HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 741 of 1681

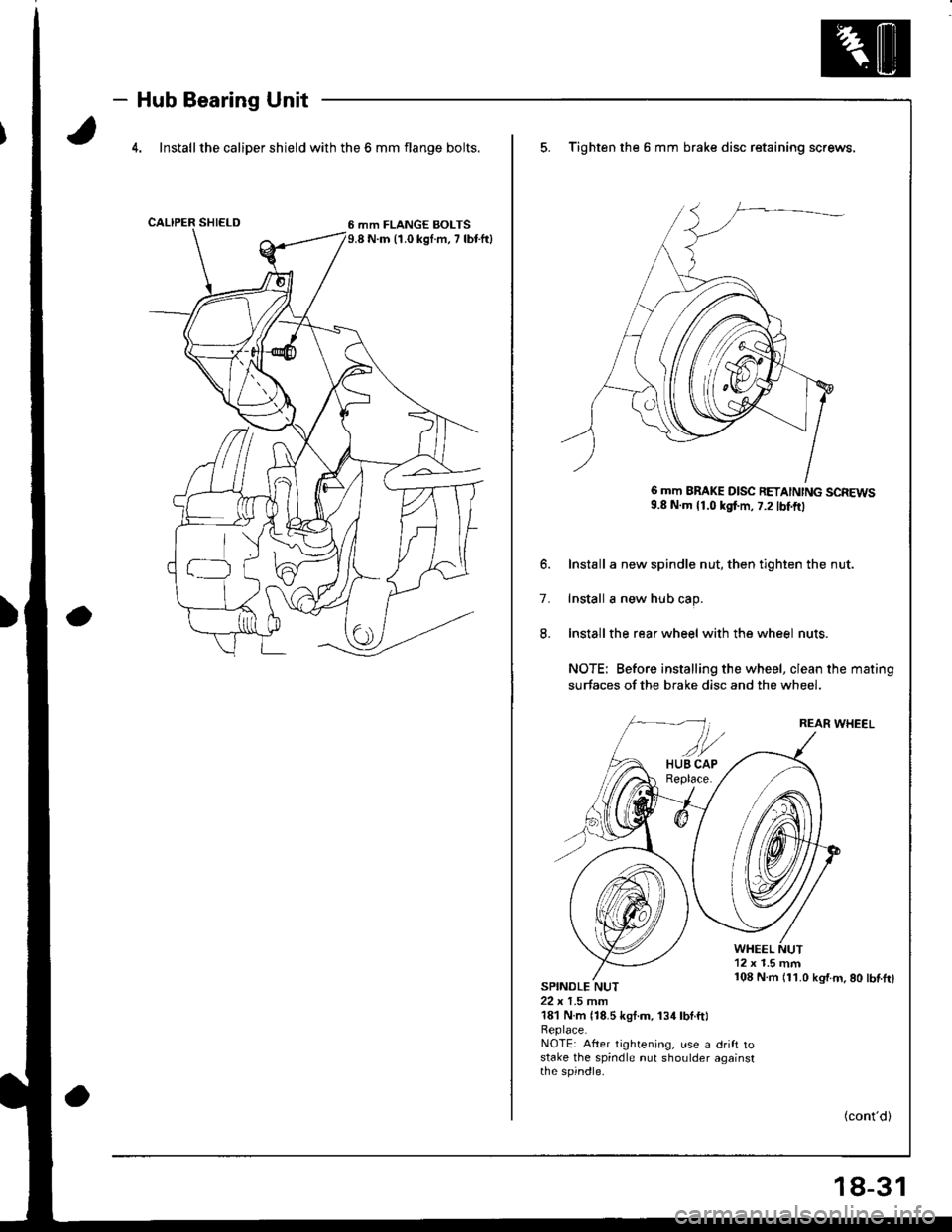

- Hub Bearing Unit

4. Install the caliper shield with the 6 mm flange bolts.

6 mm FLANGE BOLTS9.8 N.m 11.0 kgI.m, 7 lbr.ftl

5. Tighten the 6 mm brake disc retaining screws,

6 mm BBAKE D|SC RETA|NTNG SCREWS9.8 N.m 11.0 kgf.m, 7.2 tbtftl

6. Install a new spindle nut, then tighten the nut.

7. Install a new hub cap.

8. Install the rear wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

REAR WHEEL

WHEEL12 x 1.5 mm

SPINDLE NUT22 x 1.5 mm181 N.m {18.5 kgt.m. 134lbl.ftl

108 N.m 111.0 kg'f.m.80 lbf.tr)

Beplace.NOTE: After tightening, use a drift tostake the spindle nut shoulder againstthe spindle.

(cont'd)

18-31

Page 742 of 1681

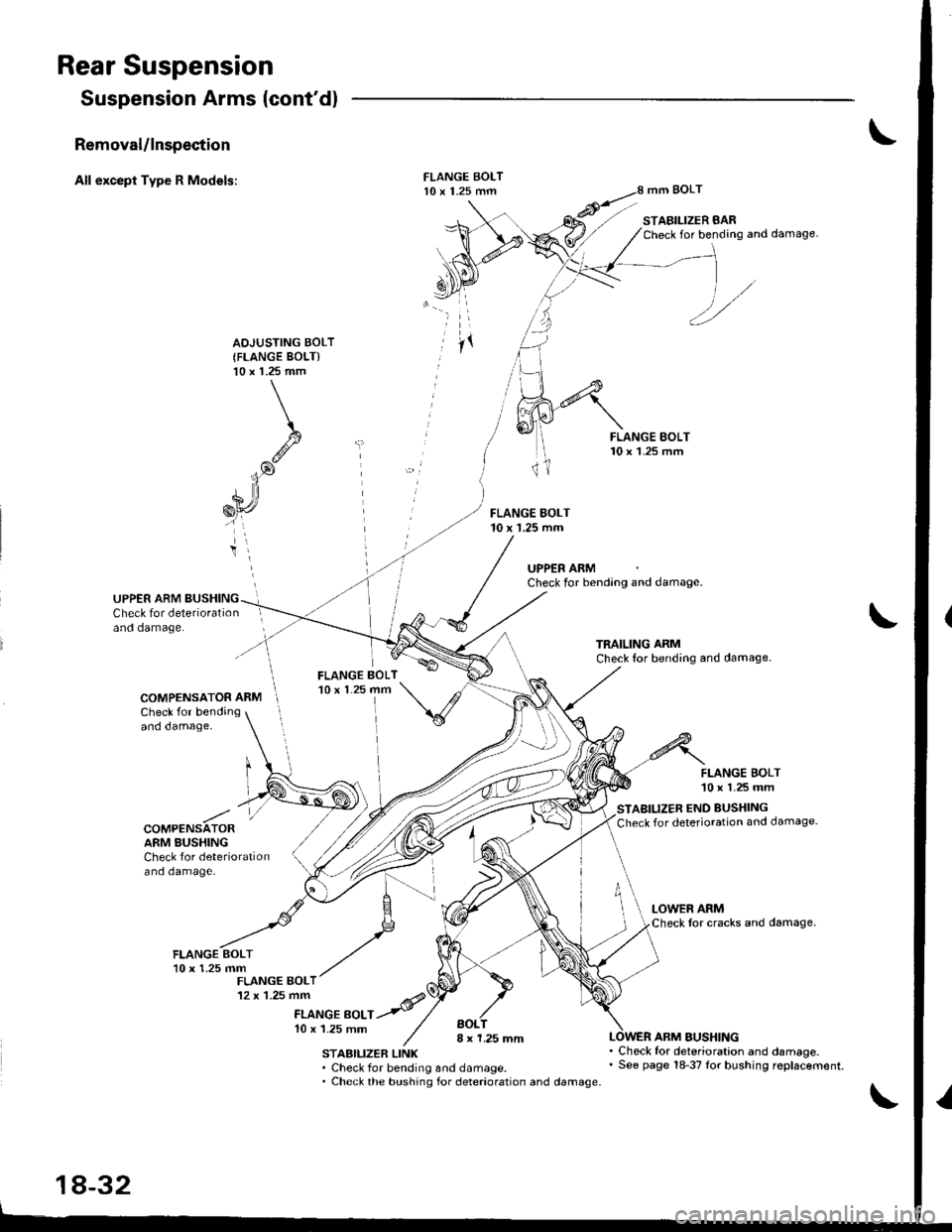

Rear Suspension

Suspension Arms (cont'dl

Removal/lnspection

All except Type R Models:mm BOLT

STABILIZER BARCheck for bending and damage.

AOJUSTING BOLT(FLANGE BOLT)'10 x 1.25 mm

FLANGE BOLT10 x 1.25 mm

UPPER ARMCheck for bending and damage.

UPPER ARM BUSHINGCheck for deteriorationand damage.

COMPENSATOR ARMCheck for bendingand damage,

FLANGE BOLT'10 x 1.25 mm

STABILIZER END BUSHING

Check for deterioration and damage.COMPENSATORARM BUSHINGCheck for deteriorationand damage-

FLANGE EOLTl0 x 1.25 mmBOL8 x 1.25 mmSTABILIZER LINK. Check for bending and damage.. Check the bushing for deterioration and damage.

ARM BUSHING

18-32

. Check for deterioration and damage.. See page 18-37Ior bushing replacement.

Page 743 of 1681

)

)

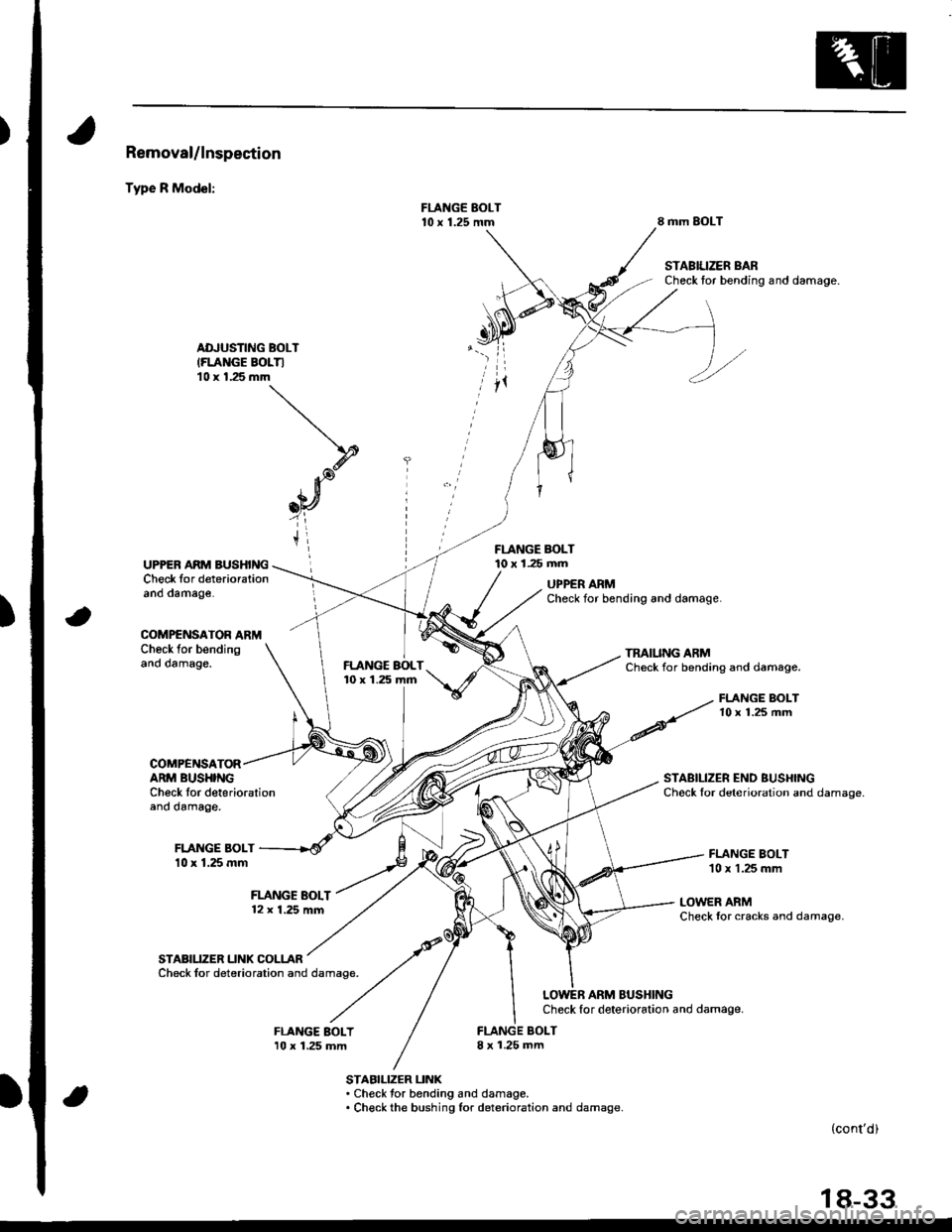

Removal/lnspection

Type R Model:

8 mm SOLT

STABIUZER BARCheck tor bending and damage.

ADJUSTING BOLT(FLANGE BOLTI10 x 1.25 mm

FLANGE BOLT10 x 1.25 mmUPPER ARM BUSHINGCheck for deteriorationano oamage.UPPER ARMCheck for bending and damage.

COMPENSATOR ARMCheck for bendingano oamage,TMIUNG ARMCheck for bending and damage.

COMPENSATORARM BUSHINGCh6ck Ior deteriorationano oamage.

FLANGE BOLT10 x 1.25 mm

STABILIZER END BUSHINGChock lor deterioration and damage.

FLANGE BOLT10 x 1.25 mm

LOWER ARMCheck tor cracks and damage.

STABIUZER UNK COLLARCheck for deterioration and damage.

LOWEB ARM BUSHINGCheck for deterioration and damage.

BOLTI x 1.25 mm

STABILIZER UNK. Check tor bending and damage.. Check the bushing lor deterioration and damage.

(cont'd)

18-33

10 x 1.25 mm

Page 744 of 1681

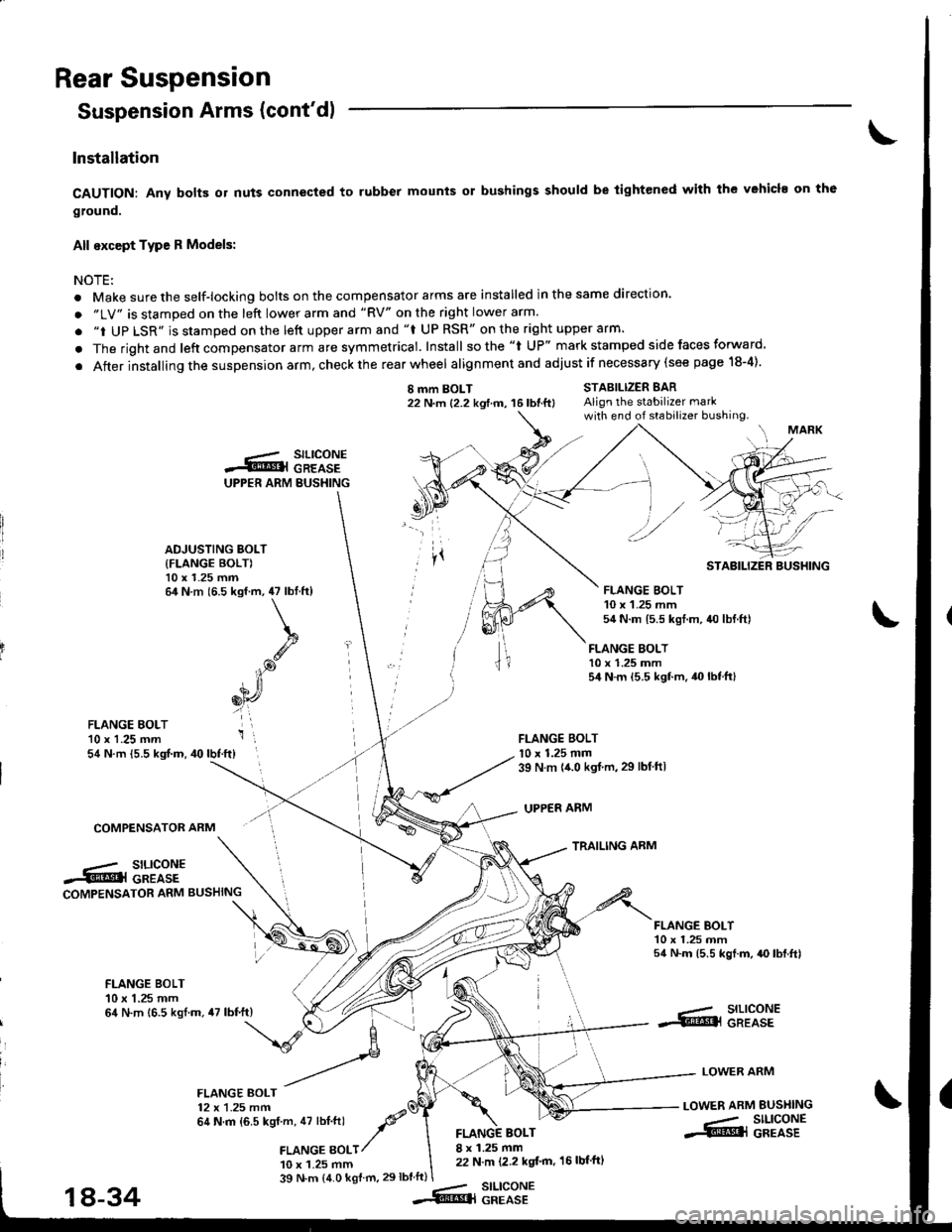

Rear Suspension

Suspension Arms (cont'dl

Installation

CAUTION: Any bolB or nuts connected to rubber mounts or bushings should be tightened with the vehicl. on th6

ground.

All except Type R Models:

NOTEi

. Make sure the self-locking bolts on the compensator arms are installed in the same direction.

. "LV" is stamped on the left lower arm and "RV" on the right lower arm.

. "i UP LSR" is stamped on the lett upper arm and "f UP RSR" on the right upper arm.

. The rightand left compensator arm are symmetrical. Install sothe "l UP" mark stamped side faces forward.

. After installing the suspension arm, check the rear wheel alignmentand adjust if necessary (see page 18-4).

I mm BOLT22 N.m {2.2 kgtm, 16lbtft}STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgf.m.40lbtft}

FLANGE BOLTl0 x 1.25 mm39 N m {{.0 kgt.m,29 lbtftl

UPPER ARM

TRAILING ARM

FLANGE EOLT'10 x 1.25 mm54 N.m {5.5 kgf.m, 40lbf.ft}

COMPENSATOR ARM

.-/ SILICONE.5tr@l GREASECOMPENSATOR ARM BUSHING

FLANGE BOI-T10 x 1.25 mm54 N.m (5.5 kgf.m, {O lbf.ft)

FLANGE BOLT10 x 1.25 mm64 N.m 16.5 kgl.m.47 lbf.ft)--- SILICONE.S!@l GREASE

LOWER ARM

LOWER ARM BUSI{ING

-- SILIGONE.S@l GREASE

FLANGE BOLT12 x 1.25 mm64 N.m {6.5 kgf m, 47 lbt.ftl -P'a

,amce gotr/

10 x 1.25 mm

BOLT8 x 1.25 mm22 N.m (2.2 kgt'm, 16 lbf'ftl

39 N.m (4.0 kgf m.29lbtft)stLtcoNEGREASE

UPPER ARM BUSHING

.-.- SILICONES@l GREASE

ADJUSTING BOLT

{FLANGE BOLT)10 x 1.25 mm64 N.m (6.5 kgf.m, 47 lbtft)

k

.g

iP

6[r,

i',

STABILIZER BUSHING

FLANGE BOLT10 x 1.25 mm54 N.m 15.5 kgt.m, 40 lbf.ftl

18-34--Rq

Page 745 of 1681

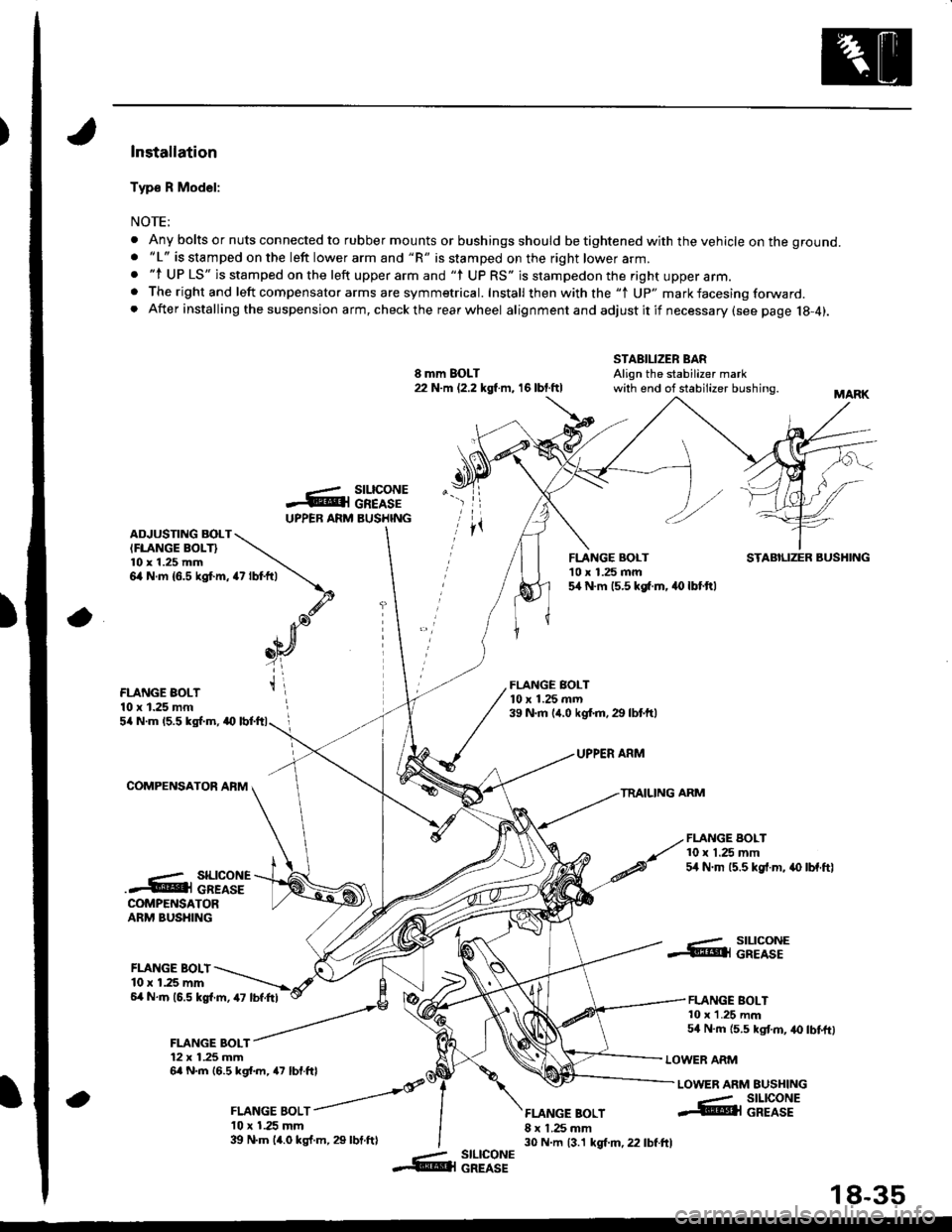

)Installation

Typ€ R Model:

NOTE;

. Any bolts or nuts connected to rubber mounts or bushings should be tightened with the vehicle on the ground.. "L" is stamped on the left lower arm and "R" is stamped on the right lower arm.. "l UP LS" is stamped on the left upper arm and "l UP RS" is stampedon the right upper arm.. The right and left compensator arms are symmetrical. Install then with the "1 Up" mark facesing forward. After installing the suspension arm, checkthe rearwheel alignmentand adjustitif necessary(see page 18-4).

8 mm BOLT22 N.m (2.2 kgl m, 16 lbt.ftl

STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

-ArUPPEB ARM

rz tot+,t \

\.d'. Ja),n[

_oY

t\

a

stLtcoNEGREASEBUSHINGADJUSTING BOLTIFLANGE BOLT}l0 x 1.25 mm6,4 N.m {6.5 kgt m,

FLANGE BOLT'10 x 1.25 mm5,[ N.m 15.5 kg[.m. 40 lbt.ftl

STABILIZER BUSHING

FLANGE BOLT10 x 1.25 mm

FLANGE BOLT10 x 1.25 mrn39 N.m (,r.0 kgf.m.29 lbtftl5/a N.m 15.5 kgl.m, a0

COMPENSATOR AFM

UPPER ARM

TRAILING ARM

FLANGE BOLT10 x 1.25 mm54 N.m 15.5 kgf.m, .{) lbf.ftl..- SILICONE.4@i cREAsECOMPENSATORARM BUSHING

FLANGE BOLI10 r 1.25 mm6,4 N.m (6.5 kgl.m, 47 lbf.Itl

FLANGE BOLT12 x 1.25 mm6a N.m 16.5 kgl.m, a7 lbf.ftl

, ror"orr /

l0 x 1.25 mm39 N.m 14.0 kgf.m, 29 lbt.ftl

FLANGE BOLT8 x 1.25 mm30 N.m 13.1 kgt m, 22 lbf.ftl

..- SILICONE.@ll GREASE

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgt m, 40 lbtftl

LOWER ARM

LOWER ARM EUSHING

a

--- SILICONE@l GREASE

-- slLlcoNE&l GREASE

18-35

Page 746 of 1681

L

I

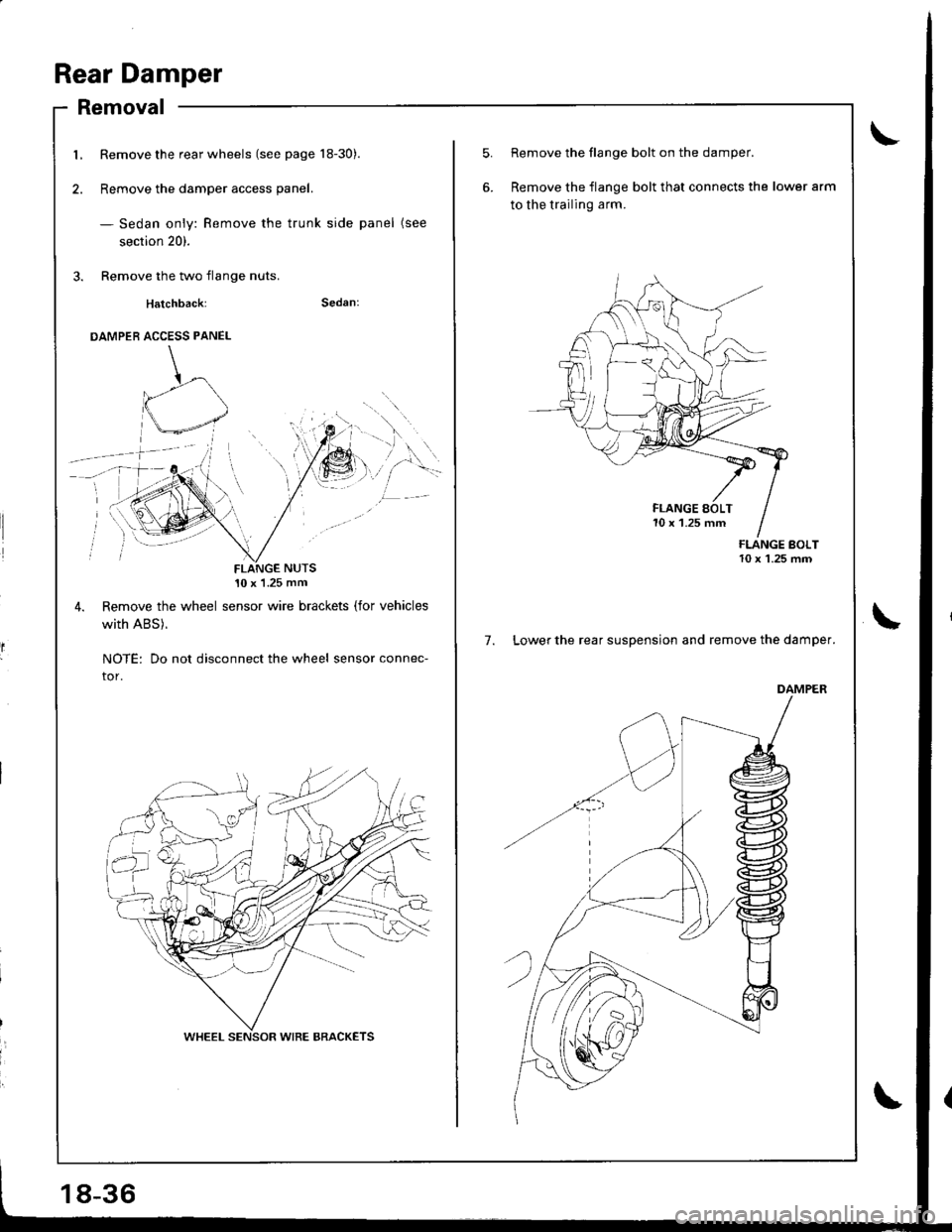

Rear Damper

Removal

Remove the rear wheels (see page 18-30).

Remove the damper access panel.

- Sedan only: Remove the trunk side panel (see

section 20).

Remove the two flange nuts.

Hatchback:

DAMPER ACCESS PANEL

10 x'1.25 mm

Remove the wheel sensor wire brackets (for vehicles

with ABS).

NOTE: Do not disconnect the wheel sensor connec-

tor.

18-36

5.Remove the flange bolt on the damper.

Remove the flange bolt that connects the lower arm

to the trailing arm.

7. Lower the rear suspension and remove the damper.

DAMPER

\

Page 747 of 1681

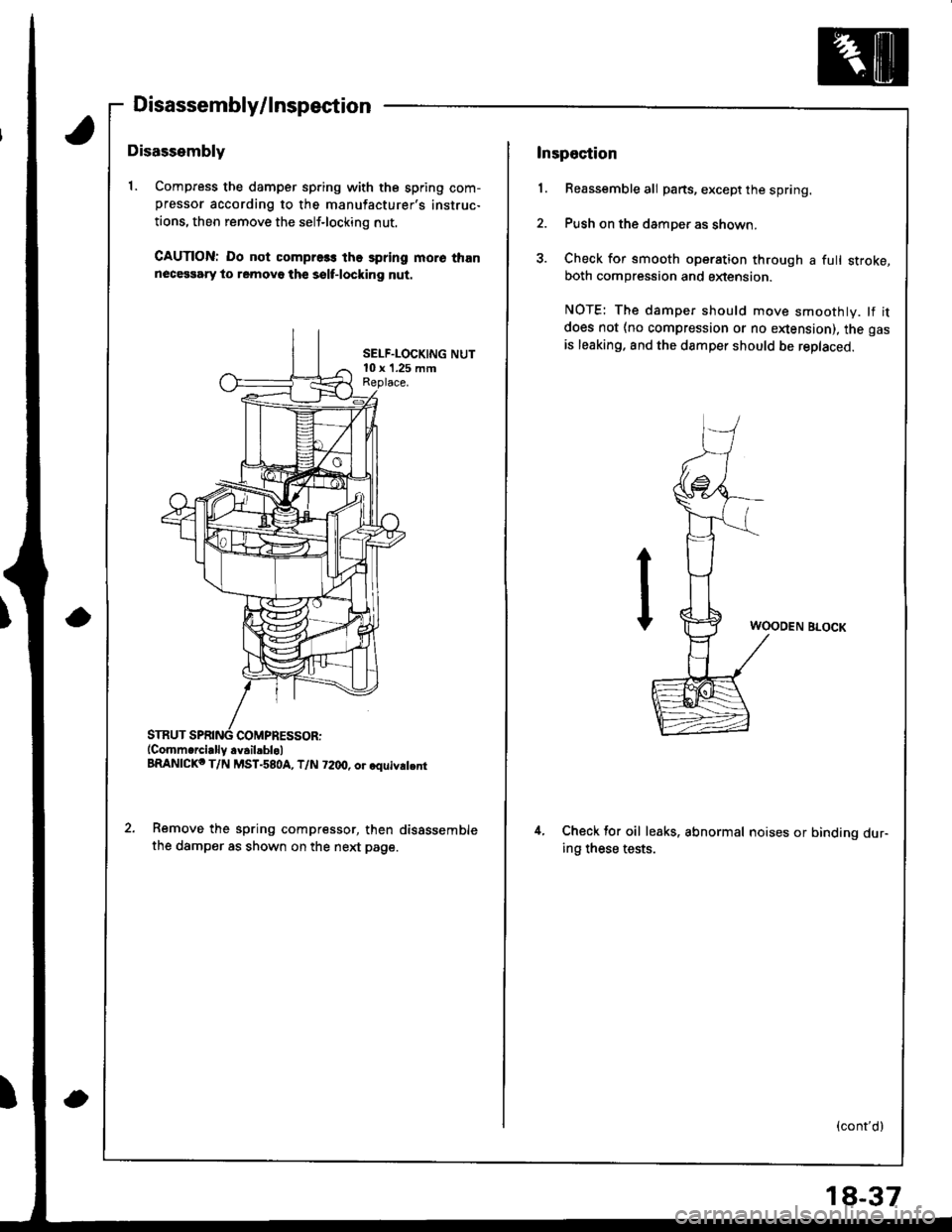

Disassembly/lnspection

Disassembly

1. Compress the damper sp.ing with the spring com-pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut.

CAUTION: Do not compre3s the spring more thannecessary to removo th€ sslf-locking nut.

SELF.LOCKING NUT10 x '1.25 mmReplace.

COMPRESSOR:(Comm.rcially.v.il.blol

BRANICKo T/N MST-580A, T/N 72dt, or.quiv.t.nr

Remove the spring compressor, then disSssemble

the damper as shown on the next page.

Inspection

1. Reassemble all parts, except the spring.

2. Push on the damper as shown.

3. Check for smooth operation through a full stroke,both compression and sxtension.

NOTE: The damper should move smoothly. lf it

does not (no compression or no enension), the gas

is leaking. and the damper should be replaced.

WOODEN BLOCK

4.Check tor oil leaks. abnormal noises or binding dur-ing these tests.

(cont'd)

18-37

Page 748 of 1681

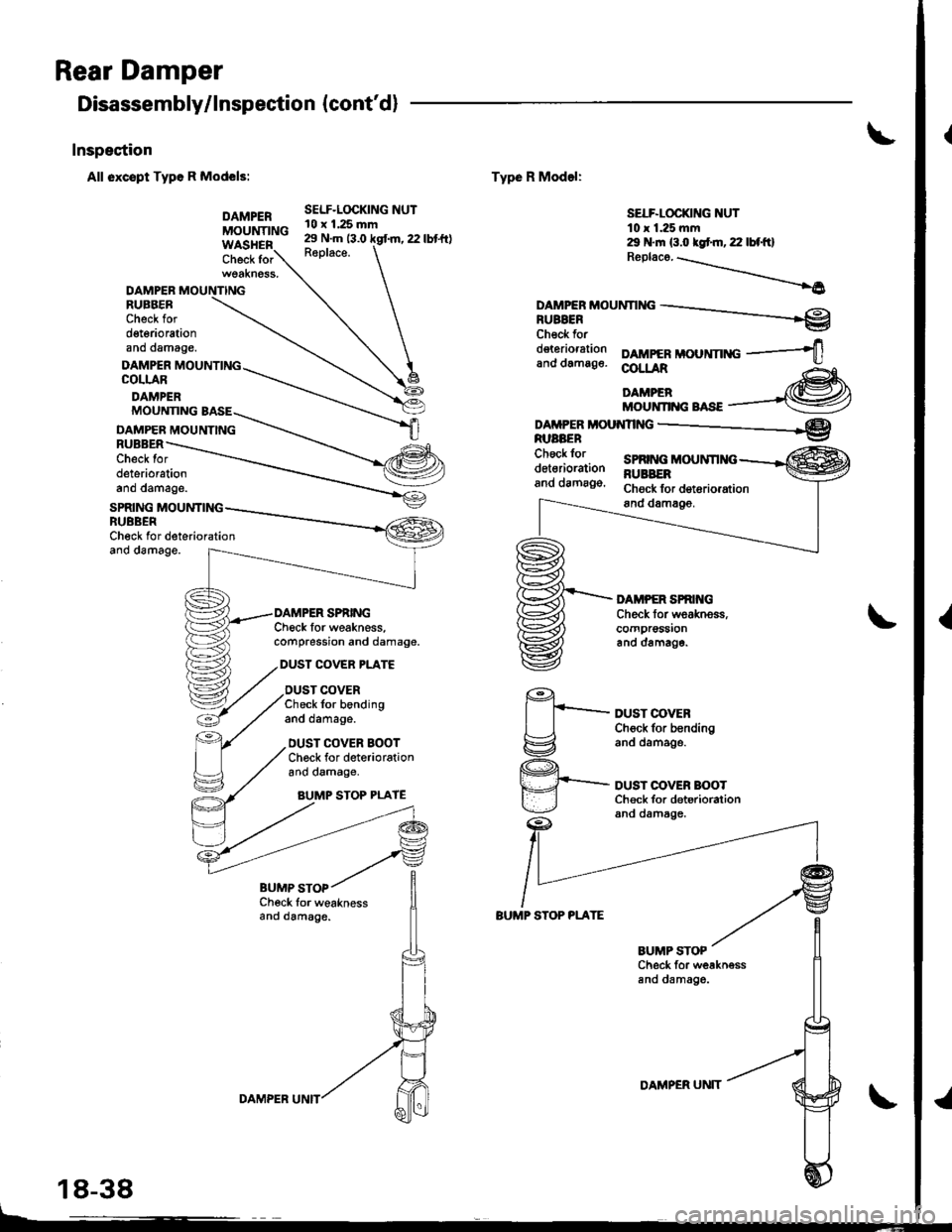

Rear Damper

Disassembly/lnspection {cont'd}

Inspestion

All oxcspt Typo R Models:

DAMPERMOUNTING

Check for

Check Ior weaknessand damag6.

DAMPERRUEBERCheck ford€t6riorationano damage.

DAMPER MOUNTINGCOLLAR

DAMPER

SELF.LOCKING NUT10 x 1.25 mm29 N.m 13.0 kgf.m, 22 lbt'ft)R6place.

Type R Model:

BUMP STOP PLATE

SELF-LOCKING NUTt0 r 1.25 mm29 N.m (3.o kgt m, 22 lbf'ft)Rep|aco. -.\-.--...\

_____6

DAMPTRMoUNnNG -.-__re

Check fordeterioration DAMPERMOUNnNG -----+,and damag6. @L!AR Ag-

liillffi*"*,--@

DAMPTR MoU.{nNG __-_____*e

DUST COVEBCh6ck for b€ndingand oamage.

DUST OOVER BOOTCh€ck for deterioralionand damage.

MOUNNNG BASE

DAMPEB MOUNTINGRUBBERCheck lordeteriorationano oamage.

SPRING MOUNTINGRUBBERCheck for deteriorationano oamage.

Check for weakness,compression and damage.

DUST COVER PLAT€

DUST COVERCheck for bendingano oamage.

DUST COVER BOOTChock for deteriorationano oamage,

AUMP STOP PLAYE

1€')

I t_--tlg:z

q._

Y

Check for weaknessand damage.

BUMP STOP

18-38

DAMPER UNTTDAMPER UN]T

Page 749 of 1681

Reassembly

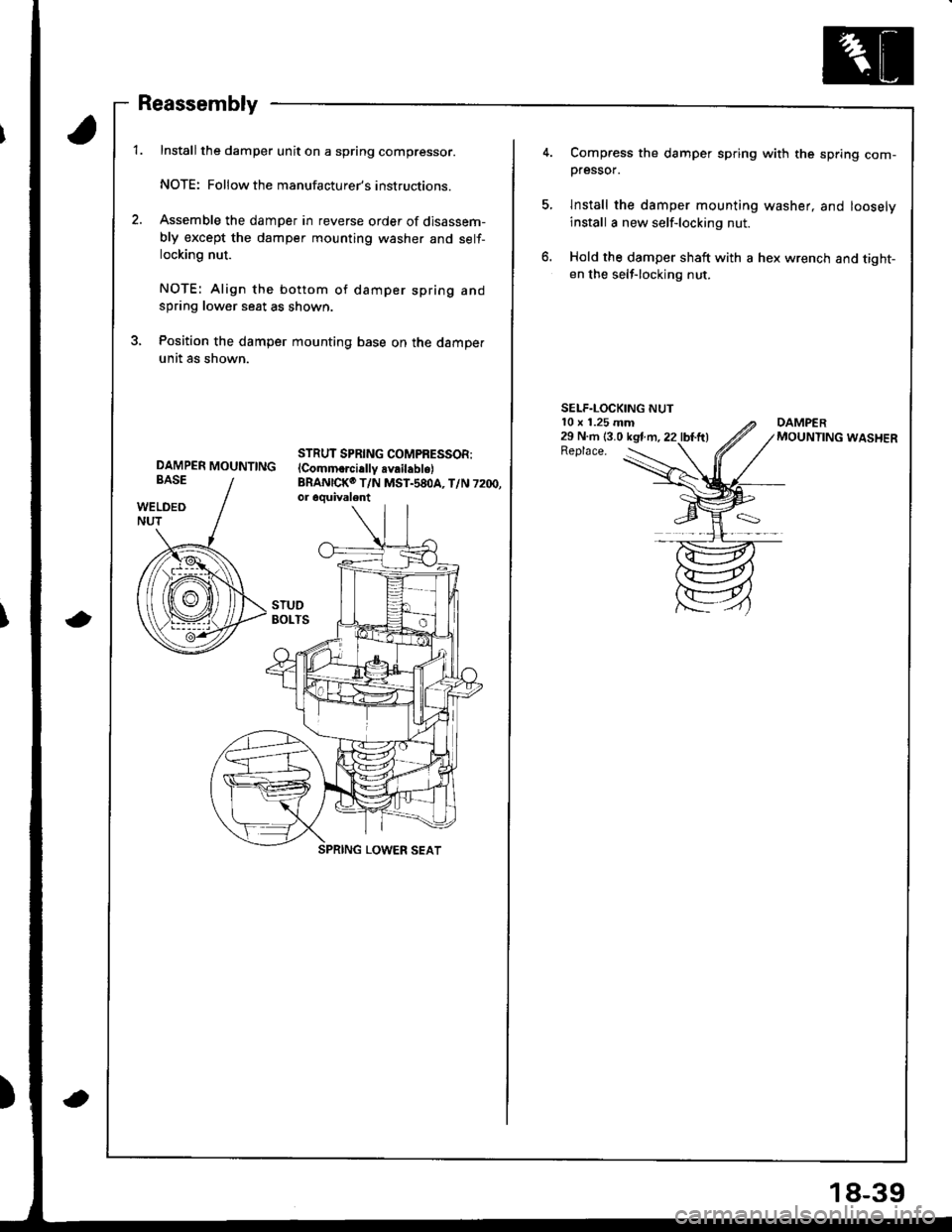

Installthe damper unit on a spring compressor.

NOTE: Followthe manufacturer's instructions.

Assemble the damper in reverse order of disassem-

bly except the damper mounting washer and self-locking nut.

NOTE: Align the bottom of damper spring andspring lower seat as shown.

Position the damper mounting base on the damper

unit as shown.

STRUT SPRING COMPRESSOR:lComm.rci.llv availabls)BRANICKO T/N MST.58OA, T/N 7200,or oquivalent

DAMPER MOUNTTNG

a

a

18-39

Compress the damper spring with the spring com-pressor.

lnstall the damper mounting washer, and loosely

install a new self-locking nut.

Hold the damper shaft with a hex wrench and tight-en the self-locking nut.

SELF.LOCKING NUT10 x 1.25 mm29 N.m (3.0 kstm.22 lbl.ft)Replace.

Page 750 of 1681

Rear Damper

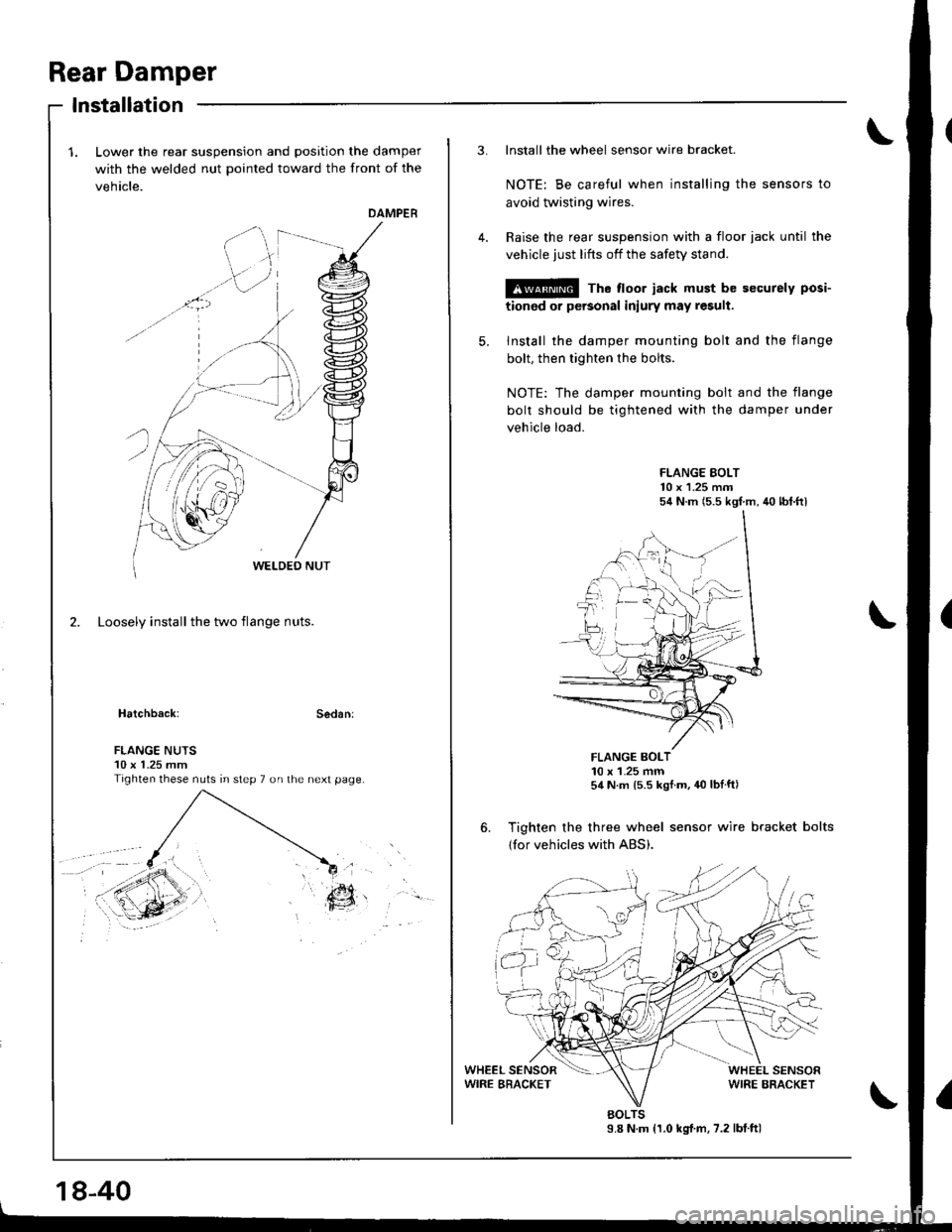

Lower the rear suspension and position the damper

with the welded nut pointed toward the front of the

vehicle.

DAMPER

2. Loosely install the two flange nuts.

Hatchback:Sedan:

lnstallation

. ',.?7,:..r9\,ir '..

EY

FLANGE NUTS10 x 1.25 mmTighten these nuts in step 7 on the next page.

18-40

3. Install the wheel sensor wire bracket.

NOTE: Be careful when installing the sensors to

avoid twisting wires.

Raise the rear suspension with a floor iack until the

vehicle just lifts off the safety stand.

@ The floor jack must be securely posi-

tionod or personal iniury may result.

5. Install the damper mounting bolt and the flange

bolt, then tighten the bolts.

NOTE: The damper mounting bolt and the flange

bolt should be tightened with the damper under

vehicle load.

FLANGE EOLT10 x 1.25 m.n54 N.m (5.5 kgf m, 40 lbt.ftl

FLANGE BOLT10 x 1-25 mm54 N.m ls.s kgf m, 40 lbtft)

6. Tighten the three wheel sensor wire bracket bolts

{for vehicles with ABS).

9.8 N.m {1.0 kg{.m, 7.2 lbtftlBOLTS