HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 721 of 1681

1.

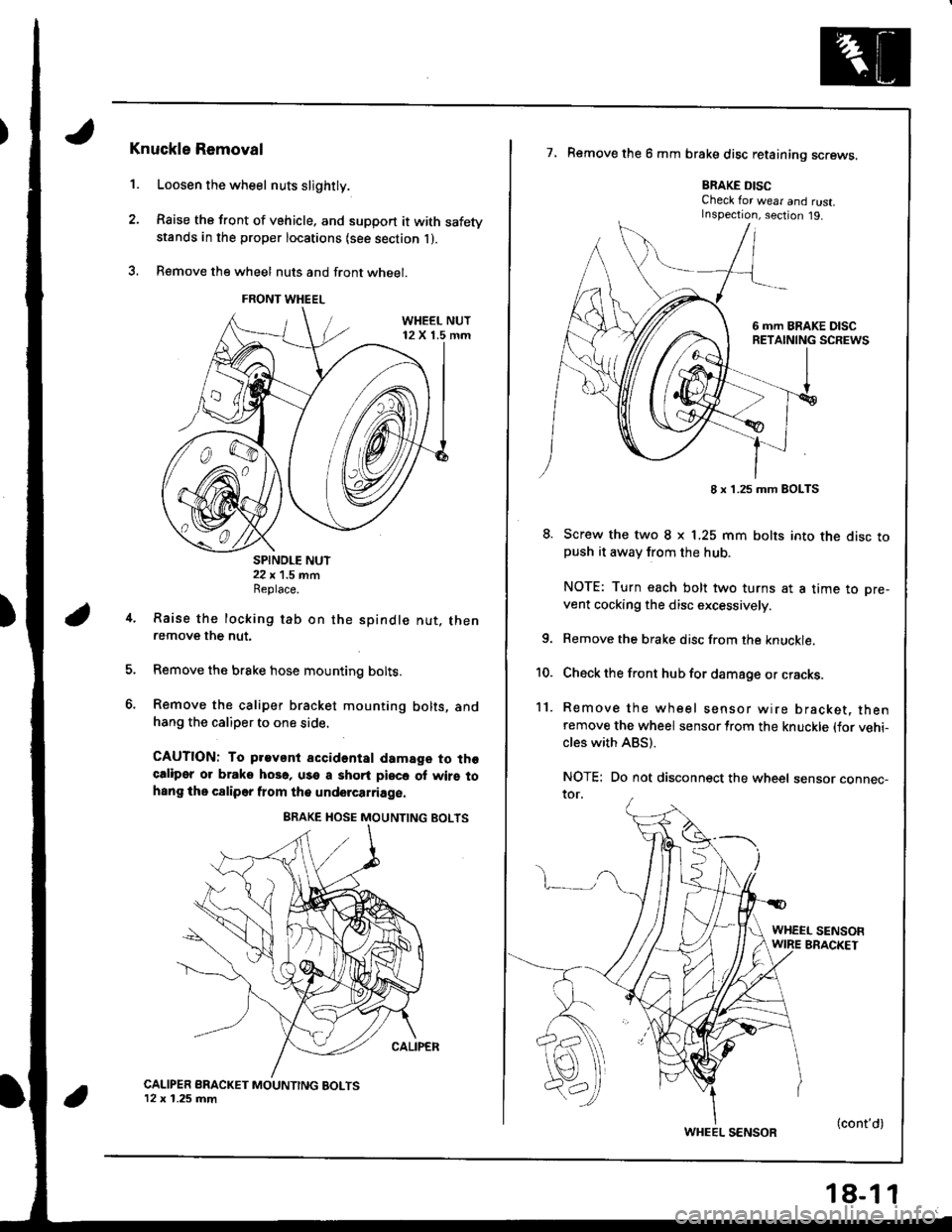

Knuckle Removal

Loosen the wheel nuts slightly.

Raise the front of vehicle. and support it with safetystands in the proper locations {see section l ).

B€move the wheel nuts and front wheel.

SPINDLE NUT22 x 1.5 mmReplace.

Raise the locking tab on the

remove the nut.

spindle nut. then

Remove the brake hose mounting bolts.

Remove the caliper bracket mounting bolts, andhang the caliper to one side.

CAUTION: To pravant accidental damage to thgcaliper or braks hoso, use a shqrt piece of wirs tohsng the c8liper flom the undercarriage.

CALIPER BRACKET MOUNTING BOLTS12 x 1.25 mm

7, Remove the 6 mm brake disc retaining screws.

BRAKE DISCCheck for wear and rust.Inspection, section j9.

8. Screw the two I x L25 mm bolts into the disc topush it awav from the hub.

NOTE: Turn each bolt two turns at a time to pre-

vent cocking the disc excessively.

Remove the brake disc from the knuckle.

Check the front hub for damage or cracks.

Remove the wheel sensor wire bracket, thenremove the wheel sensor lrom the knuckle (for vehi-cles with ABS).

NOTE: Do not disconnect the wheel sensor connec-ror.

4.

6.

10.

11.

WHEEL SENSOFWIRE BRACKET

FRONT WHEEL

8 x 1.25 mm BOLTS

WHEEL SENSOR(cont'd)

Page 722 of 1681

Front Suspension

Knuckle/Hub (cont'd)

13.

N-ur--------------*i10 x 1.25 mm \

COTTERReplace.

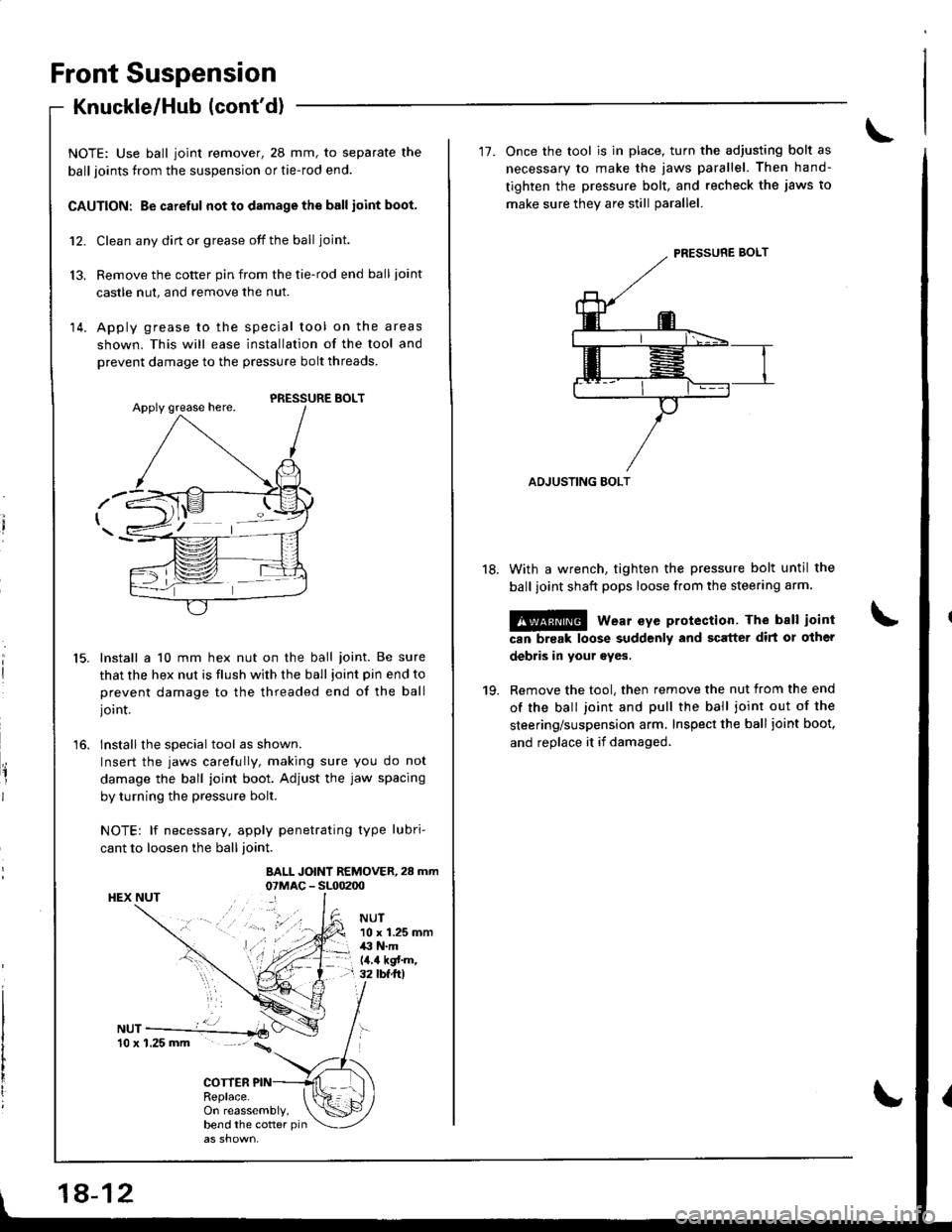

NOTE: Use ball joint remover, 28 mm, to separate the

ball joints from the suspension or tie-rod end.

CAUTIONT Be careful not to damage the ball ioint boot.

Clean any dirt or grease off the ball joint.

Remove the cotter pin from the tie-rod end balljoint

castle nut, and remove the nut.

Apply grease to the special tool on the areas

shown. This will ease installation of the tool and

prevent damage to the pressure bolt threads.

12.

14.

15.

'16.

PRESSURE BOLT

Install a 10 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end to

prevent damage to the threaded end of the ball

joint.

Installthe special tool as shown.

Insert the jaws carefully, making sure you do not

damage the ball joint boot. Adjust the jaw spacing

by turning the pressure bolt.

NOTE: lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

BALL JOINT REMOVER,28 mm07MAC - SL00200HEX NUT

NUT10 x 1.25 mm,li' N.mla.a kgf'm,32 tbf ft)

On reassembly,bend the cotter pin

18-12

'17. Once the tool is in place, turn the adiusting bolt as

necessary to make the jaws parallel. Then hand-

tighten the pressure bolt, and recheck the jaws to

make sure thev are still oarallel.

ADJUSTING BOLT

With a wrench, tighten the pressure bolt until the

ball ioint shaft pops loose from the steering arm.

@ wear eye protection. The ball ioint

can break loose suddenly and scrtter dirt or other

debris in your eyes.

Remove the tool, then remove the nut from the end

of the ball joint and pull the ball ioint out of the

steering/suspension arm, Inspect the ball joint boot,

and replace it if damaged.

18.

19.

Page 723 of 1681

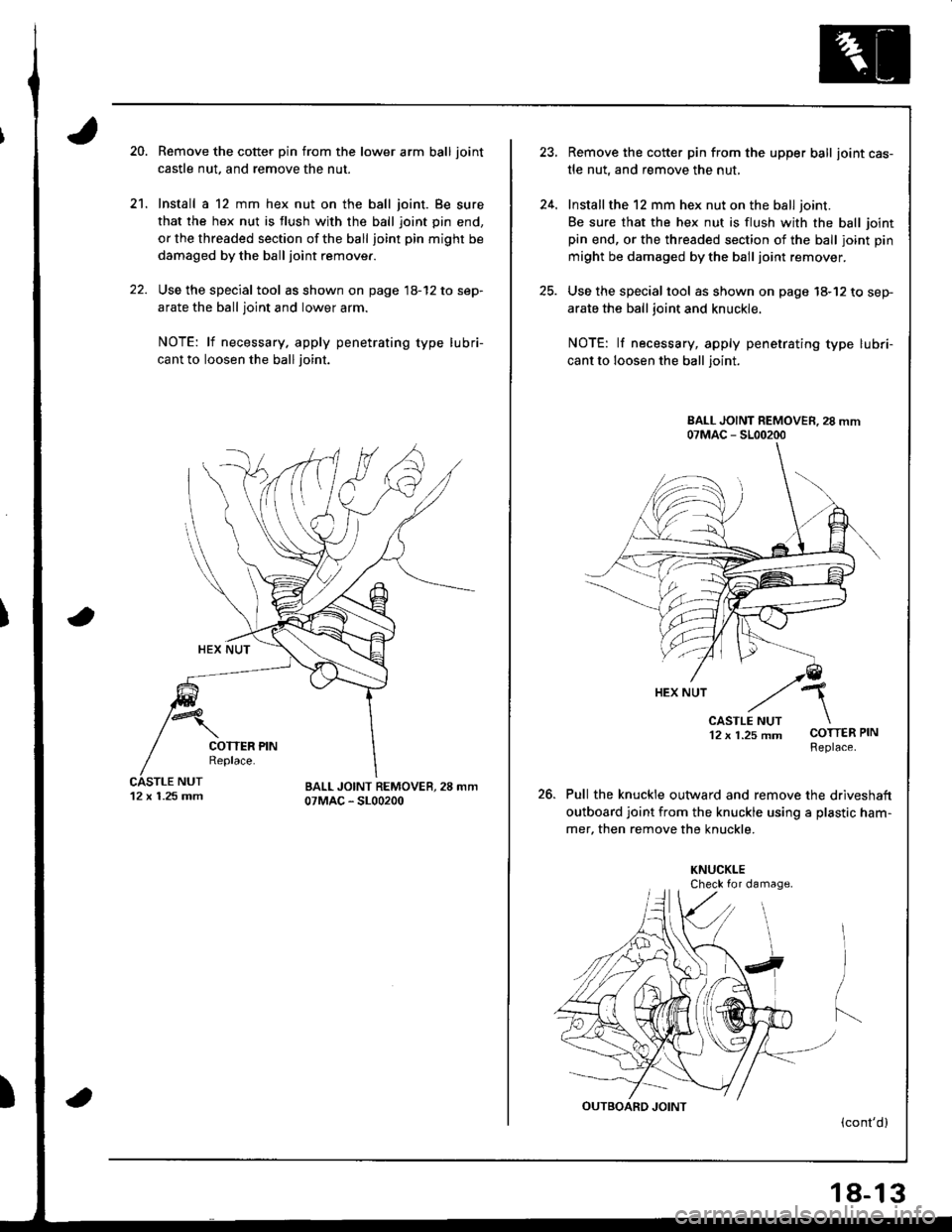

20.

21.

Remove the cotter pin from the lower arm ball joint

castle nut. and remove the nut.

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with th€ ball joint pin end,

or the threaded section of the ball joint pin might be

damaged by the ball joint remover.

Use the special tool as shown on page 18-12 to sep-

arate the ball joint and lower arm.

NOTE: lf necessary. apply penetrating type lubri-

cant to loosen the ball joint.

12 x 1.25 mm

)

23.

24.

Remove the cotter pin from the upper ball joint cas-

tle nut, and remove the nut,

Installthe 12 mm hex nut on the ball joint.

Be sure that the hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

Use the special lool as shown on page 18-12 to sep-

arate the ball joint and knuckle.

NOTE: lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

CASTLE NUT

Pull the knuckle outward and remove the driveshaft

outboard joint from the knuckle using a plastic ham-

mer, then remove the knuckle.

(cont'd)

25.

COTTERReplace.

26.

OUTBOARD JOINT

18-13

Page 724 of 1681

Front Suspension

Knuckle/Hub (cont'd)

fl

l

Ili

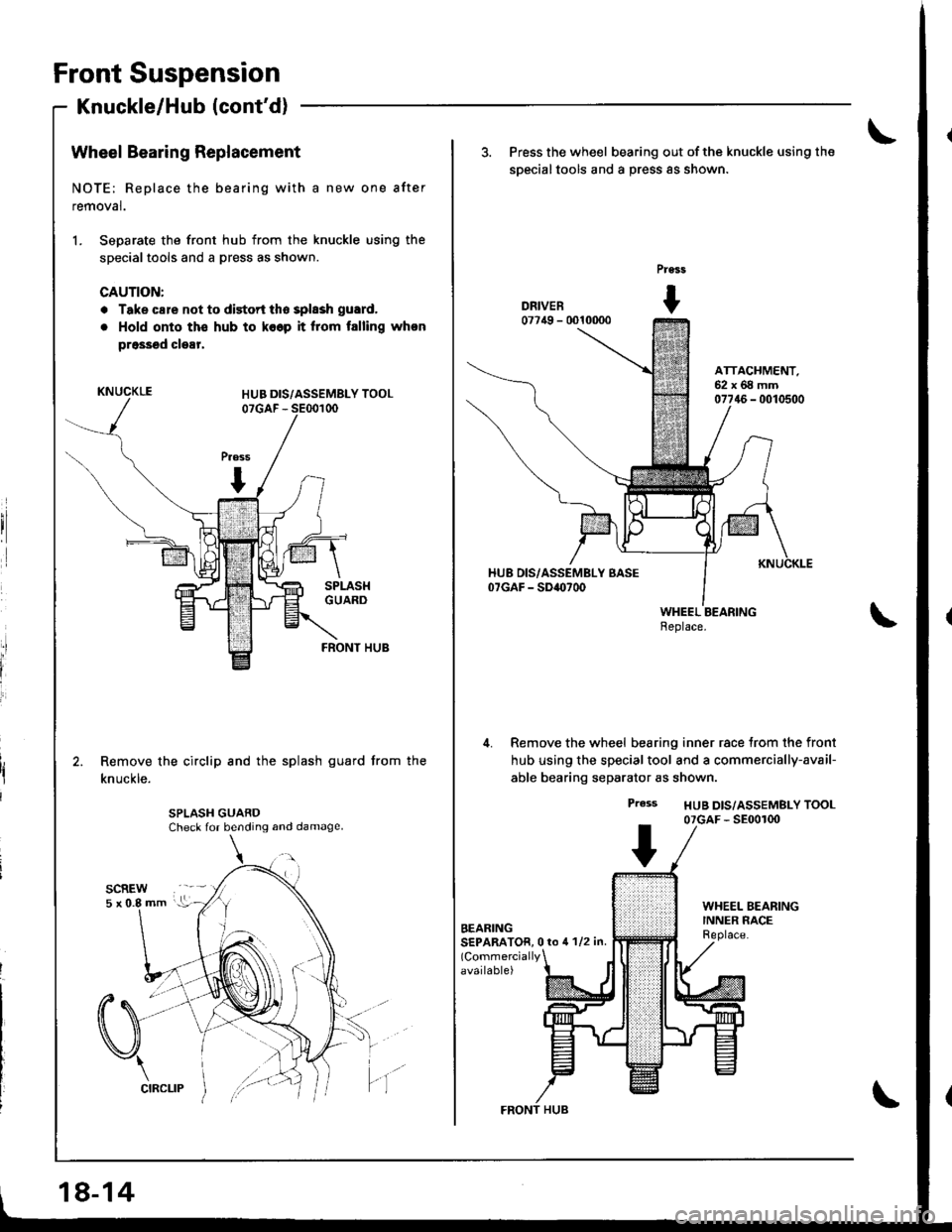

Wheel Bearing Replacement

NOTE; Replace the bearing with a new one after

removal.

1. Separate the front hub from the knuckle using the

specialtools and a press as shown.

CAUTION:

. Take cale not to distort tho splssh guard,

. Hold onto ths hub to ko6p it lrom talling whon

prossed clear,

KNUCKLE

FRONT HUB

Remove the circlip and the splash guard from the

knuckle.

SPLASH GUARDCheck for bending and damage

18-14

FRONT HUB

3. Press the wheel bearing out of the knuckle using the

soecialtools and a Dress as shown.

DRIVER07749 - 0010000

ATTACHMENT.52x68mm07746 - 0010500

Remove the wheel bearing inner race trom the front

hub using the specialtool and a commercially-avail-

able bearing separator as shown.

Press HUB D|S/ASSEMBLY TOOL07GAF - SE00100

BEARINGSEPARATOR, 0 ro 4 1/2 in.(Commercially

available)

Page 725 of 1681

\

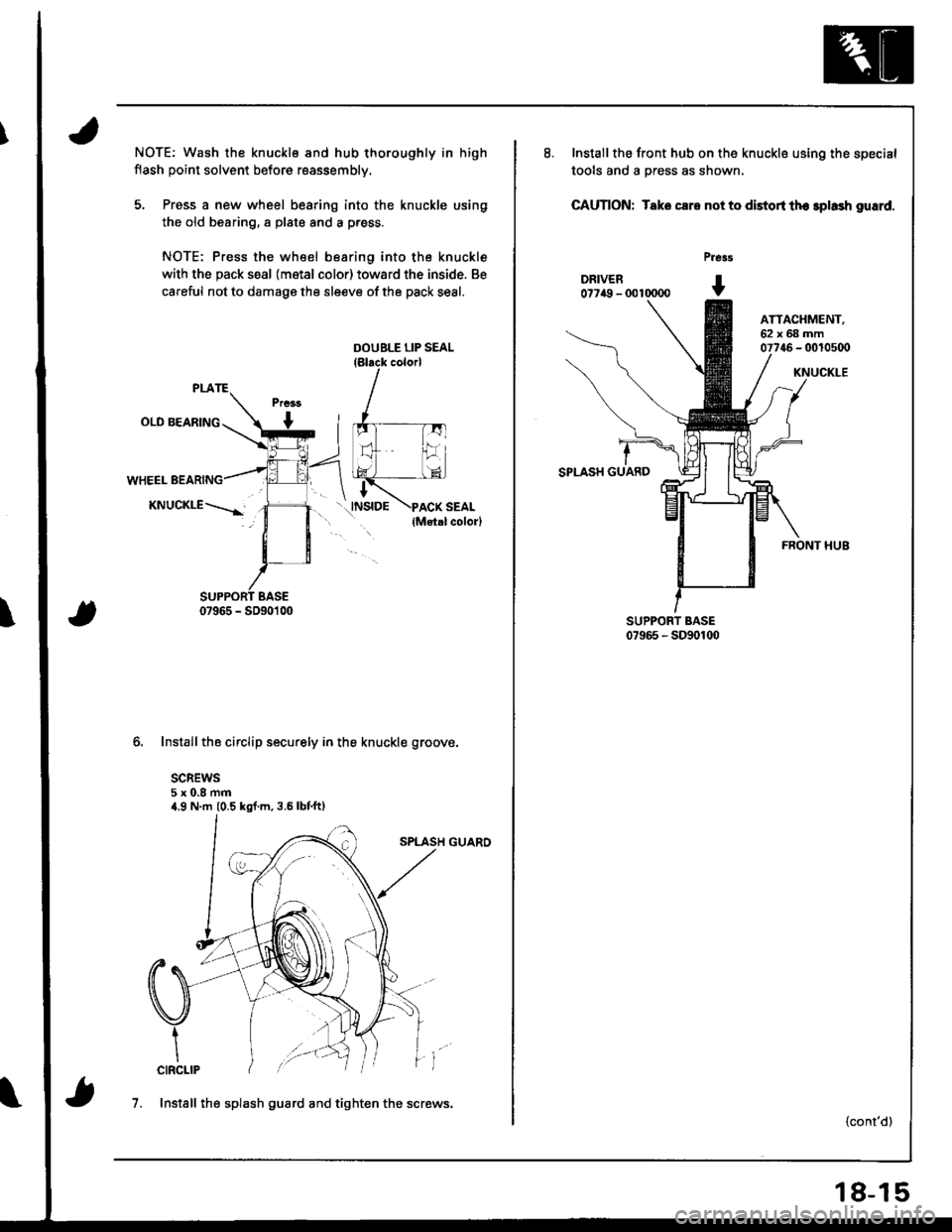

NOTE; Wash the knuckle and hub thoroughly in high

flash point solvent before reassembly.

5. Press a new wheel bearing into the knuckle using

the old bearing, a plate and a p.ess.

NOTE: Press the wheel bearing into the knuckle

with the pack seal (metal color) toward the inside. Be

careful not to damage the sleeve of the pack seal.

Installthe circlip securely in the knuckle groove.

SCREWS5x0.8mm4.9 N'm (0.5 kgf.m,3.5lbtftl

SPLASH GUARO

7. Install the splash guard and tighten the screws.

18-15

Installthe front hub on the knuckle using the special

tools and a press as shown,

CAUTION: Tako csro not to distort tho splash guard.

pre3s

DRIVER I0??a9 - 0010000 v

ATTACHMENT,62x68mm07746 - 00t0500

SPLASH GUARD

KNUCKLE

FRONT HUB

{cont'd)

Page 726 of 1681

Front Suspension

Knuckle/Hub (cont'd)

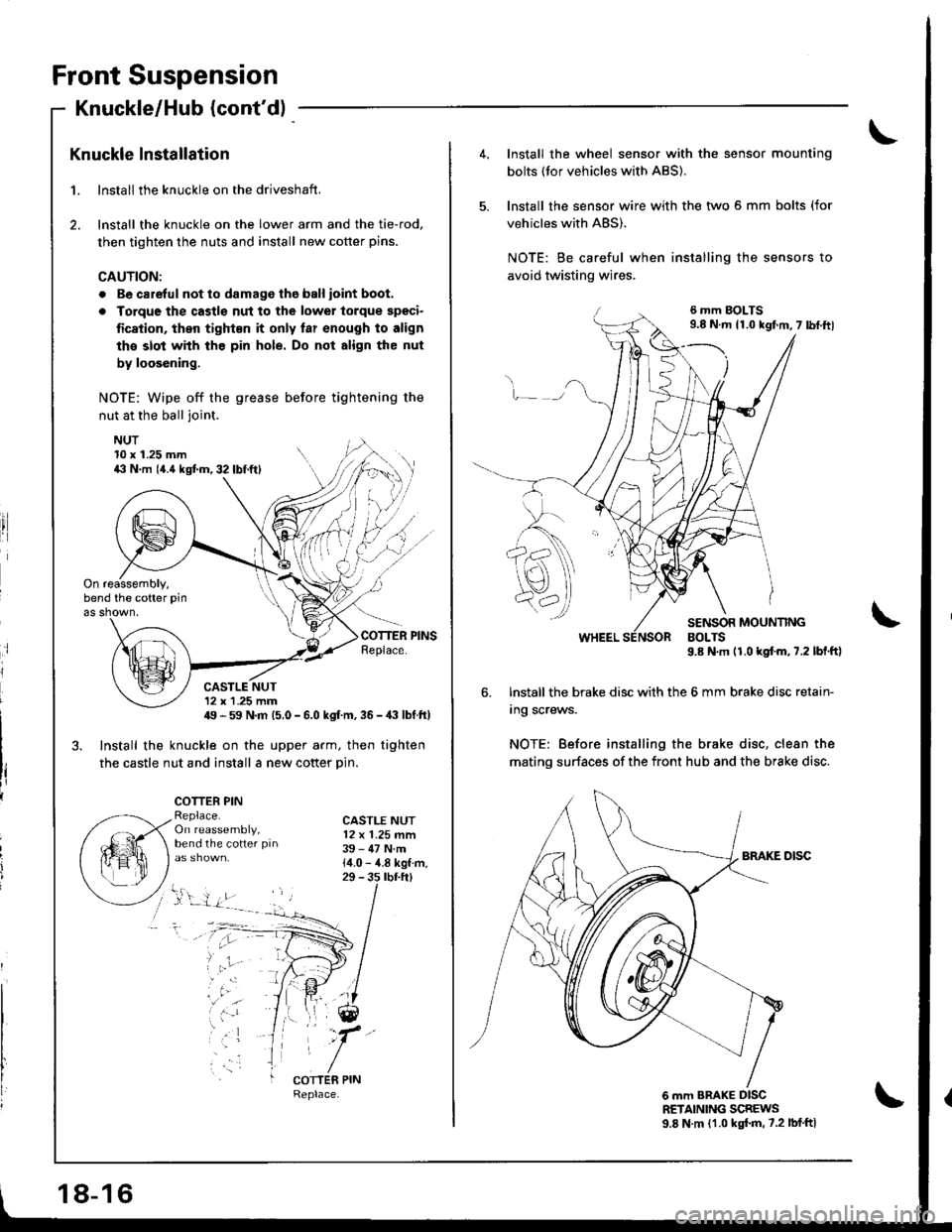

Knuckle lnstallation

1. lnstall the knuckle on the driveshaft.

2. lnstall the knuckle on the lower arm and the tie-rod,

then tighten the nuts and install new cotter pins.

CAUTION:

. Be carelul not to damage tho ball ioint boot.

a Torque the castls nut to the lowel torque spgci-

fication, then tight€n it only far enough to align

the slot with the pin hole. Do not align the nut

by loosening.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

NUT

ri

10 x 1.25 mm4il N.m (4.{ kgtm,32lbf.ftl

On reassembly,bend the cotter pin

as shown.

CASTLE NUT12 x 1 .25 mm49 - 59 N.m (5.0 - 6.0 kgf m, 36 -,|i| lbf ft)

3. Install the knuckle on the upper arm, then tighten

the castle nut and install a new cotter Din.

COTTER PINReplace.On reassembly,bend the cotter pin

CASTLE NUT12 x 1.25 mm39 - 47 N.m{4.0 - 4.8 kgf.m,29 - 3s rbr.ft)

;

, 'ar

COTTER PIN

18-16

4.Install the wheel sensor with the sensor mounting

bolts (tor vehicles with ABS).

lnstall the sensor wire with the two 5 mm bolts (for

vehicles with ABS).

NOTE: Be careful when installing the sensors to

avoid twisting wires.

6 mm BOLTS9.8 N.m 11.0 kgf.m,7 lbf.ftl

v_)

SENSOR MOUNTINGBOLTS9.8 N.m (1.0 kgf.m,7.2 lbl.ftl

6. lnstall the brake disc with the 6 mm brake disc retain-

Ing screws.

NOTE: Before installing the brake disc, clean the

mating surfaces of the front hub and the brake disc.

6 mm BRAKE DISCRETAINING SCREWS9.8 N.m 11.0 kgl.m, 7.2 lbf'ftl

Page 727 of 1681

Lower Ball Joint Replacement

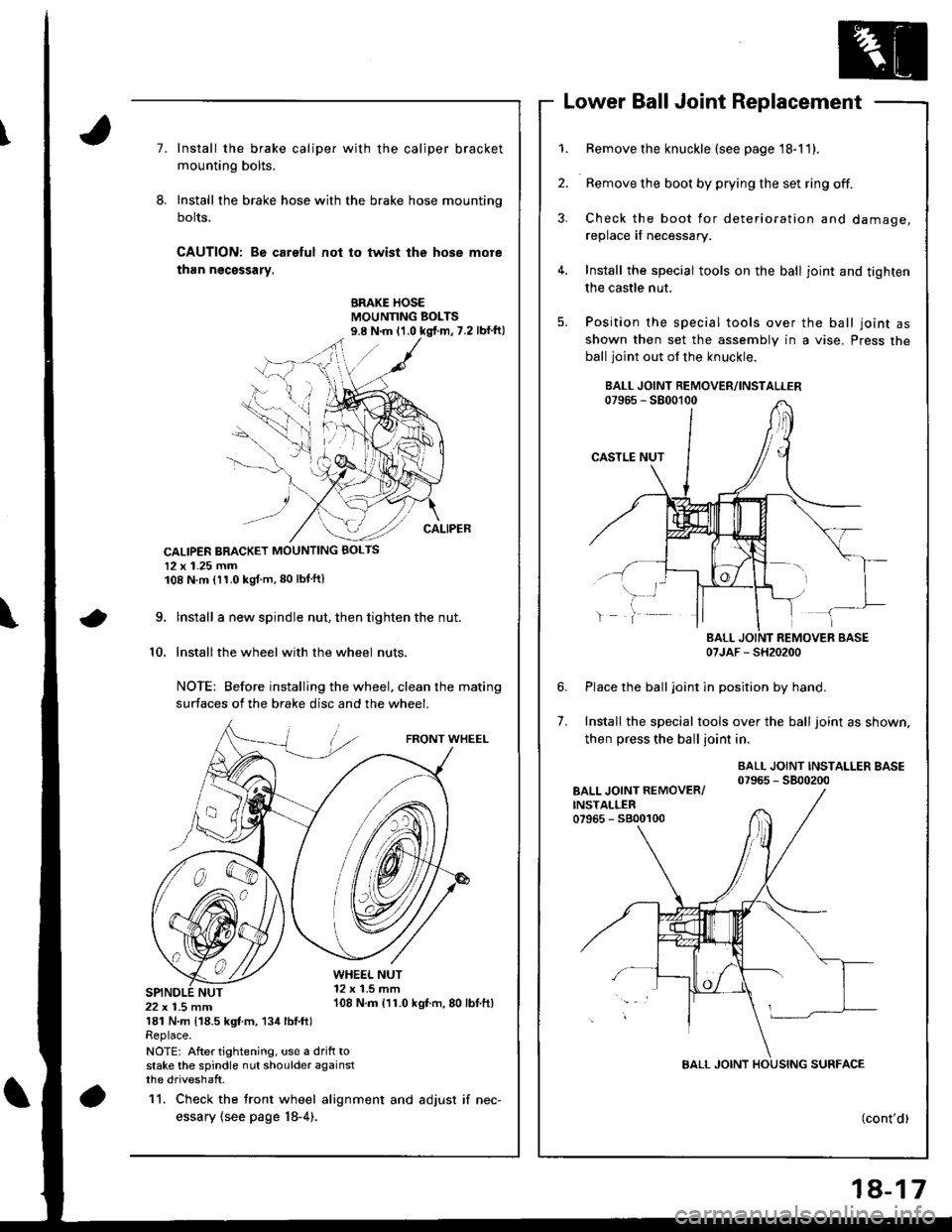

7.Install the brake caliper with the caliper bracket

mounting bolts.

Install the brake hose with the brake hose mounting

bolts.

CAUTION: Bo careful not to twist the hose more

than ngcsssary.

BRAKE HOSEMOUNNNG BOLTS

CALIPER BRACKET MOUNTING BOLTS

12 x 1.25 mm108 N.m (11.0 kgf m,80 lbtftl

\9.

10.

lnstall a new spindle nut, then tighten the nut.

Installthe wheel with the wheel nuts

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEEL

WHE€L NUT12 x 1.5 mm108 N.m {11.0 kgf.m,80 lbtft)22 x 1.5 mm181 N.m 118.5 kgt m, 134 lbl.ftlReplace.

NOTE: After tightening, us€ a drift tostake the spindle nut shoulder againstthe driveshaft.

11. Check the tront wheel alignment and adjust if nec-

essary (see page l8-4).

1.

2.

4.

5.

Remove the knuckle (see page 18-11).

Remove the boot by prying the set ring off.

Check the boot for deterioration and damage,

replace if necessary.

Install the special tools on the ball joint and tighten

the castle nut.

Position the special tools over the ball joint asshown then set the assembly in a vise. Press the

ball joint out of the knuckle.

07JAF - SH20200

Place the balljoint in position by hand.

Install the special tools over the ball joint as shown,

then press the ball joint in.

BALL JOINT INSTALLER BASE07965 - 5800200

6.

7.

(cont'd)

18-17

Page 728 of 1681

Front Suspension

Lower, Ball Joint Replacement

(confd)

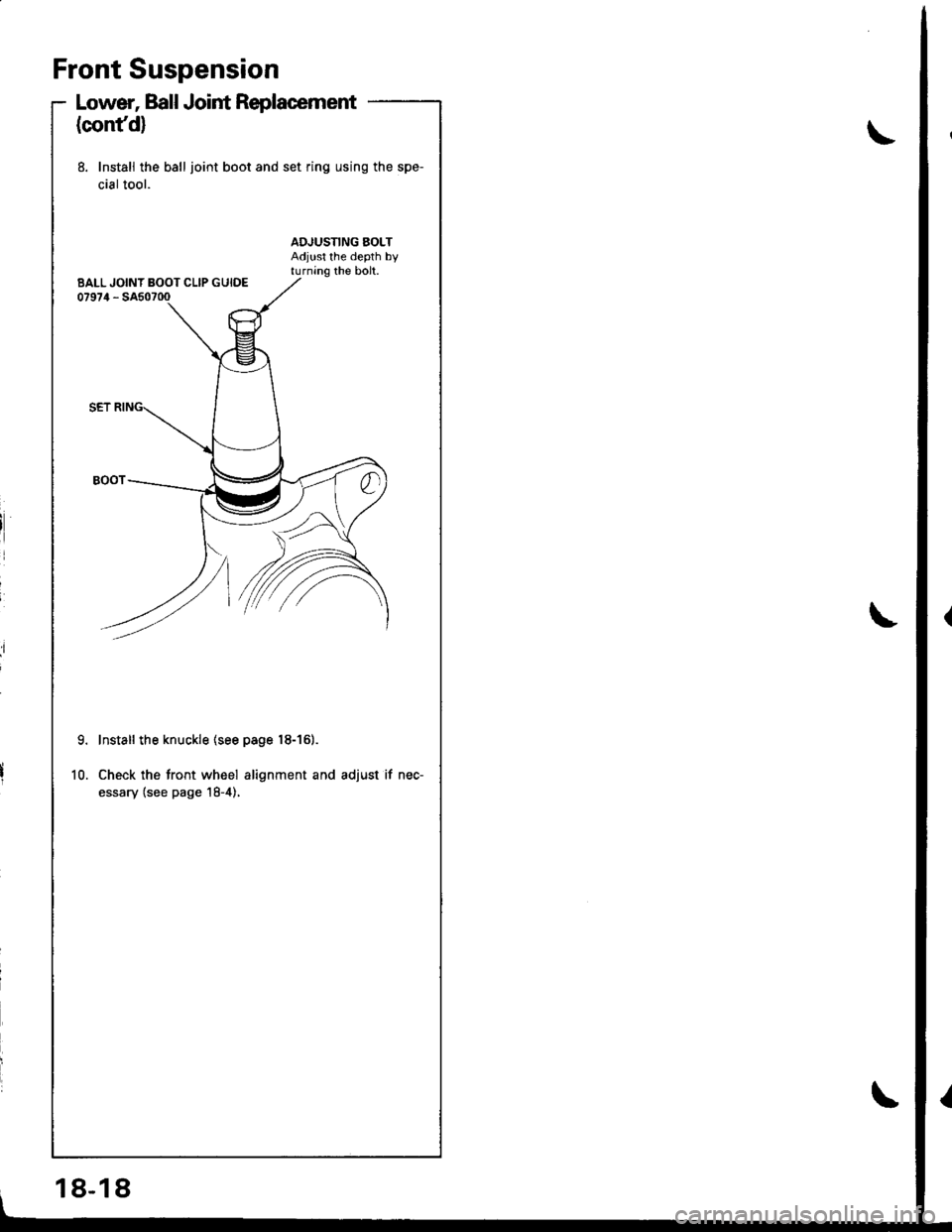

8. Install the ball joint boot and set ring using the spe-

cial tool.

9.

10.

Install the knuckle (see page 18-161.

Check the tront wheel alignment and adjust if nec-

essary (see page 18-4),

BALL JOINT BOOT CLIP GUIDE

18-18

Page 729 of 1681

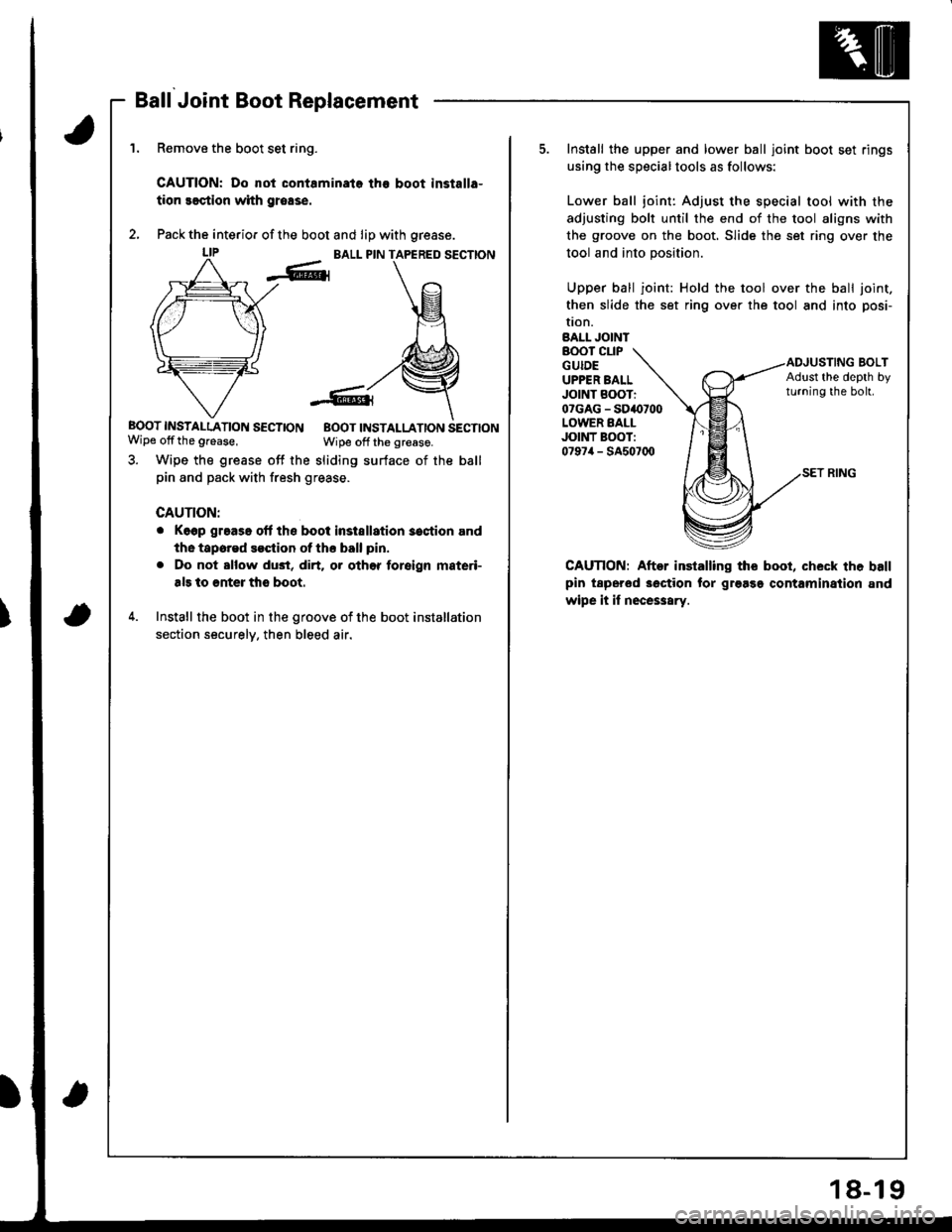

Ball Joint Boot Replacement

Remove the boot set ring.

CAUTION: Do not contaminata the boot installa-

tion seqtion with grease.

Pack the interio. of the boot and lip with grease.

BALL PIN TAPERED SECTION

BOOT INSTAI-LATION SECTION EOOT INSTALLATION SECTIONWipe offthe grease,Wipe off the greaso.

3. Wipe the grease off the sliding surface of the ball

pin and pack with fresh grease.

CAUTION:

o Keep grease olf ths boot instsllation 3ostion and

the tapored $ction ot ths ball pin.

. Do not sllow du3t, dirt. or othor foreign materi-

als to €nter tho boot.

4. Install the boot in the groove of the boot installation

section securelv, then bleed air.

Install the upper and lower ball joint boot set rings

using the specialtools as follows:

Lower ball joint: Adjust the special tool with the

adjusting bolt until the end of the tool aligns with

the groove on the boot, Slide the set ring over the

tool and into position.

Upper ball joint: Hold the tool over the ball joint.

then slide the set ring over the tool and into posi-

tron.BALL JOINTBOOT CLIPGUIDEUPPER BALLJOINT BOOTio?GAG - SD4(,700LOWER EALLJOINT BOOT:0797/r - SA507q)

BOLTAdlst the depth byturning the boh.

CAUnON: Aftor installing the booi, check the ballpin tspersd 3oction tor gr9as9 contaminaiion and

wipe it if nece$ary.

18-19

Page 730 of 1681

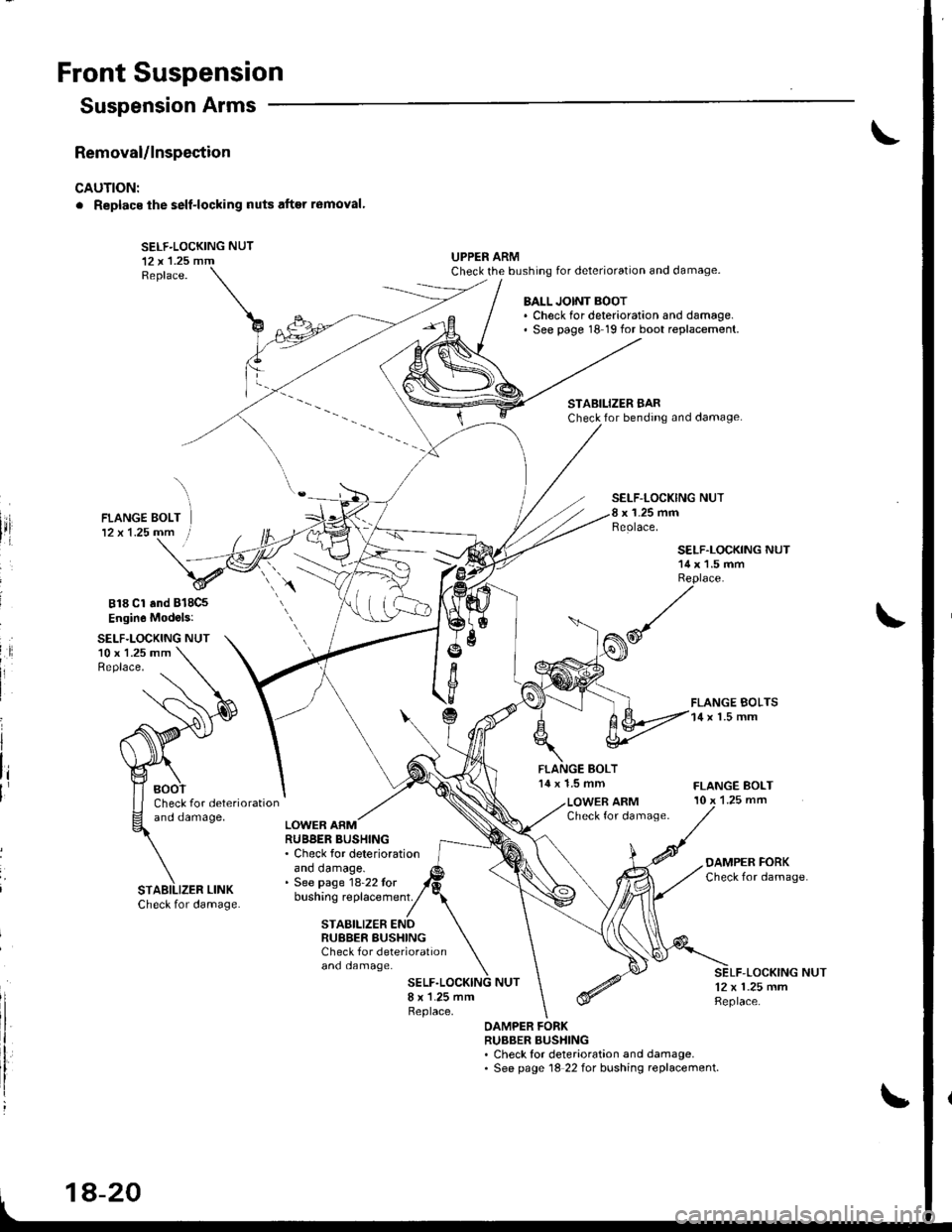

Front Suspension

Removal/lnspection

CAUTION:

. Replacs ihe self-locking nuts after r6moval'

SELF-LOCKING NUT12 x 'l.25 mmReplace.

UPPER ARMCheck the bushing for deterioration and damage.

Suspension Arms

818 Cl and B18C5

Engin6 Mod.ls:

SELF.LOCKING NUT10 x 1.25 mmReplace.

BALL JOINT BOOT. Check for deterioration and damage.' See page 18 19 for boot replacement.

STABILIZER BARCheck for bending and damage.

SELF-LOCKING NUTx 1-25 mmReolace,

14 x 1.5 mm

SELF.LOCKING NUT14 x 1.5 mmReplace.

FLANGE BOLTS14 x l.5 mm

FLANGE BOLT10 x 1.25 mmCheck for deteriorationano oamage,LOWER ARMCheck for damage.LOWER ARMRUBBER BUSHING. Check for deteriorationano oamage.. See page 18-22 tor

OAMPER FORKCheck for damage

bushing replacement.

and damage.

STABILIZER ENDRUBBER BUSHINGCheck f or deterioration

-LOCKING NUT12 x 1.25 mmReplace.

OAMPER FORKRUBBER BUSHING. Check for deterioration and damage.. See page 18 22 for bushing replacement.

STABILIZER LINK

1A-20