torque FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 244 of 413

04-05-03

Specifications

04-05-03

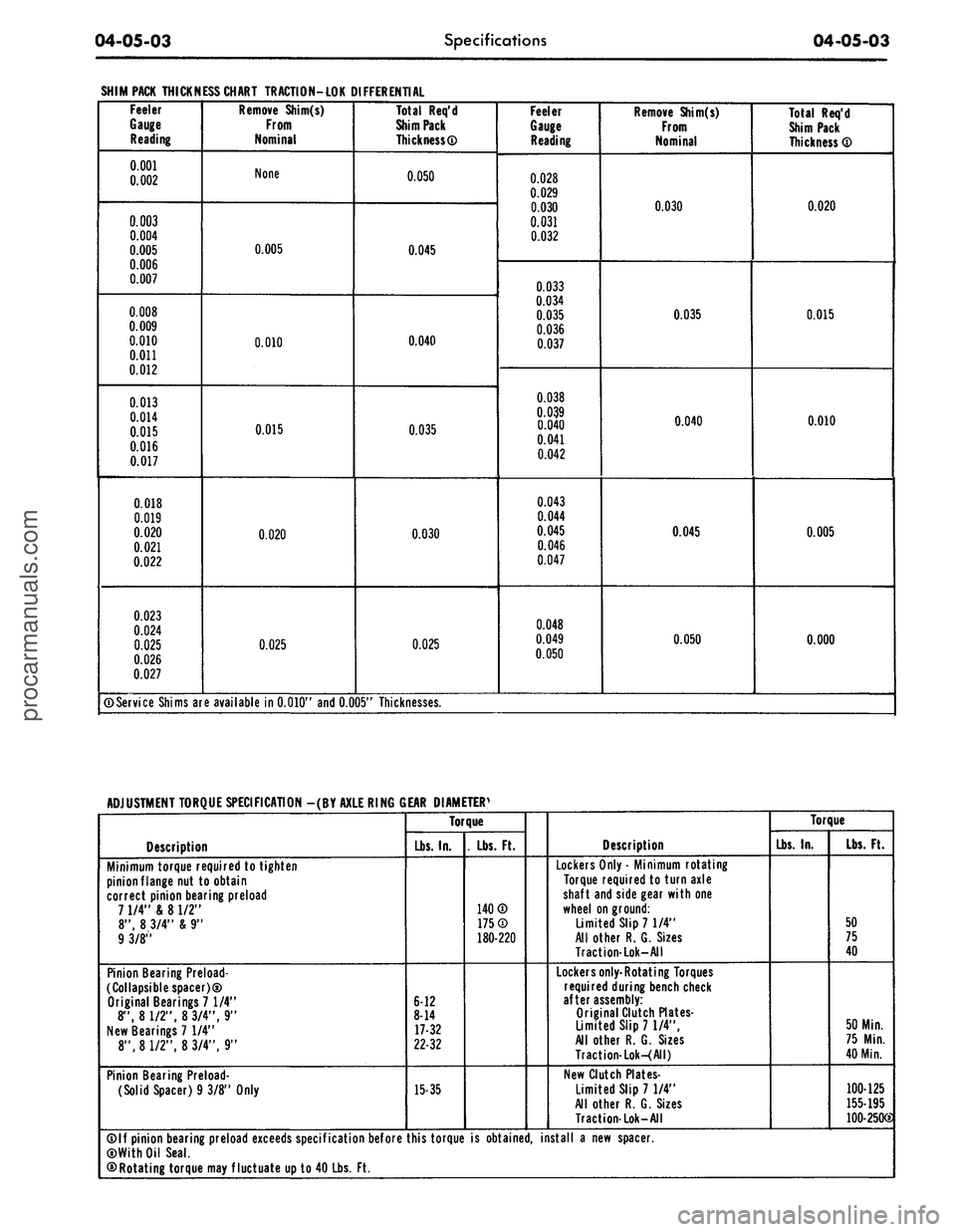

SHIM PACK THICKNESS CHART TRACTION-LOK DIFFERENTIAL

Feeler

Gauge

Reading

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0.008

0.009

0.010

0.011

0.012

0.013

0.014

0.015

0.016

0.017

0.018

0.019

0.020

0.021

0.022

0.023

0.024

0.025

0.026

0.027

Remove Shim(s)

From

Nominal

None

0.005

0.010

0.015

0.020

0.025

Total Req'd

Shim Pack

Thickness®

0.050

0.045

0.040

0.035

0.030

0.025

Feeler

Gauge

Reading

0.028

0.029

0.030

0.031

0.032

0.033

0.034

0.035

0.036

0.037

0.038

0.039

0.040

0.041

0.042

0.043

0.044

0.045

0.046

0.047

0.048

0.049

0.050

Remove Shim(s)

From

Nominal

0.030

0.035

0.040

0.045

0.050

Total Req'd

Shim Pack

Thickness ®

0.020

0.015

0.010

0.005

0.000

©Service Shims are available in 0.010" and 0.005" Thicknesses.

ADJUSTMENT TORQUE SPECIFICATION -(BY AXLE RING GEAR DIAMETERS

Description

Minimum torque required to tighten

pinion flange nut to obtain

correct pinion bearing preload

7 1/4" & 8 1/2"

8", 8 3/4" & 9"

9 3/8"

Pinion Bearing Preload-

collapsible spacer)®

Original Bearings 7 1/4"

8", 8 1/2", 8 3/4", 9"

New Bearings 7 1/4"

8", 8 1/2", 8 3/4", 9"

Pinion Bearing Preload-

(Solid Spacer) 9 3/8" Only

Torque

Lbs.

In.

6-12

8-14

17-32

22-32

15-35

. Lbs. Ft.

140®

175®

180-220

Description

Lockers Only • Minimum rotating

Torque required to turn axle

shaft and side gear with one

wheel on ground:

Limited Slip 7 1/4"

All other R. G. Sizes

Traction-Lok-All

Lockers only-Rotating Torques

required during bench check

after assembly:

Original Clutch Plates-

Limited Slip 71/4",

All other R. G. Sizes

Traction-Lok-(All)

New Clutch Plates-

Limited Slip 7 1/4"

All other R. G. Sizes

Traction-Lok-All

Torque

Lbs.

In.

Lbs.

Ft.

50

75

40

50 Min.

75 Min.

40 Min.

100-125

155-195

100-250G

©If pinion bearing preload exceeds specification before this torque is obtained, install a new spacer.

©With Oil Seal.

©Rotating torque may fluctuate up to 40 Lbs. Ft.procarmanuals.com

Page 245 of 413

04-05-04

Specifications

04-05-04

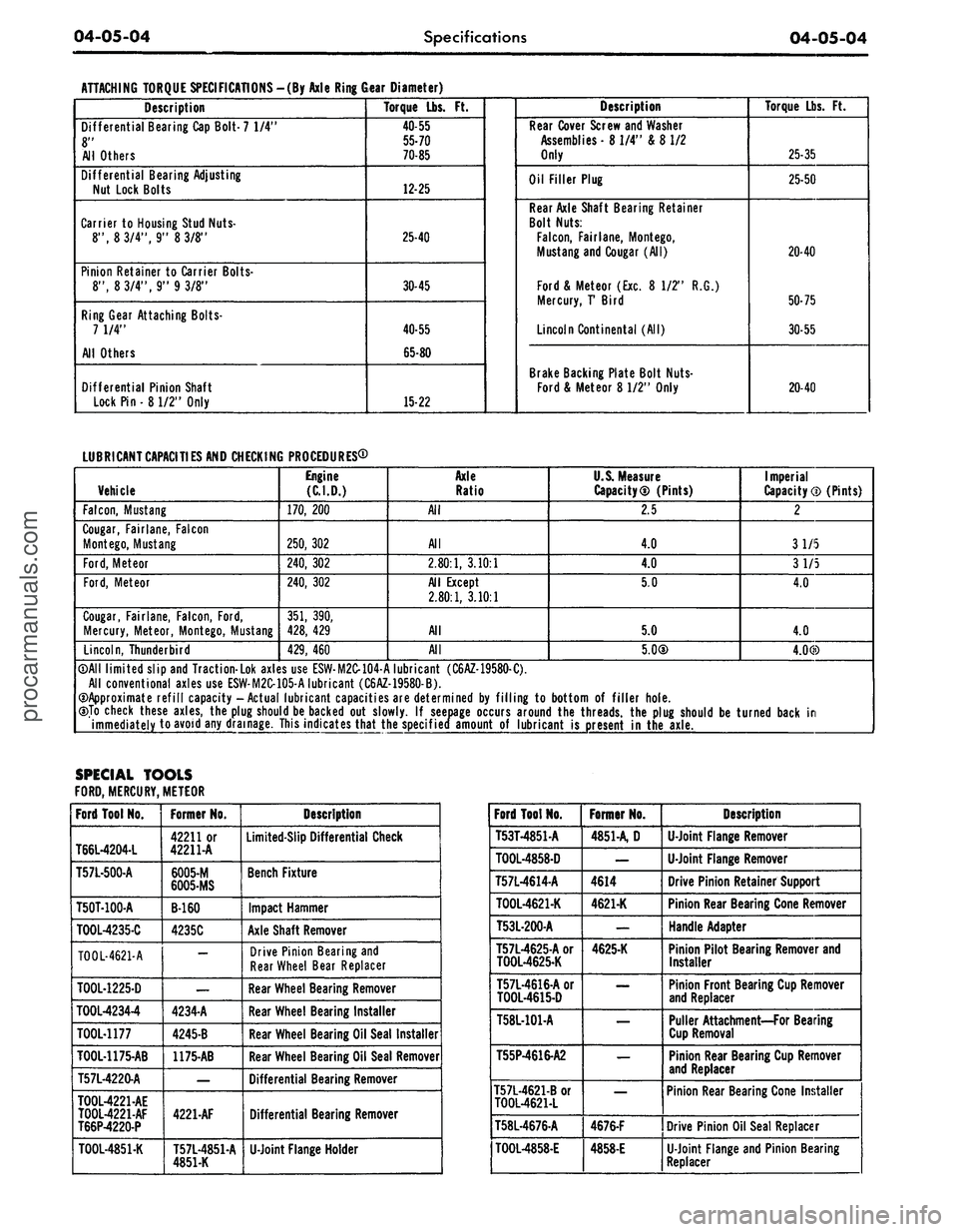

ATTACHING TORQUE SPECIFICATIONS -(By Axle Ring Gear Diameter)

Description

Differential Bearing Cap Bolt- 7 1/4"

8"

All Others

Differential Bearing Adjusting

Nut Lock Bolts

Carrier

to

Housing Stud Nuts-

8", 8 3/4", 9" 8 3/8"

Pinion Retainer

to

Carrier Bolts-

8", 8 3/4", 9" 9 3/8"

Ring Gear Attaching Bolts-

7 1/4"

All Others

Differential Pinion Shaft

Lock Pin

•

8 1/2" Only

Torque Lbs.

Ft.

40-55

55-70

70-85

12-25

25-40

30-45

40-55

65-80

15-22

Description

Rear Cover Screw and Washer

Assemblies

-8

1/4" &

8

1/2

Only

Oil Filler Plug

Rear Axle Shaft Bearing Retainer

Bolt Nuts:

Falcon,

Fairlane, Montego,

Mustang and Cougar (All)

Ford & Meteor (Exc.

8 1/2" R.G.)

Mercury,

T

Bird

Lincoln Continental (All)

Brake Backing Plate Bolt Nuts-

Ford & Meteor

8

1/2" Only

Torque Lbs.

Ft.

25-35

25-50

20-40

50-75

30-55

20-40

LUBRICANT

CAPACITIES

AND CHECKING PROCEDURES®

Vehicle

Falcon,

Mustang

Cougar, Fairlane, Falcon

Montego, Mustang

Ford,

Meteor

Ford,

Meteor

Cougar, Fairlane, Falcon, Ford,

Mercury, Meteor, Montego, Mustang

Lincoln,

Thunderbird

Engine

(C.I.D.)

170,

200

250,

302

240,

302

240,

302

351,

390,

428,

429

429,

460

Axle

Ratio

All

All

2.80:1,

3.10:1

All Except

2.80:1,

3.10:1

All

All

U.S. Measure

Capacity® (Pints)

2.5

4.0

4.0

5.0

5.0

5.0©

Imperial

Capacity

CD

(Pints)

2

31/5

3 1/5

4.0

4.0

4.0©

©All limited slip and Traction-Lok axles use ESW-M2C-104-A lubricant (C6AZ-19580-C).

All conventional axles use ESW-M2C-105-A lubricant (C6AZ-19580-B).

©Approximate refill capacity-Actual lubricant capacities are determined

by

filling

to

bottom

of

filler hole.

©To check these axles, the plug should be backed

out

slowly.

If

seepage occurs around the threads, the plug should

be

turned back

in

immediately to avoid any drainage. This indicates that the specified amount

of

lubricant

is

present

in

the axle.

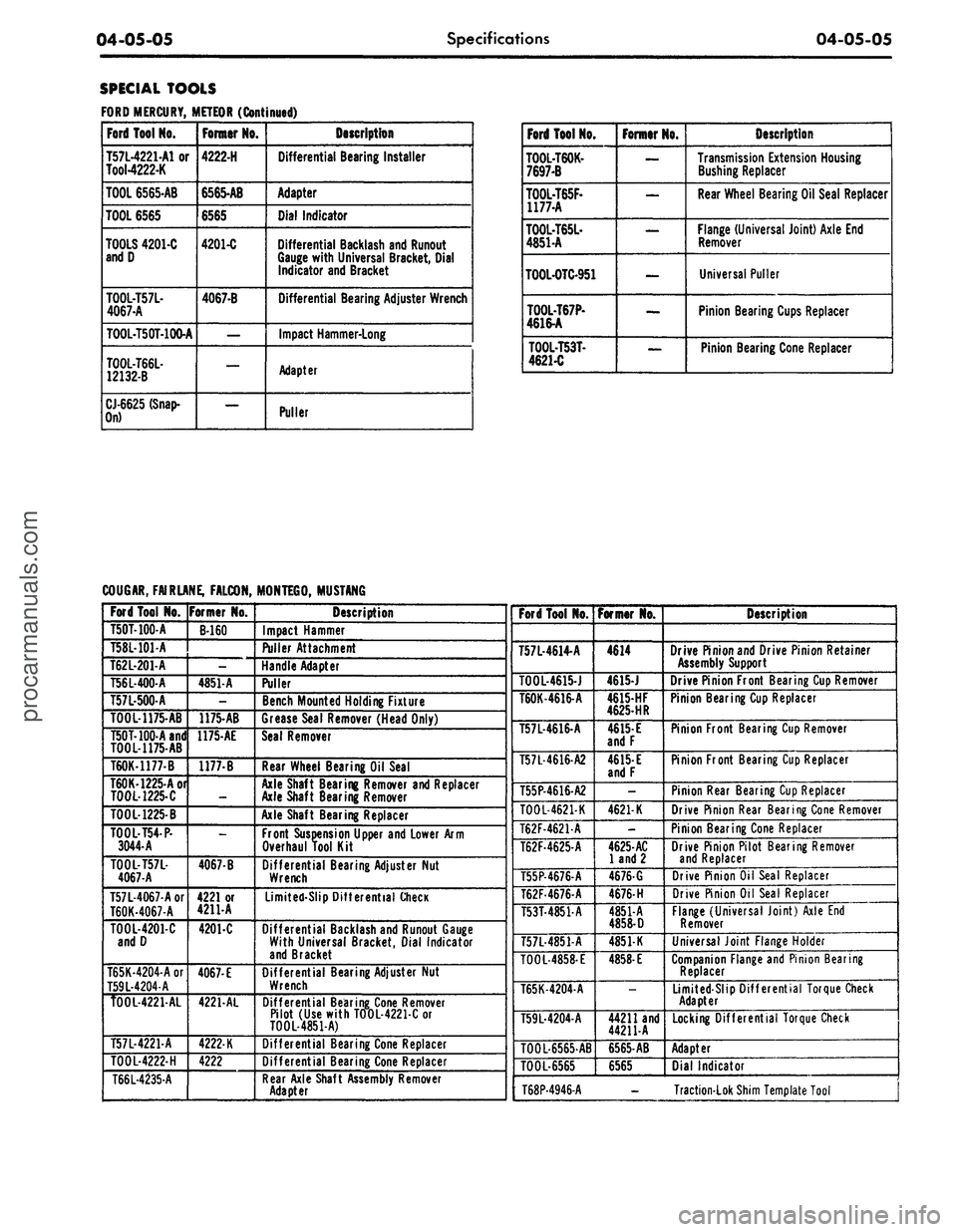

SPECIAL TOOLS

FORD,

MERCURY, METEOR

Ford Tool No.

T66L-4204-L

T57L-500-A

T50T-100-A

TOOL-4235-C

T00L-4621-A

TOOL-1225-D

T00L42344

TOOL-1177

TOOL-U75-AB

T57L4220-A

T00L4221-AE

T00L-4221-AF

T66P-4220-P

TOOL-4851-K

Former No.

42211 or

42211-A

6005-M

6005-MS

B-160

4235C

—

—

4234-A

4245-B

1175-AB

—

4221-AF

T57L-4851-A

4851-K

Description

Limited-Slip Differential Check

Bench Fixture

Impact Hammer

Axle Shaft Remover

Drive Pinion Bearing and

Rear Wheel Bear Replacer

Rear Wheel Bearing Remover

Rear Wheel Bearing Installer

Rear Wheel Bearing Oil Seal Installer

Rear Wheel Bearing Oil Seal Remover

Differential Bearing Remover

Differential Bearing Remover

U-Joint

Flange Holder

Ford Tool No.

T53T4851-A

T00L4858-D

T57L4614-A

T00L4621-K

T53L-200-A

T57L-4625-A or

T00L4625-K

T57L4616-A or

T00L4615-D

T58L-101-A

T55P4616-A2

T57L4621-B or

T00L4621-L

T58L4676-A

T00L4858-E

Former No.

4851-A, D

—

4614

4621-K

—

4625-K

—

—

—

—

4676-F

4858-E

Description

U-Joint

Flange Remover

U-Joint

Flange Remover

Drive Pinion Retainer Support

Pinion Rear Bearing Cone Remover

Handle Adapter

Pinion Pilot Bearing Remover and

Installer

Pinion Front Bearing Cup Remover

and Replacer

Puller Attachment—For Bearing

Cup Removal

Pinion Rear Bearing Cup Remover

and Replacer

Pinion Rear Bearing Cone Installer

Drive Pinion Oil Seal Replacer

U-Joint

Flange and Pinion Bearing

Replacerprocarmanuals.com

Page 246 of 413

04-05-05

Specifications

04-05-05

SPECIAL TOOLS

FORD MERCURY, METEOR (Continued)

Ford Tool No.

T57L-4221-A1 or

Tool-4222-K

TOOL 6565-AB

TOOL 6565

TOOLS 4201-C

andD

TOOL-T57L-

4067-A

TOOL-T50T-100-A

T00L-T66L-

12132-B

CJ-6625 (Snap-

On)

Foniisr

NO.

4222-H

6565-AB

6565

4201-C

4067-B

—

—

—

Description

Differential Bearing Installer

Adapter

Dial Indicator

Differential Backlash and Runout

Gauge with Universal Bracket, Dial

Indicator and Bracket

Differential Bearing Adjuster Wrench

Impact Hammer-Long

Adapter

Puller

Ford Tool No.

TOOL-T60K-

7697-B

T00L-T65F-

1177-A

T00L-T65L-

4851-A

TOOL-OTC-951

T00L-T67P-

4616-A

TOOL-T53T-

4621-C

Fomor No.

—

—

—

—

—

Description

Transmission Extension Housing

Bushing Repiacer

Rear Wheel Bearing Oil Seal Repiacer

Flange (Universal Joint) Axle End

Remover

Universal Puller

Pinion Bearing Cups Repiacer

Pinion Bearing Cone Repiacer

COUGAR, FAIRLANE, FALCON,

Ford Tool No.

T50T-100-A

T58L-101-A

T62L-201-A

T56L-400-A

T57L-500-A

T00L-1175-AB

T50T-100-Aand

TOOL-1175-AB

T60K-1177-B

T60K-1225-Aor

T00L-1225-C

TOOL-1225-B

T00L-T54-P-

3044-A

T00L-T57L-

4067-A

T57L-4067-Aor

T60K-4067-A

TOOL-4201-C

andD

T65K-4204A or

T59L-4204-A

T00L-4221-AL

T57L-4221-A

T00L-4222-H

T66L-4235-A

Former No.

B-160

-

4851-A

-

1175-AB

1175-AE

1177-B

4067-B

4221 or

4211-A

4201-C

4067-E

4221-AL

4222-K

4222

MONTEGO, MUSTANG

Description

Impact Hammer

Puller Attachment

Handle Adapter

Puller

Bench Mounted Holding Fixture

Grease Seal Remover (Head Only)

Seal Remover

Rear Wheel Bearing Oil Seal

Axle Shaft Bearing Remover and Repiacer

Axle Shaft Searing Remover

Axle Shaft Bearing Repiacer

Front Suspension Upper and Lower Arm

Overhaul Tool Kit

Differential Bearing Adjuster Nut

Wrench

Limited-Slip Differential Check

Differential Backlash and Runout Gauge

With Universal Bracket, Dial Indicator

and Bracket

Differential Bearing Adjuster Nut

Wrench

Differential Bearing Cone Remover

Pilot (Use with T00L-4221C or

T00L-4851-A)

Differential Bearing Cone Repiacer

Differential Bearing Cone Repiacer

Rear Axle Shaft Assembly Remover

Adapter

Ford Tool No.

T57L-4614-A

T00L-4615-J

T60K-4616-A

T57L-4616-A

T57L-4616-A2

T55P-4616-A2

T00L-4621-K

T62F-4621A

T62F-4625-A

T55P-4676-A

T62F4676A

T53T-4851A

T57L-4851-A

T00L-4858-E

T65K-4204-A

T59L-4204-A

T00L-6565-AB

TOOL-6565

Former No.

4614

4615-J

4615-HF

4625-HR

4615-

E

andP

4615-

E

andF

-

4621-K

4625-AC

land 2

4676-G

4676-

H

4851-A

4858-D

4851-K

4858-

E

—

44211 and

44211-A

6565-AB

6565

Description

Drive Pinion and Drive Pinion Retainer

Assembly Support

Drive Pinion Front Bearing Cup Remover

Pinion Bearing Cup Repiacer

Pinion Front Bearing Cup Remover

Pinion Front Bearing Cup Repiacer

Pinion Rear Bearing Cup Repiacer

Drive Pinion Rear Bearing Cone Remover

Pinion Bearing Cone Repiacer

Drive Pinion Pilot Bearing Remover

and Repiacer

Drive Pinion Oil Seal Repiacer

Drive Pinion Oil Seal Repiacer

Flange (Universal Joint) Axle End

Remover

Universal Joint Flange Holder

Companion Flange and Pinion Bearing

Repiacer

Limited-Slip Differential Torque Check

Adapter

Locking Differential Torque Check

Adapter

Dial Indicator

T68P-4946-A - Traction-Lok Shim Template Toolprocarmanuals.com

Page 248 of 413

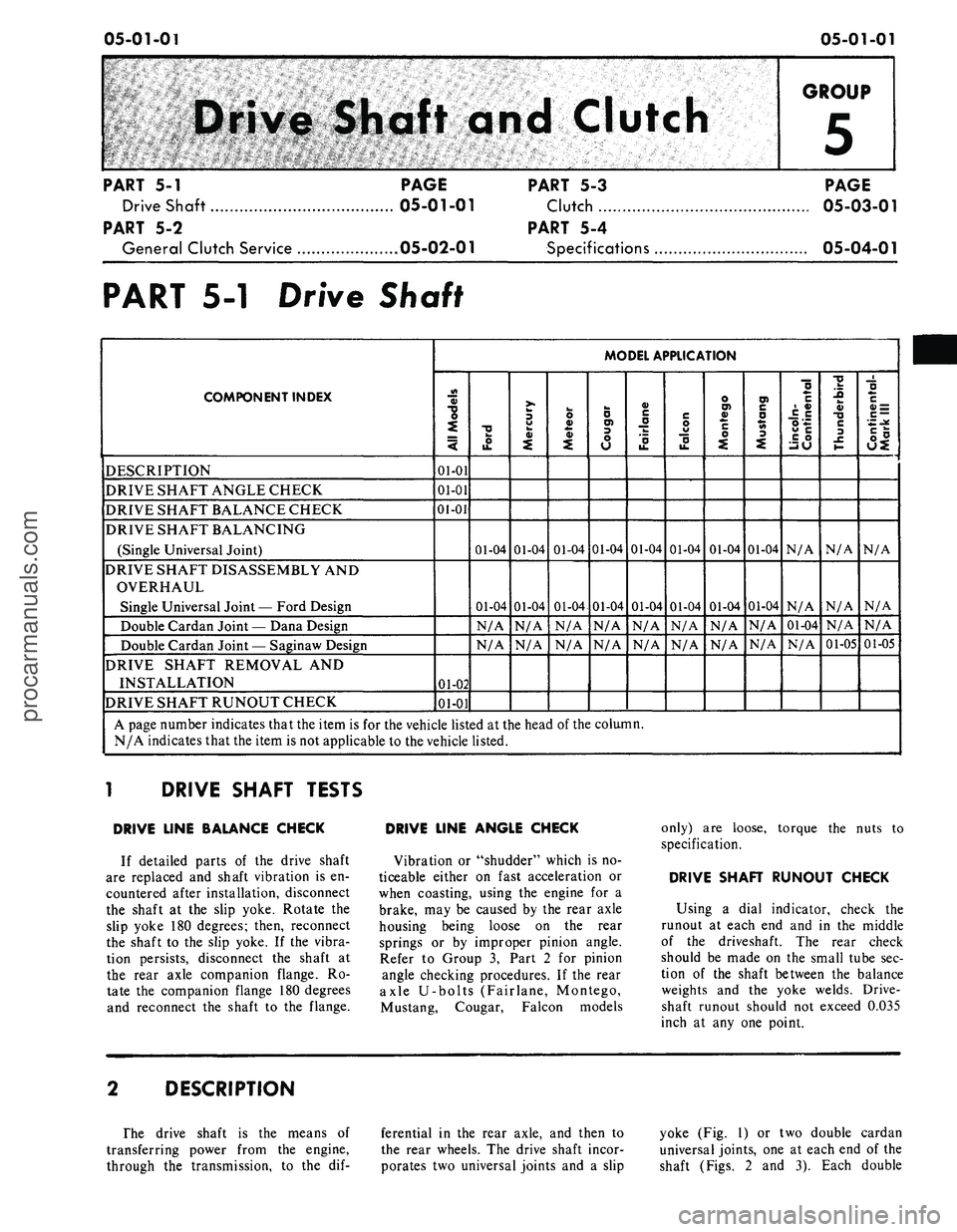

05-01-01

05-01-01

Clutch

GROUP

5

PART

5-1

PAGE

Drive Shaft 05-01-01

PART

5-2

General Clutch Service 05-02-01

PART

5-3

Clutch

PART

5-4

Specifications

PAGE

05-03-01

05-04-01

PART

5-1

Drive Shaft

COMPONENT INDEX

DESCRIPTION

DRIVE SHAFT ANGLE CHECK

DRIVE SHAFT BALANCE CHECK

DRIVE SHAFT BALANCING

(Single Universal Joint)

DRIVE SHAFT DISASSEMBLY

AND

OVERHAUL

Single Universal Joint — Ford Design

Double Cardan Joint — Dana Design

Double Cardan Joint — Saginaw Design

DRIVE SHAFT REMOVAL

AND

INSTALLATION

DRIVE SHAFT RUNOUT CHECK

MODEL APPLICATION

All

Models

01-01

01-01

01-01

01-02

01-01

Ford

01-04

01-04

N/A

N/A

Mercury

01-04

01-04

N/A

N/A

Meteor

01-04

01-04

N/A

N/A

Cougar

01-04

01-04

N/A

N/A

Fairlane

01-04

01-04

N/A

N/A

Falcon

01-04

01-04

N/A

N/A

Montego

01-04

01-04

N/A

N/A

Mustang

01-04

01-04

N/A

N/A

Lincoln-

Continental

N/A

N/A

01-04

N/A

Thunderbird

N/A

N/A

N/A

01-05

Continental-

Mark

III

N/A

N/A

N/A

01-05

A page number indicates that the item

is for the

vehicle listed

at the

head

of

the column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

DRIVE SHAFT TESTS

DRIVE LINE BALANCE CHECK

If detailed parts

of the

drive shaft

are replaced

and

shaft vibration

is en-

countered after installation, disconnect

the shaft

at the

slip yoke. Rotate

the

slip yoke

180

degrees; then, reconnect

the shaft

to the

slip yoke.

If the

vibra-

tion persists, disconnect

the

shaft

at

the rear axle companion flange.

Ro-

tate

the

companion flange

180

degrees

and reconnect

the

shaft

to the

flange.

DRIVE LINE ANGLE CHECK

Vibration

or

"shudder" which

is no-

ticeable either

on

fast acceleration

or

when coasting, using

the

engine

for a

brake,

may be

caused

by the

rear axle

housing being loose

on the

rear

springs

or by

improper pinion angle.

Refer

to

Group

3,

Part

2 for

pinion

angle checking procedures.

If the

rear

axle U-bolts (Fairlane, Montego,

Mustang, Cougar, Falcon models

only)

are

loose, torque

the

nuts

to

specification.

DRIVE SHAFT RUNOUT CHECK

Using

a

dial indicator, check

the

runout

at

each

end and in the

middle

of

the

driveshaft.

The

rear check

should

be

made

on the

small tube

sec-

tion

of the

shaft between

the

balance

weights

and the

yoke welds. Drive-

shaft runout should

not

exceed 0.035

inch

at any one

point.

DESCRIPTION

The drive shaft

is the

means

of

transferring power from

the

engine,

through

the

transmission,

to the dif-

ferential

in the

rear axle,

and

then

to

the rear wheels.

The

drive shaft incor-

porates

two

universal joints

and a

slip

yoke

(Fig. 1) or two

double cardan

universal joints,

one at

each

end of the

shaft (Figs.

2 and 3).

Each double

procarmanuals.com

Page 251 of 413

05-01-04

Drive Shaft

05-01-04

tralizing.

If a

vibration exists,

the

drive shaft should

be

disconnected

from

the

axle, rotated 180 degrees

and

reinstalled.

3.

Install

the

U-blots

and

nuts that

attach

the

U-joint

to the

drive pinion

flange. Torque

the

U-bolt nuts

to

specification.

On

vehicles equipped

with

a

double cardan joint, install

the

rear joint-to-drive pinion flange

at-

taching bolts. Torque

the

bolts

to spe-

cification.

YOKE

C1773-A

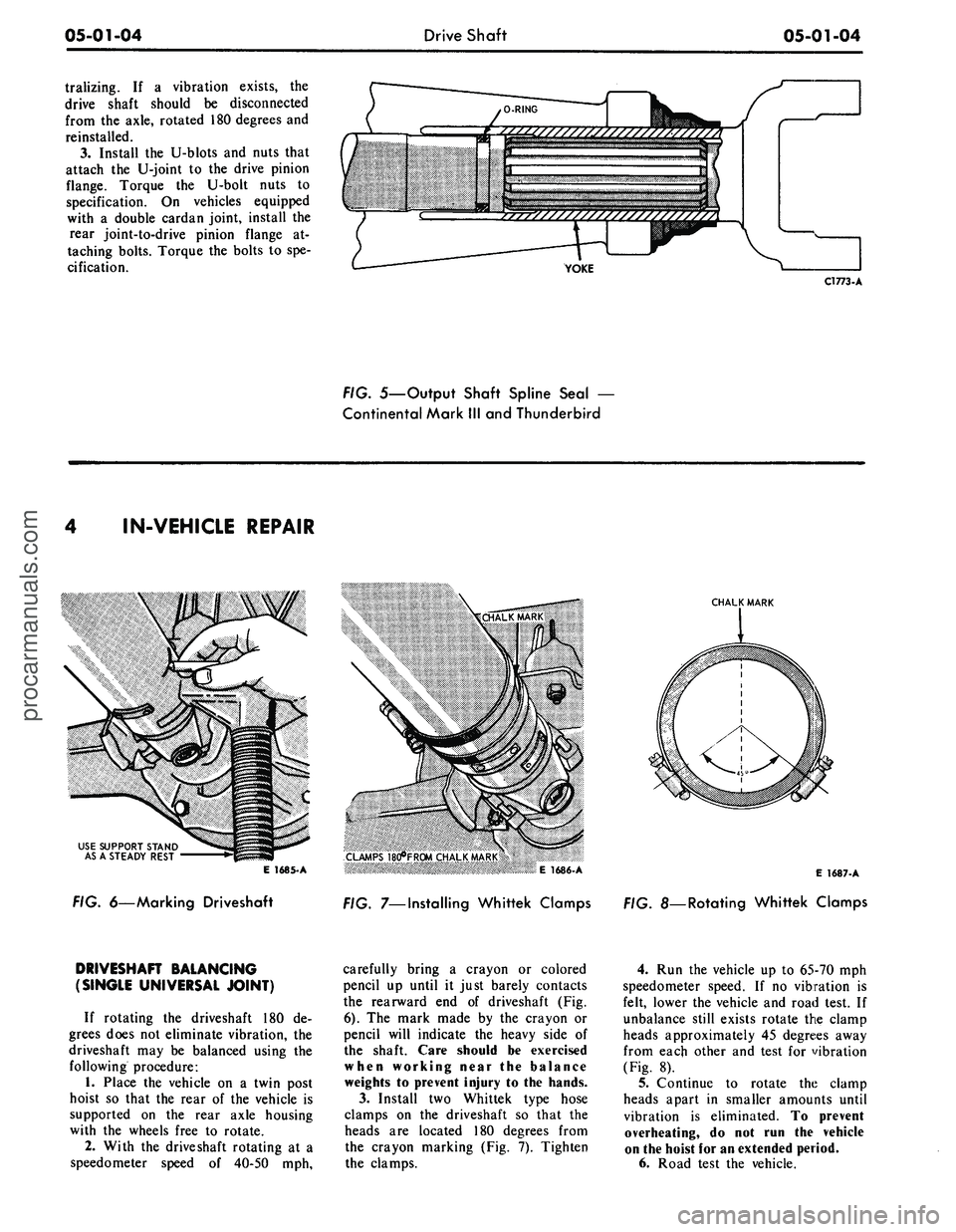

FIG. 5—Output Shaft Spline Seal

—

Continental Mark

III

and Thunderbird

IN-VEHICLE REPAIR

USE SUPPORT STAND

AS

A

STEADY REST

E 1685-A

FIG. 6—Marking Driveshaft

CHALK MARK

CLAMPS 18d*FR0M CHALK MARK

*« >

E 1686-A

FIG. 7—Installing Whittek Clamps

E

1687-

A

. 8—Rotating Whittek Clamps

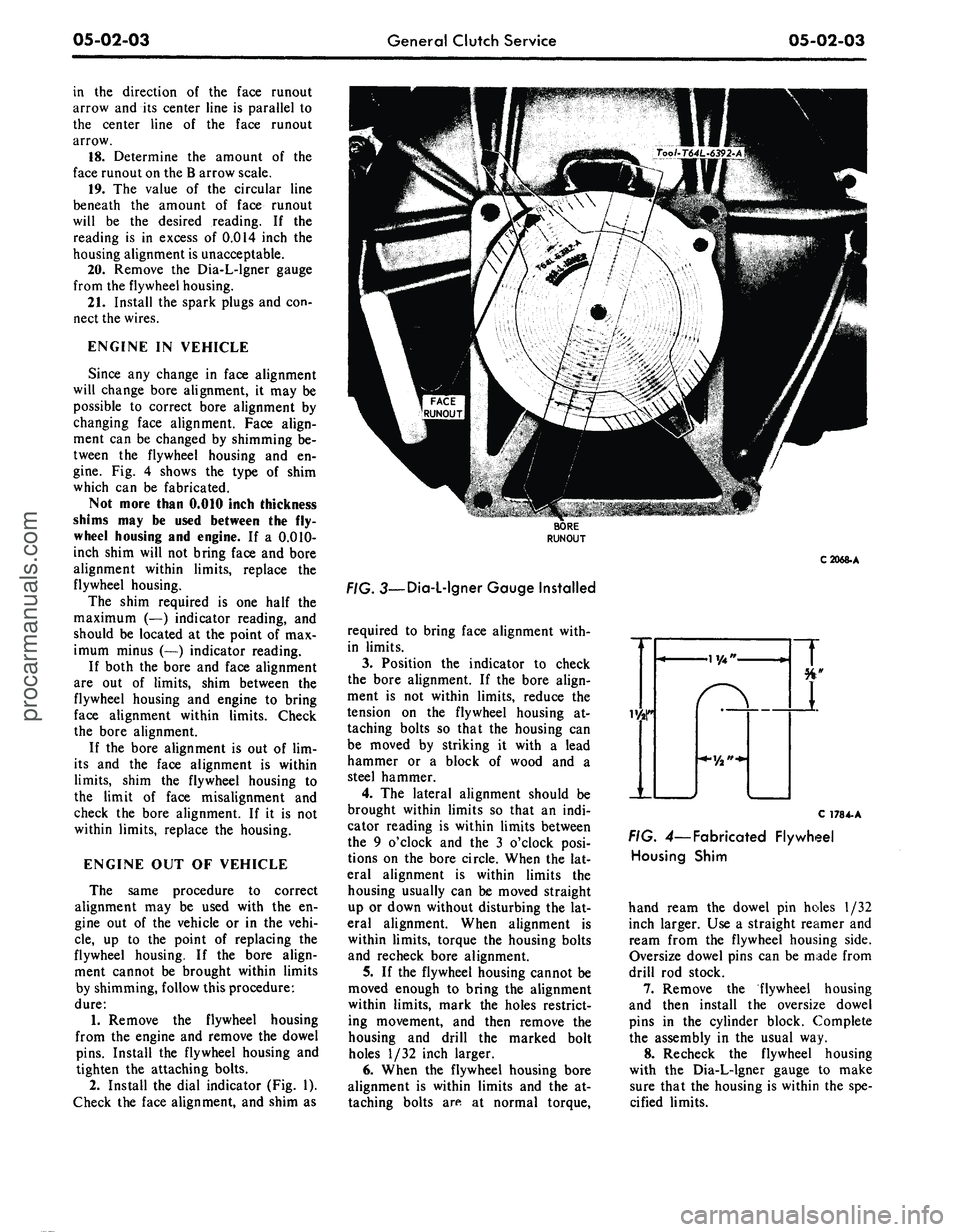

DRIVESHAFT BALANCING

(SINGLE UNIVERSAL JOINT)

If rotating

the

driveshaft

180 de-

grees does

not

eliminate vibration,

the

driveshaft

may be

balanced using

the

following procedure:

1.

Place

the

vehicle

on a

twin post

hoist

so

that

the

rear

of the

vehicle

is

supported

on the

rear axle housing

with

the

wheels free

to

rotate.

2.

With

the

driveshaft rotating

at a

speedometer speed

of

40-50

mph,

carefully bring

a

crayon

or

colored

pencil

up

until

it

just barely contacts

the rearward

end of

driveshaft

(Fig.

6).

The

mark made

by the

crayon

or

pencil will indicate

the

heavy side

of

the shaft. Care should

be

exercised

when working near

the

balance

weights

to

prevent injury

to the

hands.

3.

Install

two

Whittek type hose

clamps

on the

driveshaft

so

that

the

heads

are

located

180

degrees from

the crayon marking

(Fig. 7).

Tighten

the clamps.

4.

Run the

vehicle

up to

65-70

mph

speedometer speed.

If no

vibration

is

felt, lower

the

vehicle

and

road test.

If

unbalance still exists rotate

the

clamp

heads approximately

45

degrees away

from each other

and

test

for

vibration

(Fig.

8).

5.

Continue

to

rotate

the

clamp

heads apart

in

smaller amounts until

vibration

is

eliminated.

To

prevent

overheating,

do not run the

vehicle

on

the

hoist

for an

extended period.

6. Road test

the

vehicle.procarmanuals.com

Page 257 of 413

05-02-03

General Clutch Service

05-02-03

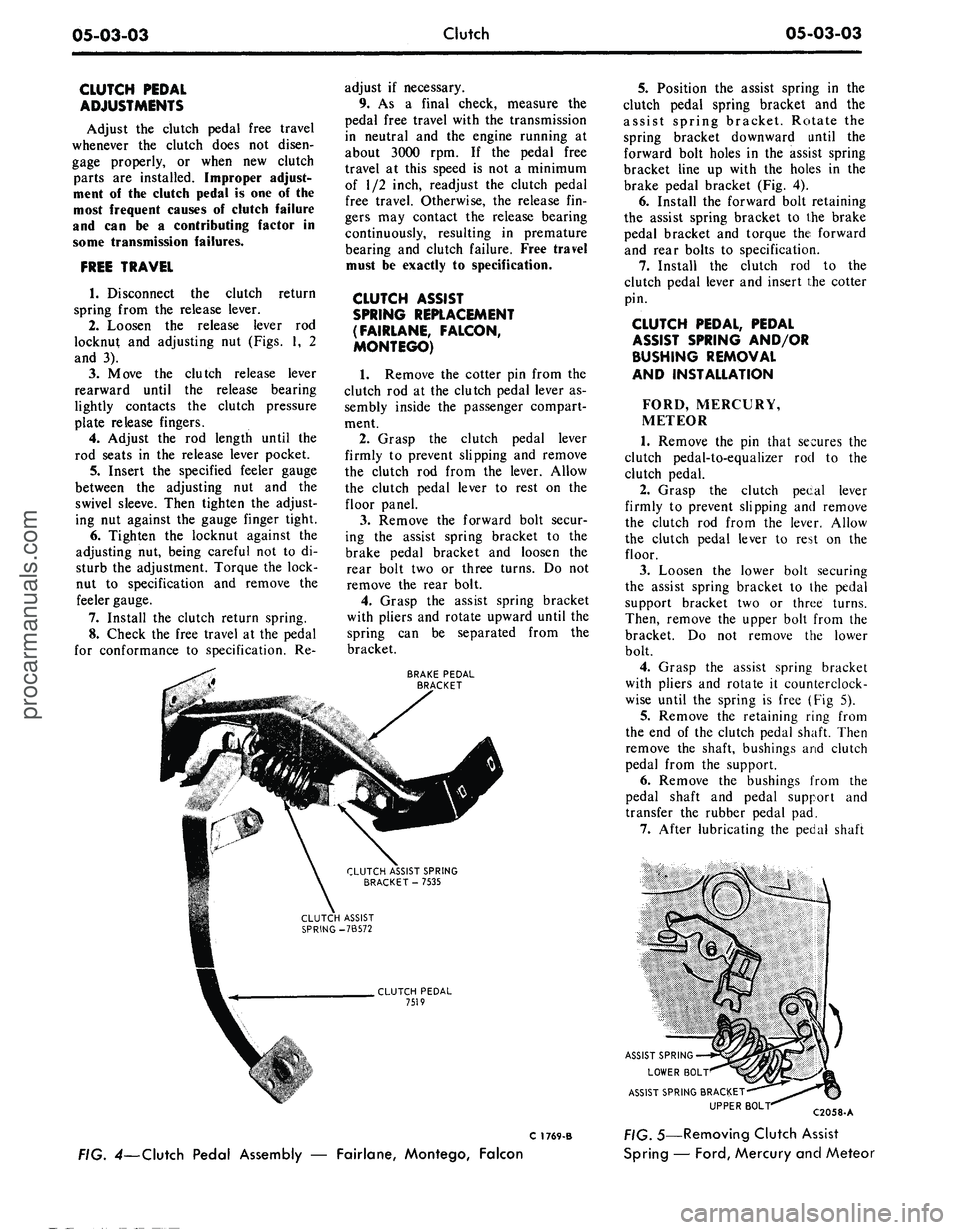

in the direction of the face runout

arrow and its center line is parallel to

the center line of the face runout

arrow.

18.

Determine the amount of the

face runout on the B arrow scale.

19.

The value of the circular line

beneath the amount of face runout

will be the desired reading. If the

reading is in excess of 0.014 inch the

housing alignment is unacceptable.

20.

Remove the Dia-L-lgner gauge

from the flywheel housing.

21.

Install the spark plugs and con-

nect the wires.

ENGINE IN VEHICLE

Since any change in face alignment

will change bore alignment, it may be

possible to correct bore alignment by

changing face alignment. Face align-

ment can be changed by shimming be-

tween the flywheel housing and en-

gine.

Fig. 4 shows the type of shim

which can be fabricated.

Not more than 0.010 inch thickness

shims may be used between the fly-

wheel housing and engine. If a 0.010-

inch shim will not bring face and bore

alignment within limits, replace the

flywheel housing.

The shim required is one half the

maximum (—) indicator reading, and

should be located at the point of max-

imum minus (—) indicator reading.

If both the bore and face alignment

are out of limits, shim between the

flywheel housing and engine to bring

face alignment within limits. Check

the bore alignment.

If the bore alignment is out of lim-

its and the face alignment is within

limits,

shim the flywheel housing to

the limit of face misalignment and

check the bore alignment. If it is not

within limits, replace the housing.

ENGINE OUT OF VEHICLE

The same procedure to correct

alignment may be used with the en-

gine out of the vehicle or in the vehi-

cle,

up to the point of replacing the

flywheel housing. If the bore align-

ment cannot be brought within limits

by shimming, follow this procedure:

dure:

1.

Remove the flywheel housing

from the engine and remove the dowel

pins.

Install the flywheel housing and

tighten the attaching bolts.

2.

Install the dial indicator (Fig. 1).

Check the face alignment, and shim as

C2068-A

. 3—Dia-L-lgner Gauge Installed

required to bring face alignment with-

in limits.

3.

Position the indicator to check

the bore alignment. If the bore align-

ment is not within limits, reduce the

tension on the flywheel housing at-

taching bolts so that the housing can

be moved by striking it with a lead

hammer or a block of wood and a

steel hammer.

4.

The lateral alignment should be

brought within limits so that an indi-

cator reading is within limits between

the 9 o'clock and the 3 o'clock posi-

tions on the bore circle. When the lat-

eral alignment is within limits the

housing usually can be moved straight

up or down without disturbing the lat-

eral alignment. When alignment is

within limits, torque the housing bolts

and recheck bore alignment.

5.

If the flywheel housing cannot be

moved enough to bring the alignment

within limits, mark the holes restrict-

ing movement, and then remove the

housing and drill the marked bolt

holes 1/32 inch larger.

6. When the flywheel housing bore

alignment is within limits and the at-

taching bolts are at normal torque,

C 178 4-A

FIG. 4— Fabricated Flywheel

Housing Shim

hand ream the dowel pin holes 1/32

inch larger. Use a straight reamer and

ream from the flywheel housing side.

Oversize dowel pins can be made from

drill rod stock.

7.

Remove the flywheel housing

and then install the oversize dowel

pins in the cylinder block. Complete

the assembly in the usual way.

8. Recheck the flywheel housing

with the Dia-L-lgner gauge to make

sure that the housing is within the spe-

cified limits.procarmanuals.com

Page 261 of 413

05-03-03

Clutch

05-03-03

CLUTCH PEDAL

ADJUSTMENTS

Adjust

the

clutch pedal free travel

whenever

the

clutch does

not

disen-

gage properly,

or

when

new

clutch

parts

are

installed. Improper adjust-

ment

of the

clutch pedal

is one of the

most frequent causes

of

clutch failure

and

can be a

contributing factor

in

some transmission failures.

FREE TRAVEL

1.

Disconnect

the

clutch return

spring from

the

release lever.

2.

Loosen

the

release lever

rod

locknut

and

adjusting

nut

(Figs.

1, 2

and

3).

3.

Move

the

clutch release lever

rearward until

the

release bearing

lightly contacts

the

clutch pressure

plate release fingers.

4.

Adjust

the rod

length until

the

rod seats

in the

release lever pocket.

5.

Insert

the

specified feeler gauge

between

the

adjusting

nut and the

swivel sleeve. Then tighten

the

adjust-

ing

nut

against

the

gauge finger tight.

6. Tighten

the

locknut against

the

adjusting

nut,

being careful

not to di-

sturb

the

adjustment. Torque

the

lock-

nut

to

specification

and

remove

the

feeler gauge.

7.

Install

the

clutch return spring.

8. Check

the

free travel

at the

pedal

for conformance

to

specification.

Re-

adjust

if

necessary.

9.

As a

final check, measure

the

pedal free travel with

the

transmission

in neutral

and the

engine running

at

about 3000

rpm. If the

pedal free

travel

at

this speed

is not a

minimum

of

1/2

inch, readjust

the

clutch pedal

free travel. Otherwise,

the

release

fin-

gers

may

contact

the

release bearing

continuously, resulting

in

premature

bearing

and

clutch failure. Free travel

must

be

exactly

to

specification.

CLUTCH ASSIST

SPRING REPLACEMENT

(FAIRLANE, FALCON,

MONTEGO)

1.

Remove

the

cotter

pin

from

the

clutch

rod at the

clutch pedal lever

as-

sembly inside

the

passenger compart-

ment.

2.

Grasp

the

clutch pedal lever

firmly

to

prevent slipping

and

remove

the clutch

rod

from

the

lever. Allow

the clutch pedal lever

to

rest

on the

floor panel.

3.

Remove

the

forward bolt secur-

ing

the

assist spring bracket

to the

brake pedal bracket

and

loosen

the

rear bolt

two or

three turns.

Do not

remove

the

rear bolt.

4.

Grasp

the

assist spring bracket

with pliers

and

rotate upward until

the

spring

can be

separated from

the

bracket.

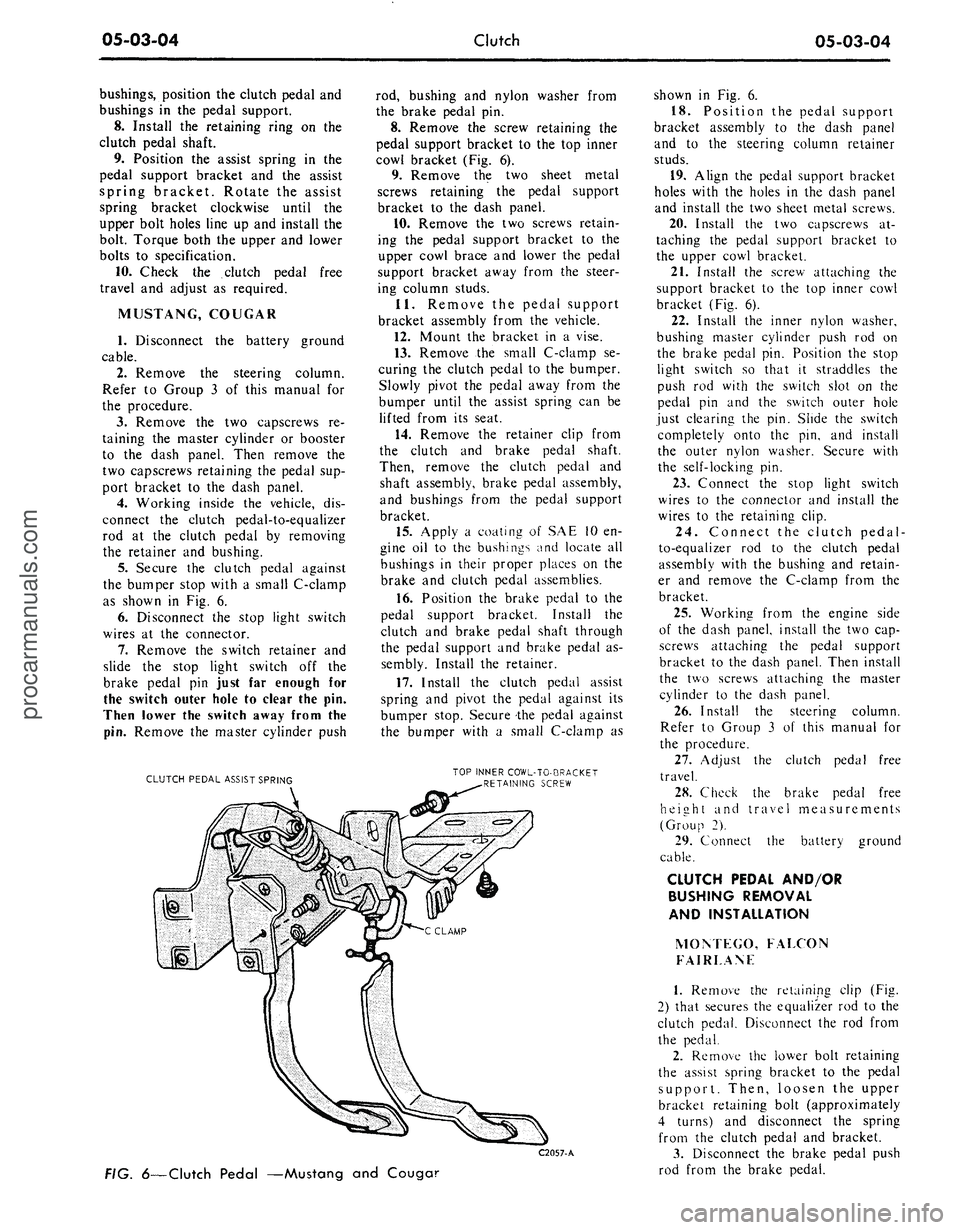

BRAKE PEDAL

BRACKET

CLUTCH ASSIST SPRING

BRACKET

-

7535

CLUTCH PEDAL

7519

5.

Position

the

assist spring

in the

clutch pedal spring bracket

and the

assist spring bracket. Rotate

the

spring bracket downward until

the

forward bolt holes

in the

assist spring

bracket line

up

with

the

holes

in the

brake pedal bracket

(Fig. 4).

6. Install

the

forward bolt retaining

the assist spring bracket

to the

brake

pedal bracket

and

torque

the

forward

and rear bolts

to

specification.

7.

Install

the

clutch

rod to the

clutch pedal lever

and

insert

the

cotter

pin.

CLUTCH PEDAL, PEDAL

ASSIST SPRING AND/OR

BUSHING REMOVAL

AND INSTALLATION

FORD, MERCURY,

METEOR

1.

Remove

the pin

that secures

the

clutch pedal-to-equalizer

rod to the

clutch pedal.

2.

Grasp

the

clutch pecal lever

firmly

to

prevent slipping

and

remove

the clutch

rod

from

the

lever. Allow

the clutch pedal lever

to

rest

on the

floor.

3.

Loosen

the

lower bolt securing

the assist spring bracket

to the

pedal

support bracket

two or

three turns.

Then, remove

the

upper bolt from

the

bracket.

Do not

remove

the

lower

bolt.

4.

Grasp

the

assist spring bracket

with pliers

and

rotate

it

counterclock-

wise until

the

spring

is

free

(Fig 5).

5.

Remove

the

retaining ring from

the

end of the

clutch pedal shaft. Then

remove

the

shaft, bushings

and

clutch

pedal from

the

support.

6. Remove

the

bushings from

the

pedal shaft

and

pedal support

and

transfer

the

rubber pedal

pad.

7.

After lubricating

the

pedal shaft

ASSIST SPRING

LOWER BOLT

ASSIST SPRING BRACKET-

UPPER

BOL"

C 1769-B

FIG. 4—Clutch Pedal Assembly

—

Fairlane, Montego, Falcon

C2058-A

;. 5—Removing Clutch Assist

Spring

—

Ford,

Mercury and Meteorprocarmanuals.com

Page 262 of 413

05-03-04

Clutch

05-03-04

bushings, position the clutch pedal and

bushings in the pedal support.

8. Install the retaining ring on the

clutch pedal shaft.

9. Position the assist spring in the

pedal support bracket and the assist

spring bracket. Rotate the assist

spring bracket clockwise until the

upper bolt holes line up and install the

bolt. Torque both the upper and lower

bolts to specification.

10.

Check the clutch pedal free

travel and adjust as required.

MUSTANG, COUGAR

1.

Disconnect the battery ground

cable.

2.

Remove the steering column.

Refer to Group 3 of this manual for

the procedure.

3.

Remove the two capscrews re-

taining the master cylinder or booster

to the dash panel. Then remove the

two capscrews retaining the pedal sup-

port bracket to the dash panel.

4.

Working inside the vehicle, dis-

connect the clutch pedal-to-equalizer

rod at the clutch pedal by removing

the retainer and bushing.

5.

Secure the clutch pedal against

the bumper stop with a small C-clamp

as shown in Fig. 6.

6. Disconnect the stop light switch

wires at the connector.

7.

Remove the switch retainer and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin.

Remove the master cylinder push

CLUTCH PEDAL ASSIST SPRING

rod, bushing and nylon washer from

the brake pedal pin.

8. Remove the screw retaining the

pedal support bracket to the top inner

cowl bracket (Fig. 6).

9. Remove the two sheet metal

screws retaining the pedal support

bracket to the dash panel.

10.

Remove the two screws retain-

ing the pedal support bracket to the

upper cowl brace and lower the pedal

support bracket away from the steer-

ing column studs.

11.

Remove the pedal support

bracket assembly from the vehicle.

12.

Mount the bracket in a vise.

13.

Remove the small C-clamp se-

curing the clutch pedal to the bumper.

Slowly pivot the pedal away from the

bumper until the assist spring can be

lifted from its seat.

14.

Remove the retainer clip from

the clutch and brake pedal shaft.

Then, remove the clutch pedal and

shaft assembly, brake pedal assembly,

and bushings from the pedal support

bracket.

15.

Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

brake and clutch pedal assemblies.

16.

Position the brake pedal to the

pedal support bracket. Install the

clutch and brake pedal shaft through

the pedal support and brake pedal as-

sembly. Install the retainer.

17.

Install the clutch pedal assist

spring and pivot the pedal against its

bumper stop. Secure the pedal against

the bumper with a small C-clamp as

TOP INNER COWL-TO-BRACKET

RETAINING SCREW

C2057-A

FIG.

6—Clutch

Pedal —Mustang and Couga?

shown in Fig. 6.

18.

Position the pedal support

bracket assembly to the dash panel

and to the steering column retainer

studs.

19.

Align the pedal support bracket

holes with the holes in the dash panel

and install the two sheet metal screws.

20.

Install the two capscrews at-

taching the pedal support bracket to

the upper cowl bracket.

21.

Install the screw attaching the

support bracket to the top inner cowl

bracket (Fig. 6).

22.

Install the inner nylon washer,

bushing master cylinder push rod on

the brake pedal pin. Position the stop

light switch so that it straddles the

push rod with the switch slot on the

pedal pin and the switch outer hole

just clearing the pin. Slide the switch

completely onto the pin, and install

the outer nylon washer. Secure with

the self-locking pin.

23.

Connect the stop light switch

wires to the connector and install the

wires to the retaining clip.

24.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and retain-

er and remove the C-clamp from the

bracket.

25.

Working from the engine side

of the dash panel, install the two cap-

screws attaching the pedal support

bracket to the dash panel. Then install

the two screws attaching the master

cylinder to the dash panel.

26.

Install the steering column.

Refer to Group 3 of this manual for

the procedure.

27.

Adjust the clutch pedal free

travel.

28.

Check the brake pedal free

height and travel measurements

(Group 2).

29.

Connect the battery ground

cable.

CLUTCH PEDAL AND/OR

BUSHING REMOVAL

AND INSTALLATION

MOM EGO, FALCON

FAIRLANF

1.

Remove the retaining clip (Fig.

2) that secures the equalizer rod to the

clutch pedal. Disconnect the rod from

the pedal.

2.

Remove the lower bolt retaining

the assist spring bracket to the pedal

support. Then, loosen the upper

bracket retaining bolt (approximately

4 turns) and disconnect the spring

from the clutch pedal and bracket.

3.

Disconnect the brake pedal push

rod from the brake pedal.procarmanuals.com

Page 263 of 413

05-03-05

Clutch

05-03-05

4.

Remove the bolt that secures the

left air vent control cable bracket to

the instrument panel. Position the

control cable to one side.

5.

Remove the retaining clip and

flat washer from the clutch pedal

shaft. Then, remove the shaft, bush-

ing, clutch pedal and brake pedal

from the support.

6. Remove the bushings from the

pedal shaft, and transfer the pedal

pad.

7.

Lubricate the clutch pedal shaft

bushings and position them on the

shaft. Then, position the brake pedal

and clutch pedal in the pedal support.

8. Install the flat washer and re-

taining clip on the pedal shaft.

9. Position the assist spring to the

pedal and bracket. Pry the bracket

forward and install the lower bolt.

Torque the bolts to specifications.

10.

Position the master cylinder

push rod, bushing, and washers on the

brake pedal and secure with a retain-

ing clip.

11.

Connect the equalizer rod to

the clutch pedal and secure it in place

with a retaining clip.

12.

Position the air vent control

cable bracket to the instrument panel

and secure with the attaching bolt.

13.

Adjust the clutch pedal free

travel.

EQUALIZER BAR AND/OR

BUSHING REMOVAL AND

INSTALLATION

FORD, MERCURY

AND METEOR

1.

Raise the vehicle and disconnect

the clutch pedal-to-equalizer rod at

the equalizer bar (Fig. 1).

2.

Disconnect the return spring and

retaining spring at the release lever.

Separate the release lever rod from

the release lever.

3.

Remove the equalizer bar frame

bracket from the frame.

4.

Remove the equalizer bar from

the pivot on the flywheel housing.

5.

Remove the wire clip to replace

the outer bushing and the snap ring

from the inner pivot stud to replace

the inner bushing.

6. Position the flat washer, felt

washer and bushing on the inner and

outer pivots. Secure these parts with

the snap ring.

7.

Position the equalizer bar on the

inner pivot and bolt the equalizer bar

frame bracket to the frame. Torque

the attaching bolts to specification.

8. Install the clutch release rod, re-

turn spring and retaining spring.

9. Connect the clutch pedal rod to

the equalizer bar.

10.

Adjust the clutch pedal free

travel.

MUSTANG, COUGAR,

MONTEGO, FALCON,

FAIRLANE (EXCEPT

MONTEGO AND FAIRLANE

WITH 390 V-8)

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar

(Figs.

2 and 3).

2.

Raise the vehicle and disconnect

the release lever, return spring at the

lever.

3.

Remove the equalizer bar outer

bracket and bushing assembly.

4.

Remove the release rod from the

equalizer bar, and then remove the

equalizer bar. Remove the bushing

and washers from the inner mounting

stud.

5.

Position the equalizer bar, wash-

ers,

inner bushing, and retainer on the

inner stud.

6. After positioning the outer bush-

ing, install the outer bracket (with the

equalizer bar in place).

7.

Connect the release rod and the

release lever return spring.

8. Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer baY and secure with the re-

taining pin.

9. Adjust the clutch pedal free trav-

el as required.

MONTEGO AND

FAIRLANE—390 V-8

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar (Fig.

2).

2.

Raise the vehicle and disconnect

the return spring at the release lever.

Disconnect the release lever rod from

the equalizer lever.

3.

Remove the equalizer bar center

bolt.

4.

Separate the equalizer bar and

remove both sections from the vehicle.

5.

Remove the bolts retaining the

equalizer bar inner bracket to the fly-

wheel housing and remove the bracket

and bushing assembly.

6. Remove the equalizer bar outer

bracket and bushing assembly.

7.

Remove the snap ring, bushing,

and felt washer from each bracket as-

sembly.

8. Position a felt washer, and bush-

ing on each bracket assembly and se-

cure with the snap ring.

9. Install the outer bracket and

bushing assembly to the frame (Fig.

2).

Torque the bracket attaching bolts

to specifications.

10.

Position the outer section of the

equalizer bar on the outer bracket

pivot.

11.

Connect the two sections of the

equalizer bar. Insert the inner bracket

pivot into the equalizer bar and install

the assembly to the flywheel housing.

Torque the attaching bolts to specifi-

cations.

12.

Install the equalizer bar center

bolt and torque to specifications.

Make sure that both ends of the

equalizer bar are against the felt

washers.

13.

Connect the release rod and the

release lever return spring.

14.

Adjust the clutch pedal free

travel.

15.

Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer bar and secure with the re-

taining clip.

16.

Check the free travel at the

pedal for conformance to specifica-

tions.

Readjust if necessary.

REMOVAL AND INSTALLATION

CLUTCH REMOVAL

1.

Raise the vehicle on a hoist.

2.

Disconnect the drive shaft from

the rear U-joint flange. Then, slide the

drive shaft off the transmission output

shaft. Insert the appropriate tool over

the output shaft and into the extension

housing oil seal.

3.

Disconnect the speedometer

cable from the extension housing.

4.

Disconnect the gear shift rods

from the transmission. If the vehicle is

equipped with a four-speed transmis-

sion, remove the bolts that secure the

four-speed transmission, disconnect

the front brake cable from the cross-

member and remove the crossmem-

member from the vehicle.

5.

Remove the bolts that attach the

transmission to the flywheel housing.

6. Move the transmission rearward

until the input shaft clears the fly-

wheel housing, then remove it from

the vehicle.

7.

Disconnect the clutch release

lever retaining spring from the release

lever.procarmanuals.com

Page 264 of 413

05-03-06

Clutch

05-03-06

8. Remove the starter cable then

remove the starter motor from the fly-

wheel housing.

9. Remove the bolts that secure the

engine rear plate to the front lower

part of the flywheel housing.

10.

Remove the flywheel housing

lower cover (390 CID housing only).

11.

Remove the bolts that attach

the housing to the cylinder block.

12.

Move the housing back just far

enough to clear the pressure plate,

then move it to the right to free the

pivot from the clutch equalizer bar. Be

careful not to disturb the linkage and

assist spring.

13.

Loosen the six pressure plate

cover attaching bolts evenly to release

the spring tension. If the same pres-

sure plate and cover is to be installed

after the clutch is overhauled, mark

the cover and flywheel so that the

pressure plate can be installed in the

same position.

14.

Remove the pressure plate and

the clutch disc from the flywheel.

CLUTCH INSTALLATION

1.

Install the clutch release lever if

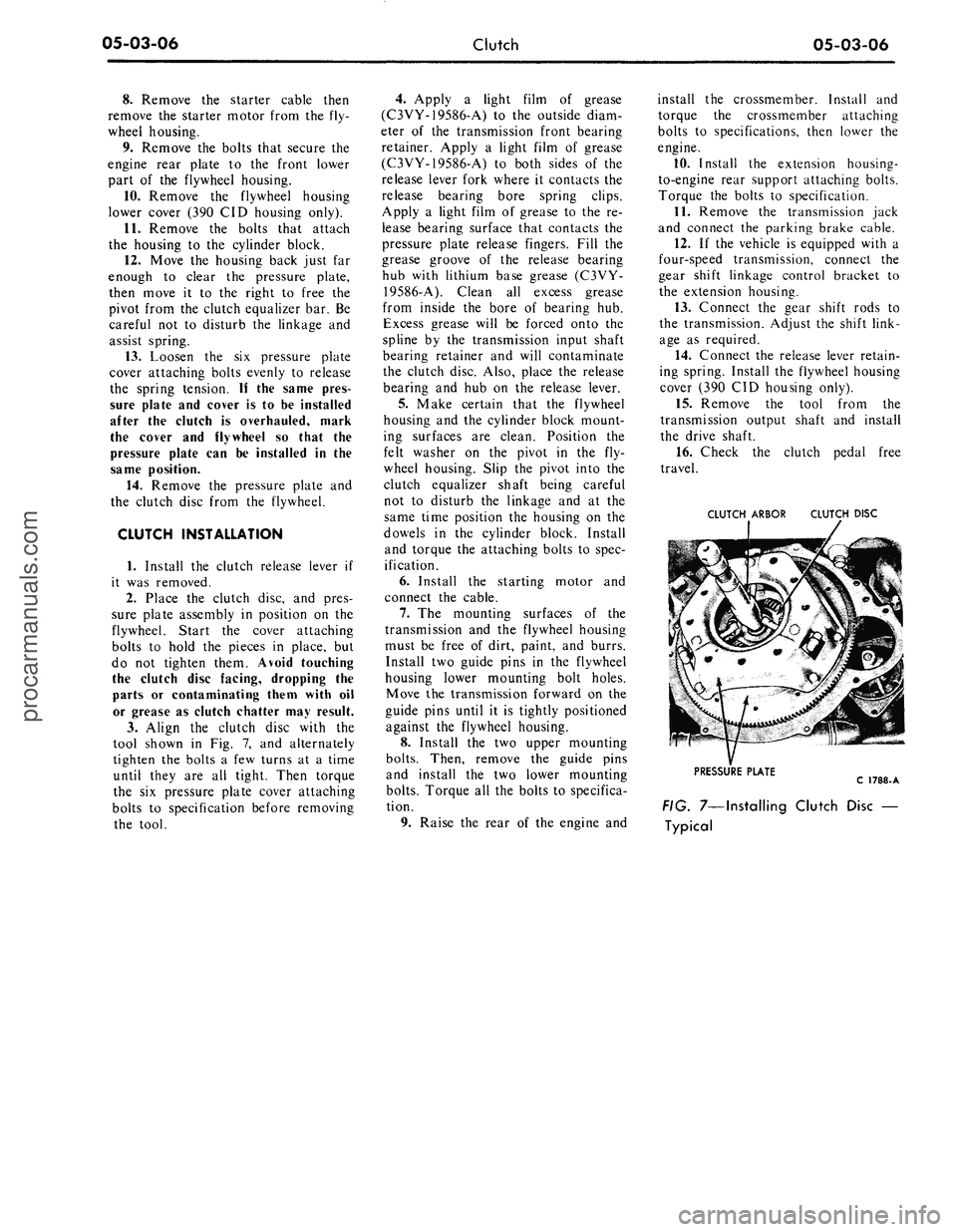

it was removed.

2.

Place the clutch disc, and pres-

sure plate assembly in position on the

flywheel. Start the cover attaching

bolts to hold the pieces in place, but

do not tighten them. Avoid touching

the clutch disc facing, dropping the

parts or contaminating them with oil

or grease as clutch chatter may result.

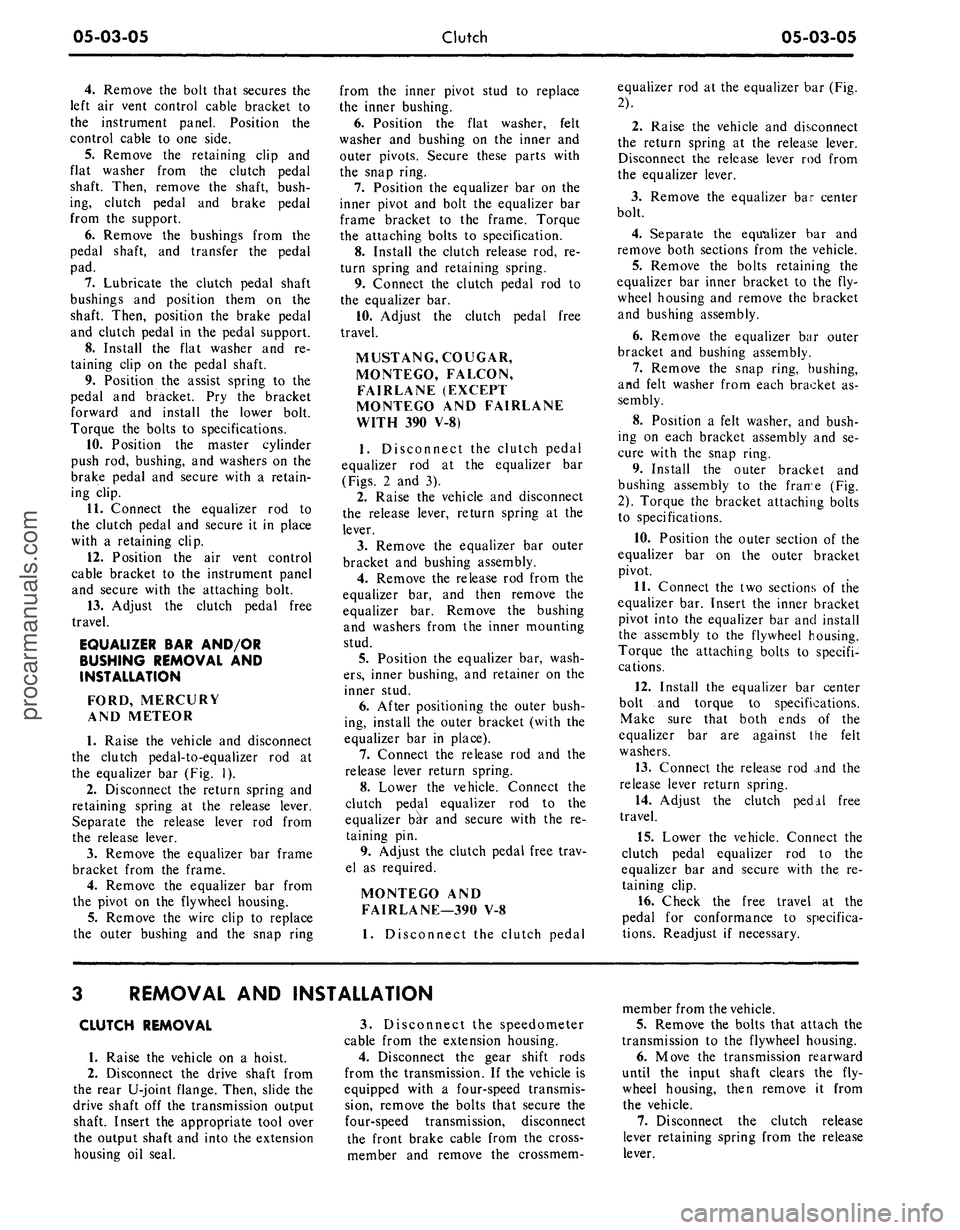

3.

Align the clutch disc with the

tool shown in Fig. 7, and alternately

tighten the bolts a few turns at a time

until they are all tight. Then torque

the six pressure plate cover attaching

bolts to specification before removing

the tool.

4.

Apply a light film of grease

(C3VY-19586-A) to the outside diam-

eter of the transmission front bearing

retainer. Apply a light film of grease

(C3VY-19586-A) to both sides of the

release lever fork where it contacts the

release bearing bore spring clips.

Apply a light film of grease to the re-

lease bearing surface that contacts the

pressure plate release fingers. Fill the

grease groove of the release bearing

hub with lithium base grease (C3VY-

19586-A). Clean all excess grease

from inside the bore of bearing hub.

Excess grease will be forced onto the

spline by the transmission input shaft

bearing retainer and will contaminate

the clutch disc. Also, place the release

bearing and hub on the release lever.

5.

Make certain that the flywheel

housing and the cylinder block mount-

ing surfaces are clean. Position the

felt washer on the pivot in the fly-

wheel housing. Slip the pivot into the

clutch equalizer shaft being careful

not to disturb the linkage and at the

same time position the housing on the

dowels in the cylinder block. Install

and torque the attaching bolts to spec-

ification.

6. Install the starting motor and

connect the cable.

7.

The mounting surfaces of the

transmission and the flywheel housing

must be free of dirt, paint, and burrs.

Install two guide pins in the flywheel

housing lower mounting bolt holes.

Move the transmission forward on the

guide pins until it is tightly positioned

against the flywheel housing.

8. Install the two upper mounting

bolts.

Then, remove the guide pins

and install the two lower mounting

bolts.

Torque all the bolts to specifica-

tion.

9. Raise the rear of the engine and

install the crossmember. Install and

torque the crossmember attaching

bolts to specifications, then lower the

engine.

10.

Install the extension housing-

to-engine rear support attaching bolts.

Torque the bolts to specification.

11.

Remove the transmission jack

and connect the parking brake cable.

12.

If the vehicle is equipped with a

four-speed transmission, connect the

gear shift linkage control bracket to

the extension housing.

13.

Connect the gear shift rods to

the transmission. Adjust the shift link-

age as required.

14.

Connect the release lever retain-

ing spring. Install the flywheel housing

cover (390 CID housing only).

15.

Remove the tool from the

transmission output shaft and install

the drive shaft.

16.

Check the clutch pedal free

travel.

CLUTCH ARBOR CLUTCH DISC

PRESSURE PLATE

C 1788-A

FIG. 7—Installing Clutch Disc —

Typicalprocarmanuals.com