DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 781 of 1502

11

- 22

EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

•

DIFFUSER

TURBINE

HOUSING

O-RING BEARING

HOUSING

LOCKPLATE

J9111-9

Fig.

17 Diffuser and Lockplate

OIL

SLINGER

MO

Fig.

18 Diffuser,

O-Ring

and Oil

Slinger

THRUST

COLLAR

OIL

BAFFLE

J9111-11

Fig.

19 Oil

Baffle,

Thrust Bearing and Collar

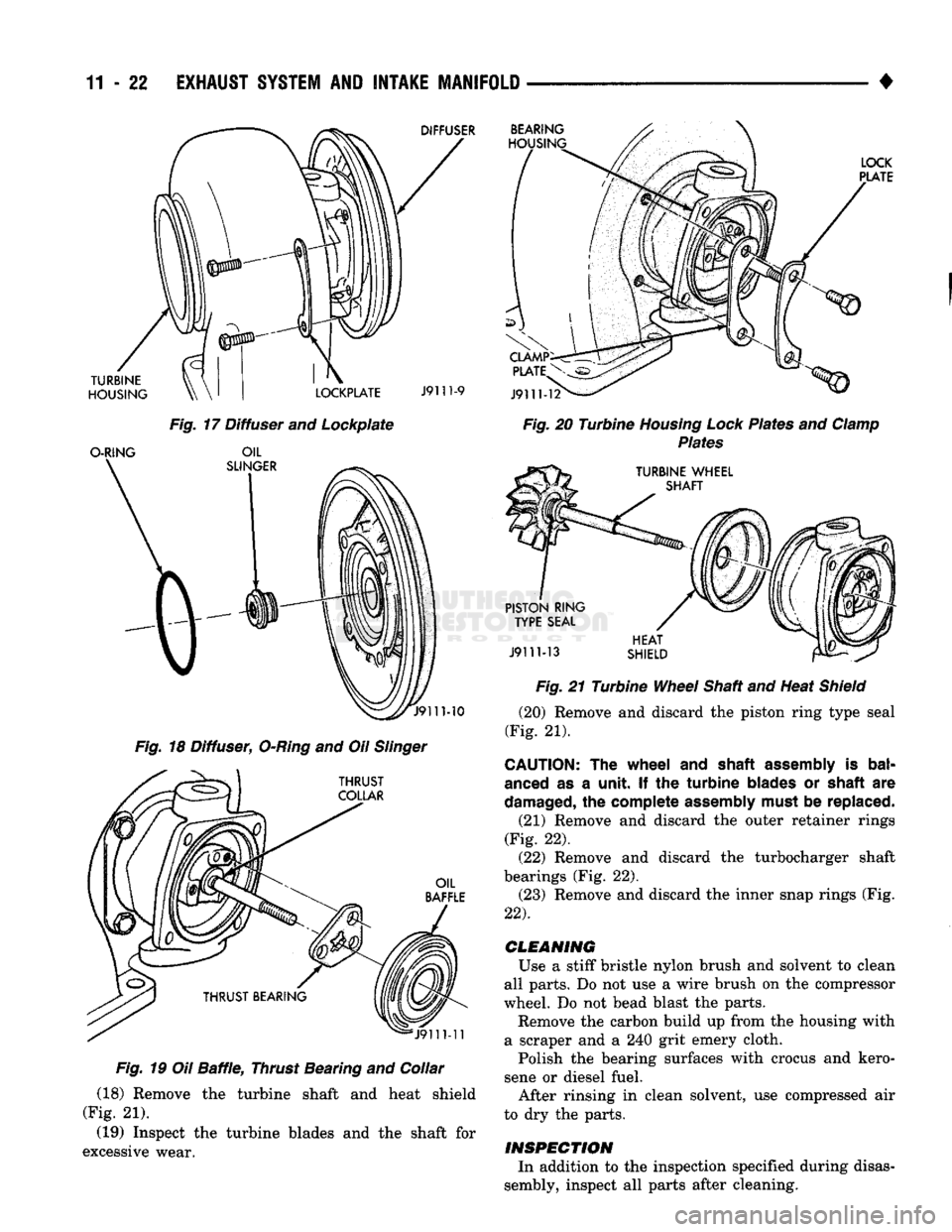

(18) Remove the turbine shaft and heat shield

(Fig. 21).

(19) Inspect the turbine blades and the shaft for

excessive wear.

LOCK

PLATE

J9111-12

Fig.

20 Turbine

Housing Lock

Plates and

Clamp

Plates

TURBINE WHEEL SHAFT

PISTON RING TYPE SEAL

J9111-13

HEAT

SHIELD Fig.

21 Turbine

Wheel

Shaft and Heat

Shield

(20) Remove and discard the piston ring type seal

(Fig. 21).

CAUTION:

The

wheel

and

shaft assembly

is

bal

anced

as a

unit.

If the

turbine blades

or

shaft

are

damaged,

the

complete assembly must

be

replaced.

(21) Remove and discard the outer retainer rings

(Fig. 22). (22) Remove and discard the turbocharger shaft

bearings (Fig. 22). (23) Remove and discard the inner snap rings (Fig.

22).

CLEANING

Use a stiff bristle nylon brush and solvent to clean

all parts. Do not use a wire brush on the compressor

wheel. Do not bead blast the parts. Remove the carbon build up from the housing with

a scraper and a 240 grit emery cloth.

Polish the bearing surfaces with crocus and kero

sene or diesel fuel. After rinsing in clean solvent, use compressed air

to dry the parts.

INSPECTION

In addition to the inspection specified during disas

sembly, inspect all parts after cleaning.

Page 782 of 1502

•

EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

11 - 23

HEAT

SHIELD

OUTER RETAINER

RINGS

BREAKING,

HOUSING

J9111-18

Fig.

24 Turbine Shaft/Heat

Shield

to Bearing

Housing

INNER

RETAINING

RINGS

INNER

RETAINING RING

J9111-14

Fig.

22

Snap Rings

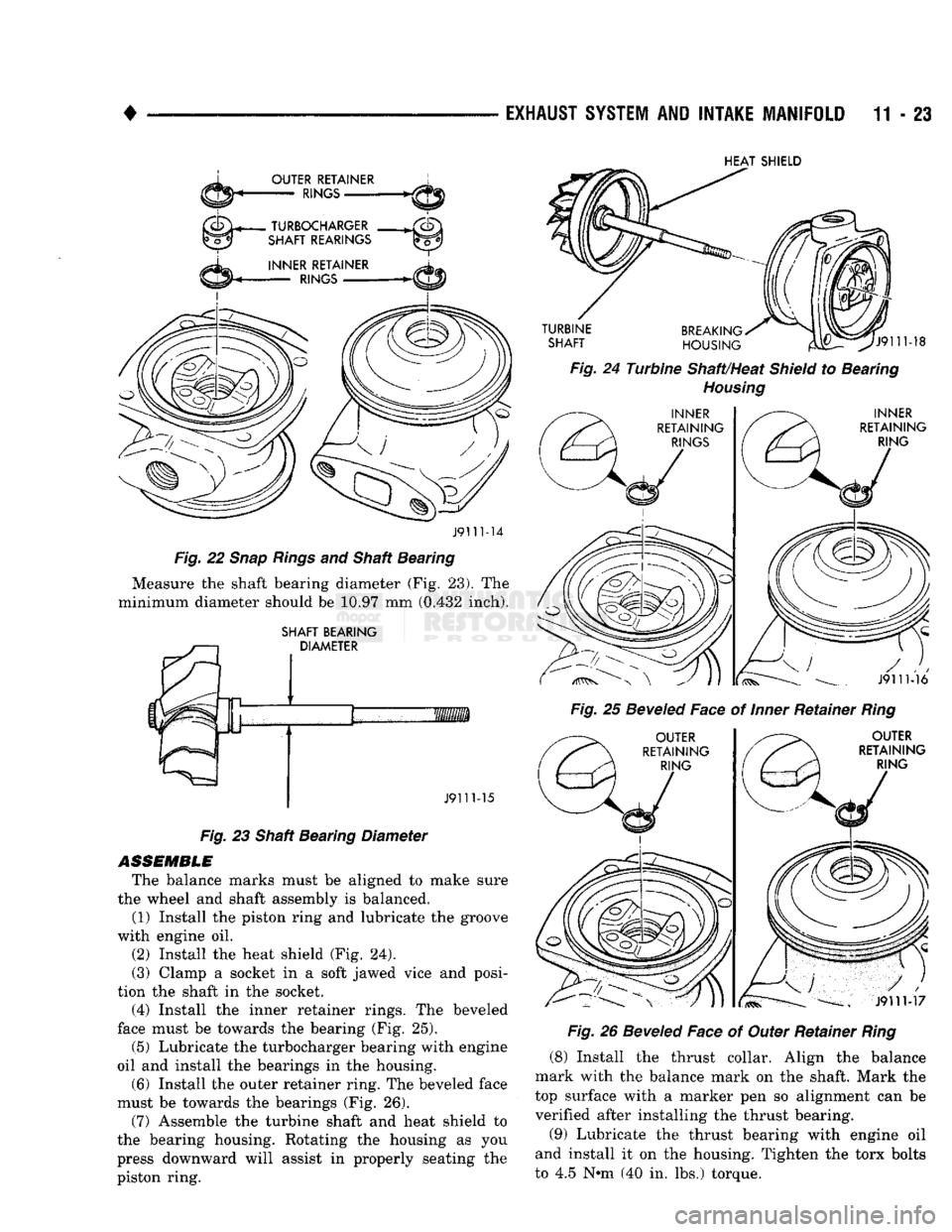

and Shaft Bearing Measure the shaft bearing diameter (Fig. 23). The

minimum diameter should be 10.97 mm (0.432 inch).

SHAFT BEARING DIAMETER Fig.

25

Beveled

Face of

Inner

Retainer

Ring

J911M6

OUTER

RETAINING RING

J9111-15

Fig.

23 Shaft Bearing Diameter

ASSEMBLE

The balance marks must be aligned to make sure

the wheel and shaft assembly is balanced. (1) Install the piston ring and lubricate the groove

with engine oil.

(2) Install the heat shield (Fig. 24).

(3) Clamp a socket in a soft jawed vice and posi

tion the shaft in the socket. (4) Install the inner retainer rings. The beveled

face must be towards the bearing (Fig. 25).

(5) Lubricate the turbocharger bearing with engine

oil and install the bearings in the housing.

(6) Install the outer retainer ring. The beveled face

must be towards the bearings (Fig. 26).

(7) Assemble the turbine shaft and heat shield to

the bearing housing. Rotating the housing as you

press downward will assist in properly seating the

piston ring.

OUTER

RETAINING RING

J9111-17

Fig.

26

Beveled

Face of Outer Retainer

Ring

(8) Install the thrust collar. Align the balance

mark with the balance mark on the shaft. Mark the

top surface with a marker pen so alignment can be verified after installing the thrust bearing.

(9) Lubricate the thrust bearing with engine oil

and install it on the housing. Tighten the torx bolts

to 4.5 N»m (40 in. lbs.) torque.

Page 783 of 1502

11

- 24

EXHAUST

SYSTEM

AND

INTAKE

MANIFOLD

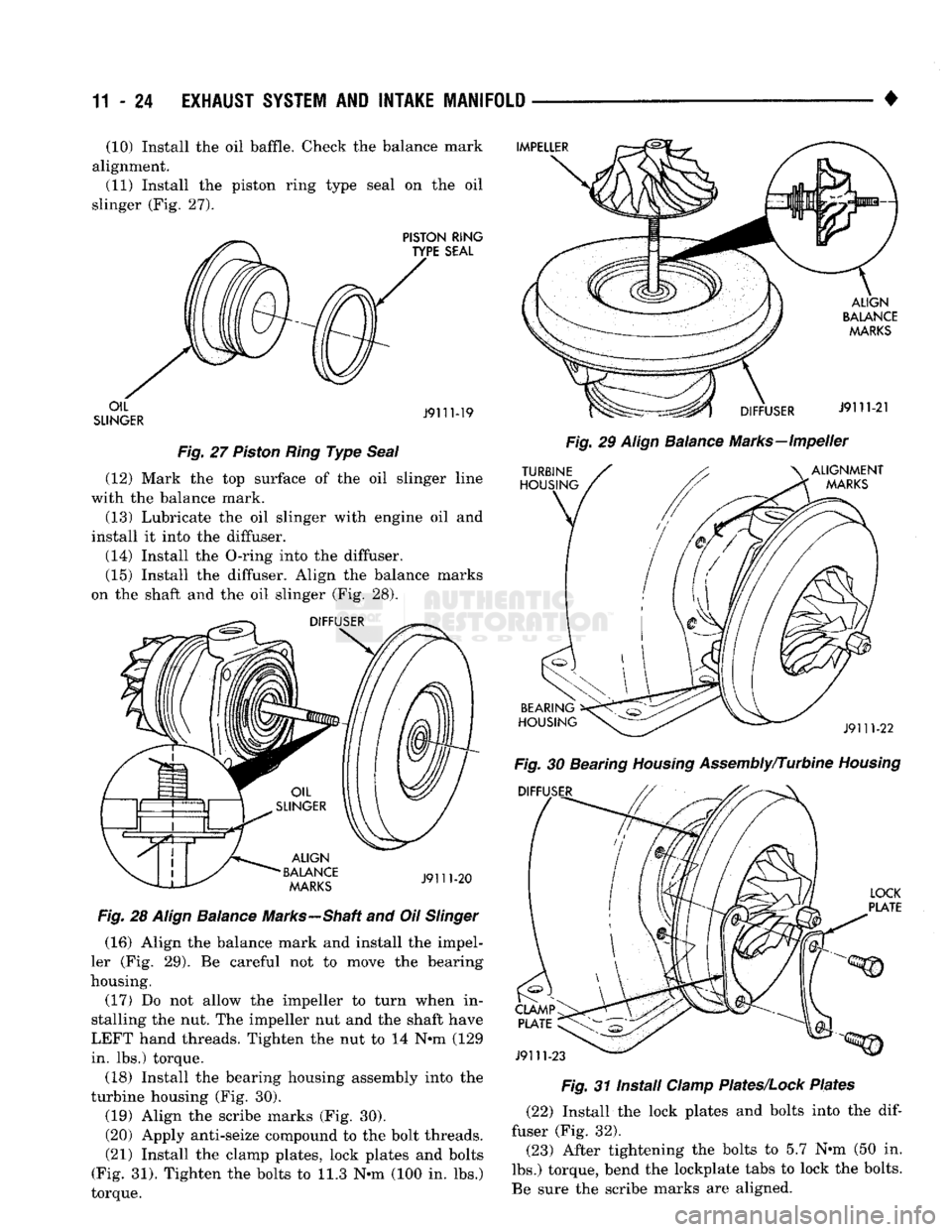

(10) Install the oil baffle. Check the balance mark

alignment. (11) Install the piston ring type seal on the oil

slinger (Fig. 27).

Fig.

27

Piston

Ring

Type

Seal

(12) Mark the top surface of the oil slinger line

with the balance mark.

(13) Lubricate the oil slinger with engine oil and

install it into the diffuser.

(14) Install the O-ring into the diffuser. (15) Install the diffuser. Align the balance marks

on the shaft and the oil slinger (Fig. 28).

Fig.

28

Align

Balance

Marks—Shaft and Oil

Slinger

(16) Align the balance mark and install the impel

ler (Fig. 29). Be careful not to move the bearing

housing. (17) Do not allow the impeller to turn when in

stalling the nut. The impeller nut and the shaft have

LEFT hand threads. Tighten the nut to 14 N-m (129

in. lbs.) torque.

(18) Install the bearing housing assembly into the

turbine housing (Fig. 30). (19) Align the scribe marks (Fig. 30).

(20) Apply anti-seize compound to the bolt threads. (21) Install the clamp plates, lock plates and bolts

(Fig. 31). Tighten the bolts to 11.3 N-m (100 in. lbs.)

torque.

Fig.

29

Align

Balance

Marks—Impeller

Fig.

30 Bearing

Housing

Assembly/Turbine

Housing

Fig.

31 Install

Clamp

Plates/Lock

Plates

(22) Install the lock plates and bolts into the

dif

fuser (Fig. 32).

(23) After tightening the bolts to 5.7 N-m (50 in.

lbs.) torque, bend the lockplate tabs to lock the bolts.

Be sure the scribe marks are aligned.

Page 784 of 1502

•

EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

11 - 25

Fig.

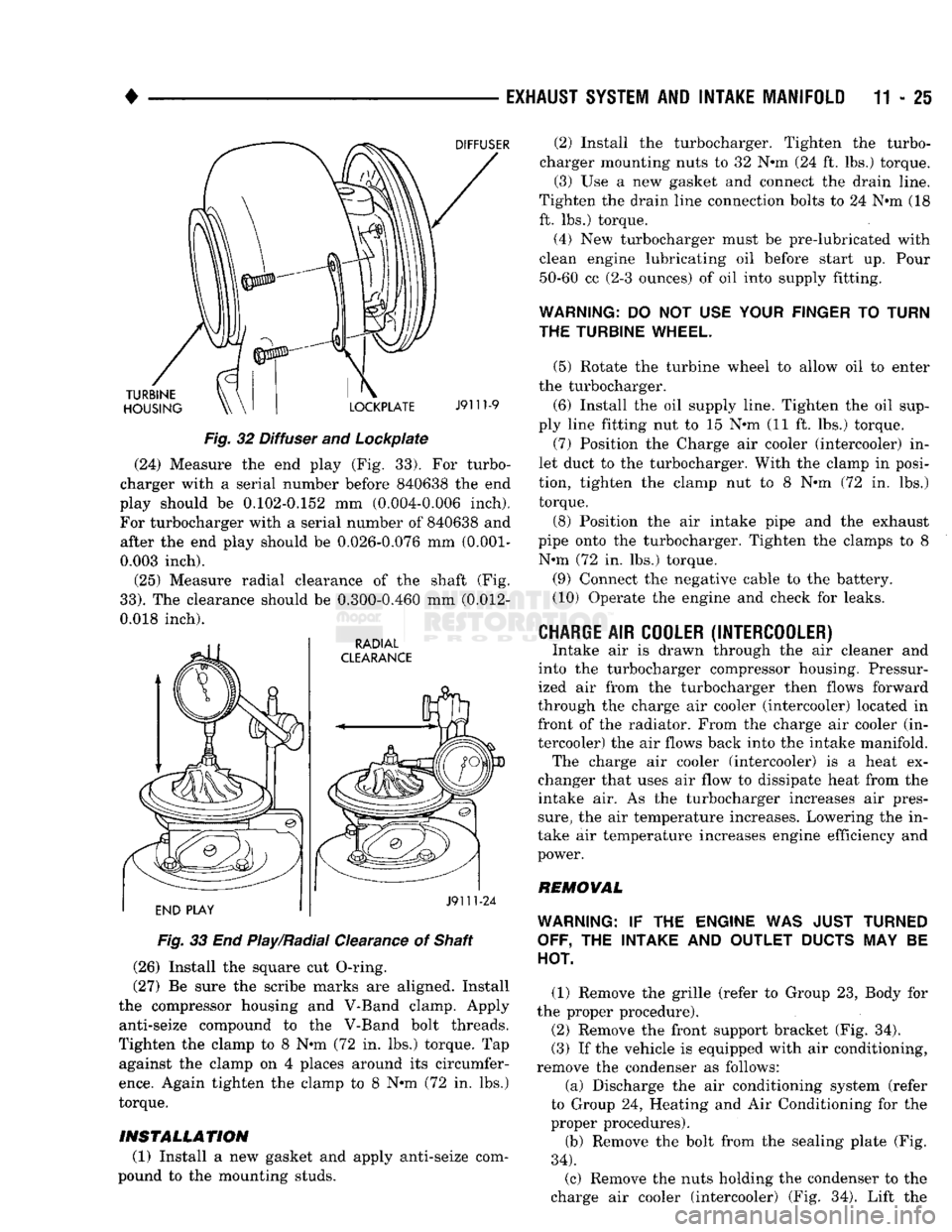

32 Diffuser and Lockpiate (24) Measure the end play (Fig. 33). For turbo

charger with a serial number before 840638 the end

play should be 0.102-0.152 mm (0.004-0.006 inch).

For turbocharger with a serial number of 840638 and after the end play should be 0.026-0.076 mm

(0.001-

0.003 inch).

(25) Measure radial clearance of the shaft (Fig.

33).

The clearance should be 0.300-0.460 mm (0.012-

0.018 inch).

Fig.

33 End Play/Radial Clearance of Shaft

(26) Install the square cut O-ring.

(27) Be sure the scribe marks are aligned. Install

the compressor housing and V-Band clamp. Apply anti-seize compound to the V-Band bolt threads.

Tighten the clamp to 8 N-m (72 in. lbs.) torque. Tap against the clamp on 4 places around its circumfer

ence.

Again tighten the clamp to 8 N-m (72 in. lbs.)

torque.

INSTALLATION

(1) Install a new gasket and apply anti-seize com

pound to the mounting studs. (2) Install the turbocharger. Tighten the turbo

charger mounting nuts to 32 N-m (24 ft. lbs.) torque. (3) Use a new gasket and connect the drain line.

Tighten the drain line connection bolts to 24 N-m (18

ft. lbs.) torque.

(4) New turbocharger must be pre-lubricated with

clean engine lubricating oil before start up. Pour 50-60 cc (2-3 ounces) of oil into supply fitting.

WARNING:

DO NOT USE

YOUR FINGER

TO

TURN

THE TURBINE WHEEL.

(5) Rotate the turbine wheel to allow oil to enter

the turbocharger.

(6) Install the oil supply line. Tighten the oil sup

ply line fitting nut to 15 N-m (11 ft. lbs.) torque. (7) Position the Charge air cooler (intercooler) in

let duct to the turbocharger. With the clamp in posi

tion, tighten the clamp nut to 8 N-m (72 in. lbs.) torque.

(8) Position the air intake pipe and the exhaust

pipe onto the turbocharger. Tighten the clamps to 8 N-m (72 in. lbs.) torque.

(9) Connect the negative cable to the battery.

(10) Operate the engine and check for leaks.

CHARGE

AIR

COOLER (INTERCOOLER)

Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressur

ized air from the turbocharger then flows forward

through the charge air cooler (intercooler) located in front of the radiator. From the charge air cooler (in

tercooler) the air flows back into the intake manifold. The charge air cooler (intercooler) is a heat ex

changer that uses air flow to dissipate heat from the

intake air. As the turbocharger increases air pres

sure,

the air temperature increases. Lowering the in

take air temperature increases engine efficiency and

power.

REMOVAL

WARNING:

IF THE

ENGINE

WAS

JUST TURNED OFF,

THE

INTAKE

AND

OUTLET

DUCTS

MAY BE

HOT.

(1) Remove the grille (refer to Group 23, Body for

the proper procedure).

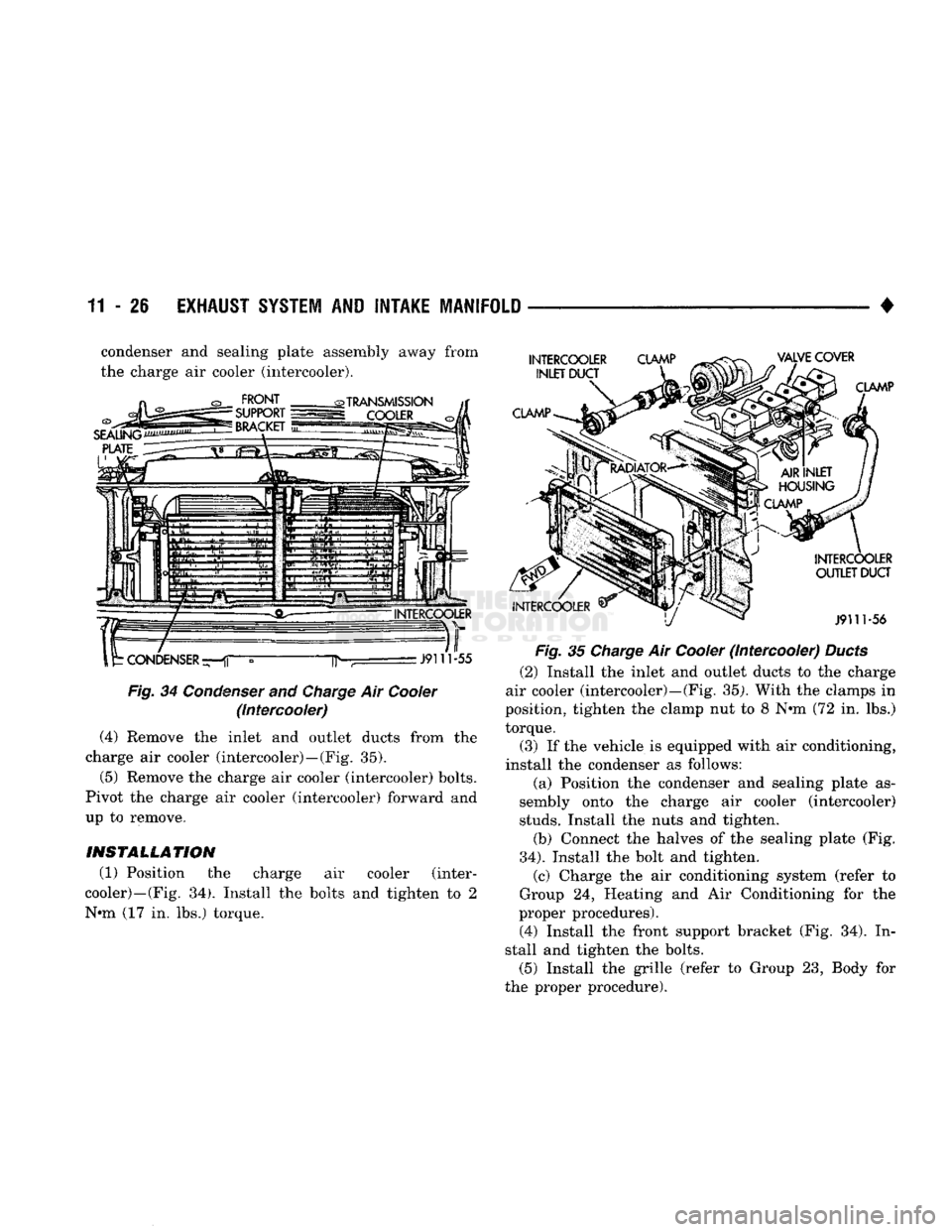

(2) Remove the front support bracket (Fig. 34).

(3) If the vehicle is equipped with air conditioning,

remove the condenser as follows:

(a) Discharge the air conditioning system (refer

to Group 24, Heating and Air Conditioning for the

proper procedures).

(b) Remove the bolt from the sealing plate (Fig.

34).

(c) Remove the nuts holding the condenser to the

charge air cooler (intercooler) (Fig. 34). Lift the

Page 785 of 1502

11 - 26

EXHAUST SYSTEM

AND

INTAKE MANIFOLD

• condenser and sealing plate assembly away from

the charge air cooler (intercooler).

Fig.

34 Condenser and

Charge

Air Cooler (Intercooler)

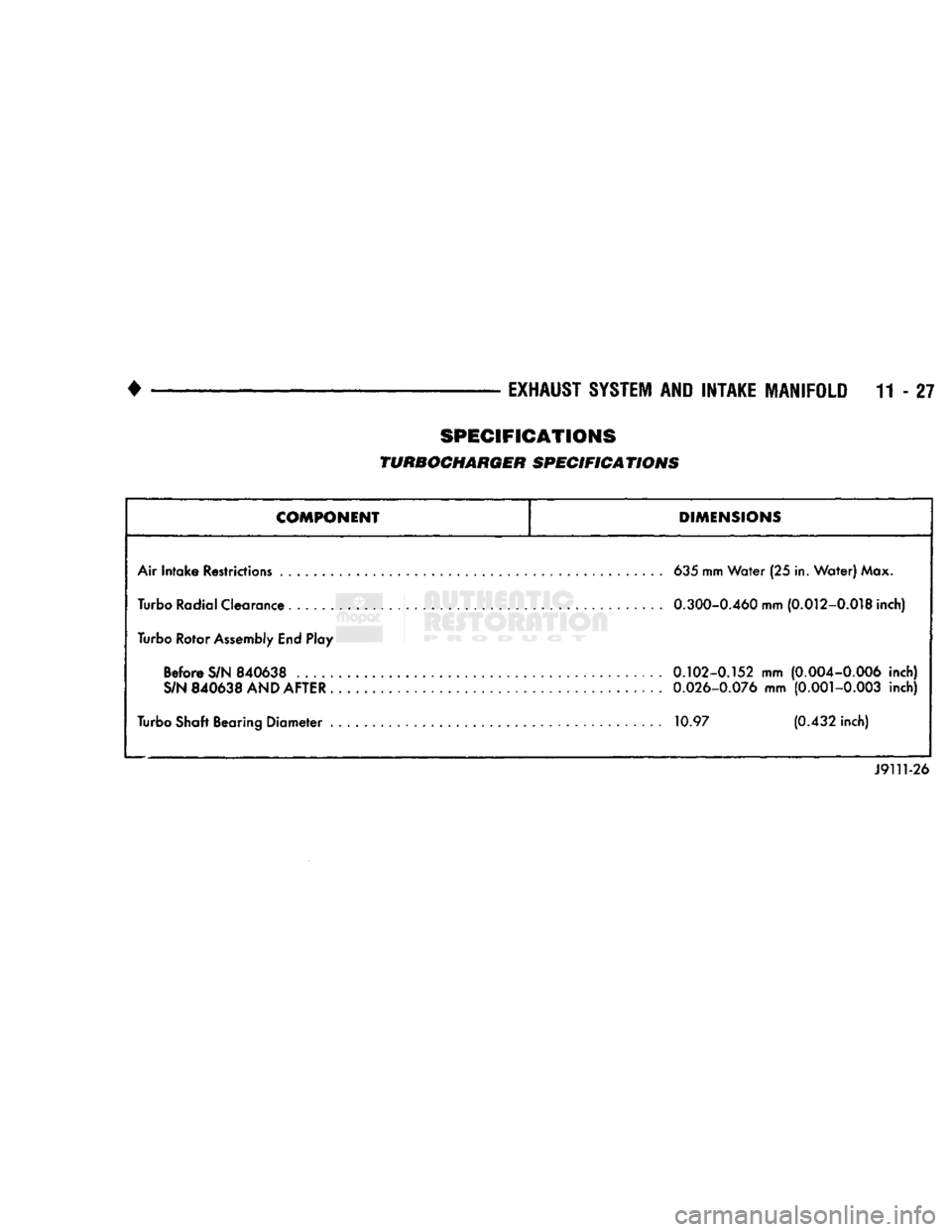

(4) Remove the inlet and outlet ducts from the

charge air cooler (intercooler)—(Fig. 35).

(5) Remove the charge air cooler (intercooler) bolts.

Pivot the charge air cooler (intercooler) forward and

up to remove.

INSTALLATION

(1) Position the charge air cooler (inter

cooler)—(Fig. 34). Install the bolts and tighten to 2

N-m (17 in. lbs.) torque.

Fig.

35 Charge Air Cooler (Intercooler) Ducts

(2) Install the inlet and outlet ducts to the charge

air cooler (intercooler)—(Fig. 35). With the clamps in

position, tighten the clamp nut to 8 N-m (72 in. lbs.)

torque.

(3) If the vehicle is equipped with air conditioning,

install the condenser as follows: (a) Position the condenser and sealing plate as

sembly onto the charge air cooler (intercooler)

studs.

Install the nuts and tighten.

(b) Connect the halves of the sealing plate (Fig.

34).

Install the bolt and tighten. (c) Charge the air conditioning system (refer to

Group 24, Heating and Air Conditioning for the

proper procedures).

(4) Install the front support bracket (Fig. 34). In

stall and tighten the bolts. (5) Install the grille (refer to Group 23, Body for

the proper procedure).

Page 786 of 1502

•

EXHAUST SYSTEM

AND

INTAKE MANIFOLD

11-27

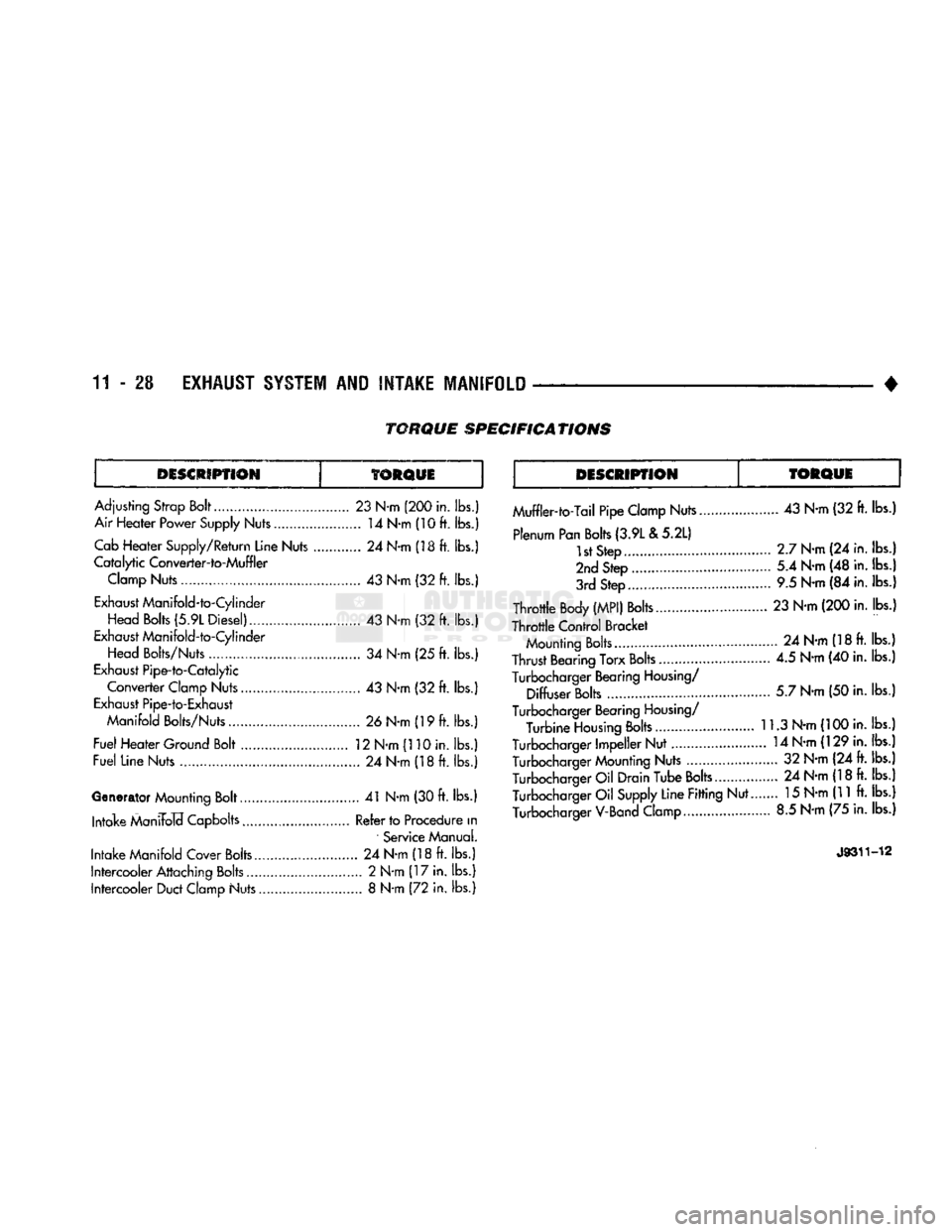

SPECIFICATIONS

TURBOCHARGER SPECIFICATIONS

COMPONENT

DIMENSIONS

Air Intake Restrictions

635

mm Water (25 in. Water) Max.

Turbo Radial Clearance

0.300-0.460

mm

(0.012-0.018

inch)

Turbo Rotor Assembly End Play Before S/N 840638 0.102-0.152 mm (0.004-0.006 inch)

S/N

840638

AND AFTER .

0.026-0.076

mm

(0.001-0.003

inch)

Turbo Shaft Bearing Diameter

10.97 (0.432

inch)

J9111-26

Page 787 of 1502

11

- 28

EXHAUST

SYSTEM

AND

INTAKE MANIFOLD

•

DESCRIPTION

TORQUE

DESCRIPTION

TORQUE

Adjusting

Strop

Bolt

23

N-m

(200 in.

lbs.)

Air Heater Power Supply Nuts 14 N-m (10

ft.

lbs.) Cab

Heater Supply/Return Line Nuts 24

N-m

(18

ft.

lbs.)

Catalytic

Converter-to-Muffler Clamp Nuts 43 N-m (32 ft. lbs.)

Exhaust Manifold-to-Cylinder

Head

Bolts

(5.9L Diesel) 43 N-m (32

ft.

lbs.)

Exhaust Manifold-to-Cylinder

Head Bolts/Nuts 34

N-m (25

ft. lbs.)

Exhaust Pipe-to-Catalytic

Converter Clamp Nuts 43 N-m (32 ft. lbs.)

Exhaust Pipe-to-Exhaust

Manifold

Bolts/Nuts 26 N-m (19 ft. lbs.)

Fuel Heater Ground Bolt . 12 N-m (110 in. lbs.)

Fuel Line Nuts 24 N-m (18ft. lbs.)

Generator Mounting Bolt 41 N-m (30 ft. lbs.) Intake ManiFolcf Capbolts Refer to Procedure

in

Service Manual.

Intake Manifold Cover Bolts 24 N-m (18 ft. lbs.)

Intercooler Attaching Bolts............................. 2 N-m (17 in. lbs.) Intercooler Duct Clamp Nuts 8 N-m (72 in. lbs.) Muffler-to-Tail Pipe Clamp Nuts 43 N-m (32 ft. lbs.)

Plenum Pan Bolts (3.9L

& 5.2L)

1st Step 2.7 N-m (24 in. lbs.)

2nd Step 5.4 N-m (48 in. lbs.)

3rd Step 9.5 N-m (84 in. lbs.)

Throttle Body

(MPI)

Bolts 23 N-m (200 in. lbs.)

Throttle Control Bracket Mounting Bolts 24 N-m (18 ft. lbs.)

Thrust Bearing Torx Bolts............................ 4.5 N-m (40 in. lbs.)

Turbocharger Bearing Housing/ Diffuser Bolts 5.7 N-m (50 in. lbs.)

Turbocharger Bearing Housing/ Turbine Housing Bolts 11.3 N-m (100 in. lbs.)

Turbocharger Impeller Nut 14 N-m (129 in. lbs.) Turbocharger Mounting Nuts 32 N-m (24 ft. lbs.)

Turbocharger Oil Drain Tube Bolts... 24 N-m (18 ft. lbs.) Turbocharger Oil Supply Line Fitting Nut.. 15 N-m (11 ft. lbs.)

Turbocharger V-Band Clamp 8.5 N-m (75 in. lbs.)

J9311-12

TORQUE

SPECIFICATIONS

Page 788 of 1502

• •

•

FRAME AND BUMPERS 13 - 1

CONTENTS

page page

ATTACHED COMPONENTS . B B. B. B . 30 FRAME 20 BUMPERS 1 SNOW PLOW 3

BUMPERS

FRONT BUMPER

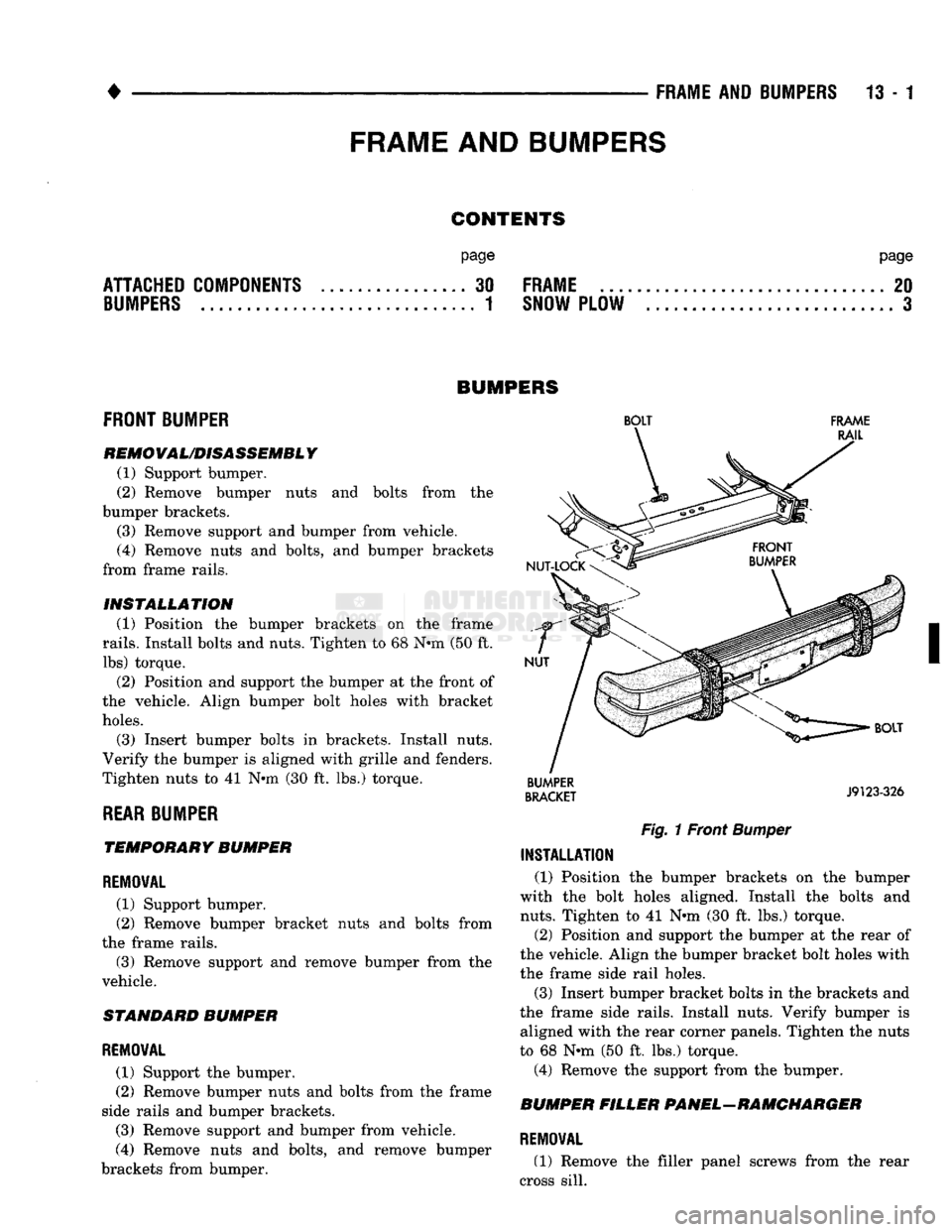

REMOVAL/DISASSEMBLY

(1) Support bumper.

(2) Remove bumper nuts and bolts from the

bumper brackets.

(3) Remove support and bumper from vehicle. (4) Remove nuts and bolts, and bumper brackets

from frame rails.

INSTALLATION (1) Position the bumper brackets on the frame

rails.

Install bolts and nuts. Tighten to 68 Nnn (50 ft. lbs) torque.

(2) Position and support the bumper at the front of

the vehicle. Align bumper bolt holes with bracket

holes.

(3) Insert bumper bolts in brackets. Install nuts.

Verify the bumper is aligned with grille and fenders.

Tighten nuts to 41 N*m (30 ft. lbs.) torque.

REAR BUMPER TEMPORARY BUMPER

REMOVAL

(1) Support bumper.

(2) Remove bumper bracket nuts and bolts from

the frame rails.

(3) Remove support and remove bumper from the

vehicle.

STANDARD BUMPER

REMOVAL

(1) Support the bumper,

(2) Remove bumper nuts and bolts from the frame

side rails and bumper brackets.

(3) Remove support and bumper from vehicle.

(4) Remove nuts and bolts, and remove bumper

brackets from bumper.

BOLT

FRAME

RAIL

NUT-LOCK

NUT

BUMPER

BRACKET

J9123-326

Fig.

1 Front

Bumper

INSTALLATION

(1) Position the bumper brackets on the bumper

with the bolt holes aligned. Install the bolts and

nuts.

Tighten to 41 N«m (30 ft. lbs.) torque.

(2) Position and support the bumper at the rear of

the vehicle. Align the bumper bracket bolt holes with

the frame side rail holes.

(3) Insert bumper bracket bolts in the brackets and

the frame side rails. Install nuts. Verify bumper is aligned with the rear corner panels. Tighten the nuts

to 68 N-m (50 ft. lbs.) torque.

(4) Remove the support from the bumper.

BUMPER FILLER PANEL-RAMCHARGER

REMOVAL

(1) Remove the filler panel screws from the rear

cross sill.

FRAME

AND

BUMPERS

Page 789 of 1502

13 - 2

FRAME

AND

BUMPERS

•

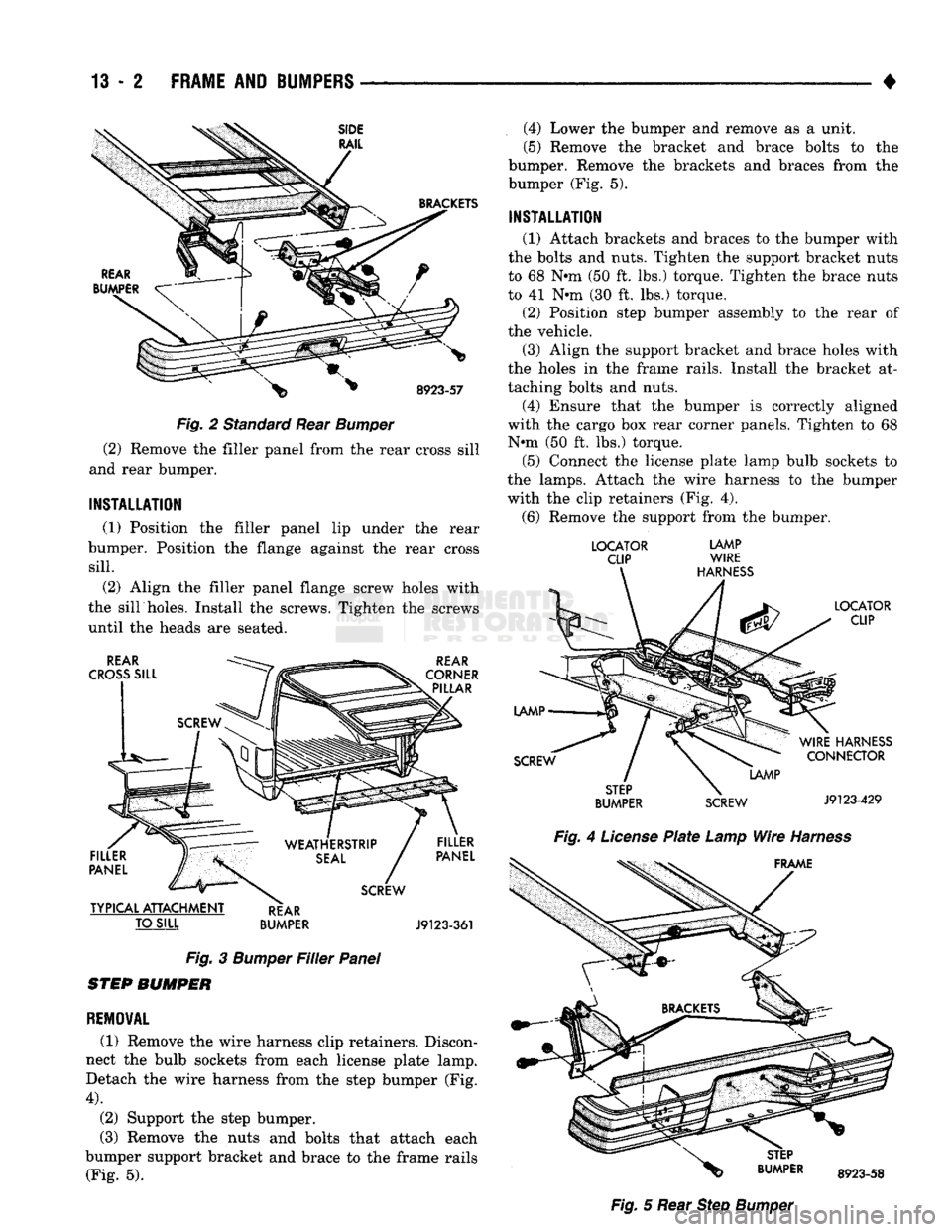

Fig. 2 Standard Rear Bumper

(2) Remove the filler panel from the rear cross sill

and rear bumper.

INSTALLATION

(1) Position the filler panel lip under the rear

bumper. Position the flange against the rear cross

sill.

(2) Align the filler panel flange screw holes with

the sill holes. Install the screws. Tighten the screws

until the heads are seated.

TO SILL

BUMPER J9123-361

Fig. 3 Bumper Filler Panel

STEP BUMPER

REMOVAL

(1) Remove the wire harness clip retainers. Discon

nect the bulb sockets from each license plate lamp.

Detach the wire harness from the step bumper (Fig.

4).

(2) Support the step bumper.

(3) Remove the nuts and bolts that attach each

bumper support bracket and brace to the frame rails (Fig. 5). (4) Lower the bumper and remove as a unit.

(5) Remove the bracket and brace bolts to the

bumper. Remove the brackets and braces from the

bumper (Fig. 5).

INSTALLATION

(1) Attach brackets and braces to the bumper with

the bolts and nuts. Tighten the support bracket nuts

to 68 N*m (50 ft. lbs.) torque. Tighten the brace nuts

to 41 N»m (30 ft. lbs.) torque.

(2) Position step bumper assembly to the rear of

the vehicle.

(3) Align the support bracket and brace holes with

the holes in the frame rails. Install the bracket at

taching bolts and nuts. (4) Ensure that the bumper is correctly aligned

with the cargo box rear corner panels. Tighten to 68 N«m (50 ft. lbs.) torque.

(5) Connect the license plate lamp bulb sockets to

the lamps. Attach the wire harness to the bumper

with the clip retainers (Fig. 4). (6) Remove the support from the bumper.

LOCATOR

LAMP

CLIP WIRE

BUMPER SCREW J9123429

Fig. 4 License Plate Lamp Wire Harness Fig. 5 Rear Step Bumper

Page 790 of 1502

•

FRAME

AND

BUMPERS

13 - 3

SNOW

PLOW

NDEX

page

Power

Angling Cylinder Service

16

Power

Unit

. . 13

Service

Information

3

Snow

Plow Control Module

17

Snow

Plow Frame

16

SERVICE

INFORMATION

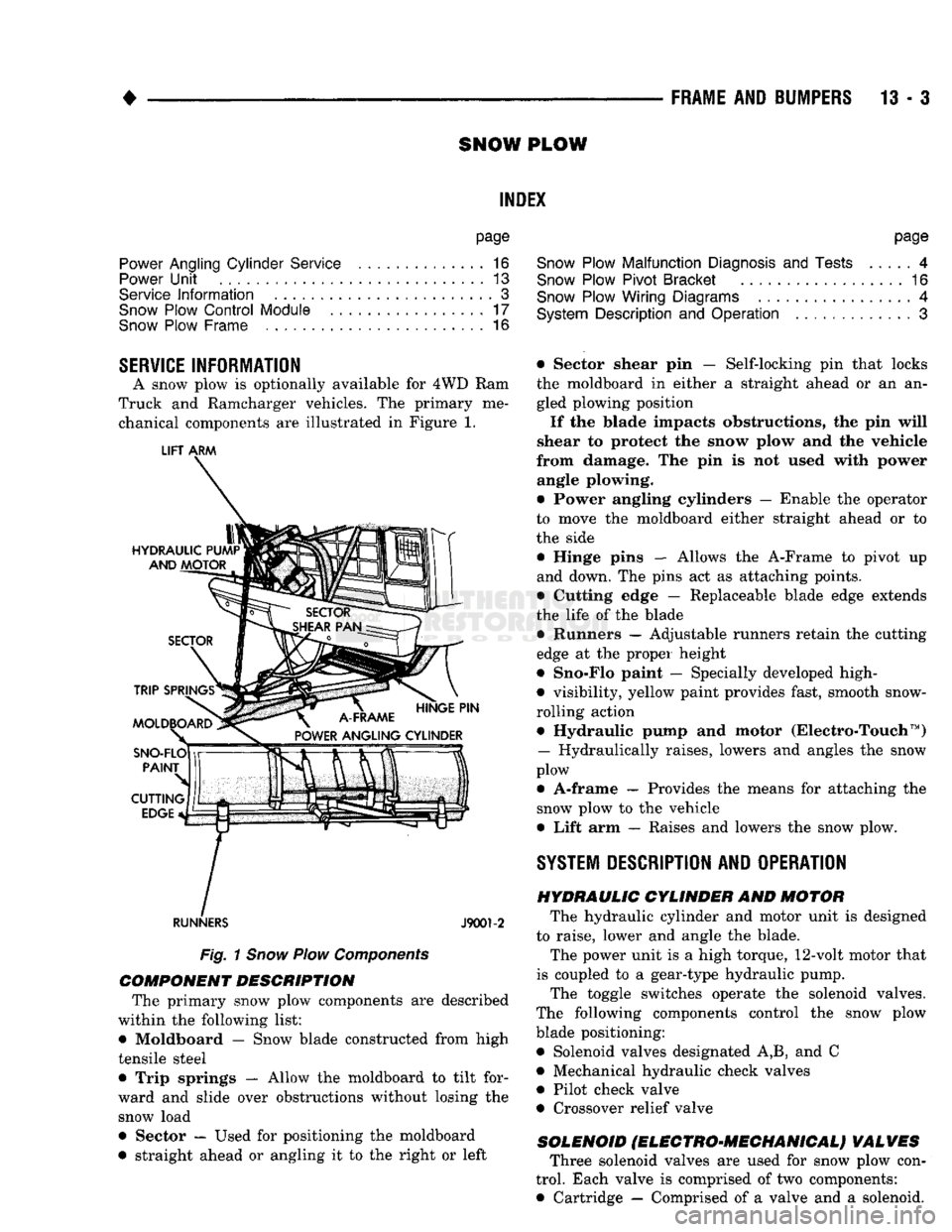

A snow plow is optionally available for 4WD Ram

Truck and Ramcharger vehicles. The primary me chanical components are illustrated in Figure 1.

LIFT

ARM

RUNNERS

J9001-2

Fig.

1

Snow

Plow

Components

COMPONENT DESCRIPTION

The primary snow plow components are described

within the following list:

• Moldboard — Snow blade constructed from high

tensile steel

• Trip springs — Allow the moldboard to tilt for

ward and slide over obstructions without losing the snow load

• Sector — Used for positioning the moldboard

• straight ahead or angling it to the right or left

page

Snow

Plow Malfunction

Diagnosis

and

Tests

4

Snow

Plow Pivot Bracket

16

Snow

Plow Wiring Diagrams

4

System

Description

and

Operation

3

• Sector shear pin — Self-locking pin that locks the moldboard in either a straight ahead or an an

gled plowing position

If the blade impacts obstructions, the pin will

shear to protect the snow plow and the vehicle

from damage. The pin is not used with power angle plowing.

• Power angling cylinders — Enable the operator

to move the moldboard either straight ahead or to

the side

• Hinge pins — Allows the A-Frame to pivot up

and down. The pins act as attaching points.

• Cutting edge — Replaceable blade edge extends

the life of the blade • Runners — Adjustable runners retain the cutting

edge at the proper height

• Sno-Flo paint — Specially developed high-

• visibility, yellow paint provides fast, smooth snow-

rolling action • Hydraulic pump and motor (Electro-Touch ™)

— Hydraulically raises, lowers and angles the snow

plow

• A-frame — Provides the means for attaching the snow plow to the vehicle

• Lift arm — Raises and lowers the snow plow.

SYSTEM

DESCRIPTION

AND OPERATION HYDRAULIC CYLINDER

AND

MOTOR

The hydraulic cylinder and motor unit is designed

to raise, lower and angle the blade. The power unit is a high torque, 12-volt motor that

is coupled to a gear-type hydraulic pump. The toggle switches operate the solenoid valves.

The following components control the snow plow blade positioning: • Solenoid valves designated A,B, and C

• Mechanical hydraulic check valves

• Pilot check valve

• Crossover relief valve

SOLENOID

fELEGTRO'MEGHANIGALj VALVES

Three solenoid valves are used for snow plow con

trol. Each valve is comprised of two components:

• Cartridge — Comprised of a valve and a solenoid.