vin INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2184 of 2395

Special Service ToolsNBST0003The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV48100700

(J26364)

Torque adapter

NT169

Measuring pinion rotating torque

ST35300000

(Ð)

Drift

NT073

Installing power steering oil pump oil seal

a: 59 mm (2.32 in) dia.

b: 45 mm (1.77 in) dia.

ST27180001

(J25726-A)

Steering wheel puller

NT544

Removing steering wheel

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV48103500

(J26357 and J26357-10)

Pressure gauge

NT547

Measuring oil pressure

KV48102500

(Ð)

Pressure gauge adapter

NT542

Measuring oil pressure

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools

ST-3

Page 2185 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(See J25765-A)

1 GG91030000

(J25765-A)

Torque wrench

2 HT62940000

(Ð)

Socket adapter

3 HT62900000

(Ð)

Socket adapter

NT541

Measuring turning torque

KV48104400

(Ð)

Rack seal ring reformer

NT550

Reforming teflon ring

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)

KV48103400

(Ð)

Torque adapter

NT236

Measuring steering transfer gear rotating

torque

KV48104200

(Ð)

Rear cover wrench

NT540

Removing and installing gear housing end

cover

a: 4 mm (0.16 in) dia.

b: 5 mm (0.20 in)

c: 3 mm (0.12 in) dia.

d: 5 mm (0.20 in)

(J43995)

Steering lock nut wrench

NT838

Adjusting steering pinion rotating torque

(J43996)

Steering rack adjustment

wrench

NT839

Adjusting steering pinion rotating torque

(J-44372)

Spring gauge

LST024

Measuring steering wheel turning force

PREPARATION

Special Service Tools (Cont'd)

ST-4

Page 2188 of 2395

SST489B

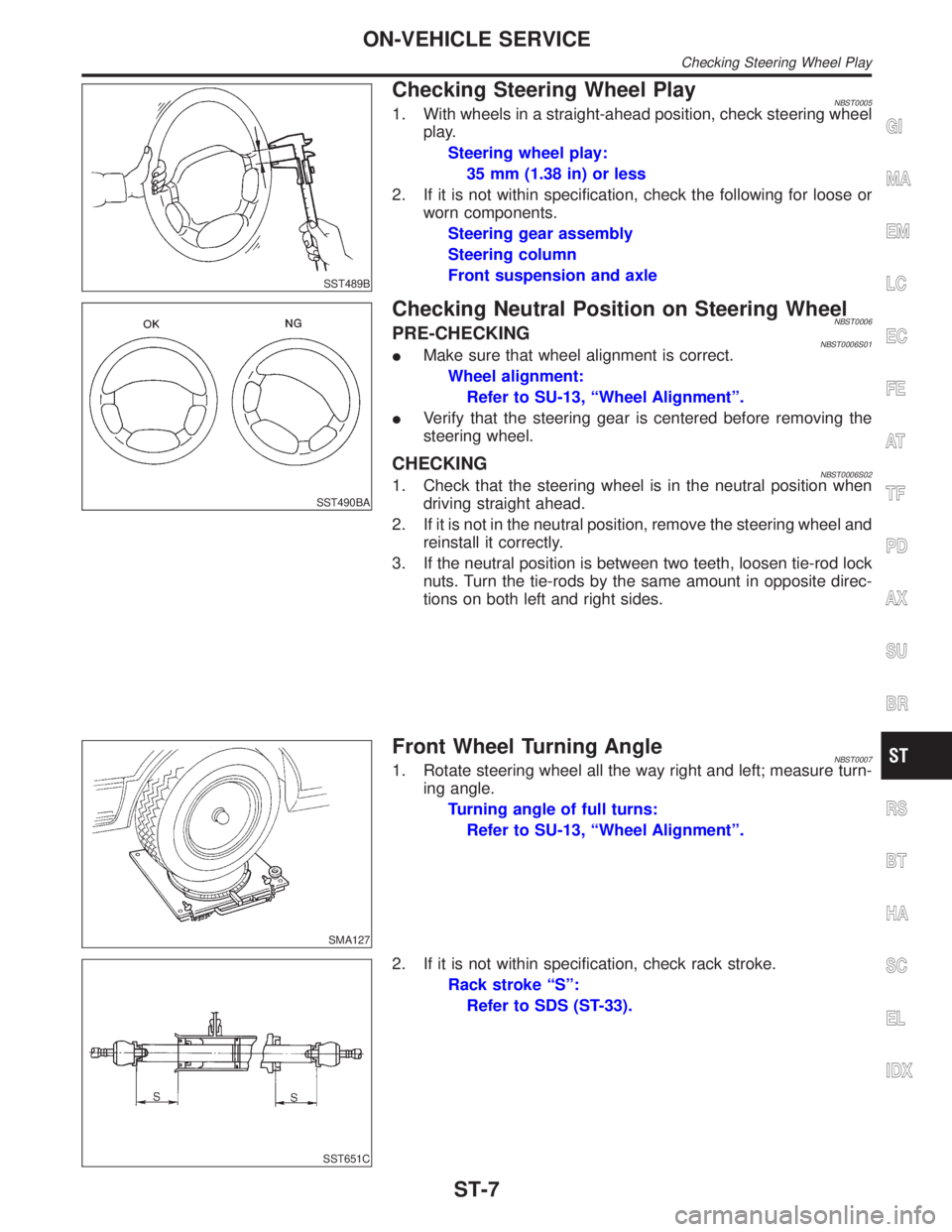

Checking Steering Wheel PlayNBST00051. With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

2. If it is not within specification, check the following for loose or

worn components.

Steering gear assembly

Steering column

Front suspension and axle

SST490BA

Checking Neutral Position on Steering WheelNBST0006PRE-CHECKINGNBST0006S01IMake sure that wheel alignment is correct.

Wheel alignment:

Refer to SU-13, ªWheel Alignmentº.

IVerify that the steering gear is centered before removing the

steering wheel.

CHECKINGNBST0006S021. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen tie-rod lock

nuts. Turn the tie-rods by the same amount in opposite direc-

tions on both left and right sides.

SMA127

Front Wheel Turning AngleNBST00071. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Turning angle of full turns:

Refer to SU-13, ªWheel Alignmentº.

SST651C

2. If it is not within specification, check rack stroke.

Rack stroke ªSº:

Refer to SDS (ST-33).

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Checking Steering Wheel Play

ST-7

Page 2189 of 2395

SST601C

Checking Gear Housing MovementNBST00081. Check the movement of steering gear housing during station-

ary steering on a dry paved surface.

IApply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

SST602C

Adjusting Rack RetainerNBST0009IPerform this driving test on a flat road.

a) Check whether vehicle moves in a straight line when steering

wheel is released.

b) Check whether steering wheel returns to neutral position when

steering wheel is released from a slightly turned (approx. 20É)

position.

IIf any abnormality is found, correct it by resetting adjusting

screw.

Checking and Adjusting Drive BeltsNBST0010Refer to MA-13, ªChecking Drive Beltsº.

SST280BA

Checking Fluid LevelNBST0011Check fluid level.

Use the correct range of the dipstick depending on the fluid tem-

perature. Use the ªHOTº range at 50 to 80ÉC (122 to 176ÉF), or the

ªCOLDº range at 0 to 30ÉC (32 to 86ÉF).

CAUTION:

IDo not overfill.

IRecommended fluid is Genuine Nissan PSF II or equiva-

lent. Refer to MA-11, ªFluids and Lubricantsº.

SST458C

Checking Fluid LeakageNBST0012Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds

and carefully check for fluid leakage.

ON-VEHICLE SERVICE

Checking Gear Housing Movement

ST-8

Page 2191 of 2395

6. If rack sliding force is not within specification, overhaul steer-

ing gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ªInspectionº, ªSTEERING WHEEL AND STEERING

COLUMNº, ST-14.

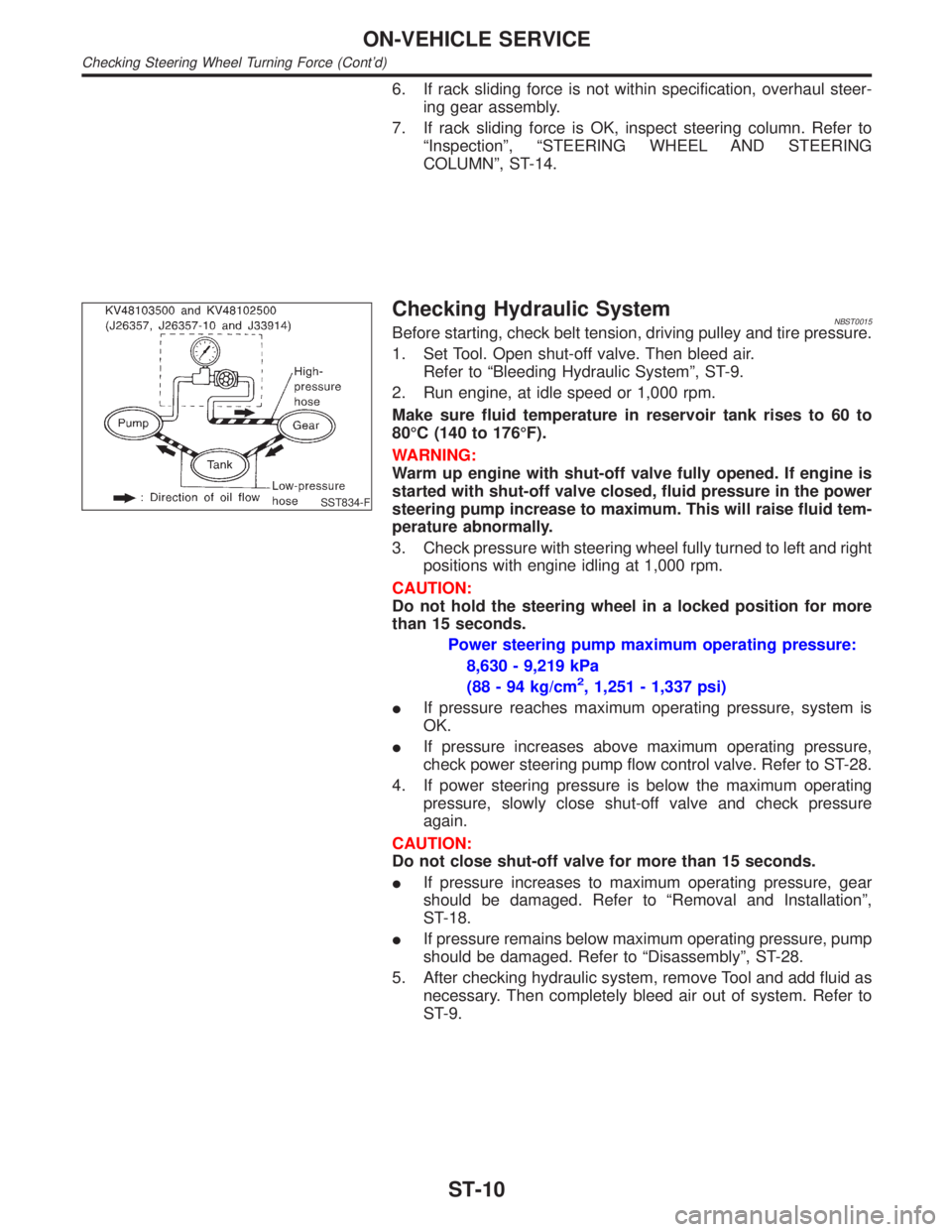

SST834-F

Checking Hydraulic SystemNBST0015Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air.

Refer to ªBleeding Hydraulic Systemº, ST-9.

2. Run engine, at idle speed or 1,000 rpm.

Make sure fluid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in the power

steering pump increase to maximum. This will raise fluid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,630 - 9,219 kPa

(88 - 94 kg/cm

2, 1,251 - 1,337 psi)

IIf pressure reaches maximum operating pressure, system is

OK.

IIf pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-28.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

IIf pressure increases to maximum operating pressure, gear

should be damaged. Refer to ªRemoval and Installationº,

ST-18.

IIf pressure remains below maximum operating pressure, pump

should be damaged. Refer to ªDisassemblyº, ST-28.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-9.

ON-VEHICLE SERVICE

Checking Steering Wheel Turning Force (Cont'd)

ST-10

Page 2192 of 2395

ComponentsNBST0016

SST843C

1. Air bag module

2. Steering wheel3. Spiral cable

4. Combination switch5. Steering column assembly

6. Column cover

CAUTION:

IThe rotation of the spiral cable (SRS ªAIR BAGº compo-

nent part) is limited. If the steering gear must be removed,

set the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

IRemove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

SBF812E

Removal and InstallationNBST0017STEERING WHEELNBST0017S011. Remove air bag module and spiral cable. Refer to RS-17,

ªRemoval Ð Air Bag Module and Spiral Cableº.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

STEERING WHEEL AND STEERING COLUMN

Components

ST-11

Page 2199 of 2395

Removal and InstallationNBST0027

SST614C

1. Gear and linkage assembly

2. Rack mounting insulator3. Gear housing mounting bracket 4. Cotter pin

SFA756B

CAUTION:

IThe rotation of the spiral cable (SRS ªAIR BAGº compo-

nent part) is limited. If the steering gear must be removed,

set the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

IRemove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

IDetach tie-rod outer sockets from knuckle arms with Tool.

SST615C

IInstall pipe connector.

IObserve specified tightening torque when tightening high-pres-

sure and low-pressure pipe connectors. Excessive tightening

will damage threads of connector or O-ring.

Connector tightening torque:

Low-pressure side ª1º

30 - 35 N´m (3.1 - 3.6 kg-m, 22 - 26 ft-lb)

High-pressure side ª2º

30 - 35 N´m (3.1 - 3.6 kg-m, 22 - 26 ft-lb)

IThe O-ring in low-pressure pipe connector is larger than that

POWER STEERING GEAR AND LINKAGE

Removal and Installation

ST-18

Page 2200 of 2395

in high-pressure connector. Take care to install the proper

O-ring.

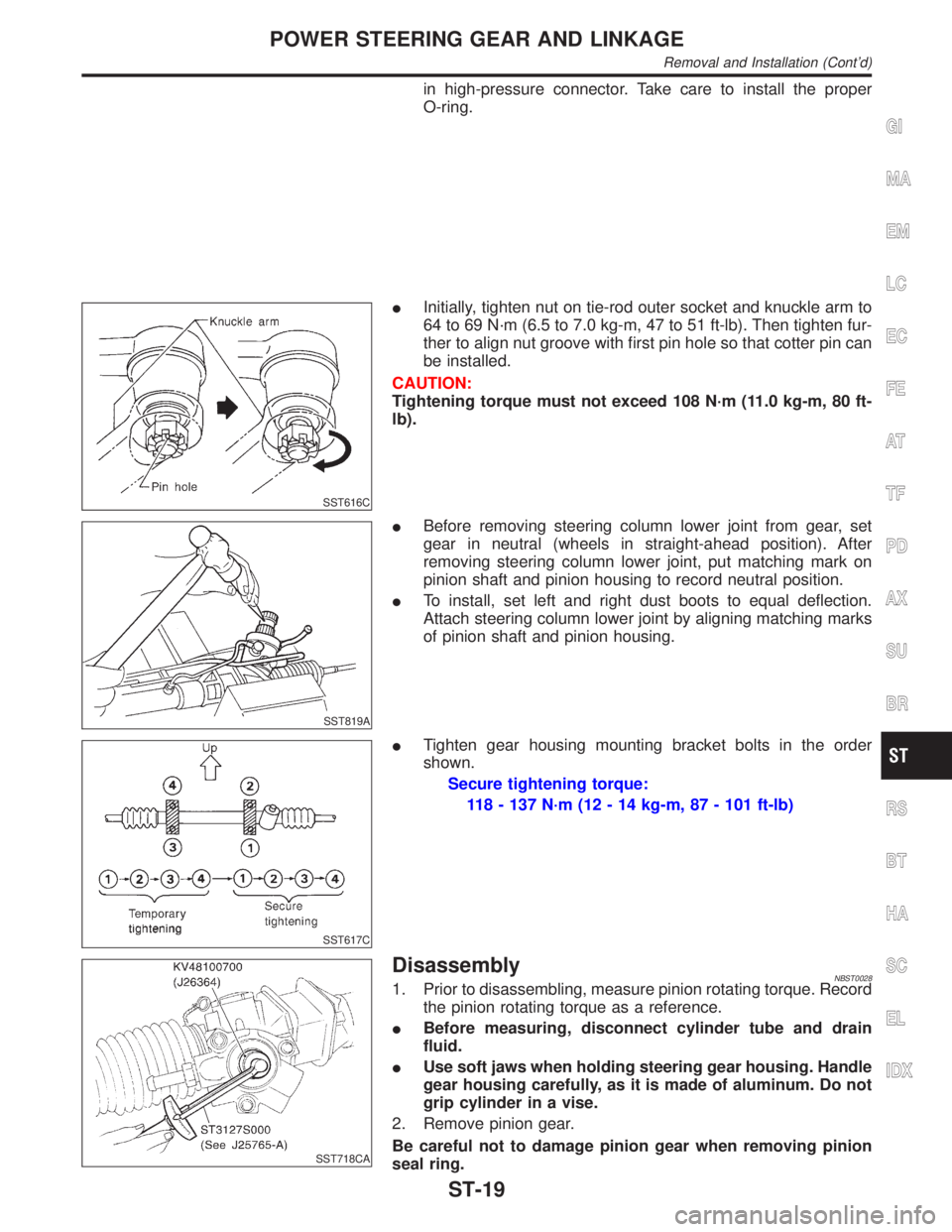

SST616C

IInitially, tighten nut on tie-rod outer socket and knuckle arm to

64 to 69 N´m (6.5 to 7.0 kg-m, 47 to 51 ft-lb). Then tighten fur-

ther to align nut groove with first pin hole so that cotter pin can

be installed.

CAUTION:

Tightening torque must not exceed 108 N´m (11.0 kg-m, 80 ft-

lb).

SST819A

IBefore removing steering column lower joint from gear, set

gear in neutral (wheels in straight-ahead position). After

removing steering column lower joint, put matching mark on

pinion shaft and pinion housing to record neutral position.

ITo install, set left and right dust boots to equal deflection.

Attach steering column lower joint by aligning matching marks

of pinion shaft and pinion housing.

SST617C

ITighten gear housing mounting bracket bolts in the order

shown.

Secure tightening torque:

118 - 137 N´m (12 - 14 kg-m, 87 - 101 ft-lb)

SST718CA

DisassemblyNBST00281. Prior to disassembling, measure pinion rotating torque. Record

the pinion rotating torque as a reference.

IBefore measuring, disconnect cylinder tube and drain

fluid.

IUse soft jaws when holding steering gear housing. Handle

gear housing carefully, as it is made of aluminum. Do not

grip cylinder in a vise.

2. Remove pinion gear.

Be careful not to damage pinion gear when removing pinion

seal ring.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont'd)

ST-19

Page 2209 of 2395

DisassemblyNBST0034CAUTION:

IParts which can be disassembled are strictly limited.

Never disassemble parts other than those specified.

IDisassemble in as clean a place as possible.

IClean your hands before disassembly.

IDo not use rags; use nylon cloths or paper towels.

IFollow the procedures and cautions in the Service

Manual.

IWhen disassembling and reassembling, do not let foreign

matter enter or contact the parts.

1. Fix power steering pump to vise.

CAUTION:

When fixing the pump to vise, use an aluminum plate or such

to avoid damaging the fitting plane of the steering pump.

2. Remove the front bracket mounting bolt, and remove the front

bracket from the casing.

3. Remove the rear cover mounting bolt, and remove the rear

cover from the casing.

4. Remove the O-ring from the casing.

SST926C

5. Remove side plate (rear side) from cam ring, then remove side

plate inner/outer seals from side plate (rear side).

6. Remove rotor snap ring using snap ring pliers, and remove

pulley from casing.

CAUTION:

Do not damage pulley shaft when removing rotor snap ring.

SST928C

7. Remove the followings from casing.

ICam ring

IRotor

IVane

ISide plate (front side)

IFlow control A valve

IFlow control valve spring

IFlow control B valve assembly

CAUTION:

Be careful not to drop flow control valve.

8. Remove inlet connector mounting bolt, and remove inlet con-

nector from casing.

9. Remove inlet connector seal from inlet connector.

10. Remove drive shaft seal from casing with a screwdriver.

CAUTION:

Do not damage casing surface with the screwdriver.

POWER STEERING OIL PUMP

Disassembly

ST-28

Page 2210 of 2395

InspectionNBST0035IIf pulley is cracked or deformed, replace it.

IIf an oil leak is found around pulley shaft oil seal, replace the

seal.

ICheck the casing and the inside of the rear body for damage.

If damages are found in the rear body, replace the entire rear

body. If the casing is damaged, replace the entire power steer-

ing pump as an assembly.

ICheck the cam ring for damage. If damage is found, replace

the cam ring, rotor and vane as a set.

ICheck the side plates (front and rear) for damage. If damage

is found, replace the side plates as a set (front and rear).

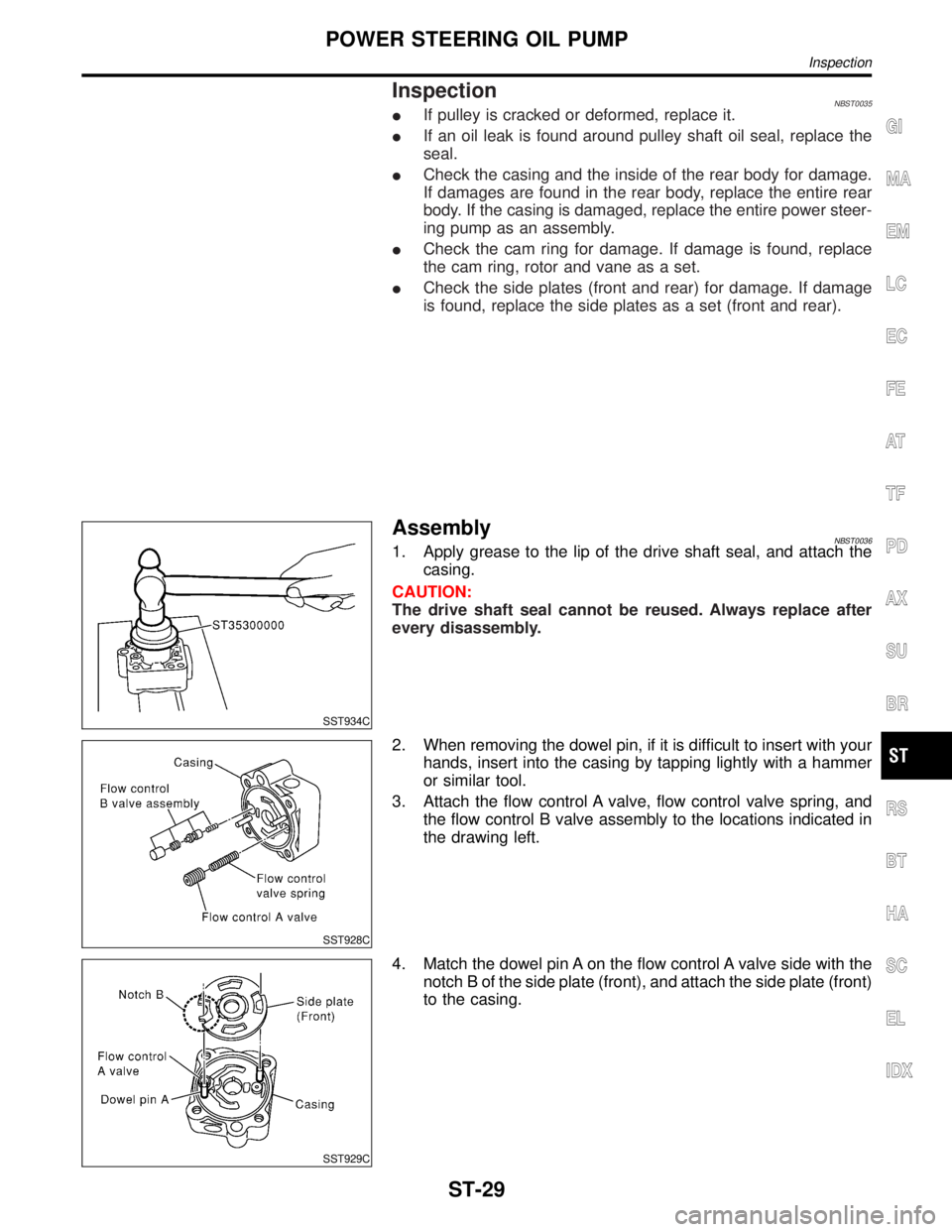

SST934C

AssemblyNBST00361. Apply grease to the lip of the drive shaft seal, and attach the

casing.

CAUTION:

The drive shaft seal cannot be reused. Always replace after

every disassembly.

SST928C

2. When removing the dowel pin, if it is difficult to insert with your

hands, insert into the casing by tapping lightly with a hammer

or similar tool.

3. Attach the flow control A valve, flow control valve spring, and

the flow control B valve assembly to the locations indicated in

the drawing left.

SST929C

4. Match the dowel pin A on the flow control A valve side with the

notch B of the side plate (front), and attach the side plate (front)

to the casing.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PUMP

Inspection

ST-29