service INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5046 of 5621

PREPARATION

RFD-3

C

E

F

G

H

I

J

K

L

MA

B

RFD

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNDS000EZ

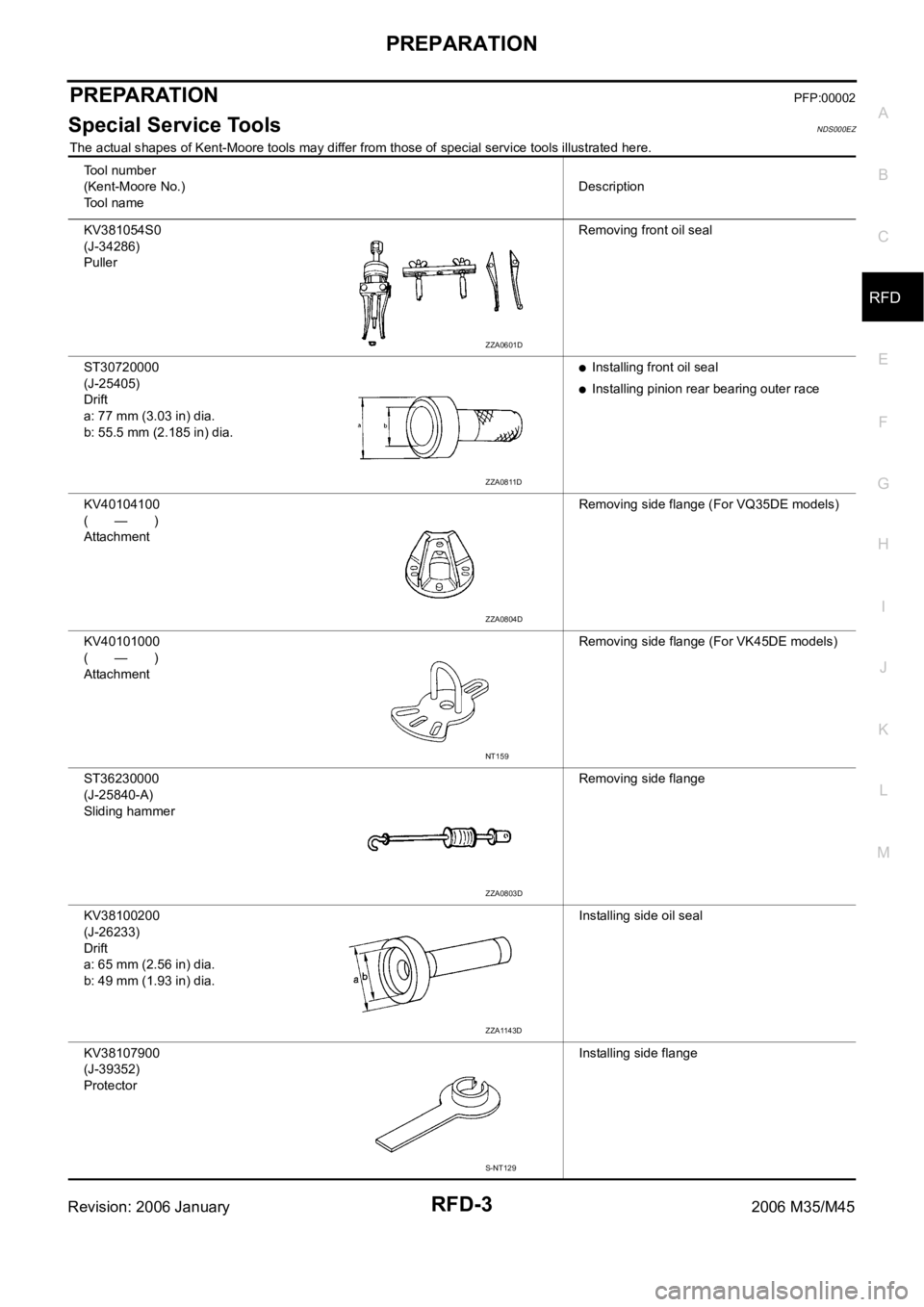

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

To o l n u m b e r

(Kent-Moore No.)

To o l n a m eDescription

KV381054S0

(J-34286)

PullerRemoving front oil seal

ST30720000

(J-25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

Installing front oil seal

Installing pinion rear bearing outer race

KV40104100

(—)

AttachmentRemoving side flange (For VQ35DE models)

KV40101000

(—)

AttachmentRemoving side flange (For VK45DE models)

ST36230000

(J-25840-A)

Sliding hammer Removing side flange

KV38100200

(J-26233)

Drift

a: 65 mm (2.56 in) dia.

b: 49 mm (1.93 in) dia.Installing side oil seal

KV38107900

(J-39352)

ProtectorInstalling side flange

ZZA0601D

ZZA0811D

ZZA0804D

NT159

ZZA0803D

ZZA1143D

S-NT129

Page 5049 of 5621

RFD-6

PREPARATION

Revision: 2006 January2006 M35/M45

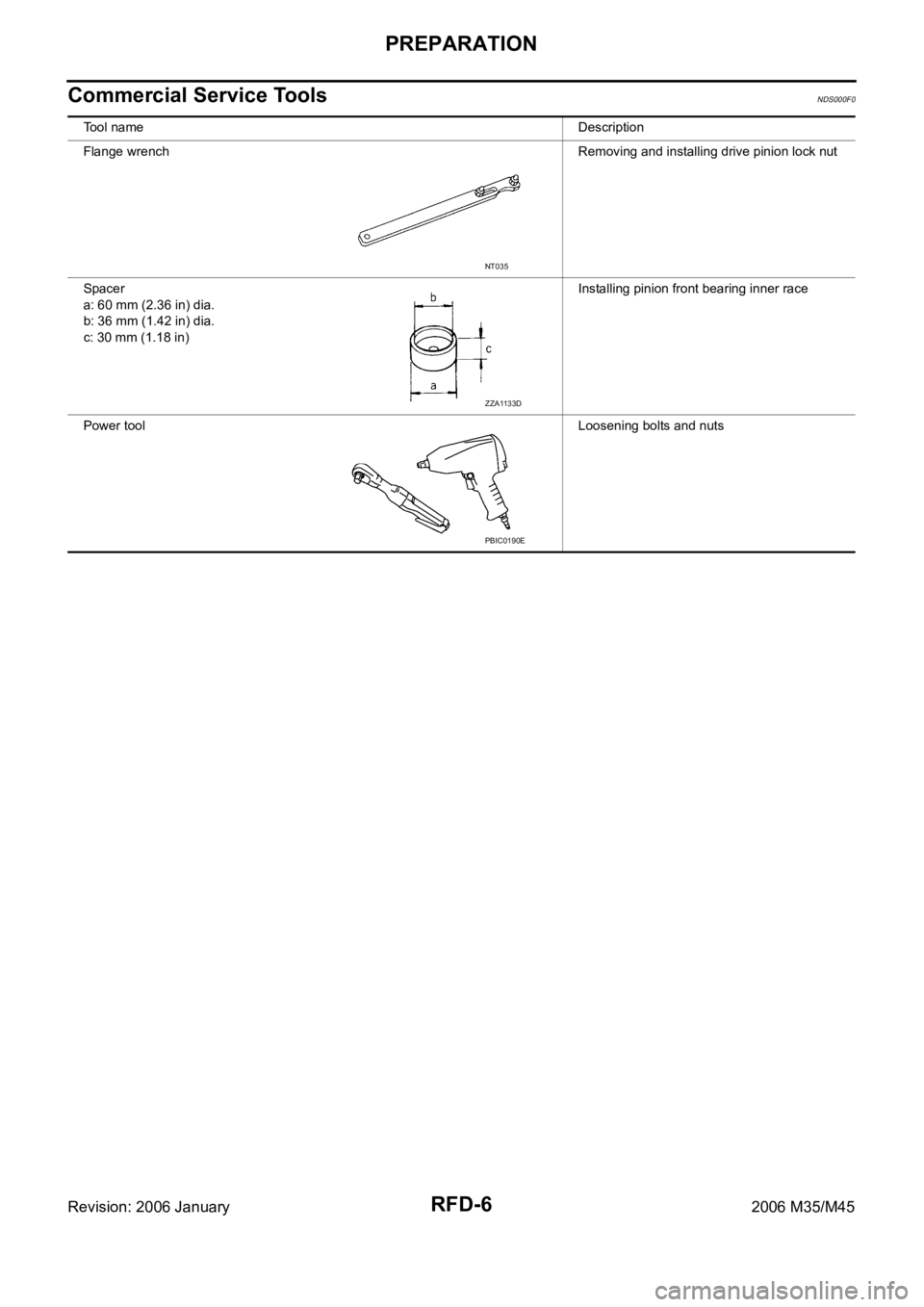

Commercial Service ToolsNDS000F0

Tool nameDescription

Flange wrench Removing and installing drive pinion lock nut

Spacer

a: 60 mm (2.36 in) dia.

b: 36 mm (1.42 in) dia.

c: 30 mm (1.18 in)Installing pinion front bearing inner race

Power toolLoosening bolts and nuts

NT035

ZZA1133D

PBIC0190E

Page 5080 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-37

C

E

F

G

H

I

J

K

L

MA

B

RFD

Revision: 2006 January2006 M35/M45

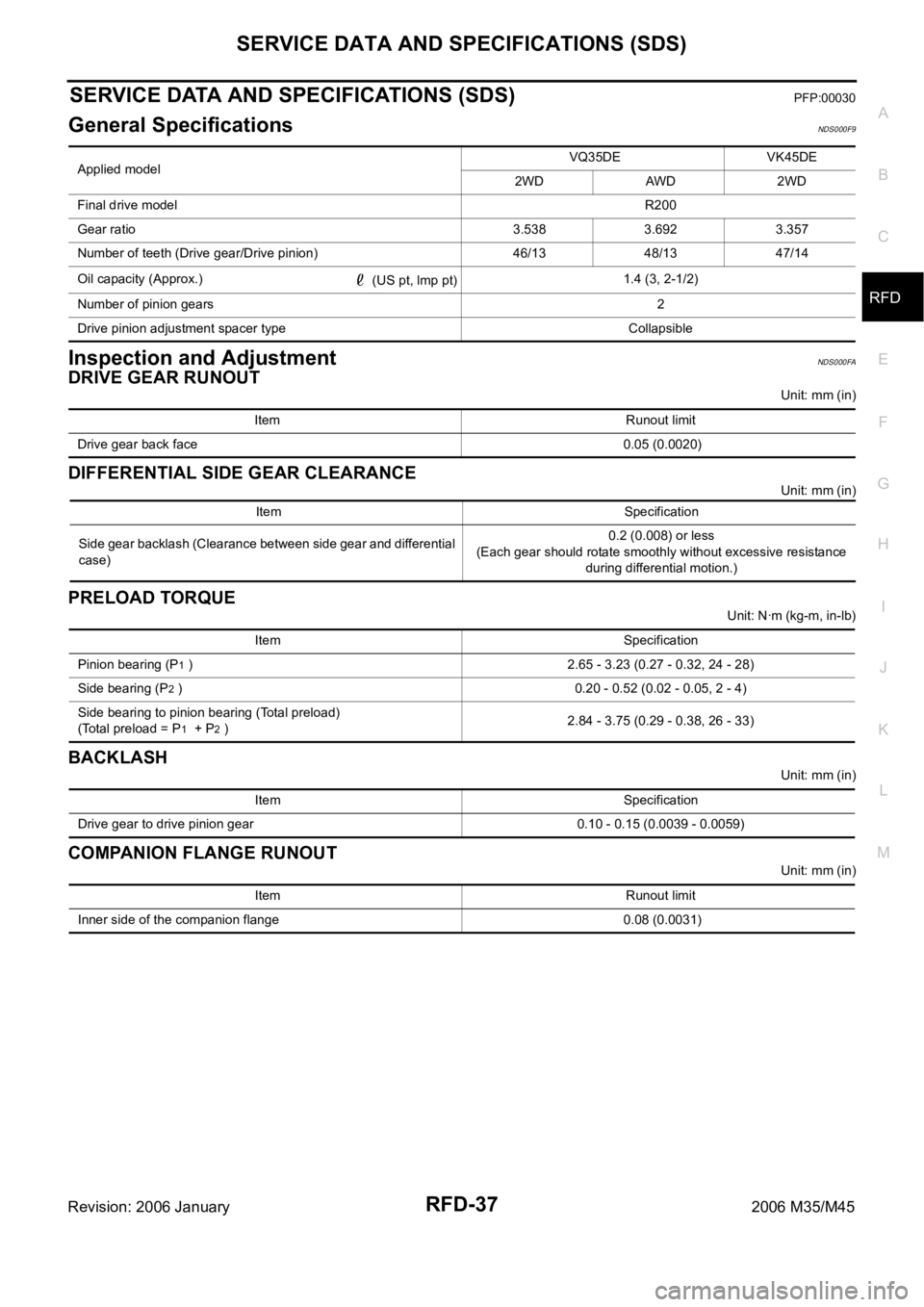

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsNDS000F9

Inspection and AdjustmentNDS000FA

DRIVE GEAR RUNOUT

Unit: mm (in)

DIFFERENTIAL SIDE GEAR CLEARANCE

Unit: mm (in)

PRELOAD TORQUE

Unit: Nꞏm (kg-m, in-lb)

BACKLASH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in) Applied modelVQ35DE VK45DE

2WD AWD 2WD

Final drive modelR200

Gear ratio 3.538 3.692 3.357

Number of teeth (Drive gear/Drive pinion) 46/13 48/13 47/14

Oil capacity (Approx.)

(US pt, lmp pt)1.4 (3, 2-1/2)

Number of pinion gears2

Drive pinion adjustment spacer type Collapsible

Item Runout limit

Drive gear back face 0.05 (0.0020)

Item Specification

Side gear backlash (Clearance between side gear and differential

case)0.2 (0.008) or less

(Each gear should rotate smoothly without excessive resistance

during differential motion.)

Item Specification

Pinion bearing (P

1 ) 2.65 - 3.23 (0.27 - 0.32, 24 - 28)

Side bearing (P

2 ) 0.20 - 0.52 (0.02 - 0.05, 2 - 4)

Side bearing to pinion bearing (Total preload)

(Total preload = P

1 + P2 )2.84 - 3.75 (0.29 - 0.38, 26 - 33)

Item Specification

Drive gear to drive pinion gear 0.10 - 0.15 (0.0039 - 0.0059)

Item Runout limit

Inner side of the companion flange 0.08 (0.0031)

Page 5081 of 5621

RFD-38

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SELECTIVE PARTS

Side Gear Thrust Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Pinion Height Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Side Bearing Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information. Thickness Part number* Thickness Part number*

0.75 (0.0295)

0.78 (0.0307)

0.81 (0.0319)

0.84 (0.0331)38424 EC000

38424 EC001

38424 EC002

38424 EC0030.87 (0.0343)

0.90 (0.0350)

0.93 (0.0366)38424 EC004

38424 EC005

38424 EC006

Thickness Part number* Thickness Part number*

3.05 (0.1201)

3.08 (0.1213)

3.11 (0.1224)

3.14 (0.1236)38154 0C000

38154 0C001

38154 0C002

38154 0C0033.17 (0.1248)

3.20 (0.1260)

3.23 (0.1272)

3.26 (0.1283)38154 0C004

38154 0C005

38154 0C006

38154 0C007

Thickness Part number* Thickness Part number*

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)

2.25 (0.0886)

2.30 (0.0906)38453 N3100

38453 N3101

38453 N3102

38453 N3103

38453 N3104

38453 N3105

38453 N31062.35 (0.0925)

2.40 (0.0945)

2.45 (0.0965)

2.50 (0.0984)

2.55 (0.1004)

2.60 (0.1024)

2.65 (0.1043)38453 N3107

38453 N3108

38453 N3109

38453 N3110

38453 N3111

38453 N3112

38453 N3113

Page 5082 of 5621

RSU-1

REAR SUSPENSION

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTION RSU

A

B

RSU

Revision: 2006 January2006 M35/M45

REAR SUSPENSION

PRECAUTIONS .......................................................... 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special Service Tools [SST] ..................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Troubleshooting Chart ..................................... 4

REAR SUSPENSION ASSEMBLY ............................. 5

On-Vehicle Inspection and Service .......................... 5

SUSPENSION ARM BALL JOINT AXIAL END

PLAY INSPECTION .............................................. 5

SHOCK ABSORBER INSPECTION ..................... 5

Wheel Alignment Inspection ..................................... 5

DESCRIPTION ...................................................... 5

PRELIMINARY INSPECTION ............................... 5

GENERAL INFORMATION AND RECOMMEN-

DATIONS .............................................................. 5

THE ALIGNMENT PROCESS .............................. 6

CAMBER INSPECTION ........................................ 6

TOE-IN .................................................................. 6

Components ............................................................. 7

Removal and Installation .......................................... 8

REMOVAL ........................................................

..... 8

INSTALLATION ..................................................... 8

SHOCK ABSORBER ................................................ 10

Removal and Installation ........................................ 10

REMOVAL ........................................................

... 10

INSPECTION AFTER REMOVAL ....................... 10

INSTALLATION ................................................... 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY .......................................................... 11SUSPENSION ARM .................................................. 12

Removal and Installation ........................................ 12

REMOVAL ........................................................

... 12

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 13

RADIUS ROD ............................................................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSPECTION AFTER REMOVAL ....................... 14

INSTALLATION ................................................... 14

FRONT LOWER LINK .............................................. 15

Removal and Installation ........................................ 15

REMOVAL ........................................................

... 15

INSPECTION AFTER REMOVAL ....................... 15

INSTALLATION ................................................... 15

REAR LOWER LINK & COIL SPRING ..................

... 16

Removal and Installation ........................................ 16

REMOVAL ........................................................

... 16

INSPECTION AFTER REMOVAL ....................... 16

INSTALLATION ................................................... 16

STABILIZER BAR ..................................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................

... 17

INSPECTION AFTER REMOVAL ....................... 17

INSTALLATION ................................................... 17

SERVICE DATA ........................................................ 18

Wheel Alignment (Unladen)* .................................. 18

Ball Joint ................................................................. 18

Wheelarch Height (Unladen*) ................................. 18

Page 5084 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NES000J3

The actual shapes of Kent-Moore tools may differ from those of INFINITI M35 2006 Factory Service Manual PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NES000J3

The actual shapes of Kent-Moore tools may differ from those of](/img/42/57023/w960_57023-5083.png)

PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NES000J3

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsNES000J4

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(See J25742-1)

Preload Gauge

1. GG91030000

(J25765)

Torque wrench

2. HT62940000

(—)

Socket adapter

3. HT62900000

(—)

Socket adapterMeasuring rotating torque of ball joint

NT124

Tool nameDescription

Power tool

Removing wheel nuts

Removing brake caliper assembly

Removing rear suspension component

parts

PBIC0190E

Page 5086 of 5621

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

REAR SUSPENSION ASSEMBLYPFP:55020

On-Vehicle Inspection and ServiceNES000J6

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

SUSPENSION ARM BALL JOINT AXIAL END PLAY INSPECTION

Measure axial end play by placing and moving up/down with an iron pry bar or something similar between sus-

pension arm and axle.

CAUTION:

Be careful not to damage ball joint boot.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace if malfunction is detected.

Wheel Alignment InspectionNES000J7

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats in designated positions.

PRELIMINARY INSPECTION

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6, "

ROAD WHEEL" .

3. Wheel bearing axial end play. Refer to RAX-5, "

WHEEL BEARING INSPECTION" .

4. Ball joint axial end play of suspension arm. Refer to RSU-5, "

SUSPENSION ARM BALL JOINT AXIAL

END PLAY INSPECTION" .

5. Shock absorber operation.

6. Each mounting point of axle and suspension for looseness and deformation.

7. Each of front lower link, rear lower link, radius rod, rear suspension member, suspension arm and shock

absorber for cracks, deformation, and other damage.

8. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

–This type of alignment is recommended for any NISSAN/INFINITI vehicle.

–The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel is

centered.

–The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

–The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

–Your alignment equipment should be regularly calibrated in order to give correct information.

–Check with the manufacturer of your specific equipment for their recommended Service/Calibration

Schedule.Standard value

Axial end play : 0 mm (0 in)

Page 5087 of 5621

RSU-6

REAR SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

THE ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specifications listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

–The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

–This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). DO NOT use this “Rolling Compensation”

method.

–Use the “Jacking Compensation Method”. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

–See Instructions in the alignment machine you're using for more information on this.

CAMBER INSPECTION

Measure camber of both right and left wheels with a suitable alignment gauge.

Adjust in accordance with the following procedures.

If outside the standard value, adjust with adjusting bolt in front

lower link.

NOTE:

After adjusting camber, be sure to check toe-in.

TOE-IN

If toe-in is not within the specification, adjust with adjusting bolt in

rear lower link.

CAUTION:

Be sure to adjust equally on RH and LH side with adjusting bolt.

If toe-in is not still within the specification, inspect and replace any

damaged or worn rear suspension parts.Standard value

Camber : Refer to RSU-18, "

SERVICE DATA" .

SRA096A

SEIA0227E

SEIA0228E

Page 5099 of 5621

RSU-18

SERVICE DATA

Revision: 2006 January2006 M35/M45

SERVICE DATAPFP:00030

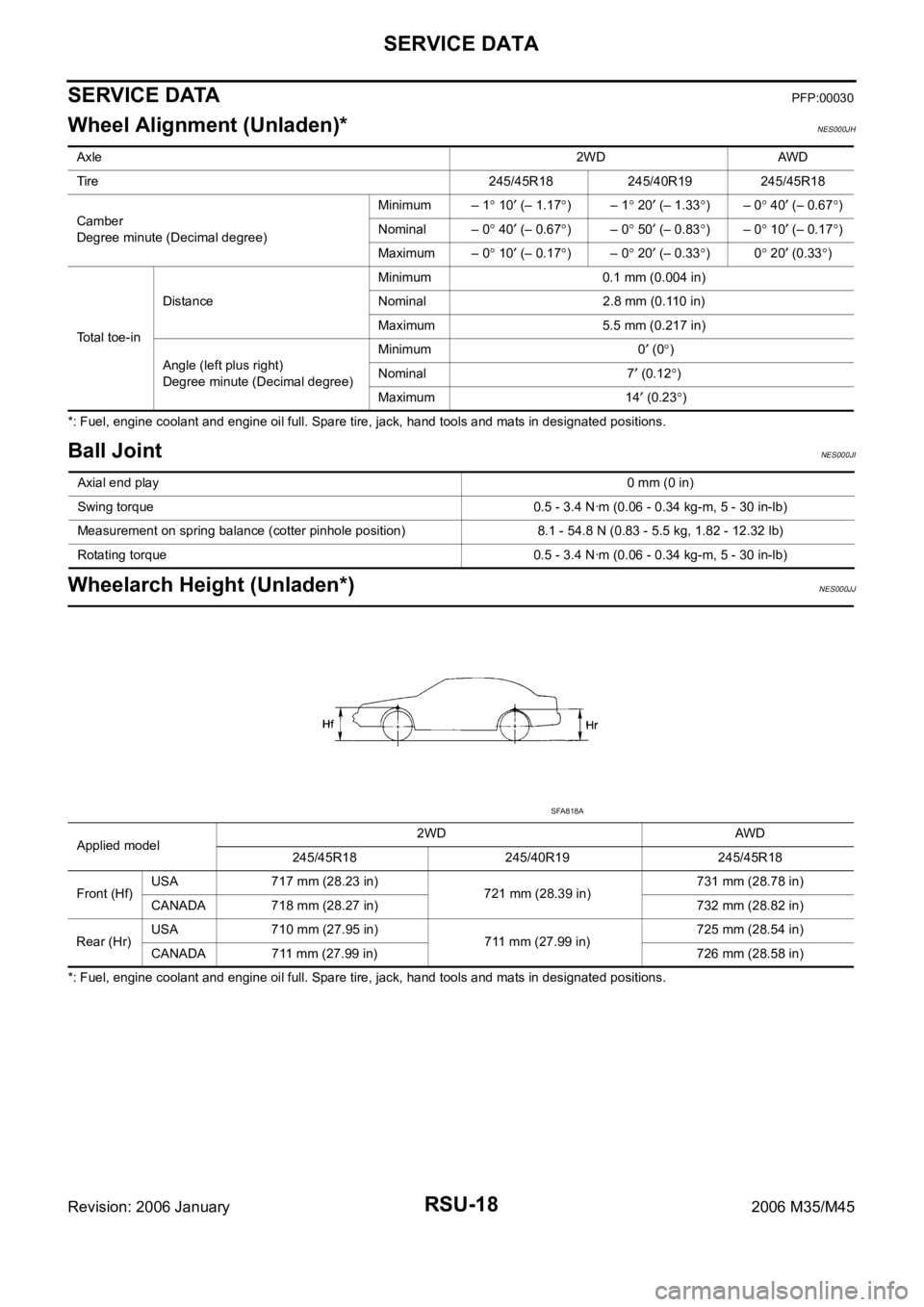

Wheel Alignment (Unladen)*NES000JH

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Ball JointNES000JI

Wheelarch Height (Unladen*)NES000JJ

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Axle2WD AWD

Tire 245/45R18 245/40R19 245/45R18

Camber

Degree minute (Decimal degree)Minimum – 1

10 (– 1.17)– 1 20 (– 1.33)– 0 40 (– 0.67)

Nominal – 0

40 (– 0.67)– 0 50 (– 0.83)– 0 10 (– 0.17)

Maximum – 0

10 (– 0.17)– 0 20 (– 0.33)0 20 (0.33)

Total toe-inDistanceMinimum 0.1 mm (0.004 in)

Nominal 2.8 mm (0.110 in)

Maximum 5.5 mm (0.217 in)

Angle (left plus right)

Degree minute (Decimal degree)Minimum 0

(0)

Nominal 7

(0.12)

Maximum 14

(0.23)

Axial end play0 mm (0 in)

Swing torque 0.5 - 3.4 Nꞏm (0.06 - 0.34 kg-m, 5 - 30 in-lb)

Measurement on spring balance (cotter pinhole position) 8.1 - 54.8 N (0.83 - 5.5 kg, 1.82 - 12.32 lb)

Rotating torque 0.5 - 3.4 Nꞏm (0.06 - 0.34 kg-m, 5 - 30 in-lb)

Applied model2WD AWD

245/45R18 245/40R19 245/45R18

Front (Hf)USA 717 mm (28.23 in)

721 mm (28.39 in)731 mm (28.78 in)

CANADA 718 mm (28.27 in) 732 mm (28.82 in)

Rear (Hr)USA 710 mm (27.95 in)

711 mm (27.99 in)725 mm (28.54 in)

CANADA 711 mm (27.99 in) 726 mm (28.58 in)

SFA818A

Page 5100 of 5621

SB-1

SEAT BELTS

H RESTRAINTS

CONTENTS

C

D

E

F

G

I

J

K

L

M

SECTION SB

A

B

SB

Revision: 2006 January2006 M35/M45

SEAT BELTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precaution for Seat Belt Service .............................. 2

AFTER A COLLISION ........................................... 2

PRE-CRASH SEAT BELT .......................................... 3

Component Parts and Harness Connector Location ..... 3

System Description .................................................. 3

FUNCTION DESCRIPTION .................................. 4

FAIL-SAFE MODE ................................................ 4

CAN Communication System Description ................ 5

CAN Communication Unit ........................................ 5

Schematic ................................................................ 6

Wiring Diagram — PSB — ....................................... 7

Terminals and Reference Value for Pre-Crash Seat

Belt Control Unit ..................................................... 13

Work Flow .............................................................. 13

CONSULT-II Function (PRECRASH SEATBELT) ... 14

CONSULT-II INSPECTION PROCEDURE ......... 14

HOW TO READ SELF-DIAGNOSTIC RESULTS ... 15

SELF-DIAGNOSTIC RESULTS ITEM CHART ... 15

DATA MONITOR ITEM CHART .......................... 15

Preliminary Check .................................................. 16

PRE-CRASH SEAT BELT OPERATION

INSPECTION ...................................................... 16

Diagnoses Symptom Chart .................................... 16

Check CAN Communication System Inspection

[U1000] ................................................................... 16

Ignition Power Supply Circuit Check ...................... 17

Motor Power Supply and Ground Circuit Check

[B2454] ................................................................... 17

Seat Belt Buckle Switch (Driver Side) Circuit Check ... 19

Seat Belt Buckle Switch (Passenger Side) Circuit

Check ..................................................................... 21

Brake Pedal Stroke Sensor Circuit Check [B2453] ... 22

Pre-Crash Seat Belt Motor LH Circuit Check [B2452]

... 25

Pre-Crash Seat Belt Motor RH Circuit Check [B2451] ................................................................... 27

Brake Pedal Stroke Sensor Shield Wire Circuit

Check ..................................................................... 28

Removal and Installation of Pre-Crash Seat Belt

Control Unit ............................................................. 29

REMOVAL ........................................................

... 29

INSTALLATION ................................................... 29

SEAT BELTS ............................................................. 30

System Description ................................................. 30

SEAT BELT WARNING CHIME ........................... 30

SEAT BELT WARNING LAMP ............................. 30

Removal and Installation of Front Seat Belt ........... 30

REMOVAL OF SEAT BELT RETRACTOR .......... 30

INSTALLATION OF SEAT BELT RETRACTOR ... 31

REMOVAL OF SEAT BELT BUCKLE .................. 31

INSTALLATION OF SEAT BELT BUCKLE .......

... 31

Removal and Installation of Rear Seat Belt ............ 32

REMOVAL OF SEAT BELT RETRACTOR .......... 32

INSTALLATION OF SEAT BELT RETRACTOR ... 32

REMOVAL OF SEAT BELT BUCKLE .................. 32

INSTALLATION OF SEAT BELT BUCKLE .......... 33

Seat Belt Inspection ................................................ 33

AFTER A COLLISION ......................................... 33

PRELIMINARY CHECKS .................................... 33

SEAT BELT RETRACTOR ON-VEHICLE

CHECK ................................................................ 34

SEAT BELT RETRACTOR OFF-VEHICLE

CHECK (FRONT SEAT BELT) ............................ 35

SEAT BELT RETRACTOR OFF-VEHICLE

CHECK (REAR SEAT BELT) ............................... 35

LATCH (LOWER ANCHORS AND TETHER FOR

CHILDREN) SYSTEM ............................................... 36

Removal and Installation ........................................ 36

REMOVAL ........................................................

... 36

INSTALLATION ................................................... 36

TOP TETHER STRAP CHILD RESTRAINT ............. 37

Removal and Installation ........................................ 37

REMOVAL ........................................................

... 37

INSTALLATION ................................................... 37