torque FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 225 of 413

04-03-05

Rear Axles — Integral Carrier Type

04-03-05

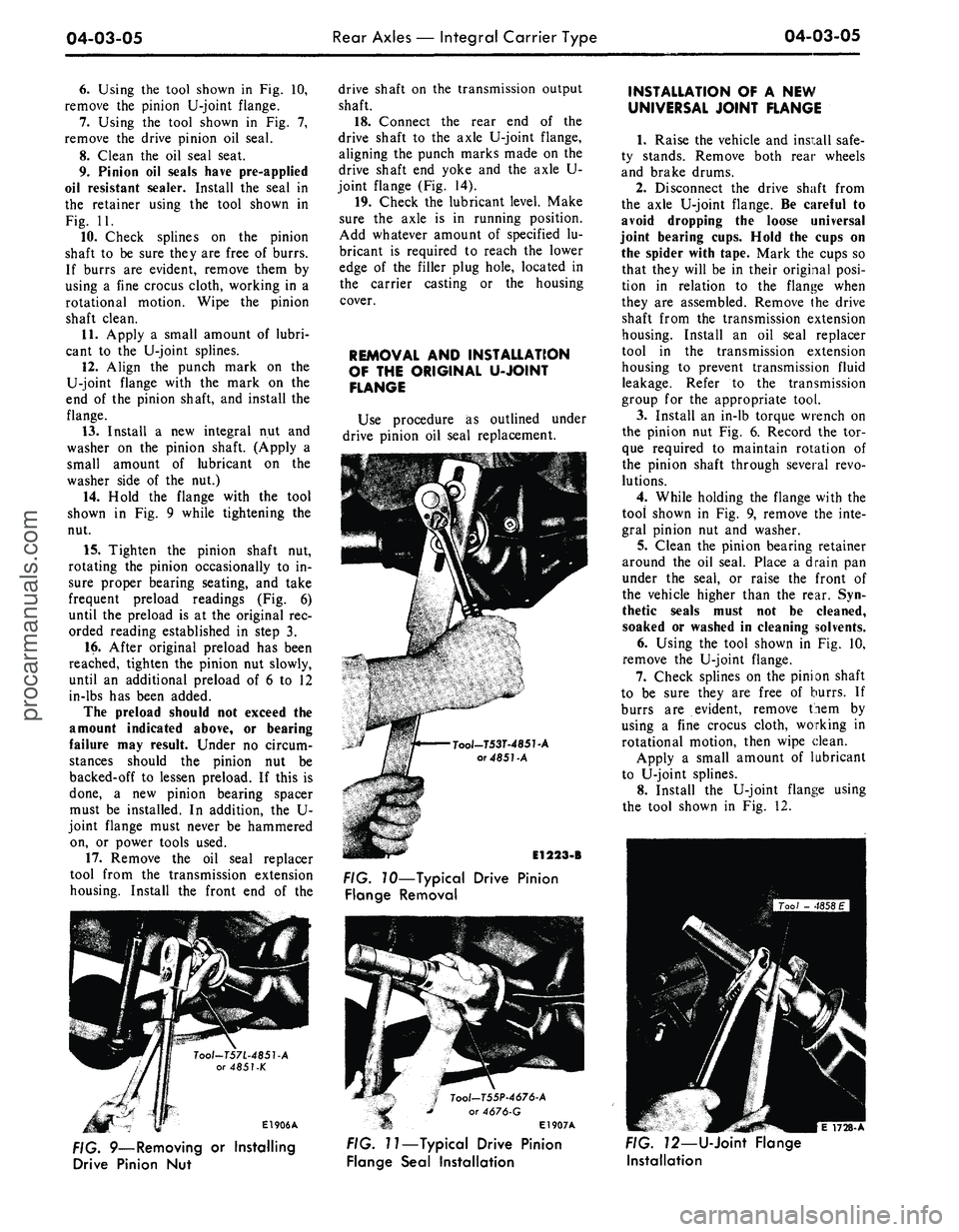

6. Using the tool shown in Fig. 10,

remove the pinion U-joint flange.

7.

Using the tool shown in Fig. 7,

remove the drive pinion oil seal.

8. Clean the oil seal seat.

9. Pinion oil seals have pre-applied

oil resistant sealer. Install the seal in

the retainer using the tool shown in

Fig. 11.

10.

Check splines on the pinion

shaft to be sure they are free of burrs.

If burrs are evident, remove them by

using a fine crocus cloth, working in a

rotational motion. Wipe the pinion

shaft clean.

11.

Apply a small amount of lubri-

cant to the U-joint splines.

12.

Align the punch mark on the

U-joint flange with the mark on the

end of the pinion shaft, and install the

flange.

13.

Install a new integral nut and

washer on the pinion shaft. (Apply a

small amount of lubricant on the

washer side of the nut.)

14.

Hold the flange with the tool

shown in Fig. 9 while tightening the

nut.

15.

Tighten the pinion shaft nut,

rotating the pinion occasionally to in-

sure proper bearing seating, and take

frequent preload readings (Fig. 6)

until the preload is at the original rec-

orded reading established in step 3.

16.

After original preload has been

reached, tighten the pinion nut slowly,

until an additional preload of 6 to 12

in-lbs has been added.

The preload should not exceed the

amount indicated above, or bearing

failure may result. Under no circum-

stances should the pinion nut be

backed-off to lessen preload. If this is

done, a new pinion bearing spacer

must be installed. In addition, the U-

joint flange must never be hammered

on, or power tools used.

17.

Remove the oil seal replacer

tool from the transmission extension

housing. Install the front end of the

drive shaft on the transmission output

shaft.

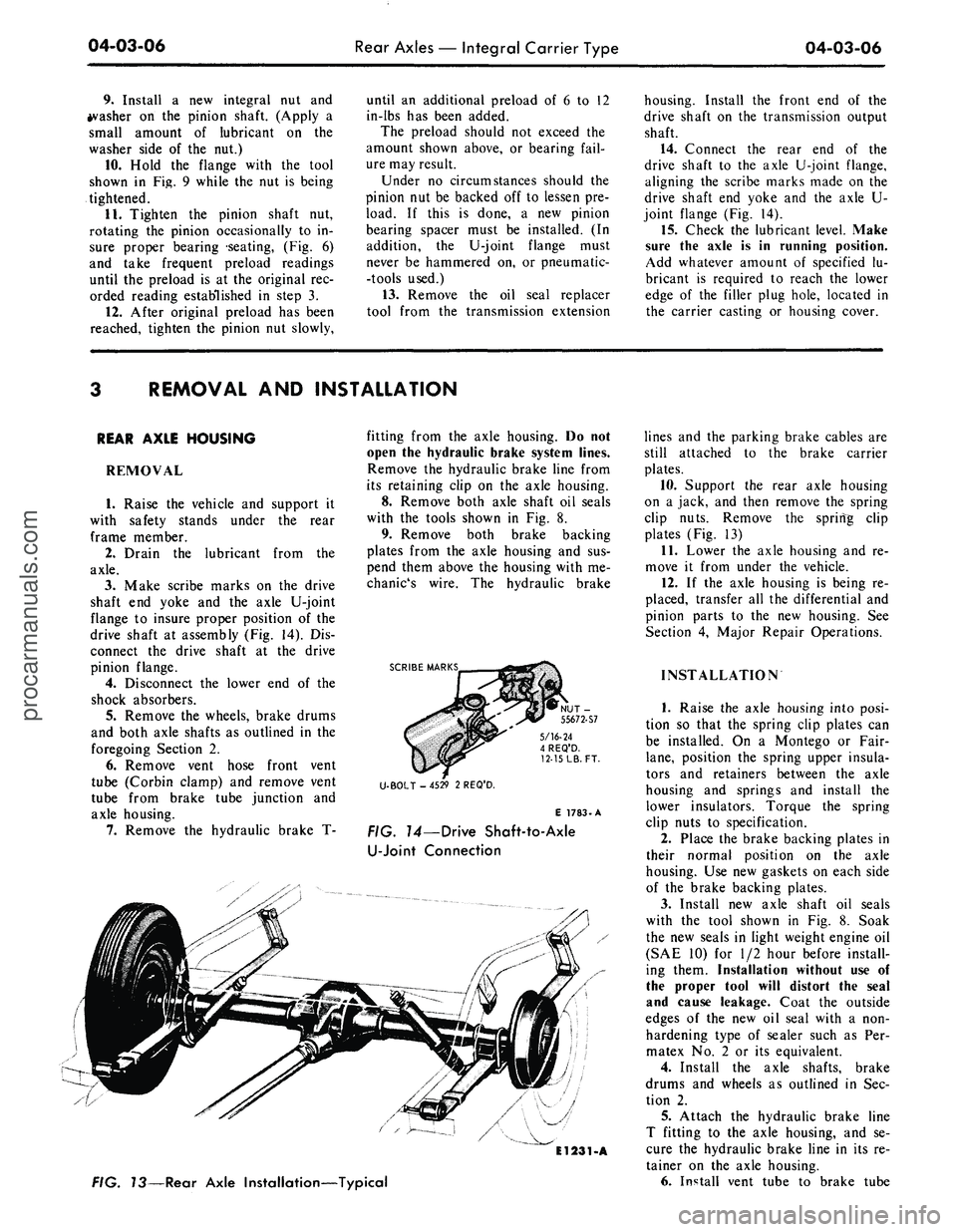

18.

Connect the rear end of the

drive shaft to the axle U-joint flange,

aligning the punch marks made on the

drive shaft end yoke and the axle U-

joint flange (Fig. 14).

19.

Check the lubricant level. Make

sure the axle is in running position.

Add whatever amount of specified lu-

bricant is required to reach the lower

edge of the filler plug hole, located in

the carrier casting or the housing

cover.

REMOVAL AND INSTALLATION

OF THE ORIGINAL U-JOINT

FLANGE

Use procedure as outlined under

drive pinion oil seal replacement.

Tool-T53T-4857-A

or

4851 -A

E1223-B

FIG. 10—Typical Drive Pinion

Flange Removal

El 906A

Tool-T55P-4676-A

or 4676-G

E1907A

INSTALLATION OF A NEW

UNIVERSAL JOINT FLANGE

1.

Raise the vehicle and install safe-

ty stands. Remove both rear wheels

and brake drums.

2.

Disconnect the drive shaft from

the axle U-joint flange. Be careful to

avoid dropping the loose universal

joint bearing cups. Hold the cups on

the spider with tape. Mark the cups so

that they will be in their original posi-

tion in relation to the flange when

they are assembled. Remove the drive

shaft from the transmission extension

housing. Install an oil seal replacer

tool in the transmission extension

housing to prevent transmission fluid

leakage. Refer to the transmission

group for the appropriate tool.

3.

Install an in-lb torque wrench on

the pinion nut Fig. 6. Record the tor-

que required to maintain rotation of

the pinion shaft through several revo-

lutions.

4.

While holding the flange with the

tool shown in Fig. 9, remove the inte-

gral pinion nut and washer.

5.

Clean the pinion bearing retainer

around the oil seal. Place a drain pan

under the seal, or raise the front of

the vehicle higher than the rear. Syn-

thetic seals must not be cleaned,

soaked or washed in cleaning solvents.

6. Using the tool shown in Fig. 10,

remove the U-joint flange.

7.

Check splines on the pinion shaft

to be sure they are free of burrs. If

burrs are evident, remove them by

using a fine crocus cloth, working in

rotational motion, then wipe clean.

Apply a small amount of lubricant

to U-joint splines.

8. Install the U-joint flange using

the tool shown in Fig. 12.

FIG. 9—Removing or Installing

Drive Pinion Nut

FIG.

11

— Typical Drive Pinion

Flange Seal Installation

FIG. 12—U-Joint Flange

Installationprocarmanuals.com

Page 226 of 413

04-03-06

Rear Axles — Integral Carrier Type

04-03-06

9. Install a new integral nut and

ivasher on the pinion shaft. (Apply a

small amount of lubricant on the

washer side of the nut.)

10.

Hold the flange with the tool

shown in Fig. 9 while the nut is being

tightened.

11.

Tighten the pinion shaft nut,

rotating the pinion occasionally to in-

sure proper bearing seating, (Fig. 6)

and take frequent preload readings

until the preload is at the original rec-

orded reading established in step 3.

12.

After original preload has been

reached, tighten the pinion nut slowly,

until an additional preload of 6 to 12

in-lbs has been added.

The preload should not exceed the

amount shown above, or bearing fail-

ure may result.

Under no circumstances should the

pinion nut be backed off to lessen pre-

load. If this is done, a new pinion

bearing spacer must be installed. (In

addition, the U-joint flange must

never be hammered on, or pneumatic-

-tools used.)

13.

Remove the oil seal replacer

tool from the transmission extension

housing. Install the front end of the

drive shaft on the transmission output

shaft.

14.

Connect the rear end of the

drive shaft to the axle U-joint flange,

aligning the scribe marks made on the

drive shaft end yoke and the axle U-

joint flange (Fig. 14).

15.

Check the lubricant level. Make

sure the axle is in running position.

Add whatever amount of specified lu-

bricant is required to reach the lower

edge of the filler plug hole, located in

the carrier casting or housing cover.

REMOVAL AND INSTALLATION

REAR AXLE HOUSING

REMOVAL

1.

Raise the vehicle and support it

with safety stands under the rear

frame member.

2.

Drain the lubricant from the

axle.

3.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly (Fig. 14). Dis-

connect the drive shaft at the drive

pinion flange.

4.

Disconnect the lower end of the

shock absorbers.

5.

Remove the wheels, brake drums

and both axle shafts as outlined in the

foregoing Section 2.

6. Remove vent hose front vent

tube (Corbin clamp) and remove vent

tube from brake tube junction and

axle housing.

7.

Remove the hydraulic brake T-

fitting from the axle housing. Do not

open the hydraulic brake system lines.

Remove the hydraulic brake line from

its retaining clip on the axle housing.

8. Remove both axle shaft oil seals

with the tools shown in Fig. 8.

9. Remove both brake backing

plates from the axle housing and sus-

pend them above the housing with me-

chanic's wire. The hydraulic brake

SCRIBE MARKS

5/16-24

4 REQ'D.

12-15

LB.

FT.

U-BOLT - 4529 2 REQ'D.

E 1783-A

FIG. 14—Drive Shaft-to-Axle

U-Joint

Connection

El231-A

FIG. 73—Rear Axle Installation—Typical

lines and the parking brake cables are

still attached to the brake carrier

plates.

10.

Support the rear axle housing

on a jack, and then remove the spring

clip nuts. Remove the spring clip

plates (Fig. 13)

11.

Lower the axle housing and re-

move it from under the vehicle.

12.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. See

Section 4, Major Repair Operations.

INSTALLATION

1.

Raise the axle housing into posi-

tion so that the spring clip plates can

be installed. On a Montego or Fair-

lane,

position the spring upper insula-

tors and retainers between the axle

housing and springs and install the

lower insulators. Torque the spring

clip nuts to specification.

2.

Place the brake backing plates in

their normal position on the axle

housing. Use new gaskets on each side

of the brake backing plates.

3.

Install new axle shaft oil seals

with the tool shown in Fig. 8. Soak

the new seals in light weight engine oil

(SAE 10) for 1/2 hour before install-

ing them. Installation without use of

the proper tool will distort the seal

and cause leakage. Coat the outside

edges of the new oil seal with a non-

hardening type of sealer such as Per-

matex No. 2 or its equivalent.

4.

Install the axle shafts, brake

drums and wheels as outlined in Sec-

tion 2.

5.

Attach the hydraulic brake line

T fitting to the axle housing, and se-

cure the hydraulic brake line in its re-

tainer on the axle housing.

6. Install vent tube to brake tubeprocarmanuals.com

Page 230 of 413

04-03-10

Rear Axles

—

Integral Carrier Type

04-03-10

in

the

case. Drive

the

shaft into place

and install

the

lock

pin

(Fig.

21).

6. Place

the

ring gear

on the

differ-

ential case

and

install

the

bolts.

Tor-

que

the

bolts

to

specification.

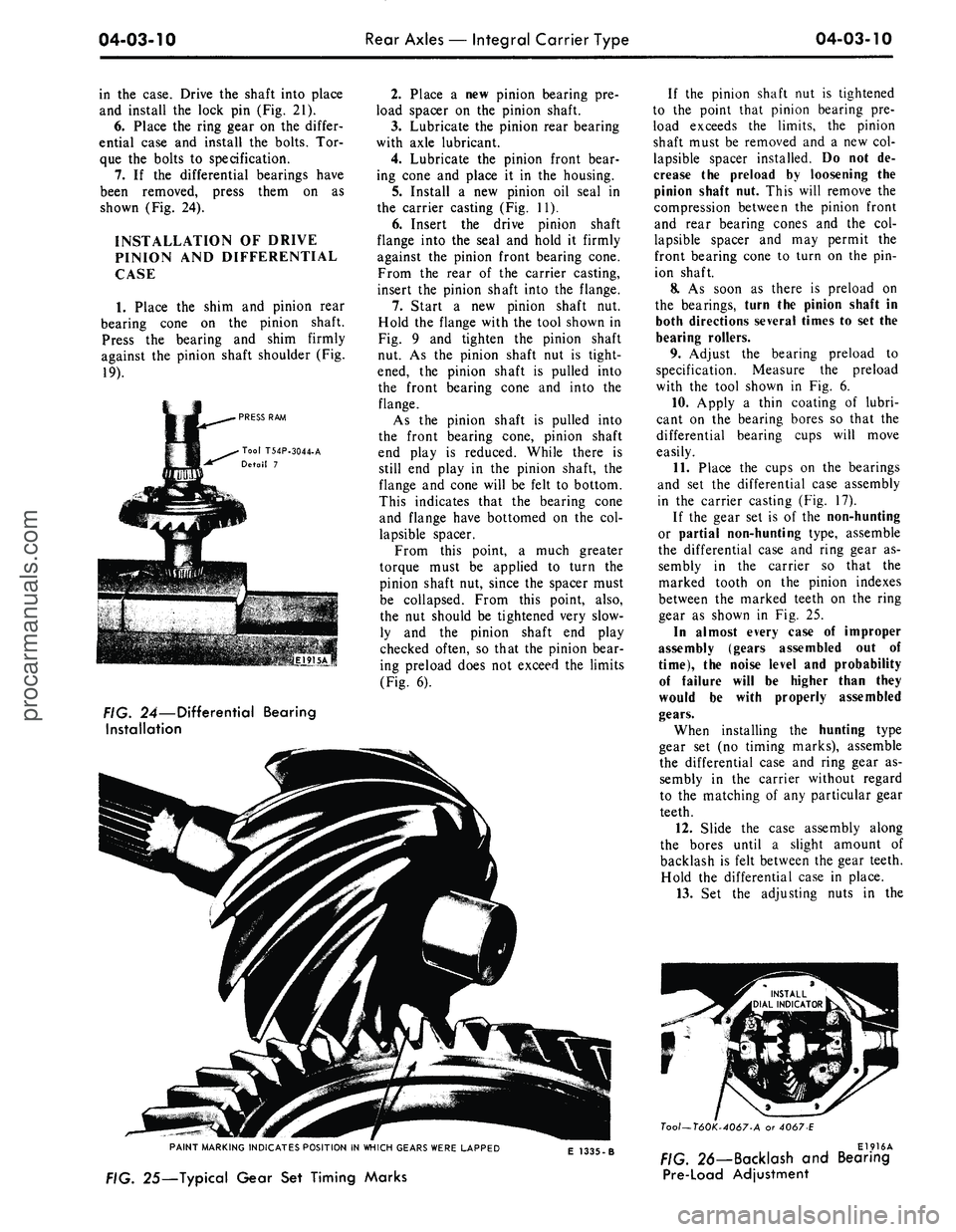

7.

If the

differential bearings have

been removed, press them

on as

shown (Fig.

24).

INSTALLATION

OF

DRIVE

PINION

AND

DIFFERENTIAL

CASE

1.

Place

the

shim

and

pinion rear

bearing cone

on the

pinion shaft.

Press

the

bearing

and

shim firmly

against

the

pinion shaft shoulder (Fig.

19).

PRESS RAM

Tool T54P-3044-A

Detail

7

2.

Place

a new

pinion bearing

pre-

load spacer

on the

pinion shaft.

3.

Lubricate

the

pinion rear bearing

with axle lubricant.

4.

Lubricate

the

pinion front bear-

ing cone

and

place

it in the

housing.

5.

Install

a new

pinion

oil

seal

in

the carrier casting (Fig.

11).

6. Insert

the

drive pinion shaft

flange into

the

seal

and

hold

it

firmly

against

the

pinion front bearing cone.

From

the

rear

of the

carrier casting,

insert

the

pinion shaft into

the

flange.

7.

Start

a new

pinion shaft

nut.

Hold

the

flange with

the

tool shown

in

Fig.

9 and

tighten

the

pinion shaft

nut.

As the

pinion shaft

nut is

tight-

ened,

the

pinion shaft

is

pulled into

the front bearing cone

and

into

the

flange.

As

the

pinion shaft

is

pulled into

the front bearing cone, pinion shaft

end play

is

reduced. While there

is

still

end

play

in the

pinion shaft,

the

flange

and

cone will

be

felt

to

bottom.

This indicates that

the

bearing cone

and flange have bottomed

on the col-

lapsible spacer.

From this point,

a

much greater

torque must

be

applied

to

turn

the

pinion shaft

nut,

since

the

spacer must

be collapsed. From this point, also,

the

nut

should

be

tightened very slow-

ly

and the

pinion shaft

end

play

checked often,

so

that

the

pinion bear-

ing preload does

not

exceed

the

limits

(Fig.

6).

FIG. 24—Differential Bearing

Installation

If

the

pinion shaft

nut is

tightened

to

the

point that pinion bearing

pre-

load exceeds

the

limits,

the

pinion

shaft must

be

removed

and a

new

col-

lapsible spacer installed.

Do not de-

crease

the

preload

by

loosening

the

pinion shaft

nut.

This will remove

the

compression between

the

pinion front

and rear bearing cones

and the col-

lapsible spacer

and may

permit

the

front bearing cone

to

turn

on the pin-

ion shaft.

&

As

soon

as

there

is

preload

on

the bearings, turn

the

pinion shaft

in

both directions several times

to set the

bearing rollers.

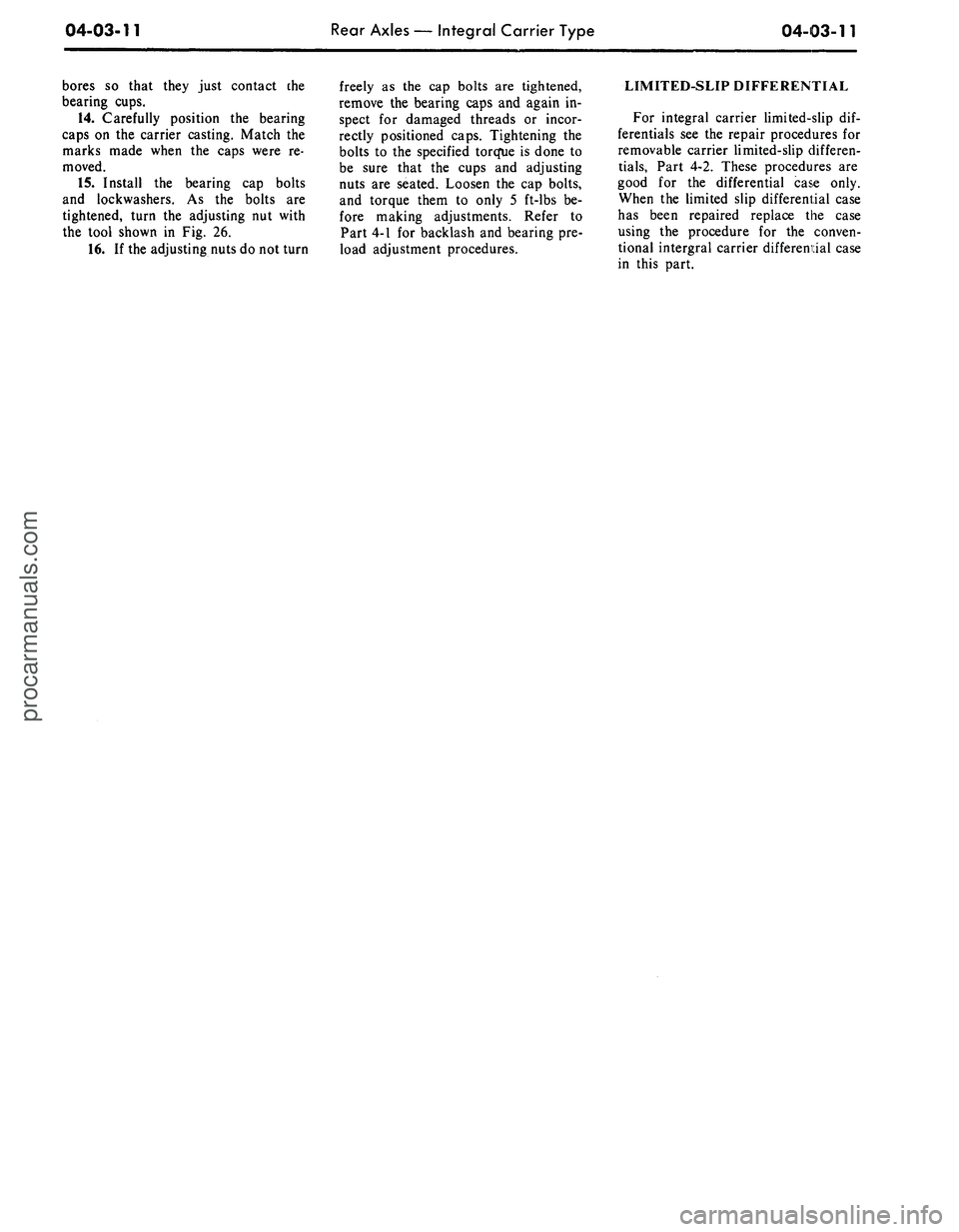

9. Adjust

the

bearing preload

to

specification. Measure

the

preload

with

the

tool shown

in Fig. 6.

10.

Apply

a

thin coating

of

lubri-

cant

on the

bearing bores

so

that

the

differential bearing cups will move

easily.

11.

Place

the

cups

on the

bearings

and

set the

differential case assembly

in

the

carrier casting (Fig.

17).

If

the

gear

set is of the

non-hunting

or partial non-hunting type, assemble

the differential case

and

ring gear

as-

sembly

in the

carrier

so

that

the

marked tooth

on the

pinion indexes

between

the

marked teeth

on the

ring

gear

as

shown

in Fig. 25.

In almost every case

of

improper

assembly (gears assembled

out of

time),

the

noise level

and

probability

of failure will

be

higher than they

would

be

with properly assembled

gears.

When installing

the

hunting type

gear

set (no

timing marks), assemble

the differential case

and

ring gear

as-

sembly

in the

carrier without regard

to

the

matching

of any

particular gear

teeth.

12.

Slide

the

case assembly along

the bores until

a

slight amount

of

backlash

is

felt between

the

gear teeth.

Hold

the

differential case

in

place.

13.

Set the

adjusting nuts

in the

PAINT MARKING INDICATES POSITION

IN

WHICH GEARS WERE LAPPED

E 1335-B

FIG. 25—Typical Gear

Set

Timing Marks

7oo/—T60K-4067-A or 4067 E

E1916A

FIG. 26—Backlash

and

Bearing

Pre-Load Adjustmentprocarmanuals.com

Page 231 of 413

04-03-11

Rear Axles — Integral Carrier Type

04-03-11

bores so that they just contact the

bearing cups.

14.

Carefully position the bearing

caps on the carrier casting. Match the

marks made when the caps were re-

moved.

15.

Install the bearing cap bolts

and lockwashers. As the bolts are

tightened, turn the adjusting nut with

the tool shown in Fig. 26.

16.

If the adjusting nuts do not turn

freely as the cap bolts are tightened,

remove the bearing caps and again in-

spect for damaged threads or incor-

rectly positioned caps. Tightening the

bolts to the specified torcfue is done to

be sure that the cups and adjusting

nuts are seated. Loosen the cap bolts,

and torque them to only 5 ft-lbs be-

fore making adjustments. Refer to

Part 4-1 for backlash and bearing pre-

load adjustment procedures.

LIMITED-SLIP DIFFERENTIAL

For integral carrier limited-slip dif-

ferentials see the repair procedures for

removable carrier limited-slip differen-

tials,

Part 4-2. These procedures are

good for the differential case only.

When the limited slip differential case

has been repaired replace the case

using the procedure for the conven-

tional intergral carrier differendal case

in this part.procarmanuals.com

Page 234 of 413

04-04-03

Rear Axle

—

Ford Light-Duty (WER)

04-04-03

LOCK BOLT

DIFFERENTIAL PINION SHAFT

E 1596- A

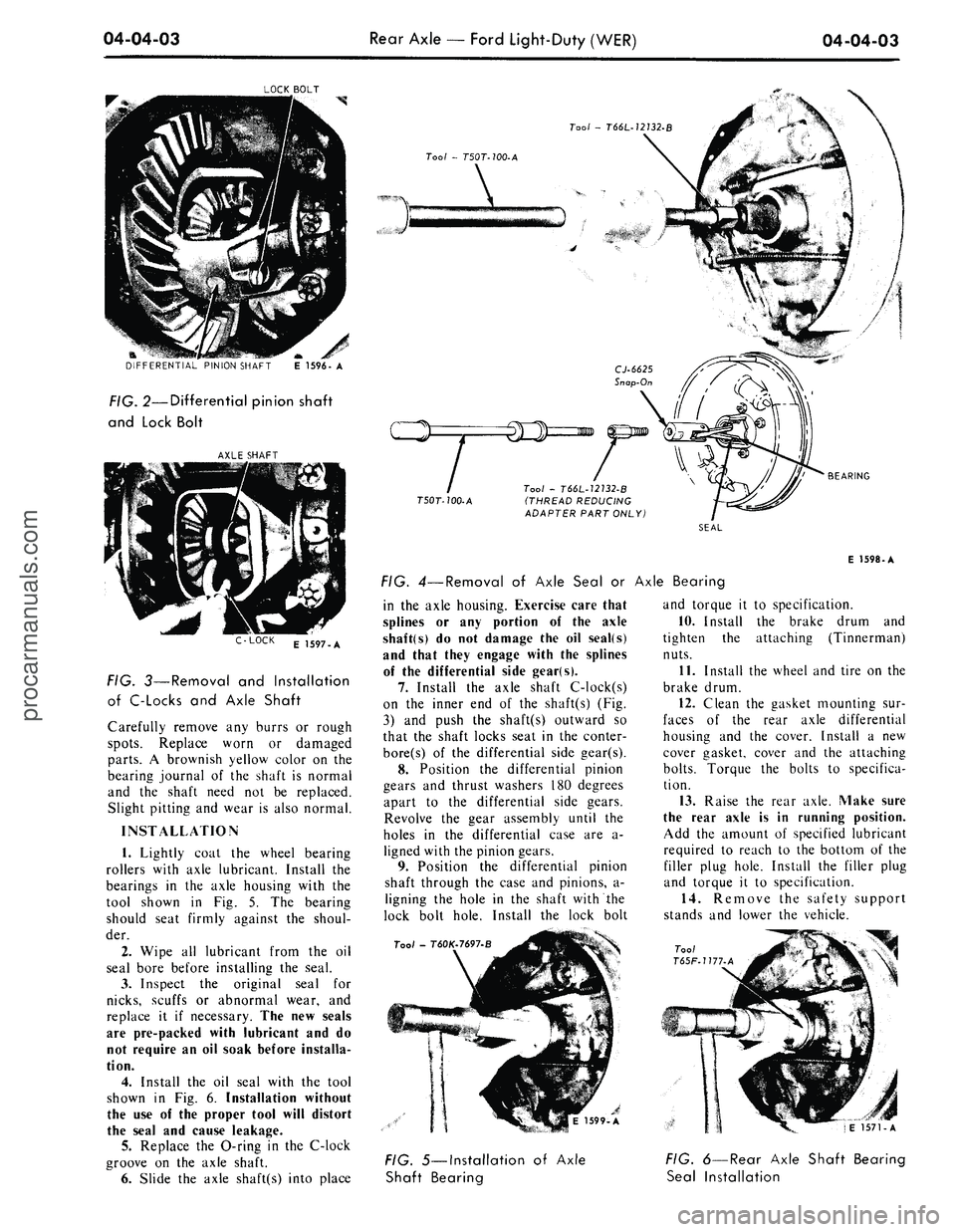

FIG.

2—Differential pinion shaft

and Lock Bolt

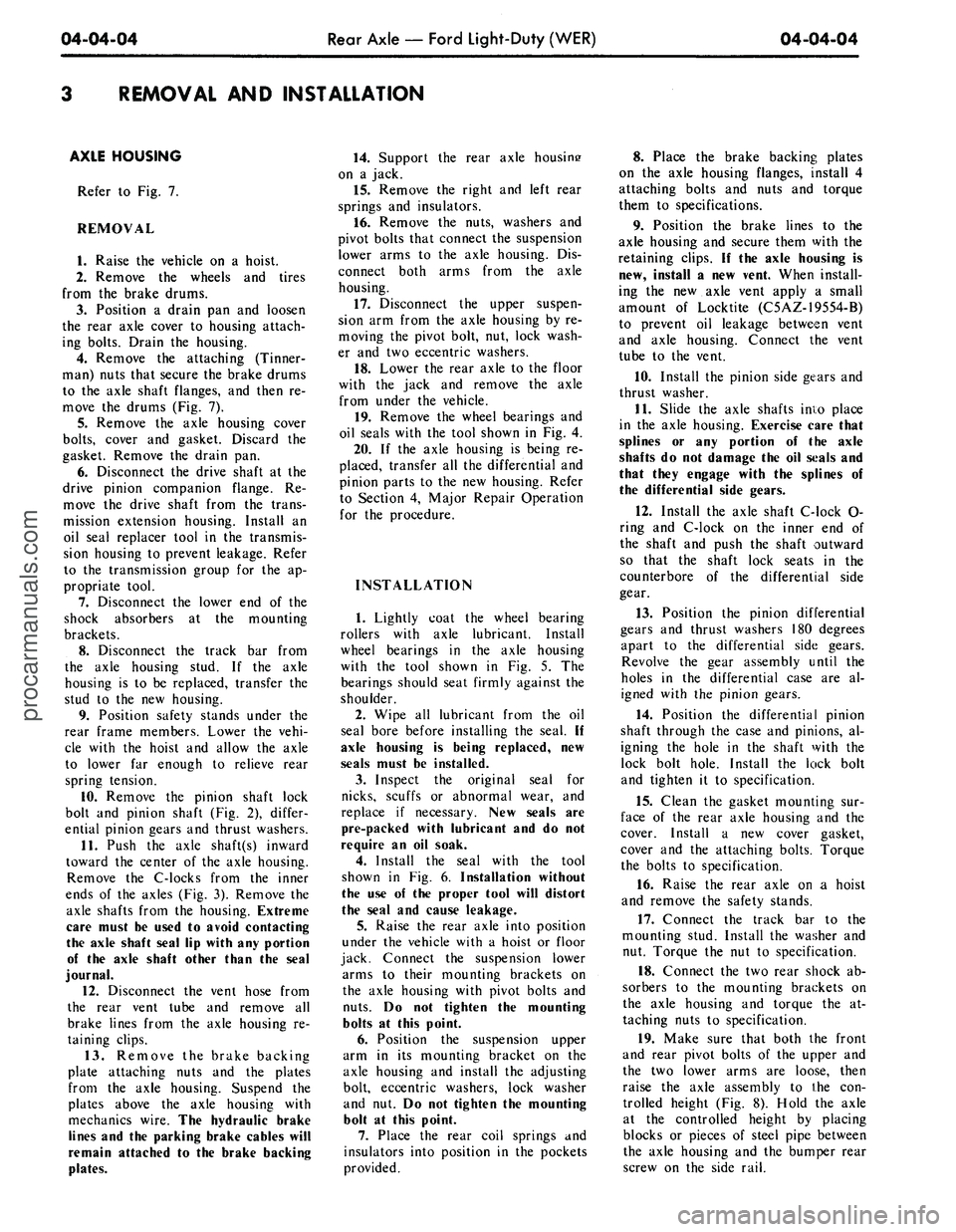

AXLE SHAFT

LOCK

E 1597-A

FIG. 3—Removal

and

Installation

of C-Locks

and

Axle Shaft

Carefully remove

any

burrs

or

rough

spots.

Replace worn

or

damaged

parts.

A

brownish yellow color

on the

bearing journal

of the

shaft

is

normal

and

the

shaft need

not be

replaced.

Slight pitting

and

wear

is

also normal.

INSTALLATION

1.

Lightly coat

the

wheel bearing

rollers with axle lubricant. Install

the

bearings

in the

axle housing with

the

tool shown

in Fig. 5. The

bearing

should seat firmly against

the

shoul-

der.

2.

Wipe

all

lubricant from

the oil

seal bore before installing

the

seal.

3.

Inspect

the

original seal

for

nicks,

scuffs

or

abnormal wear,

and

replace

it if

necessary.

The new

seals

are pre-packed with lubricant

and do

not require

an oil

soak before installa-

tion.

4.

Install

the oil

seal with

the

tool

shown

in Fig. 6.

Installation without

the

use of the

proper tool will distort

the seal

and

cause leakage.

5. Replace

the

O-ring

in the

C-lock

groove

on the

axle shaft.

6. Slide

the

axle shaft(s) into place

Tool

-

T66L-12132

Tool

-

7507- 700-A

\

1

T50T-100-A

BEARING

Tool - 766L-72J32-8

(THREAD

REDUCING

ADAPTER PART ONLY)

SEAL

FIG. 4—Removal

of

Axle Seal

or

in

the

axle housing. Exercise care that

splines

or any

portion

of the

axle

shaft(s)

do not

damage

the oil

seal(s)

and that they engage with

the

splines

of

the

differential side gear(s).

7. Install

the

axle shaft C-lock(s)

on

the

inner

end of the

shaft(s)

(Fig.

3)

and

push

the

shaft(s) outward

so

that

the

shaft locks seat

in the

conter-

bore(s)

of the

differential side gear(s).

8. Position

the

differential pinion

gears

and

thrust washers

180

degrees

apart

to the

differential side gears.

Revolve

the

gear assembly until

the

holes

in the

differential case

are a-

ligned with the pinion gears.

9. Position

the

differential pinion

shaft through

the

case

and

pinions,

a-

ligning

the

hole

in the

shaft with

the

lock bolt hole. Install

the

lock bolt

Tool

-

760K-7697.fi

E 1598.A

Axle Bearing

and torque

it to

specification.

10.

Install

the

brake drum

and

tighten

the

attaching (Tinnerman)

nuts.

11.

Install

the

wheel

and

tire

on the

brake drum.

12.

Clean

the

gasket mounting

sur-

faces

of the

rear axle differential

housing

and the

cover. Install

a new

cover gasket, cover

and the

attaching

bolts.

Torque

the

bolts

to

specifica-

tion.

13.

Raise

the

rear axle. Make sure

the rear axle

is in

running position.

Add

the

amount

of

specified lubricant

required

to

reach

to the

bottom

of the

filler plug hole. Install

the

filler plug

and torque

it to

specification.

14.

Remove

the

safety support

stands

and

lower

the

vehicle.

7oo/

765F-7 777-A

E 1571-A

FIG. 5—Installation

of

Axle

Shaft Bearing

FIG.

6—Rear

Axle Shaft Bearing

Seal Installationprocarmanuals.com

Page 235 of 413

04-04-04

Rear Axle — Ford Light-Duty (WER)

04-04-04

REMOVAL AND INSTALLATION

AXLE HOUSING

Refer to Fig. 7.

REMOVAL

1.

Raise the vehicle on a hoist.

2.

Remove the wheels and tires

from the brake drums.

3.

Position a drain pan and loosen

the rear axle cover to housing attach-

ing bolts. Drain the housing.

4.

Remove the attaching (Tinner-

man) nuts that secure the brake drums

to the axle shaft flanges, and then re-

move the drums (Fig. 7).

5.

Remove the axle housing cover

bolts,

cover and gasket. Discard the

gasket. Remove the drain pan.

6. Disconnect the drive shaft at the

drive pinion companion flange. Re-

move the drive shaft from the trans-

mission extension housing. Install an

oil seal replacer tool in the transmis-

sion housing to prevent leakage. Refer

to the transmission group for the ap-

propriate tool.

7.

Disconnect the lower end of the

shock absorbers at the mounting

brackets.

8. Disconnect the track bar from

the axle housing stud. If the axle

housing is to be replaced, transfer the

stud to the new housing.

9. Position safety stands under the

rear frame members. Lower the vehi-

cle with the hoist and allow the axle

to lower far enough to relieve rear

spring tension.

10.

Remove the pinion shaft lock

bolt and pinion shaft (Fig. 2), differ-

ential pinion gears and thrust washers.

11.

Push the axle shaft(s) inward

toward the center of the axle housing.

Remove the C-locks from the inner

ends of the axles (Fig. 3). Remove the

axle shafts from the housing. Extreme

care must be used to avoid contacting

the axle shaft seal lip with any portion

of the axle shaft other than the seal

journal.

12.

Disconnect the vent hose from

the rear vent tube and remove all

brake lines from the axle housing re-

taining clips.

13.

Remove the brake backing

plate attaching nuts and the plates

from the axle housing. Suspend the

plates above the axle housing with

mechanics wire. The hydraulic brake

lines and the parking brake cables will

remain attached to the brake backing

plates.

14.

Support the rear axle housine

on a jack.

15.

Remove the right and left rear

springs and insulators.

16.

Remove the nuts, washers and

pivot bolts that connect the suspension

lower arms to the axle housing. Dis-

connect both arms from the axle

housing.

17.

Disconnect the upper suspen-

sion arm from the axle housing by re-

moving the pivot bolt, nut, lock wash-

er and two eccentric washers.

18.

Lower the rear axle to the floor

with the jack and remove the axle

from under the vehicle.

19.

Remove the wheel bearings and

oil seals with the tool shown in Fig. 4.

20.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. Refer

to Section 4, Major Repair Operation

for the procedure.

INSTALLATION

1.

Lightly coat the wheel bearing

rollers with axle lubricant. Install

wheel bearings in the axle housing

with the tool shown in Fig. 5. The

bearings should seat firmly against the

shoulder.

2.

Wipe all lubricant from the oil

seal bore before installing the seal. If

axle housing is being replaced, new

seals must be installed.

3.

Inspect the original seal for

nicks,

scuffs or abnormal wear, and

replace if necessary. New seals are

pre-packed with lubricant and do not

require an oil soak.

4.

Install the seal with the tool

shown in Fig. 6. Installation without

the use of the proper tool will distort

the seal and cause leakage.

5. Raise the rear axle into position

under the vehicle with a hoist or floor

jack. Connect the suspension lower

arms to their mounting brackets on

the axle housing with pivot bolts and

nuts.

Do not tighten the mounting

bolts at this point.

6. Position the suspension upper

arm in its mounting bracket on the

axle housing and install the adjusting

bolt, eccentric washers, lock washer

and nut. Do not tighten the mounting

bolt at this point.

7.

Place the rear coil springs and

insulators into position in the pockets

provided.

8. Place the brake backing plates

on the axle housing flanges, install 4

attaching bolts and nuts and torque

them to specifications.

9. Position the brake lines to the

axle housing and secure them with the

retaining clips. If the axle housing is

new, install a new vent. When install-

ing the new axle vent apply a small

amount of Locktite (C5AZ-19554-B)

to prevent oil leakage between vent

and axle housing. Connect the vent

tube to the vent.

10.

Install the pinion side gears and

thrust washer.

11.

Slide the axle shafts into place

in the axle housing. Exercise care that

splines or any portion of the axle

shafts do not damage the oil seals and

that they engage with the splines of

the differential side gears.

12.

Install the axle shaft C-lock O-

ring and C-lock on the inner end of

the shaft and push the shaft outward

so that the shaft lock seats in the

counterbore of the differential side

gear.

13.

Position the pinion differential

gears and thrust washers 180 degrees

apart to the differential side gears.

Revolve the gear assembly until the

holes in the differential case are al-

igned with the pinion gears.

14.

Position the differential pinion

shaft through the case and pinions, al-

igning the hole in the shaft with the

lock bolt hole. Install the lock bolt

and tighten it to specification.

15.

Clean the gasket mounting sur-

face of the rear axle housing and the

cover. Install a new cover gasket,

cover and the attaching bolts. Torque

the bolts to specification.

16.

Raise the rear axle on a hoist

and remove the safety stands.

17.

Connect the track bar to the

mounting stud. Install the washer and

nut. Torque the nut to specification.

18.

Connect the two rear shock ab-

sorbers to the mounting brackets on

the axle housing and torque the at-

taching nuts to specification.

19.

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, then

raise the axle assembly to the con-

trolled height (Fig. 8). Hold the axle

at the controlled height by placing

blocks or pieces of steel pipe between

the axle housing and the bumper rear

screw on the side rail.procarmanuals.com

Page 237 of 413

04-04-06

Rear Axle — Ford Light-Duty (WER)

04-04-06

20.

With the axle at controlled

height, torque the suspension upper

and lower arm front pivot bolts and

nuts to specifications. Torque the

lower arm to axle housing pivot bolts

and nuts to specifications.

21.

Remove the oil seal replacer

from the transmission extension hous-

ing. Install the drive shaft in the ex-

tension housing. Align the scribe

marks on the cups, flange and drive

shaft and connect the drive shaft at

the drive pinion flange. Torque the at-

taching bolts to specification

FRAME

TIGHTEN ARM

ATTACHING BOLTS

AT 5-45/64 INCH

HEIGHT POSITION

5-45/64 INCH

HEIGHT FOR

INSTALLATION

OF ARMS

E 1600-B

FIG.8—

Axle

Normal Curb Height

and Controlled Height for Arm

Installation

22.

Install the brake drum and at-

taching (Tinnerman) nuts.

23.

Install the wheel and tire on the

brake drum. Install the wheel covers.

24.

Adjust the drive shaft and pin-

ion angle to specification.

25.

Add the amount of specified lu-

bricant required to reach to the bot-

tom of the filler plug hole. Make sure

the rear axle is in running position.

Install the filler plug and torque it to

specification.

26.

Lower the vehicle.

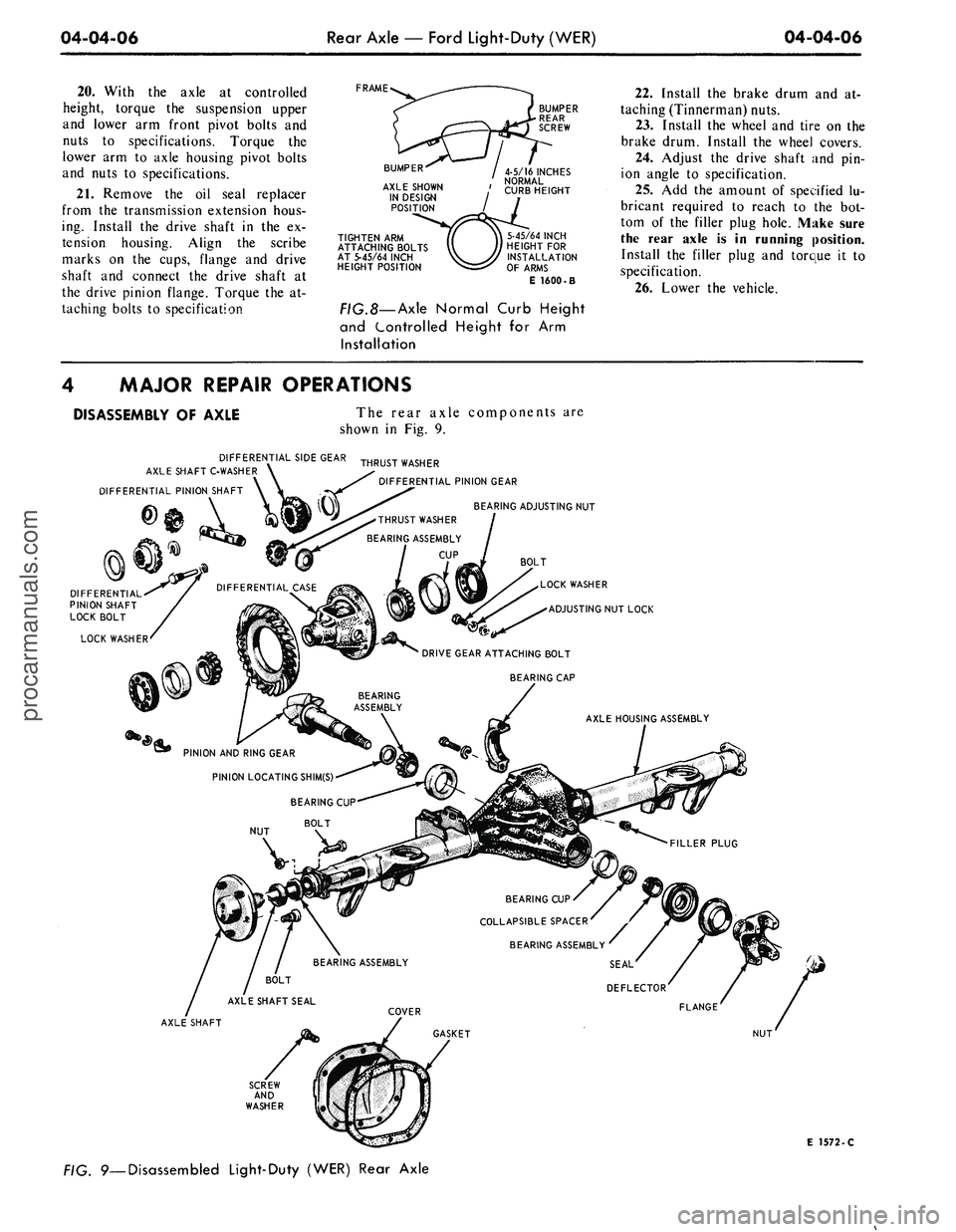

4 MAJOR REPAIR OPERATIONS

DISASSEMBLY OF AXLE

The rear axle components are

shown in Fig. 9.

DIFFERENTIAL SIDE GEAR

AXLE SHAFT C-WASHER \

DIFFERENTIAL PINION SHAFT

THRUST WASHER

BEARING ASSEMBLY

CUP

THRUST WASHER

^^ DIFFERENTIAL PINION GEAR

BEARING ADJUSTING NUT

DIFFERENTIAL

PINION SHAFT

LOCK BOLT

LOCK WASHER

BOLT

LOCK WASHER

ADJUSTING NUT LOCK

DRIVE GEAR ATTACHING BOLT

BEARING CAP

AXLE HOUSING ASSEMBLY

PINION AND RING GEAR

PINION LOCATING SHIM(S)

BEARING CUP

BOLT

NUT

BEARING CUP

COLLAPSIBLE SPACER

AXLE SHAFT

E 1572-C

FIG. 9—Disassembled Light-Duty (WER) Rear Axleprocarmanuals.com

Page 240 of 413

04-04-09

Rear Axle — Ford Light-Duty (WER)

04-04-09

case several revolutions in each direc-

tion while the bearings are loaded to

seat the bearings in their cups. This

step is important.

5. Again loosen the right nut to re-

lease the preload. Check to see that

the left nut contacts the bearing cup.

Using the dial indicator set-up shown

in Fig. 13, Part 4-1, adjust the preload

to 0.008 to 0.012 case spread for new

bearings or 0.005 to 0.008 for the

original bearings, if re-used.

6. Check the runout of the differen-

tial case flange with a dial indicator.

If the runout does not now exceed

specifications, install a new ring gear,

if the runout still exceeds specifica-

tions,

the ring gear is true and the

trouble is due to either a defective

casting or worn bearings.

7.

Remove the differential case

from the carrier and remove the side

bearings from the case.

8. Install new bearings on the case

hubs,

and again install the differential

assembly in the carrier without the

ring gear.

9. Check the case runout again with

the new bearings. If the runout is now

within limits, the old bearings were

excessively worn. Use the new bear-

ings for assembly. If the runout is still

excessive, the case is defective and

should be replaced.

ASSEMBLY OF AXLE

Refer to Part 4-1 of this Shop

Manual for Cleaning and Inspection

procedures before starting assembly

operations.

ASSEMBLY OF

DIFFERENTIAL CASE

1.

Place the ring gear on the differ-

ential case. Install the retaining bolts

and torque them to specification.

2.

If the differential bearings were

removed, press them on as shown in

Fig. 17.

3.

Insert the pinion gear shaft lock

bolt into the case (loosely).

INSTALLATION OF DRIVE

PINION AND

DIFFERENTIAL CASE

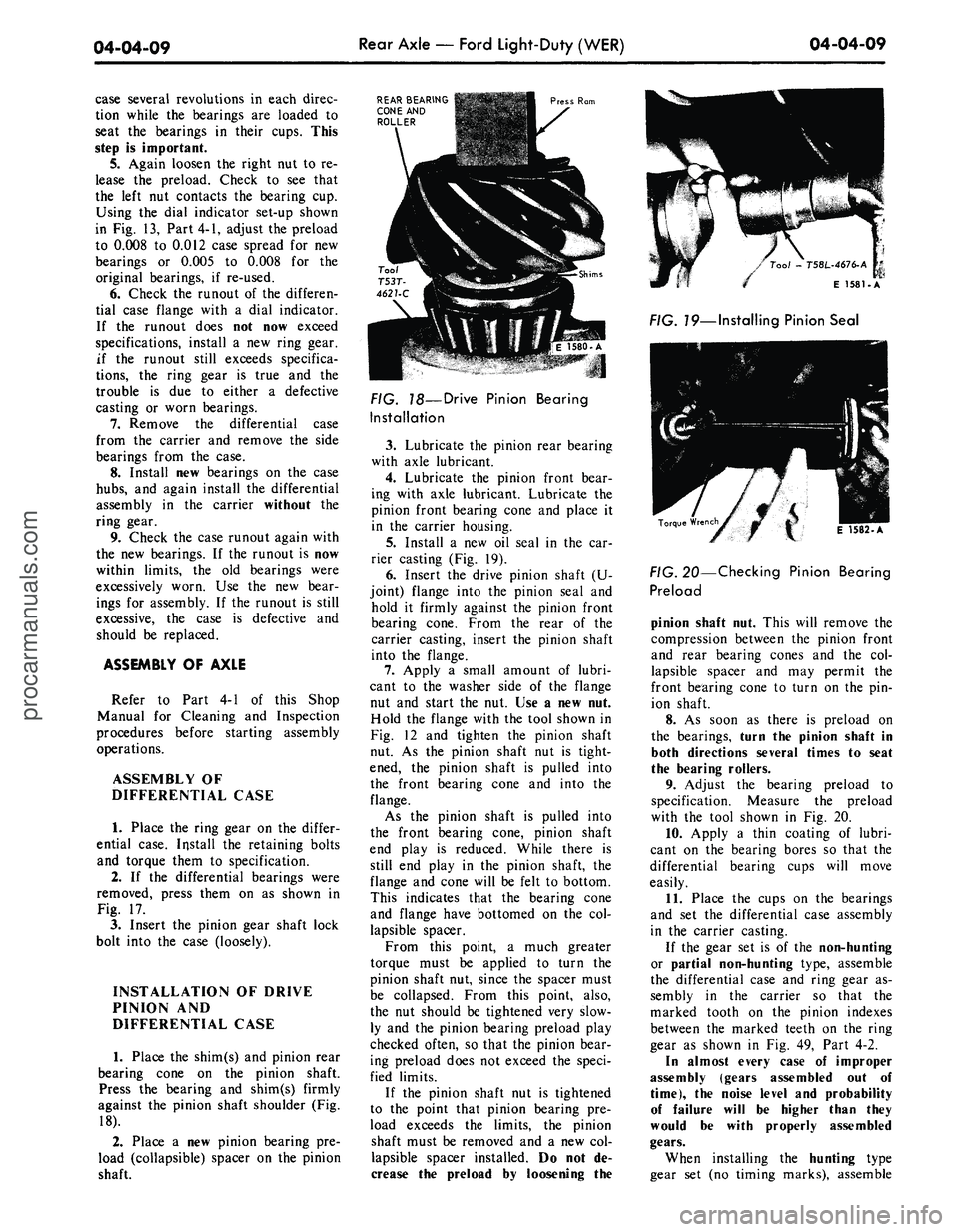

1.

Place the shim(s) and pinion rear

bearing cone on the pinion shaft.

Press the bearing and shim(s) firmly

against the pinion shaft shoulder (Fig.

18).

2.

Place a new pinion bearing pre-

load (collapsible) spacer on the pinion

shaft.

REAR BEARING

CONE AND

ROLLER

Press Ram

FIG. 18—Drive Pinion Bearing

Installation

3.

Lubricate the pinion rear bearing

with axle lubricant.

4.

Lubricate the pinion front bear-

ing with axle lubricant. Lubricate the

pinion front bearing cone and place it

in the carrier housing.

5.

Install a new oil seal in the car-

rier casting (Fig. 19).

6. Insert the drive pinion shaft (U-

joint) flange into the pinion seal and

hold it firmly against the pinion front

bearing cone. From the rear of the

carrier casting, insert the pinion shaft

into the flange.

7.

Apply a small amount of lubri-

cant to the washer side of the flange

nut and start the nut. Use a new nut.

Hold the flange with the tool shown in

Fig. 12 and tighten the pinion shaft

nut. As the pinion shaft nut is tight-

ened, the pinion shaft is pulled into

the front bearing cone and into the

flange.

As the pinion shaft is pulled into

the front bearing cone, pinion shaft

end play is reduced. While there is

still end play in the pinion shaft, the

flange and cone will be felt to bottom.

This indicates that the bearing cone

and flange have bottomed on the col-

lapsible spacer.

From this point, a much greater

torque must be applied to turn the

pinion shaft nut, since the spacer must

be collapsed. From this point, also,

the nut should be tightened very slow-

ly and the pinion bearing preload play

checked often, so that the pinion bear-

ing preload does not exceed the speci-

fied limits.

If the pinion shaft nut is tightened

to the point that pinion bearing pre-

load exceeds the limits, the pinion

shaft must be removed and a new col-

lapsible spacer installed. Do not de-

crease the preload by loosening the

/

Tool

-

T58L-4676-A

/ E

1581-A

FIG. 19—Installing Pinion Seal

E 1582-A

FIG. 20—Checking Pinion Bearing

Preload

pinion shaft nut. This will remove the

compression between the pinion front

and rear bearing cones and the col-

lapsible spacer and may permit the

front bearing cone to turn on the pin-

ion shaft.

8. As soon as there is preload on

the bearings, turn the pinion shaft in

both directions several times to seat

the bearing rollers.

9. Adjust the bearing preload to

specification. Measure the preload

with the tool shown in Fig. 20.

10.

Apply a thin coating of lubri-

cant on the bearing bores so that the

differential bearing cups will move

easily.

11.

Place the cups on the bearings

and set the differential case assembly

in the carrier casting.

If the gear set is of the non-hunting

or partial non-hunting type, assemble

the differential case and ring gear as-

sembly in the carrier so that the

marked tooth on the pinion indexes

between the marked teeth on the ring

gear as shown in Fig. 49, Part 4-2.

In almost every case of improper

assembly (gears assembled out of

time),

the noise level and probability

of failure will be higher than they

would be with properly assembled

gears.

When installing the hunting type

gear set (no timing marks), assembleprocarmanuals.com

Page 241 of 413

04-04-10

Rear Axle — Ford Light-Duty (WER)

04-04-10

the differential case and ring gear as-

sembly in the carrier without regard

to the matching of any particular gear

teeth.

12.

Slide the case assembly along

the bores until a slight amount of

backlash is felt between the gear teeth.

Hold the differential case in place.

13.

Set the adjusting nuts in the

bores so that they just contact the

bearing cups.

14.

Carefully position the bearing

caps on the carrier casting. Match the

marks made when the caps were re-

moved (Fig. 21).

15.

Install the bearing cap bolts

and lockwashers. As the bolts are

tightened, turn the adjusting nut with

the tool shown in Fig. 21.

16.

If the adjusting nuts do not turn

freely as the cap bolts are tightened,

remove the bearing caps and again in-

spect for damaged threads or incor-

rectly positioned caps. Tightening the

bolts to the specified torque is done to

be sure that the cups and adjusting

.BEARING CAP IDENTIFICATION-j

MARKS

A

T57L-4067-A

E 1583-A

27—Bearing Cap Installation

nuts are seated. Loosen the cap bolts,

and torque them to only 5 ft-)bs be-

fore making adjustments. Refer to

part 4-1, Section 2 of this shop manu-

al for backlash and bearing preload

adjustment procedures.

17.

Clean the marking compound

from the gear teeth.

18.

Install both side bearing adjust-

ing nut locks (bolts) and torque them

to specification.

19.

Install the differential pinion

side gears and thrust washers.

20.

Install the rear wheel bearings

seals,

rear axle shafts, wheels and tires

and the axle carrier cover as outlined

under Part 4-3, Section 2, Rear Axle

Shaft, Wheel Bearing and Oil Seal

Replacement, Steps 10 through 19.

21.

Raise the axle all the way up.

Rdnove the safety support stands.

22.

Connect the track bar to the

mounting stud. Install the washer and

retaining nut, and torque the nut to

specification.

23.

Remove the oil seal replacer

tool from the transmission extension

housing. Install the front end of the

drive shaft on the transmission.output

shaft. Align the scribe marks on the

cups,

flange and drive shaft and con-

nect the rear end of the drive shaft to

the axle U-joint flange. Torque the re-

taining bolts to specification.

24.

Lower the vehicle.procarmanuals.com

Page 242 of 413

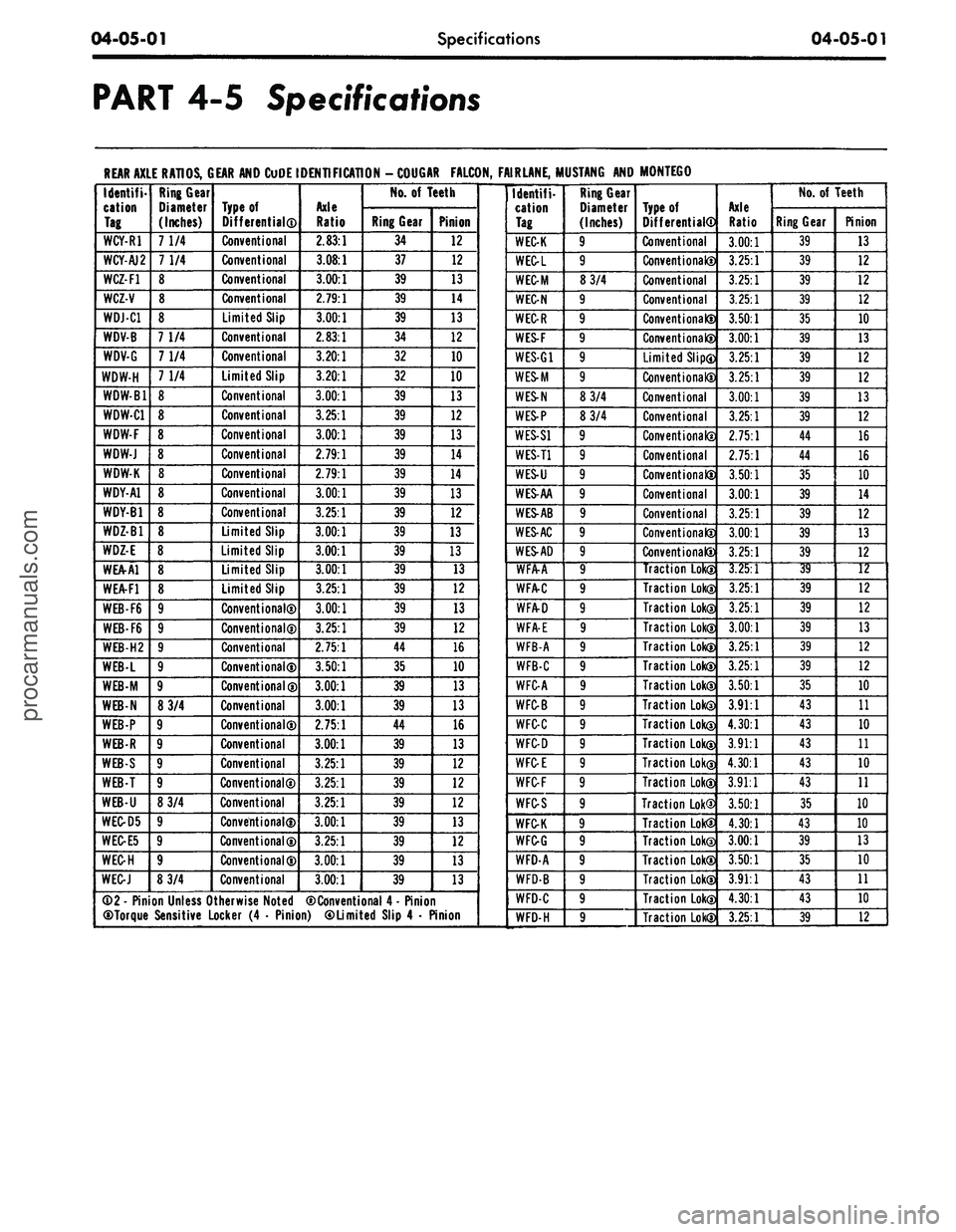

04-05-01

Specifications

04-05-01

PART

4-5

Specifications

REAR AXLE RATIOS. GEAR AND CuDE IDENTIFICATION

-

COUGAR FALCON. FAIRLANE. MUSTANG AND MONTEGO

Identifi-

cation

Tag

WCY-R1

WCY-AJ2

WCZ-F1

WCZ-V

WDJ-C1

WDV-B

WDV-G

WDW-H

WDW-B1

WDW-C1

WDW-F

WDW-J

WDW-K

WDY-A1

WDY-B1

WDZ-B1

WDZ-E

WEA-A1

WEA-F1

WEB-F6

WEB-F6

WEB-H2

WEB-L

WEB-M

WEB-N

WEB-P

WEB-R

WEB-S

WEB-T

WEB-U

WEC-D5

WEC-E5

WEC-H

WEC-J

©2-

Pini

©Torque

Ring Gear

Diameter

(Inches)

7 1/4

7

1/4

8

8

8

7

1/4

7 1/4

7 1/4

8

8

8

8

8

8

8

8

8

8

8

9

9

9

9

9

8 3/4

9

9

9

9

8 3/4

9

9

9

8

3/4

Type

of

Differential®

Conventional

Conventional

Conventional

Conventional

Limited Slip

Conventional

Conventional

Limited Slip

Conventional

Conventional

Conventional

Conventional

Conventional

Conventional

Conventional

Limited Slip

Limited Slip

Limited Slip

Limited Slip

Conventional®

Conventional®

Conventional

Conventional®

Conventional®

Conventional

Conventional®

Conventional

Conventional

Conventional®

Conventional

Conventional®

Conventional®

Conventional®

Conventional

Axle

Ratio

2.83:1

3.08:1

3.00:1

2.79:1

3.00:1

2.83:1

3.20:1

3.20:1

3.00:1

3.25:1

3.00:1

2.79:1

2.79:1

3.00:1

3.25:1

3.00:1

3.00:1

3.00:1

3.25:1

3.00:1

3.25:1

2.75:1

3.50:1

3.00:1

3.00:1

2.75:1

3.00:1

3.25:1

3.25:1

3.25:1

3.00:1

3.25:1

3.00:1

3.00:1

No.

of

Teeth

Ring Gear

34

37

39

39

39

34

32

32

39

39

39

39

39

39

39

39

39

39

39

39

39

44

35

39

39

44

39

39

39

39

39

39

39

39

Pinion

12

12

13

14

13

12

10

10

13

12

13

14

14

13

12

13

13

13

12

13

12

16

10

13

13

16

13

12

12

12

13

12

13

13

on Unless Otherwise Noted ©Conventional

4 •

Pinion

Sensitive Locker

(4 •

Pinion) ©Limited Slip

4 -

Pinion

Identifi-

cation

Tag

WEC-K

WEC-L

WEC-M

WEC-N

WEC-R

WES-F

WES-G1

WES-M

WES-N

WES-P

WES-SI

WES-T1

WES-U

WES-AA

WES-AB

WES-AC

WES-AD

WFA-A

WFA-C

WFA-D

WFA-E

WFB-A

WFB-C

WFC-A

WFC-B

WFC-C

WFC-D

WFC-E

WFC-F

WFOS

WFC-K

WFC-G

WFD-A

WFD-B

WFD-C

WFD-H

Ring Gear

Diameter

(Inches)

9

9

8 3/4

9

9

9

9

9

8 3/4

8 3/4

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

Type

of

Differential®

Conventional

Conventional®

Conventional

Conventional

Conventional®

Conventional®

Limited Slip®

Conventional®

Conventional

Conventional

Conventional®

Conventional

Conventional®

Conventional

Conventional

Conventional®

Conventional®

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok©

Traction Lok©

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Traction LokCD

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Traction Lok®

Axle

Ratio

3.00:1

3.25:1

3.25:1

3.25:1

3.50:1

3.00:1

3.25:1

3.25:1

3.00:1

3.25:1

2.75:1

2.75:1

3.50:1

3.00:1

3.25:1

3.00:1

3.25:1

3.25:1

3.25:1

3.25:1

3.00:1

3.25:1

3.25:1

3.50:1

3.91:1

4.30:1

3.91:1

4.30:1

3.91:1

3.50:1

4.30:1

3.00:1

3.50:1

3.91:1

4.30:1

3.25:1

No.

of

Teeth

Ring Gear

39

39

39

39

35

39

39

39

39

39

44

44

35

39

39

39

39

39

39

39

39

39

39

35

43

43

43

43

43

35

43

39

35

43

43

39

Pinion

13

12

12

12

10

13

12

12

13

12

16

16

10

14

12

13

12

12

12

12

13

12

12

10

11

10

11

10

11

10

10

13

10

11

10

12procarmanuals.com