check engine HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 315 of 1681

ldle Control System

Fast ldle Thermo Valve (A/T model onlylFast ldle I nermo valve (A/ | mooel

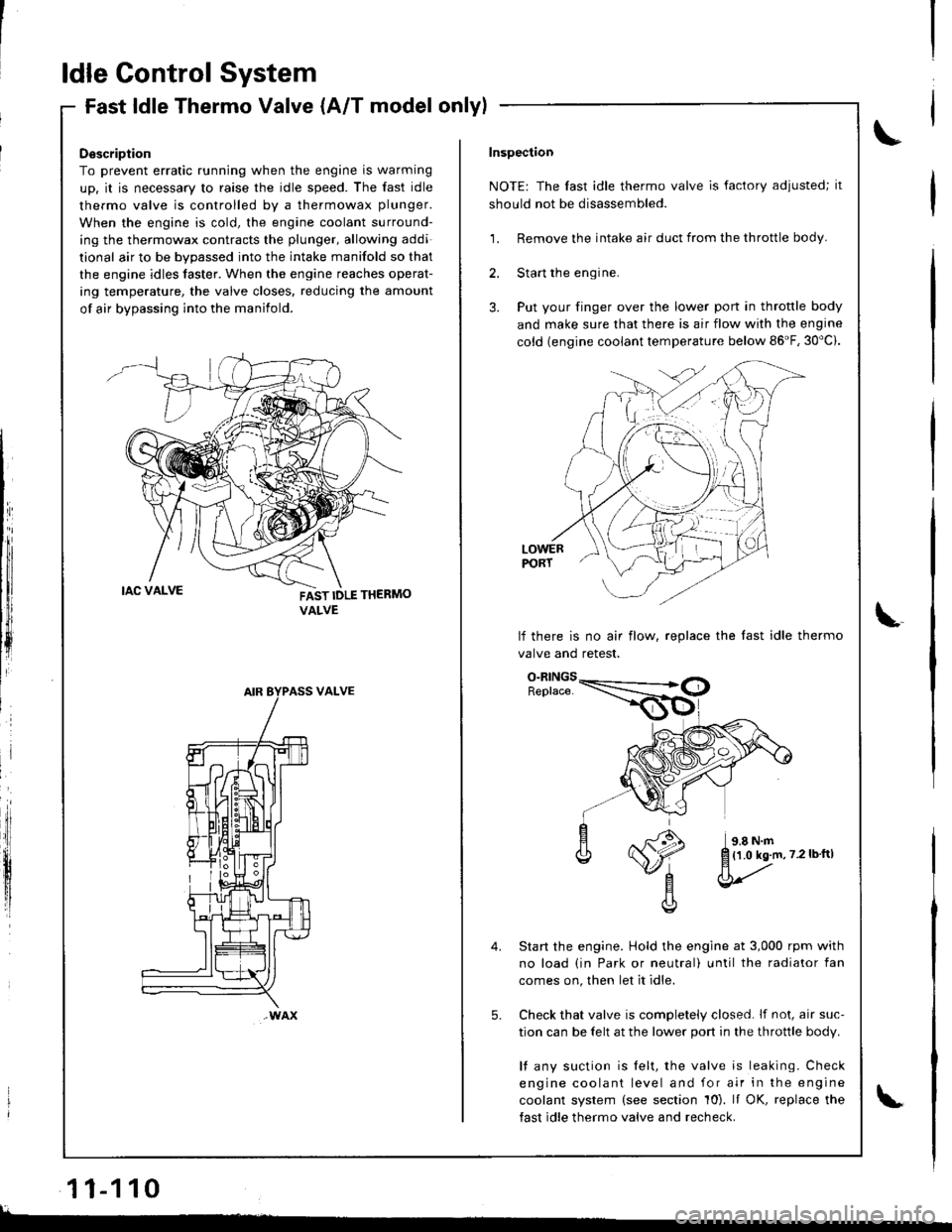

Description

To prevent erratic running when the engine is warming

up. it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi

tional air to be bvoassed into the intake manifold so that

the engine idles taster. When the engine reaches operat-

ing temperature, the valve closes. reducing the amount

of air bypassing into the manifold.

FAST IDLE THERMO

VALVE

VALVE

wAx

Inspection

NOTE: The fast idle thermo valve is factory adiusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine.

3. Put your finger over the lower port in throttle body

and make sure that there is air flow with the engine

cold {engine coolant temperature below 86'F, 30"c).

LOWERPORT

lf there is no air flow, replace the last idle thermo

valve and retest.

Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Check that valve is completely closed. lf not, air suc-

tion can be felt at the lower port in the throttle body.

l{ any suction is felt, the valve is leaking. Check

engine coolant level and for air in the engine

coolant system (see section 10). It OK, replace the

fast idle thermo valve and recheck.

5.

{1.0 kg.m,7.2lbftl

l

11-110

lL.�

Page 316 of 1681

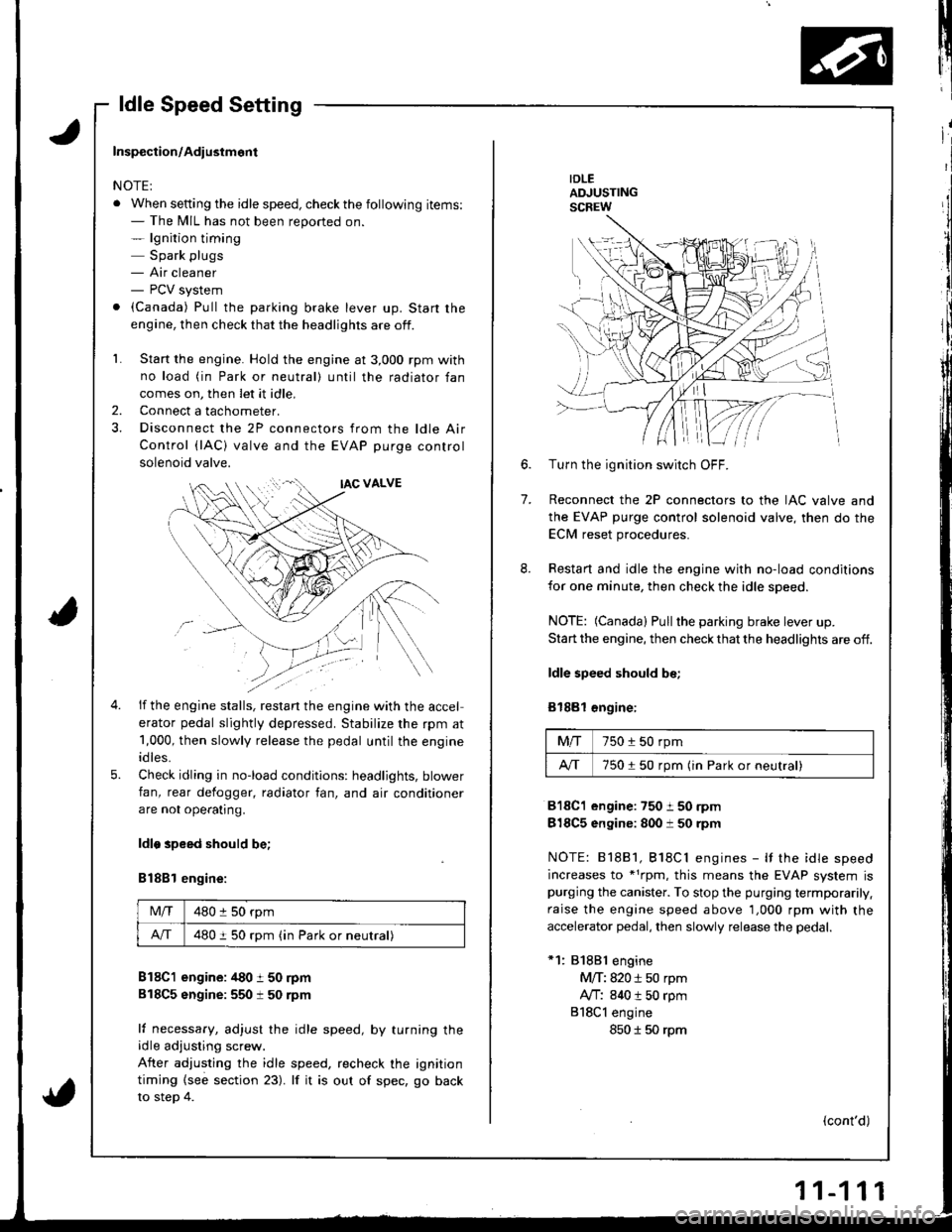

ldle Speed Setting

IDLEADJUSTINGSCREW

7.

6.Turn the ignition switch OFF.

Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM reset procedures.

Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pullthe parking brake lever up.

Start the engine, then check that the headlights are off.

ldle speed should be;

Bl88l €ngine:

Mfi750 i 50 rpm

A/T750150 rpm (in Park or neutral)

818C1 engine:750 i 50 rpm

818C5 engine: 800 i 50 rpm

NOTE: 81881, Bl8Cl engines - It the idle speed

increases to *1rpm, this means the EVAP system ispurging the canister. To stop the purging termporarily.

raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.

*1: 81881 engine

M/T: 820 i 50 rpm

Ay'T: 840 t 50 rpm

818Cl engine

850 I 50 rpm

(cont'd)

Inspection/Adiustmont

NOTE:

. When setting the idle speed, checkthe following items:- The MIL has not been reported on.- lgnition timing

Spark plugs- Air cleaner- PCV system

. (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Disconnect the 2P connectors from the ldle Air

Control (lAC) valve and the EVAP purge control

solenoid valve.

2.

5.

if the engine stalls, restan the engine with the accel

erator pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and air conditioner

are not ope€tlng.

ldlo speed should be;

B188l engine:

Mlf480 :l 50 rpm

A/T480 i 50 rpm (in Park or neutral)

B18C1 engine: /t80 t 50 rpm

818C5 sngine:550 t 50 rpm

lf necessary, adjust the idle speed, by turning theidle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing {see section 23). lf it is out of spec, go back

to steo 4.

Page 317 of 1681

ldle Control System

ldle Speed Setting (cont'dl

ldle the engine for one minute with headlights (Low)

ON and check the idle speed.

ldle 3peed should b€;

B1881 engine:

MIT750 t 50 rpm

750 i 50 rDm (in Park or neutrall

818C1 engine: 7501 50 nm

818C5 engine: 8001 50 rpm

Turn the headlights off. ldle the engine for one min-

ute with heater fan switch at Hl and air conditioner

on, then check the idle speed.

ldl. spood should be;

Bl8Bl ongin.:

M/T820 i 50 rpm

lvT840 t 50 rpm (in Park or neutral)

818C1 €ngino: 850 i 50 rpm

818C5 engino: 1,050 t 50 rpm

NOTE: lf the idle speed is not within specification.

see Symptom Chart on page 1!-36.

\

L

i

lIh:

lffiiltfl!

ffi

| 11-112

\

I

Page 322 of 1681

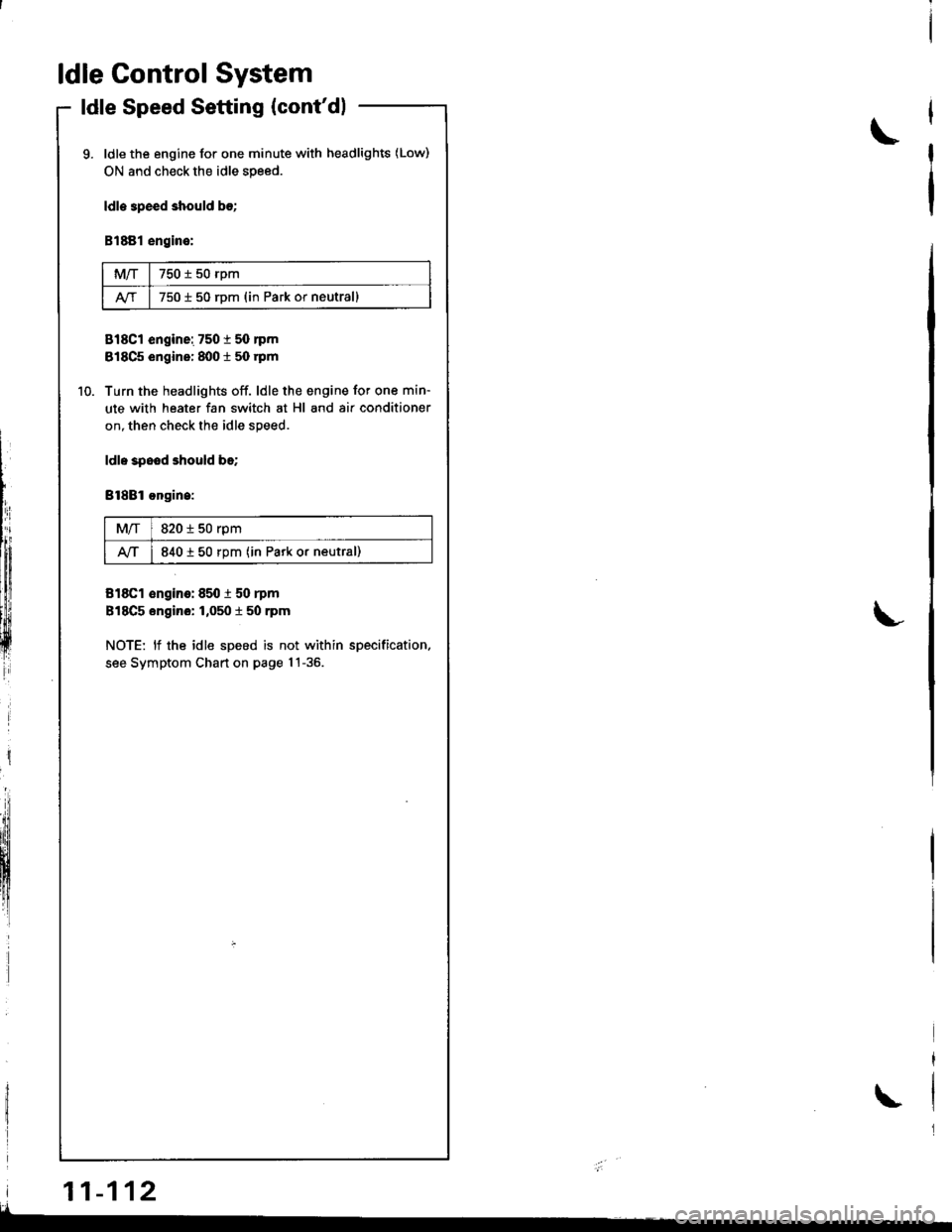

Before connecting a new fuel tube/quick-connect fitting

assembly, remove the old retainer from the mating pipe.

With rhetabs pulled

apart, Pullthe retaineroff

New FUEL TUBE/OUICK.CONNECTFTflNG ASSEMBLY

3. Align the quick-connect fittings with the pipe, and

align the retainer locking pawls with the connector

grooves. Then press the quick connect fittings onto

the pipe until both retainer pawls lock with a click-

Ing souno.

NOTE: lf it is hard to connect, put a small amount of

new engine oil on the pipe end.

Connection with new retainer:

5.

Make sure the connection is secure and the pawls

are lirmly locked into place; check visually and by

pulling the connector.

RETAINER

Reconnect the battery negative cable, and turn the

ignition switch ON (ll) the fuel pump wjll run for about

two seconds, and fuel pressure will rise. Repeat two

or three times, and check that there is no leakage in

the fuel supply system.

11-117

Page 325 of 1681

I

Fuel Supply System

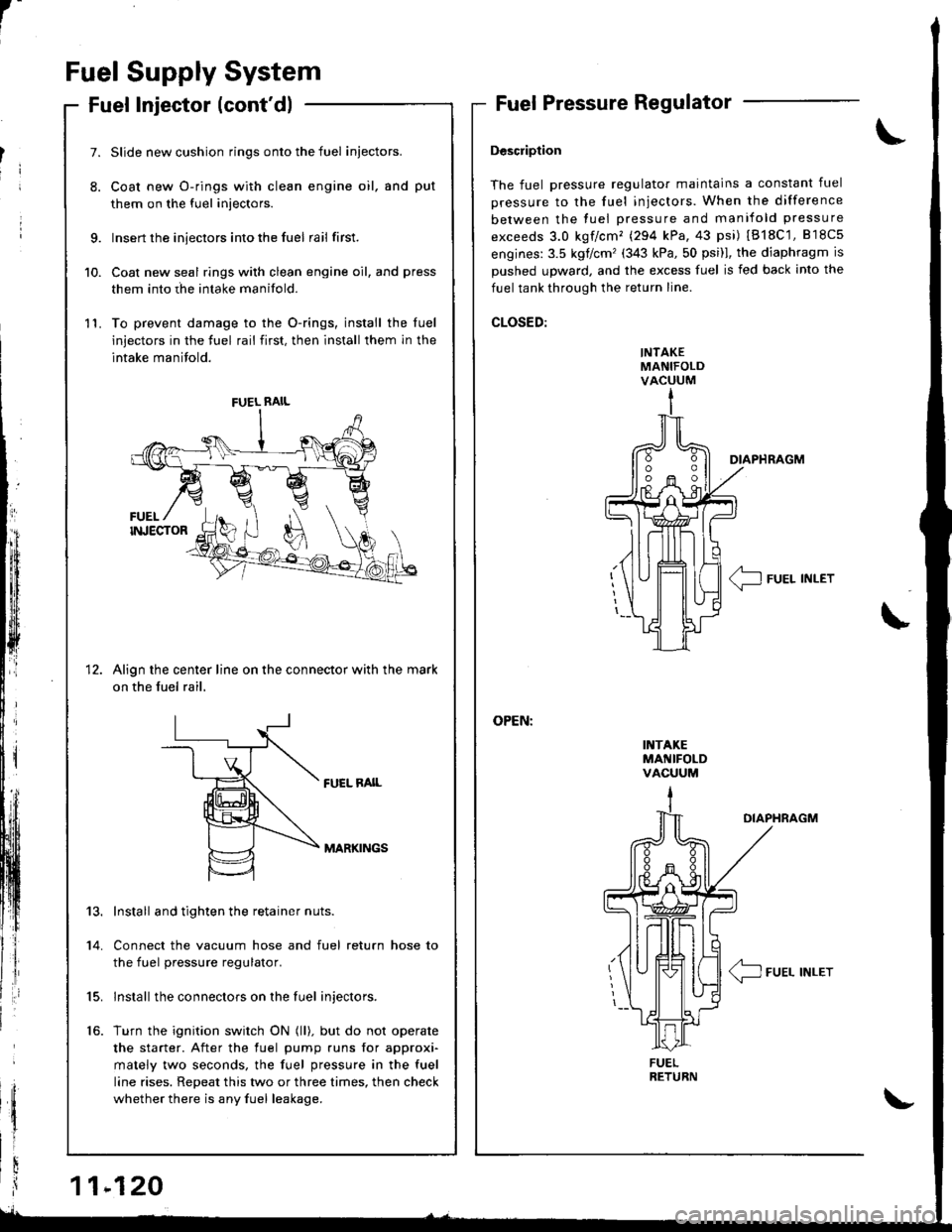

Fuel Injector (cont'dlFuel Pressure Regulator

Description

The fuel pressure regulator maintains a constant fuel

pressure to the fuel injectors. When the difference

between the fuel pressure and manifold pressure

exceeds 3.0 kgf/cm'� (294 kPa,43 psi) IB18C'1,818c5

engines:3.5 kglcm'(343 kPa,50 psi)l, the diaphragm is

Dushed uDward, and the excess fuel is fed back into the

fuel tank through the return line.

CLOSED:

INTAKEMANIFOLDVACUUM

I1{TAKEMANIFOLDVACUUM

DIAPHRAGM

< IFUEL INLET\-

\

OIAPHRAGM

/4_\T-J FUEL INLET

9.

10.

11.

7.

8.

1t

Slide new cushion rings onto the fuel iniectors.

Coat new O-rings with clean engine oil, and put

them on the fuel injectors.

Insert the injectors into the fuel rail first.

Coat new seal rings with clean engine oil, and press

them into rhe intake manifold.

To prevent damage to the O-rings, install the luel

injectors in the fuel rail first, then install them in the

intake manifold.

Align the center line on the connector with the mark

on the fuel rail,

FUEL RAIL

MARKINGS

13.

14.

15.

16.

Install and tighten the retainer nuts.

Connect the vacuum hose and fuel return hose to

the fuel pressure regulator.

lnstall the connectors on the fuel injectors.

Turn the ignition switch ON (ll). but do not operate

the starter. After the fuel pump runs for approxi'

mately two seconds, the fuel pressure in the fuel

line rises. Repeat this two or three times, then check

whether there is any fuel leakage.

FUEL RAIL

FUEL

Page 326 of 1681

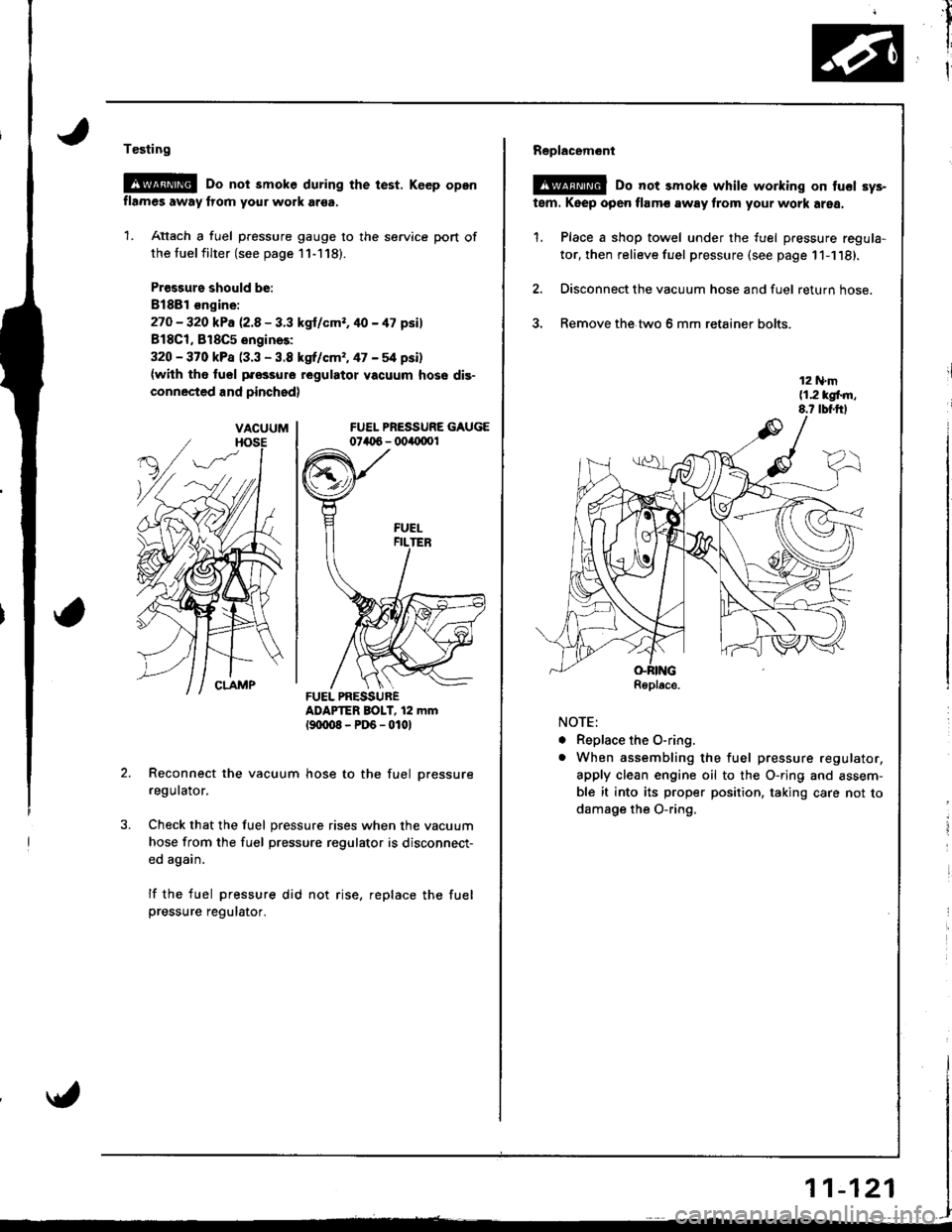

Testing

@G Do not smoke during the test. Keep opon

flames away lrom your work ar€a.

1. Attach a fuel pressure gauge to the service port of

the tuel filter (see page 11-118).

Pr€ssurs should be:

8188l €ngine:

27O - 320 kPa 12.8 - 3.3 kgl/cmr. 40 - 47 psil

818C1, 818C5 engines:

320 - 370 kPa (3.3 - 3.8 kgrf/cm,, 47 - 54 psi)

{with tho fuol pfossure regulatot vacuum hose dis-

connected and pinchsd)

FUEL PRESSURE GAUGE074t 6 - 004{1001

ADAPTER BOIT, 12 mm(9txt08-PD6-0101

Reconnect the vacuum hose to the fuel pressure

regulator.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed again.

lf the fuel pressure did not rise, replace the fuelpressure regulator.

VACUUM

FUEL PRESSURER€place.

AA

,il

I

I

Replacem6nl

@ Do not smoke while working on tucl sys-

tem. Keep open flamc away from your work area.

1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1'18).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the.two 6 mm retainer bolts.

NOTE:

. Replace the O-ring.

o When assembling the fuel pressure regulator,

apply clean engine oil to the O-ring and assem-

ble it into its proper position, taking care not to

damage the O-ring.

r1

i

i

11-121

Page 329 of 1681

1L

i

!i

!

{

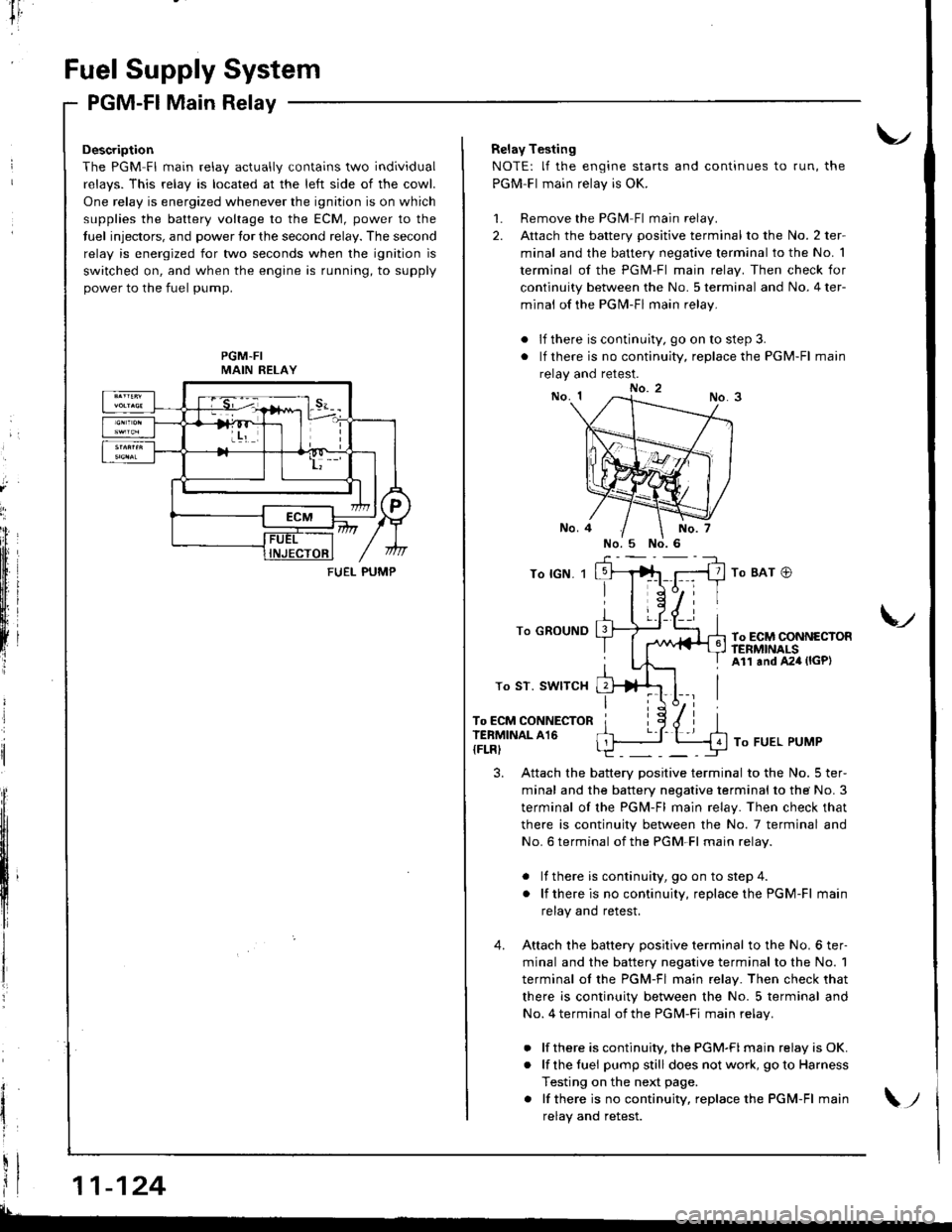

Fuel Supply System

PGM-Fl Main Relay

Description

The PGM Fl main relav actuallv contains two individual

relavs. This relav is located at the left side of the cowl.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

tuel injectors, and power tor the second relay. The second

relay is energized for two seconds when the ignition is

switched on, and when the engine is running, to supply

power to the fuel pump.

PGM-FIMAIN RELAY

11-124

FUEI- PUMP

Relay Testing

NOTE: lf the engine starts and continues to run, the

PGM-Fl main relay is OK.

1. Remove the PGlvl Fl main relay.

2. Attach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check for

continuity between the No. 5 terminal and No. 4 ter-

minal of the PGN4-Fl main relay.

. lf there is continuity, go on to step 3.

. lf there is no continuity, replace the PGM-Fl main

relay and retest.

To lGN. 1

To GROUND

To ST. SWITCH

To ECM CONNECTORTERMINAL A16

{FLRI

To BAT @

To ECM CONNECTORftNMNALSAll and A24 (lGP)

V

To FUEL PUMP

3. Attach the battery positive terminal to the No. 5 ter-

minal and the battery negative terminal to the No. 3

terminal of the PGM-Fl main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-Fl main relav.

. lf there is continuity, goon tostep4.

. lf thereis nocontinuity, replacethe PGM-Fl main

relay and retest.

4. Attach the batterv oositive terminal to the No. 6 ter-

minal and the battery negative terminal to the No. 1

terminal ol the PGM-Fl main relay. Then check that

there is continuity between the No. 5 terminal and

No. 4 terminal of the PGM-Fi main relav.

. lf there is continuity, the PGM-FI main relay is OK.

. lf the fuei pumpstill does not work, goto Harness

Testing on the next page.

. lf thereis nocontinuity, replacethe PGM-Fl main

relav and retest.\;

Page 330 of 1681

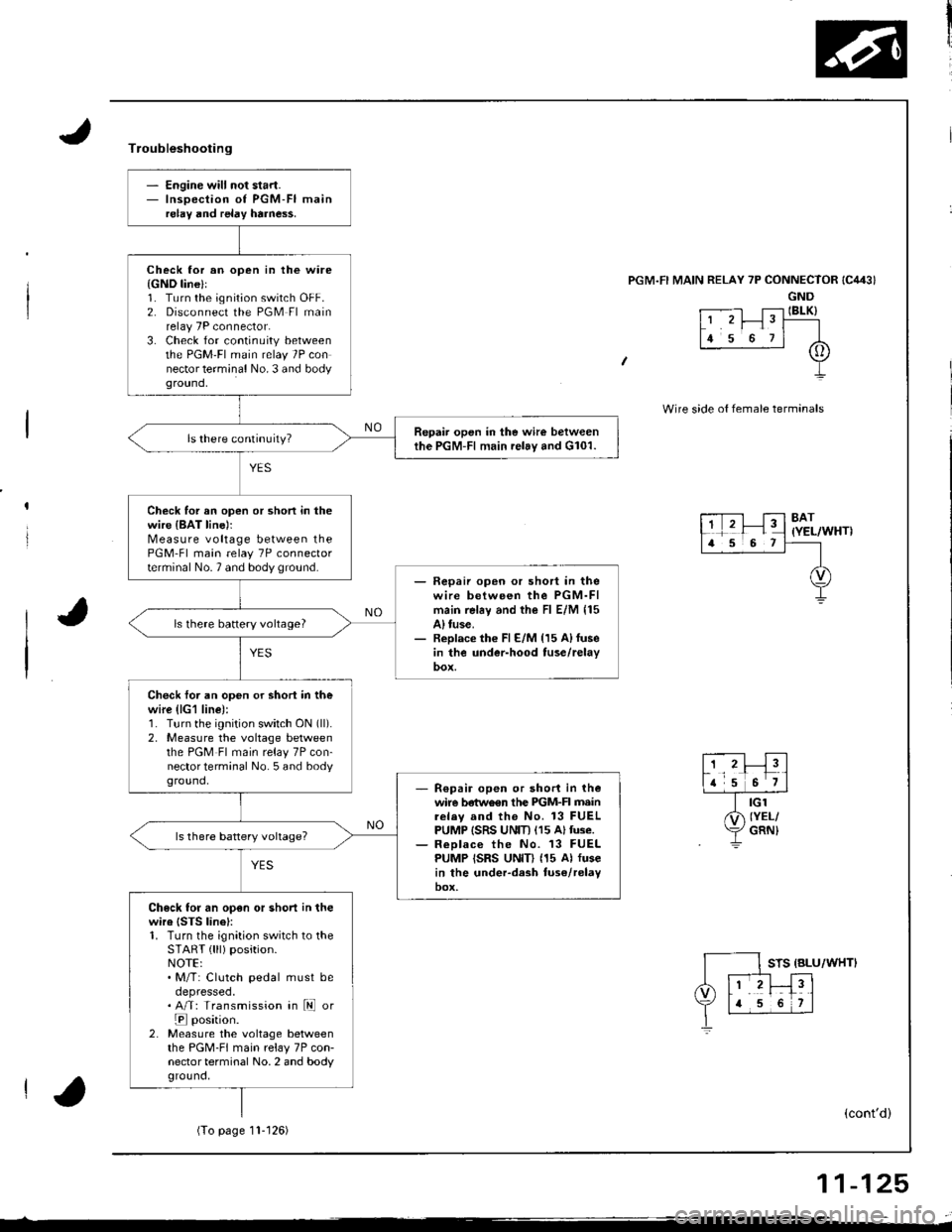

I

tr,

- Engine will not start.- Inspection of PGM-FI mainrelay and relay harne$.

Check lor an open in the ware{GND line}l1. Turn the ignition switch OFF.2. Disconnect the PGM Fl mainrelay 7P connector.3. Check for continuity betweenthe PGM'FI main relay 7P connector terminal No. 3 and bodyground,

Repair open in the wire betweenthe PGM-Fl main relay and G101.

Check for an open or shon in thewire {BAT line)rMeasure voltage between thePGM-Fl main relay 7P connectorterminal No.7 and body ground.- Fepaii open or short in thewire between the PGM-FImain rel6y and the Fl E/M 115A) tuse.- Replace th€ Fl E/M {15 A)fusein the under-hood tuse/relay

ls there battery vohage?

Check foi an open or shori in thewire (lG1 line):1. Turn the ignition switch ON (ll).

2, Measure the voltage betweenthe PGM Fl main relay 7P con-nector terminal No. 5 and bodyground,R€pair open or short in thewire betwo€n the PIGM-FI mainrelav and the No. 13 FUELPUMP ISRS UNIT) (15 Altuse.ReDlace the No. 13 FUELPUMP ISRS UNID (15 Al fusein the under-dash tuse/relayoox,

Check for an open or short in thewire {STS linel:1. Turn the ignition switch to theSTART { lll) position.NOTE:. M/T: Clutch pedal must beoepresseo.. A/T: Transmission in ld or

E position.2. Measure the voltage betweenthe PGM-FI main relay 7P con-nector terminal No. 2 and bodyground,

Troubleshooting

'l RELAY 7P CONNECTOR

GND

t .--.-l T;-l IBLK)L' 'r I" T----

lr s o rl A

+

Wire side o{ female termanals

8AT(YEL/WHT)

STS {BLU/WHTI

(cont'd)

(To page11- t 26)

11-125

Page 335 of 1681

l-

Intake Air System

LOCKNUT

DEFLECTION10-12mmBIA- 112in.l

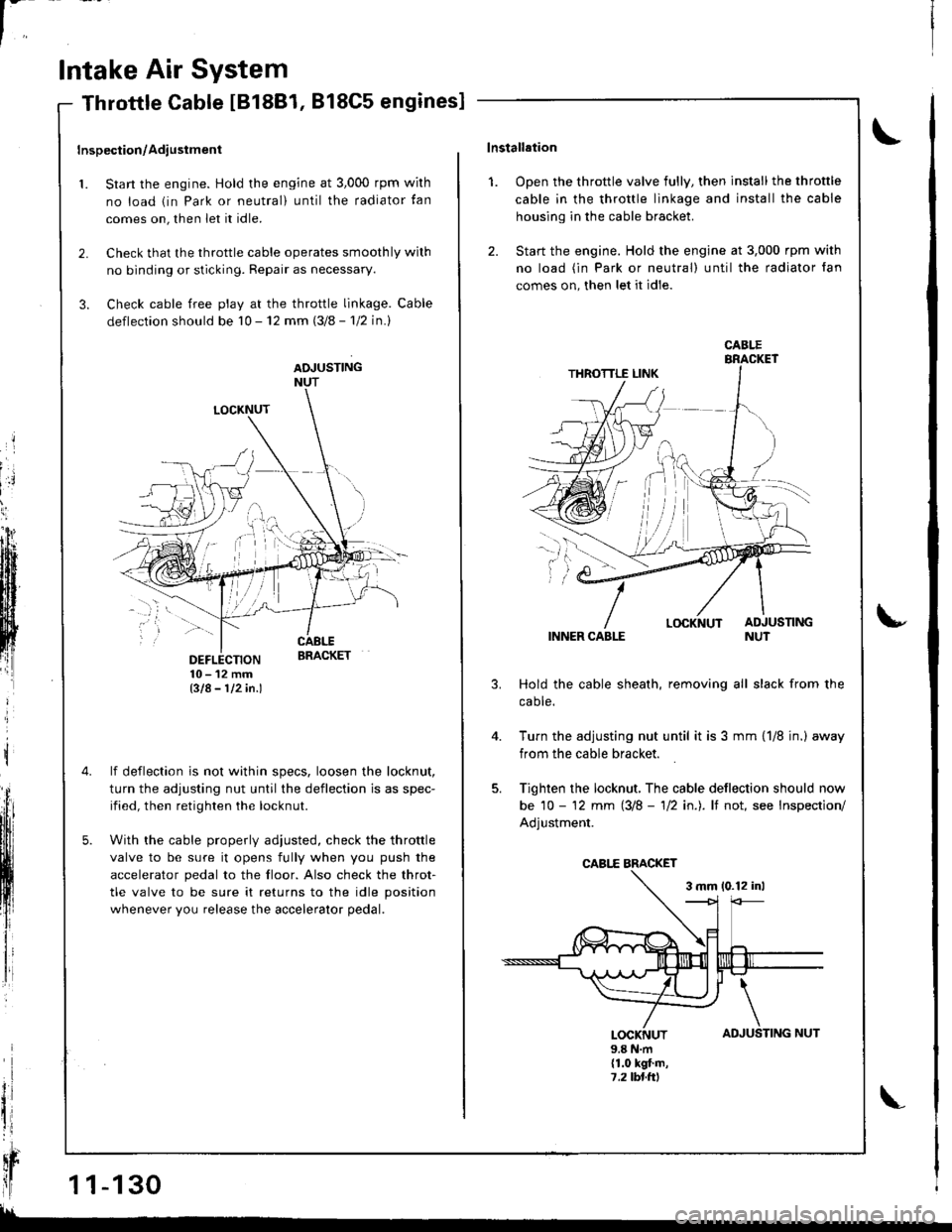

lf deflection is not within specs, loosen the locknut,

turn the adjusting nut until the deflection is as spec-

ified, then retighten the locknut.

With the cable properly adiusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

Throttle Cable IB18B1, 818C5 engines]

Inspection/Adiustment

1. Start the engine. Hold the engine at 3,000 rpm wirh

no load (in Park or neutral) until the radiator tan

comes on, then let it idle.

2. Check that the throttle cable operates smoothly wilh

no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10 - 12 mm (3/8 - 'l12 in.l

ADJUSTINGNUT

t

il

qr

ll1 1-130

!!

TING NUT

\lnstallation

1. Open the throttle valve fully, then install the throttle

cable in the throttle linkage and install the cable

housing in the cable bracket.

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

INNER CABLE

Hold the cable sheath, removing all slack from the

caote.

Turn the adjusting nut until it is 3 mm {1/8 jn.) away

from the cable bracket.

Tighten the locknut, The cable deflection should now

be 10 - '12 mm (3/8 - 'll2 in.). lf not, see Inspection/

Adjustment.

3 mm 10.12 inl

u

4.

AD

\

JUSLOCKNUT9.8 N.m(1.0 kgt.m,7,2lbl.ttl

CABI.E

CABI,E BMCKET

Page 336 of 1681

't.

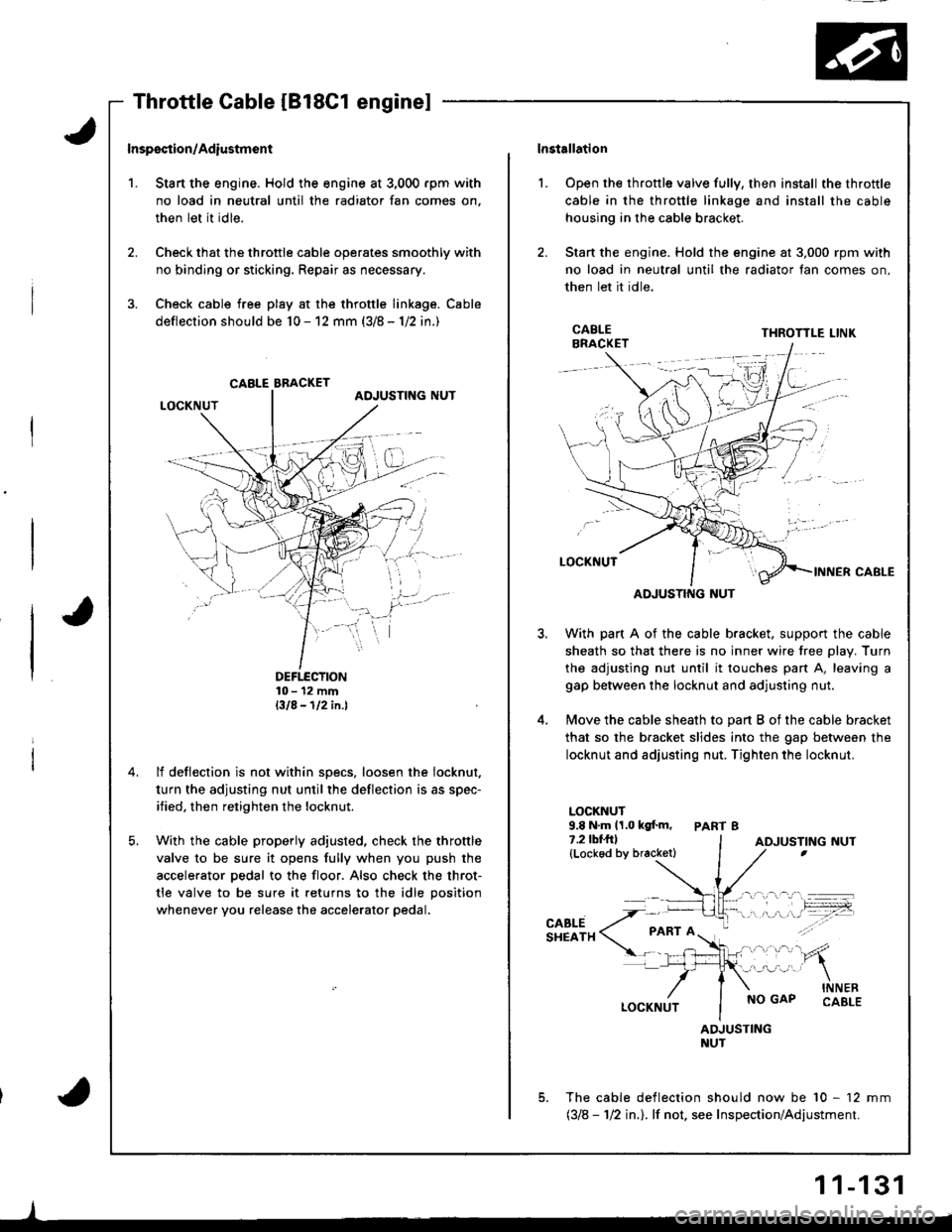

Inspsction/Adiustmsnt

Stan the engine. Hold the engine at 3,000 rpm with

no load in neutral until the radiator fan comes on,

then let it idle.

Check that the throttle cable operates smoothly with

no binding or sticking. Repair as necessary.

Check cable free play at the throttle linkage. Cable

deflection should be 10 - 12 mm (3/8 - 1/2 in.)

DEFTECTION10- 12 mmBIA-112in.l

lf deflection is not within specs, loosen the iocknut.

turn the adjusting nut until the deflection is as spec-

ified, then retighten the locknut.

With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

CABLE BBACKET

lnstallation

Open the throttle valve fully, then install the throttle

cable in the throttle linkage and install the cable

housing in the cable bracket.

Stan the engine. Hold the engine at 3,000 rpm with

no load in neutral until the radiator fan comes on,

then let it idle.

l.

3.

5.

CABLEBRACKETTHROTTLE LINK

ADJUSTING NUT

With part A of the cable bracket. support the cable

sheath so that there is no inner wire tree plav. Turn

the adjusting nut until it touches part A, leaving a

gap between the locknut and adjusting nut.

Move the cable sheath to oart B of the cable bracket

that so the bracket slides into the gap between the

locknut and adjusting nut. Tighten the locknut.

LOCKNUT9.8 N.m 11.0 kgf.m, PART 87.2lbf.frl(Lockod by bracketl

CABLESHEATH

NO GAPINNERCABLE

ADJUSTINGNUT

The cable deflection should now be 10 - 12 mm(318 - 112 in.l. lf not. see Inspection/Adjustment.

ADJUSTING NUT

1 1-131