ignition HONDA INTEGRA 1998 4.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 493 of 1681

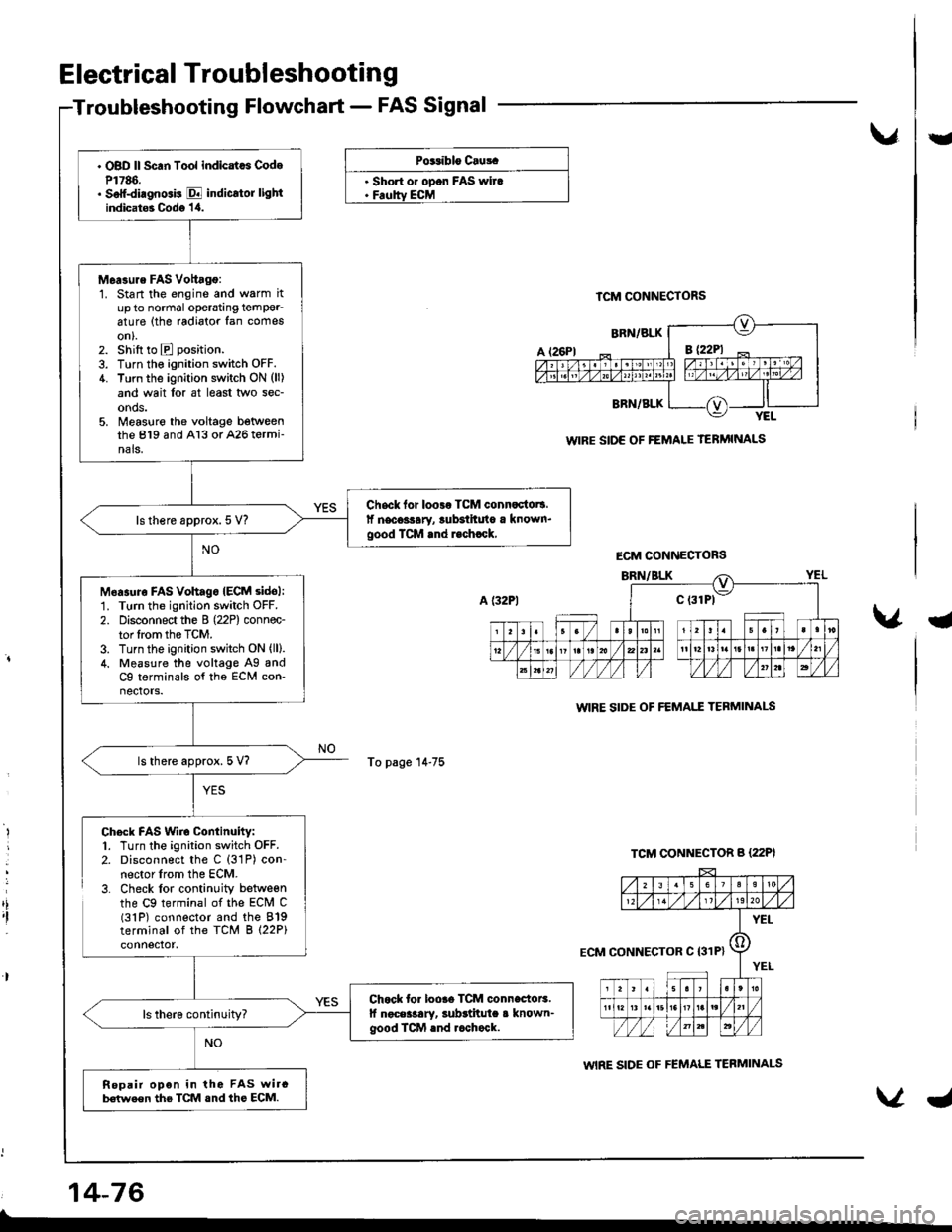

. OBD ll Scan Tool indicatcs CodeP1786.. Soff-diagnGis E indicrtor lightindicat6 Codo '1,0.

M6a3ure FAS Vottago:1. Start the engine and warm itup to normal operatang temPer_6ture (the radiator fan comeson).2. shift to E position.

3. Turn the ignition switch OFF.4. Turn the ignition switch ON (ll)

and wait lor at least two sec-onds.5. Measlre the voltage betweenthe 819 and A13 or A26 termi-nals.

Chsck for loo3r TCM connactot!.lf necoslary, lubsihuto a known.good TCM rnd r.chrck,ls there approx. 5 V?

M6asuro FAs vohagoIECM sidol:1. Turn the ignition switch OFF.

2. Disconnect the B (22P) connec-tor lrom the TCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage Ag andC9 terminals of tho ECM con-nectors.

ls there approx. 5 V?

Chock for loore TCM connectoE.lf noceilary, subrtitula a known-good ICM rnd rcchock.

Repair opon in the FAS wircb€(we€n the TCM snd ths ECM.

Electrical Troubleshooting

Troubleshooting Flowchart - FAS Signal

vU

PG.iblo Cru!.

. Short o. opon FAS wira. Feoltv ECM

To page 14-75

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

WIRE SIDE OF FEMAI.T TEBMINAI-S

WIRE SIDE OF FEMALE TERMINALS

a

,i,I

Chock FAS Wiro Continuity:1. Turn the ignition switch OFF.2. Disconnect the C (31P) con-nector lrom the ECM.3. Check lor continuity betweenthe C9 terminal of the ECM C(31P) connector and the 819terminal of the TCM B (22P)

14-76

ECM CONNECTORS

ECM CONNECTOR C I31P}

Page 494 of 1681

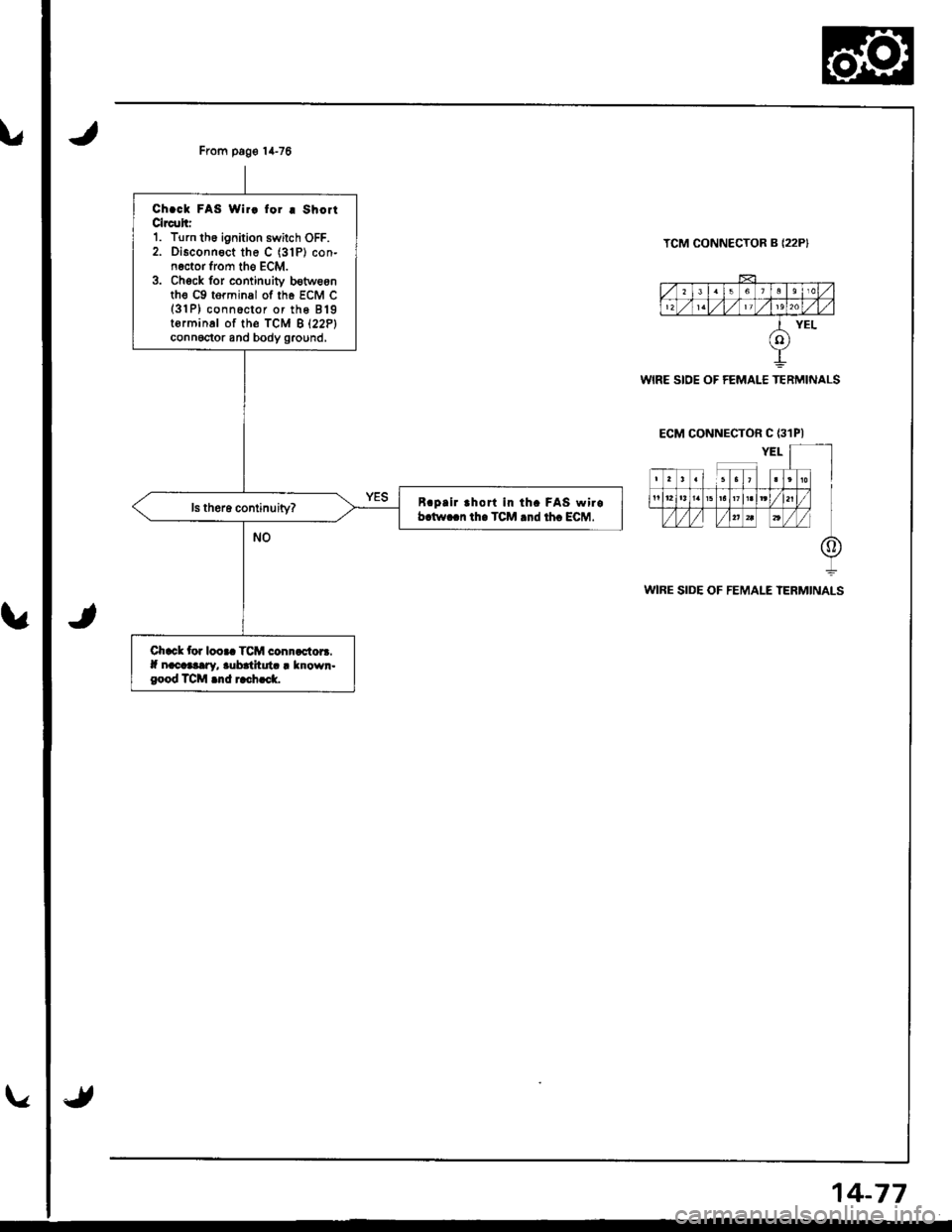

From pag€ 14-76

Ch.ck FAS Wir! for I ShoitClrc!hr1. Turn th6 ignition swilch OFF.2. Disconnect the C (31P) con-n€ctor from tho ECM.3. Chock for continuiv b€tweonth€ c9 torminal of th6 EcM c(3'lP) conn6ctor or the 819torminal of th€ fcM B l22Plconnoctor and body ground,

B.pllr rhort in th. FAS wirob.tw..n th. TCM .nd th. ECM.

Chack tor looaa TCM connactora.lf nacaaary, aubatltuta I known.good TCM .nd rach..k.

TCM CONNECTOR B {22P}

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR C {31PI

WIRE SIDE OF FEMALE TERMINALS

14-77

Page 497 of 1681

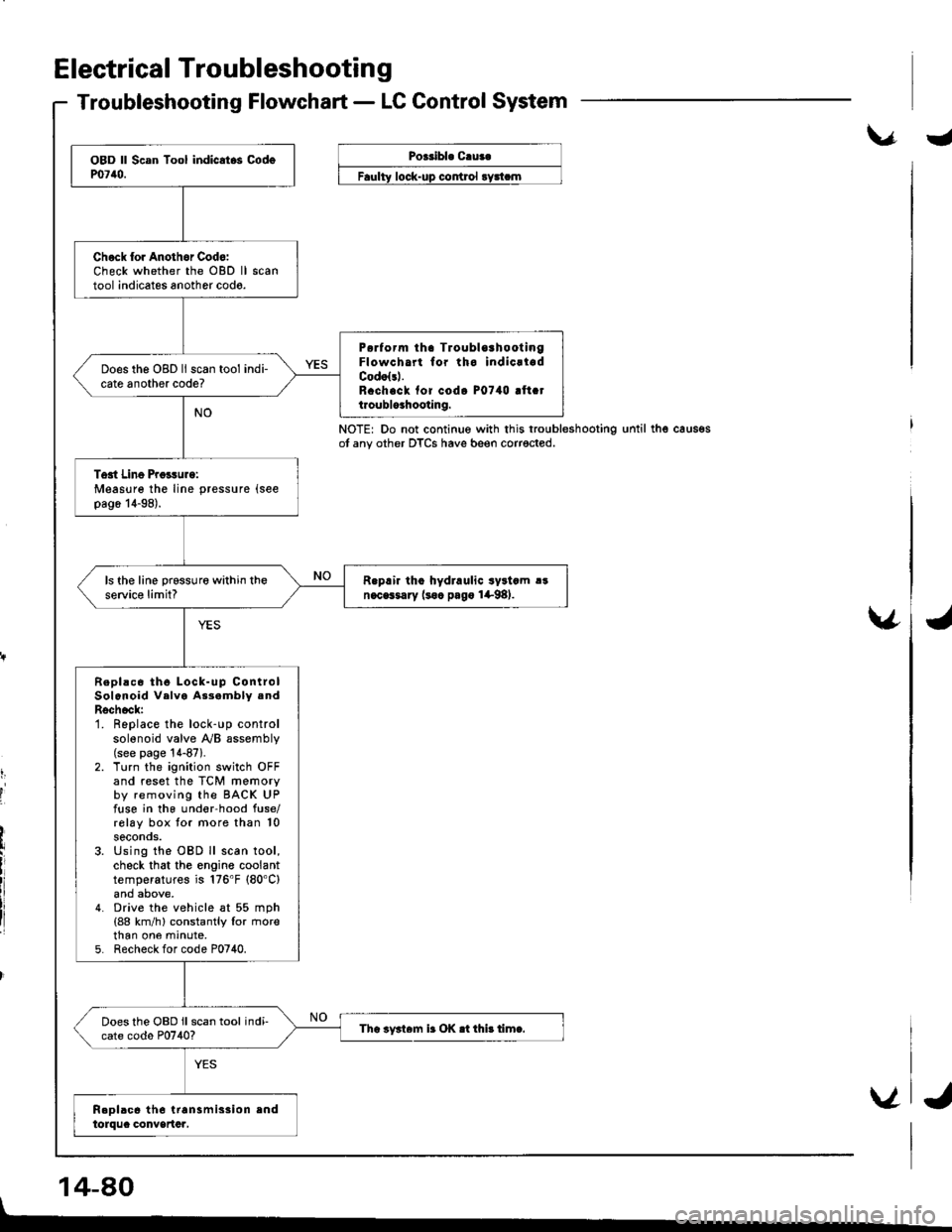

Electrical Troubleshootin g

Troubleshooting Flowchart - LC Control System

\.r.Poeribl. C.ua.

control

NOTE: Do not continue with this troubleshootingot any other DTCS have beeo corrected.until thg caus€s

v

t,

I

'I

14-80

Chock lor Anothor Cod6:Check whether the OBD lltool indicates another codo.

P6rform tha TroublorhootingFlowcha for tho indicrladCodolsl.R.ch.ck fof codo P0740 !ft.tt.oublo3hooting.

Does the OBD ll scan tool indi-cate another code?

Tost Line Proisurg:Measure the line pressure (see

pag6 14-98).

R.prir tho hydraulic syltcm !!n.cGsary (soc pago 1+98).ls the line prsssure within theservic€ limit?

Repl!c6 th6 Lock-up ControlSolenoid Velva As3ambly .ndRschock:1. Replace the lock-up controlsolenoid valve y'y'B assembly(see page '!4-87).

2. Turn the ignition switch OFFand reset the TCM memoryby removing the BACK UPfuse in the und€r-hood fuse/rolay box tor more than 10seconos.3. Using the OBD ll scan tool,check that the engine coolanttemperatures is 176'F (80'C)

4. Drive the vehicle at 55 mph(88 km/h) constantly lor rnorethan one mrnute,5. Recheck for code P0740.

Does the OBD ll scan tool indi-cate codo P0740?Tha iy3t6m ir OK .t thi! timc.

V

I

J

Page 498 of 1681

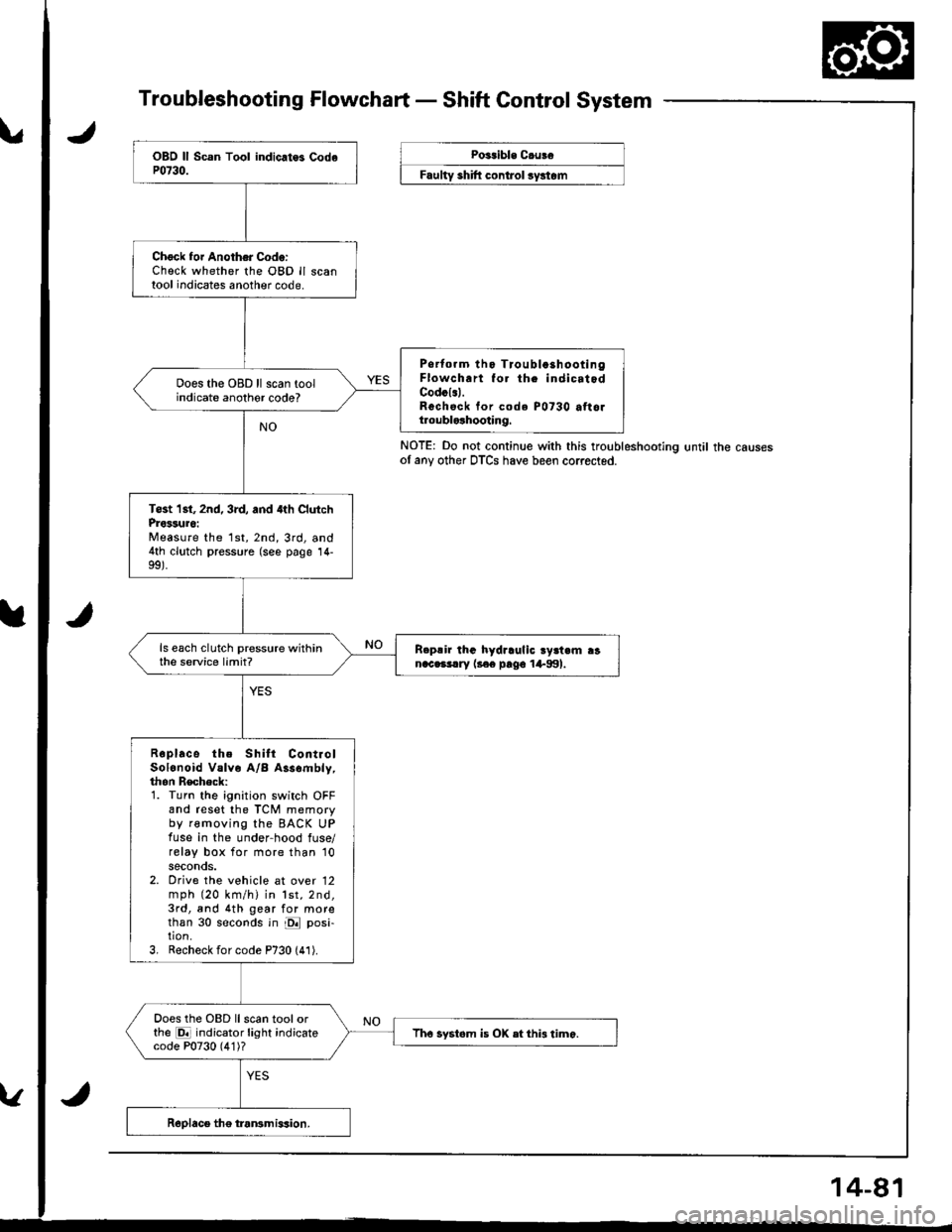

Troubleshooting Flowchart - Shaft Control System

NOTE: Do not continue with this troubleshootlng until the causesof any other DTCS have been corrected.

Chock foi Another Code:Check whether the OBD ll scantool indicates another code.

Psrtorm tho Tioubla3hootingFlowch.rt fo. th. indicatodCodcl.l.Rechsck tor code P0730 attoltroublolhooting.

Does the OBD ll scan toolindicate anothor code?

Tost 1st, 2nd, 3rd, and 4th ClutchProssuro:Measure the 1st,2nd,3rd, and4th clutch pressure (see page 14-

ls each clutch pressure withinthe service limit?R.p!ir lhG hydraulic ry3t.m ranac.3!.ry l3€e pago 1+991.

Roplace the Shilt ContiolSolonoid Valve A/B Assombly,thon Recheck:1. Turn the ignition switch OFFand reset the TCM memoryby removing the BACK UPfuse in the under-hood fuse/relay box for more than '10

seconds.2. Orive the vehicle at over 12mph (20 km/h) in lst,2nd,3rd, and 4th gear for morethan 30 seconds in E posi-tion.3, Recheck for code P730 (41).

Does the OBD llscan toolorthe E indicator light indicatecode P0730 (4'1)?Tho systom is OX etthi3 timo.

Poitible C.uBe

F""lty "hlft ".^t..t ",/"t".

Page 499 of 1681

Electrical Troubleshooting

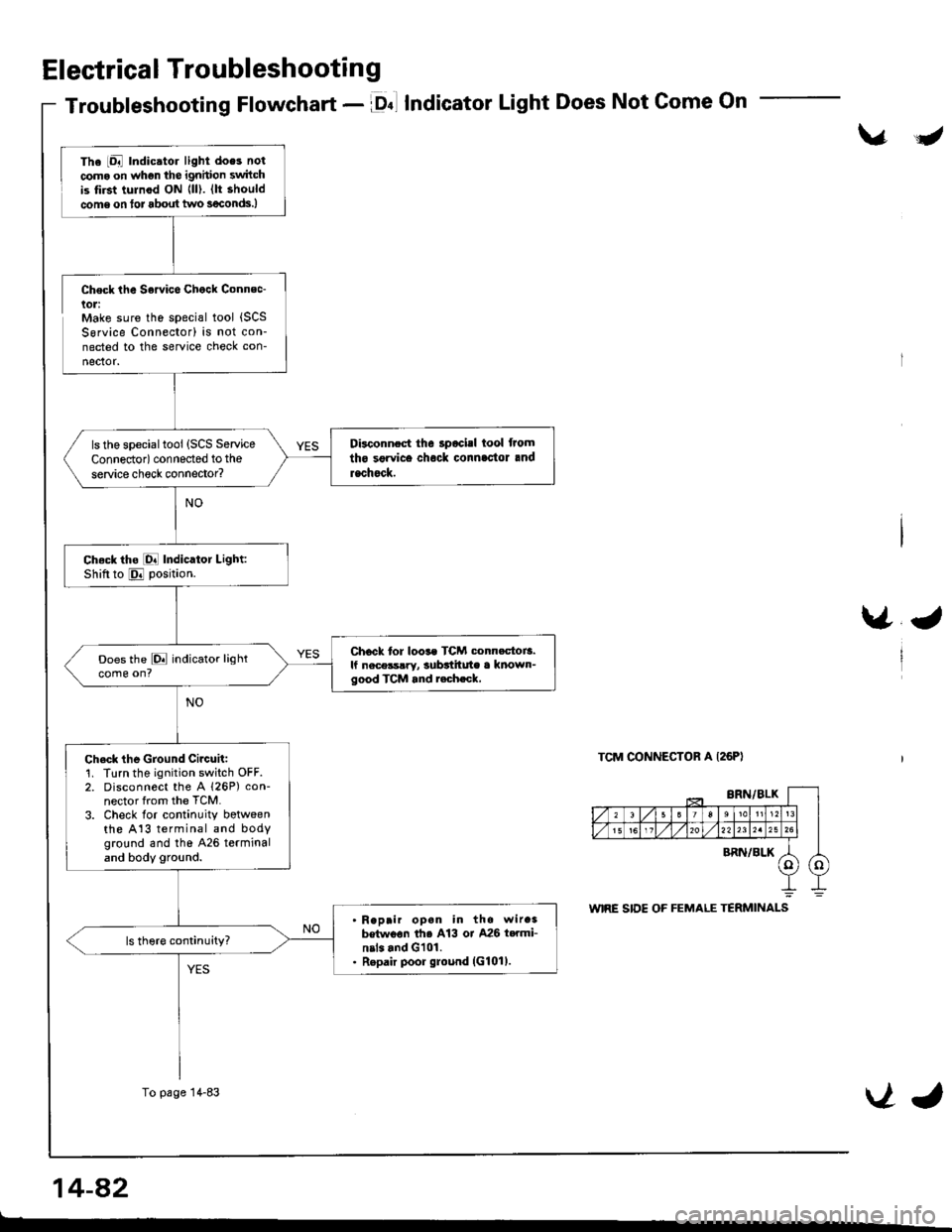

Troubleshooting Flowchart - lDnl IndicatorLight Does Not Come On

\/J

Check the Sowice Chock Connec-lol:Make sure the special tool {SCSSorvice Connector) is not con-nected to the service check con-

nector.

\/J

TCM CONNECTOR A I26PI

The iDal Indic.tor light does not

coma on whgn the ignhion switchis tirst tulnod ON {ll). (lt should

come on tor about two s€conds.)

Disconnect the 3pocisl tool from

tho sgrvice chock connlc'tor and

rachock.

ls the specialtool (SCS Service

Connedor) connected to the

service check connector?

Ch.ck tho [O! Indicator Light:Shiftto E position.

Chock tor loos. TCM conn.ctoi3.lf nece3s!ry, subttitute a known-good TCM and r.ch.ck,

Does the E indicator lightcome on?

Ch.ck the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the A 126P) con-nector from the TCM.

3. Check lor continuity botweenthe A13 terminal and bodyground and tho 426 terminaland body ground.

Reprir opan in the wir.3betwoon th6 A13 or A26 t..mi-nil. and G101.Repair poor ground (G101).

To page 14-83VJ

14-a2

t-

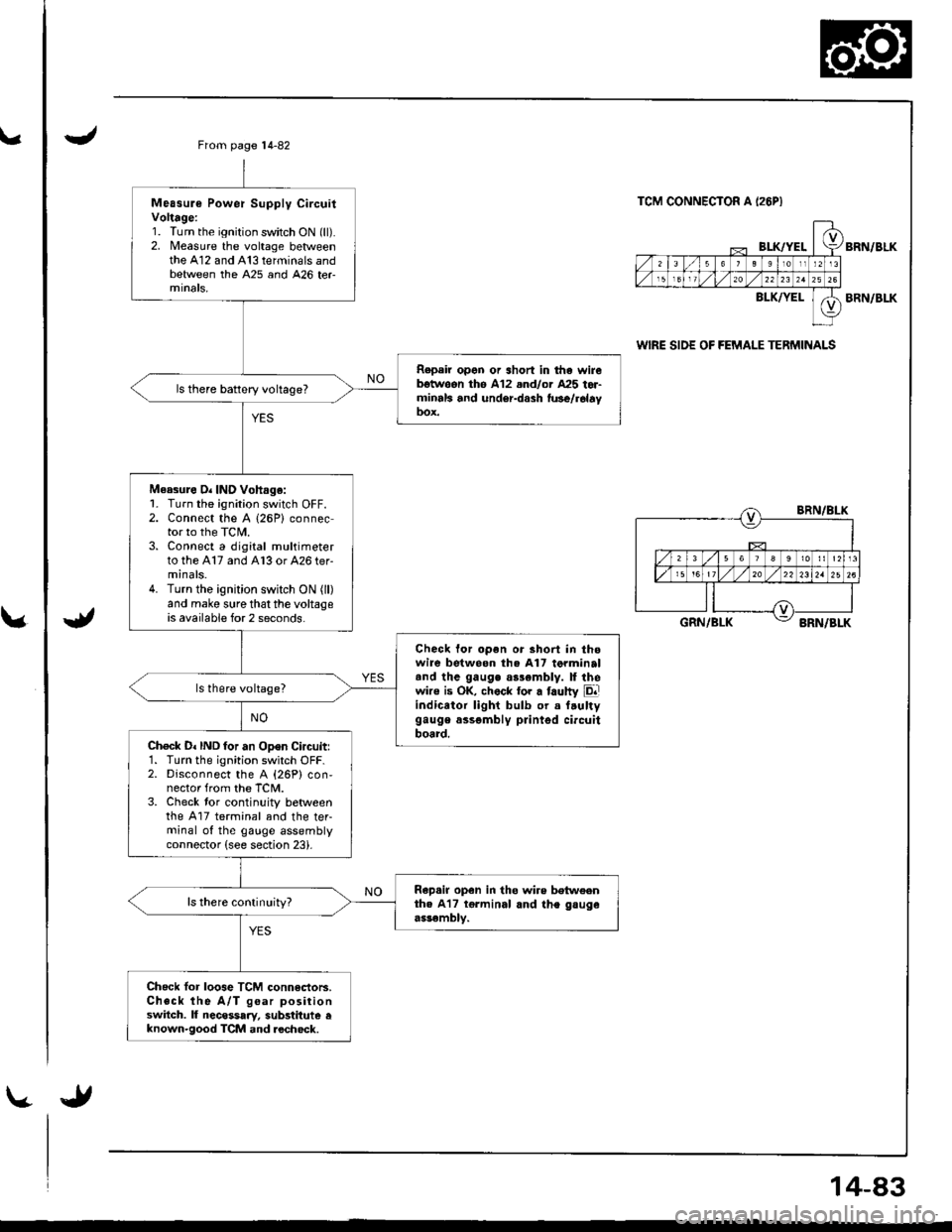

Page 500 of 1681

\.

\.

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON (ll).2. Measure the voltage betweenthe A12 and A13 terminals andbetween the A25 and 426 ter

Repeir open or short in tha wirebgtwoon th6 A12 .nd/or A25 tor-minrls and under-dash fu3e/r6layDox.

ls there battery voltage?

Measure O. IND Vohag.:1- Turn the ignition switch OFF.2. Connect the A (26P) connector to the TCIL3. Connect a digital multimeterto the A17 and A13 or 426 ter-minals.4. Turn the ignition switch ON (ll)

and make sure that the voltageis available for 2 seconds.

Check for open or short in thowire betweon the A17 torminaltnd the gauge as3emblv. ll thewire is OK, chock tor a faulty Eliindicator light bulb or a f.ultygauge assgmbly printgd circuitboard.Ch€ck D. IND for an Open Circuitr1. Turn the ignition switch OFF.2. Disconnect the A {26P} con,nector from the TCM.3. Check tor continuity betweenthe A17 terminal and the teFminal of the gauge assemblyconnector (see section 23).

Rap.ir open in tho wire betweenth. A17 tgrminal and the gsugeassembly.

ls there conlinuity?

Check lor loose TCM connectoB.Check the A/T goar positionswitch. lf necessary, substitute eknown-good TCM and.echock.

From page 14-82

TCM CONNECTOR A I26PI

BI-K/YELBRN/BLK

BLK/YELBRN/BLK

wlRE SIDE OF FEMALE TERMINALS

BRN/BLK

GRN/BLKBRN/BLK

14-83

Page 501 of 1681

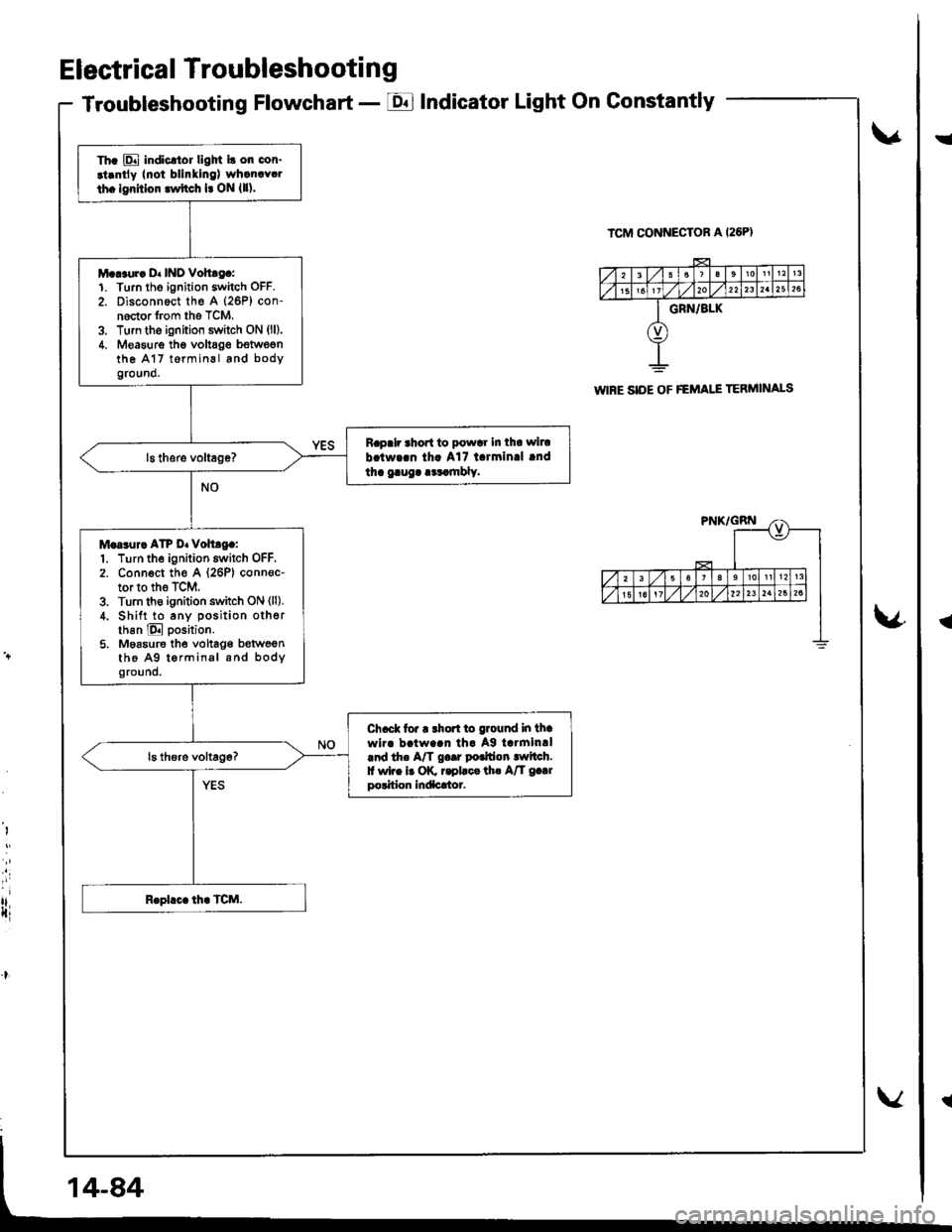

Electrical Troubleshooting

Troubleshooting Flowchart - EIndicator Light On Gonstantly

v

ICM CONNECTOR A I26PI

\4

I

i

rlIti

Th. E indicltor ligM i! on cor.

.t.ntly Inoi blinllng) wh.n.Y.l

th. lgrhior lwftch l. ON {ll).

M...ur. D. INO Vohtg.:1. Turn tho ignition switch OFF.

2. Disconnect th€ A (26P) con-noctor from the TCM.3. Turn the ignition switch ON (ll).

4. Measure thg voltag€ bstwegnthe A17 t6rminal and bodyground.

Rapalr ahort to powar In tha wiru

b.tw..n th. A17 l.rmin.l lnd

tha gaug. .cr.mbly.

M.a3ur. ATP D. voh.g.:1. Turn the ignition switch OFF.2. Conn€ct th€ A (26P) conn€c-tor to the TCM.3. Turn th€ ignition switch ON (ll).

4, Shift to any position otherthan E position.

5. Moasure the vohag€ b€tweenthe A9 tormin.l and bodyground.

Ch.ck tor r rhort to ground in thawir. b!tw..n th. Ag tarmin.l.nd th. A/T g..r potfion lwltch.f wi.e b OK r.pllca th. A/T g.|rpolition Indacrtor.

WIRE SIDE OF FEMAI.I TERMINALS

!

{

Page 503 of 1681

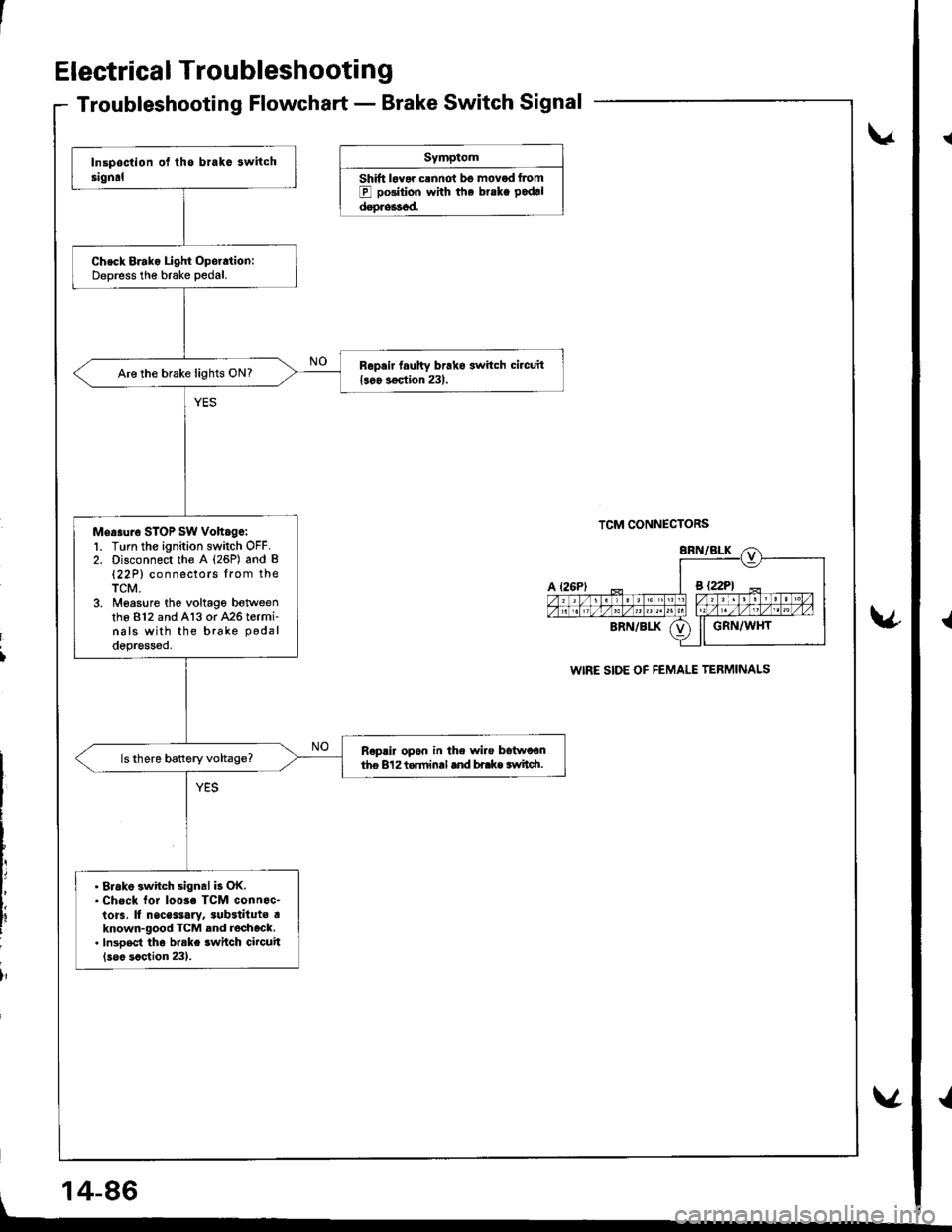

Electrica I Troubleshooti n g

Troubleshooting Flowchart - Brake Switch Signal

Symptom

Shift lovar clnnot bo moved Itom

E pGition with the brske pod.l

dsoressod.

v

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

v

i

lr

Check Brako Light Oporation:Deoress the brake Dedal.

Repair taulty brako switch circuit{soo 3€qtion 231.Are the brake lights ON?

Mea.ur6 STOP sw voh.ge:1. Turn the ignition switch OFF.2. Disconnect the A (26P) and B(22P) connectors lrom theTCM.3. Moasure the voltage botweenthe 812 and A13 or 426 termi-nals with the brake podal

depressed.

R€plir opon in the wire Itstwoonth€ 8'l2 torminal and bi.ke svtidt.

. 8rak6 switch signal b OK.. check lor loose TcM connoc-to]s, lf nsce$ary, sub3tituts aknown-good TcM and rochock.. lnsooct tho brake swilch circuit(soo scction 231.

, 14-86

v

{

{

Page 591 of 1681

)

I

t

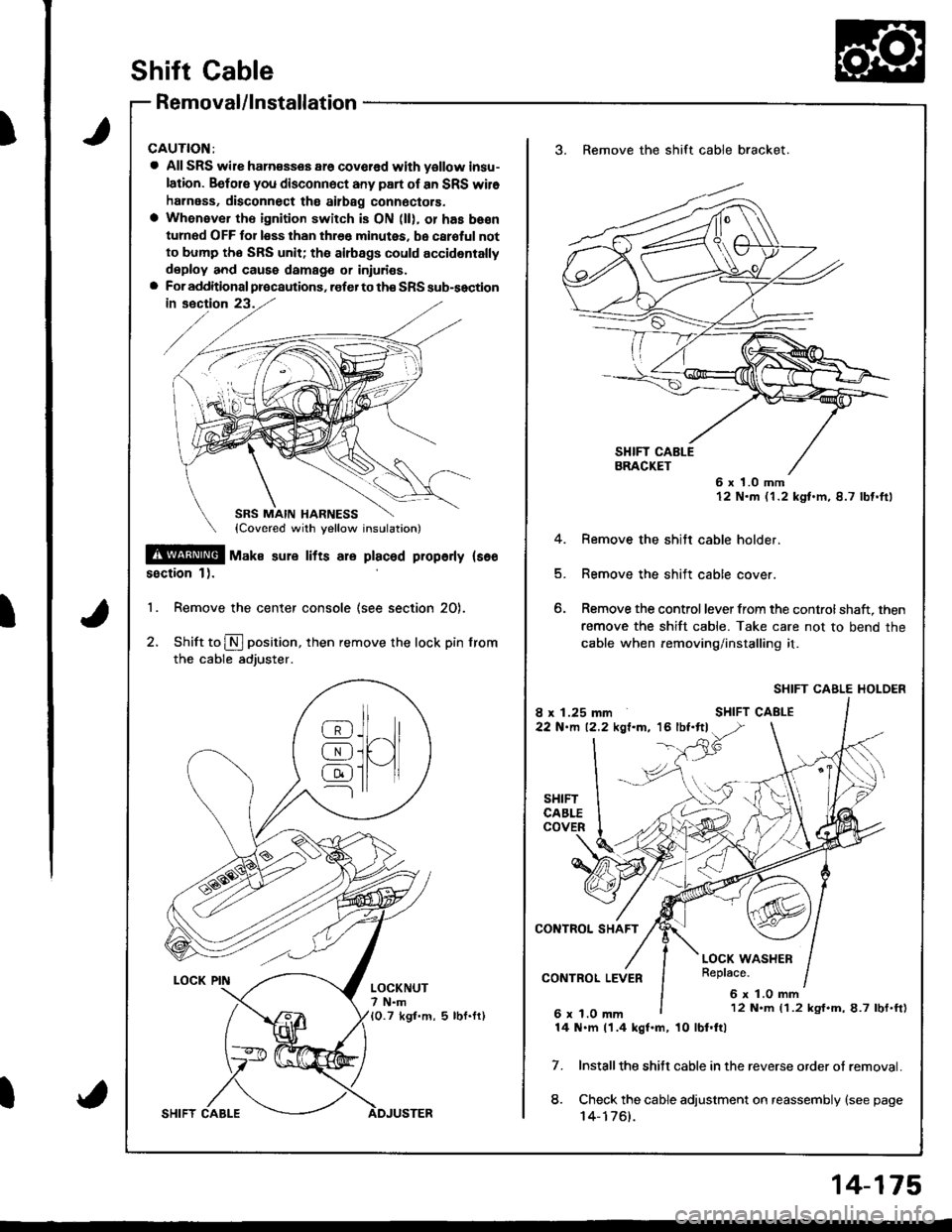

Shift Cable

Removal/lnstallation

CAUTION:

a All SRS wile ham€sses ar6 covcred with yollow insu-

lation. Befols you disconnect any part of an SRS wil6

harness, disconnect tho ailbag connoctors.

a Whenever th€ ignition switch is ON (ll), or has be€n

turned OFF for less than thr€e minutes, be caroful not

to bump tho SRS unit; tha airbags could accidentally

deploy and caus6 damags or iniuri€s.a For additional precautions, .ofer to th€ SRS sub-soction

!@! -u^" sure rrrs are praceq propeny rs€o

ssction 1).

'1. Remove the center console (see section 20).

2. Shift to N position, then remove the lock pin from

the cable adjuster.

_llr_8J.ll^/l

@i[ )l

@ll-11---l rr

LOCKNUT7 N.m10.7 kgt.m, 5 lbf.fr)

3. Remove the shift cable bracket.

6 x 1.0 mm12 N.m (1.2 kgt.m,8.7 lbf.ftl

4. Remove the shitt cable holder.

5. Remove the shift cable cover.

6. Remove the control lever from the controlshaft, then

remove the shift cable. Take care not to bend the

cable when removing/installing it.

SHIFT CABLE HOLDER

Installthe shitt cable in the reverse order ot removal.

Check the cable adjustment on reassembly {see page't 4-1761.

7.

8.

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m 11.4 kgf.m, 10 lbl.ftl

14-175

Page 592 of 1681

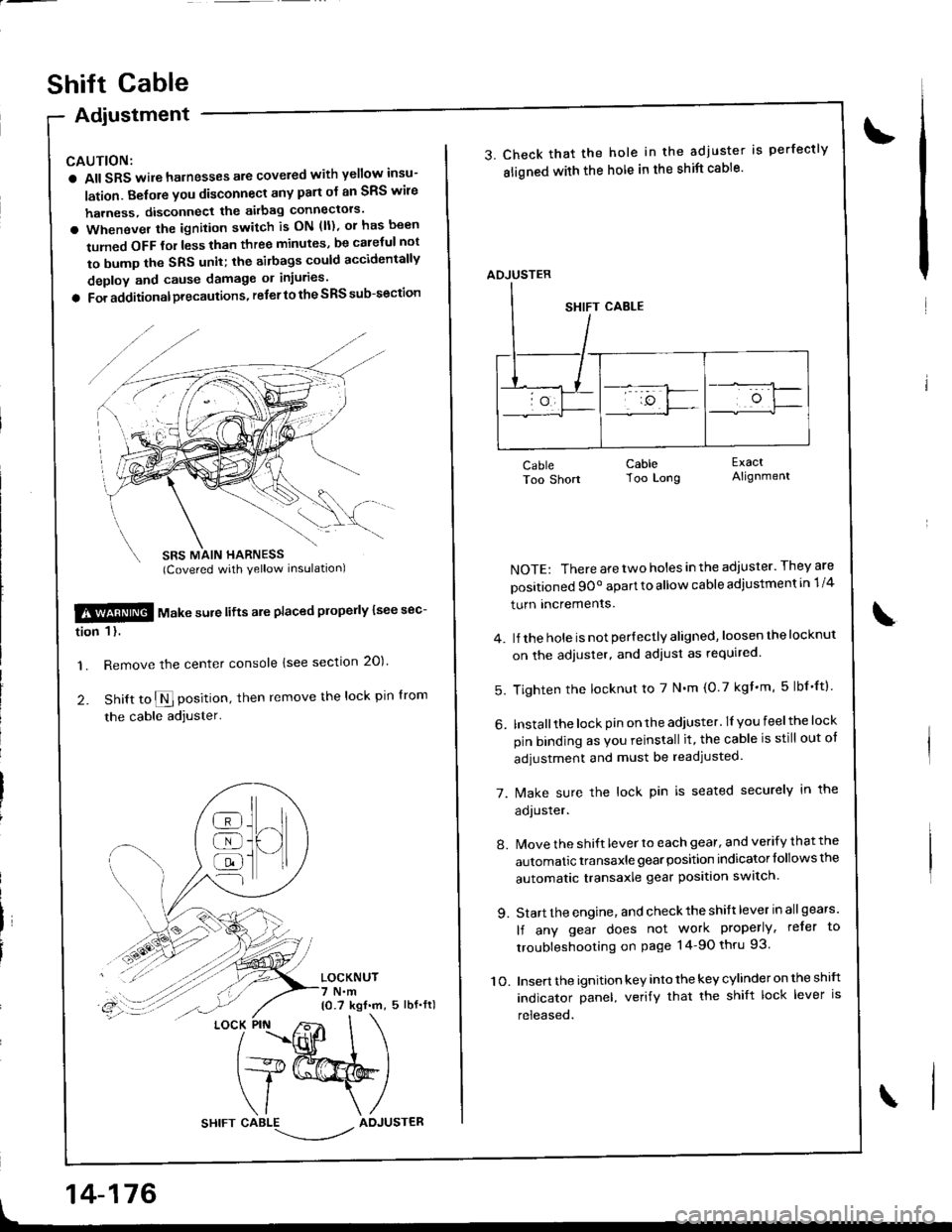

Adiustment

CAUTION:

a All SRS wile harnesses are covered with yellow insu-

lation. Belore you disconnect any part ol an SRS wire

harness, disconnect the akbag connectors'

a Whenever the ignition switch is ON (ll), or has been

tumed OFF tol less than three minutes, be caletul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries'

a For additionalprecautions, referto the SRS sub-section

SBS MAIN HARNESS(Covered with yellow inslrlationl

$!@ rtl"t . "ure lifts are placed plope y lsee sec-

tion 1 l.

'1. Remove the center console lsee section 20)'

2. Snitt to $ position, then remove the lock pin lrom

the cable adjuster'

LOCKNUT7 N.m10.7 kgf.m, 5 lbf.fl)

t

]H

@

@

@

{l

LOCK PIN

14-176

shift cable

3. Check that the hole in the adjuster is perfectly

sligned with the hole in the shift cable'

CableToo Short

NOTE: There are two holes in the adjuster. They are

positioned 9Oo apart to allow cable adiustment in 1/4

turn Incremenrs.

4. lJ the hole is not per{ectly aligned, loosen the locknut

on the adjuster, and adiust as required.

5. Tighten the locknut to 7 N'm (0.7 kgf'm, 5lbf'ftl

6. Installthe lock pin on the adiuster. lI you feelthe lock

pin binding as Vou reinstall it, the cable is still out ot

adjustment and must be readjusted.

7. [/ake sure the lock pin is seated securely in the

aoJusrer.

8. Move the shift lever to each gear, and verify that the

automatic transaxle gear position indicator follows the

automatic transaxle gear position swatch.

9. Start the engine, and check the shift lever in allgears'

lf any gear does not work properly, refer to

troubleshooting on page 14-90 thru 93.

10. Insert the ignition key into the key cylinder on the shift

indicator panel, verify that the shift lock lever is

released.

CableToo Long

ExactAlignment

\

ADJUSTER