DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 911 of 1502

14-92

FUEL

SYSTEM

• A broken injection pump timing mechanism spring

will cause the timing to be fully advanced resulting

in torque loss, a fuel knock and possible engine over

heating.

An improperly operating KSB (cold start) solenoid

will cause white smoke during engine warm-up. The

KSB solenoid is not serviceable.

A defective or non-adjustable fuel injection pump

can cause starting problems or prevent the engine

from revving up. It can also cause:

• Engine surge at idle • Rough idle (warm engine)

• Engine miss under load

• Low power

• Excessive fuel consumption

• Poor performance

• Low power

• Black smoke from the exhaust • Blue or white fog like exhaust

• Incorrect idle or maximum speed A worn fuel injection pump plunger can effect fuel

pressure and the amount of fuel injected. This results in reduced engine power. In most cases, if the injec

tion pump is delivering fuel from one outlet, it will deliver fuel from all outlets. If the internal plunger is defective, the fuel injection pump must be re

placed.

Engine power is also effected by the governor set

ting and performance. Do not attempt to adjust the governor. If the governor seals on the external adjustment screw are broken, the fuel rate may

be out of adjustment. The warranty of the injec tion pump and the engine may be void if the

seals have been tampered with or removed.

FUEL

INJECTORS

A leaking fuel injector can cause fuel knock, poor

performance, black smoke, poor fuel economy and

rough engine idle. If the fuel injector needle valve

does not operate properly, the engine may misfire and produce low power. A leak in the injection pump-to-injector high pres

sure fuel line can cause many of the same symptoms as a malfunctioning injector. Inspect for a leak in the

high pressure lines before checking for a malfunc

tioning fuel injector.

WARNING:

THE

INJECTION PUMP SUPPLIES HIGH

PRESSURE

FUEL

OF

APPROXIMATELY

59,000

KPA

(8,000

PSI) TO

EACH INDIVIDUAL INJECTOR

THROUGH THE HIGH

PRESSURE

LINES. FUEL UN

DER

THIS AMOUNT

OF

PRESSURE

CAN

PENE

TRATE THE SKIN AND CAUSE PERSONAL INJURY,

WEAR

SAFETY GOGGLES

AND

ADEQUATE PRO

TECTIVE CLOTHING. AVOID CONTACT

WITH

FUEL

SPRAY

WHEN BLEEDING HIGH

PRESSURE

FUEL

LINES.

WARNING:

DO NOT

BLEED

AIR

FROM

THE

FUEL

SYSTEM

OF A

HOT ENGINE.

DO

NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING

AIR

FROM THE FUEL SYSTEM.

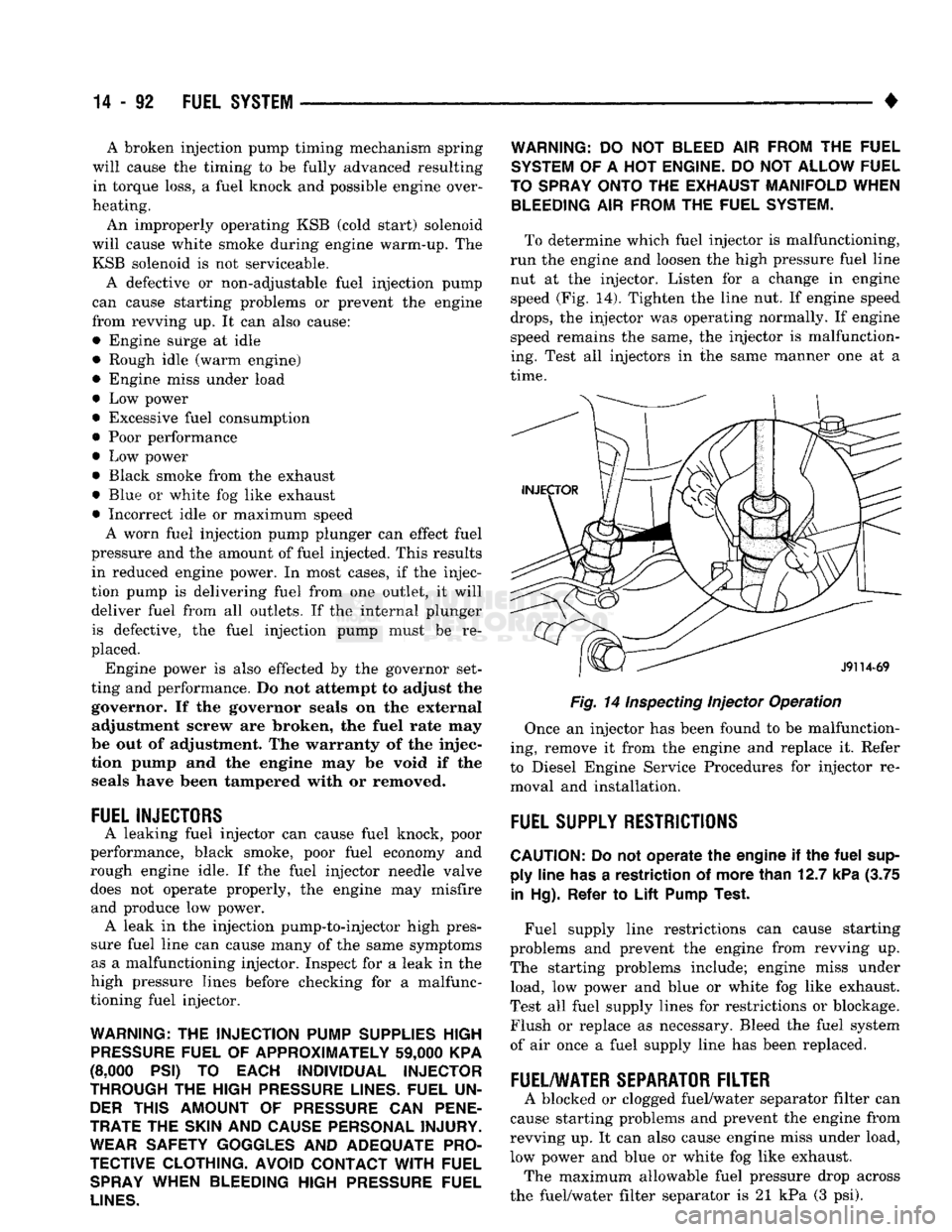

To determine which fuel injector is malfunctioning,

run the engine and loosen the high pressure fuel line nut at the injector. Listen for a change in engine

speed (Fig. 14). Tighten the line nut. If engine speed

drops,

the injector was operating normally. If engine

speed remains the same, the injector is malfunction

ing. Test all injectors in the same manner one at a

time.

Fig. 14

Inspecting

Injector Operation

Once an injector has been found to be malfunction

ing, remove it from the engine and replace it. Refer

to Diesel Engine Service Procedures for injector re moval and installation.

FUEL

SUPPLY

RESTRICTIONS

CAUTION:

Do not

operate

the

engine

if the

fuel

sup ply

line

has

a

restriction

of

more

than

12.7

kPa

(3.75

in

Hg).

Refer

to

Lift

Pump

Test.

Fuel supply line restrictions can cause starting

problems and prevent the engine from revving up.

The starting problems include; engine miss under load, low power and blue or white fog like exhaust.

Test all fuel supply lines for restrictions or blockage.

Flush or replace as necessary. Bleed the fuel system

of air once a fuel supply line has been replaced.

FUEL/WATER

SEPARATOR

FILTER

A blocked or clogged fuel/water separator filter can

cause starting problems and prevent the engine from

revving up. It can also cause engine miss under load,

low power and blue or white fog like exhaust. The maximum allowable fuel pressure drop across

the fuel/water filter separator is 21 kPa (3 psi).

Page 912 of 1502

•

FUEL SYSTEM

14-93 There is a drain at the bottom of the separator fil

ter (Fig. 13). Place a drain pan under the drain tube. With the engine not running, hold the drain open

until all water and contaminants have been removed and clean fuel exits the drain. Dispose of mixture in

drain pan according to applicable regulations.

If excess water gathers in separator/filter in a short

time,

the fuel tank must be removed, drained and cleaned.

HIGH

PRESSURE FUEL LINE RESTRICTIONS

High pressure fuel line leaks can cause starting

problems, poor engine performance and engine miss under load. Restricted high pressure lines can cause starting problems, poor engine performance, engine

miss under load and black smoke from exhaust.

WARNING:

USE

EXTREME

CAUTION

WHEN

IN

SPECTING

FOR HIGH

PRESSURE

FUEL

LEAKS.

IN

SPECT

FOR HIGH

PRESSURE

FUEL

LEAKS

WITH

A

SHEET

OF

CARDBOARD.

HIGH

FUEL

INJECTION

PRESSURE

CAN

CAUSE

PERSONAL

INJURY

IF

CONTACT

IS

MADE

WITH

THE

SKIN.

Start the engine. Move the cardboard over the high

pressure fuel lines and check for fuel spray onto the cardboard. If a high pressure line connection is leak

ing, bleed the system and tighten the connection. Re

fer to the 5.9L Diesel Service Procedures section for air bleeding procedures. Replace damaged, restricted

or leaking high pressure fuel lines with the correct replacement line.

CAUTION:

The

high pressure

fuel

lines must

be

clamped securely

in

place

in the

holders.

The

lines cannot contact each other

or

other components.

Do

not

attempt

to

weld high pressure

fuel

lines

or to

repair lines

that

are

damaged. Only

use the

recom

mended lines when replacement

of

high pressure

fuel

line

is

necessary.

KSB

SOLENOID

The KSB solenoid will click when it is energized

and de-energized. If the solenoid does not click when 12 volts is sup

plied to it, replace the solenoid.

MECHANICAL

LIFT

PUMP

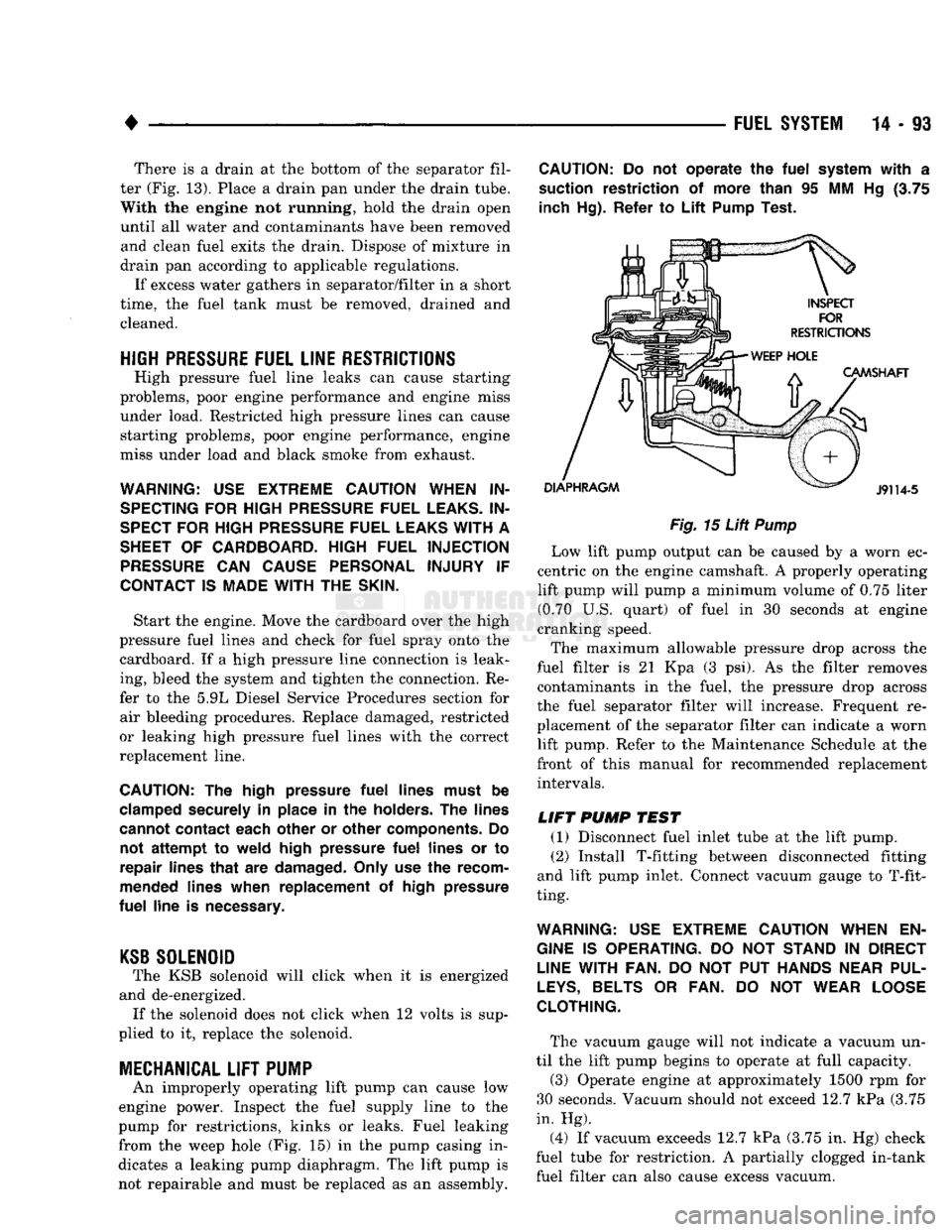

An improperly operating lift pump can cause low

engine power. Inspect the fuel supply line to the

pump for restrictions, kinks or leaks. Fuel leaking

from the weep hole (Fig. 15) in the pump casing in

dicates a leaking pump diaphragm. The lift pump is not repairable and must be replaced as an assembly.

CAUTION:

Do not

operate

the

fuel

system

with

a

suction restriction

of

more than

95 MM Hg (3.75

inch Hg). Refer

to

Lift

Pump Test.

Fig.

15

Lift

Pump

Low lift pump output can be caused by a worn ec

centric on the engine camshaft. A properly operating lift pump will pump a minimum volume of 0.75 liter (0.70 U.S. quart) of fuel in 30 seconds at engine

cranking speed.

The maximum allowable pressure drop across the

fuel filter is 21 Kpa (3 psi). As the filter removes contaminants in the fuel, the pressure drop across

the fuel separator filter will increase. Frequent re

placement of the separator filter can indicate a worn lift pump. Refer to the Maintenance Schedule at the

front of this manual for recommended replacement intervals.

LIFT

PUMP

TEST

(1) Disconnect fuel inlet tube at the lift pump. (2) Install T-fitting between disconnected fitting

and lift pump inlet. Connect vacuum gauge to T-fit

ting.

WARNING:

USE

EXTREME

CAUTION

WHEN

EN

GINE

IS

OPERATING.

DO NOT

STAND

IN

DIRECT

LINE

WITH FAN.

DO NOT PUT

HANDS

NEAR

PUL

LEYS,

BELTS

OR FAN. DO NOT

WEAR

LOOSE

CLOTHING.

The vacuum gauge will not indicate a vacuum un

til the lift pump begins to operate at full capacity.

(3) Operate engine at approximately 1500 rpm for

30 seconds. Vacuum should not exceed 12.7 kPa (3.75

in. Hg).

(4) If vacuum exceeds 12.7 kPa (3.75 in. Hg) check

fuel tube for restriction. A partially clogged in-tank fuel filter can also cause excess vacuum.

Page 913 of 1502

14

- 94

FUEL

SYSTEM

•

THROTTLE POSITION

SENSOR

TEST

CAUTION;

Before checking

the

TPS,

the

throttle

linkage must

be

checked

for

correct

adjustment.

The

throttle

lever must

contact

the low idle

speed screw.

The

throttle

lever must reach breakover when

the

throttle

is

wide

open. Refer

to the

Accelerator Pedal and

Throttle

Cable section

of

Group

14,

Fuel Systems.

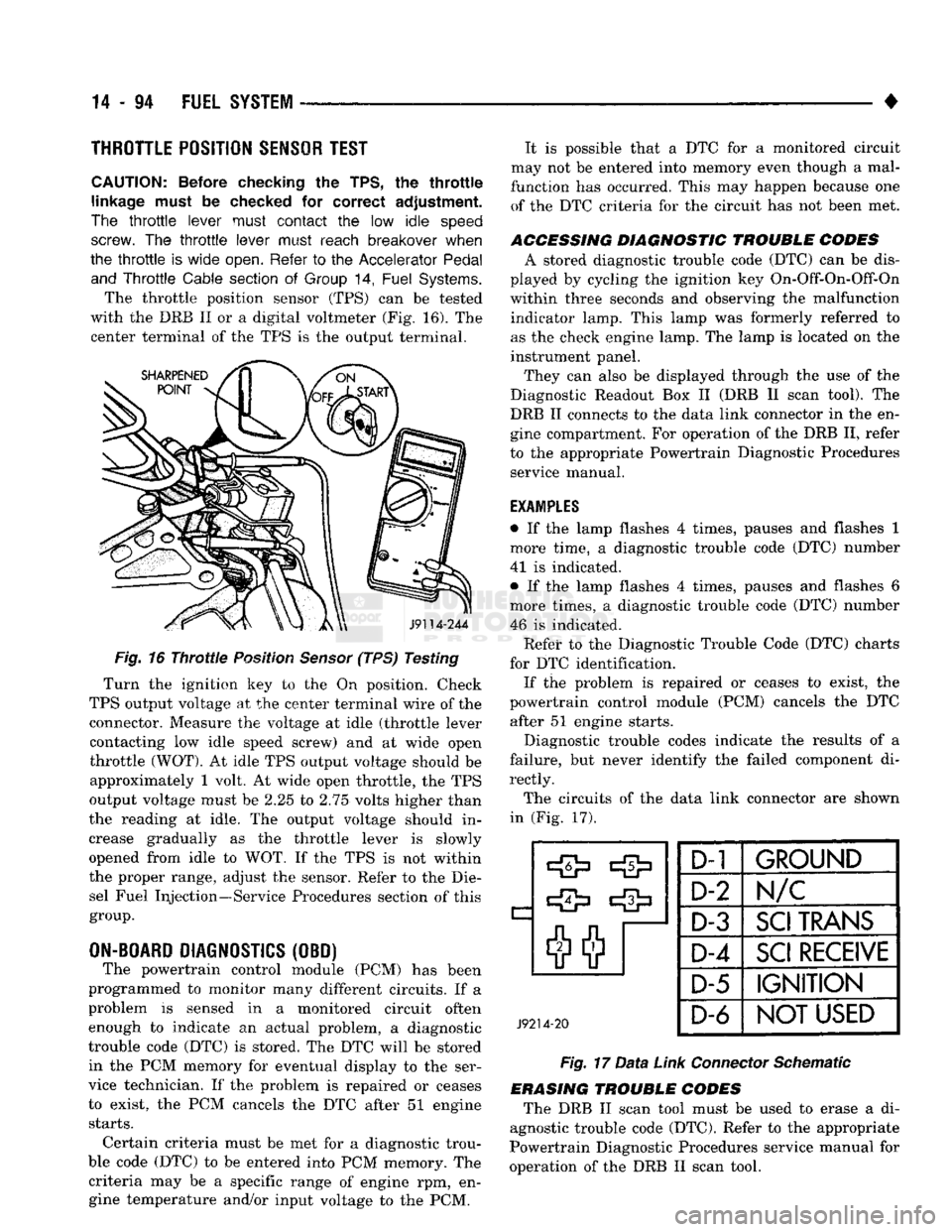

The throttle position sensor (TPS) can be tested

with the DRB II or a digital voltmeter (Fig. 16). The center terminal of the TPS is the output terminal.

J9114-244

Fig.

16

Throttle

Position

Sensor

(TPS) Testing

Turn the ignition key to the On position. Check

TPS output voltage at the center terminal wire of the connector. Measure the voltage at idle (throttle lever contacting low idle speed screw) and at wide open

throttle

(WOT).

At idle TPS output voltage should be approximately 1 volt. At wide open throttle, the TPS

output voltage must be 2.25 to 2.75 volts higher than

the reading at idle. The output voltage should in

crease gradually as the throttle lever is slowly

opened from idle to WOT. If the TPS is not within

the proper range, adjust the sensor. Refer to the Die sel Fuel Injection—Service Procedures section of this

group.

ON-BOARD

DIAGNOSTICS

(OBD) The powertrain control module (PCM) has been

programmed to monitor many different circuits. If a

problem is sensed in a monitored circuit often enough to indicate an actual problem, a diagnostic

trouble code (DTC) is stored. The DTC will be stored in the PCM memory for eventual display to the ser

vice technician. If the problem is repaired or ceases

to exist, the PCM cancels the DTC after 51 engine

starts.

Certain criteria must be met for a diagnostic trou

ble code (DTC) to be entered into PCM memory. The criteria may be a specific range of engine rpm, engine temperature and/or input voltage to the PCM. It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal

function has occurred. This may happen because one of the DTC criteria for the circuit has not been met.

ACCESSING DIAGNOSTIC TROUBLE CODES A stored diagnostic trouble code (DTC) can be dis

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction indicator lamp. This lamp was formerly referred to

as the check engine lamp. The lamp is located on the

instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box II (DRB II scan tool). The

DRB II connects to the data link connector in the en

gine compartment. For operation of the DRB II, refer

to the appropriate Powertrain Diagnostic Procedures service manual.

EXAMPLES

• If the lamp flashes 4 times, pauses and flashes 1

more time, a diagnostic trouble code (DTC) number

41 is indicated.

• If the lamp flashes 4 times, pauses and flashes 6

more times, a diagnostic trouble code (DTC) number 46 is indicated. Refet* to the Diagnostic Trouble Code (DTC) charts

for DTC identification. If the problem is repaired or ceases to exist, the

powertrain control module (PCM) cancels the DTC after 51 engine starts.

Diagnostic trouble codes indicate the results of a

failure, but never identify the failed component di

rectly.

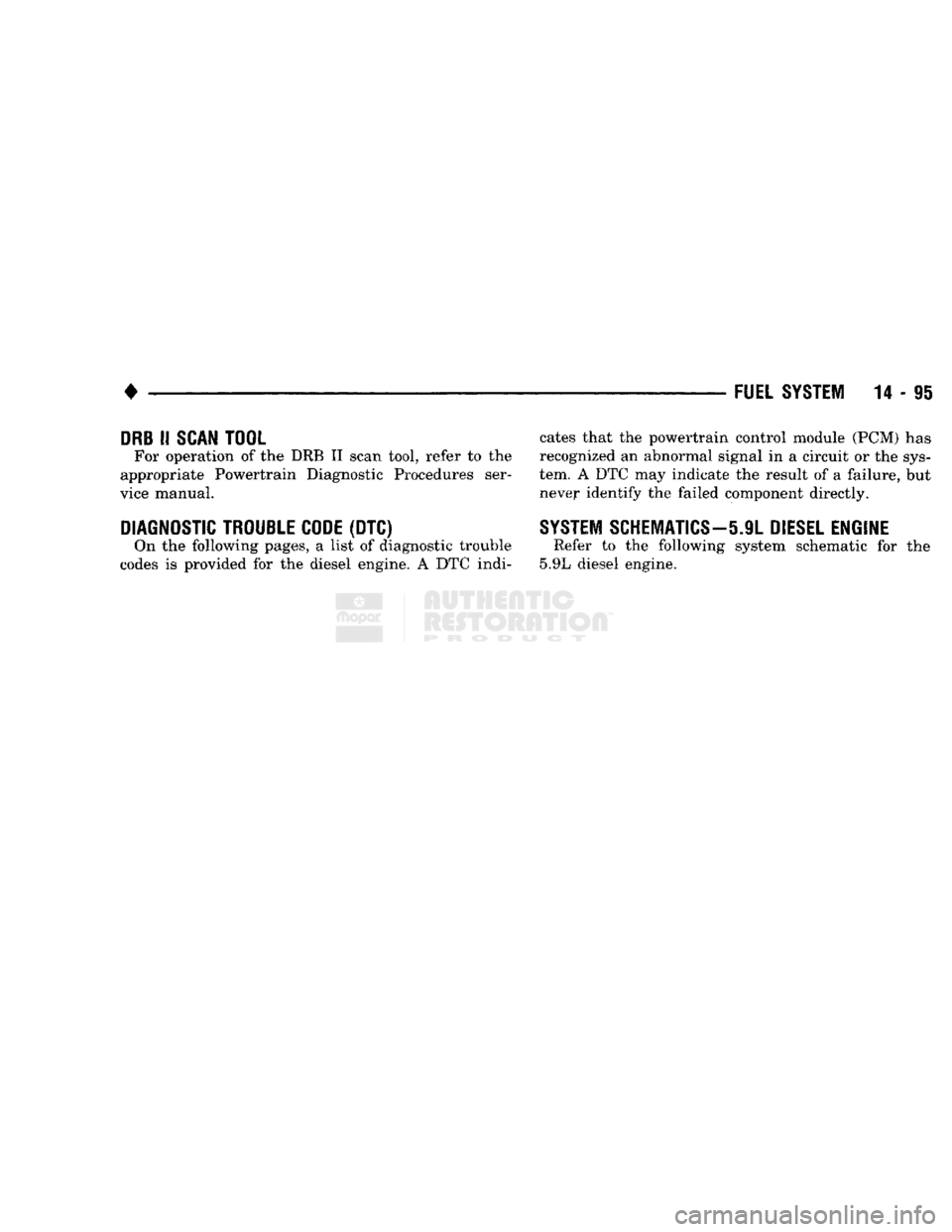

The circuits of the data link connector are shown

in (Fig. 17).

J9214-20

D-1

1

GROUND

D-2

N/C

D-3

SCI

TRANS

D-4

SCI

RECEIVE

D-5 IGNITION

D-6

NOT USED

Fig.

17

Data

Link

Connector

Schematic

ERASING TROUBLE CODES The DRB II scan tool must be used to erase a di

agnostic trouble code (DTC). Refer to the appropriate

Powertrain Diagnostic Procedures service manual for

operation of the DRB II scan tool.

Page 914 of 1502

•

FUEL SYSTEM

14 - 95

DRB

II

SCAN

TOOL

For operation

of the DRB II

scan tool, refer

to the

appropriate Powertrain Diagnostic Procedures ser

vice manual.

DIAGNOSTIC TROUBLE CODE (DTC)

On

the

following pages,

a

list

of

diagnostic trouble

codes

is

provided

for the

diesel engine.

A DTC

indi cates that

the

powertrain control module

(PCM) has

recognized

an

abnormal signal

in a

circuit

or the

sys

tem.

A DTC may

indicate

the

result

of a

failure,

but

never identify

the

failed component directly.

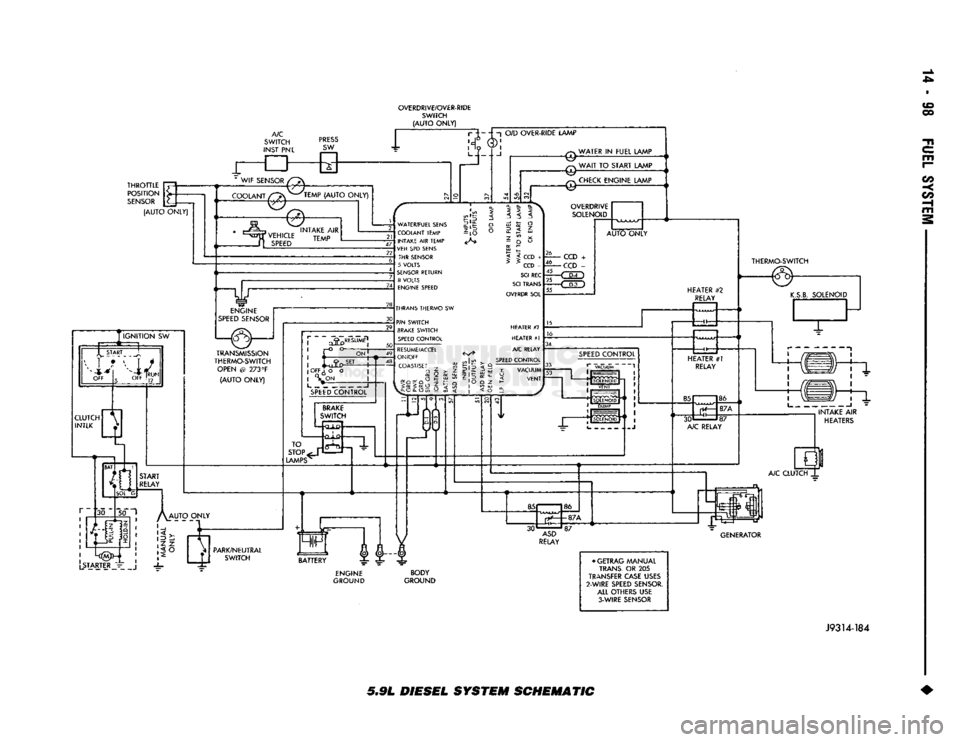

SYSTEM SCHEMATICS—5.9L DIESEL ENGINE

Refer

to the

following system schematic

for the

5.9L diesel engine.

Page 915 of 1502

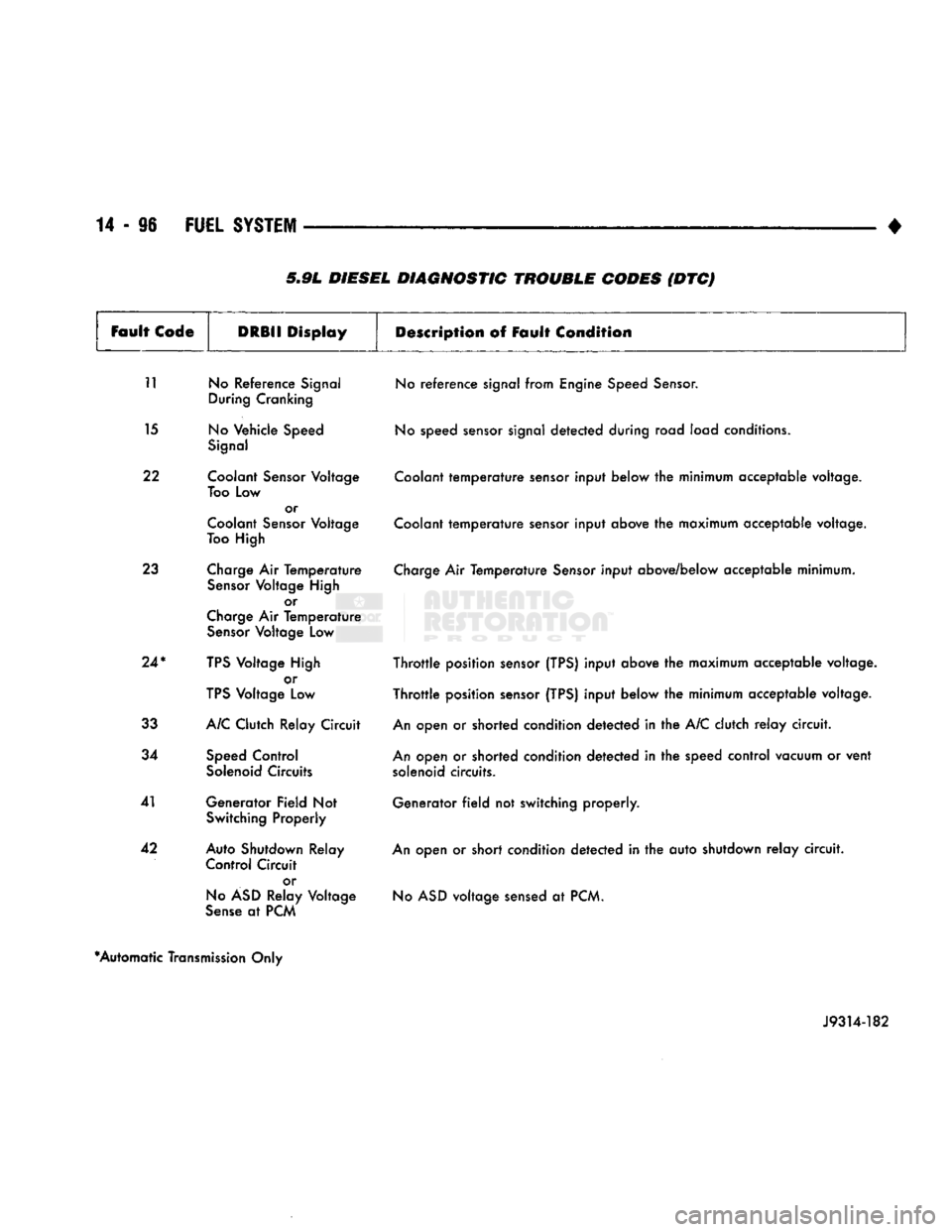

5.9L DIESEL DIAGNOSTIC TROUBLE CODES (DTC)

Fault

Code

DRBII

Display

Description

of Fault

Condition

11 No Reference Signal During Cranking

15 No Vehicle Speed Signal

22 Coolant Sensor Voltage Too Low or

Coolant Sensor Voltage

Too High

23 Charge Air Temperature Sensor Voltage High or

Charge Air Temperature Sensor Voltage Low

24*

TPS Voltage High or

TPS Voltage Low

33 A/C Clutch Relay Circuit

34 Speed Control Solenoid Circuits

41 Generator Field Not Switching Properly

42 Auto Shutdown Relay Control Circuit

or

No ASD Relay Voltage

Sense at PCM No reference signal from Engine Speed Sensor.

No speed sensor signal detected during road load conditions.

Coolant temperature sensor input below the minimum acceptable voltage.

Coolant temperature sensor input above the maximum acceptable voltage.

Charge Air Temperature Sensor input above/below acceptable minimum.

Throttle position sensor (TPS) input above the maximum acceptable voltage.

Throttle position sensor (TPS) input below the minimum acceptable voltage.

An open or shorted condition detected in the A/C clutch relay circuit.

An open or shorted condition detected in the speed control vacuum or vent solenoid circuits.

Generator field not switching properly.

An open or short condition detected in the auto shutdown relay circuit. No ASD voltage sensed at PCM.

*Automatic Transmission Only

J9314-182

Page 916 of 1502

FUEL

SYSTEM

14 - 97

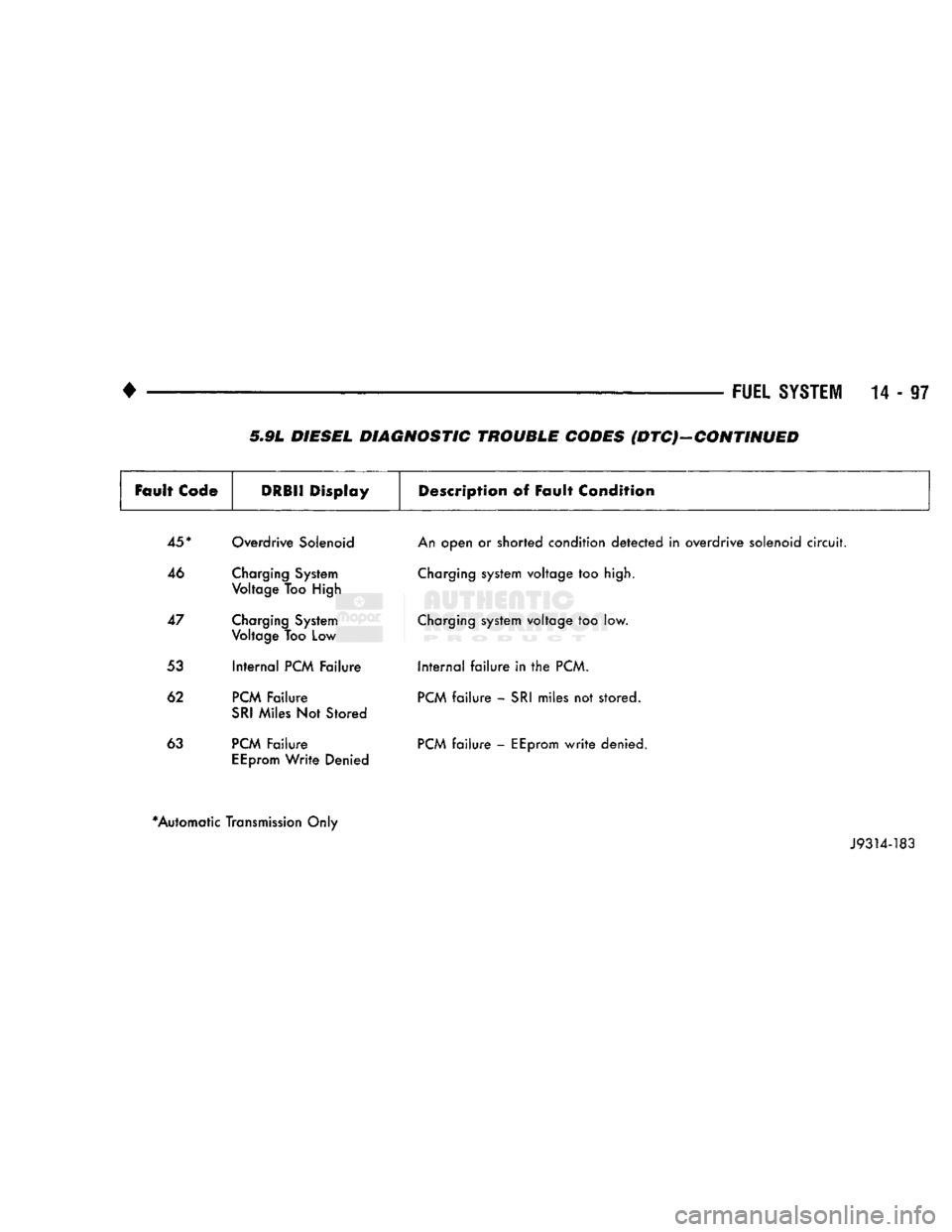

5„9L DIESEL DIAGNOSTIC TROUBLE CODES {DTC}-CONTINUED

Fault

Code

DRBII Display

Description

of Fault Condition

45*

Overdrive Solenoid

46 Charging System Voltage Too High

47 Charging System Voltage Too Low

53 Internal PCM Failure

62 PCM Failure SRI Miles Not Stored

63 PCM Failure EEprom Write Denied An open or shorted condition detected in overdrive solenoid circuit.

Charging system voltage too high.

Charging system voltage too low. Internal failure in the PCM.

PCM failure - SRI miles not stored.

PCM failure - EEprom write denied.

*Automatic Transmission Only J9314-183

Page 917 of 1502

OVERDRIVE/OVER-RIDE

SWITCH

(AUTO

ONLY) CO

oo

c/3 -<

LSTARJERJ^

_ j

J9314-184

5.91.

DIESEL SYSTEM SCHEMATIC •

Page 918 of 1502

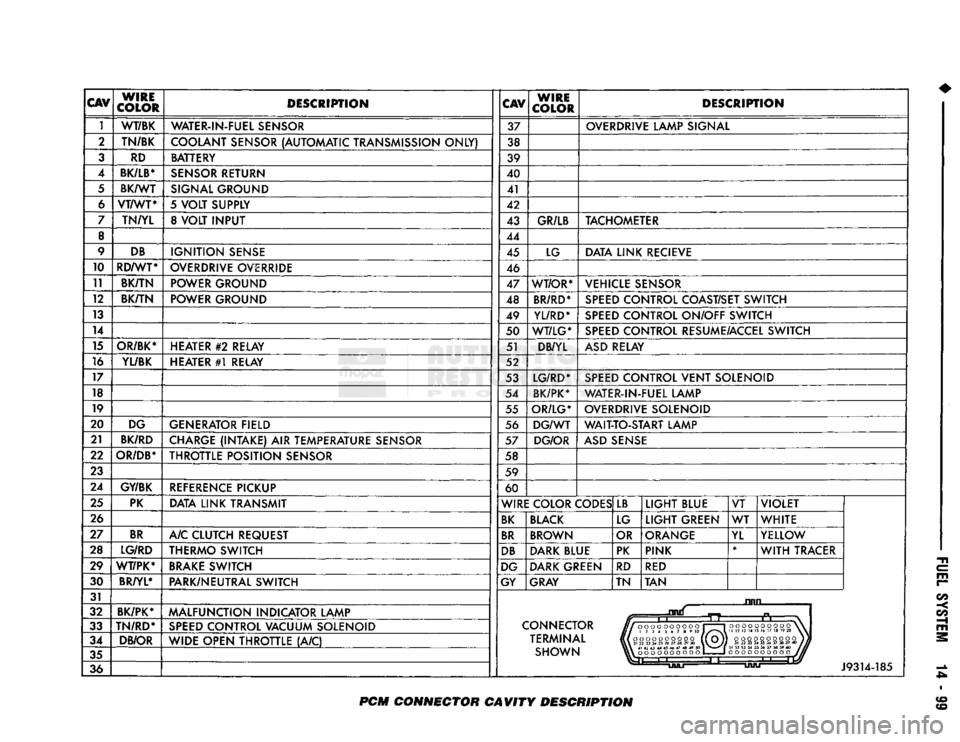

CAV

WIRE

COLOR DESCRIPTION

CAV

WIRE

COLOR DESCRIPTION

1 WT/BK

WATER-IN-FUEL SENSOR 37 OVERDRIVE LAMP SIGNAL

2 TN/BK

COOLANT SENSOR (AUTOMATIC TRANSMISSION ONLY) 38

3 RD BATTERY

39

4

BK/LB*

SENSOR RETURN 40

5 BK/WT

SIGNAL GROUND 41

6 VT/WT*

5 VOLT SUPPLY 42

7 TN/YL 8 VOLT INPUT 43 GR/LB TACHOMETER

8 44

9 DB

IGNITION SENSE 45 LG DATA LINK RECIEVE

10 RD/WT*

OVERDRIVE OVERRIDE 46

11 BK/TN POWER GROUND

47 WT/OR* VEHICLE SENSOR

12 BK/TN

POWER GROUND 48 BR/RD* SPEED CONTROL COAST/SET SWITCH

13 49 YL/RD* SPEED CONTROL ON/OFF SWITCH

14 50 WT/LG* SPEED CONTROL RESUME/ACCEL SWITCH

15 OR/BK* HEATER

#2

RELAY 51 DB/YL ASD RELAY

16 YL/BK HEATER #1 RELAY 52

17 53 LG/RD* SPEED CONTROL VENT SOLENOID

18 54 BK/PK* WATER-IN-FUEL LAMP

19 55 OR/LG* OVERDRIVE SOLENOID

20 DG GENERATOR FIELD 56 DG/WT WAIT-TO-START LAMP

21 BK/RD

CHARGE (INTAKE) AIR TEMPERATURE SENSOR 57 DG/OR ASD SENSE

22

OR/DB*

THROTTLE POSITION SENSOR 58

23 59

24 GY/BK

REFERENCE PICKUP 60

25 PK

DATA LINK TRANSMIT WIRE COLOR CODES LB

LIGHT BLUE VT VIOLET

26 BK BLACK LG LIGHT GREEN WT

WHITE

27 BR

A/C CLUTCH REQUEST BR BROWN OR ORANGE

YL YELLOW

28 LG/RD THERMO SWITCH DB DARK BLUE PK PINK *

WITH TRACER

29 WT/PK* BRAKE SWITCH DG DARK GREEN

RD RED

30 BR/YL*

PARK/NEUTRAL SWITCH GY GRAY TN TAN

31 ruin

32 BK/PK*

MALFUNCTION INDICATOR LAMP

n

33 TN/RD*

SPEED CONTROL VACUUM SOLENOID CONNECTOR

J//000OOOOOOO

1 1

HI

173456789

10 J/^"*\

Hi

oooooooooo (1 Oj]

VlX

21

22

23

24

25

26

27

28

29

30

\V~V//

oooooooooo

\

II

12 13

14 15

16 17 18

19 20

\

34 DB/OR

WIDE OPEN THROTTLE (A/C) TERMINAL

J//000OOOOOOO

1 1

HI

173456789

10 J/^"*\

Hi

oooooooooo (1 Oj]

VlX

21

22

23

24

25

26

27

28

29

30

\V~V//

oooooooooo)}

31

32 33 34 35 36 37 38 39 40

1JU

35 SHOWN \\\

41 42 43 44 45 46 47 48 49

SO

1

^m^^

|

oooooooooo

1

1

oooooooooo

J//

36

Li

J9314-185

PCM

CONNECTOR CAVITY DESCRIPTION

Page 919 of 1502

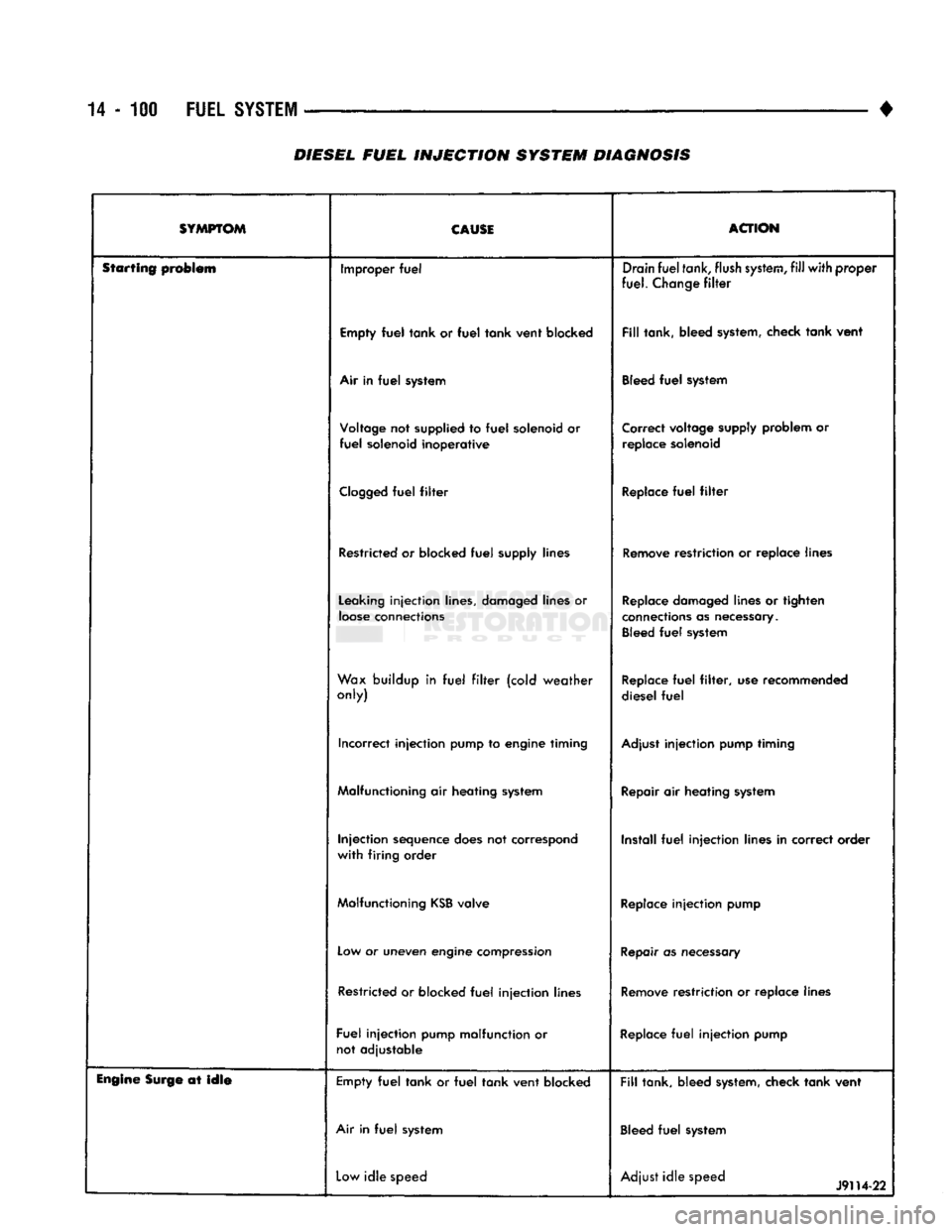

14-100

FUEL

SYSTEM

•

DIESEL

FUEL

INJECTION

SYSTEM DIAGNOSIS

SYMPTOM CAUSE

ACTION

Starting problem Improper

fuel

Drain

fuel

tank,

flush

system,

fill

with

proper

fuel.

Change

filter

Empty

fuel

tank

or

fuel

tank

vent

blocked

Fill

tank, bleed system, check

tank

vent

Air in

fuel

system Bleed

fuel

system

Voltage not supplied to

fuel

solenoid or

fuel

solenoid

inoperative

Correct voltage supply problem or

replace solenoid

Clogged

fuel

filter

Replace

fuel

filter

Restricted or blocked

fuel

supply lines Remove restriction or replace lines

Leaking

injection

lines, damaged lines or

loose

connections Replace damaged lines or tighten

connections as necessary. Bleed

fuel

system

Wax buildup in

fuel

filter

(cold

weather

only) Replace

fuel

filter,

use recommended

diesel

fuel

Incorrect

injection

pump to engine timing Adjust

injection

pump timing

Malfunctioning air heating system Repair air heating system

Injection

sequence does not correspond

with

firing

order Install

fuel

injection

lines in correct order

Malfunctioning

KSB

valve Replace

injection

pump

Low or uneven engine compression Repair as necessary

Restricted or blocked

fuel

injection

lines Remove restriction or replace lines

Fuel

injection

pump malfunction or not adjustable Replace

fuel

injection

pump

Engine

Surge at

idle

Empty

fuel

tank

or

fuel

tank

vent

blocked

Fill

tank, bleed system, check

tank

vent

Air in

fuel

system Bleed

fuel

system

Low

idle

speed Adjust

idle

speed

J9H4-22

Page 920 of 1502

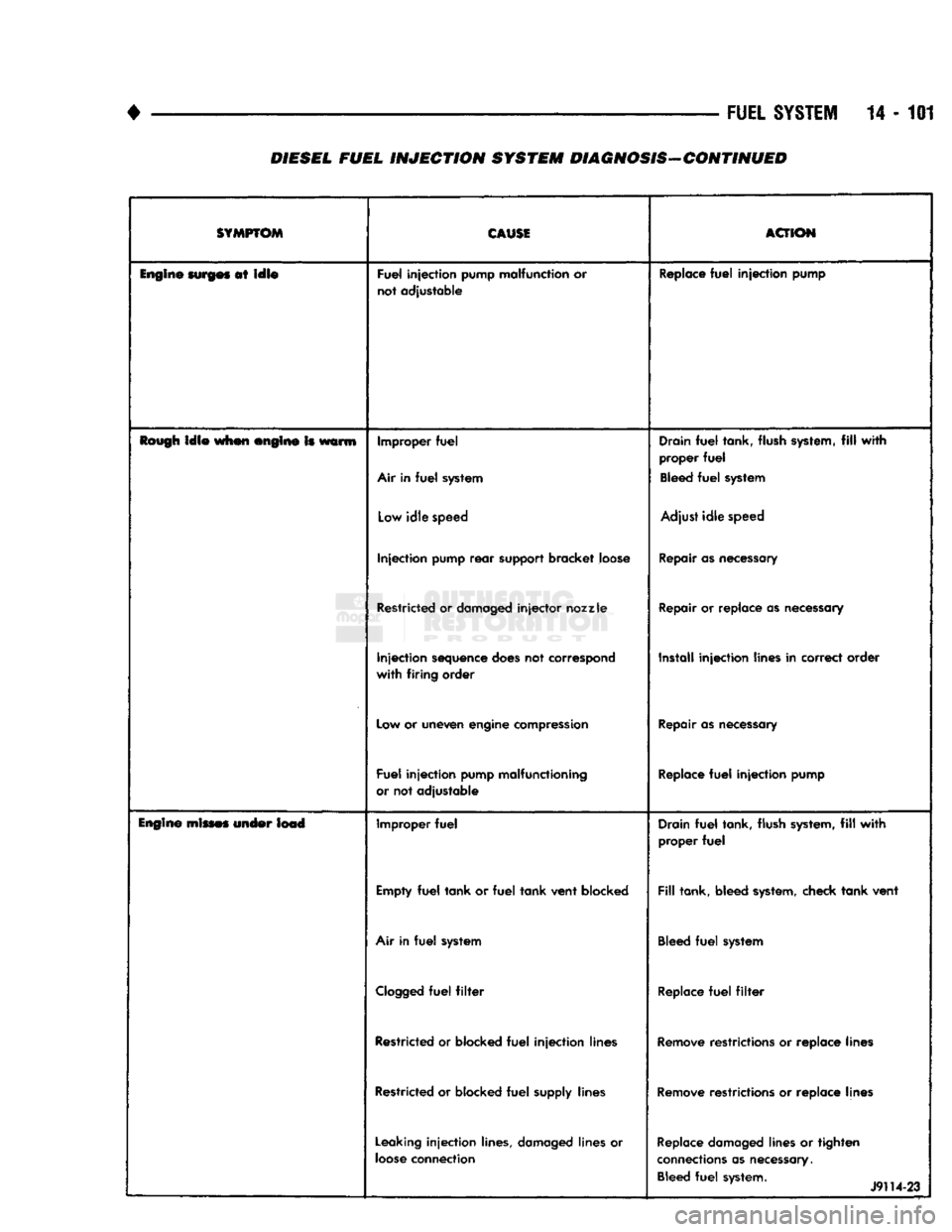

•

FUEL

SYSTEM

14 - 101

DIESEL FUEL

INJECTION

SYSTEM DIAGNOSIS-CONTINUED

SYMPTOM

CAUSE

ACTION

Engine

surges

at

idle

Fuel

injection

pump malfunction or

not adjustable Replace

fuel

injection

pump

Rough

idle

when engine Is warm Improper

fuel

Air in

fuel

system Drain

fuel

tank, flush system,

fill

with

proper

fuel

Bleed

fuel

system

Low

idle

speed Adjust

idle

speed

Injection

pump

rear

support bracket loose Repair as necessary

Restricted or damaged

injector

nozzle

Repair or replace as necessary

Injection

sequence does not correspond

with

firing

order Install

injection

lines in correct order

Low or uneven engine compression Repair as necessary

Fuel

injection

pump malfunctioning

or not adjustable Replace

fuel

injection

pump

Engine

mines under lead Improper

fuel

Drain

fuel

tank, flush system,

fill

with

proper

fuel

Empty

fuel

tank

or

fuel

tank

vent

blocked

Fill

tank, bleed system, check

tank

vent

Air in

fuel

system Bleed

fuel

system

Clogged

fuel

filter

Replace

fuel

filter

Restricted or blocked

fuel

injection

lines Remove restrictions or replace lines

Restricted or blocked

fuel

supply lines Remove restrictions or replace lines

Leaking

injection

lines, damaged lines or

loose

connection Replace damaged lines or

tighten

connections as necessary. Bleed

fuel

system. 1

J9114-23