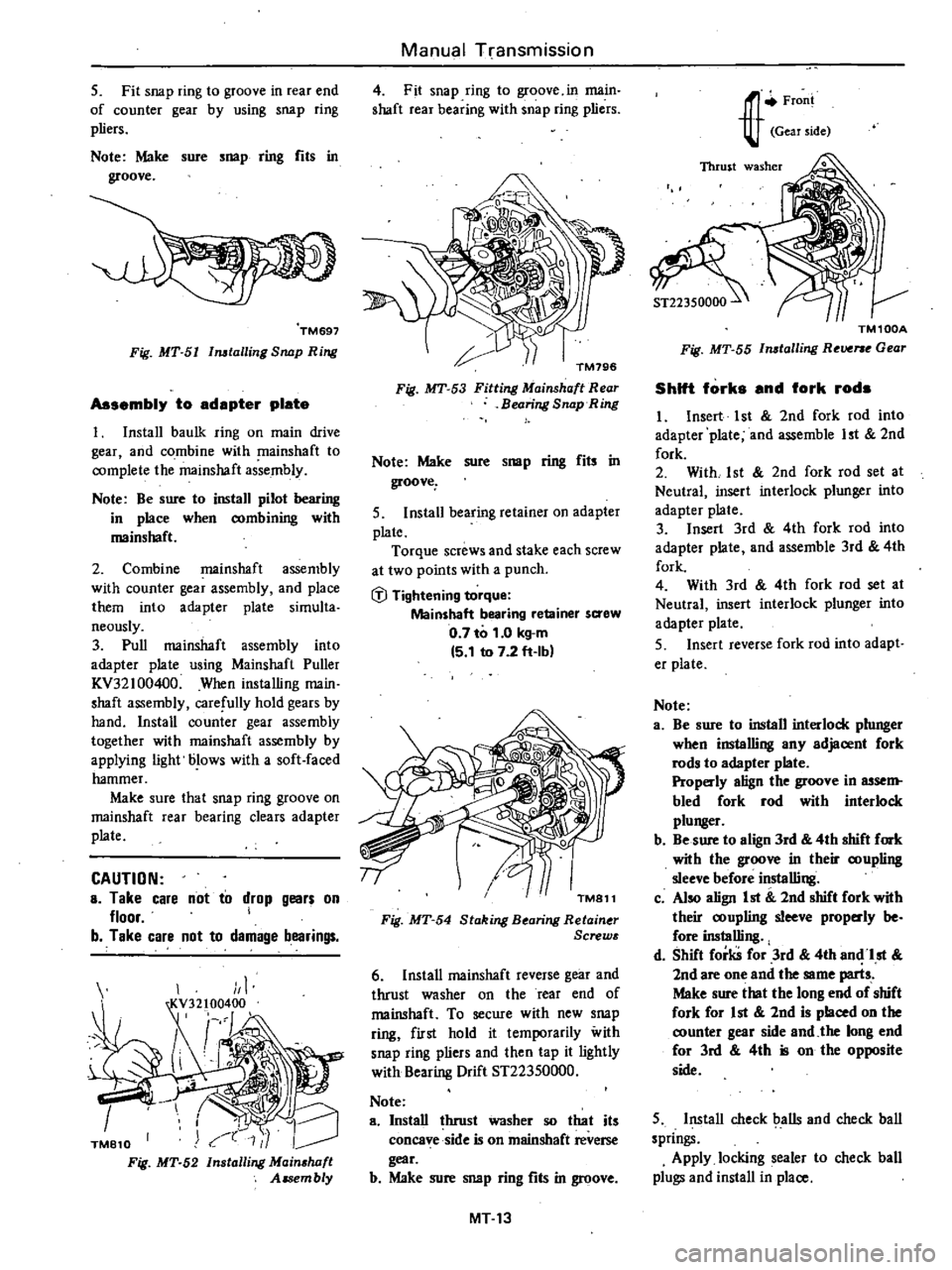

Synchronizers

Assemble

synchronizer

assembly

in

the

following

procedures

Place

synchro

hub

into

coupling

sleeve

2

Fit

shifting

inserts

in

three

3

grooves

in

synchro

hub

3

Insert

protrusion

of

spread

spring

into

groove

so

that

insert

is

securely

attached

to

inner

side

of

coupling

sleeve

Install

the

other

spread

spring

on

the

opposite

side

of

synchro

hub

Note

e

Be

careful

not

to

hook

front

and

rear

ends

of

the

spread

spring

to

the

same

insert

b

Be

sure

that

hub

and

sleeve

oper

ates

smoothly

and

correctly

by

hand

TM017

Fig

MT

42

Installing

Spread

Spring

MT

11

TM131A

Fig

MT

43

Installing

Spread

Spring

2

Mainshaft

Assemble

2nd

gear

needle

bear

ing

2nd

gear

baulk

ting

1

st

2nd

speed

synchronizer

assembly

I

st

gear

baulk

ring

1st

gear

bushing

needle

bearing

1st

gear

and

thrust

washer

on

mainshaft

2

Press

mainshaft

bearing

onto

mainshaft

using

Mainshaft

Bearing

Drift

ST22350000

H

ST22350000

TM711

Fig

MT

44

Installing

Mainshaft

Bearing

3

Position

3rd

gear

needle

bearing

3rd

gear

baulk

ring

and

3rd

4th

synchronizer

assembly

on

the

front

side

of

mainshaft

4

Fit

a

new

suitable

snap

ring

in

place

so

that

there

exists

a

minimum

clearance

between

end

face

of

hub

and

ring

Note

Make

sure

snap

ring

fits

in

groove

Available

snap

rings

No

Thickness

mm

in

1

55

to

1

60

0

0610

to

0

0630

1

60

to

1

65

0

0630

to

0

0650

1

65

to

I

70

0

0650

to

0

0669

1

2

3

Page 229 of 548

5

Fit

snap

ring

to

groove

in

rear

end

of

counter

gear

by

using

snap

ring

pliers

Note

Maire

sure

snap

ring

fits

in

groove

TM697

Fig

MT

5I

Imtalling

Snap

Ring

Assembly

to

adapter

plate

t

Install

baulk

ring

on

main

drive

gear

and

combine

with

mainshaft

to

complete

the

mainshaft

assembly

Note

Be

sure

to

install

pilot

bearing

in

place

when

combining

with

mainshaft

2

Combine

mainshaft

assembly

with

counter

gear

assembly

and

place

them

into

adapter

plate

simulta

neously

3

Pull

mainshaft

assembly

into

adapter

plate

using

Mainshaft

Puller

KV32

100400

When

installing

main

shaft

assembly

carefully

hold

gears

by

hand

Install

counter

gear

assembly

together

with

mainshaft

assembly

by

applying

light

blows

with

a

soft

faced

hammer

Make

sure

that

snap

ring

groove

on

mainshaft

rear

bearing

clears

adapter

plate

CAUTION

a

Take

care

not

to

drop

gears

on

floor

I

b

Take

care

not

to

damage

bearings

TM810

Fig

MT

52

1

Installing

Mainshaft

Assembly

Manual

Transmission

4

Fit

snap

ring

to

groove

in

main

shaft

rear

bearing

with

snap

ring

pliers

TM796

Fig

MT

53

Fitting

Mainshaft

Rear

Bearing

Snap

Ring

Note

Make

sure

snap

ring

fils

in

groove

5

Install

bearing

retainer

on

adapter

plate

Torque

screws

and

stake

each

screw

at

two

points

with

a

punch

fj

Tightening

torque

Mainshaft

bearing

retainer

saew

0

7

to

1

0

kg

m

15

1

to

7

2

ft

Ibl

TM811

Fig

MT

54

Staking

B

aring

Retain

r

Screw

6

Install

mainshaft

reverse

gear

and

thrust

washer

on

the

rear

end

of

mainshaft

To

secure

with

new

snap

ring

first

hold

it

temporarily

with

snap

ring

pliers

and

then

tap

it

lightly

with

Bearing

Drift

ST22350000

Note

a

Install

lhrust

washer

so

that

its

concave

side

is

on

mainshaet

reverse

gear

b

Make

sure

snap

ring

fits

in

groove

MT

13

J

r

Froni

Gear

side

TM100A

Fig

MT

55

Imtalling

R

Vf

e

Gear

Shift

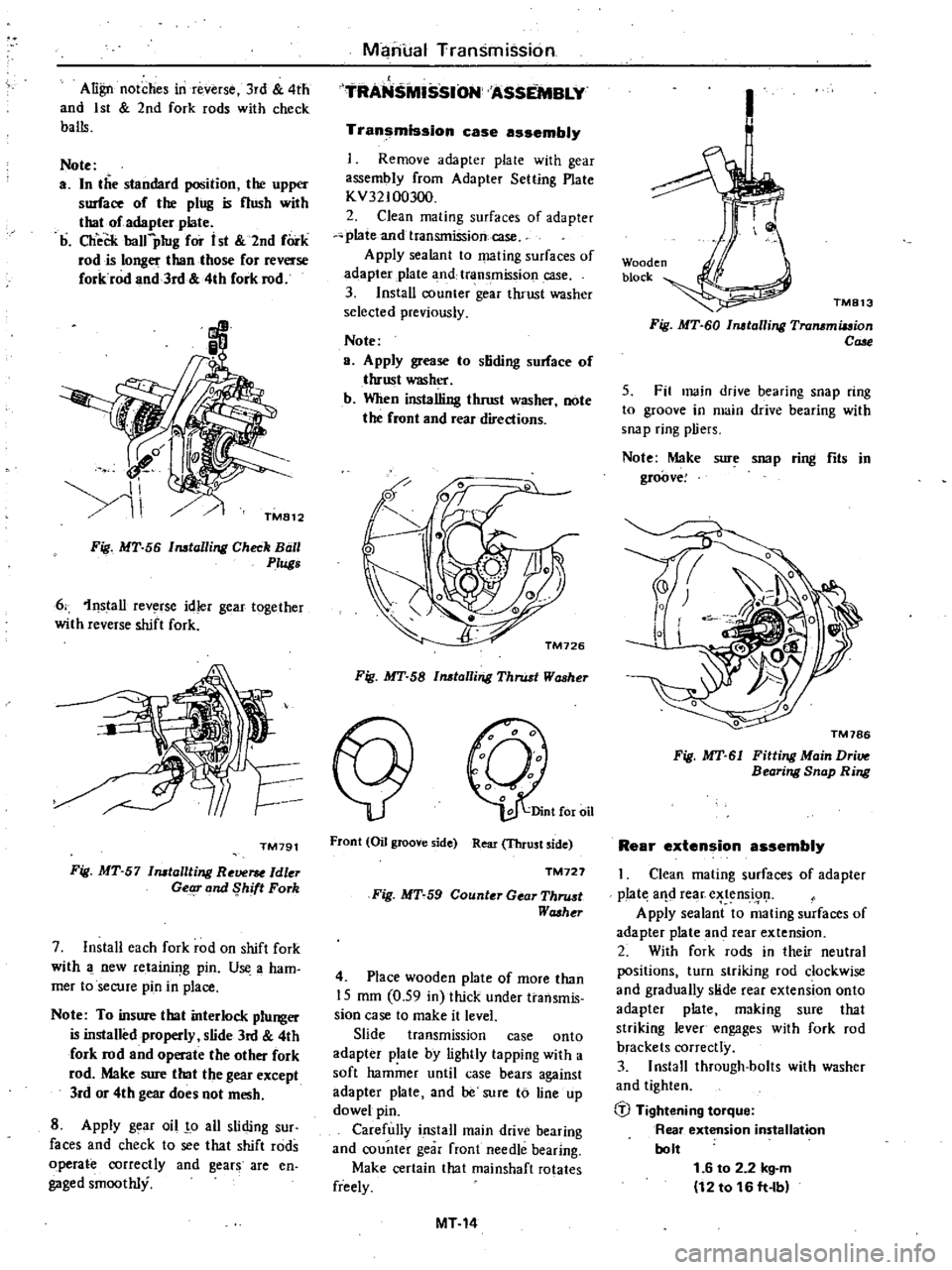

forks

and

fork

rods

I

Insert

1st

2nd

fork

rod

into

adapter

plate

and

assemble

1st

2nd

fork

2

With

1st

2nd

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

3

Insert

3rd

4th

fork

rod

into

adapter

plate

and

assemble

3rd

4th

fork

4

With

3rd

4th

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

S

Insert

reverse

fork

rod

into

adapt

er

plate

Nole

a

Be

sure

to

install

interlock

plunger

when

installing

any

adjacent

fork

rods

to

adapter

plate

Properly

align

the

groove

in

assem

bled

fork

rod

with

interlock

plunger

b

Be

sure

to

align

3rd

4th

shift

fork

wilh

the

groove

in

their

coupling

sleeve

before

installing

c

Also

align

1st

2nd

shift

fork

with

their

coupling

sleeve

prop

dy

be

fore

inslalling

d

Shift

forks

for

3rd

4th

an

1st

2nd

are

one

and

the

same

parts

Make

sure

that

the

long

end

of

shift

fork

for

1st

2nd

is

placed

on

the

counter

gear

side

and

the

long

end

for

3rd

4th

is

on

the

opposite

side

5

Install

check

balls

and

check

ball

springs

Apply

locking

sealer

to

check

ball

plugs

and

install

in

place

Page 230 of 548

Align

notches

in

reverse

3rd

4th

and

1st

2nd

fork

rods

with

check

balls

Note

a

In

the

standard

position

the

upper

surface

of

the

ping

is

nush

with

thaI

of

adapter

plate

b

CheCk

balfpIug

for

i

st

2nd

fork

rod

is

longer

than

those

for

reverse

forkrod

and

3rd

4th

fork

rod

Manual

Transmission

TRANS

SSION

ASSEMBLY

Transmission

case

assembly

Remove

adapter

plale

with

gear

assembly

from

Adapter

Setting

Plate

KV32100300

2

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

3

nd

transmission

case

3

Install

counter

gear

thrust

washer

selected

previously

Note

a

Apply

grease

to

stiding

sorface

of

thrust

washer

b

When

installing

thrust

washer

note

the

front

and

rear

directions

Fig

MT

56

Installing

Check

Ball

0

Plugs

6

1nstall

rev

rse

idler

gear

together

with

reverse

shift

fork

TM791

Fig

MT

57

Installting

Re

ldler

Getg

and

Shift

Fork

7

Install

each

fork

rod

on

shift

fork

with

new

retainif

g

pin

U

a

ham

mer

toseCUfe

pin

in

place

Note

To

insure

that

interlock

plunger

is

installed

properly

slide

3rd

4th

fork

rod

and

operate

the

other

fork

rod

Make

sure

that

the

gear

except

lrd

or

4th

gear

does

not

mesh

8

Apply

g

ar

oil

o

all

sliding

sur

faces

and

check

to

see

that

shift

rods

operate

correctly

and

gears

are

en

gaged

smoothly

Fig

MT

58

Installing

Thrust

Washer

Front

Oil

groove

side

Rear

Thrust

side

TM727

Fig

MT

59

Counter

Gear

Thru

t

Washt

r

4

Place

wooden

plate

of

more

than

15

mm

0

59

in

thick

under

transmis

sion

case

to

make

it

level

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

and

be

sure

to

line

up

dowel

pin

Carefully

install

main

drive

bearing

and

counter

gear

front

needle

bearing

Make

certain

that

rnainshaft

rotates

freely

MT14

1

Wooden

block

TM813

Fig

MT

60

Installing

Transmiuion

Cale

5

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

with

snap

ring

pliers

Note

Make

sure

snap

ring

fits

in

groove

Fig

MT

61

Fitting

Main

Dri

Bearing

Snap

Ring

Rear

extension

assembly

Clean

mating

surfaces

of

adapter

p

Iat

aIld

rear

e

tens

i91

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

rear

extension

2

With

fork

rods

in

their

neutral

positions

turn

striking

rod

clockwise

and

gradually

slide

rear

extension

onto

adapter

plate

making

sure

that

striking

lever

engages

with

fork

rod

brackets

correctly

3

Install

through

bolts

with

washer

and

tighten

b

Tightening

torque

Rear

extension

installation

bolt

1

6

to

2

2

kg

m

12

to

16

ft

lb