DODGE TRUCK 1993 Service Owners Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 91 of 1502

2

- 38

FRONT

SUSPENSION

AND

AXLE

•

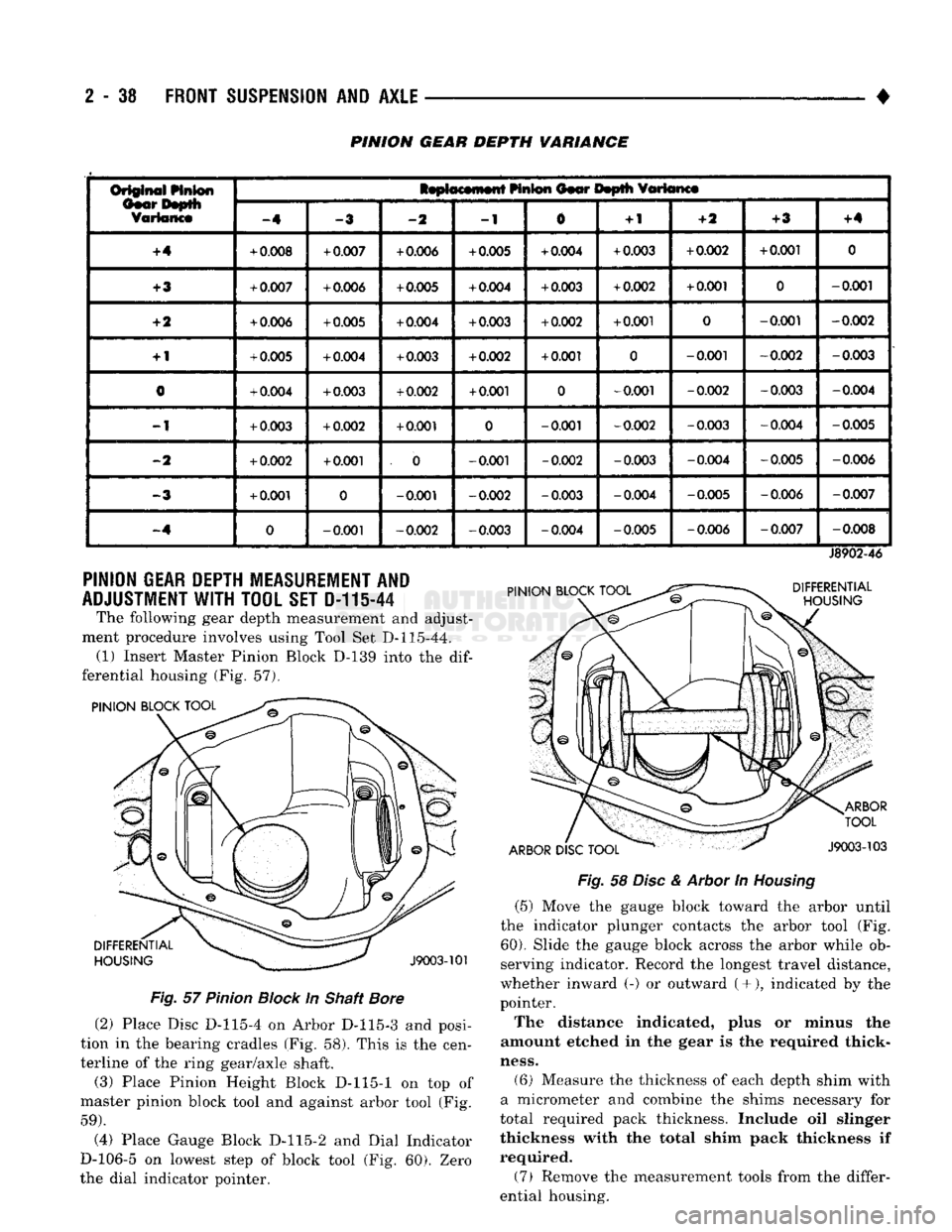

PINION GEAR DEPTH VARIANCE

Or§@ift^i

Linton

IsptocMnwtt

HnS®n

Oior Itoplli

fflttanct

Or§@ift^i

Linton

-4

-2

-1

0

+

1

-ft

+3

+4

+4

+

0.008

+

0.007

+

0.006

+

0.005

+

0.004

+

0.003

+

0.002

+

0.001

0

+3

+

0.007

+

0.006

+

0.005

+

0.004

+

0.003

+

0.002

+

0.001

0

-0.001

+2

+

0.006

+

0.005

+

0.004

+

0.003

+

0.002

+

0.001

0

-0.001

-0.002

+

1

+

0.005

+

0.004

+

0.003

+

0.002

+

0.001

0

-0.001

-0.002

-0.003

0

+

0.004

+

0.003

+

0.002

+

0.001

0

-0.001

-0.002

-0.003

-0.004

-1

+

0.003

+

0.002

+

0.001

0

-0.001

-0.002

-0.003 -0.004

-0.005

-2

+

0.002

+

0.001

. 0

-0.001

-0.002

-0.003 -0.004

-0.005 -0.006

-3

+

0.001

0

-0.001

-0.002

-0.003 -0.004

-0.005 -0.006

-0.007

-.4

0

-0.001

-0.002

-0.003 -0.004 -0.005

-0.006

-0.007

-0.008

PINION

GEAR

DEPTH

MEASUREMENT

AND

ADJUSTMENT

WITH TOOL SET D-11144

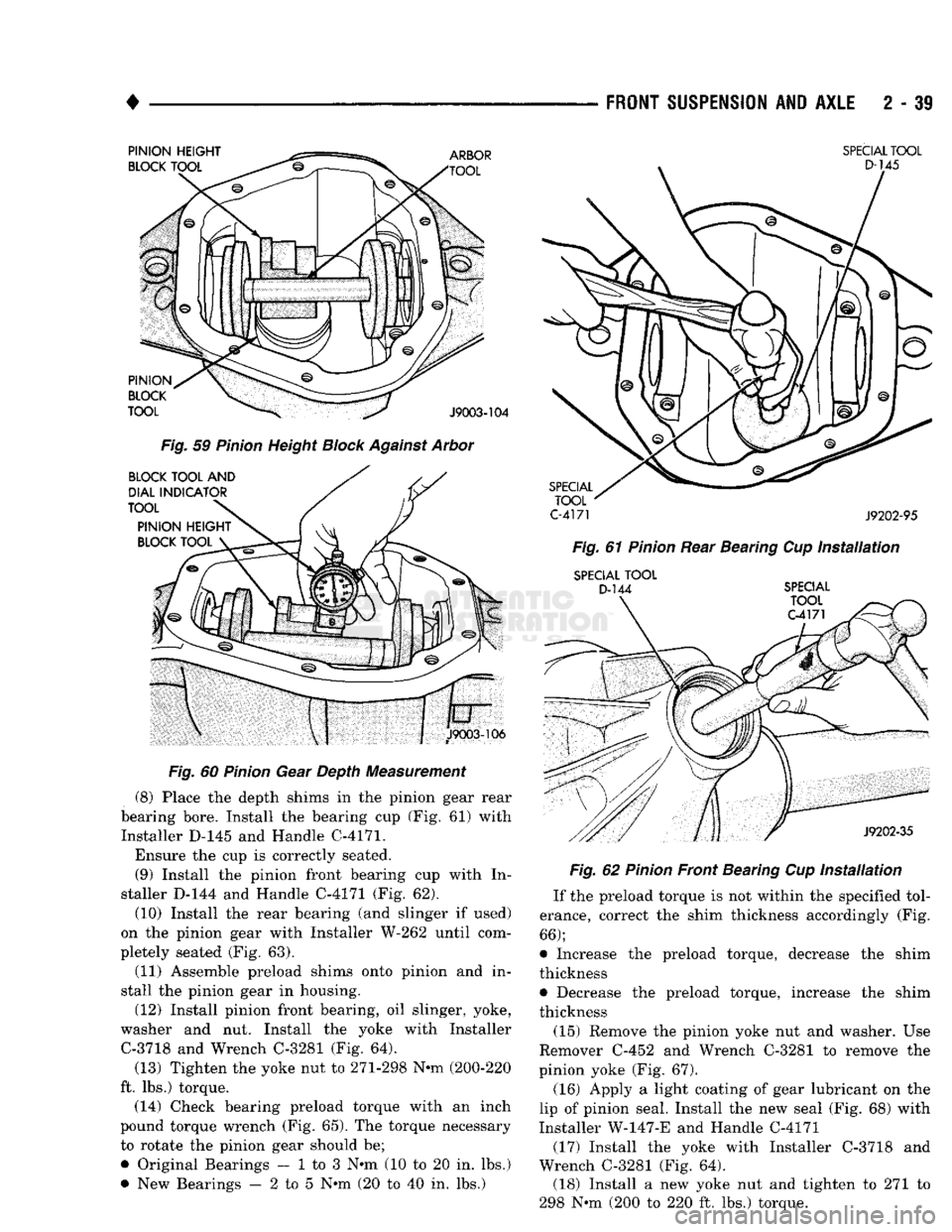

The following gear depth measurement and adjust

ment procedure involves using Tool Set D-115-44. (1) Insert Master Pinion Block D-139 into the

dif

ferential housing (Fig. 57).

PINION BLOCK TOOL PINION BLOCK TOOL

J8902-46

DIFFERENTIAL

HOUSING

ARBOR

DISC

TOOL

ARBOR

TOOL

J9003-103

DIFFERENTIAL

HOUSING

J9003-101

Fig.

57

Pinion

Block

In Shaft

Bore

(2) Place Disc D-115-4 on Arbor D-115-3 and posi

tion in the bearing cradles (Fig. 58). This is the cen

terline of the ring gear/axle shaft. (3) Place Pinion Height Block D-115-1 on top of

master pinion block tool and against arbor tool (Fig.

59).

(4) Place Gauge Block D-115-2 and Dial Indicator

D-106-5 on lowest step of block tool (Fig. 60). Zero

the dial indicator pointer.

Fig.

58

Disc

&

Arbor

In

Housing

(5) Move the gauge block toward the arbor until

the indicator plunger contacts the arbor tool (Fig.

60).

Slide the gauge block across the arbor while ob

serving indicator. Record the longest travel distance,

whether inward (-) or outward (+•), indicated by the

pointer.

The distance indicated, plus or minus the

amount etched in the gear is the required thick

ness.

(6) Measure the thickness of each depth shim with

a micrometer and combine the shims necessary for

total required pack thickness. Include oil slinger

thickness with the total shim pack thickness if

required.

(7) Remove the measurement tools from the differ

ential housing.

Page 92 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 39

Fig.

59

Pinion

Height

Block

Against

Arbor

Fig.

60

Pinion

Gear Depth Measurement

(8) Place the depth shims in the pinion gear rear

bearing bore. Install the bearing cup (Fig. 61) with Installer D-145 and Handle C-4171.

Ensure the cup is correctly seated. (9) Install the pinion front bearing cup with In

staller D-144 and Handle C-4171 (Fig. 62).

(10) Install the rear bearing (and slinger if used)

on the pinion gear with Installer W-262 until com

pletely seated (Fig. 63).

(11) Assemble preload shims onto pinion and in

stall the pinion gear in housing.

(12) Install pinion front bearing, oil slinger, yoke,

washer and nut. Install the yoke with Installer C-3718 and Wrench C-3281 (Fig. 64).

(13) Tighten the yoke nut to 271-298 N-m (200-220

ft. lbs.) torque. (14) Check bearing preload torque with an inch

pound torque wrench (Fig. 65). The torque necessary

to rotate the pinion gear should be;

• Original Bearings — 1 to 3 N*m (10 to 20 in. lbs.)

• New Bearings — 2 to 5 N*m (20 to 40 in. lbs.)

SPECIAL

TOOL

C-4171

J9202-95

Fig.

61

Pinion

Rear Bearing Cup

Installation

SPECIAL

TOOL

D-144

SPECIAL Fig.

62

Pinion

Front Bearing Cup

Installation

If the preload torque is not within the specified tol

erance, correct the shim thickness accordingly (Fig.

66);

• Increase the preload torque, decrease the shim

thickness

• Decrease the preload torque, increase the shim

thickness

(15) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 67).

(16) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 68) with

Installer W-147-E and Handle C-4171

(17) Install the yoke with Installer C-3718 and

Wrench C-3281 (Fig. 64). (18) Install a new yoke nut and tighten to 271 to

298 N-m (200 to 220 ft. lbs.) torque.

Page 93 of 1502

2

- 40

FRONT

SUSPENSION

AND

AXLE

•

SHIM PACKS

RY660

J9103-21

Fig.

64

Pinion

Yoke

Installation

PINION

GEAR

DEPTH

MEASUREMENT AND

ADJUSTMENT

WITH

TOOL

SET

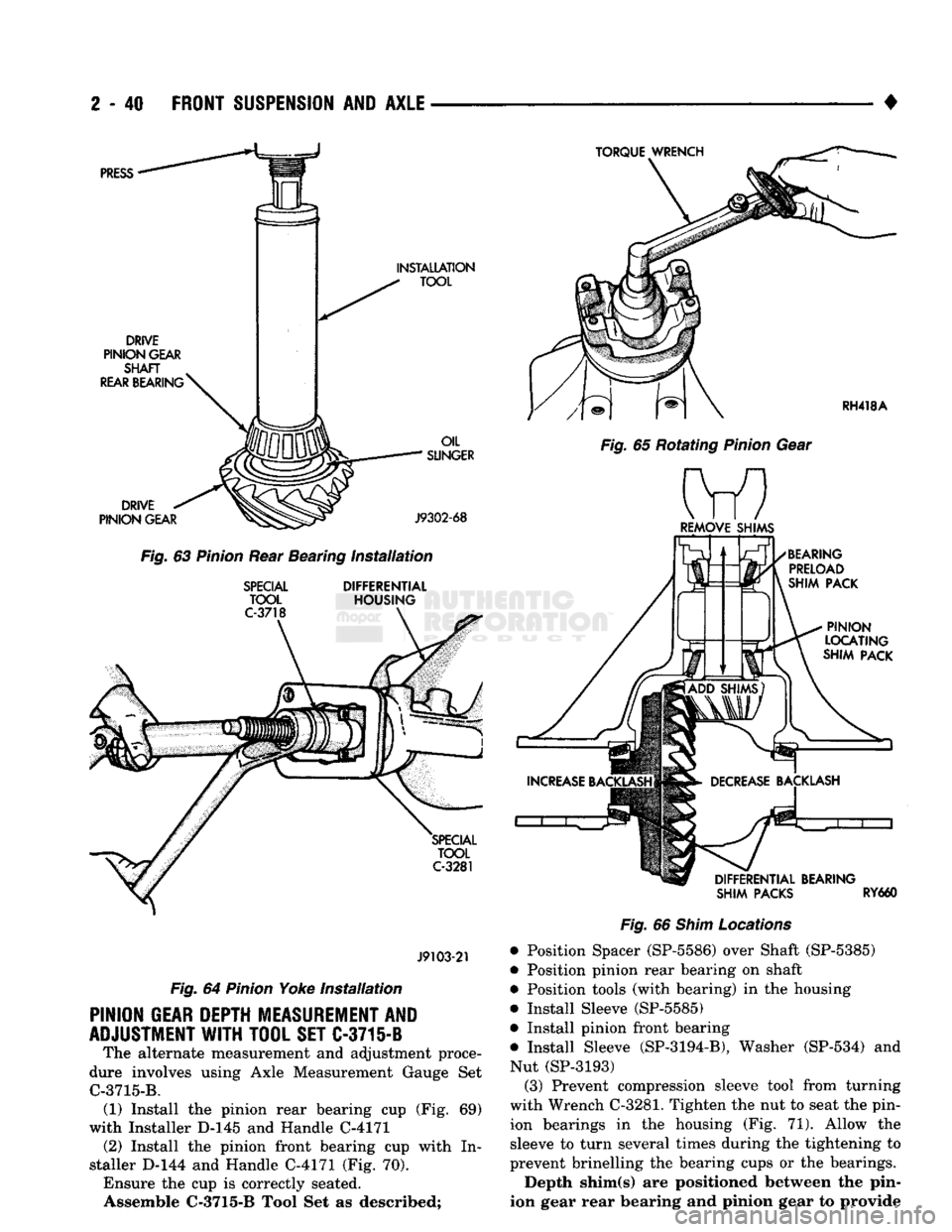

C-3715-B The alternate measurement and adjustment proce

dure involves using Axle Measurement Gauge Set C-3715-B. (1) Install the pinion rear bearing cup (Fig. 69)

with Installer D-145 and Handle C-4171 (2) Install the pinion front bearing cup with In

staller D-144 and Handle C-4171 (Fig. 70). Ensure the cup is correctly seated.

Assemble

C-3715-B

Tool Set as described;

Fig.

66

Shim

Locations

• Position Spacer (SP-5586) over Shaft (SP-5385)

• Position pinion rear bearing on shaft

• Position tools (with bearing) in the housing

• Install Sleeve (SP-5585)

• Install pinion front bearing

m Install Sleeve (SP-3194-B), Washer (SP-534) and Nut (SP-3193) (3) Prevent compression sleeve tool from turning

with Wrench C-3281. Tighten the nut to seat the pin

ion bearings in the housing (Fig. 71). Allow the

sleeve to turn several times during the tightening to

prevent brinelling the bearing cups or the bearings.

Depth shim(s) are positioned between the pin

ion gear rear bearing and pinion gear to provide

Page 94 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 41

SPECIAL

TOOL

D-145

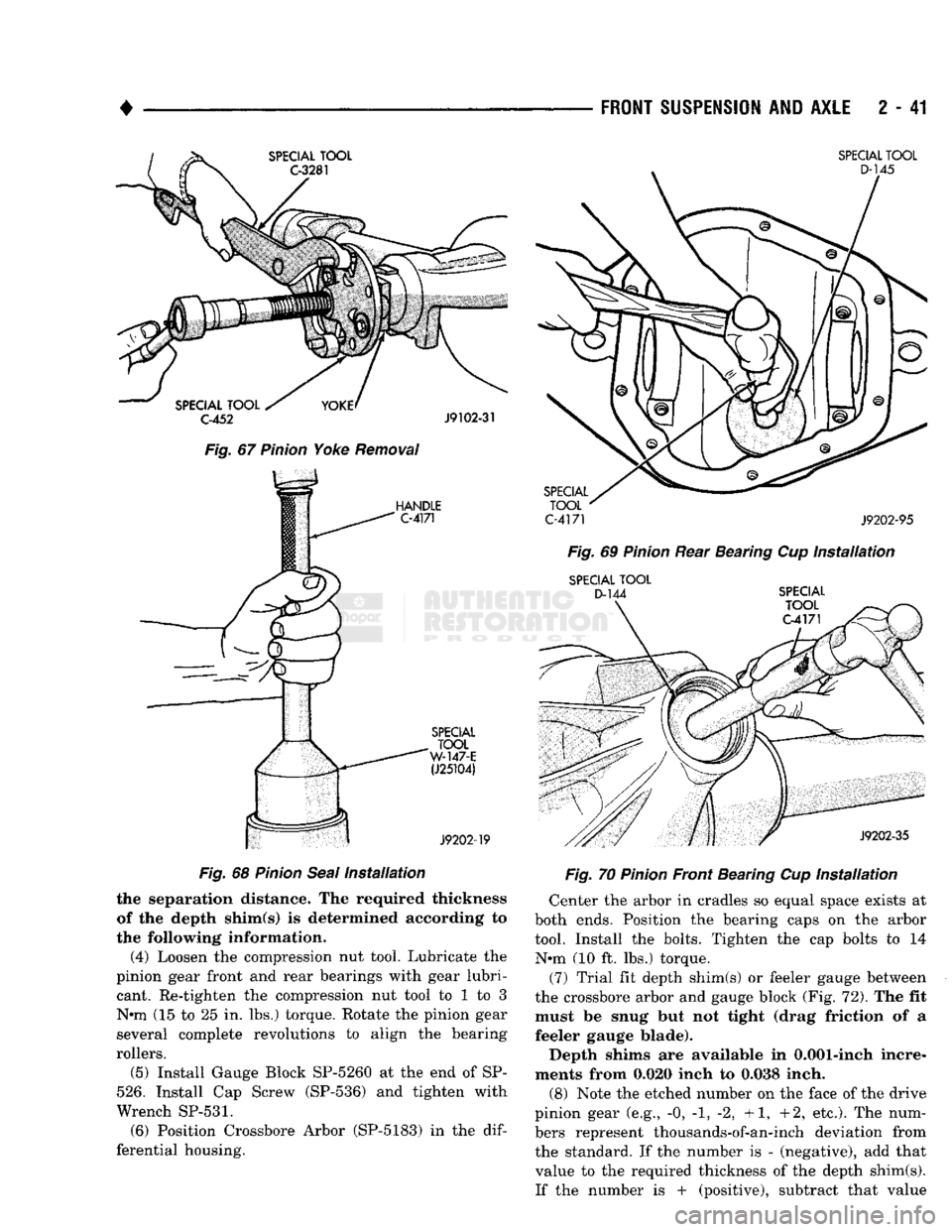

Fig.

67

Pinion

Yoke

Removal

HANDLE

C-4171

SPECIAL

TOOL

C-4171

J9202-95 Fig.

69

Pinion

Rear Bearing Cup

Installation

SPECIAL

TOOL

D-144

SPECIAL

TOOL

C-4171

SPECIAL

TOOL

W-147-E

(J25104)

J9202-19

Fig.

68

Pinion

Seal

Installation

the separation distance. The required thickness

of the depth shim(s) is determined according to

the following information.

(4) Loosen the compression nut tool. Lubricate the

pinion gear front and rear bearings with gear lubri cant. Re-tighten the compression nut tool to 1 to 3

N«m (15 to 25 in. lbs.) torque. Rotate the pinion gear

several complete revolutions to align the bearing

rollers.

(5) Install Gauge Block SP-5260 at the end of SP-

526.

Install Cap Screw (SP-536) and tighten with

Wrench

SP-531.

(6) Position Crossbore Arbor (SP-5183) in the

dif

ferential housing.

J9202-35

Fig.

70

Pinion

Front Bearing Cup

Installation

Center the arbor in cradles so equal space exists at

both ends. Position the bearing caps on the arbor

tool. Install the bolts. Tighten the cap bolts to 14 N*m (10 ft. lbs.) torque.

(7) Trial fit depth shim(s) or feeler gauge between

the crossbore arbor and gauge block (Fig. 72). The fit must be snug but not tight (drag friction of a

feeler gauge blade).

Depth shims are available in 0.001-inch incre

ments from 0.020 inch to 0.038 inch.

(8) Note the etched number on the face of the drive

pinion gear (e.g., -0, -1, -2, +1, +2, etc.). The num

bers represent thousands-of-an-inch deviation from

the standard. If the number is - (negative), add that value to the required thickness of the depth shim(s).

If the number is + (positive), subtract that value

Page 95 of 1502

2

- 42

FRONT

SUSPENSION

AND

AXLE

DIFFERENTIAL HOUSING HAMMER

DRIVER

HANDLE

YOKE

HOLDING TOOL

C-3281

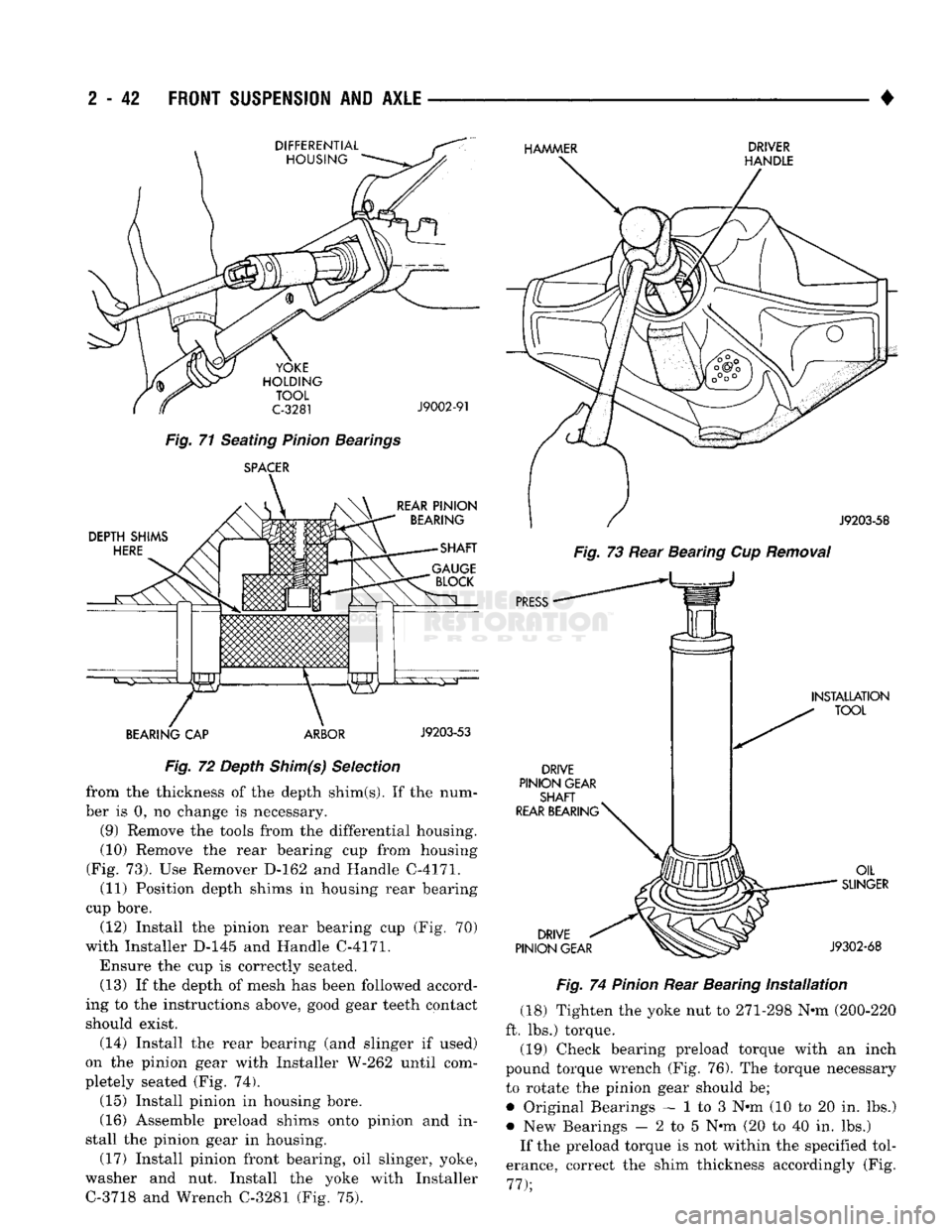

Fig.

71 Seating Pinion Bearings SPACER

J9002-91

DEPTH

SHIMS

HERE

REAR

PINION

BEARING

SHAFT

BEARING

CAP ARBOR

J9203-53

Fig.

72 Depth Shim(s) Selection from the thickness of the depth shim(s). If the num

ber is 0, no change is necessary.

(9) Remove the tools from the differential housing.

(10) Remove the rear bearing cup from housing

(Fig. 73). Use Remover D-162 and Handle C-4171. (11) Position depth shims in housing rear bearing

cup bore.

(12) Install the pinion rear bearing cup (Fig. 70)

with Installer D-145 and Handle C-4171.

Ensure the cup is correctly seated. (13) If the depth of mesh has been followed accord

ing to the instructions above, good gear teeth contact

should exist.

(14) Install the rear bearing (and slinger if used)

on the pinion gear with Installer W-262 until com

pletely seated (Fig. 74).

(15) Install pinion in housing bore.

(16) Assemble preload shims onto pinion and in

stall the pinion gear in housing. (17) Install pinion front bearing, oil slinger, yoke,

washer and nut. Install the yoke with Installer C-3718 and Wrench C-3281 (Fig. 75).

J9203-58

Fig.

73 Rear Bearing Cup

Removal

PRESS

•

DRIVE

PINION

GEAR

SHAFT

REAR BEARING

^

INSTALLATION

TOOL

DRIVE

PINION

GEAR

OIL

SUNGER

J9302-68

Fig.

74

Pinion

Rear Bearing

Installation

(18) Tighten the yoke nut to 271-298 N-m (200-220

ft. lbs.) torque.

(19) Check bearing preload torque with an inch

pound torque wrench (Fig. 76). The torque necessary to rotate the pinion gear should be;

• Original Bearings — 1 to 3 N-m (10 to 20 in. lbs.)

• New Bearings — 2 to 5 N-m (20 to 40 in. lbs.) If the preload torque is not within the specified tol

erance, correct the shim thickness accordingly (Fig.

77);

Page 96 of 1502

FRONT SUSPENSION

AND

AXLE

2 43

SPECIAL

DIFFERENTIAL

TOOL

HOUSING J9103-21

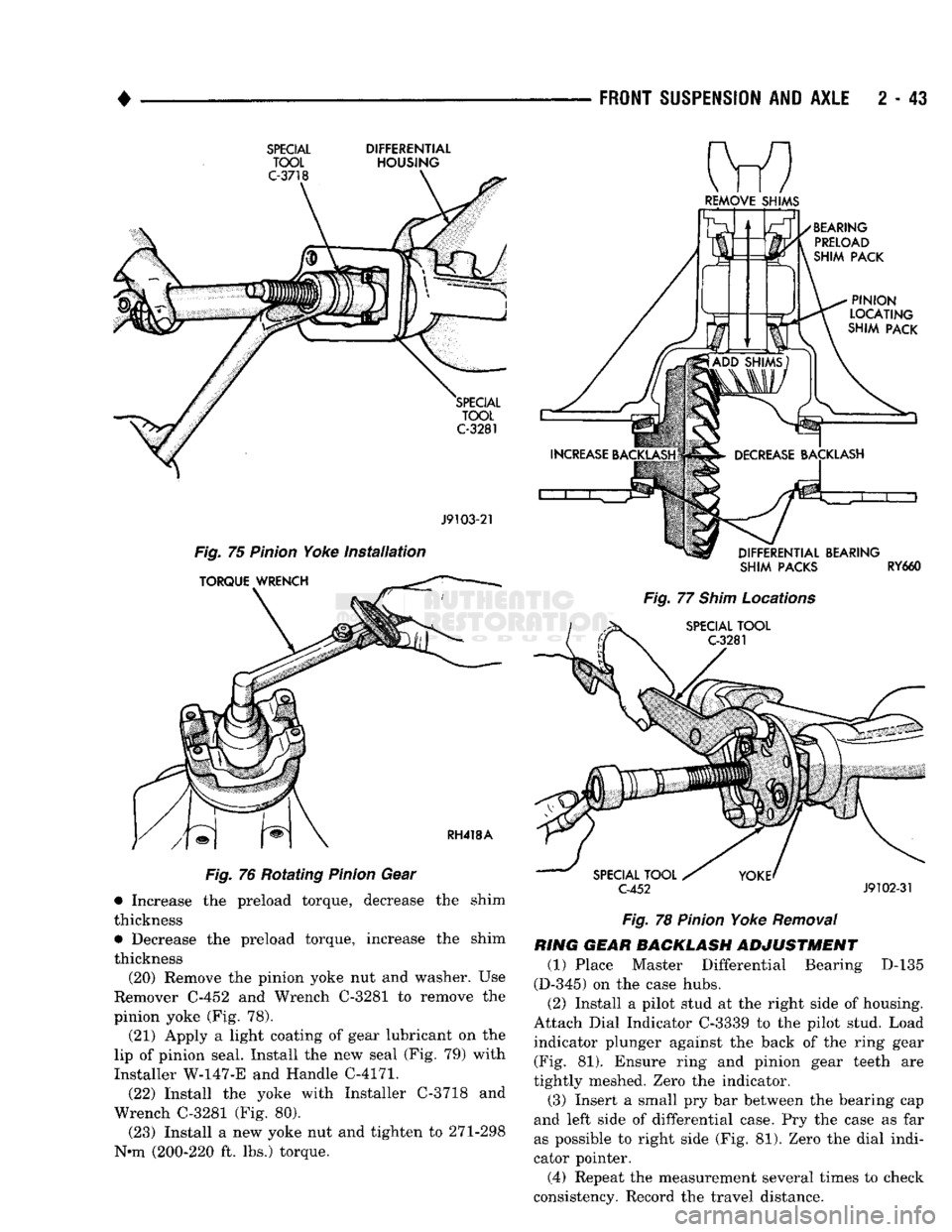

Fig. 75 Pinion Yoke Installation

Fig. 76 Rotating Pinion Gear • Increase the preload torque, decrease the shim

thickness • Decrease the preload torque, increase the shim

thickness

(20) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 78).

(21) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 79) with

Installer

W-147-E

and Handle C-4171.

(22) Install the yoke with Installer C-3718 and

Wrench C-3281 (Fig. 80).

(23) Install a new yoke nut and tighten to 271-298

N*m (200-220 ft. lbs.) torque.

REMOVE

SHIMS

SHIM

PACKS

RY660

Fig. 77 Shim Locations

C-452

J9102-31

Fig. 78 Pinion Yoke Removal

RING

GEAR BACKLASH

ADJUSTMENT

(1) Place Master Differential Bearing D-135

(D-345) on the case hubs.

(2) Install a pilot stud at the right side of housing.

Attach Dial Indicator C-3339 to the pilot stud. Load indicator plunger against the back of the ring gear (Fig. 81). Ensure ring and pinion gear teeth are

tightly meshed. Zero the indicator.

(3) Insert a small pry bar between the bearing cap

and left side of differential case. Pry the case as far

as possible to right side (Fig. 81). Zero the dial indi

cator pointer.

(4) Repeat the measurement several times to check

consistency. Record the travel distance.

Page 97 of 1502

2

- 44

FRONT

SUSPENSION

AND

AXLE

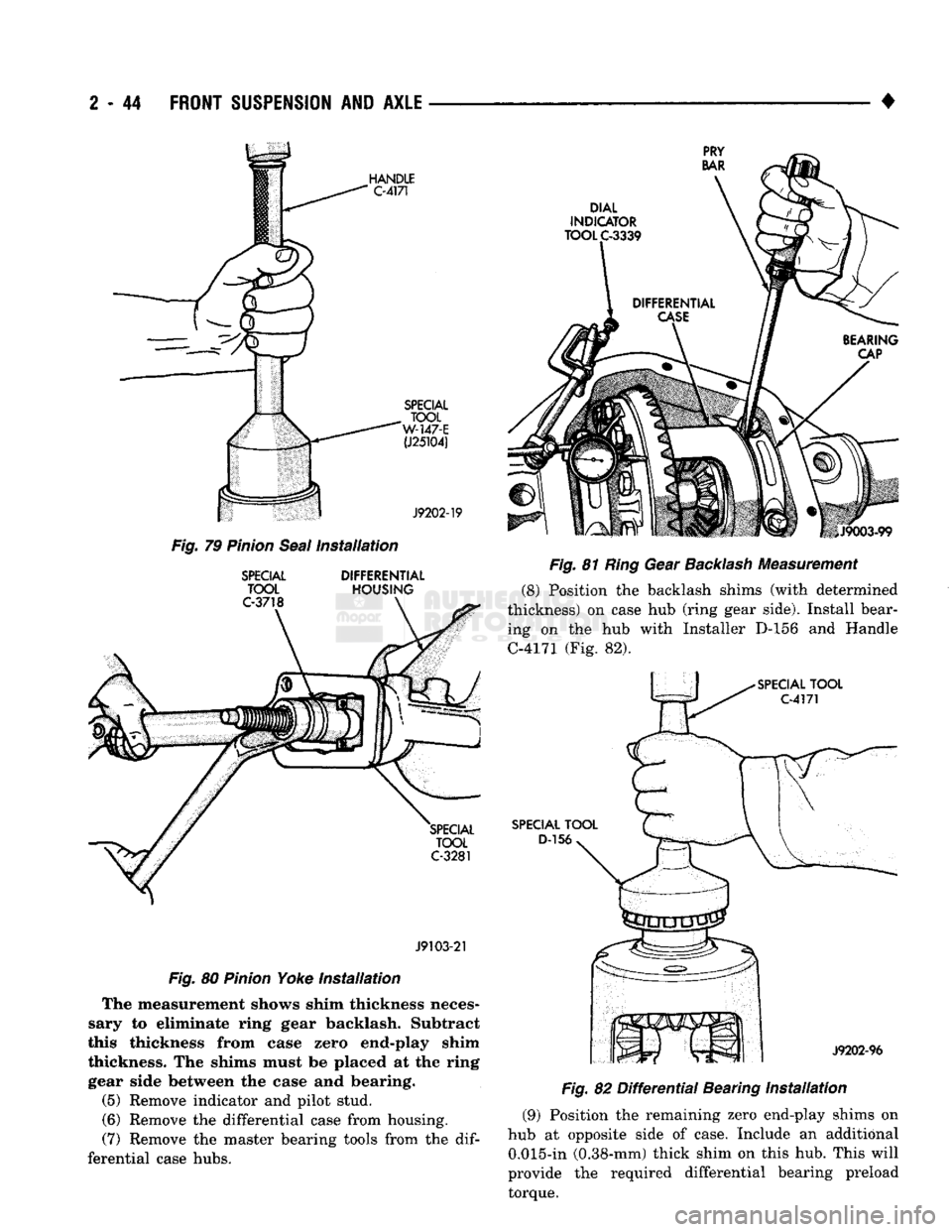

Fig.

79

Pinion

Seal

Installation

SPECIAL

DIFFERENTIAL

TOOL

HOUSING

J9103-21

Fig.

80

Pinion

Yoke Installation The measurement shows shim thickness neces

sary to eliminate ring gear backlash. Subtract

this thickness from case zero end-play shim

thickness. The shims must be placed at the ring gear side between the case and bearing.

(5) Remove indicator and pilot stud.

(6) Remove the differential case from housing.

(7) Remove the master bearing tools from the

dif

ferential case hubs. •

Fig.

81

Ring

Gear

Backlash

Measurement (8) Position the backlash shims (with determined

thickness) on case hub (ring gear side). Install bear ing on the hub with Installer D-156 and Handle

C-4171 (Fig. 82).

Fig.

82

Differential

Bearing Installation

(9) Position the remaining zero end-play shims on

hub at opposite side of case. Include an additional 0.015-in (0.38-mm) thick shim on this hub. This will

provide the required differential bearing preload torque.

Page 98 of 1502

4

____________

(10) Install bearing

on hub

with Installer

D-156

and Handle C-4171

(Fig. 82).

(11) Install

new

axle shaft

oil

seal

in

differential

housing with Installer D-112-44. Apply lubricant

to

lip

of

seal. (12) Match each bearing

cup

with bearing (origi

nal).

Install

the

cups

on the

bearings.

(13) Position Spreader W-129-A with

the

tool

dowel pins seated

in the

locating holes

(Fig. 83). In

stall

the

holddown clamps

and

tighten

the

tool turn-

buckle finger-tight.

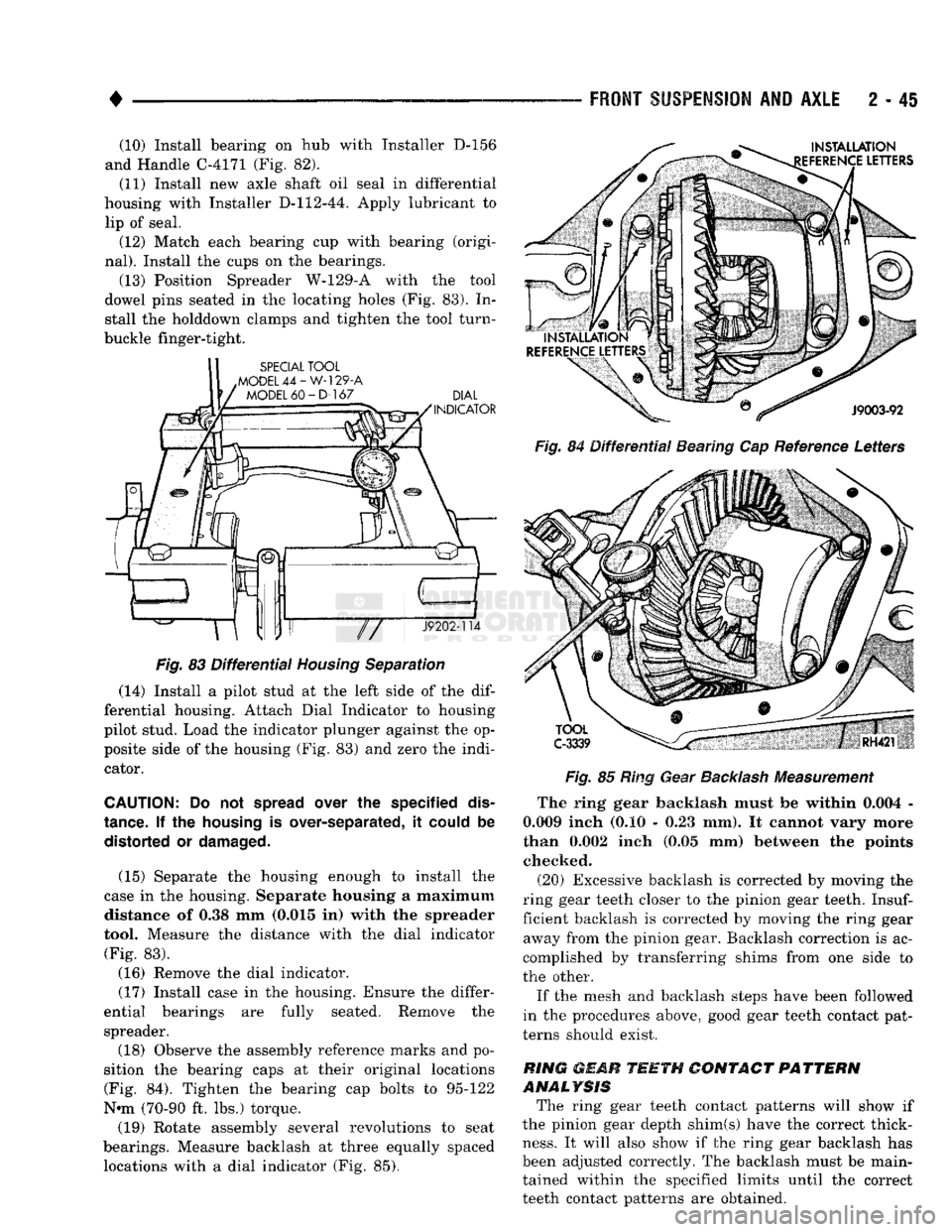

Fig.

83

Differential

Housing

Separation

(14) Install

a

pilot stud

at the

left side

of the dif

ferential housing. Attach Dial Indicator

to

housing

pilot stud. Load

the

indicator plunger against

the op

posite side

of the

housing

(Fig. 83) and

zero

the

indi cator.

CAUTION:

Do not

spread

over

the

specified

dis

tance.

If the

housing

is

over-separated,

it

could

be

distorted

or

damaged.

(15) Separate

the

housing enough

to

install

the

case

in the

housing. Separate housing

a

maximum distance

of 0.38 mm

(0.015

in)

with

the

spreader

tool. Measure

the

distance with

the

dial indicator (Fig.

83).

(16) Remove

the

dial indicator.

(17) Install case

in the

housing. Ensure

the

differ

ential bearings

are

fully seated. Remove

the

spreader.

(18) Observe

the

assembly reference marks

and po

sition

the

bearing caps

at

their original locations (Fig.

84).

Tighten

the

bearing

cap

bolts

to

95-122

N-m (70-90

ft. lbs.)

torque.

(19) Rotate assembly several revolutions

to

seat

bearings. Measure backlash

at

three equally spaced locations with

a

dial indicator

(Fig. 85).

FRONT

SUSPENSION

AND

AXLE

2 - 45

Fig.

84

Differential

Bearing

Cap

Reference Letters

Fig.

85

Ring Gear

Backlash

Measurement

The ring gear backlash must

be

within 0.004

-

0.009 inch

(0.10 - 0.23 mm). It

cannot vary more

than 0.002 inch

(0.05 mm)

between

the

points checked.

(20) Excessive backlash

is

corrected

by

moving

the

ring gear teeth closer

to the

pinion gear teeth.

Insuf

ficient backlash

is

corrected

by

moving

the

ring gear away from

the

pinion gear. Backlash correction

is ac

complished

by

transferring shims from

one

side

to

the other.

If

the

mesh

and

backlash steps have been followed

in

the

procedures above, good gear teeth contact pat

terns should exist.

RING

mMR

TEETH

CONTACT

PATTERN

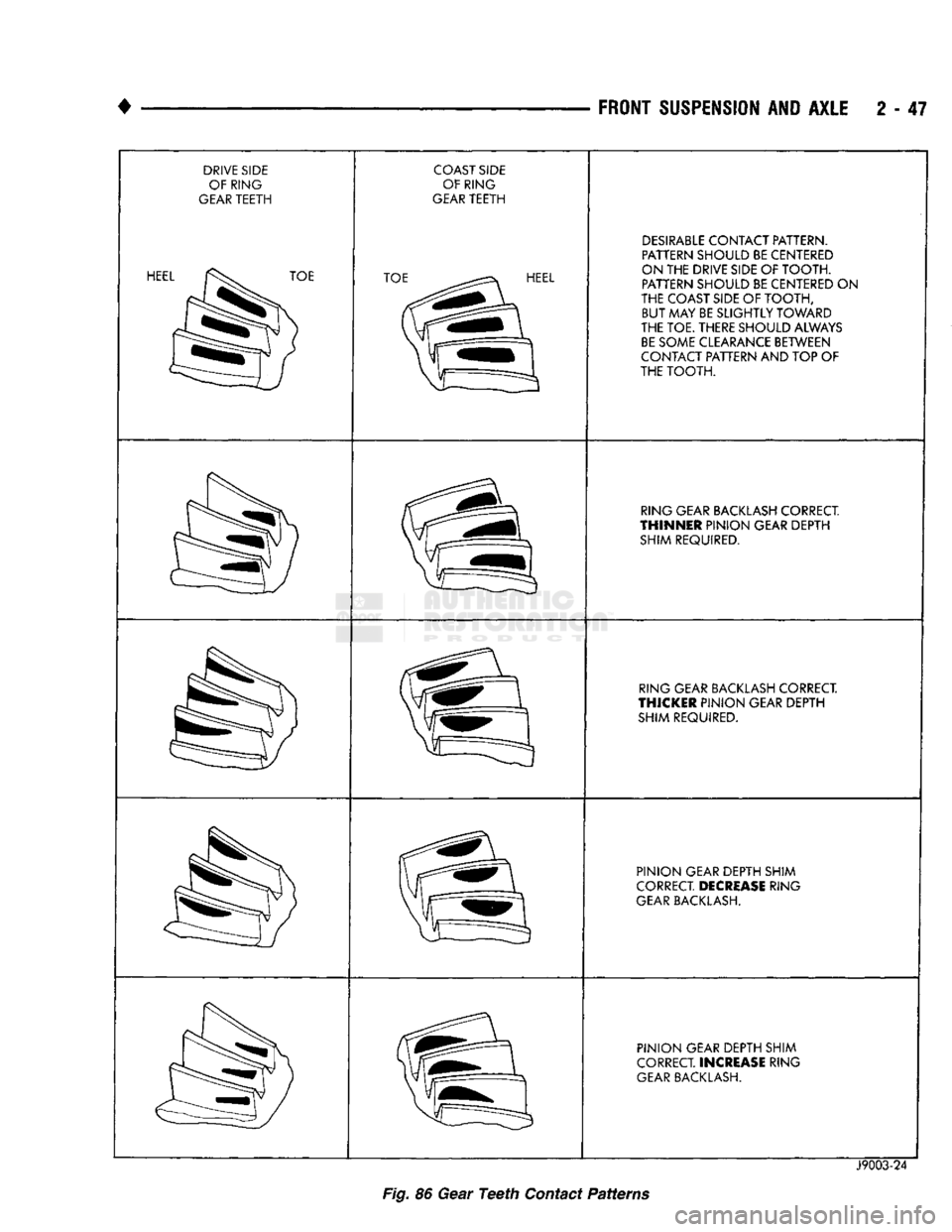

ANALYSIS The ring gear teeth contact patterns will show

if

the pinion gear depth shim(s) have

the

correct thick

ness.

It

will also show

if the

ring gear backlash

has

been adjusted correctly.

The

backlash must

be

main tained within

the

specified limits until

the

correct

teeth contact patterns

are

obtained.

Page 99 of 1502

2

- 46

FRONT

SUSPENSION

AND

AXLE

• (1) Apply a thin coat of hydrated ferric oxide, to

the ring gear teeth. (2) Rotate the ring gear one complete revolution in

both directions while a load is being applied. Insert a

pry bar between the differential housing and the case

flange. This action will produce distinct contact pat

terns on both the drive side and coast side of the ring gear teeth.

(3)

Note patterns in compound. Refer to (Fig. 86)

for interpretation of contact patterns and adjust ac cordingly.

(4) Install the axle shafts. Refer to Axle Shaft In

stallation within this group.

(5)

Install the housing cover. Refill the differential

with lubricant. Refer to Axle Shaft Installation.

Page 100 of 1502

FRONT

SUSPENSION

AND AXLE

2 - 47

DRIVE

SIDE

OF RING

GEAR

TEETH

HEEL

TOE

COAST

SIDE

OF RING

GEAR

TEETH TOE

HEEL

DESIRABLE

CONTACT PATTERN.

PATTERN SHOULD BE CENTERED

ON THE DRIVE SIDE OF TOOTH. PATTERN SHOULD BE CENTERED

ON

THE COAST SIDE OF TOOTH, BUT MAY BE SLIGHTLY TOWARD

THE TOE. THERE SHOULD ALWAYS

BE

SOME CLEARANCE BETWEEN

CONTACT PATTERN AND TOP

OF

THE TOOTH.

RING GEAR

BACKLASH

CORRECT

THINNER

PINION GEAR DEPTH SHIM REQUIRED.

RING GEAR

BACKLASH

CORRECT.

THICKER

PINION GEAR DEPTH

SHIM REQUIRED.

PINION GEAR DEPTH SHIM

CORRECT

DECREASE

RING

GEAR

BACKLASH.

PINION GEAR DEPTH SHIM

CORRECT

INCREASE

RING

GEAR

BACKLASH.

Fig.

86 Gear

Teeth

Contact Patterns

J9003-24