vin INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1989 of 2395

SLC066B

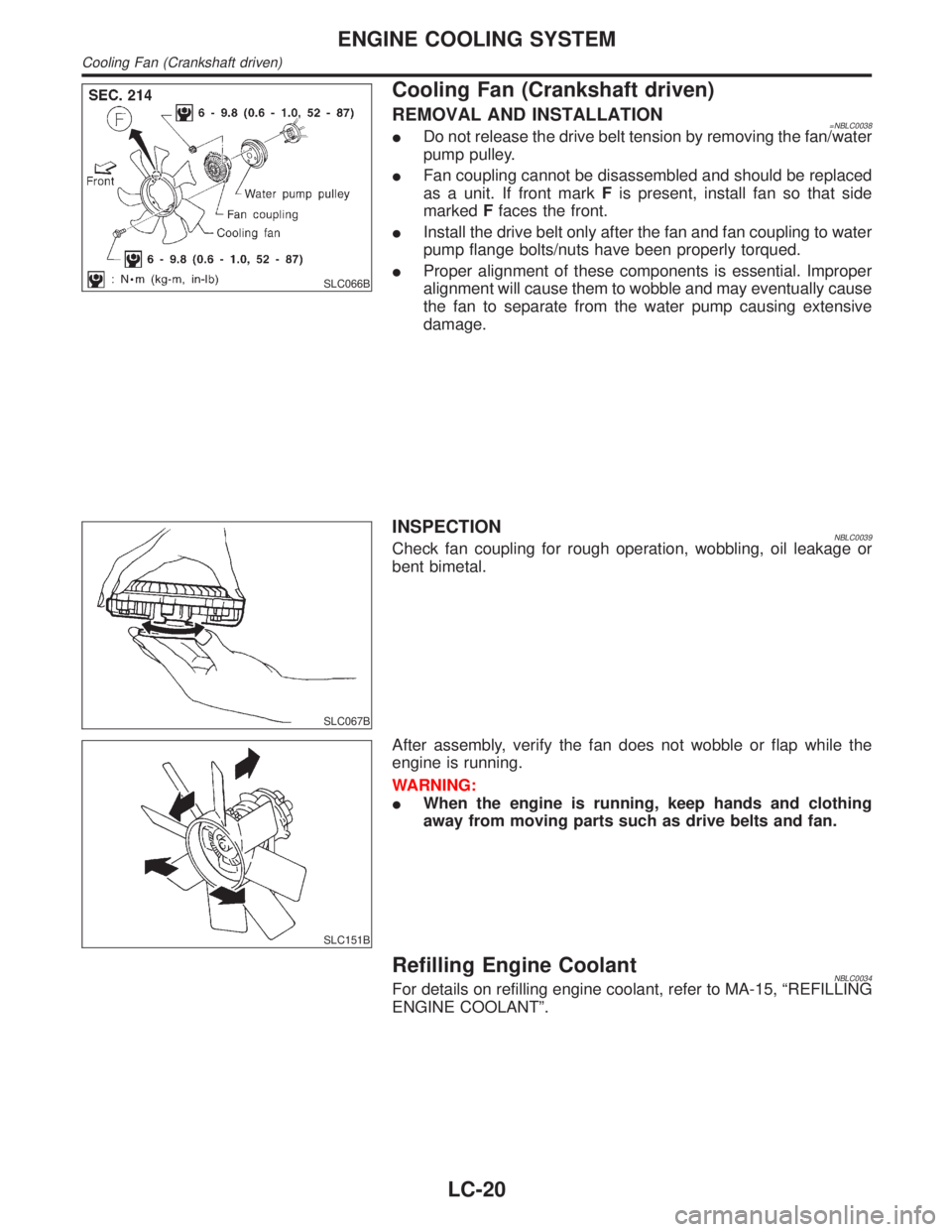

Cooling Fan (Crankshaft driven)

REMOVAL AND INSTALLATION=NBLC0038IDo not release the drive belt tension by removing the fan/water

pump pulley.

IFan coupling cannot be disassembled and should be replaced

as a unit. If front markFis present, install fan so that side

markedFfaces the front.

IInstall the drive belt only after the fan and fan coupling to water

pump flange bolts/nuts have been properly torqued.

IProper alignment of these components is essential. Improper

alignment will cause them to wobble and may eventually cause

the fan to separate from the water pump causing extensive

damage.

SLC067B

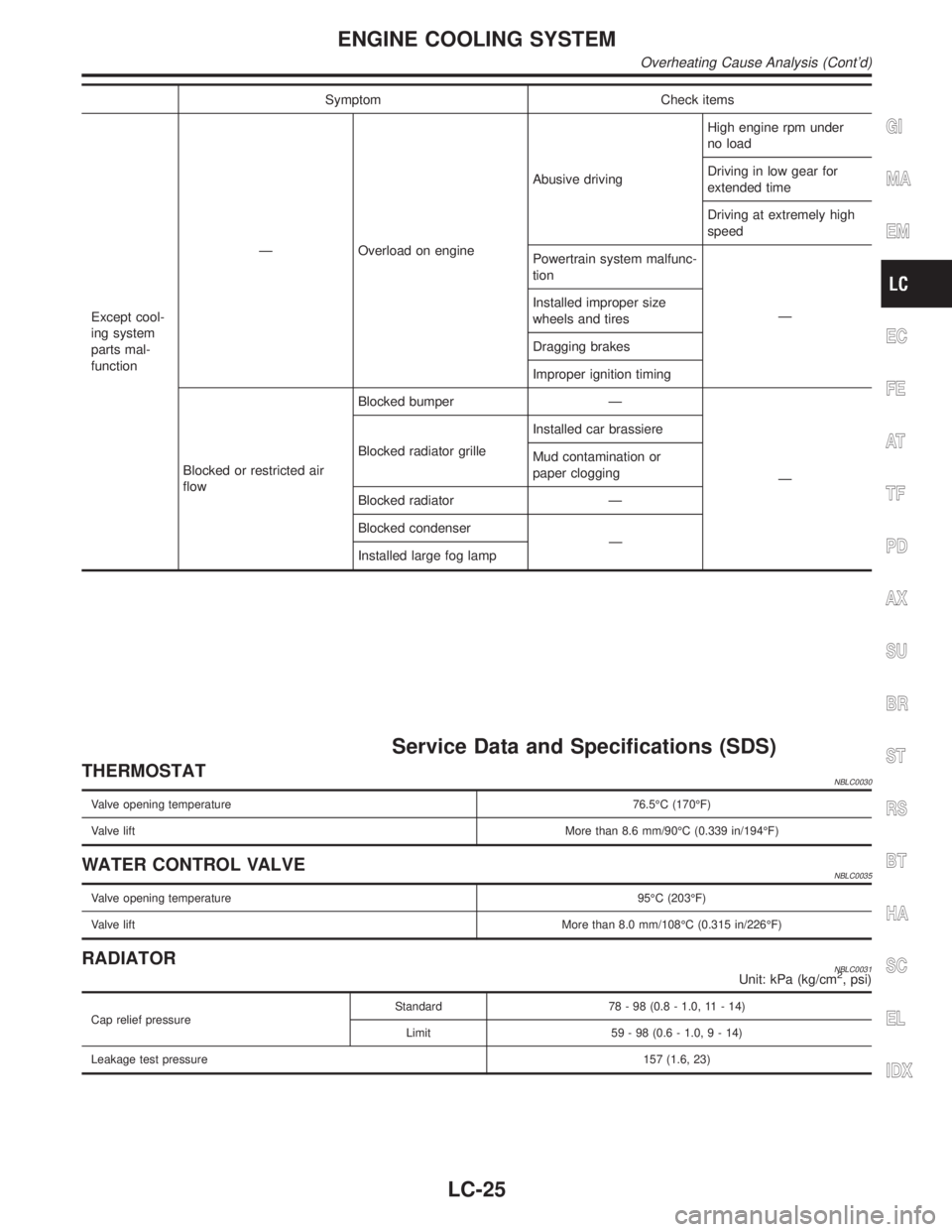

INSPECTIONNBLC0039Check fan coupling for rough operation, wobbling, oil leakage or

bent bimetal.

SLC151B

After assembly, verify the fan does not wobble or flap while the

engine is running.

WARNING:

IWhen the engine is running, keep hands and clothing

away from moving parts such as drive belts and fan.

Refilling Engine CoolantNBLC0034For details on refilling engine coolant, refer to MA-15, ªREFILLING

ENGINE COOLANTº.

ENGINE COOLING SYSTEM

Cooling Fan (Crankshaft driven)

LC-20

Page 1994 of 2395

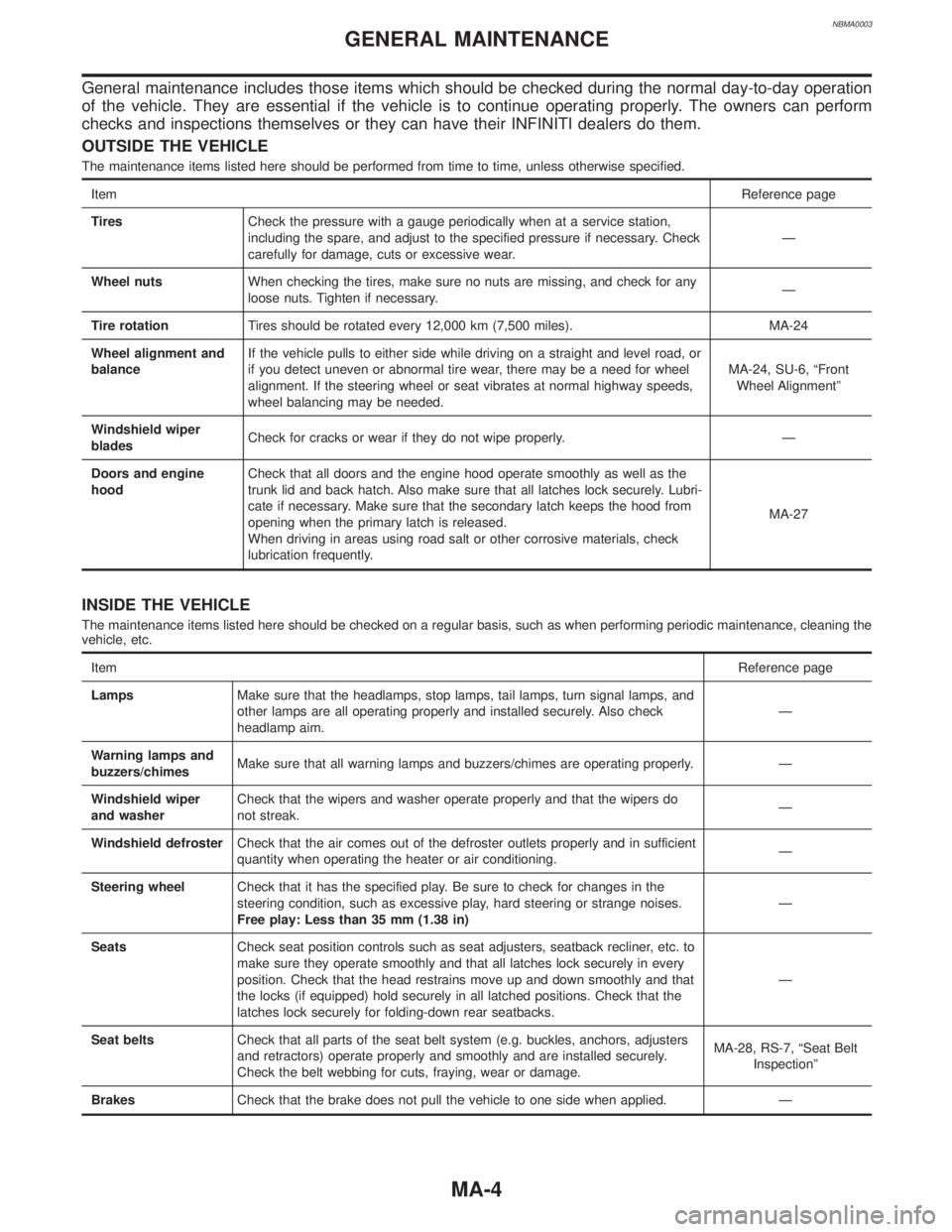

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNBLC0030

Valve opening temperature76.5ÉC (170ÉF)

Valve liftMore than 8.6 mm/90ÉC (0.339 in/194ÉF)

WATER CONTROL VALVENBLC0035

Valve opening temperature95ÉC (203ÉF)

Valve liftMore than 8.0 mm/108ÉC (0.315 in/226ÉF)

RADIATORNBLC0031Unit: kPa (kg/cm2, psi)

Cap relief pressureStandard 78 - 98 (0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.6 - 1.0,9-14)

Leakage test pressure157 (1.6, 23)

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Overheating Cause Analysis (Cont'd)

LC-25

Page 1998 of 2395

Special Service ToolNBMA0002The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV10115801

(J38956)

Oil filter cap wrench

NT375

Removing oil filter

a: 64.3 mm (2.531 in)

Commercial Service ToolNBMA0041

Tool name

(Kent-Moore No.)Description

Belt tension gauge

(BT3373-F)

AMA126

Checking drive belt tension

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tool

MA-3

Page 1999 of 2395

NBMA0003

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or they can have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

ItemReference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.Ð

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.Ð

Tire rotationTires should be rotated every 12,000 km (7,500 miles). MA-24

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.MA-24, SU-6, ªFront

Wheel Alignmentº

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubri-

cate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.MA-27

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

ItemReference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.Ð

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly. Ð

Windshield wiper

and washerCheck that the wipers and washer operate properly and that the wipers do

not streak.Ð

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning.Ð

Steering wheelCheck that it has the specified play. Be sure to check for changes in the

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-28, RS-7, ªSeat Belt

Inspectionº

BrakesCheck that the brake does not pull the vehicle to one side when applied. Ð

GENERAL MAINTENANCE

MA-4

Page 2001 of 2395

NBMA0004

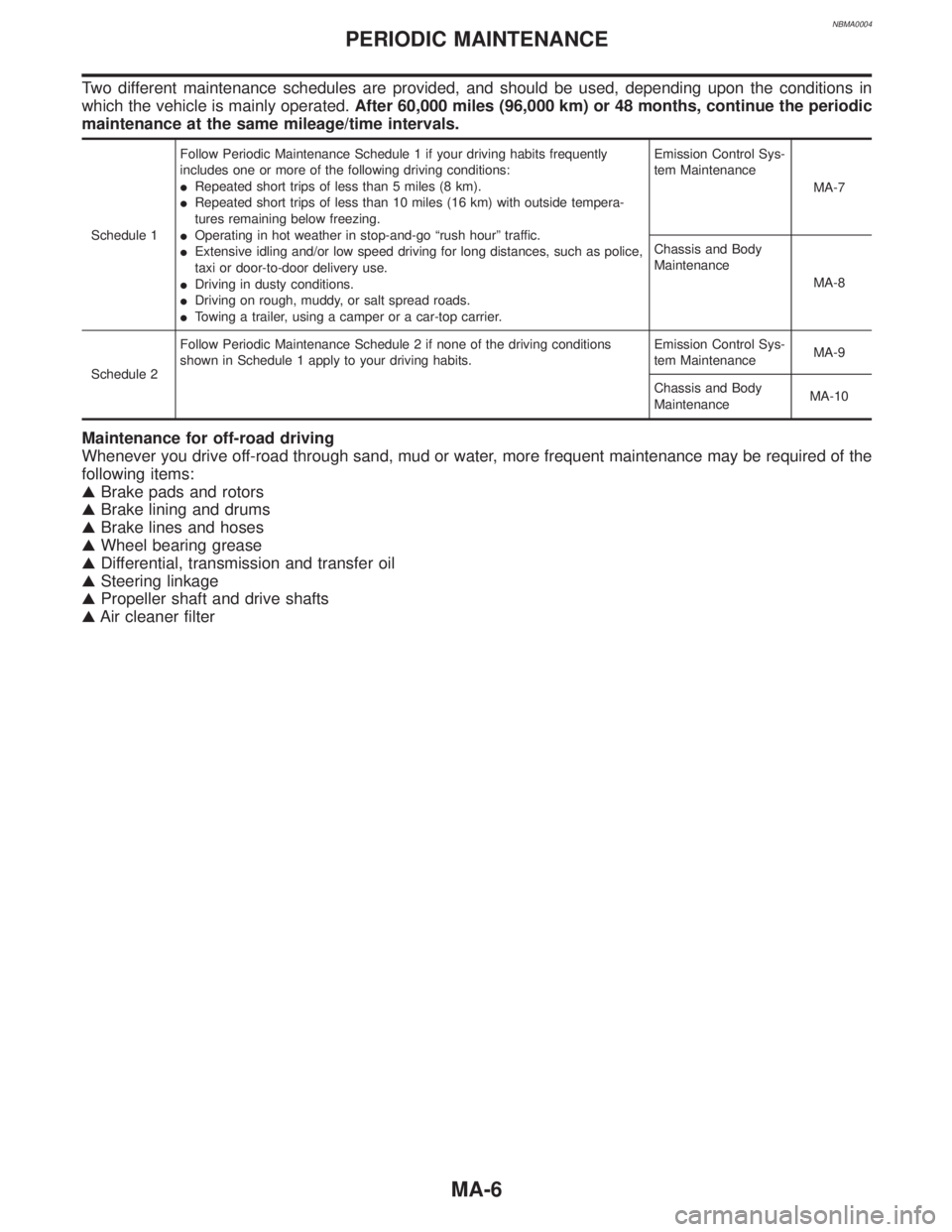

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated.After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently

includes one or more of the following driving conditions:

IRepeated short trips of less than 5 miles (8 km).

IRepeated short trips of less than 10 miles (16 km) with outside tempera-

tures remaining below freezing.

IOperating in hot weather in stop-and-go ªrush hourº traffic.

IExtensive idling and/or low speed driving for long distances, such as police,

taxi or door-to-door delivery use.

IDriving in dusty conditions.

IDriving on rough, muddy, or salt spread roads.

ITowing a trailer, using a camper or a car-top carrier.Emission Control Sys-

tem Maintenance

MA-7

Chassis and Body

Maintenance

MA-8

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions

shown in Schedule 1 apply to your driving habits.Emission Control Sys-

tem MaintenanceMA-9

Chassis and Body

MaintenanceMA-10

Maintenance for off-road driving

Whenever you drive off-road through sand, mud or water, more frequent maintenance may be required of the

following items:

GBrake pads and rotors

GBrake lining and drums

GBrake lines and hoses

GWheel bearing grease

GDifferential, transmission and transfer oil

GSteering linkage

GPropeller shaft and drive shafts

GAir cleaner filter

PERIODIC MAINTENANCE

MA-6

Page 2003 of 2395

CHASSIS AND BODY MAINTENANCENBMA0004S0102

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section

- Page or

- Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.5

(12)

611.25

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

2433.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Brake lines & cables I I I I MA-25

Brake pads, rotors, drums & linings I IIIIIIIMA-25, 26

Automatic transmission & all-mode

4WD transfer fluid & differential

gear oil (exc. LSD)NOTE (1) I I I I MA-21, 22, 23

LSD gear oil NOTE (1) I R I R MA-24

Steering gear, linkage & transfer

gear, axle & suspension partsIIIIIIIIMA-26

NOTE (6)

Tire rotation NOTE (2)MA-4

Drive shaft boots (

) IIIIIIIIAX-10, ªDrive

Shaftº

Propeller shaft NOTE (3) L LLLLLLLMA-23

Front wheel bearing grease (4x2) I I

Front wheel bearing

grease (

)NOTE (4) I R I RAX-4, ªFront

Wheel Bearingº

Exhaust system I IIIIIIIMA-21

Supplemental air bag systems NOTE (5)RS-14, ªMainte-

nance Itemsº

Ventilation air filter I RIRIRIRHA-159, ªVentila-

tion Air Filterº

ASCD vacuum hoses I I I IEL-237, ªASCD

ACTUATOR/

PUMP CHECKº

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fluid (A/T, all mode 4WD transfer)/differential gear oil (exc.

LSD) at every 30,000 miles (48,000 km) or 24 months, and change LSD gear oil every 15,000 miles (24,000 km) or 12 months.

(2) Refer to ªTire rotationº under the ªGENERAL MAINTENANCEº heading earlier in this section.

(3) The propeller shaft should be re-greased after being immersed in water.

(4) If operating frequently in water, replace grease every 3,750 miles (6,000 km) or 3 months.

(5) Inspect the air bag system 10 years after the date of manufacture noted on the FMVSS certification label.

(6) Refer to SU-5, ªFront Suspension Partsº and SU-16, ªRear Suspension Partsº, AX-3, ªFront Axle Partsº and AX-18, ªRear Axle Partsº.

PERIODIC MAINTENANCE

Schedule 1 (Cont'd)

MA-8

Page 2006 of 2395

NBMA0005

Fluids and LubricantsNBMA0005S01

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp measure Liter

Engine oilDrain and

refillWith oil filter 5-1/4 qt 4-3/8 qt 5.0

IAPI Certification Mark*1

IAPI grade SG/SH, Energy Conserv-

ingI&IIorAPIgrade SJ, Energy

Conserving*1

IILSAC grade GF-I & GF-II*1 Without oil

filter5-1/8 qt 4-1/4 qt 4.8

Dry engine

(Engine overhaul)7-1/4 qt 6 qt 6.8

Cooling system (With reservoir) 9-3/4 qt 8-1/8 qt 9.2Genuine Nissan anti-freeze coolant or

equivalent

All-mode 4WD transfer fluid 3-1/8 qt 2-5/8 qt 3.0Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*2

Differential

carrier gear

oilFront (4WD) 3-7/8 pt 3-1/4 pt 1.85Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear:

Use only LSD gear oil API GL-5 and

SAE 80W-90*5 approved for Nissan

LSD*6. Rear 5-7/8 pt 4-7/8 pt 2.8

Automatic transmission fluid2WD

9 qt 7-1/2 qt 8.5Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*3 4WD

Power steering fluid Ð Ð Ð Genuine NISSAN PSF II or equivalent*7

Brake fluid Ð Ð ÐGenuine Nissan Brake Fluid*4 or

equivalent DOT 3 (U.S. FMVSS No.

116)

Propeller shaft grease Ð Ð ÐNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Outside the continental United States and Alaska contact an authorized INFINITI dealership for more information regarding suitable

fluids, including recommended brand(s) of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: DEXRONTMIII/MERCONTMor equivalent may also be used. Outside the continental United States and Alaska contact an autho-

rized INFINITI dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTMIII/MERCONTM

Automatic Transmission Fluid.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF).

*6: Contact an INFINITI dealer for a list of approved oils.

*7: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, DEXRON

TMIII/MERCONTMor equivalent ATF may also be

used.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-11

Page 2011 of 2395

steps 4 through 8 until coolant level no longer drops.

IClean excess coolant from engine.

ÐFLUSHING COOLING SYSTEMÐNBMA0011S031. Open air relief plug.

2. Fill radiator with water until water spills from the air relief holes,

then close air relief plugs. Fill radiator and reservoir tank with

water and reinstall radiator cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from

radiator.

SMA803A

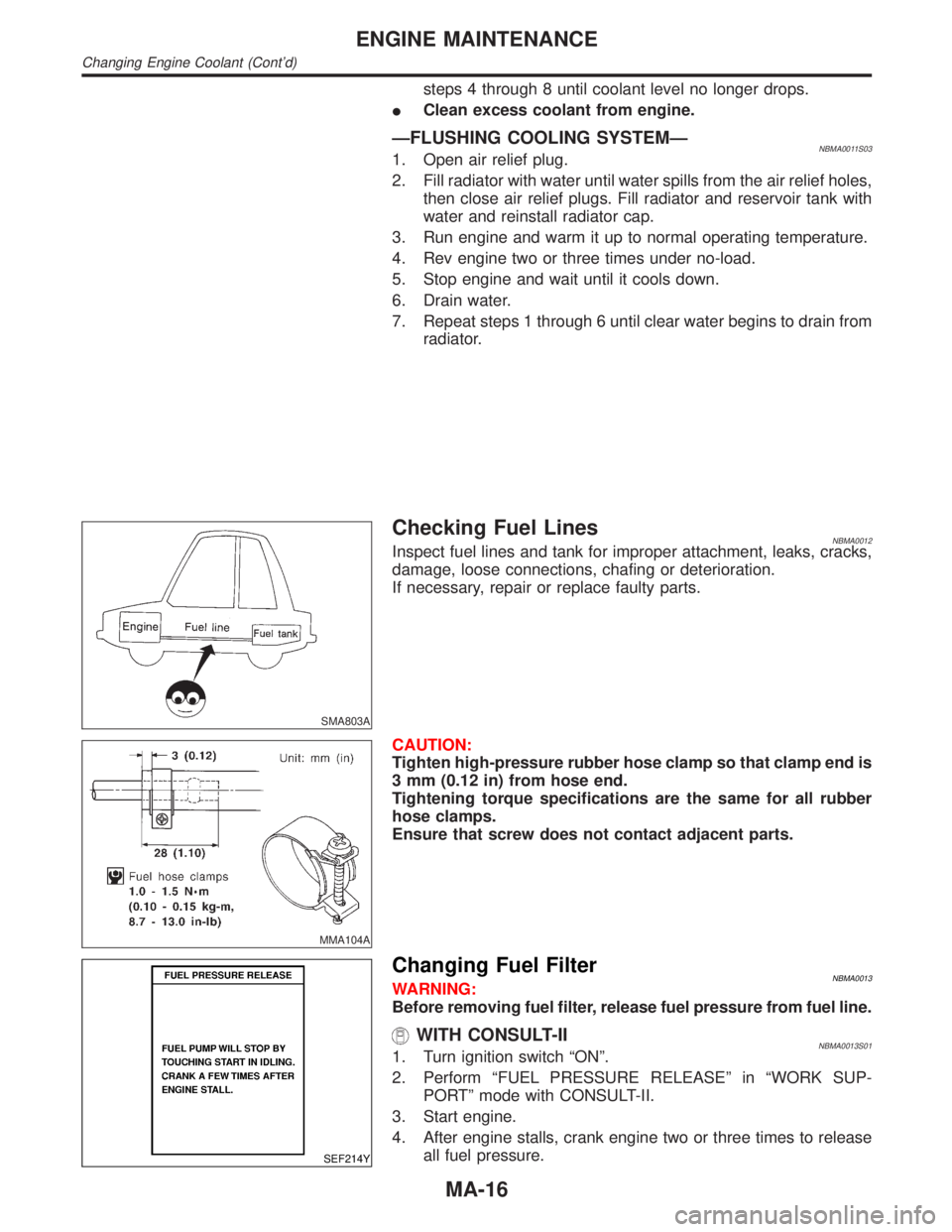

Checking Fuel LinesNBMA0012Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

SEF214Y

Changing Fuel FilterNBMA0013WARNING:

Before removing fuel filter, release fuel pressure from fuel line.

WITH CONSULT-IINBMA0013S011. Turn ignition switch ªONº.

2. Perform ªFUEL PRESSURE RELEASEº in ªWORK SUP-

PORTº mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank engine two or three times to release

all fuel pressure.

ENGINE MAINTENANCE

Changing Engine Coolant (Cont'd)

MA-16

Page 2013 of 2395

SMA096D

Changing Engine OilNBMA0015WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait for more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity

IAPI grade SG or SH, Energy ConservingI&IIorAPIgrade

SJ, Energy Conserving

IAPI Certification Mark

IILSAC grade GF-I & GF-II

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº, MA-11.

Oil capacity (Approximately):

Unit:(US qt, Imp qt)

Drain and refillWith oil filter change 5.0 (5-1/4, 4-3/8)

Without oil filter change 4.8 (5-1/8, 4-1/4)

Dry engine (engine overhaul) 6.8 (7-1/4, 6)

CAUTION:

IBe sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

JMA122D

5. Warm up engine and check area around drain plug and oil fil-

ter for oil leakage.

6. Stop engine and wait for more than 10 minutes.

7. Check oil level.

SMA097D

Changing Oil FilterNBMA00161. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

The filter is a full-flow cartridge type and is provided with a relief

valve.

Refer to LC-7, ªOil Filterº.

ENGINE MAINTENANCE

Changing Engine Oil

MA-18

Page 2014 of 2395

SMA010

2. Clean oil filter mounting surface on cylinder block. Coat rubber

seal of new oil filter with engine oil.

SMA702C

3. Screw in the oil filter until a slight resistance is felt, then tighten

an additional 2/3 turn.

4. Add engine oil.

Refer to MA-18, ªChanging Engine Oilº.

IClean excess oil from engine.

SMA098D

Changing Spark PlugsNBMA00171. Remove engine cover.

2. Remove throttle wires.

3. Remove air duct with air cleaner assembly.

4. Disconnect harness connectors and harness brackets around

ignition coil sides.

5. Remove throttle body. (Only when removing the No. 4 cylinder

spark plug)

6. Disconnect ignition coil harness connectors.

7. Loosen ignition coil fixing bolts and pull out coil from intake

manifold connector.

Ignition coil:

: 8.5 - 10.7 N´m (0.86 - 1.1 kg-m, 75 - 95 in-lb)

SEM294A

8. Check type and gap of new spark plug.

Spark plug type:

Symbol Make

Standard type PLFR5A-11 NGK

Cold type PLFR6A-11 NGK

Hot type PLFR4A-11 NGK

Gap (Nominal): 1.1 mm (0.043 in)

Spark plug:

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE MAINTENANCE

Changing Oil Filter (Cont'd)

MA-19