vin INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1934 of 2395

RHA060GB

COMPONENT INSPECTIONNBHA0045In-vehicle SensorNBHA0045S01After disconnecting in-vehicle sensor harness connector, measure

resistance between terminals 1 and 2 at sensor harness side, using

the table below.

Temperature ÉC (ÉF) Resistance kW

þ15 (5) 12.73

þ10 (14) 9.92

þ5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

If NG, replace in-vehicle sensor.

RHA639F

Sunload Sensor Circuit

COMPONENT DESCRIPTIONNBHA0046The sunload sensor is located on the right defroster grille. It detects

sunload entering through windshield by means of a photo diode.

The sensor converts the sunload into a current value which is then

input into the auto amplifier.

SUNLOAD INPUT PROCESSNBHA0047The auto amp. also includes a processing circuit which ªaverageº

the variations in detected sunload over a period of time. This pre-

vents drastic swings in the ATC system operation due to small or

quick variations in detected sunload.

For example, consider driving along a road bordered by an occa-

sional group of large trees. The sunload detected by the sunload

sensor will vary whenever the trees obstruct the sunlight. The pro-

cessing circuit averages the detected sunload over a period of

time, so that the (insignificant) effect of the trees momentarily

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

In-vehicle Sensor Circuit (Cont'd)

HA-135

Page 1949 of 2395

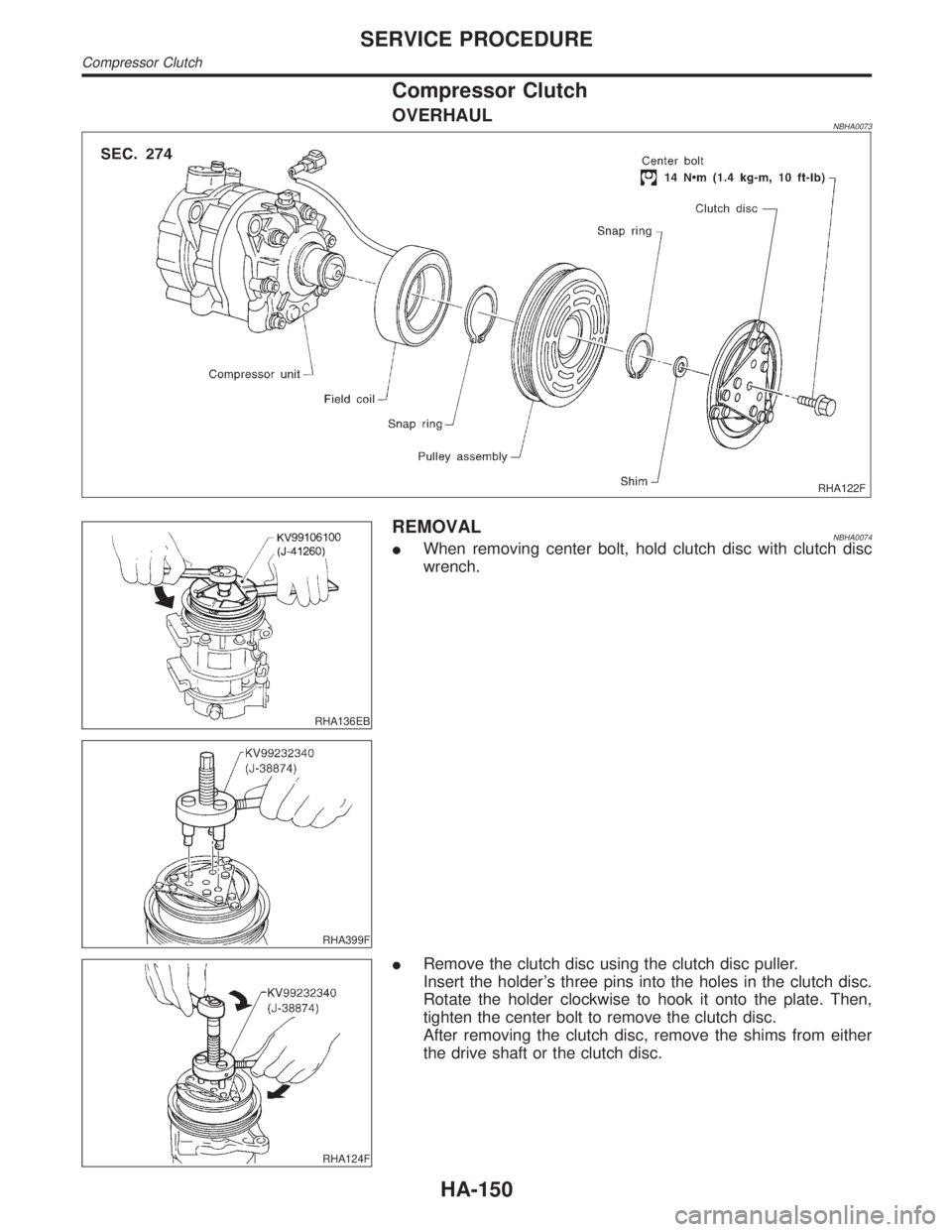

Compressor Clutch

OVERHAULNBHA0073

RHA122F

RHA136EB

REMOVALNBHA0074IWhen removing center bolt, hold clutch disc with clutch disc

wrench.

RHA399F

RHA124F

IRemove the clutch disc using the clutch disc puller.

Insert the holder's three pins into the holes in the clutch disc.

Rotate the holder clockwise to hook it onto the plate. Then,

tighten the center bolt to remove the clutch disc.

After removing the clutch disc, remove the shims from either

the drive shaft or the clutch disc.

SERVICE PROCEDURE

Compressor Clutch

HA-150

Page 1950 of 2395

RHA138E

IRemove the snap ring using external snap ring pliers.

RHA139E

IPulley removal

Position the center pulley puller on the end of the drive shaft,

and remove the pulley assembly using any commercially avail-

able pulley puller.

To prevent the pulley groove from being deformed, the

puller claws should be positioned onto the edge of the

pulley assembly.

RHA125F

IRemove the field coil harness clip using a pair of pliers.

RHA145E

IRemove the snap ring using external snap ring pliers.

RHA126F

INSPECTIONNBHA0075Clutch DiscNBHA0075S01If the contact surface shows signs of damage due to excessive

heat, replace clutch disc and pulley.

PulleyNBHA0075S02Check the appearance of the pulley assembly. If the contact sur-

face of pulley shows signs of excessive grooving, replace clutch

disc and pulley. The contact surfaces of the pulley assembly should

be cleaned with a suitable solvent before reinstallation.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDURE

Compressor Clutch (Cont'd)

HA-151

Page 1954 of 2395

CHECKING FOR REFRIGERANT LEAKS=NBHA0078IPerform a visual inspection of all refrigeration parts, fittings,

hoses and components for signs of A/C lubricant leakage,

damage and corrosion. A/C lubricant leakage may indicate an

area of refrigerant leakage. Allow extra inspection time in these

areas when using either an electronic refrigerant leak detector

or fluorescent dye leak detector.

IIf dye is observed, confirm the leak with an electronic refriger-

ant leak detector. It is possible a prior leak was repaired and

not properly cleaned.

IWhen searching for leaks, do not stop when one leak is found

but continue to check for additional leaks at all system compo-

nents and connections.

IWhen searching for refrigerant leaks using an electronic leak

detector, move the probe along the suspected leak area at 1

to 2 inches per second and no further than 1/4 inch from the

component.

NOTE:

Moving the electronic leak detector probe slower and closer to

the suspected leak area will improve the chances of finding a

leak.

CHECKING SYSTEM FOR LEAKS USING THE

FLUORESCENT LEAK DETECTOR

NBHA01161. Check A/C system for leaks using the UV lamp and safety

glasses (J-42220) in a low sunlight area (area without windows

preferable). Illuminate all components, fittings and lines. The

dye will appear as a bright green/yellow area at the point of

leakage. Fluorescent dye observed at the evaporator drain

opening indicates an evaporator core assembly (tubes, core or

TXV) leak.

2. If the suspected area is difficult to see, use an adjustable mir-

ror or wipe the area with a clean shop rag or cloth, then check

the cloth with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye

cleaner (J-43872) to prevent future misdiagnosis.

4. Perform a system performance check and verify the leak repair

with an approved electronic refrigerant leak detector.

NOTE:

IOther gases in the work area or substances on the A/C

components, for example, anti-freeze, windshield washer

fluid, solvents and lubricants, may falsely trigger the leak

detector. Make sure the surfaces to be checked are clean.

Clean with a dry cloth or blow off with shop air.

IDo not allow the sensor tip of the detector to contact with

any substance. This can also cause false readings and

may damage the detector.

DYE INJECTIONNBHA0117(This procedure is only necessary when re-charging the system or

when the compressor has seized and was replaced.)

1. Check A/C system static (at rest) Pressure. Pressure must be

at least 345 kPa (50 psi).

2. Pour one bottle (1/4 ounce /7.4 cc) of the A/C refrigerant dye

into the injector tool (J-41459).

3. Connect the injector tool to the A/C LOW PRESSURE side

service fitting.

4. Start engine and switch A/C ON.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-155

Page 1956 of 2395

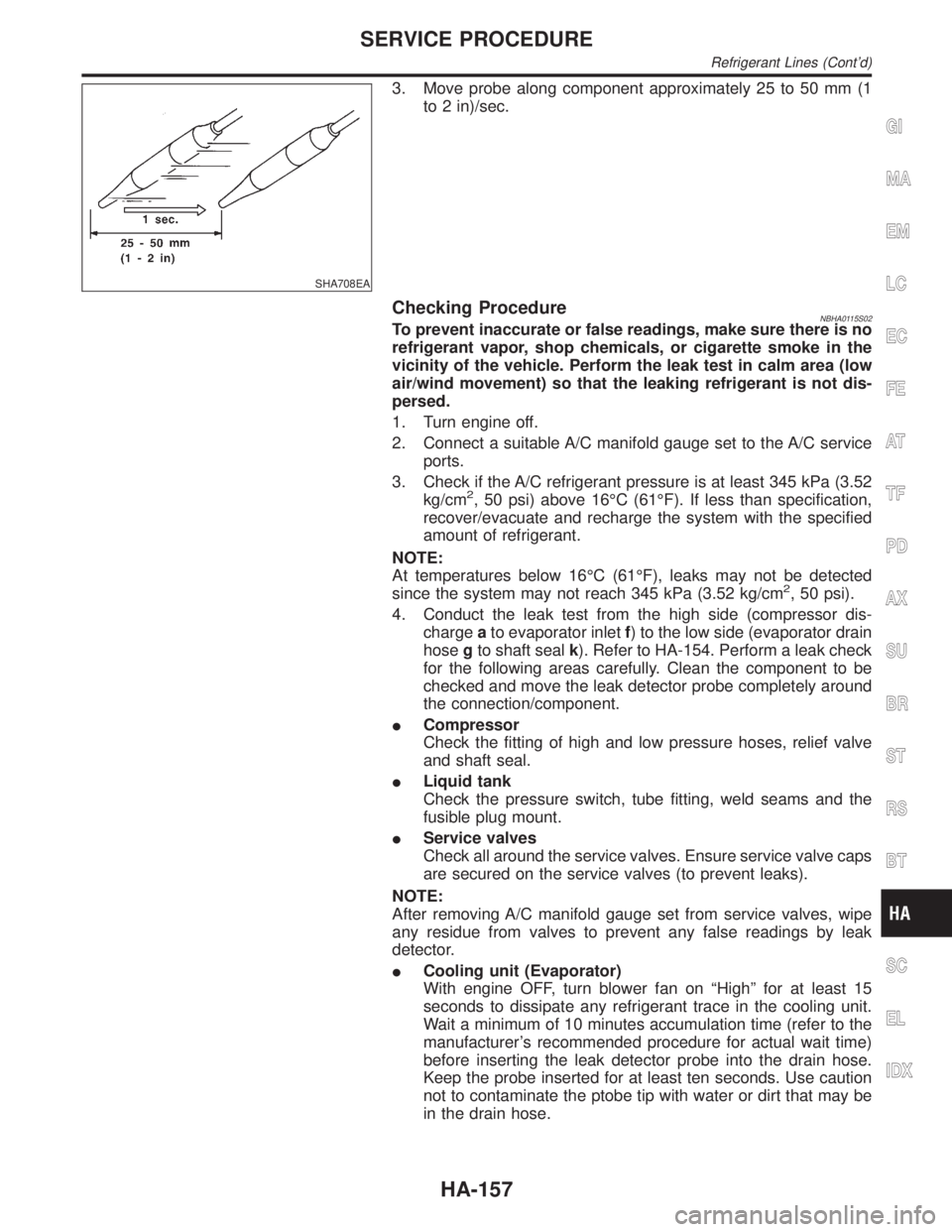

SHA708EA

3. Move probe along component approximately 25 to 50 mm (1

to 2 in)/sec.

Checking ProcedureNBHA0115S02To prevent inaccurate or false readings, make sure there is no

refrigerant vapor, shop chemicals, or cigarette smoke in the

vicinity of the vehicle. Perform the leak test in calm area (low

air/wind movement) so that the leaking refrigerant is not dis-

persed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.52

kg/cm

2, 50 psi) above 16ÉC (61ÉF). If less than specification,

recover/evacuate and recharge the system with the specified

amount of refrigerant.

NOTE:

At temperatures below 16ÉC (61ÉF), leaks may not be detected

since the system may not reach 345 kPa (3.52 kg/cm

2, 50 psi).

4. Conduct the leak test from the high side (compressor dis-

chargeato evaporator inletf) to the low side (evaporator drain

hosegto shaft sealk). Refer to HA-154. Perform a leak check

for the following areas carefully. Clean the component to be

checked and move the leak detector probe completely around

the connection/component.

ICompressor

Check the fitting of high and low pressure hoses, relief valve

and shaft seal.

ILiquid tank

Check the pressure switch, tube fitting, weld seams and the

fusible plug mount.

IService valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe

any residue from valves to prevent any false readings by leak

detector.

ICooling unit (Evaporator)

With engine OFF, turn blower fan on ªHighº for at least 15

seconds to dissipate any refrigerant trace in the cooling unit.

Wait a minimum of 10 minutes accumulation time (refer to the

manufacturer's recommended procedure for actual wait time)

before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least ten seconds. Use caution

not to contaminate the ptobe tip with water or dirt that may be

in the drain hose.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-157

Page 1972 of 2395

COMMERCIAL SERVICE TOOLNBLC0040

Tool name Description

Deep socket

NT818

Removing and installing oil pressure switch

Deep socket 26 mm, 3/8 drive

Lubrication CircuitNBLC0003

SLC350BA

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEM

Preparation (Cont'd)

LC-3

Page 1974 of 2395

b. Apply Genuine RTV silicone sealant Part No. 999MP-A7007 or

equivalent to the thread and tighten.

13 - 17 N´m (1.25 - 1.75 kg-m,9-12ft-lb)

Oil Pump

REMOVAL AND INSTALLATIONNBLC00051. Remove timing chain. Refer to EM-23, ªRemovalº.

2. Remove oil pump assembly.

IInspect the oil pump after removing it.

3. Reinstall any parts removed in reverse order of removal.

DISASSEMBLY AND ASSEMBLYNBLC0006

SLC323B

IWhen installing oil pump, apply engine oil to rotors.

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEM

Oil Pressure Check (Cont'd)

LC-5

Page 1977 of 2395

IInspect the oil cooler after removing it.

SLC333B

3. Installation is in reverse order of removal.

IWhen installing the oil cooler, align the oil cooler stopper

with the stopper of the oil cooler bracket.

INSPECTIONNBLC0037Oil CoolerNBLC0037S011. Check oil cooler for cracks.

2. Check oil cooler for clogging by blowing through coolant inlet.

If necessary, replace oil cooler assembly.

Oil Pressure Relief ValveNBLC0037S02Inspect oil pressure relief valve for movement, cracks and breaks

by pushing the ball. If replacement is necessary, remove valve by

prying it out with a suitable tool. Install a new valve in place by

tapping it.

Service Data and Specifications (SDS)

OIL PRESSURENBLC0010

Engine speed

rpmApproximate discharge pressure

kPa (kg/cm2, psi)

Idle speed

2,000More than 98 (1.0, 14)

294 (3.0, 43)

REGULATOR VALVENBLC0011Unit: mm (in)

Regulator valve to oil pump cover clearance 0.040 - 0.097 (0.0016 - 0.0038)

OIL PUMPNBLC0012Unit: mm (in)

Body to outer rotor radial clearance 0.114 - 0.200 (0.0045 - 0.0079)

Inner rotor to outer rotor tip clearance Below 0.18 (0.0071)

Body to inner rotor axial clearance 0.030 - 0.070 (0.0012 - 0.0028)

Body to outer rotor axial clearance 0.050 - 0.110 (0.0020 - 0.0043)

Inner rotor to brazed portion of housing clearance 0.045 - 0.091 (0.0018 - 0.0036)

ENGINE LUBRICATION SYSTEM

Oil Cooler (Cont'd)

LC-8

Page 1978 of 2395

SEM164F

AEM080

Precautions

LIQUID GASKET APPLICATION PROCEDURENBLC00131. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.)

IFor oil pan, be sure liquid gasket diameter is 4.0 to 5.0 mm

(0.157 to 0.197 in).

IFor areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

Preparation

SPECIAL SERVICE TOOLSNBLC0014The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

WS39930000

(Ð)

Tube pressure

NT052

Pressing the tube of liquid gasket

EG17650301

(J33984-A)

Radiator cap tester

adapter

NT564

Adapting radiator cap tester to radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

(Ð)

Radiator plate pliers A

NT224

Installing radiator upper and lower tanks

KV99103520

(Ð)

Radiator plate pliers B

NT225

Removing radiator upper and lower tanks

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Precautions

LC-9

Page 1981 of 2395

SLC756A

CHECKING COOLING SYSTEM FOR LEAKSNBLC0016S04To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.6 kg/cm

2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator

damage.

Water Pump

REMOVAL AND INSTALLATIONNBLC0017CAUTION:

IWhen removing water pump assembly, be careful not to

get coolant on drive belt.

IWater pump cannot be disassembled and should be

replaced as a unit.

IAfter installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

SLC326B

SLC327B

REMOVALNBLC00181. Remove under cover.

2. Remove suspension member stay.

3. Drain coolant from radiator.

4. Remove radiator shrouds.

5. Remove drive belts.

6. Remove cooling fan.

7. Remove water drain plug on water pump side of cylinder block.

8. Remove chain tensioner cover and water pump cover.

ENGINE COOLING SYSTEM

System Check (Cont'd)

LC-12