DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 771 of 1502

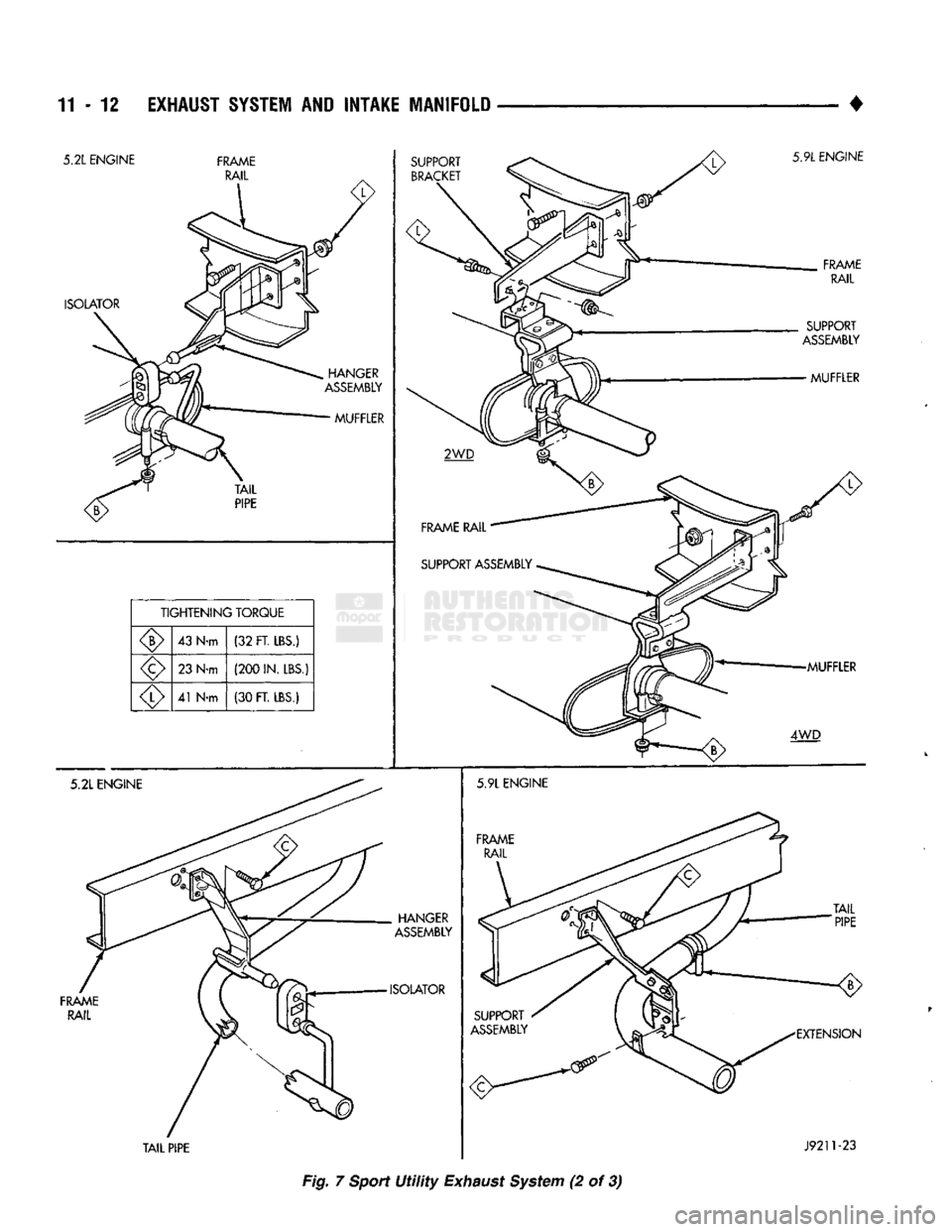

11-12 EXHAUST SYSTEM AND INTAKE MANIFOLD

•

Fig. 7

Sport

Utility

Exhaust

System (2 of 3)

Page 772 of 1502

•

EXHAUST SYSTEM

AND

INTAKE MANIFOLD

11-13

TIGHTENING

TORQUE

23

N-m

(200

IN. LBS.)

7

N-m

(65

IN. LBS.)

5 N-m

(40

IN. LBS.)

HEAT

SHIELD CATALYTIC

CONVERTER

LOWER HEAT SHIELD HEAT

SHIELD UPPER

HEAT

SHIELD

CROSSMEMBER

SKID

PLATE

UPPER HEAT SHIELD

(6 IN.

RAIL) CONED WASHER

UPPER HEAT SHIELD

(7 IN.

RAIL)

J9211-21

Fig.

8

Sport

Utility

Exhaust

System—Exhaust

Heat

Shields

(3 of 3)

INTAKE MANIFOLD

The aluminum intake manifold is a single plane

design with equal length runners. The manifold is sealed by flange side gaskets with front and rear

cross-over gaskets. The intake manifold has internal

EGR.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (refer to Group 7,

Cooling System for the proper procedures).

(3) Remove the generator.

(4) Remove the air cleaner.

(5) Disconnect the fuel lines.

(6) Disconnect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(7) Remove the return spring.

(8) Remove the distributor cap and wires.

(9) Disconnect the coil wires.

(10) Disconnect the heat indicator sending unit

wire.

(11) Disconnect the heater hoses and bypass hose.

(12) Remove the closed crankcase ventilation and

evaporation control systems. (13) Remove intake manifold bolts.

(14) Lift the intake manifold and throttle body out

of the engine compartment as an assembly. (15) Remove and discard the flange side gaskets

and the front and rear cross-over gaskets.

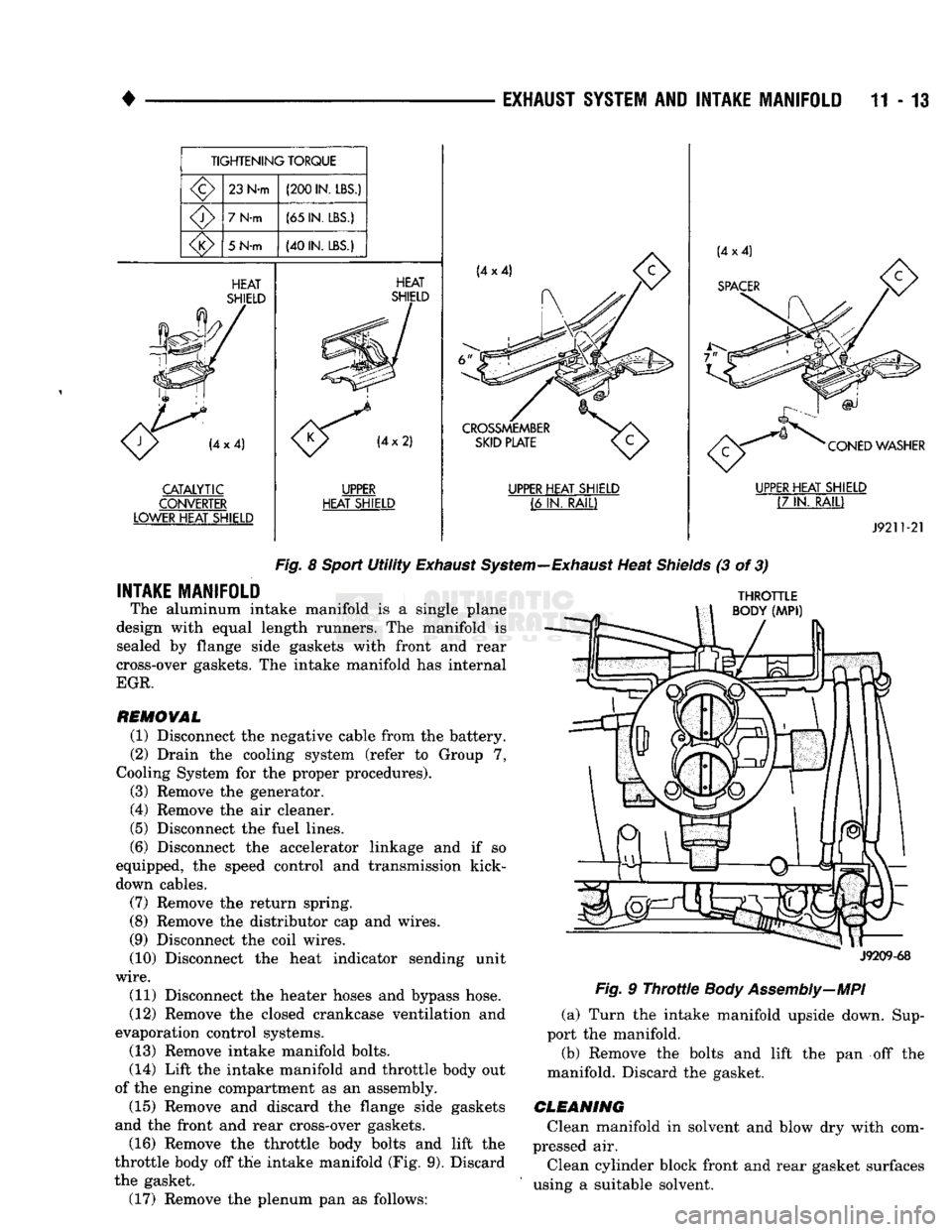

(16) Remove the throttle body bolts and lift the

throttle body off the intake manifold (Fig. 9). Discard

the gasket. (17) Remove the plenum pan as follows:

THROTTLE

BODY

(MPI)

J9209-68

Fig.

9

Throttle

Body Assembly—MPI

(a) Turn the intake manifold upside down. Sup

port the manifold.

(b) Remove the bolts and lift the pan off the

manifold. Discard the gasket.

CLEANING

Clean manifold in solvent and blow dry with com

pressed air.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

Page 773 of 1502

11-14

EXHAUST

SYSTEM

AND

INTAKE

MANIFOLD

• The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) Install the plenum pan, if removed, as follows: (a) Turn the intake manifold upside down. Sup

port the manifold.

(b) Place a new plenum pan gasket onto the seal

rail of the intake manifold. Position the pan over

the gasket. Align all the gasket and pan holes with

the intake manifold. (c) Hand start all bolts.

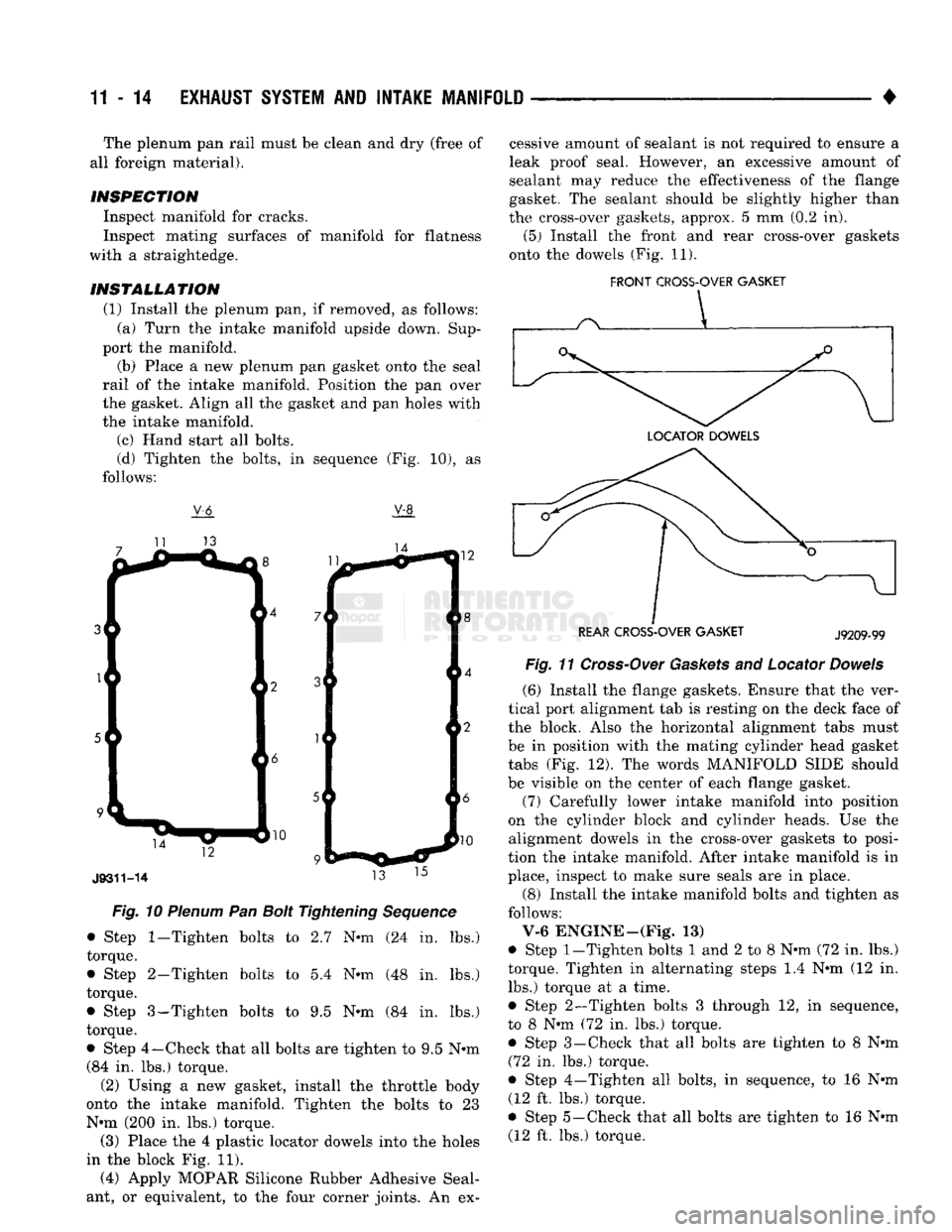

(d) Tighten the bolts, in sequence (Fig. 10), as

follows:

V-6

V-8

Fig.

10

Plenum

Pan

Bolt

Tightening

Sequence

• Step

1-Tighten

bolts to 2.7 N*m (24 in. lbs.)

torque.

• Step 2-Tighten bolts to 5.4 N«m (48 in. lbs.)

torque.

• Step 3-Tighten bolts to 9.5 Nnn (84 in. lbs.)

torque.

• Step 4—Check that all bolts are tighten to 9.5 N®m (84 in. lbs.) torque.

(2) Using a new gasket, install the throttle body

onto the intake manifold. Tighten the bolts to 23

Nun (200 in. lbs.) torque. (3) Place the 4 plastic locator dowels into the holes

in the block Fig. 11).

(4) Apply MOPAR Silicone Rubber Adhesive Seal

ant, or equivalent, to the four corner joints. An ex cessive amount of sealant is not required to ensure a

leak proof seal. However, an excessive amount of

sealant may reduce the effectiveness of the flange

gasket. The sealant should be slightly higher than

the cross-over gaskets, approx. 5 mm (0.2 in).

(5) Install the front and rear cross-over gaskets

onto the dowels (Fig. 11).

FRONT

CROSS-OVER

GASKET

REAR

CROSS-OVER

GASKET

J9209-99

Fig

11

Cross-Over

Gaskets

and Locator

Dowels

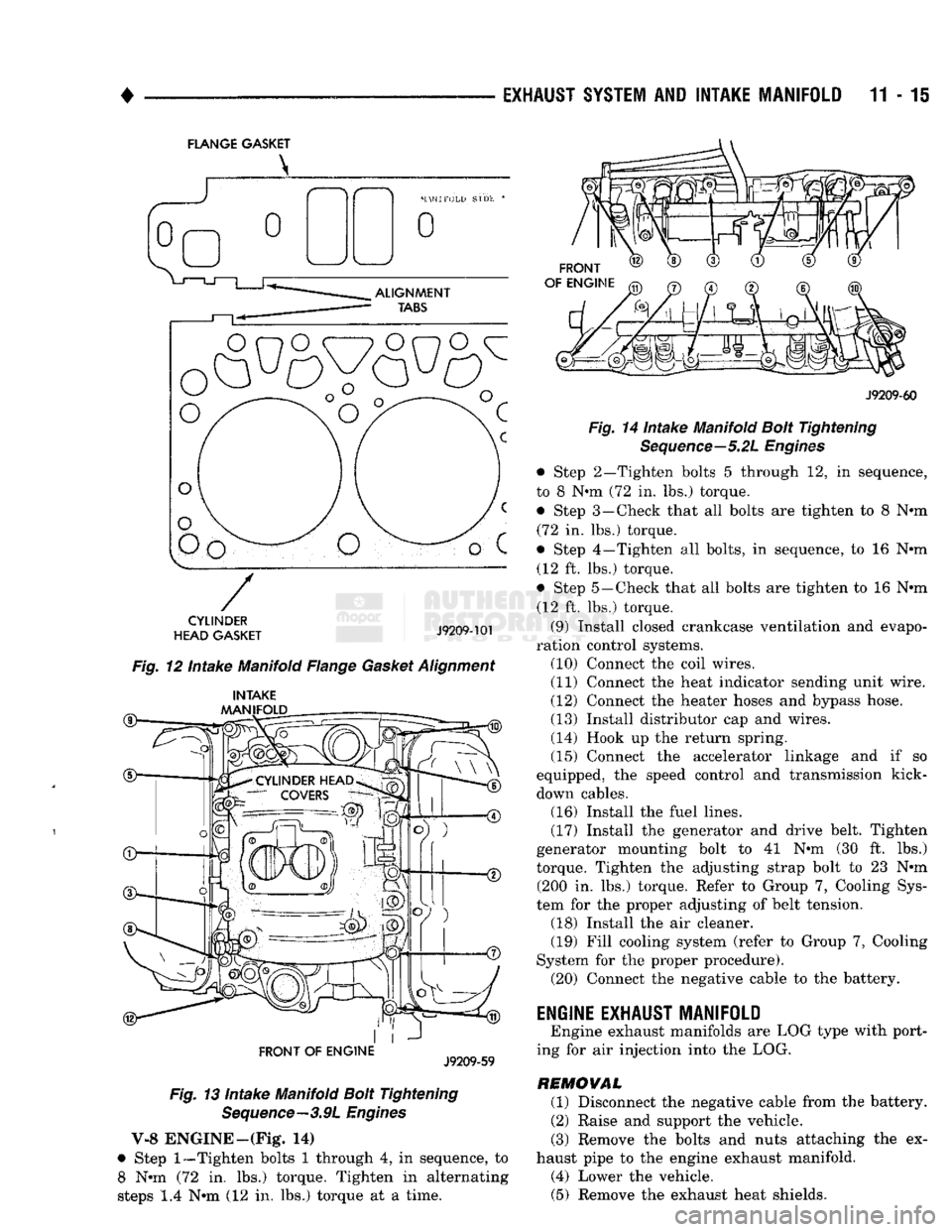

(6) Install the flange gaskets. Ensure that the ver

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must

be in position with the mating cylinder head gasket

tabs (Fig. 12). The words MANIFOLD SIDE should

be visible on the center of each flange gasket.

(7) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. Use the alignment dowels in the cross-over gaskets to posi

tion the intake manifold. After intake manifold is in

place, inspect to make sure seals are in place.

(8) Install the intake manifold bolts and tighten as

follows:

V-6 ENGINE—(Fig. 13)

• Step

1-Tighten

bolts 1 and 2 to 8 Nun (72 in. lbs.)

torque. Tighten in alternating steps 1.4 Nun (12 in. lbs.) torque at a time.

• Step 2—Tighten bolts 3 through 12, in sequence,

to 8 Nun (72 in. lbs.) torque.

• Step 3—Check that all bolts are tighten to 8 Nun (72 in. lbs.) torque.

• Step 4—Tighten all bolts, in sequence, to 16 Nun (12 ft. lbs.) torque.

• Step 5—Check that all bolts are tighten to 16 Nun (12 ft. lbs.) torque.

Page 774 of 1502

EXHAUST SYSTEM

AND

INTAKE MANIFOLD

11-15

FLANGE GASKET

o

o

CYLINDER

HEAD GASKET

J9209-101

Fig. 12 Intake Manifold Flange Gasket Alignment

®— INTAKE

MANIFOLD

FRONT OF

ENGINE

J9209-59

Fig. 13 Intake Manifold Bolt Tightening Sequence—3.9L Engines

V-8 ENGINE—(Fig* 14)

• Step

1—Tighten

bolts 1 through 4, in sequence, to 8 Nun (72 in. lbs.) torque. Tighten in alternating

steps 1.4 Nun (12 in. lbs.) torque at a time.

FRONT

OF ENGINE

J9209-60

Fig. 14 Intake Manifold Bolt Tightening Sequence—5.2L Engines

• Step 2—Tighten bolts 5 through 12, in sequence,

to 8 Nun (72 in. lbs.) torque. • Step 3—Check that all bolts are tighten to 8 Nun (72 in. lbs.) torque.

• Step 4—Tighten all bolts, in sequence, to 16 Nun (12 ft. lbs.) torque.

• Step 5—Check that all bolts are tighten to 16 Nun (12 ft. lbs.) torque.

(9) Install closed crankcase ventilation and evapo

ration control systems. (10) Connect the coil wires.

(11) Connect the heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Hook up the return spring.

(15) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables. (16) Install the fuel lines,

(17) Install the generator and drive belt. Tighten

generator mounting bolt to 41 Nun (30 ft. lbs.)

torque. Tighten the adjusting strap bolt to 23 Nun (200 in. lbs.) torque. Refer to Group 7, Cooling Sys

tem for the proper adjusting of belt tension. (18) Install the air cleaner. (19) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure). (20) Connect the negative cable to the battery.

ENGINE EXHAUST MANIFOLD

Engine exhaust manifolds are LOG type with port

ing for air injection into the LOG.

REMOVAL (1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the ex

haust pipe to the engine exhaust manifold. (4) Lower the vehicle. (5) Remove the exhaust heat shields.

Page 775 of 1502

11-16

EXHAUST

SYSTEM

AND

INTAKE

MANIFOLD

• (6) Remove bolts, nuts and washers attaching

manifold to cylinder head. (7) Remove manifold from the cylinder head.

CLEANING Clean mating surfaces on cylinder head and mani

fold. Wash with solvent and blow dry with com

pressed air.

INSPECTION Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

CAUTION:

If the studs came out

with

the nuts when removing the engine exhaust

manifold,

install

new

studs.

Apply sealer on the coarse

thread

ends.

Wa

ter leaks may develop at the studs if

this

precaution

is

not taken.

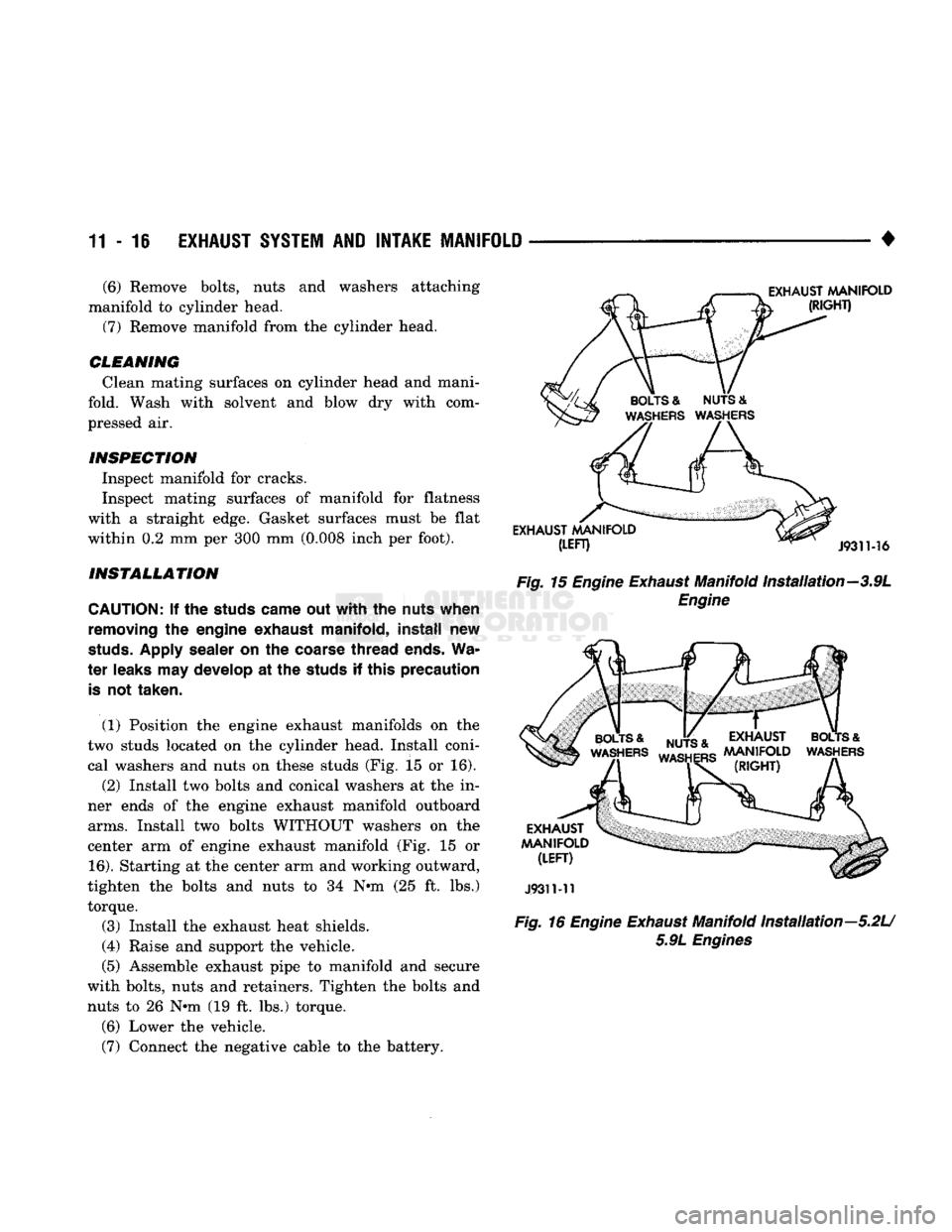

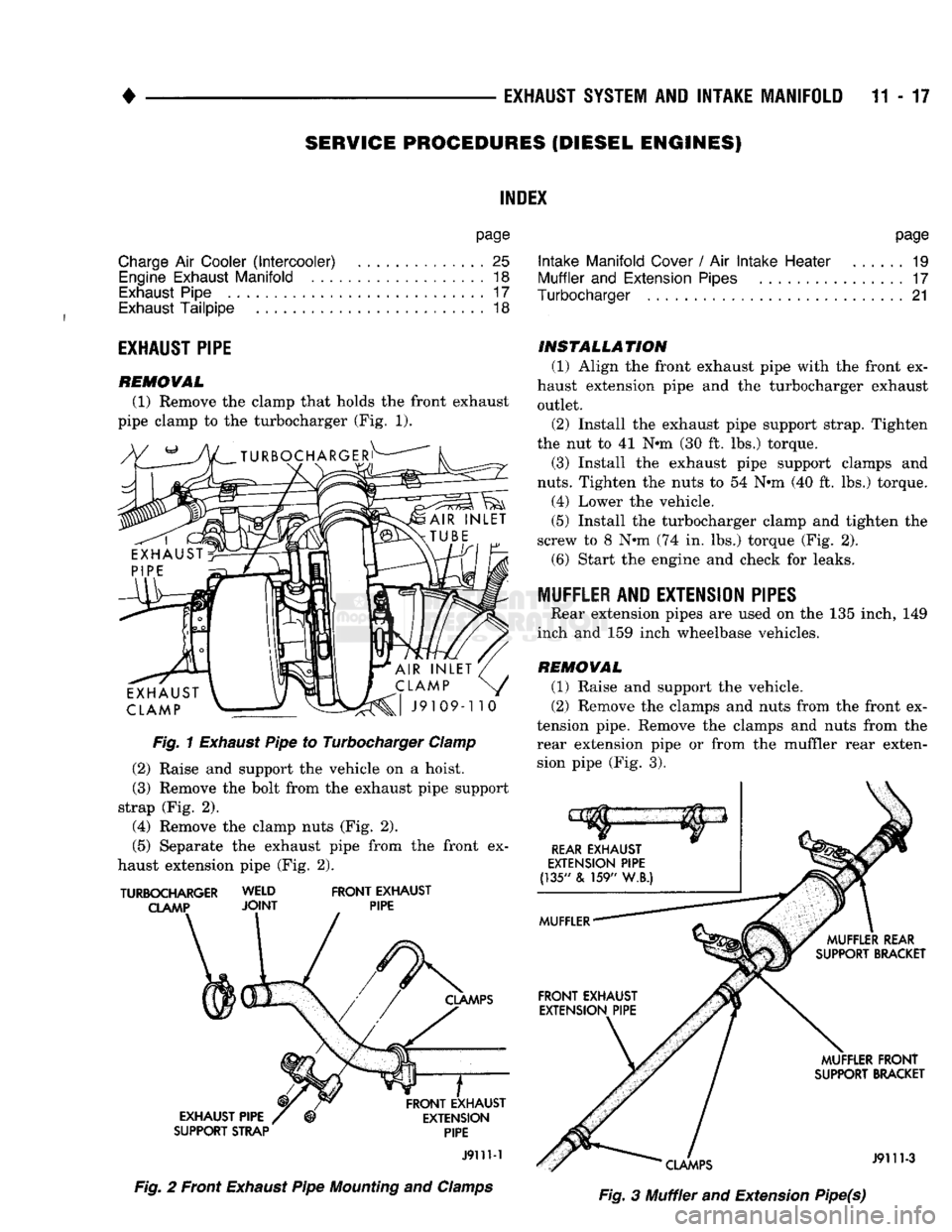

(1) Position the engine exhaust manifolds on the

two studs located on the cylinder head. Install coni cal washers and nuts on these studs (Fig. 15 or 16). (2) Install two bolts and conical washers at the in

ner ends of the engine exhaust manifold outboard

arms.

Install two bolts WITHOUT washers on the

center arm of engine exhaust manifold (Fig. 15 or

16).

Starting at the center arm and working outward,

tighten the bolts and nuts to 34

Nth

(25 ft. lbs.) torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and nuts to 26

N-m

(19 ft. lbs.) torque.

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

Fig.

15

Engine

Exhaust

Manifold Installation—3.9L

Engine

J9311-11

Fig.

16

Engine

Exhaust

Manifold Installation—5.2U 5.9L

Engines

Page 776 of 1502

•

EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 17 8ERY1CE PROCEDURES

(DIESEL ENGINES)

INDEX

page

Charge

Air

Cooler

(Intercooler)

25

Engine

Exhaust

Manifold

18

Exhaust

Pipe

17

Exhaust

Tailpipe

18

EXHAUST PIPE

REMOVAL

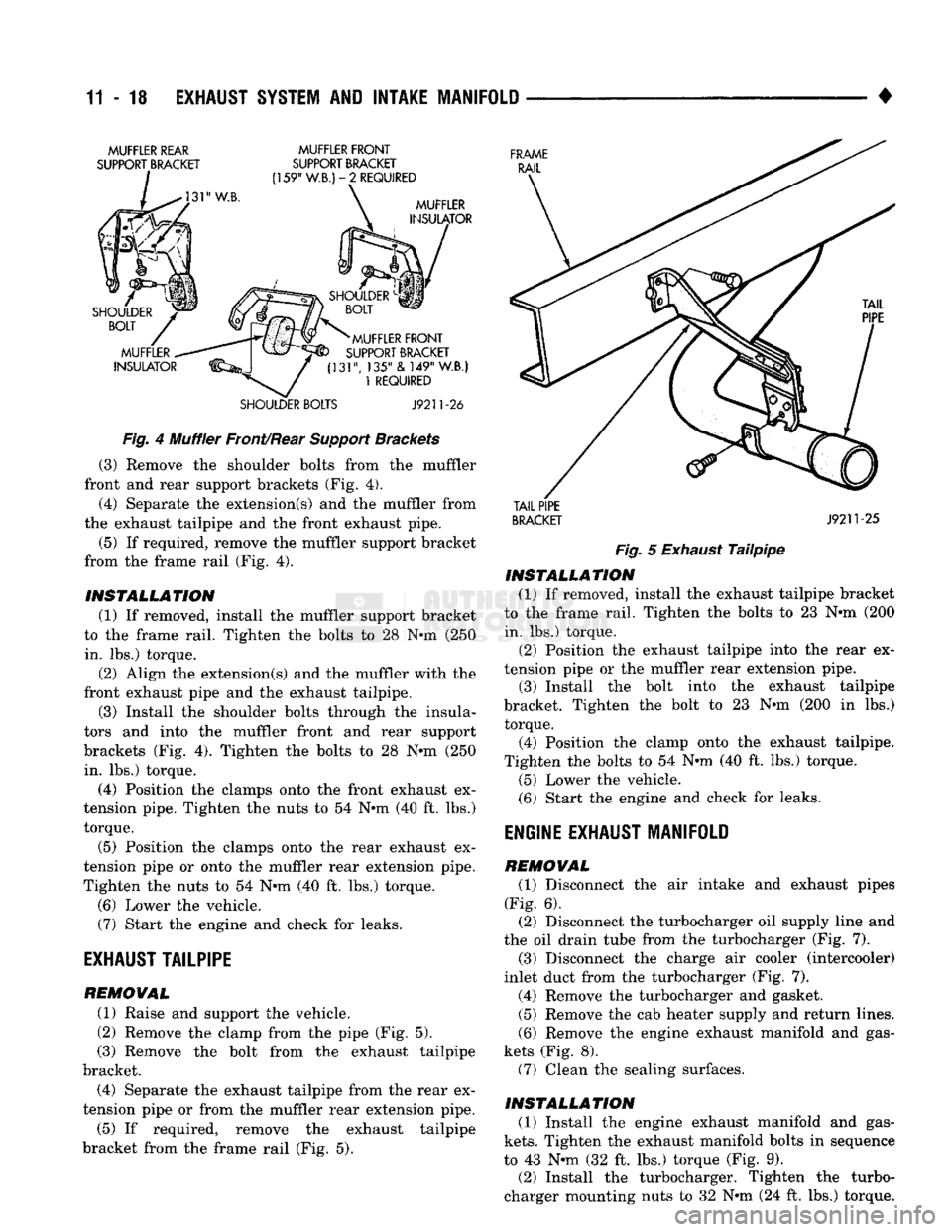

(1) Remove the clamp that holds the front exhaust

pipe clamp to the turbocharger (Fig. 1).

Fig.

1

Exhaust

Pipe to Turbocharger

Clamp

(2)

Raise and support the vehicle on a hoist.

(3)

Remove the bolt from the exhaust pipe support

strap (Fig. 2).

(4)

Remove the clamp nuts (Fig. 2).

(5)

Separate the exhaust pipe from the front ex

haust extension pipe (Fig. 2).

TURBOCHARGER WELD

FRONT

EXHAUST

CLAMP

JOINT

PIPE

SUPPORT STRAP

PIPE

J911M

Fig.

2 Front

Exhaust

Pipe

Mounting

and

Clamps

page

Intake

Manifold

Cover

/ Air

Intake

Heater

19

Muffler

and

Extension

Pipes

17

Turbocharger

21

INSTALLATION

(1)

Align the front exhaust pipe with the front ex

haust extension pipe and the turbocharger exhaust outlet.

(2)

Install the exhaust pipe support strap. Tighten

the nut to 41 Nun (30 ft. lbs.) torque.

(3)

Install the exhaust pipe support clamps and

nuts.

Tighten the nuts to 54 Nun (40 ft. lbs.) torque.

(4)

Lower the vehicle.

(5)

Install the turbocharger clamp and tighten the

screw to 8 Nun (74 in. lbs.) torque (Fig. 2). (6) Start the engine and check for leaks.

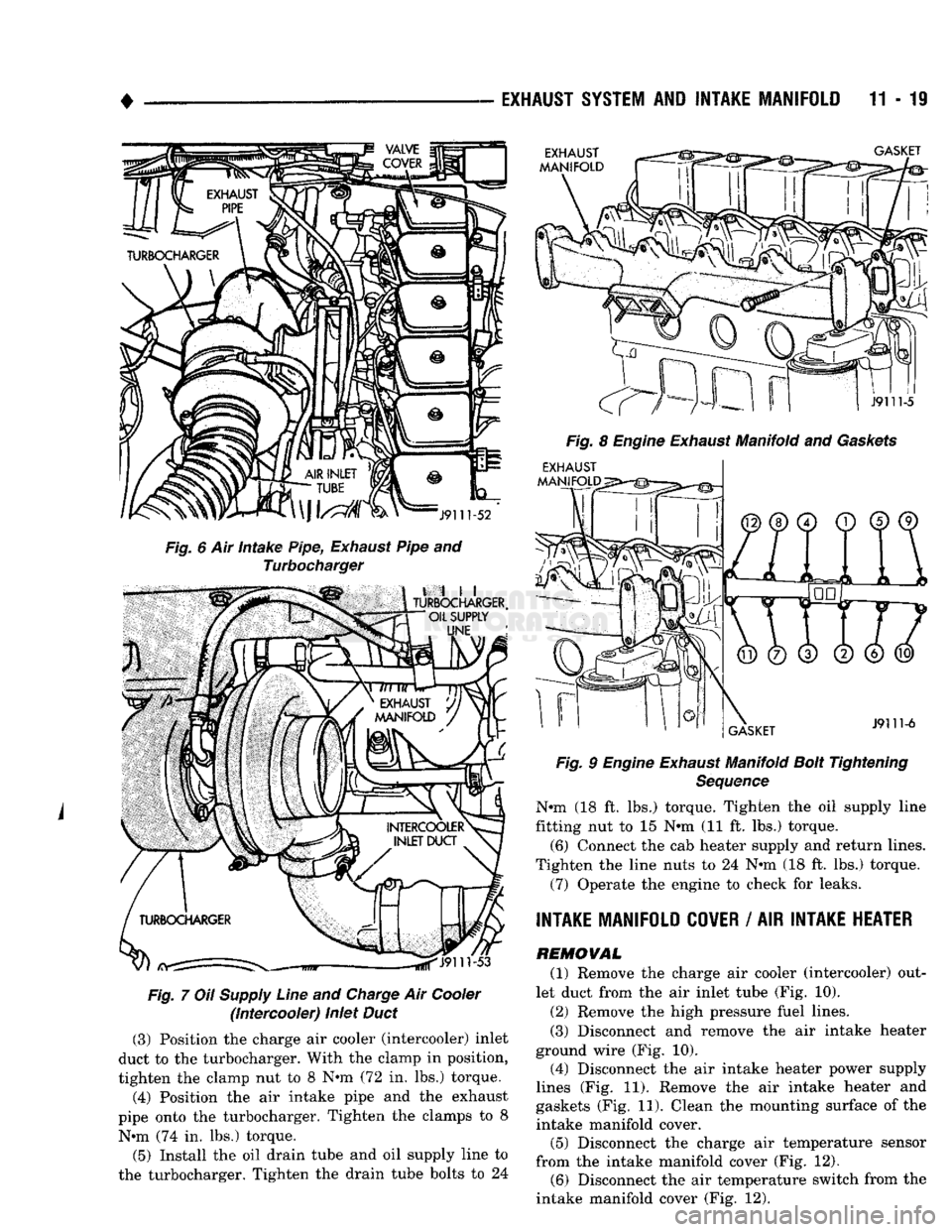

MUFFLER AND EXTENSION PIPES Rear extension pipes are used on the 135 inch, 149

inch and 159 inch wheelbase vehicles.

REMOVAL

(1)

Raise and support the vehicle.

(2)

Remove the clamps and nuts from the front ex

tension pipe. Remove the clamps and nuts from the rear extension pipe or from the muffler rear extension pipe (Fig. 3).

Fig.

3 Muffler and Extension Pipe(s)

Page 777 of 1502

11-18 EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

MUFFLER

REAR

SUPPORT

BRACKET

MUFFLER

FRONT

SUPPORT BRACKET

159"

W.B.)-2

REQUIRED

MUFFLER

INSULATOR

FRAME

RAIL

/

SHOULDER

BOLT

MUFFLER

INSULATOR

MUFFLER

FRONT

SUPPORT BRACKET

(131", 135" & 149" W.B.] 1 REQUIRED

SHOULDER BOLTS

J9211-26

Fig.

4 Muffler Front/Rear

Support

Brackets (3) Remove the shoulder bolts from the muffler

front and rear support brackets (Fig. 4).

(4) Separate the extension(s) and the muffler from

the exhaust tailpipe and the front exhaust pipe.

(5) If required, remove the muffler support bracket

from the frame rail (Fig. 4).

INSTALLATION (1) If removed, install the muffler support bracket

to the frame rail. Tighten the bolts to 28 Nun (250 in. lbs.) torque.

(2) Align the extension(s) and the muffler with the

front exhaust pipe and the exhaust tailpipe.

(3) Install the shoulder bolts through the insula

tors and into the muffler front and rear support

brackets (Fig. 4). Tighten the bolts to 28 N-m (250 in. lbs.) torque.

(4) Position the clamps onto the front exhaust ex

tension pipe. Tighten the nuts to 54 Nun (40 ft. lbs.) torque.

(5) Position the clamps onto the rear exhaust ex

tension pipe or onto the muffler rear extension pipe.

Tighten the nuts to 54 Nun (40 ft. lbs.) torque.

(6) Lower the vehicle. (7) Start the engine and check for leaks.

EXHAUST

TAILPIPE

REMOVAL (1) Raise and support the vehicle.

(2) Remove the clamp from the pipe (Fig. 5).

(3) Remove the bolt from the exhaust tailpipe

bracket. (4) Separate the exhaust tailpipe from the rear ex

tension pipe or from the muffler rear extension pipe. (5) If required, remove the exhaust tailpipe

bracket from the frame rail (Fig. 5).

TAIL

PIPE

BRACKET

J9211-25

Fig.

5

Exhaust

Tailpipe

INSTALLATION

(1) If removed, install the exhaust tailpipe bracket

to the frame rail. Tighten the bolts to 23 Nun (200 in. lbs.) torque. (2) Position the exhaust tailpipe into the rear ex

tension pipe or the muffler rear extension pipe. (3) Install the bolt into the exhaust tailpipe

bracket. Tighten the bolt to 23 Nun (200 in lbs.) torque.

(4) Position the clamp onto the exhaust tailpipe.

Tighten the bolts to 54 Nun (40 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Start the engine and check for leaks.

ENGINE

EXHAUST MANIFOLD

REMOVAL (1) Disconnect the air intake and exhaust pipes

(Fig. 6). (2) Disconnect the turbocharger oil supply line and

the oil drain tube from the turbocharger (Fig. 7). (3) Disconnect the charge air cooler (intercooler)

inlet duct from the turbocharger (Fig. 7). (4) Remove the turbocharger and gasket. (5) Remove the cab heater supply and return lines.

(6) Remove the engine exhaust manifold and gas

kets (Fig. 8). (7) Clean the sealing surfaces.

INSTALLATION (1) Install the engine exhaust manifold and gas

kets.

Tighten the exhaust manifold bolts in sequence

to 43 Nun (32 ft. lbs.) torque (Fig. 9). (2) Install the turbocharger. Tighten the turbo

charger mounting nuts to 32 Nun (24 ft. lbs.) torque.

Page 778 of 1502

EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 19

EXHAUST

MANIFOLD

GASKET

J9111-52

Fig.

6 Air intake Pipe,

Exhaust

Pipe and

Turbocharger

,

till

TURBOCHARGER,

OIL SUPPLY

UNE

^J9111-53

Fig.

7

OH

Supply Line and Charge Air Cooler (intercooler) inlet

Duct

(3) Position the charge air cooler (intercooler) inlet

duct to the turbocharger. With the clamp in position,

tighten the clamp nut to 8 Nun (72 in. lbs.) torque.

(4) Position the air intake pipe and the exhaust

pipe onto the turbocharger. Tighten the clamps to 8 Nun (74 in. lbs.) torque.

(5) Install the oil drain tube and oil supply line to

the turbocharger. Tighten the drain tube bolts to 24

J9111-5

Fig.

8

Engine

Exhaust

Manifold and

Gaskets

EXHAUST

MANIFOLD^^^^

GASKET

J9111-6

Fig.

9

Engine

Exhaust

Manifold

Bolt

Tightening

Sequence

Nun (18 ft. lbs.) torque. Tighten the oil supply line

fitting nut to 15 Nun (11 ft. lbs.) torque. (6) Connect the cab heater supply and return lines.

Tighten the line nuts to 24 Nun (18 ft. lbs.) torque. (7) Operate the engine to check for leaks.

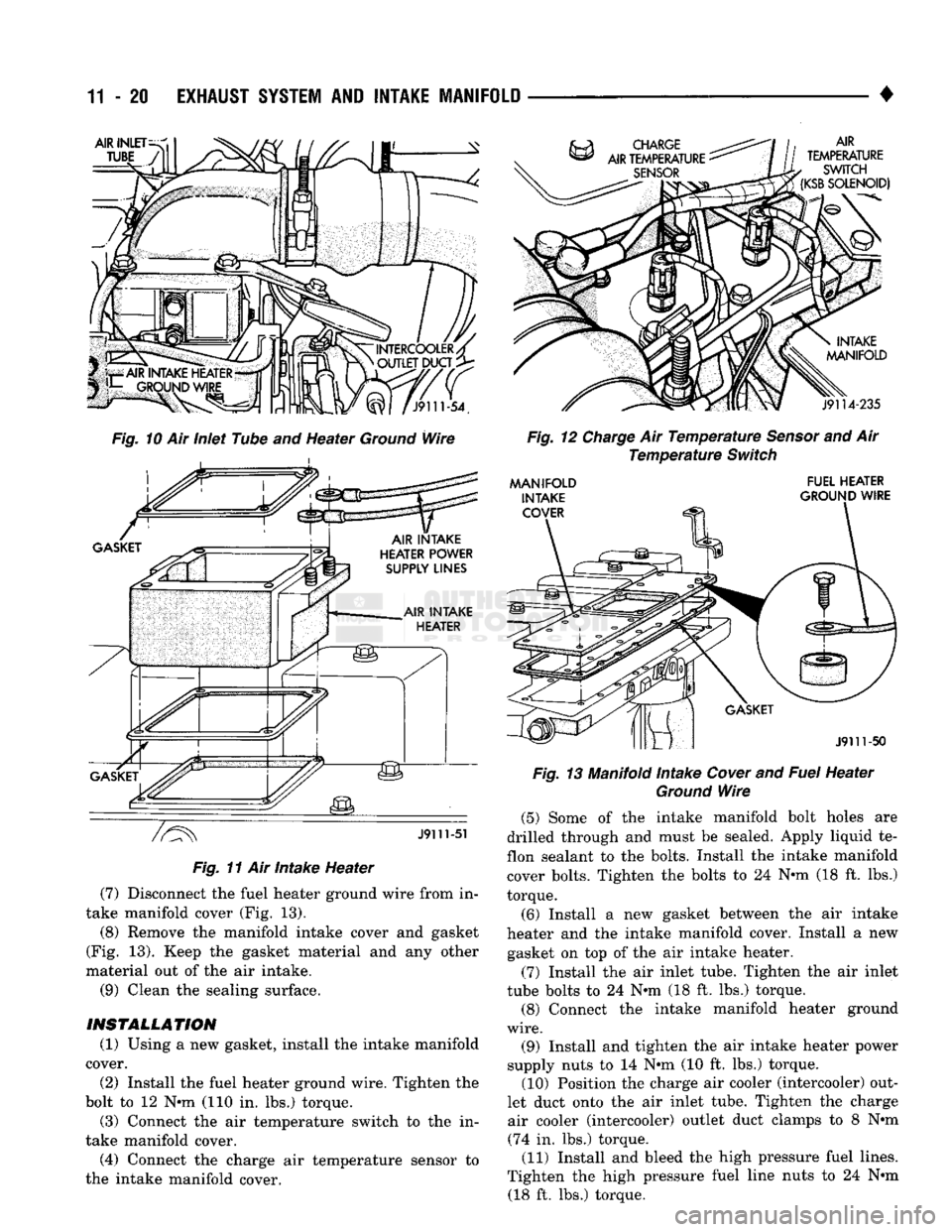

INTAKE MANIFOLD COVER / AIR INTAKE HEATER

REMOVAL (1) Remove the charge air cooler (intercooler) out

let duct from the air inlet tube (Fig. 10). (2) Remove the high pressure fuel lines. (3) Disconnect and remove the air intake heater

ground wire (Fig. 10). (4) Disconnect the air intake heater power supply

lines (Fig. 11). Remove the air intake heater and

gaskets (Fig. 11). Clean the mounting surface of the

intake manifold cover. (5) Disconnect the charge air temperature sensor

from the intake manifold cover (Fig. 12). (6) Disconnect the air temperature switch from the

intake manifold cover (Fig. 12).

Page 779 of 1502

11-20 EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

AIR INLET

INTERCOOLER/ OUTLET DUCT

X^l

/J9111-54.

Fig.

10 Air Inlet Tube and Heater

Ground

Wire

J9111-51

Fig.

11 Air Intake Heater (7) Disconnect the fuel heater ground wire from in

take manifold cover (Fig. 13).

(8) Remove the manifold intake cover and gasket

(Fig. 13). Keep the gasket material and any other

material out of the air intake.

(9) Clean the sealing surface.

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover. (2) Install the fuel heater ground wire. Tighten the

bolt to 12 Nun (110 in. lbs.) torque.

(3) Connect the air temperature switch to the in

take manifold cover.

(4) Connect the charge air temperature sensor to

the intake manifold cover.

AIR

TEMPERATURE

SWITCH

(KSB

SOLENOID)

J9114-235

Fig.

12

Charge

Air

Temperature

Sensor

and Air

Temperature

Switch

AAANIFOLD INTAKE COVER FUEL HEATER

GROUND WIRE

J9111-50

Fig.

13 Manifold Intake

Cover

and

Fuel

Heater

Ground

Wire

(5) Some of the intake manifold bolt holes are

drilled through and must be sealed. Apply liquid te

flon sealant to the bolts. Install the intake manifold

cover bolts. Tighten the bolts to 24 Nun (18 ft. lbs.)

torque.

(6) Install a new gasket between the air intake

heater and the intake manifold cover. Install a new gasket on top of the air intake heater.

(7) Install the air inlet tube. Tighten the air inlet

tube bolts to 24 Nun (18 ft. lbs.) torque. (8) Connect the intake manifold heater ground

wire.

(9) Install and tighten the air intake heater power

supply nuts to 14 Nun (10 ft. lbs.) torque. (10) Position the charge air cooler (intercooler) out

let duct onto the air inlet tube. Tighten the charge air cooler (intercooler) outlet duct clamps to 8 Nun (74 in. lbs.) torque. (11) Install and bleed the high pressure fuel lines.

Tighten the high pressure fuel line nuts to 24 Nun (18 ft. lbs.) torque.

Page 780 of 1502

•

EXHAUST

SYSTEM

AND

INTAKE

MANIFOLD

11 - 21

TURBOCHARGER

REMOVAL (1) Disconnect the negative cable from the battery. (2) Disconnect the air intake pipe and exhaust pipe

(Fig. 14).

Fig.

14 Air Intake Pipe,

Exhaust

Pipe and Turbocharger

(3) Remove the oil drain tube bolts.

(4) Remove the oil supply line (Fig. 15).

(5) Disconnect the charge air cooler (intercooler)

inlet duct from the turbocharger (Fig. 15).

(6) Remove the turbocharger mounting nuts and

the turbocharger.

(7)

If the turbocharger is not to be installed imme

diately, cover the opening to prevent material from

entering into the manifold.

(8) Clean and inspect the sealing surface.

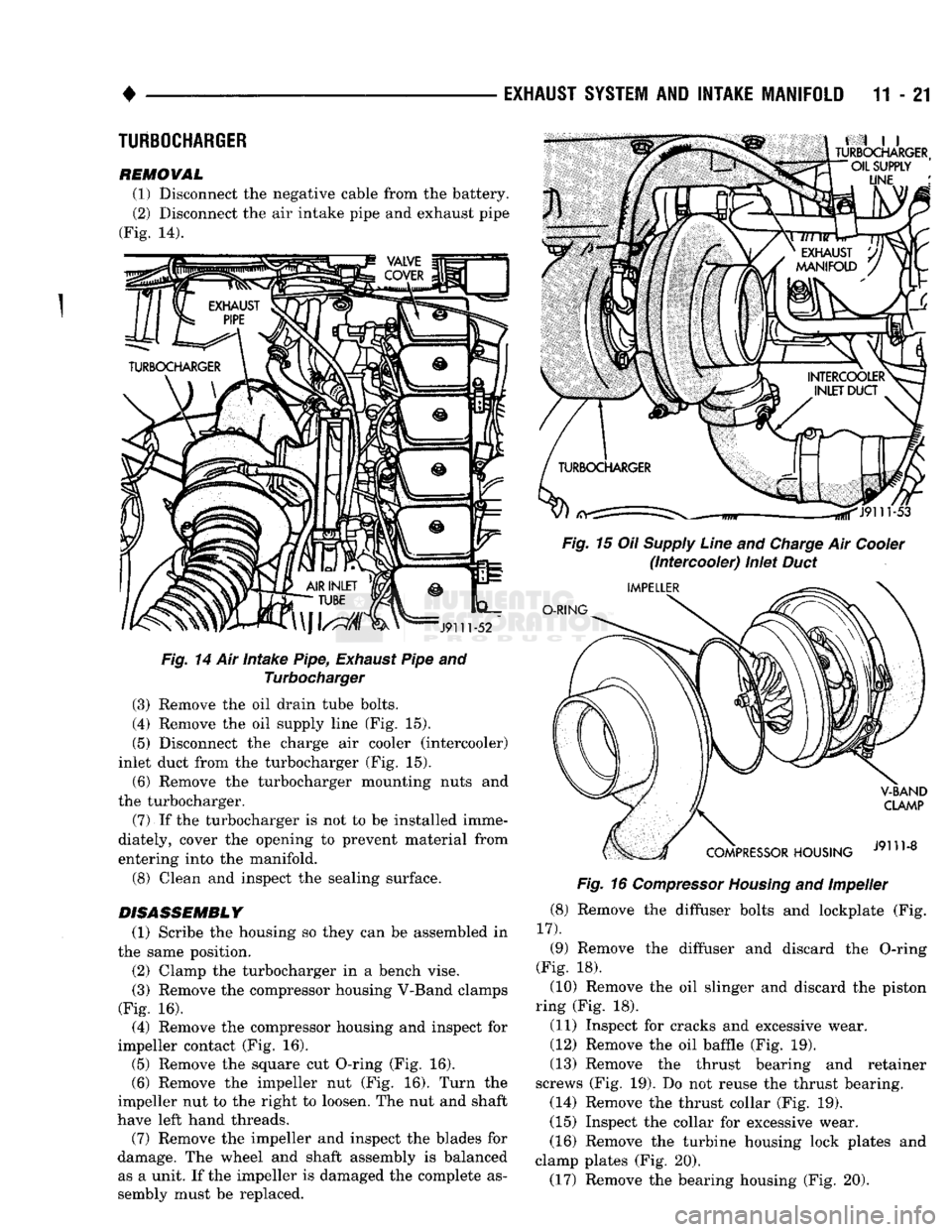

DISASSEMBLY

(1) Scribe the housing so they can be assembled in

the same position.

(2) Clamp the turbocharger in a bench vise.

(3) Remove the compressor housing V-Band clamps

(Fig. 16). (4) Remove the compressor housing and inspect for

impeller contact (Fig. 16). (5) Remove the square cut O-ring (Fig. 16). (6) Remove the impeller nut (Fig. 16). Turn the

impeller nut to the right to loosen. The nut and shaft

have left hand threads. (7) Remove the impeller and inspect the blades for

damage. The wheel and shaft assembly is balanced as a unit. If the impeller is damaged the complete as

sembly must be replaced.

Fig.

16

Compressor

Housing

and Impeller

(8) Remove the diffuser bolts and lockplate (Fig.

17).

(9) Remove the diffuser and discard the O-ring

(Fig. 18). (10) Remove the oil slinger and discard the piston

ring (Fig. 18).

(11) Inspect for cracks and excessive wear.

(12) Remove the oil baffle (Fig. 19).

(13) Remove the thrust bearing and retainer

screws (Fig. 19). Do not reuse the thrust bearing. (14) Remove the thrust collar (Fig. 19).

(15) Inspect the collar for excessive wear.

(16) Remove the turbine housing lock plates and

clamp plates (Fig. 20). (17) Remove the bearing housing (Fig. 20).