lock DATSUN 210 1979 Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 276 of 548

X

F

1

2

dll

U

Sflift

lllvI

21

I

S

nd

lock

6

Ir

II

P

UX

6

I

Mo

ol

f

L

t

u

uu

u

u

I

f5

LI

P

OI

I

Go

o

fo

d

P

I

ren

e

2nd

eer

Torqul

con

rter

Oil

pump

Oil

tool

RIAr

Ivbri

cor

ion

D

Orain

fa

hi

Front

lubrici

lti

0

0

0

1

I

tU

x

j

Pr

l

UQU

010r

Yol

u

1

Automatic

Transmission

Front

lulch

Riot

x

l

N

r

N

N

I

I

i

l

I

18

16

ahl

J

@

Vacuum

Huottl

Vol

if

J

II

Throttl

drain

yol

l

II

@2ft

3rd

Shiff

101

1

iii

1J

g

2nd

3rd

timino

101

11

8

Goy

rnor

prlUUAI

Torque

Cony

tar

pr

r

Th

toni

pt

ure

Slcondor

governor

vol

1

Primo

00

vlrnor

va

AT461

Fig

AT

21

Oil

Pr

Circuit

Dwgrom

12

ro

2nd

ear

AT

24

Page 277 of 548

Automatic

Transmission

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

car

pay

attention

to

the

following

points

I

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Trouble

shooting

Chart

and

dis

mount

it

only

when

coll5idered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

REMOVAL

In

dismounting

automatic

transmis

sion

from

car

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Disengage

torsion

shaft

from

ac

eelerator

linkage

3

Jack

up

vehicle

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

4

Remove

propeller

shaft

Note

Pl

ll

up

the

openina

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

S

Disconnect

front

exhaust

tube

6

Disconnect

selector

ra

8e

lever

from

manual

shaft

7

Disconnect

wire

connections

at

inhibitor

switch

8

Disconnect

vacuum

lube

from

vacuum

diaphragm

and

wire

connee

tions

at

downshift

solenoid

9

Disconnect

speedometer

cable

from

rear

exlension

10

Disconnect

oil

charging

pipe

II

Disconnect

oil

cooler

inlet

and

outlet

tubes

al

transmission

case

12

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

a

transmission

jack

CAUTION

Do

not

plecs

the

jack

under

the

oil

pin

dnin

plug

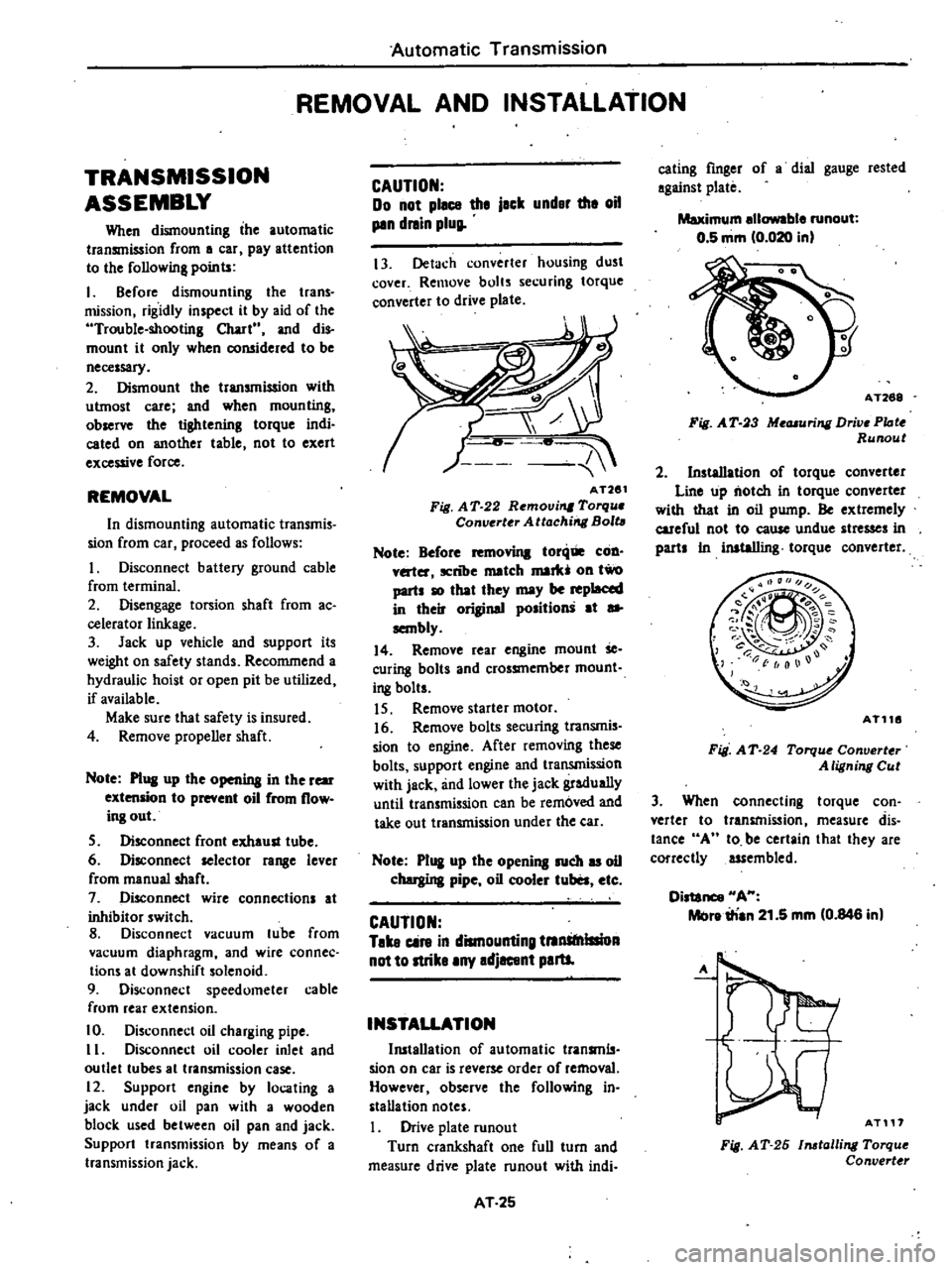

13

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

AT261

Fig

A

T

22

Removi

Torqu

Converter

Attachirrg

Bolt

Note

Before

toni

COD

v

ter

ICnlJe

match

mark

011

two

parts

10

that

they

may

be

replaced

in

their

original

position

at

sa

sembly

14

Remove

rear

engine

mount

Se

curing

bolts

and

crossmember

mount

i

8

bolts

IS

Remove

starter

motor

16

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

ear

Note

P1

I

up

the

opening

such

u

oil

chergina

pipe

oil

cooler

tuba

etc

CAUTION

Take

cin

in

dismounting

tnnStnlllioA

not

to

strike

any

adjacent

paru

INSTALLATION

Ill5tallation

of

automatic

transmls

sian

on

car

is

reverse

order

of

removal

However

observe

the

following

in

stallation

notes

Drive

plate

runout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

runout

with

indi

AT

25

eating

finger

of

a

dial

gauge

rested

against

plate

Maximum

ellowable

runout

0

5

mm

0

020

in

AT268

Fig

A

T

3

Me

uring

Drive

PIote

Runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

eause

undue

stresses

in

parts

In

inataIIing

torque

converter

AT116

Fig

A

T

24

Torqu

Converter

A

ligning

Cut

3

When

connecting

torque

con

verter

to

transmission

measure

dis

tance

A

10

be

certain

that

they

are

correctly

assembled

Distance

HA

Melre

irian

21

5

mm

0

846

in

A

AT117

Fig

AT

26

1116talling

Torque

Convert

r

Page 279 of 548

Automatic

Transmission

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

advisable

that

repair

opera

tions

be

carried

out

in

a

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

They

do

however

have

common

adjust

ment

and

repair

procedures

as

well

as

cleaning

and

inspection

procedures

outlined

hereinafter

3

During

repair

operations

refer

to

Service

Data

and

Specific3ti

H1s

see

tion

for

the

correct

parts

for

each

model

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

prevent

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

or

paper

cloth

6

After

disassembling

wash

all

dis

assembled

parts

and

examine

them

to

see

if

there

3re

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

As

a

rule

packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

TORQUE

CONVERTER

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

INSPECTION

I

Check

torque

convert

for

any

sign

of

damage

bending

oil

leak

or

deformation

If

necessary

replace

2

Remove

rust

from

pilots

and

bosses

completely

If

torque

converter

oil

is

fouled

or

contaminated

due

to

burnt

clutch

flush

the

torque

converter

as

follows

I

Drain

oil

in

torque

converter

2

Pour

non

lead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

J

V

S

pt

U

Imp

pt

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

with

torque

converter

oil

approximately

0

5

liter

I

J

V

S

pt

U

Imp

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

TRANSMISSION

DISASSEM

LY

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07g70000

or

ST07860000

Remove

oil

pan

AT118

Fig

A

T

26

R

movin

g

Oil

Pan

2

Remove

bolts

securing

converter

housing

to

transmission

case

Remove

torque

converter

housing

3

Remove

speedometer

pinion

sleeve

bolt

Withdraw

pinion

4

Remove

downshift

solenoid

and

vacuum

diaphragm

Do

not

leave

dia

phragm

rod

at

this

stage

of

dis

assembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

Fig

A

T

27

Dowmhift

Solenoid

and

Vacuum

Diaphragm

AT

27

5

Remove

bolts

which

hold

valve

body

to

transmission

case

Fig

AT

28

Removing

Valve

Body

6

Loosen

lock

nut

CV

on

piston

stem

CD

Then

tighten

piston

stem

in

order

to

prevent

front

clutch

drum

from

falling

when

oil

pump

is

withdrawn

AT121

Fig

AT

29

Loosening

Band

Se11

Jo

7

Pull

out

input

shaft

8

Withdraw

oil

pump

using

Sliding

Hammer

ST25850000

Do

not

allow

front

clutch

to

come

out

of

position

and

drop

onto

floor

AT122

Fig

AT

30

Removing

Oil

Pump

Page 281 of 548

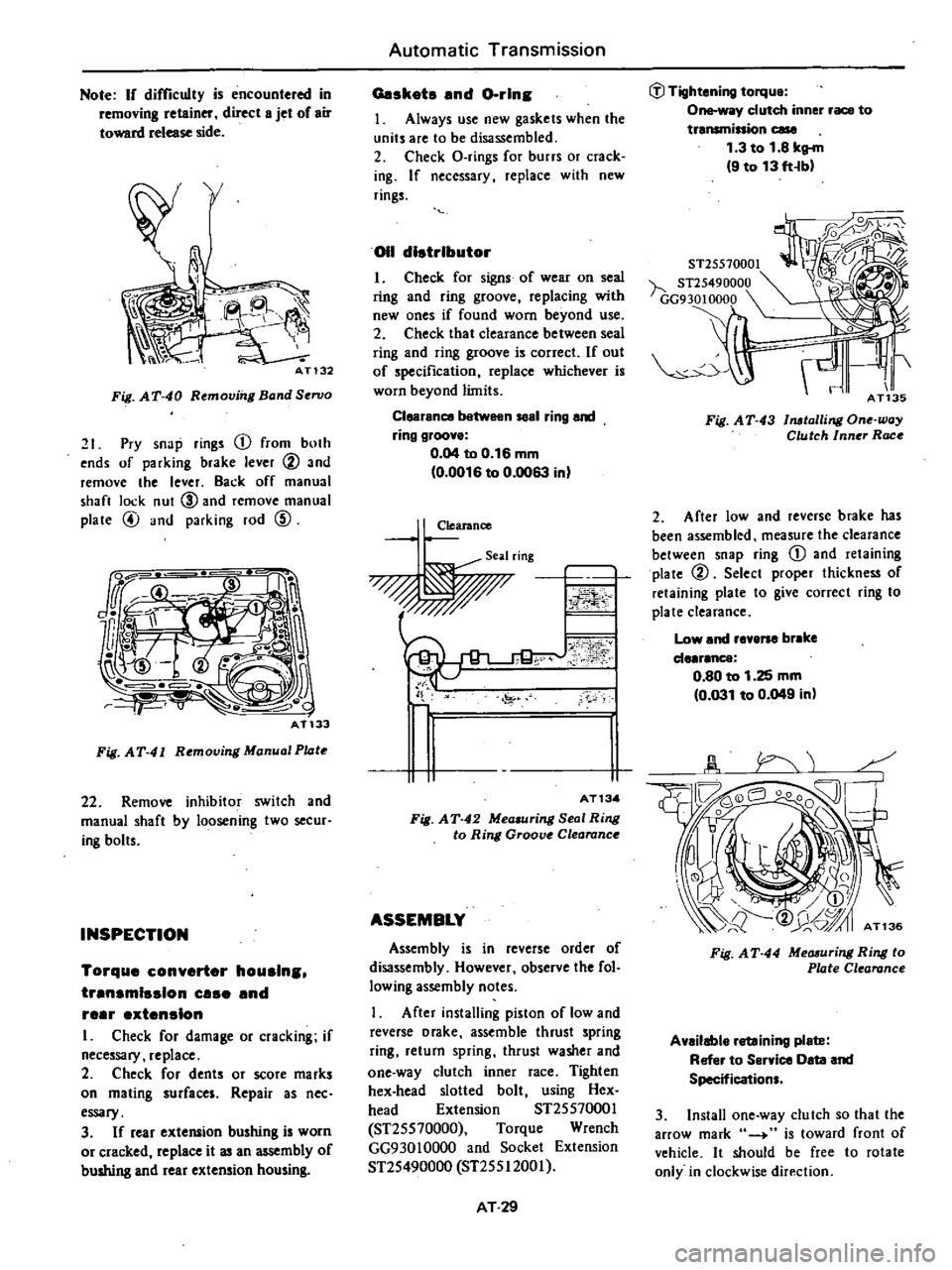

Note

If

difficulty

is

encountered

in

removing

retainer

direct

8

jet

of

air

toward

release

side

Ph

i

AT132

Fig

AT

40

Remov

I

Band

Servo

21

Pry

snap

rings

CD

from

both

ends

of

parking

brake

lever

@

and

remove

the

lever

Back

off

manual

shan

lock

nut

CID

and

remove

manual

plate

@

and

parking

rod

CID

Fig

AT

41

Rtmoving

Manual

Pl4tt

22

Remove

inhibitor

switch

and

manual

shaft

by

loosening

two

secur

ing

bolts

INSPECTION

Torque

converter

houslns

trensmlsslon

use

end

reer

extension

I

Check

for

damage

or

cracking

if

necessary

replace

2

Check

for

dents

or

score

marks

on

mating

surfaces

Repair

as

nee

essary

3

If

rear

extelUlion

bushing

is

worn

or

cracked

replace

it

an

mbly

of

bushing

and

rear

extension

housing

Automatic

Transmission

Geskots

end

Gorin

J

Always

use

new

gaskets

when

the

units

are

to

be

disassembled

2

Check

O

rings

for

burrs

or

crack

ing

If

necessary

replace

with

new

rings

011

distributor

I

Check

for

signs

of

wear

on

seal

ring

and

ring

groove

replacing

with

new

ones

if

found

worn

beyond

use

2

Check

that

clearance

between

seal

ring

and

ring

groove

is

correct

If

out

of

specification

replace

whichever

is

worn

beyond

limits

Clearence

1

n

58el

ring

end

ring

groove

0

04

to

0

16

mm

0

0016

to

0

0063

in

Clearance

Seal

ring

0

o

ii

J

0

1

FI

AT13

Fig

AT

42

Mea

uring

Seal

Ring

to

Ring

Groove

Clearance

ASSEMBLY

Assembly

is

in

reverse

order

of

disassembly

However

observe

the

fol

lowing

assembly

notes

After

installing

piston

of

low

and

reverse

Drake

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Tighten

hex

head

slotted

bolt

using

Hex

head

Extension

ST2SS7000J

ST2SS70000

Torque

Wrench

GG930JOOOO

and

Socket

Extension

ST2S490000

ST2SSI200J

AT

29

J

Tightening

torque

One

way

clutch

inner

race

to

transminion

case

1

3

to

1

8

kg

m

9

to

13

ft

b

ST25570001

h

ST25490000

GG9

30

10000

Fig

AT

43

1

lalli

ll

One

way

Clutch

Inner

Race

2

After

low

and

reverse

brake

has

been

assembled

measure

the

clearance

between

snap

ring

CD

and

retaining

plate

@

Select

proper

thickness

of

retaining

plate

to

give

correct

ring

to

plate

clearance

Low

and

revene

br

ke

de

r

nce

0

80

to

1

25

mm

0

031

to

0

049

in

Fig

A

T

44

Measuring

Ring

to

Plate

Clearance

Available

retaining

plete

Refer

to

Service

Oeta

and

Specifications

3

Install

one

way

clutch

so

that

the

arrow

mark

4

is

toward

front

of

vehicle

It

should

be

free

to

rotate

only

in

clockwise

direction

Page 282 of 548

ITU

lmQO

d

fJ

AT137

Fig

A

T

45

One

way

Cluleh

4

After

installing

rear

extension

tighten

attaching

bolts

Place

manual

lever

in

P

range

and

check

to

be

sure

that

rear

outpul

shaft

is

securely

blocked

fl

Tightening

torque

Transmission

case

to

rear

extension

2

0

to

2

5

kg

m

14

to

18

fHbl

5

Tighten

servo

retainer

temporari

Iy

at

this

stage

of

assembly

6

Place

rear

clutch

assembly

with

needle

bearing

on

front

assembly

7

Install

rear

clutch

4

lb

and

front

planetary

carrier

AT142

Fig

AT

46

talling

Planetary

Carrier

8

Assemble

connecting

shell

and

other

parts

up

to

front

clutch

in

reverse

order

of

disassembiy

AT143

Fig

AT

47

talling

Canneetin

Shell

Automatic

Transmission

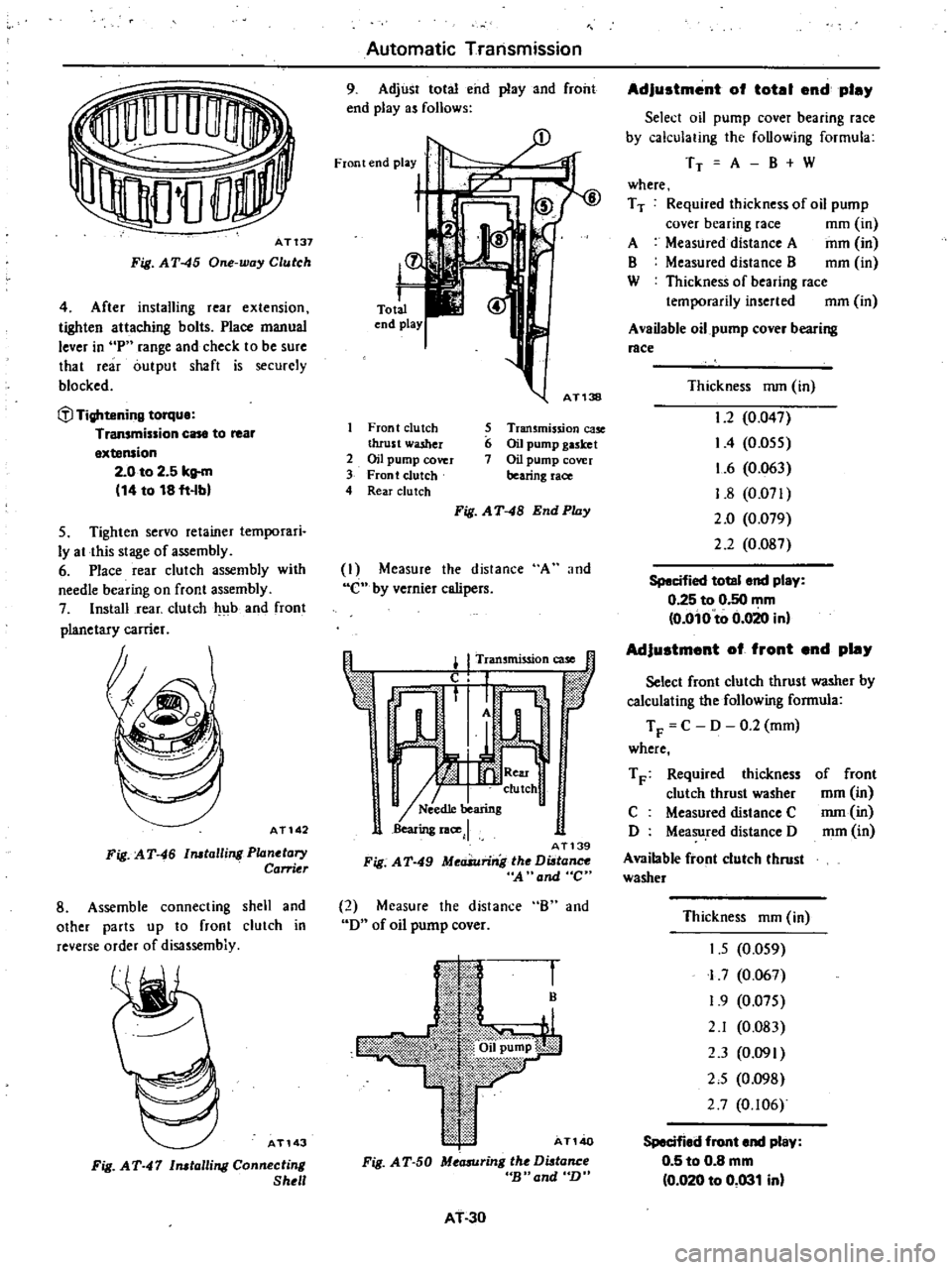

9

Adjust

total

end

play

and

front

end

playas

follows

Front

end

play

t

Zl

L

r

Total

end

play

AT138

Front

clutch

5

Transmission

ca5e

thrust

washer

6

Oil

pump

gasket

2

OH

pump

cover

7

Oil

pump

cover

3

Front

clutch

bearing

race

4

Rear

clu

tch

Fig

AT

48

End

Play

I

Measure

the

distance

A

and

C

by

vernier

calipers

I

I

Tran

mission

case

t

f

l

1

I

n

0

tic

r

1

A

W

I

I

II

clulch

I

N

ed1e

bearing

Bearing

lace

J

AT139

Fig

A

T

49

MeaSuring

the

Di

tance

A

and

C

2

Measure

the

distance

B

and

D

of

oil

pump

cover

B

AT140

Fig

A

T

50

Measuring

the

Di

tance

cB

and

n

AT

30

Adjustment

of

totel

end

pley

Select

oil

pump

cover

bearing

race

by

calculating

thc

following

formula

TT

A

B

W

where

T

T

Required

thickness

of

oD

pump

cover

bearing

race

mm

in

A

Measured

distance

A

mm

in

B

Measured

distance

B

mm

in

W

Thickness

of

bearing

race

temporarily

inserted

mm

in

A

vaDable

oil

pump

cover

bearing

race

Thickness

nun

in

1

2

0

047

I

4

0

055

1

6

0

063

1

8

0

071

2

0

0

079

2

2

0

Og7

Specified

totel

end

play

0

25

to

0

50

mm

o

oio

to

0

020

inl

Adjustment

of

front

end

pley

Select

front

clutch

thrust

washer

by

calculating

the

following

formula

T

F

C

D

0

2

mm

where

T

F

Required

thickness

clutch

thrust

washer

C

Measured

distance

C

D

Measu

red

distance

D

Available

front

clutch

thrust

washer

of

front

mm

in

nun

in

mm

in

Thickness

mm

in

1

5

0

059

I

7

0

067

1

9

0

075

2

1

0

083

2

3

0

091

2

5

0

098

2

7

0

106

Specified

front

end

pley

0

5

to

0

8

mm

0

020

to

0

031

inl

Page 283 of 548

Note

L

C

llTect

thid

ness

of

bearing

race

end

thrust

washer

is

always

the

one

which

is

nearest

the

calculated

one

b

InsteJled

thid

noss

of

oil

pump

gasket

is

0

4

mm

0

016

in

10

Check

to

b

sure

that

brake

servo

piston

moves

freely

For

detailed

procedure

refer

to

page

AT

33

for

Servo

Piston

Use

care

to

prevent

piston

from

coming

out

of

place

dur

ing

testing

since

servo

retainer

is

not

tightened

at

this

point

of

assembly

II

Make

sure

that

brake

band

strut

is

correctly

installed

Tighten

piston

stem

Back

off

two

full

turns

end

secure

with

lock

nul

l

l

Tightening

torqUl

Piston

stem

1

2

to

1

5

kg

m

9

to

11

ft

lbl

Piston

tem

lock

nut

1

5

to

4

0

kg

m

11

to

29

ft

lbl

Available

diaphragm

rod

Distance

measured

L

mm

in

Under

25

55

1

0059

25

65

to

26

05

1

0098

to

1

0256

26

15

to

26

55

1

0295

to

1

0453

26

65

to

27

05

1

0492

to

1

0650

Over

27

15

1

0689

COMPONENT

PARTS

The

transmission

consists

of

many

all

parts

that

are

quite

alike

in

oonstruction

yet

machined

to

very

close

tolerances

When

disassembling

parts

be

sure

to

place

them

in

order

in

part

rack

so

they

can

be

restored

in

the

unit

in

their

proper

positions

It

is

also

very

important

to

perform

func

lional

test

whenever

it

is

designated

Automatic

Transmission

12

After

inhibitor

switch

is

in

stalled

check

to

be

sure

that

it

op

erates

properly

in

each

range

For

detailed

procedure

refer

to

page

AT

40

for

Checking

and

Adjusting

lnhibi

tor

Switch

13

Check

the

length

L

between

case

end

to

rod

end

of

vacuum

throttle

valve

fully

pushed

in

Then

select

adequate

diaphragm

rod

of

corre

sponding

measured

length

1

11f1

n

1

11

1

1

f

c

dllidf

i

L

AT145

Fig

A

T

51

M

asuring

the

Dutance

L

Diaphragm

rod

length

mm

in

29

0

1

142

295

1

161

30

0

I

181

30

5

1

201

31

0

1

220

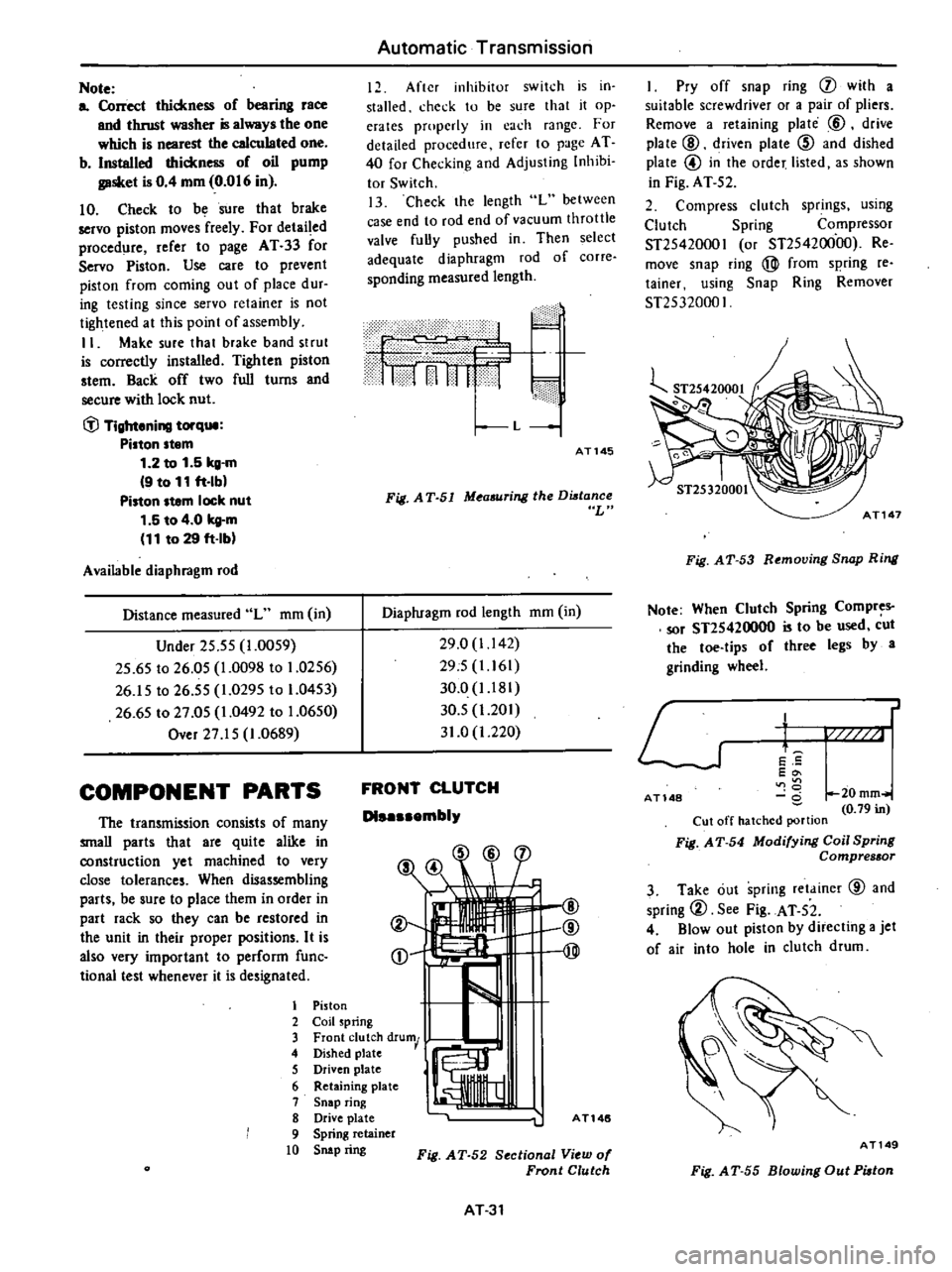

FRONT

CLUTCH

Dl

mbly

@

@

@

I

Piston

2

Coil

spring

3

Front

clutch

drum

4

Dished

plate

5

Driven

plate

I

6

R

I

etammg

plate

7

Snap

ring

8

Drive

plate

A

T146

9

Spring

retainer

10

Snip

ring

Fig

AT

52

Section

1

View

of

Fronl

Clulch

AT31

I

Pry

off

snap

ring

j

with

a

suitable

screwdriver

or

a

pair

of

pliers

Remove

a

retaining

plate

@

drive

plate

@

driven

plate

@

and

dished

plate

@

in

the

order

listed

as

shown

in

Fig

AT

52

2

Compress

clutch

springs

using

Clutch

Spring

Compressor

ST25420001

or

ST25420000

Re

move

snap

ring

@

from

spring

reo

tainer

using

Snap

Ring

Remover

ST25320001

Fig

AT

53

Removing

Snap

Ring

Note

When

Clutch

Spring

Compres

sor

ST2S420000

is

to

be

used

cut

the

toe

tips

of

three

legs

by

a

grinding

wheel

L

J

t

E

5

Eo

U

0

20mm

0

79

in

Cut

off

hatched

portion

Fig

A

T

54

Modifying

Coil

Spring

Compressor

AT

148

3

Take

out

spring

retainer

@

and

spring

2

See

Fig

AT

52

4

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

clutch

drum

AT149

Fig

A

T

55

Blowing

Out

Piolon

Page 288 of 548

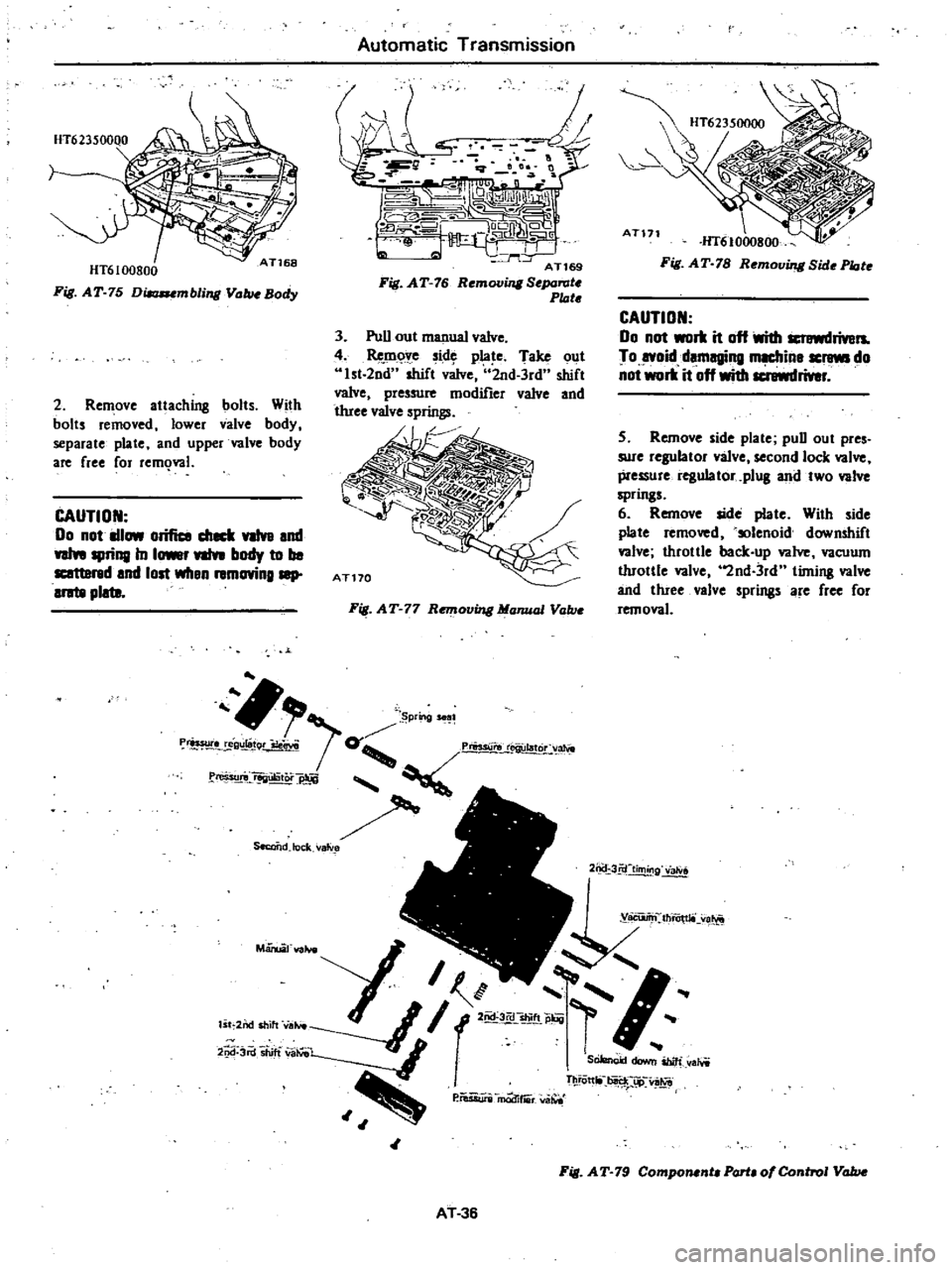

HT6100800

Fig

AT

75

Dilaaumbling

ValwBady

2

Remove

attaching

bolts

With

bolts

removed

lower

valve

body

separate

plate

and

upper

valve

body

are

free

for

rem

wl

CAUTION

00

not

IIlow

orifice

c111C1l

VIlv8

end

weIn

spring

In

1

nIn

body

to

be

I

and

lost

wilen

removinglllp

aratll

plata

Automatic

Transmission

Sf

3

Pull

out

manual

valve

4

Remove

side

plate

Take

out

Ist

2nd

shift

dve

2nd

3rd

shift

valve

pressure

modifier

valve

and

Wee

valve

springs

Fig

AT

77

Remouing

Manual

Vallie

r

p

g

1

Prasur

e

ul8t

m

g

qrJ

0

ew

o

afW

e

f

rio

UIiltOi

SeccQdJock

V81V

AT171

HT61000800

Fig

AT

78

Remouing

Bide

Plote

CAUTION

00

not

work

it

off

With

rivers

To

syoid

damaging

m

in8

screws

do

not

work

it

off

with

screwdriver

5

Remove

side

plate

pull

out

pres

sure

regulator

valve

second

lock

valve

pressure

regulator

plug

and

two

valve

springs

6

Remove

side

plate

With

side

plate

removed

solenoid

downshift

valve

throttle

back

up

valve

vacuum

throttle

valve

2nd

3rd

timing

valve

and

three

valve

springs

are

free

for

removal

2ncr

3fiftiming

2

Jd

3rd

shift

WiIVeL

q

SOJe

nod

00

ibiIi

aMi

P

iWWi

m

d

fiii

va

iOtt

tii

jJ

v

Fig

AT

79

ComponentaPartaofeontrol

Value

AT

36

Page 289 of 548

Automatic

Transmission

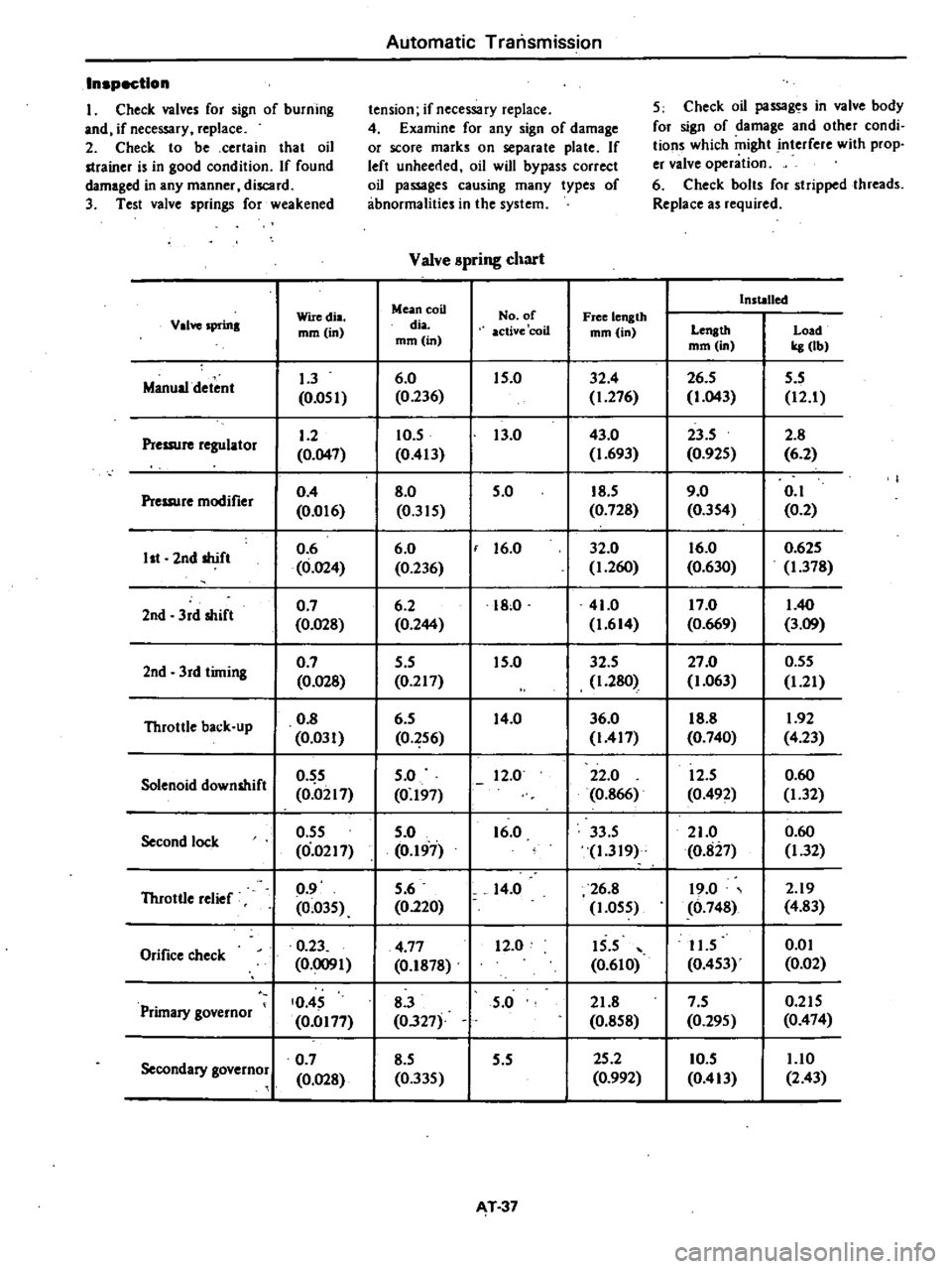

Inspection

I

Check

valves

for

sign

of

burning

tension

if

necessary

replace

5

Check

oil

passages

in

valve

body

and

if

necessary

replace

4

Examine

for

any

sign

of

damage

for

sign

of

damage

and

other

condi

2

Check

to

be

certain

that

oil

or

score

marks

on

separate

plate

If

tions

which

might

interfere

with

prop

strainer

is

in

good

condition

If

found

left

unheerlcd

oil

will

bypass

correct

er

valve

operation

damaged

in

any

manner

discard

oil

passages

causing

many

types

of

6

Check

bolts

for

stripped

threads

3

Test

valve

springs

for

weakened

abnormalities

in

the

system

Replace

as

required

Valve

spring

chart

Mean

coil

Installed

Wiredia

No

of

Free

length

Valve

sprma

mm

in

dia

active

coil

mm

in

Length

Load

mm

in

mm

in

kg

lbl

Manual

detent

1

3

6

0

15

0

32

4

26

5

5

5

0

051

0

236

1

276

1

043

12

1

Pressure

regulator

1

2

10

5

13

0

43

0

23

5

2

8

0

047

0

413

1

693

0

925

6

2

Pressure

modifier

0

4

8

0

5

0

18

5

9

0

0

1

0

01

6

0

315

0

728

0

354

0

2

2nd

shift

0

6

6

0

f

16

0

32

0

16

0

0

625

1st

0

024

0

236

1

260

0

630

1

378

2nd

3rd

shift

0

7

6

2

18

0

41

0

17

0

1

40

0

028

0

244

1

614

0

669

3

09

2nd

3rd

timing

0

7

5

5

15

0

32

5

27

0

0

55

0

028

0

217

1

280

1

063

1

21

Throttle

back

up

0

8

6

5

14

0

36

0

18

8

1

92

0

031

0

256

1417

0

740

4

23

Solenoid

downshift

0

5

5

0

12

0

22

0

12

5

0

60

0

0217

0

197

0

866

0

492

1

32

Second

lock

0

55

5

0

16

0

33

5

21

0

0

60

0

0217

0

197

1

319

0

827

1

32

Throttle

relief

0

9

5

6

14

0

26

8

19

0

2

19

0

035

0

220

1

055

0

74g

4

83

Orifice

check

0

23

4

77

12

0

15

5

11

5

om

0

0091

0

lg78

0

610

0

453

0

02

Primary

governor

0

45

8

3

5

0

21

8

7

5

0

215

0

0177

0327

0

858

0

295

0

474

Secondary

governor

0

7

8

5

5

5

25

2

10

5

1

10

0

028

0

335

0

992

0

413

2

43

T

37

Page 302 of 548

Oldel

Others

Automatic

Transmission

Test

item

4

Shift

down

Or

O

O

5

Shift

down

Or

I

1

6

Shift

down

0

2

7

Shift

up

1

1

8

Shift

up

or

down

when

start

ing

in

2

ranae

9

Parking

Abnormal

shock

oil

leakage

Procedure

Check

vehicle

speeds

and

engine

rpm

in

shifting

down

from

3rd

2nd

1st

sequentiaUy

while

coasting

with

accelerater

pedal

released

in

0

range

and

engine

vacuum

pressure

of

about

450

mmHg

17

72

inHg

Check

for

shifti

ng

do

n

I

I

nd

engine

blaking

and

further

for

shifting

down

I

I

and

engine

braking

tel

shifting

the

leyer

into

I

range

with

the

accelerator

pedal

released

and

the

engine

vacuum

pressure

of

0

mmHg

0

inHg

while

driving

at

about

50

km

h

30

MPH

in

0

range

Check

for

quick

shifting

down

OJ

2

and

engine

braking

after

shifting

the

lever

into

2

range

while

driving

at

about

50

km

h

30

MPH

in

0

range

Further

chec

for

locking

of

the

transmission

i

2nd

gear

ratio

regardless

of

vehicle

sPeed

Check

for

failure

of

the

transmission

to

shift

up

during

acceleration

when

starting

in

range

Check

the

transmission

for

not

shifting

up

or

down

during

acceleration

or

deceleration

when

starting

in

2

range

Confirm

that

yehicle

will

notmoye

on

grade

when

shifting

to

pn

range

Enter

into

record

conditions

observed

durq

these

lests

such

as

gear

noise

abnormal

clutch

noise

and

acceleration

performance

AT

50

Page 304 of 548

Automatic

Transmission

Low

eve

se

br

ke

Number

of

drive

plates

N

wnbe

of

driven

plates

Clearance

Thickness

of

retaining

plate

ml11

in

mm

in

3

3

0

80

to

1

25

0

031

to

0

049

15

8

0

622

16

0

0

630

16

2

0

638

16

4

0

646

16

6

0

654

16

8

0

661

Brake

band

Piston

size

Big

dia

Small

dia

mm

in

60

236

40

1

57

Control

valve

assembly

Stamped

mark

on

strainer

Non

California

models

Sedan

and

Hatchback

LEA

California

models

All

models

and

Non

California

models

Wagon

LRJ

Governor

assembly

Stamped

mark

on

governor

body

35

Stall

revolution

AI4

engine

AI5

engine

rpm

1

900

t02

200

1

850

to

2

150

TI

htenln

torque

Drive

plate

to

crankshaft

AI4

AI5

kg

m

ft

lb

Drive

plate

to

torque

converter

Converter

housing

to

engine

Hexagon

bolts

with

washer

Hexagon

flange

head

bolts

Transmission

case

to

converter

housing

Oil

pan

to

transmission

cue

Servo

piston

retainer

to

transmission

case

Piston

stem

when

adjusting

band

brake

Piston

stem

lock

nut

8

0

to

9

0

58

to

65

8

5

to

9

5

61

to

69

4

0

to

5

0

29

to

36

2

0

to

2

5

14

to

18

1

6

to

2

2

I2to

16

4

5

to

5

5

33

to

40

0

5

to

0

7

3

6

to

5

1

0

5

to

0

7

3

6

to

5

1

1

2

to

1

5

9

to

11

1

5

to

4

0

II

to

29

1

3

to

1

8

9

to

13

0

55

to

0

75

4

0

to

5

4

0

25

to

035

1

8

to

2

5

0

25

to

0

35

1

8

to

2

5

0

5

to

0

7

3

6

to

5

1

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plate

to

control

valve

body

Nut

for

control

valve

reamer

bolt

AT

52