HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 711 of 1681

Suspension

Special Tools ............. 18-2

Component Location

lndex ................ ...... 18-3

Wheel Alignment

Caster ............... ...... 18-4

Camber .................. 18-4

Front Toe Inspection/

Adjustment ........ 18-5

Rear Toe Inspection/

Adiustment ........ 18-5

Turning Angle Inspection ................ 18-6

^'heel/Hub Inspection

tBearing End Play .............................. 18-7

Wheel Runout ....... 18-7

Front Suspension

Torque Specifications ...................... 18-8

Knuckle/Hub

lllustrated lndex .........,................. 18-9

Knuckle Removal ......................... 18-11

Wheel Bearing Replacement ...... 18-14

Knuckle 1nsta11ation ..................... 18-16

Lower Ball Joint Replacement ....... 18-17

Ball Joint Boot Replacement .......... 18-19

Suspension Arms

Removal/lnspection .................... 18-20

lnstallation ......... 18-21

Front Dampel

Removal ................. 18-22

Disassembly/lnspection ............. ..... 18-22

Reassembly ........... 18-24

fnstaffation ............. 1A-25

Rear Suspension

Torque Specifications ...................... 18-26

Hub Bearing Unit

f f f ustrated lndex ................ ........... 18-27

Removal ............. 18-29

lnstallation ......... 18-30

Suspension Arms

Removal/lnspection .................... 18-32

lnstallation ......... 18-34

Rear Damper

Removal ................. 18-36

Disassembly/lnspection .................. 18-37

Reassembly ........... 18-39

Installation ............. 18-40

Page 712 of 1681

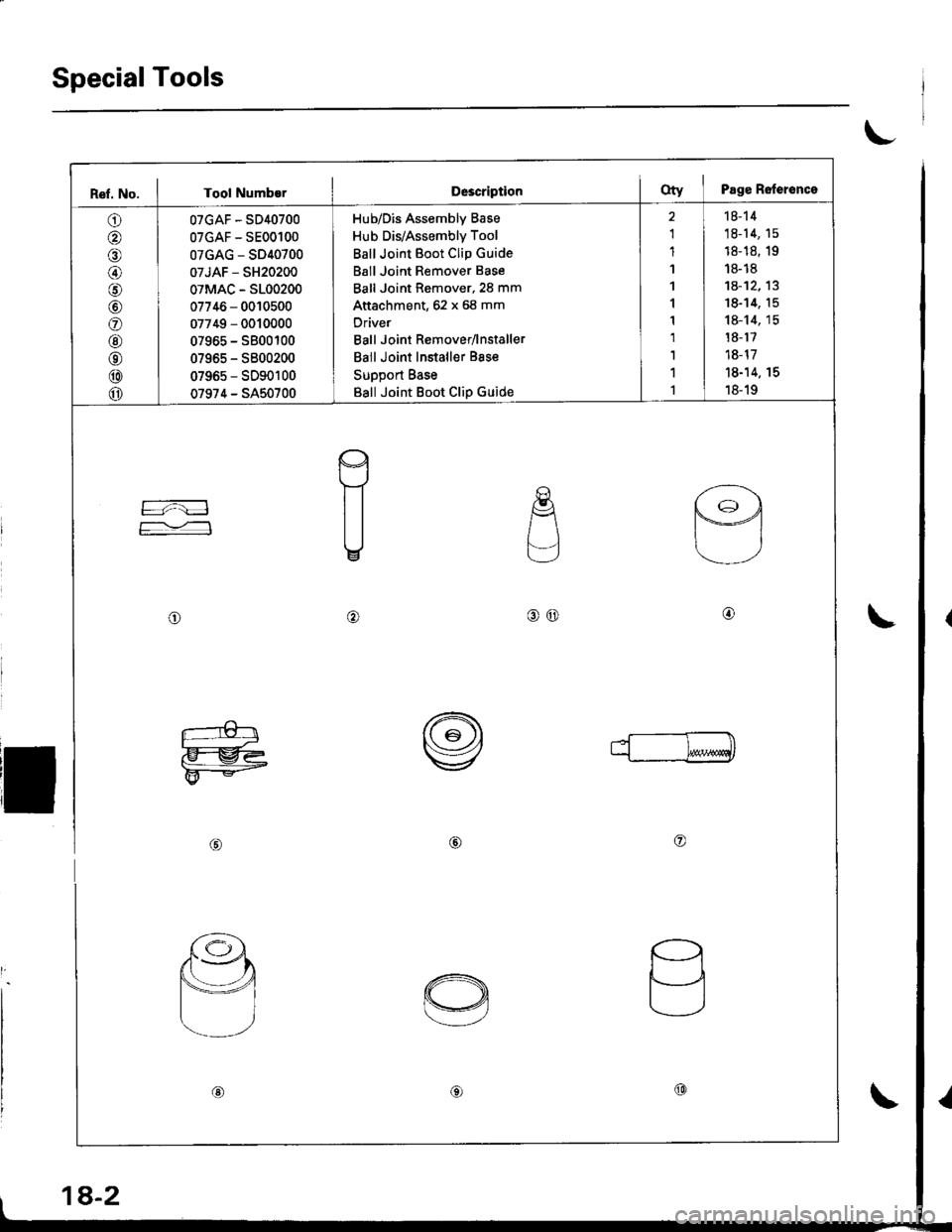

SpecialTools

t

Ref. No. I Tool Numb€rD63criptionoty I Page Relerence

O I oTcAF-sD4o7oo

@ | oTGAF-sEooloo

O I 0TGAG-sD4o7oo

@ 0TJAF - sH2o2oo

O I oTMAc - sLoo2oo

O | 07746 - oolosoo

@ | 07749-ooloooo

@ | 07965-sBooloo

@ | 0796s-sBoo2oo

@ I 07965-sDgo1oo

o 07974 - SA50700

Hub/Dis Assembly Base

Hub Dis/Assembly Tool

Ball Joint Boot Clip Guide

Ball Joint Remover Base

Ball Joint Remover,2S mm

Attachment, 62 x 68 mm

Oriver

Ball Joint Remover/lnstaller

Ball Joint Installer Bsse

Support Base

Ball Joint Boot Clip Guide

2 | 18-14

1 | 18-14, 15

1 | 18-1s, 1e

1 | r8-r8

1 I 1A-12.13

1 18-14. 15

1 I 18-14, 15

r I r8-r7

1 | 18-17

r | 18-14. rs

r I 18-19

re

F=:

E

.E{

L-]

o@

I

o@@

L-€tr

F@

rr--ml

@@o

d sJ4.'

Y@

a

ti

@€)@

1A-2

Page 713 of 1681

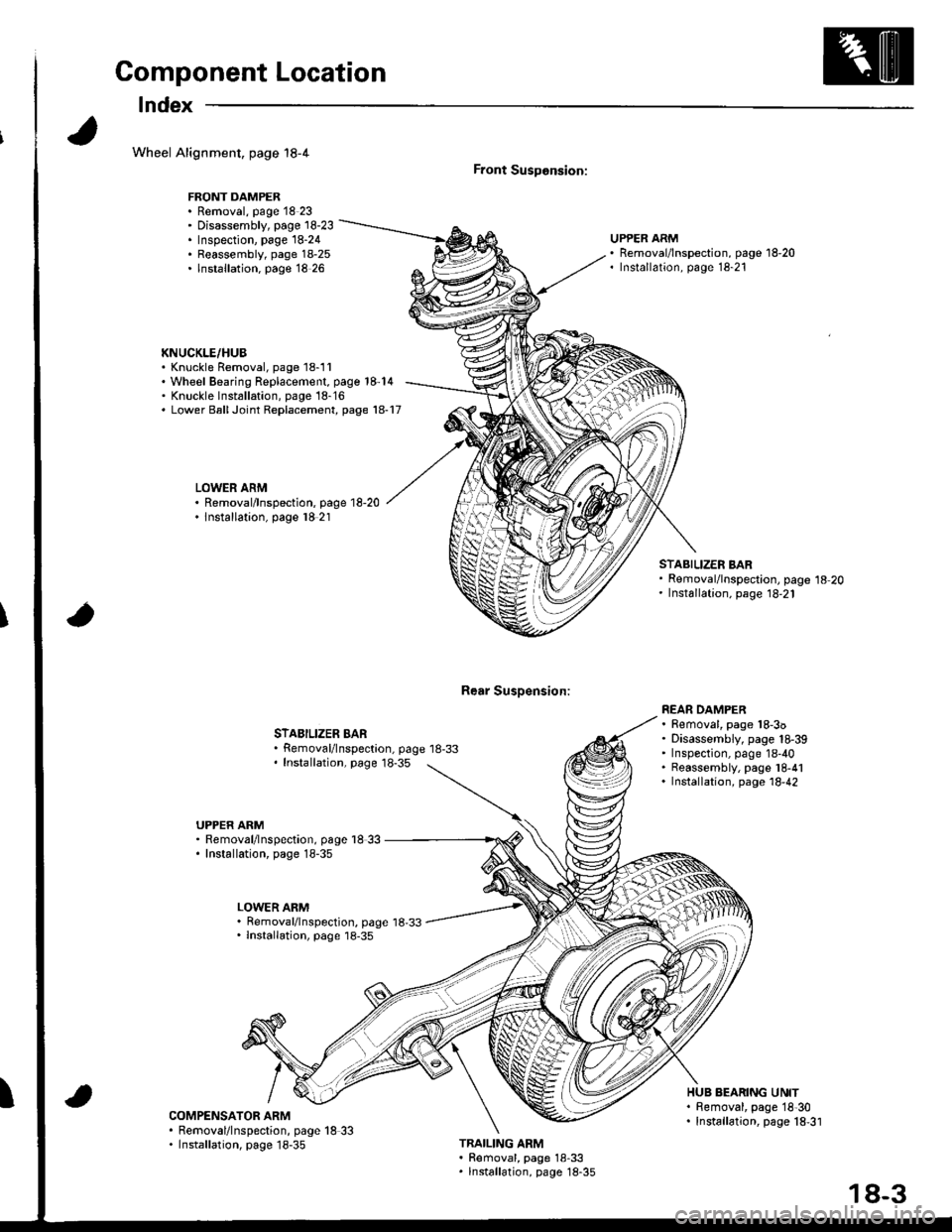

Component Location

lndex

Wheel Alignment, page 18-4

FRONT DAMPER. Removal, page 18 23' Disassembly, page 18-23. Inspection, page 18-24. Reassembly, page 18-25. lnstallation. page 18 26

KNUCKLE/HUB. Knuckle Removal, page 18-11'Wheel Bearing Replacement, page 18-14' Knuckle lnst6llation, page 18-16. Lower BallJoint Replacement, page 18-17

LOWER ARM. Removal/lnspection, page 18-20. lnstallation, page l8 21

Front SusDonsion:

Rear Susoension:

UPPER ARMRemoval/lnspection, page 18-20Installation, page 18-21

STABILIZER BARRemoval/lnspectaon, page 18-33Installation, page 18-35

STABILIZER BARRemoval/lnspection, page 18-20Installation, page 18,21

REAR DAMPER. Removal, page 18-3o. Disassembly, page 18-39' Inspection, page 18-40. Reassembly, page l8-41. Installation, page 18,42

UPPER ARM. Removal/lnspection, page l8 33. Installation, page 18-35

LOWER ARM. Removal/lnspection, page 18,33. lnstallation, page 18-35

ICOMPENSATOR ARM. Removal/lnspection, page 18 33. Installation, page 18-35

HUB BEARING UNIT. Bemoval, page 18'30. Installation, page 18,31

TRAILING ARM. Removal, page 18-33. lnstallation, page 18-35

18-3

Page 714 of 1681

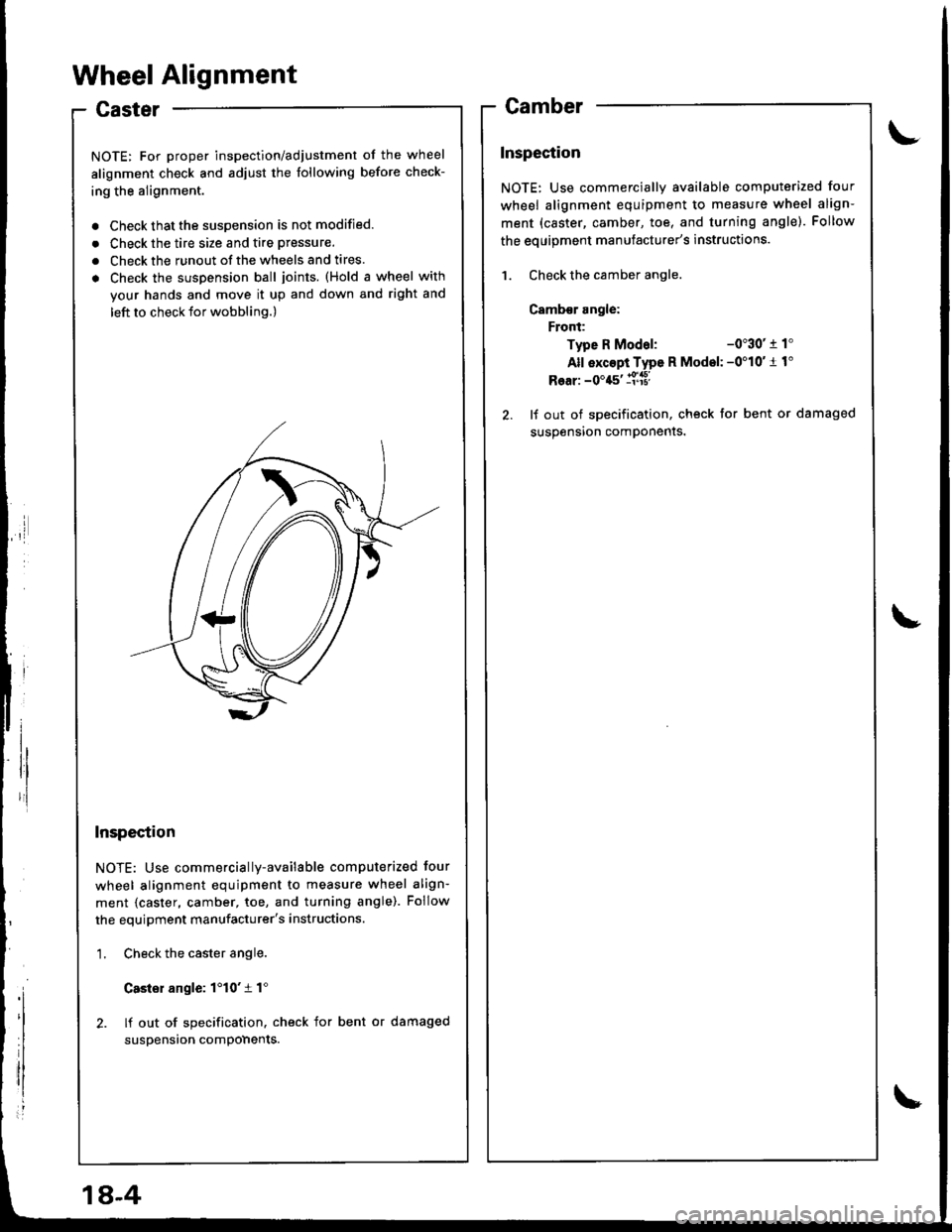

Wheel Alignment

Caster

NOTE: For proper inspection/adjustment of the wheel

alignment check and adjust the following before check-

ing the alignment.

. Check that the susoension is not modified.

. Check the tire size and tire pressure.

. Check the runout of the wheels and tires.

. Check the suspension ball joints. (Hold a wheel with

your hands and move it up and down and right and

left to check tor wobbling.)

Inspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment {caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the caster angle.

Casler angle: 1'10't 1"

2. lf out of specification. check for bent or damaged

suspension compohents.

Camber

Inspection

NOTE: Use commercially available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the eouioment manufacturer's instructions.

1. Check the camber angle.

Camb€r angle:

Front:

Type R Modal:-0"30' r 1'

All exc6pi Type R Model: -0'10'1 1"

Rear: -0'45' ll['a8l

2. lf out of specification, check for bent or damaged

susoension comDonents.

1A-4

Page 715 of 1681

\

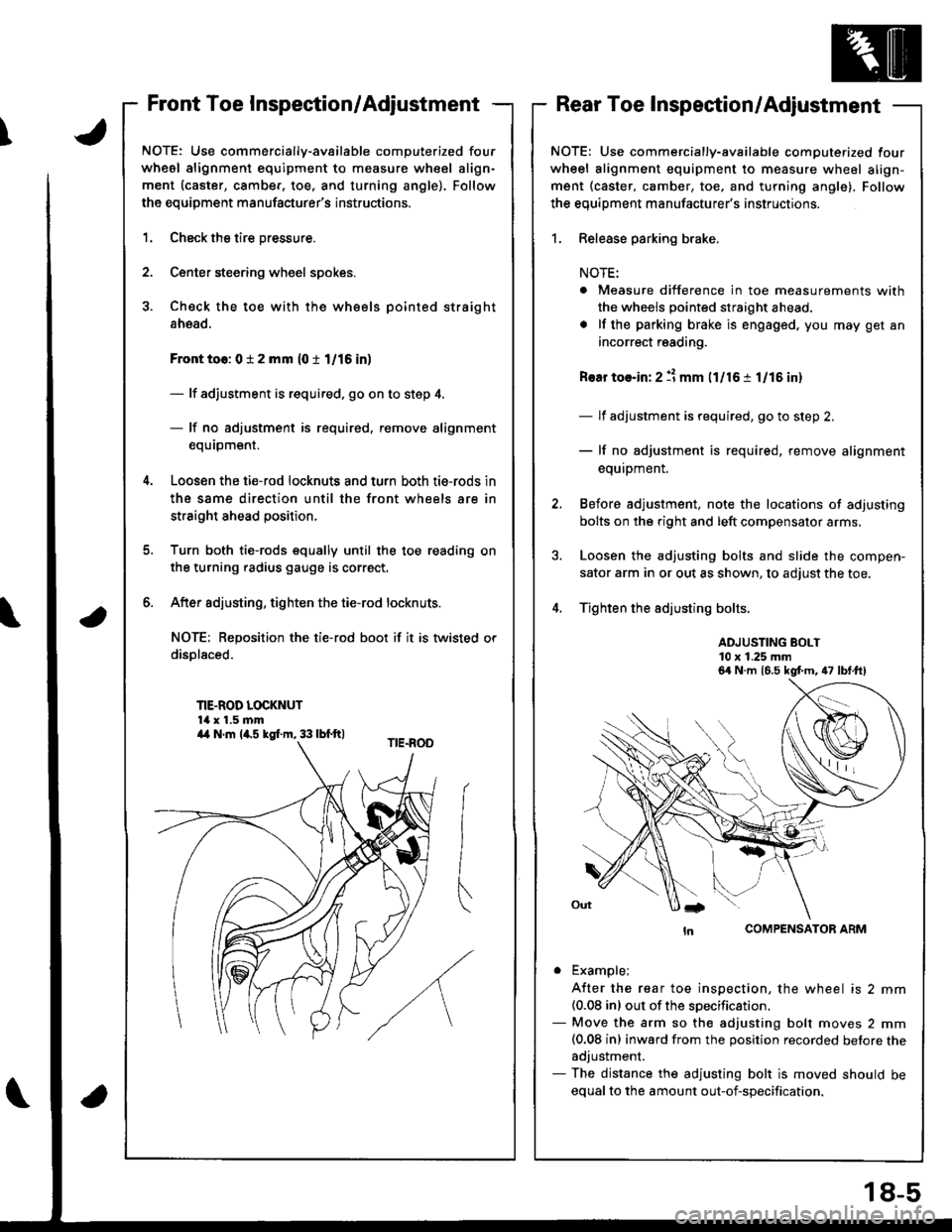

Front Toe Inspection/AdjustmentRear Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

whesl alignment equipment to measure wheel align-

ment (caster, camber, toe. and turning angle). Follow

the equipment manufacturer's instructions.

1.

2.

Check the tire pressure.

C€nter steering wheel spokes.

Check the toe with the wh€els pointed straight

ahead.

Front to6: 0 i 2 mm (0 t 1/16 in)

- lf adjustment is required. go on to step 4.

- lf no adjustment is required, remove alignment

equrpm€nr,

Loosen the ti€-rod locknuts and turn both tie-rods in

the same direction until the front wheels are in

straight ahead position.

Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

After sdjusting, tighten the tie-rod locknuts.

NOT€: Reposition the tie-rod boot if it is twisted or

displaced.

TIE-ROD LOCKNUT14 x 1.5 mm

6.

a

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle), Follow

the equiDment manufacturer's instructions.

1. Release parking brake.

NOTE:

. Measure difference in toe measurements with

the wheels pointed straight ahead.

. lf the parking brake is engaged. you may get an

incorrect reading.

Rear toe-in: 2 11 mm l1l16 i 1/15 in)

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts and slide the compen-

sator arm in or out as shown, to adjust the toe.

Tighten the adjusting bolts.

ADJUSTING BOLT10 x 1.25 mm

COMPENSATOR ARM

. Example;

A{ter the rear toe inspection, the wheel is 2 mm(0.08 inl out of the soecification.- Move the arm so the adjusting bolt moves 2 mm(0.08 inl inward from the position recorded betore theadjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

6a N.m 16.5 kgt m, 47 lbt.ft)

a4 N.m la.s kgI.m, 33 lbf.ft)

18-5

Page 716 of 1681

l,

Wheel Alignment

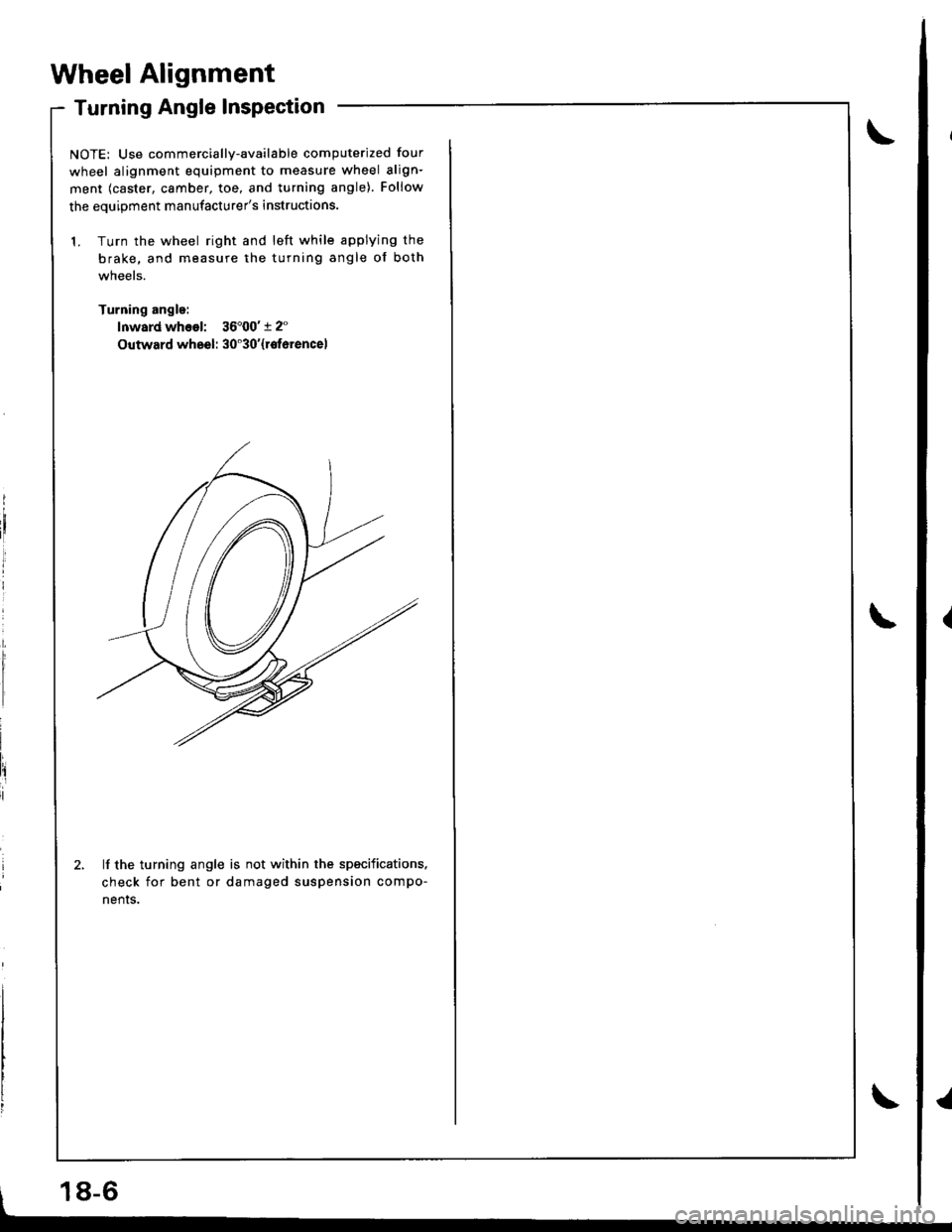

Turning Angle Inspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equioment manufacturer's instructions.

1. Turn the wheel right and left while applying the

brake, and measure the turning angle of both

wneels.

Turning angle:

lnward whsol: 36'00't 2"

Outward wheel: 30'30'{rotorencel

lf the turning angle is not within the specifications.

check for bent or damaged suspension compo-

nenrs.

18-6

Page 717 of 1681

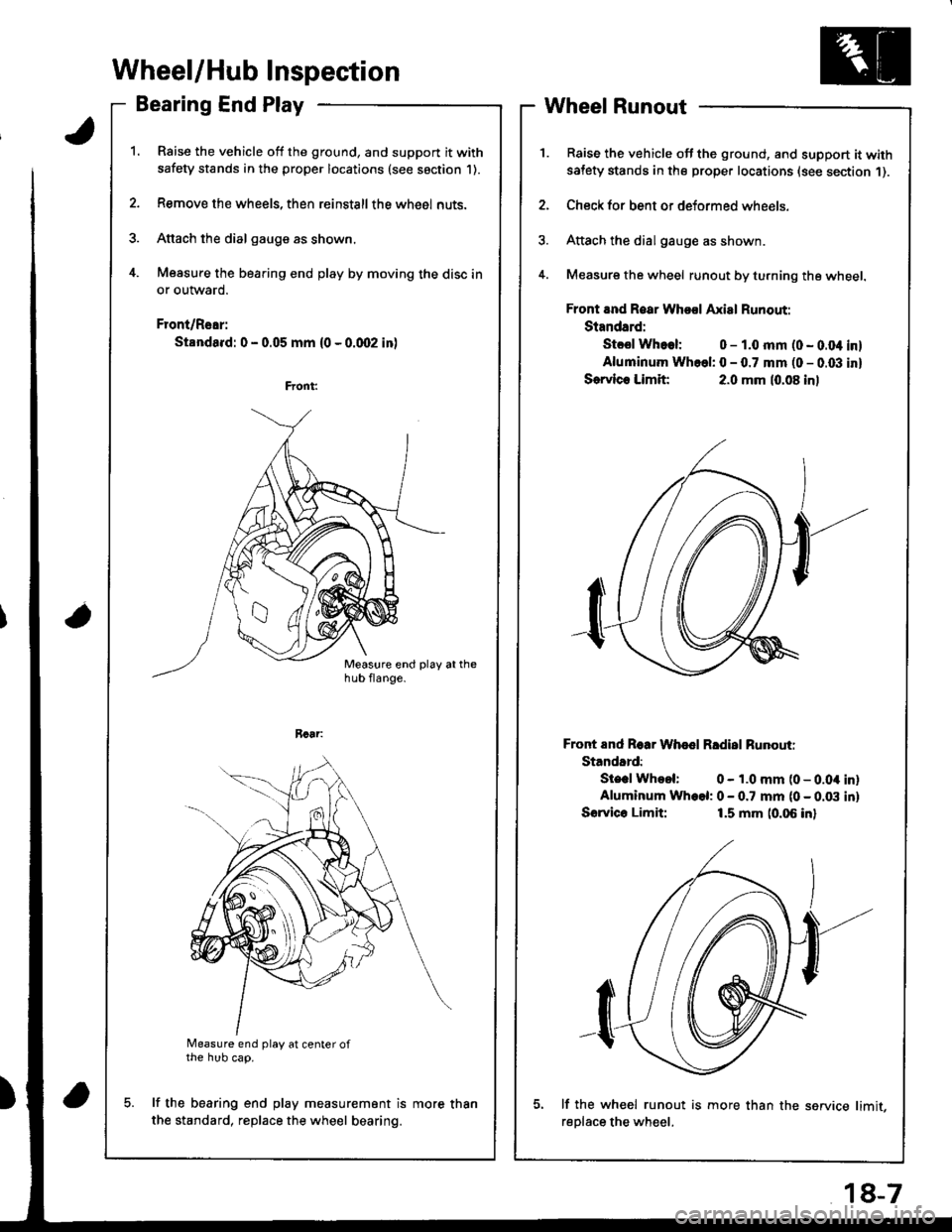

Wheel/Hub Inspection

Bearing End Play

Raise the vehicle off the ground, and support it with

safety stands in the proper locations (see saction 1).

Remove the wheels, then reinstallthe whe6l nuts.

Attach the dial gauge as shown.

Measure the bearing end play by moving the disc in

or outward.

Front/Rear:

Standa.d: 0 - 0.05 mm (0 - 0.qr2 in)

a

Measure end play at center ofthe hub cap.

lf the bearing end play measurement is

the standard, replace the wheel bearing.

Wheel Runout

Raise the vehicle off the ground, and support it withsatety stands in the proper locations (see section 1).

Check for bent or deformed wheels.

Attach the dial gauge as shown.

Measure the wheel runout by turning the wheel.

Front and Roar Whool Axial Runout:

Standard:

Stcsl Whoel: 0 - 1.0 mm (0 - 0.04 inl

Aluminum Whcel: 0 - 0.7 mm (0 - 0.03 inl

Sorvlc. Limit:2.0 mm (0.08 inl

Front End Roar Whod Rldisl Runouti

Standard:

Ste.l Whool: 0 - 1.0 mm (0 - 0.04 inlAluminum Wh.el: 0 - 0.7 mm (0 - 0.03 inl

Sorvico Limit:1.5 mm (0.06 inl

lf the wh€el runout is more than the service limit,

reDlace the wheel.

more than

18-7

Page 718 of 1681

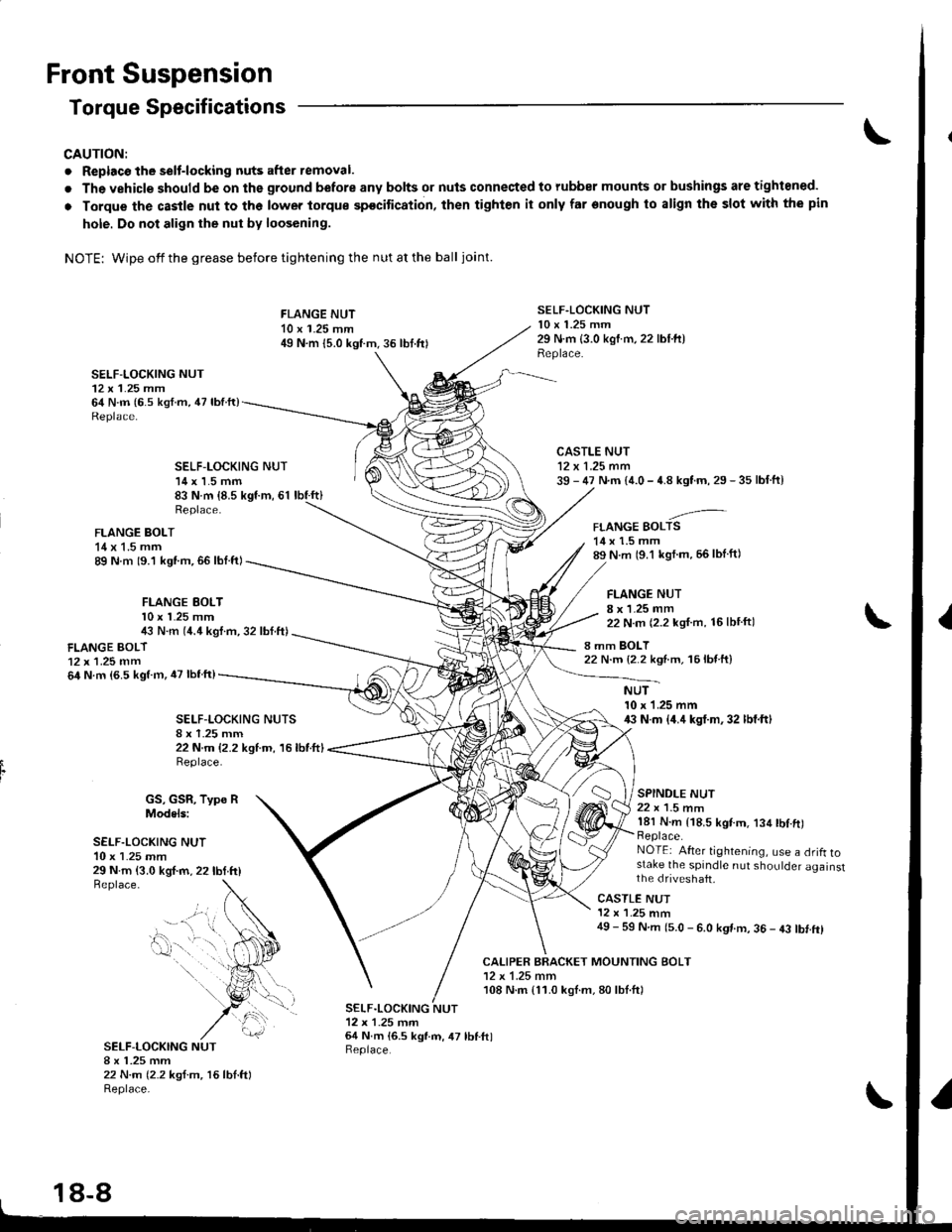

Front Suspension

Torque Specifications

CAUTION:

. Replacc the selt-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuls connected to rubber mounts or bushings are tightoned.

o Torque thc castle nut to the lower torque spocitication, then tighten it only far onough to align the slot with the pin

hole. Do not align the nut bv loosening.

NOTE: Wipe offthegrease before tightening the nutatthe ball joint.

SELF-LOCKING NUT12 x 1.25 mm64 N.m (6.s ksf.m, 47 lbfft)

FLANGE NUT10 x 1.25 mm49 N.m {5.0 kgtm.36 lbt.frl

SELF.LOCKING NUT10 x 1.25 mm29 N.m {3.0 kgtm,22 lbl.ft)Replace.

CALIPER BRACKET MOUNTING BOLT12 x 1.25 mm108 N.m {11.0 kgl.m,80lbl.ftl

SELF-LOCKING NUT14 x 1.5 mm83 N.m {8.5 kgf.m, 61 lbf.ft}

CASTLE NUT12 x 1.25 mm39 - 47 N.m {4.0 - 4.8 kgtm, 29 - 35 lbf.ft}

-'-FLANGE BOLTS14 x 1.5 mm89 N.m (9.1 kgl m, 56lblft)

FLANGE NUT8 x 1.25 mm22 N.m (2.2 kgf.m, 16lbtftl

8 mm BOLT22 N.m {2.2 ksnm, 16lb{ ft}

Replace.

FLANGE BOLT14 x 1.5 mm89 N m 19.1 kgt.m,66 lbl.ftl

FLANGE EOLTl0 x l�25 mm4i, N.m (4.4 kgl.m, 32 lbf.ft)

FLANGE BOLT12x 1.25 mm64 N.m (6.5 kgtm, iU lbfftl

SELF-I-OCKING NUTS

22 N.m {2.2 kgtm, 16lbtftlReplace.

NUT10 x 1.25 mm43 N.m {4.4 kgt.m,32 lbf.ftl

SPINDLE NUT22 x 1.5 nm181 N.m {18.5 kgtm. 134 tbl.ft)Replace.NOTEi After tightening, use a drifl tostake the spindle nut shoulder againstthe dfiveshaft,29 N.m {3.0 kgf.m, 22lbtttlBeplace.

GS, GSR, Type RModels:

SELF.LOCKING NUT10 x 1.25 mm

SELF-LOCKING NUTI x 1.25 mm22 N.m (2.2 ksf.m, 16lbl.ftlReplace-

CASTLE NUT12 x '1.25 mm49 - 59 N.m (5.0 - 6.0 kgt m, 36 - 43 tbt.ftl

SELF.LOCKING NUT12x 1-25 tnrn64 N.m 16.5 kgl.m, 47 lbf.ftlReplace.

- --.." t,..

0-. .

18-8

Page 719 of 1681

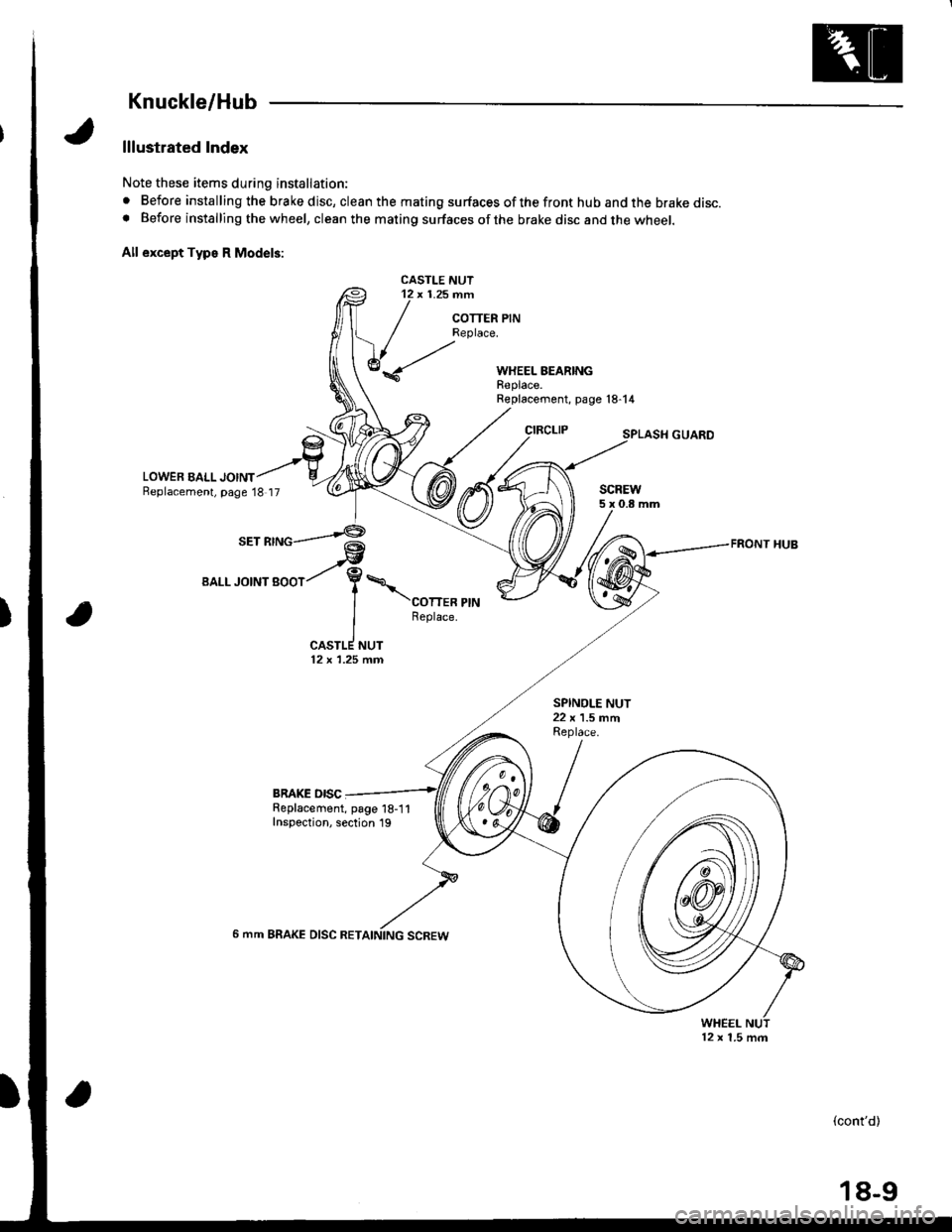

Knuckle/Hub

lllustrated Index

Note these items during installation:

. Before installing the brake disc, clean the mating surfaces of the front hub and the brake disc.o Before installing the wheel, clean the mating surfaces ofthe brake disc and the wheel.

All except Typs R Model3:

CASTLE NUT12 x 1.25 nn

COTTER PINReplace.

WHEEL BEARINGReplace.

LOWER EALL JOINTBeplacement, page 18 17

Replacement, page l8-14

CIRCLIP

SCREW5x0.8mm

FRONT HUB@tV,/- ai.1eetL.rotNtgoot/ Y\

| \conen erru

I Reptace.

ICASTLE NUT12 x 1.25 fin

BRAKE OISCReplacement, page 18-1 1Inspection, section 19

6 mm BRAKE DISC RET

WHEEL

(cont'd)

12 x 1.5 m.n

18-9

Page 720 of 1681

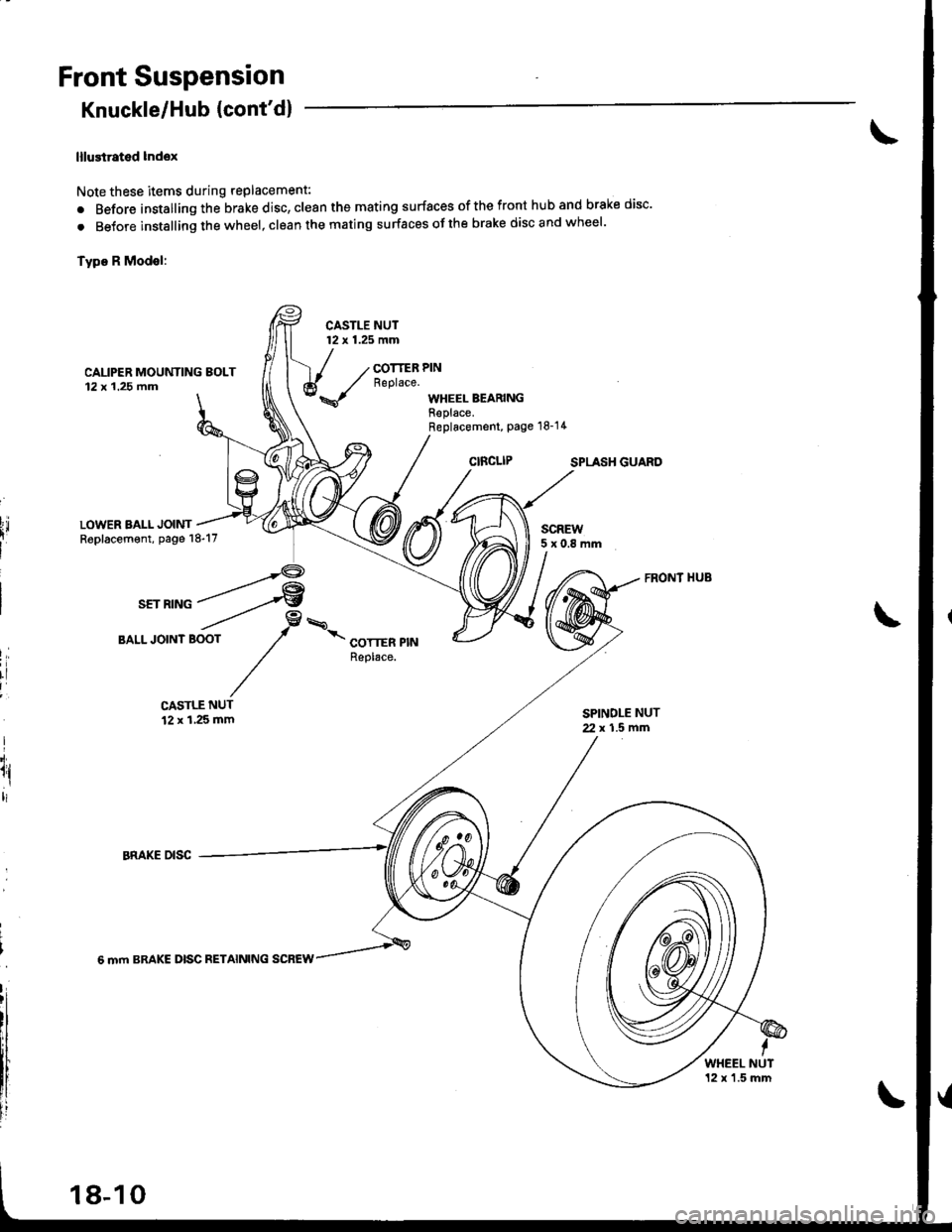

Front Suspension

Knuckle/Hub {cont'd}

lllustrated lndox

Note these items during replacement:

. Before installing the brake disc, clean the mating surfaces of the front hub and brake disc'

. BeJore instslling the wheel, clean the mating surfaces ofthe brake disc and wheel'

Type R Modsl:

CASTLE NUT12 x 1.25 mm

CAUPER MOUNTING EOLT12x 1.25 fim

COTTER PINReplace.

WHEEL BEARINGReplace.Replacement, Page 18-14

SPLASH GUARO

LOWER BALL JOINTReplacement, page 18-17SCREW5x0.8mm

I,

rl

I

I'i.

1l,ltl

CASTLE NUT12 x 1,25 mmSPINDLE NUT2. x 1.5 mfi

6 mm BRAKE DISC RETAINING SCREW

WHEEL NUT12 x'1.5 mm

18-10