vin INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2217 of 2395

SBR686C

Precautions

PRECAUTIONSNBSU0001IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

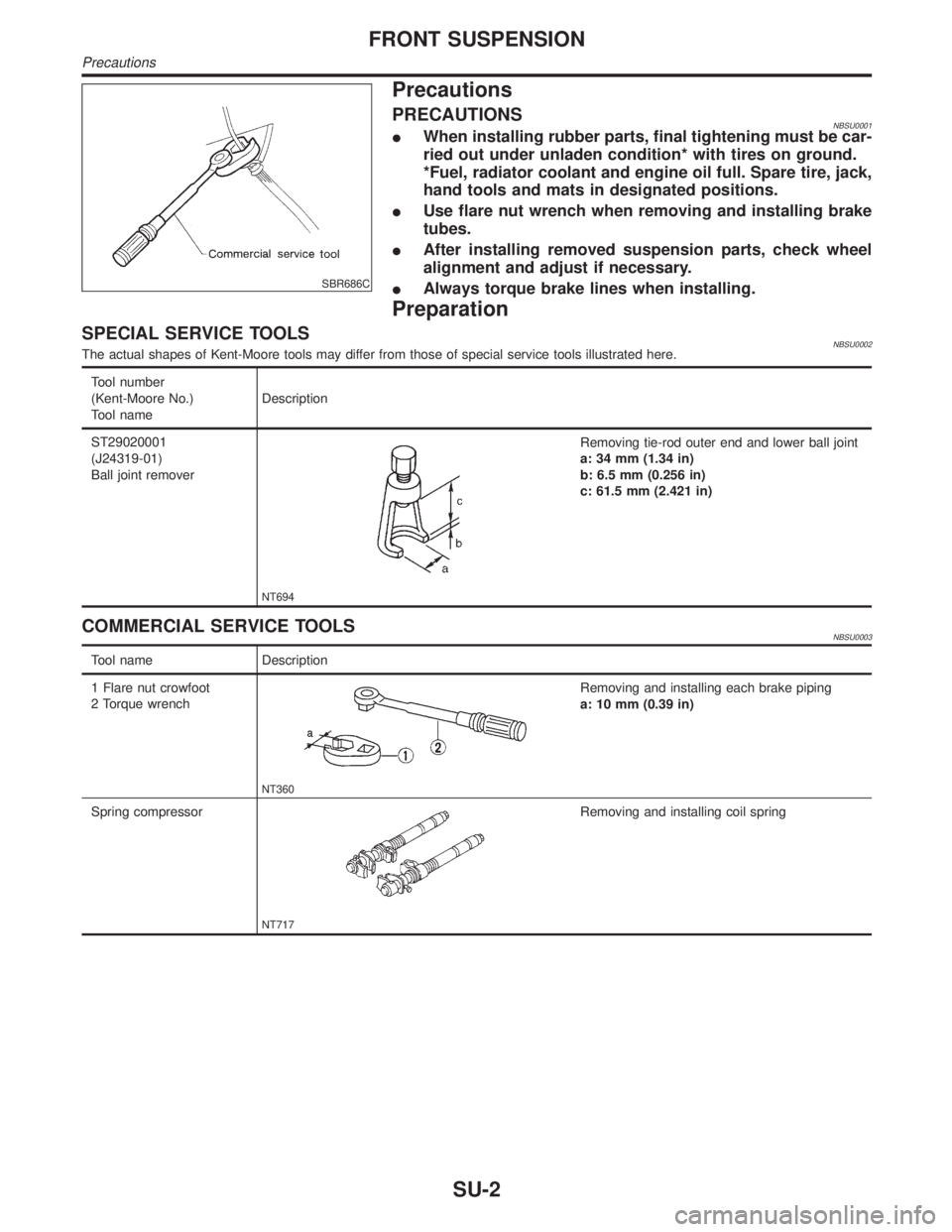

SPECIAL SERVICE TOOLSNBSU0002The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing tie-rod outer end and lower ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

COMMERCIAL SERVICE TOOLSNBSU0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Spring compressor

NT717

Removing and installing coil spring

FRONT SUSPENSION

Precautions

SU-2

Page 2225 of 2395

SFA725B

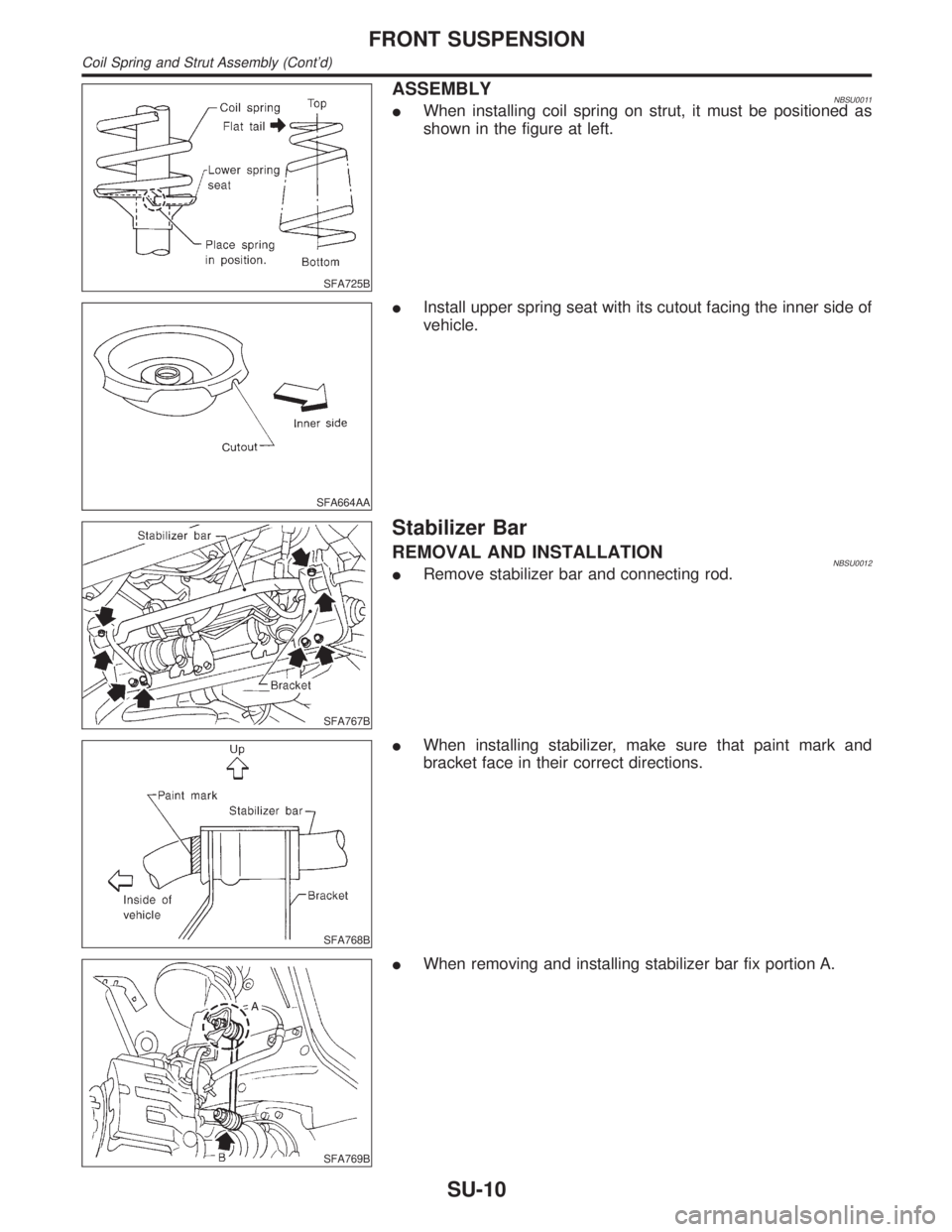

ASSEMBLYNBSU0011IWhen installing coil spring on strut, it must be positioned as

shown in the figure at left.

SFA664AA

IInstall upper spring seat with its cutout facing the inner side of

vehicle.

SFA767B

Stabilizer Bar

REMOVAL AND INSTALLATIONNBSU0012IRemove stabilizer bar and connecting rod.

SFA768B

IWhen installing stabilizer, make sure that paint mark and

bracket face in their correct directions.

SFA769B

IWhen removing and installing stabilizer bar fix portion A.

FRONT SUSPENSION

Coil Spring and Strut Assembly (Cont'd)

SU-10

Page 2230 of 2395

SBR686C

Precautions

PRECAUTIONSNBSU0021IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

COMMERCIAL SERVICE TOOLSNBSU0023

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBSU0036Refer to ªNoise, Vibration and Harshness (NVH) Troubleshootingº,

ªFRONT SUSPENSIONº, SU-3.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Precautions

SU-15

Page 2232 of 2395

SBR686C

Removal and InstallationNBSU00261. Support axle and suspension components with a suitable jack

and block.

2. Disconnect brake hydraulic line and parking brake cables at

back plates.

CAUTION:

IUse flare nut wrench when removing and installing brake

tubes.

IBefore removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Then move

it away from the rear suspension assembly. Failure to do

so may result in damage to the sensor wires and the sen-

sor becoming inoperative.

3. Remove stabilizer bar from body.

4. Remove upper links and lower links from body.

5. Remove panhard rod from body.

6. Disconnect rear end of propeller shaft. Refer to PD-6,

ªRemoval and Installationº.

7. Remove upper end nuts of shock absorber.

SRA935

Final tightening for rubber parts requires to be carried out

under unladen condition with tires on ground.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Removal and Installation

SU-17

Page 2235 of 2395

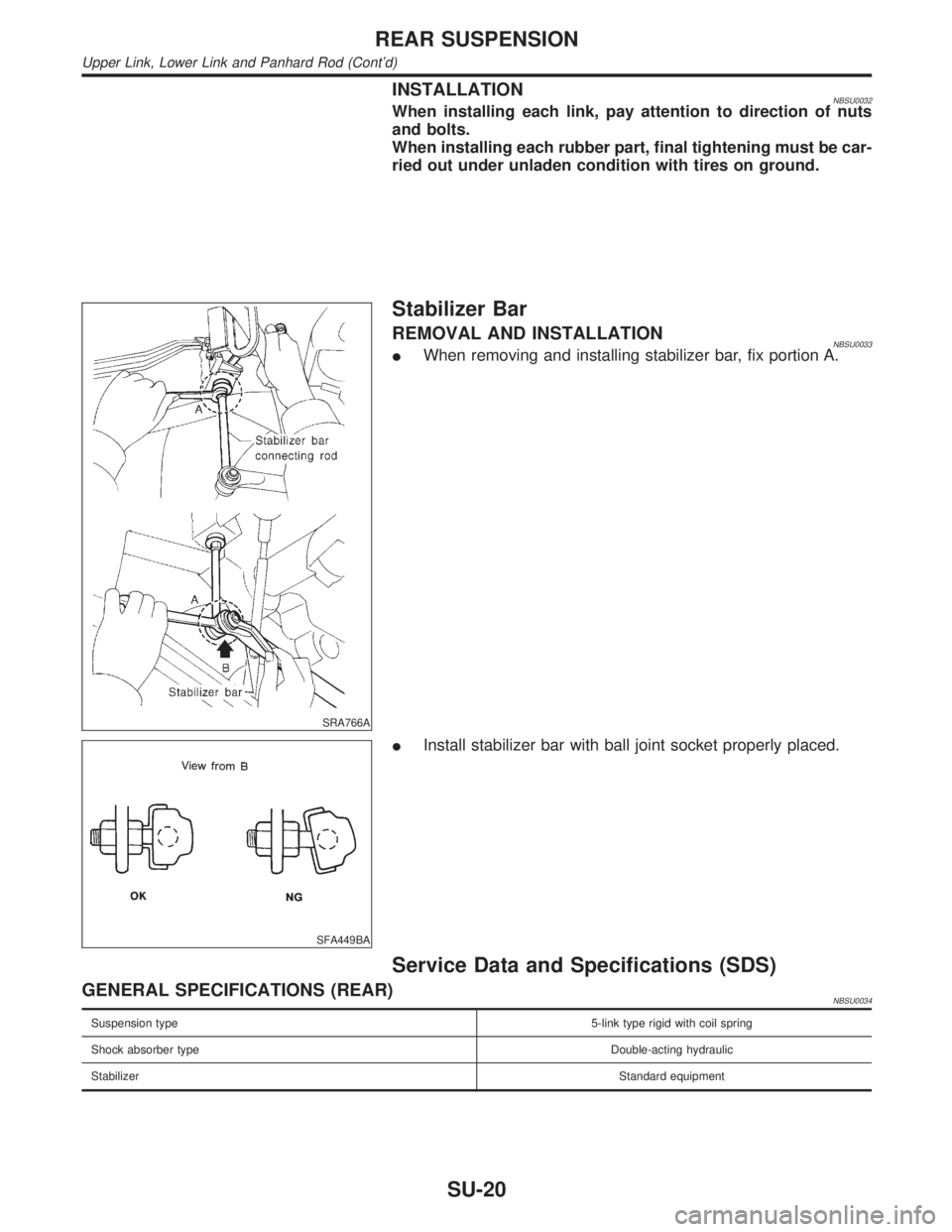

INSTALLATIONNBSU0032When installing each link, pay attention to direction of nuts

and bolts.

When installing each rubber part, final tightening must be car-

ried out under unladen condition with tires on ground.

SRA766A

Stabilizer Bar

REMOVAL AND INSTALLATIONNBSU0033IWhen removing and installing stabilizer bar, fix portion A.

SFA449BA

IInstall stabilizer bar with ball joint socket properly placed.

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (REAR)NBSU0034

Suspension type5-link type rigid with coil spring

Shock absorber typeDouble-acting hydraulic

StabilizerStandard equipment

REAR SUSPENSION

Upper Link, Lower Link and Panhard Rod (Cont'd)

SU-20

Page 2240 of 2395

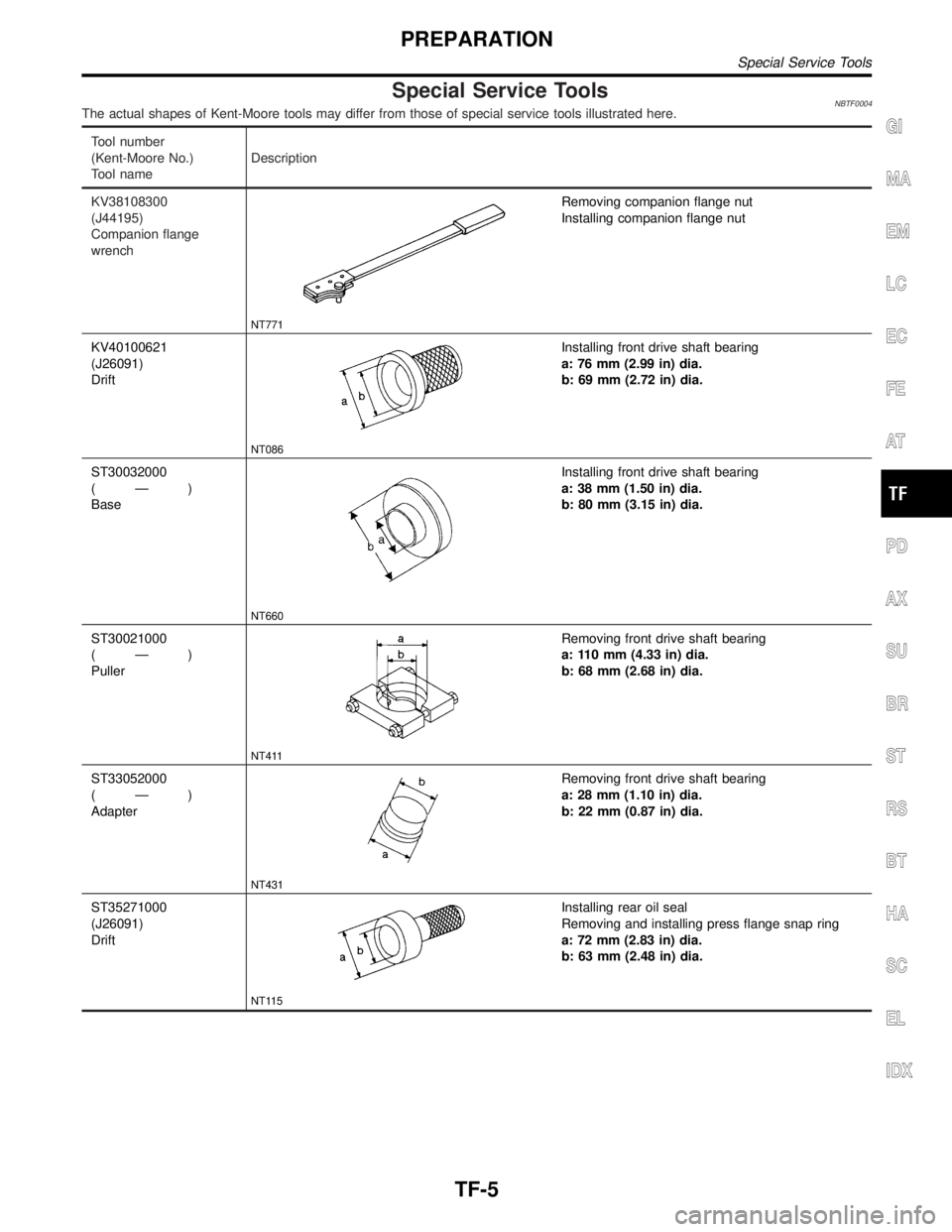

Special Service ToolsNBTF0004The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV38108300

(J44195)

Companion flange

wrench

NT771

Removing companion flange nut

Installing companion flange nut

KV40100621

(J26091)

Drift

NT086

Installing front drive shaft bearing

a: 76 mm (2.99 in) dia.

b: 69 mm (2.72 in) dia.

ST30032000

(Ð)

Base

NT660

Installing front drive shaft bearing

a: 38 mm (1.50 in) dia.

b: 80 mm (3.15 in) dia.

ST30021000

(Ð)

Puller

NT411

Removing front drive shaft bearing

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

ST33052000

(Ð)

Adapter

NT431

Removing front drive shaft bearing

a: 28 mm (1.10 in) dia.

b: 22 mm (0.87 in) dia.

ST35271000

(J26091)

Drift

NT115

Installing rear oil seal

Removing and installing press flange snap ring

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools

TF-5

Page 2241 of 2395

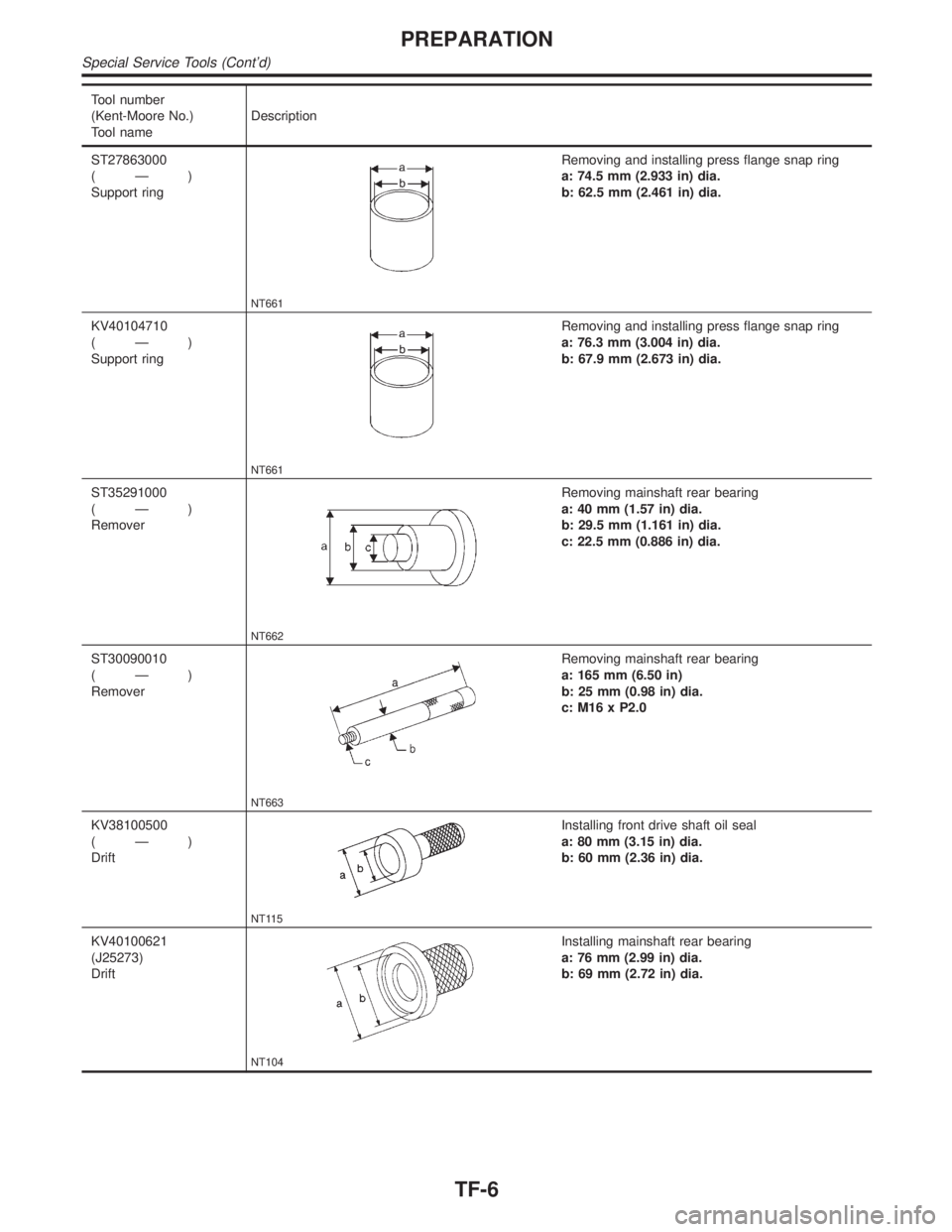

Tool number

(Kent-Moore No.)

Tool nameDescription

ST27863000

(Ð)

Support ring

NT661

Removing and installing press flange snap ring

a: 74.5 mm (2.933 in) dia.

b: 62.5 mm (2.461 in) dia.

KV40104710

(Ð)

Support ring

NT661

Removing and installing press flange snap ring

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST35291000

(Ð)

Remover

NT662

Removing mainshaft rear bearing

a: 40 mm (1.57 in) dia.

b: 29.5 mm (1.161 in) dia.

c: 22.5 mm (0.886 in) dia.

ST30090010

(Ð)

Remover

NT663

Removing mainshaft rear bearing

a: 165 mm (6.50 in)

b: 25 mm (0.98 in) dia.

c: M16 x P2.0

KV38100500

(Ð)

Drift

NT115

Installing front drive shaft oil seal

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.

KV40100621

(J25273)

Drift

NT104

Installing mainshaft rear bearing

a: 76 mm (2.99 in) dia.

b: 69 mm (2.72 in) dia.

PREPARATION

Special Service Tools (Cont'd)

TF-6

Page 2242 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

KV32101100

(Ð)

Pin punch

NT410

Removing and installing L-H fork, 2-4 fork

a: 6 mm (0.24 in) dia.

ST3306S001

(J22888-D)

Differential side bearing

puller set

1: ST33051001

(Ð)

Puller

2: ST33061000

(J8107-2)

Adapter

NT072

Installing mainshaft rear bearing

Removing sun gear assembly

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

ST30911000

(Ð)

Puller

NT664

Installing mainshaft and planetary carrier assembly

a: 98 mm (3.86 in) dia.

b: 40.5 mm (1.594 in) dia.

KV381054S0

(Ð)

Outer race puller

NT665

Removing rear oil seal

KV40105230

(Ð)

Adapter

NT666

Installing planetary carrier assembly

a: 92 mm (3.62 in) dia.

b: 86 mm (3.39 in) dia.

c: 12 mm (0.47 in)

KV40105310

(Ð)

Support ring

NT661

Installing planetary carrier assembly

a: 89.1 mm (3.508 in) dia.

b: 80.7 mm (3.177 in) dia.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools (Cont'd)

TF-7

Page 2243 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40105500

(Ð)

Support

NT667

Installing planetary carrier assembly

a: 69 mm (2.72 in) dia.

b: 52 mm (2.05 in) dia.

c: 120 mm (4.72 in) dia.

KV38100200

(Ð)

Drift

NT673

Installing transfer cover oil seal

a: 65 mm (2.56 in) dia.

b: 49 mm (1.93 in) dia.

KV31103300

(Ð)

Drift

NT668

Removing and installing press flange snap ring

a: 76.3 mm (3.004 in) dia.

b: 130 mm (5.12 in)

KV31103400

(Ð)

Clutch piston attachment

1 Shaft-drift

2 Guide-cylinder

NT669

Installing clutch piston

a: 88.5 mm (3.484 in) dia.

b: 158 mm (6.22 in) dia.

ST33290001

(J25810-A)

Puller

NT414

Removing center case oil seal

Removing rear oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33051001

(J22888)

Puller

NT824

Removing companion flange

a: 135 mm (5.31 in)

b: 100 mm (3.94 in)

c: 170 mm (6.69 in)

PREPARATION

Special Service Tools (Cont'd)

TF-8

Page 2244 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

(J35864)

Drift

NT671

Installing oil seal

Commercial Service ToolsNBTF0005

Tool name Description

Puller

NT077

Removing companion flange, clutch gear and

mainshaft gear bearing

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools (Cont'd)

TF-9