INFINITI QX4 2001 Factory Service Manual

QX4 2001

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57027/w960_57027-0.png

INFINITI QX4 2001 Factory Service Manual

Trending: radio antenna, wheel bolt torque, trailer, battery capacity, weight, battery replacement, Bleed

Page 301 of 2395

SAT935A

c. While pushing detent spring down, remove manual plate and

parking rod from transmission case.

SAT043B

d. Remove manual shaft from transmission case.

SAT934A

e. Remove spacer and detent spring from transmission case.

SAT044B

f. Remove oil seal from transmission case.

DISASSEMBLY

AT-296

Page 302 of 2395

Oil Pump

COMPONENTSNBAT0112

SAT648AB

SAT649A

DISASSEMBLYNBAT01131. Loosen bolts in numerical order and remove oil pump cover.

SAT650A

2. Remove rotor, vane rings and vanes.

IInscribe a mark on back of rotor for identification of fore-

aft direction when reassembling rotor. Then remove rotor.

SAT651A

3. While pushing on cam ring remove pivot pin.

IBe careful not to scratch oil pump housing.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Oil Pump

AT-297

Page 303 of 2395

SAT652A

4. While holding cam ring and spring lift out cam ring spring.

IBe careful not to damage oil pump housing.

IHold cam ring spring to prevent it from jumping.

SAT653A

5. Remove cam ring and cam ring spring from oil pump housing.

SAT654A

6. Remove pivot pin from control piston and remove control pis-

ton assembly.

SAT655A

7. Remove oil seal from oil pump housing.

IBe careful not to scratch oil pump housing.

SAT656A

INSPECTIONNBAT0114Oil Pump Cover, Rotor, Vanes, Control Piston, Side

Seals, Cam Ring and Friction Ring

NBAT0114S01ICheck for wear or damage.

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-298

Page 304 of 2395

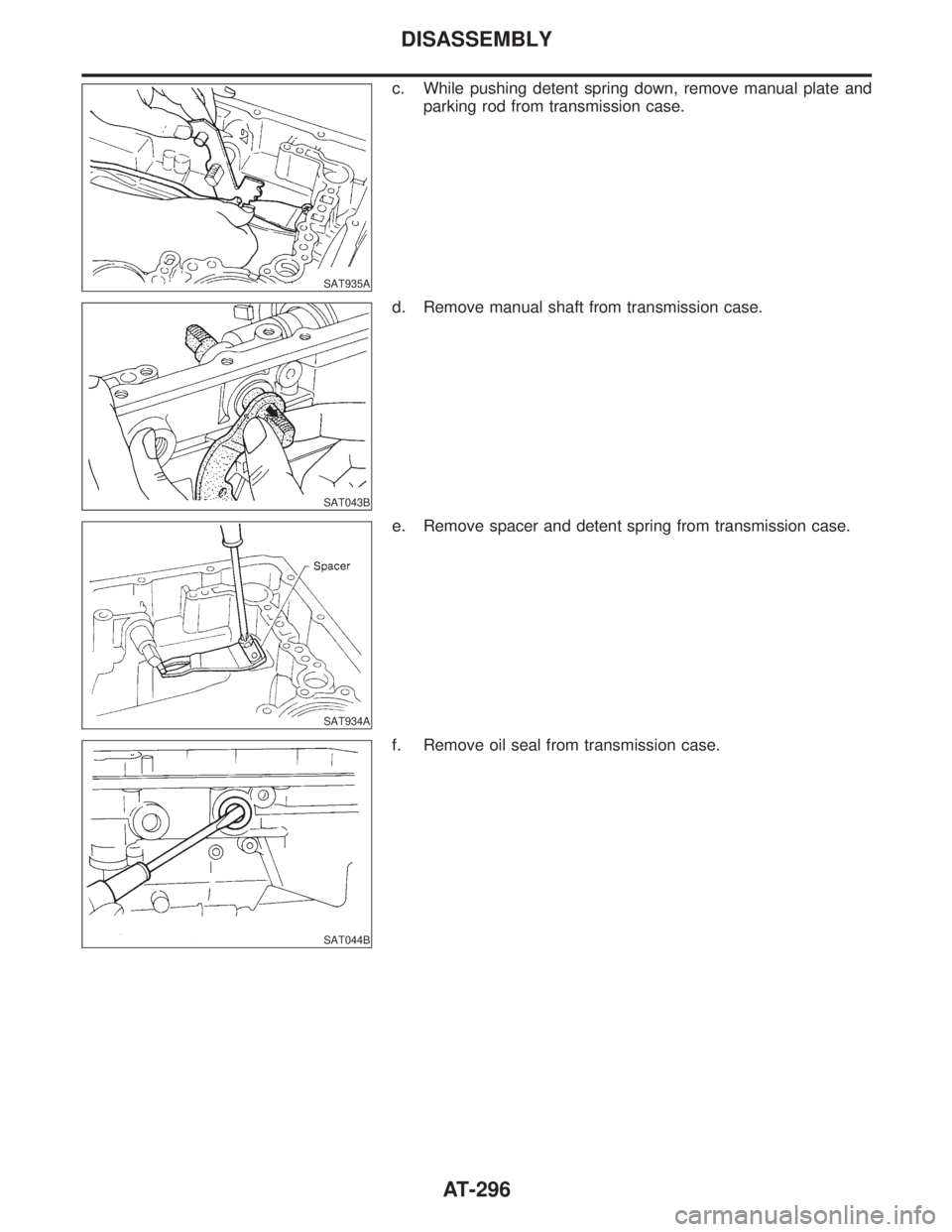

SAT657A

SAT658A

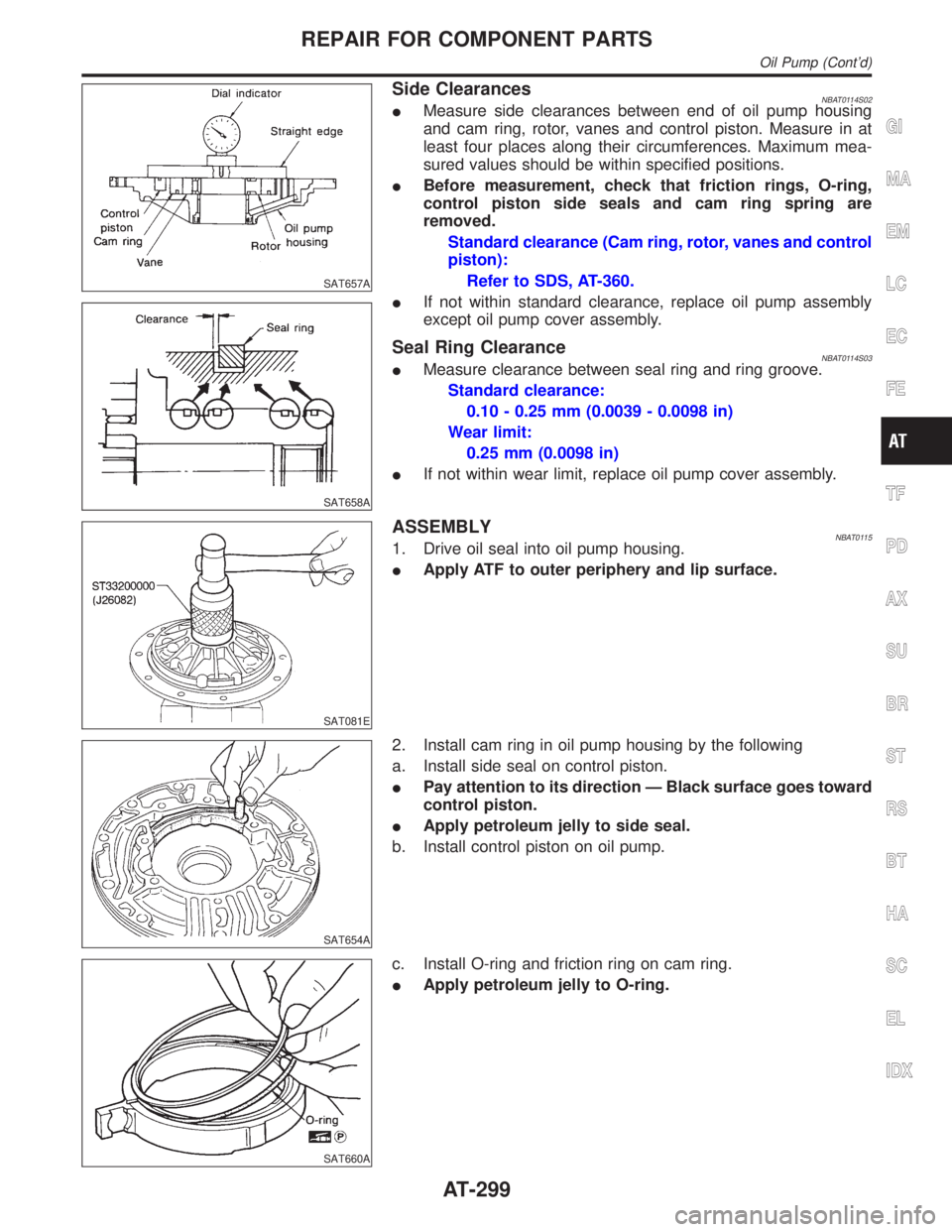

Side ClearancesNBAT0114S02IMeasure side clearances between end of oil pump housing

and cam ring, rotor, vanes and control piston. Measure in at

least four places along their circumferences. Maximum mea-

sured values should be within specified positions.

IBefore measurement, check that friction rings, O-ring,

control piston side seals and cam ring spring are

removed.

Standard clearance (Cam ring, rotor, vanes and control

piston):

Refer to SDS, AT-360.

IIf not within standard clearance, replace oil pump assembly

except oil pump cover assembly.

Seal Ring ClearanceNBAT0114S03IMeasure clearance between seal ring and ring groove.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Wear limit:

0.25 mm (0.0098 in)

IIf not within wear limit, replace oil pump cover assembly.

SAT081E

ASSEMBLYNBAT01151. Drive oil seal into oil pump housing.

IApply ATF to outer periphery and lip surface.

SAT654A

2. Install cam ring in oil pump housing by the following

a. Install side seal on control piston.

IPay attention to its direction Ð Black surface goes toward

control piston.

IApply petroleum jelly to side seal.

b. Install control piston on oil pump.

SAT660A

c. Install O-ring and friction ring on cam ring.

IApply petroleum jelly to O-ring.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-299

Page 305 of 2395

SAT661A

d. Assemble cam ring, cam ring spring and spring seat. Install

spring by pushing it against pump housing.

SAT651A

e. While pushing on cam ring install pivot pin.

SAT662A

3. Install rotor, vanes and vane rings.

IPay attention to direction of rotor.

SAT649A

4. Install oil pump housing and oil pump cover.

a. Wrap masking tape around splines of oil pump cover assem-

bly to protect seal. Position oil pump cover assembly in oil

pump housing assembly, then remove masking tape.

b. Tighten bolts in a criss-cross pattern.

SAT663A

5. Install new seal rings carefully after packing ring grooves with

petroleum jelly. Press rings down into jelly to a close fit.

ISeal rings come in two different diameters. Check fit care-

fully in each groove.

Small dia. seal ring:

No mark

Large dia. seal ring:

Yellow mark in area shown by arrow

IDo not spread gap of seal ring excessively while install-

ing. It may deform ring.

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-300

Page 306 of 2395

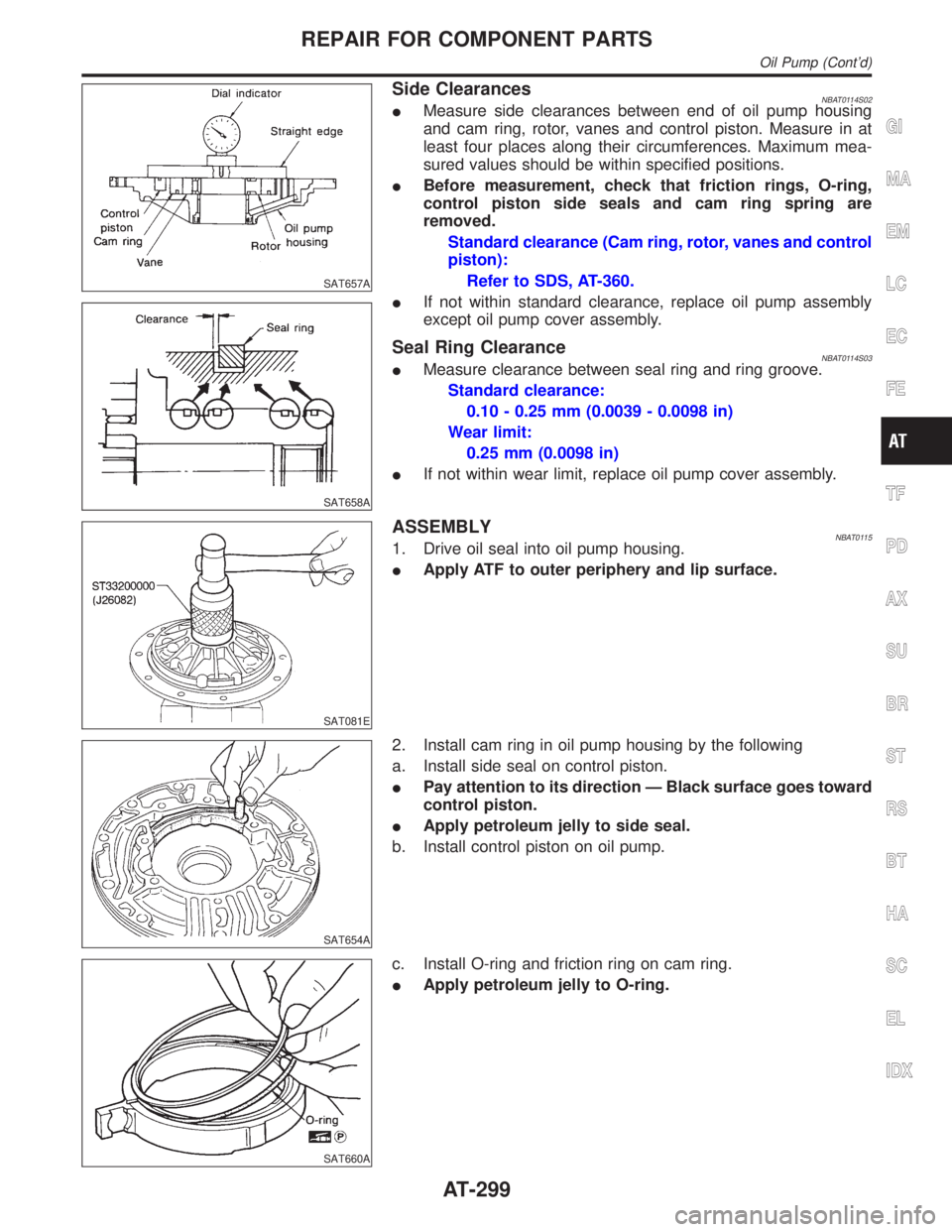

Control Valve Assembly

COMPONENTSNBAT0116

SAT156K

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly

AT-301

Page 307 of 2395

SAT194B

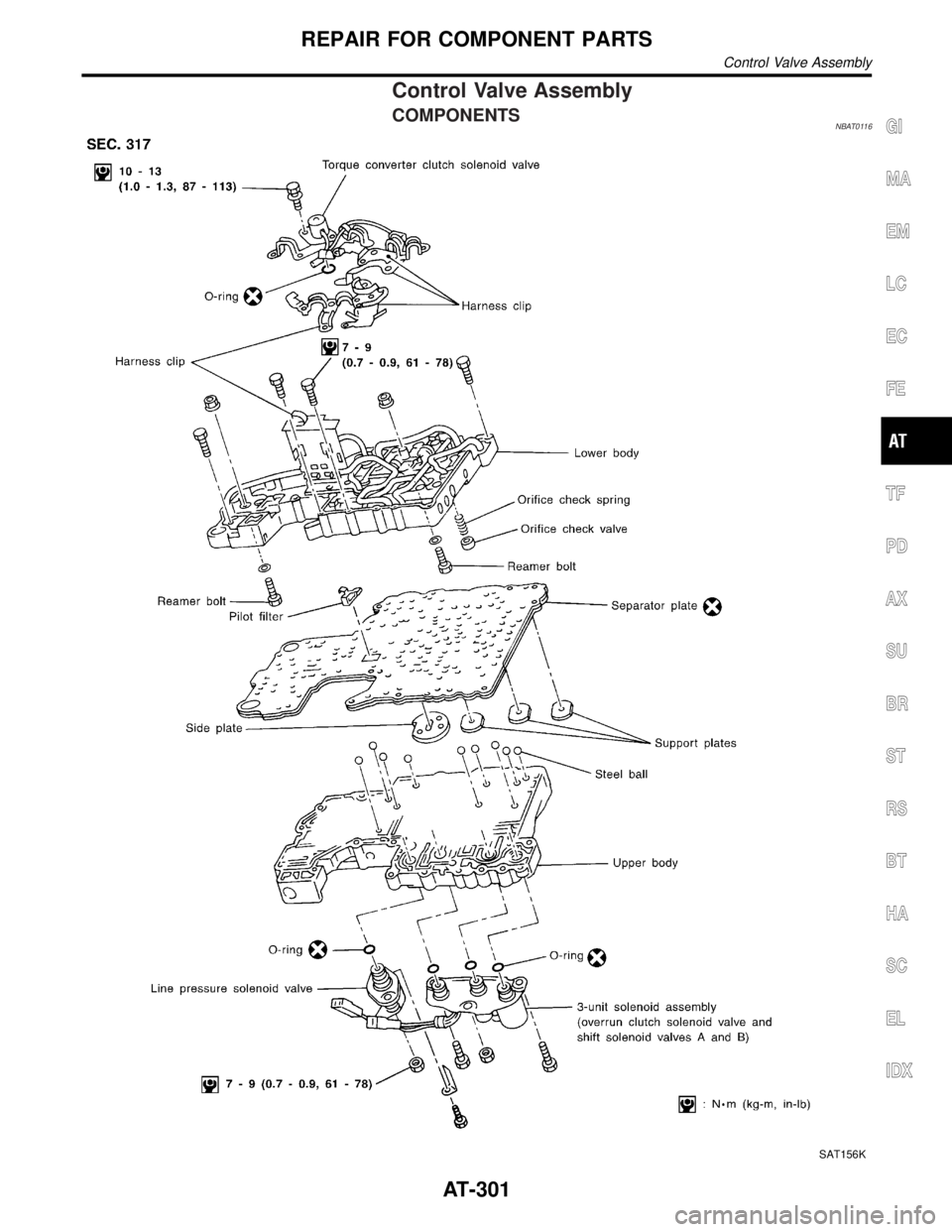

DISASSEMBLYNBAT01171. Remove solenoids.

a. Remove torque converter clutch solenoid valve and side plate

from lower body.

b. Remove O-ring from solenoid.

SAT667A

c. Remove line pressure solenoid valve from upper body.

d. Remove O-ring from solenoid.

SAT043G

e. Remove 3-unit solenoid assembly from upper body.

f. Remove O-rings from solenoids.

SAT195B

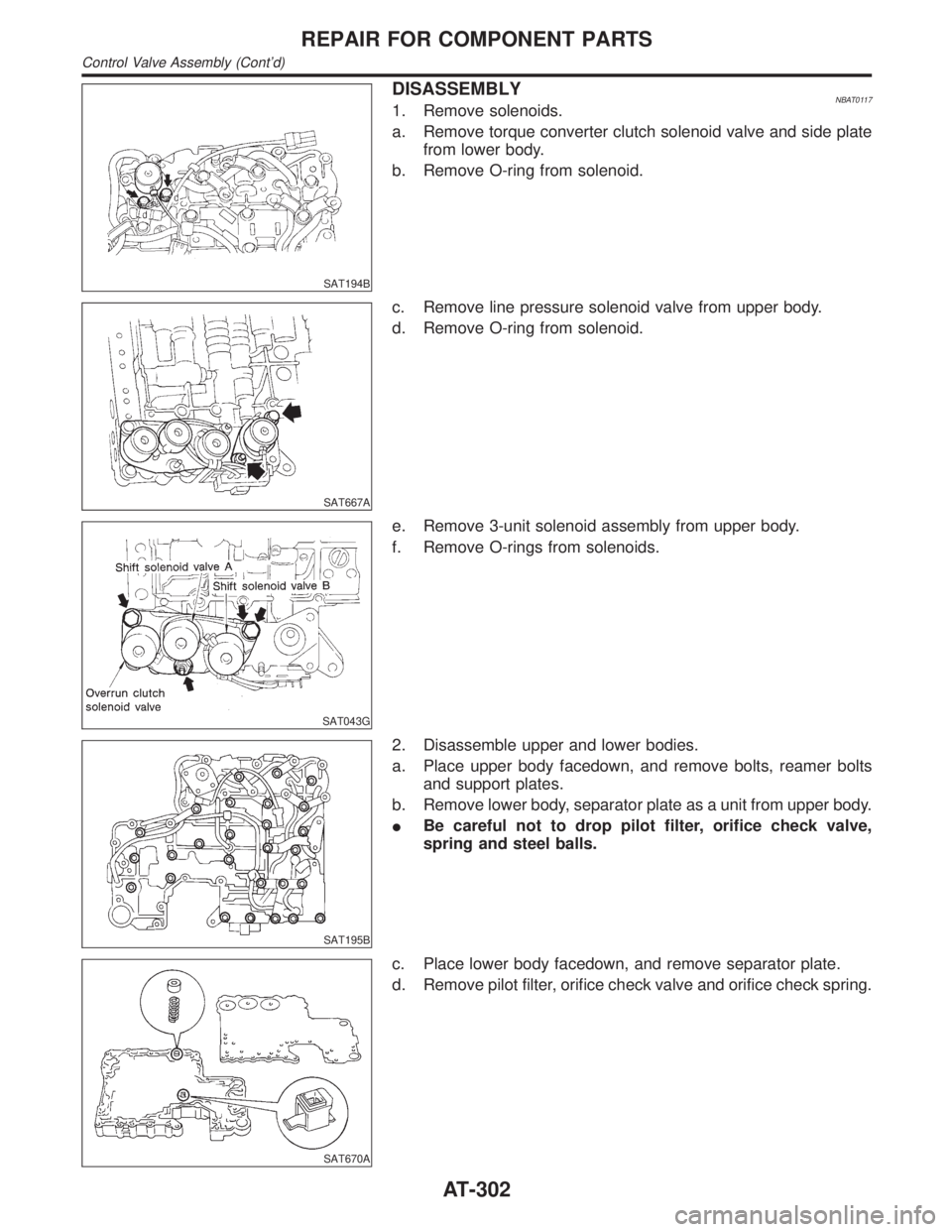

2. Disassemble upper and lower bodies.

a. Place upper body facedown, and remove bolts, reamer bolts

and support plates.

b. Remove lower body, separator plate as a unit from upper body.

IBe careful not to drop pilot filter, orifice check valve,

spring and steel balls.

SAT670A

c. Place lower body facedown, and remove separator plate.

d. Remove pilot filter, orifice check valve and orifice check spring.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-302

Page 308 of 2395

SAT671A

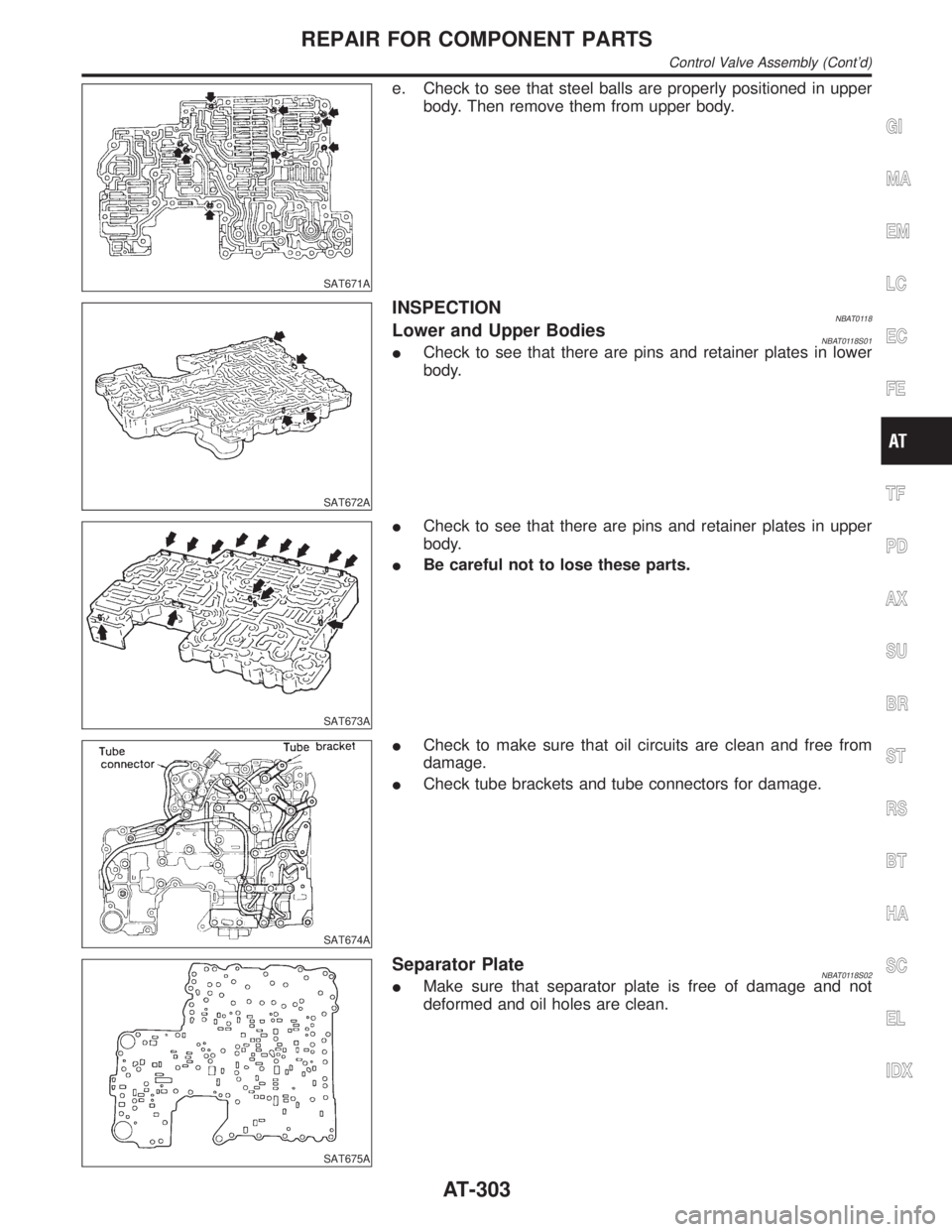

e. Check to see that steel balls are properly positioned in upper

body. Then remove them from upper body.

SAT672A

INSPECTIONNBAT0118Lower and Upper BodiesNBAT0118S01ICheck to see that there are pins and retainer plates in lower

body.

SAT673A

ICheck to see that there are pins and retainer plates in upper

body.

IBe careful not to lose these parts.

SAT674A

ICheck to make sure that oil circuits are clean and free from

damage.

ICheck tube brackets and tube connectors for damage.

SAT675A

Separator PlateNBAT0118S02IMake sure that separator plate is free of damage and not

deformed and oil holes are clean.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-303

Page 309 of 2395

SAT676A

Pilot FilterNBAT0118S03ICheck to make sure that filter is not clogged or damaged.

SAT149G

Torque Converter Clutch Solenoid ValveNBAT0118S04ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-152.

Line Pressure Solenoid ValveNBAT0118S05ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-167.

SAT095B

3-Unit Solenoid Assembly (Overrun Clutch Solenoid

Valve and Shift Solenoid Valves A and B)

NBAT0118S06IMeasure resistance of each solenoid. Refer to ªComponent

Inspectionº, AT-171, AT-175 and AT-189.

SAT096BA

A/T Fluid Temperature Sensor and SwitchNBAT0118S07IMeasure resistance. Refer to ªComponent Inspectionº, AT-110

and AT-264.

SAT671A

ASSEMBLYNBAT01191. Install upper and lower bodies.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-304

Page 310 of 2395

SAT681A

b. Install reamer bolts from bottom of upper body.

SAT682A

c. Place oil circuit of lower body face up. Install orifice check

spring, orifice check valve and pilot filter.

SAT197B

d. Install lower separator plate on lower body.

e. Install and temporarily tighten support plates, A/T fluid tem-

perature sensor and tube brackets.

SAT198B

f. Temporarily assemble lower and upper bodies, using reamer

bolt as a guide.

IBe careful not to dislocate or drop steel balls, orifice

check spring, orifice check valve and pilot filter.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-305

Trending: trunk, coolant temperature, transmission fluid, Oil sensor plug, maintenance schedule, gas type, P0171