transmission INFINITI QX56 2007 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 348 of 3061

AT-278

< SERVICE INFORMATION >

ASSEMBLY

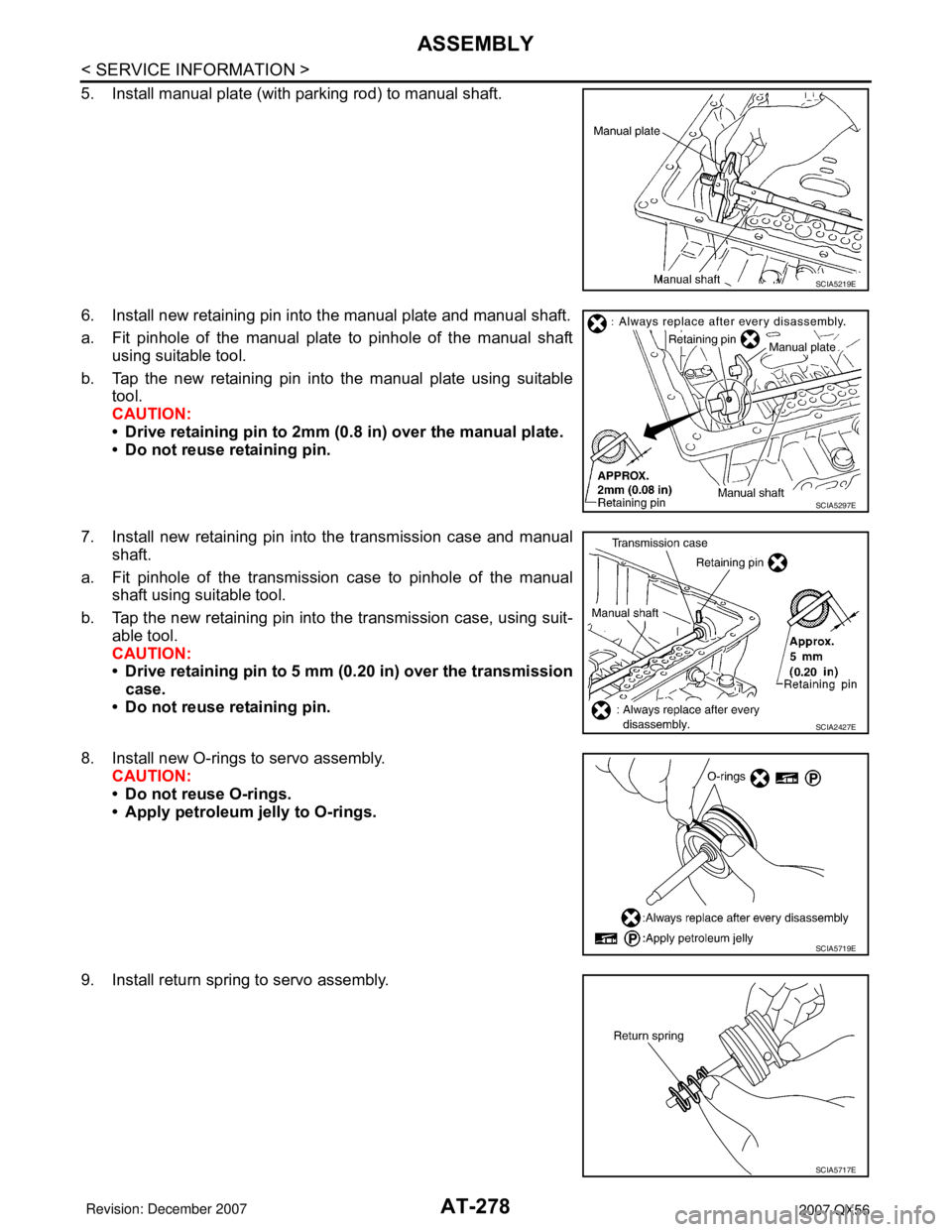

5. Install manual plate (with parking rod) to manual shaft.

6. Install new retaining pin into the manual plate and manual shaft.

a. Fit pinhole of the manual plate to pinhole of the manual shaft

using suitable tool.

b. Tap the new retaining pin into the manual plate using suitable

tool.

CAUTION:

• Drive retaining pin to 2mm (0.8 in) over the manual plate.

• Do not reuse retaining pin.

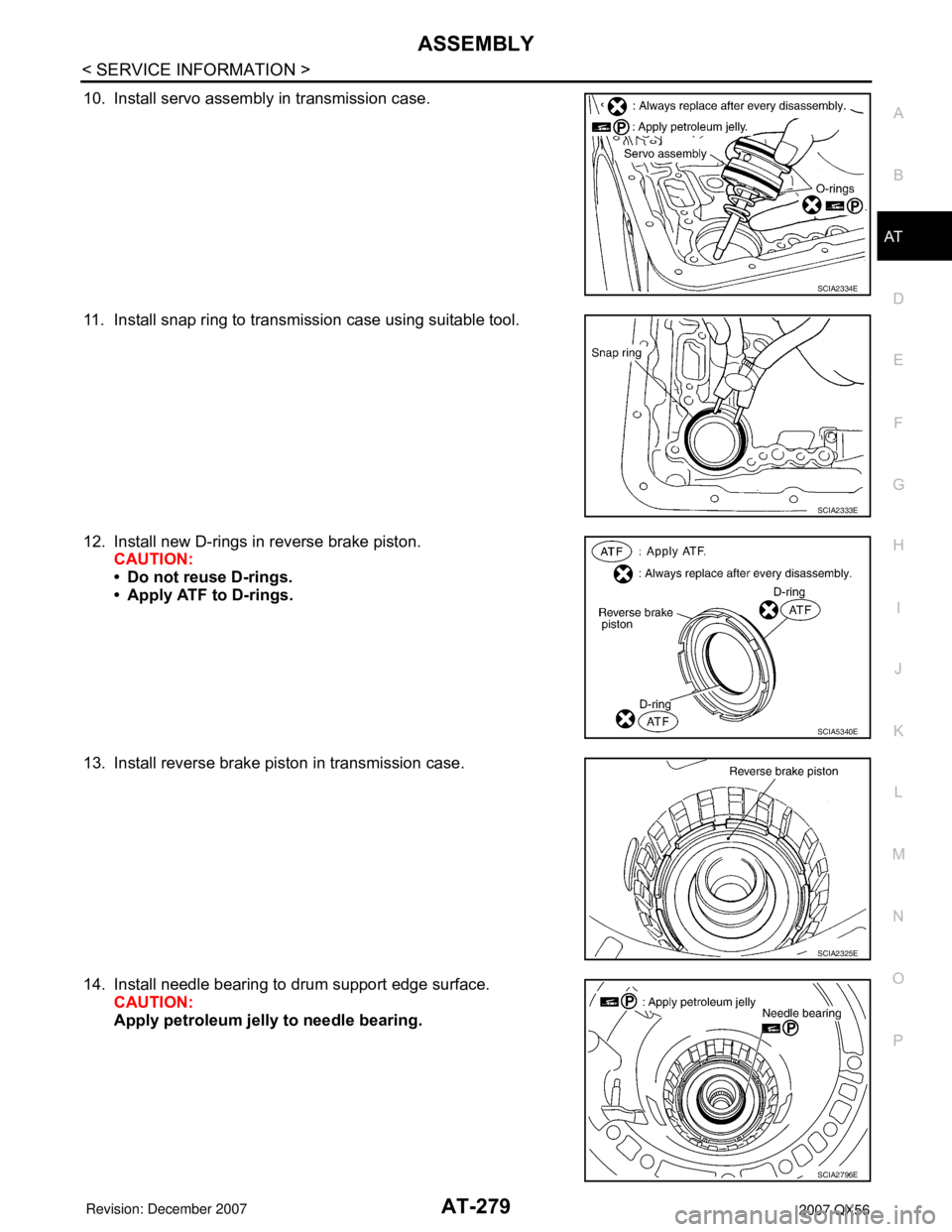

7. Install new retaining pin into the transmission case and manual

shaft.

a. Fit pinhole of the transmission case to pinhole of the manual

shaft using suitable tool.

b. Tap the new retaining pin into the transmission case, using suit-

able tool.

CAUTION:

• Drive retaining pin to 5 mm (0.20 in) over the transmission

case.

• Do not reuse retaining pin.

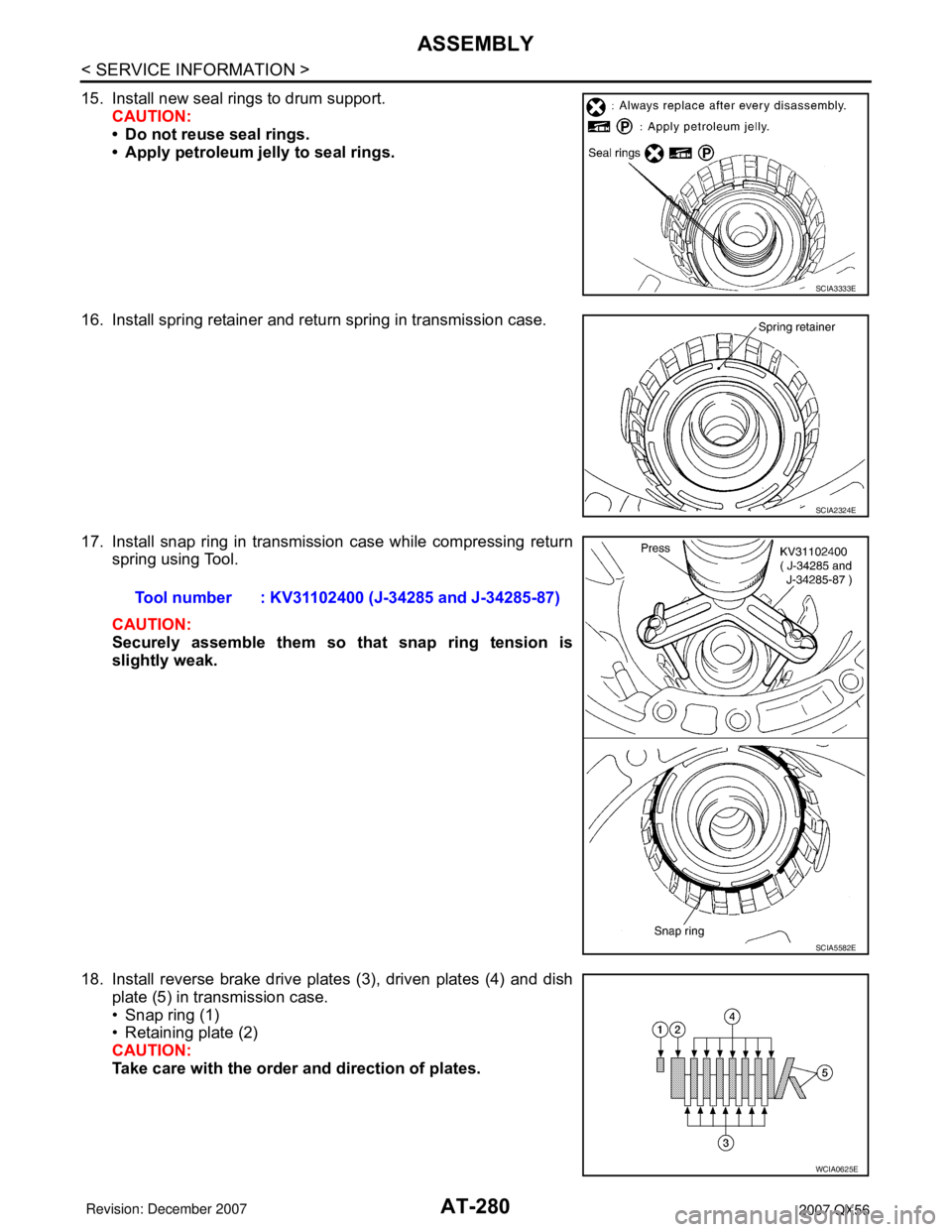

8. Install new O-rings to servo assembly.

CAUTION:

• Do not reuse O-rings.

• Apply petroleum jelly to O-rings.

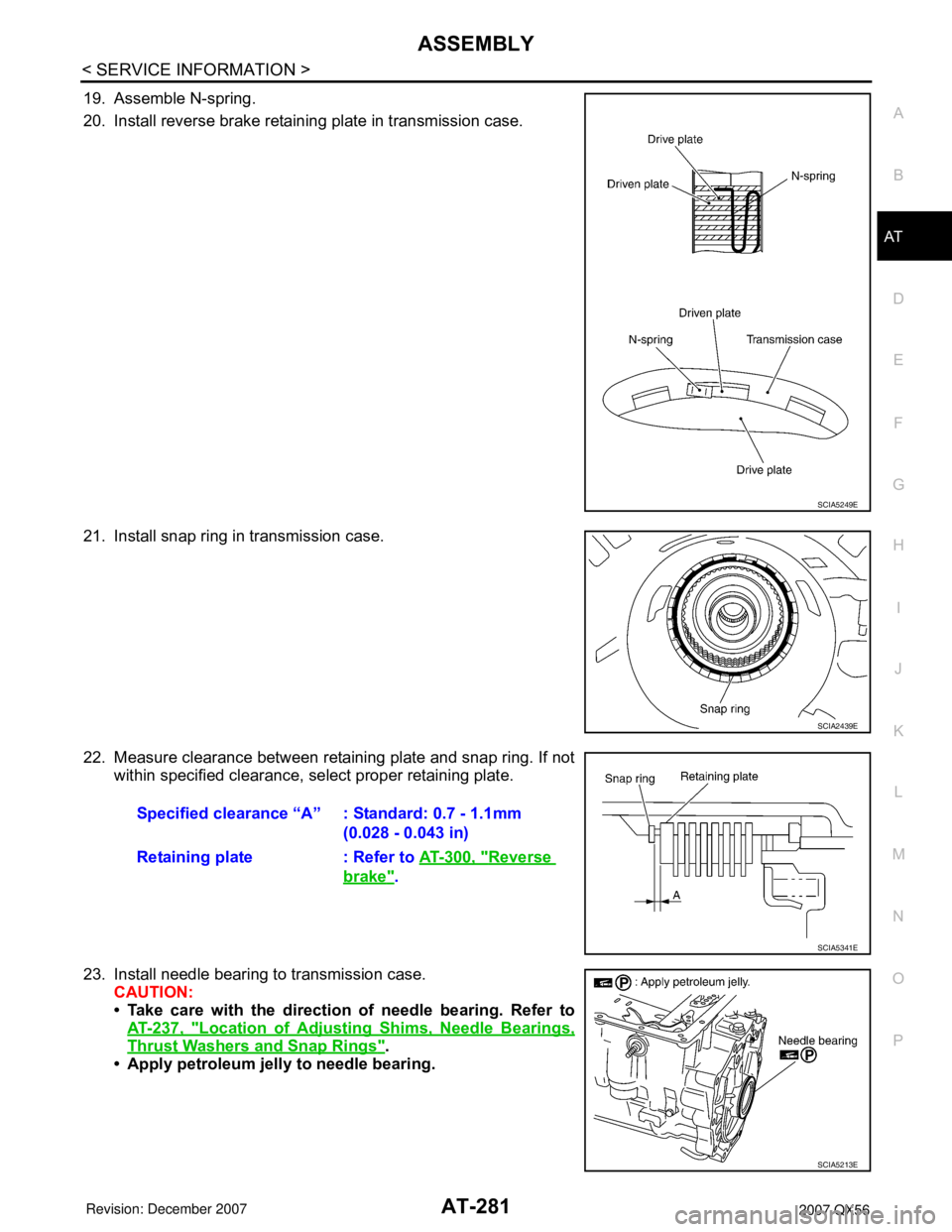

9. Install return spring to servo assembly.

SCIA5219E

SCIA5297E

SCIA2427E

SCIA5719E

SCIA5717E

Page 349 of 3061

ASSEMBLY

AT-279

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

10. Install servo assembly in transmission case.

11. Install snap ring to transmission case using suitable tool.

12. Install new D-rings in reverse brake piston.

CAUTION:

• Do not reuse D-rings.

• Apply ATF to D-rings.

13. Install reverse brake piston in transmission case.

14. Install needle bearing to drum support edge surface.

CAUTION:

Apply petroleum jelly to needle bearing.

SCIA2334E

SCIA2333E

SCIA5340E

SCIA2325E

SCIA2796E

Page 350 of 3061

AT-280

< SERVICE INFORMATION >

ASSEMBLY

15. Install new seal rings to drum support.

CAUTION:

• Do not reuse seal rings.

• Apply petroleum jelly to seal rings.

16. Install spring retainer and return spring in transmission case.

17. Install snap ring in transmission case while compressing return

spring using Tool.

CAUTION:

Securely assemble them so that snap ring tension is

slightly weak.

18. Install reverse brake drive plates (3), driven plates (4) and dish

plate (5) in transmission case.

• Snap ring (1)

• Retaining plate (2)

CAUTION:

Take care with the order and direction of plates.

SCIA3333E

SCIA2324E

Tool number : KV31102400 (J-34285 and J-34285-87)

SCIA5582E

WCIA0625E

Page 351 of 3061

ASSEMBLY

AT-281

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

19. Assemble N-spring.

20. Install reverse brake retaining plate in transmission case.

21. Install snap ring in transmission case.

22. Measure clearance between retaining plate and snap ring. If not

within specified clearance, select proper retaining plate.

23. Install needle bearing to transmission case.

CAUTION:

• Take care with the direction of needle bearing. Refer to

AT-237, "

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

• Apply petroleum jelly to needle bearing.

SCIA5249E

SCIA2439E

Specified clearance “A” : Standard: 0.7 - 1.1mm

(0.028 - 0.043 in)

Retaining plate : Refer to AT-300, "

Reverse

brake".

SCIA5341E

SCIA5213E

Page 352 of 3061

AT-282

< SERVICE INFORMATION >

ASSEMBLY

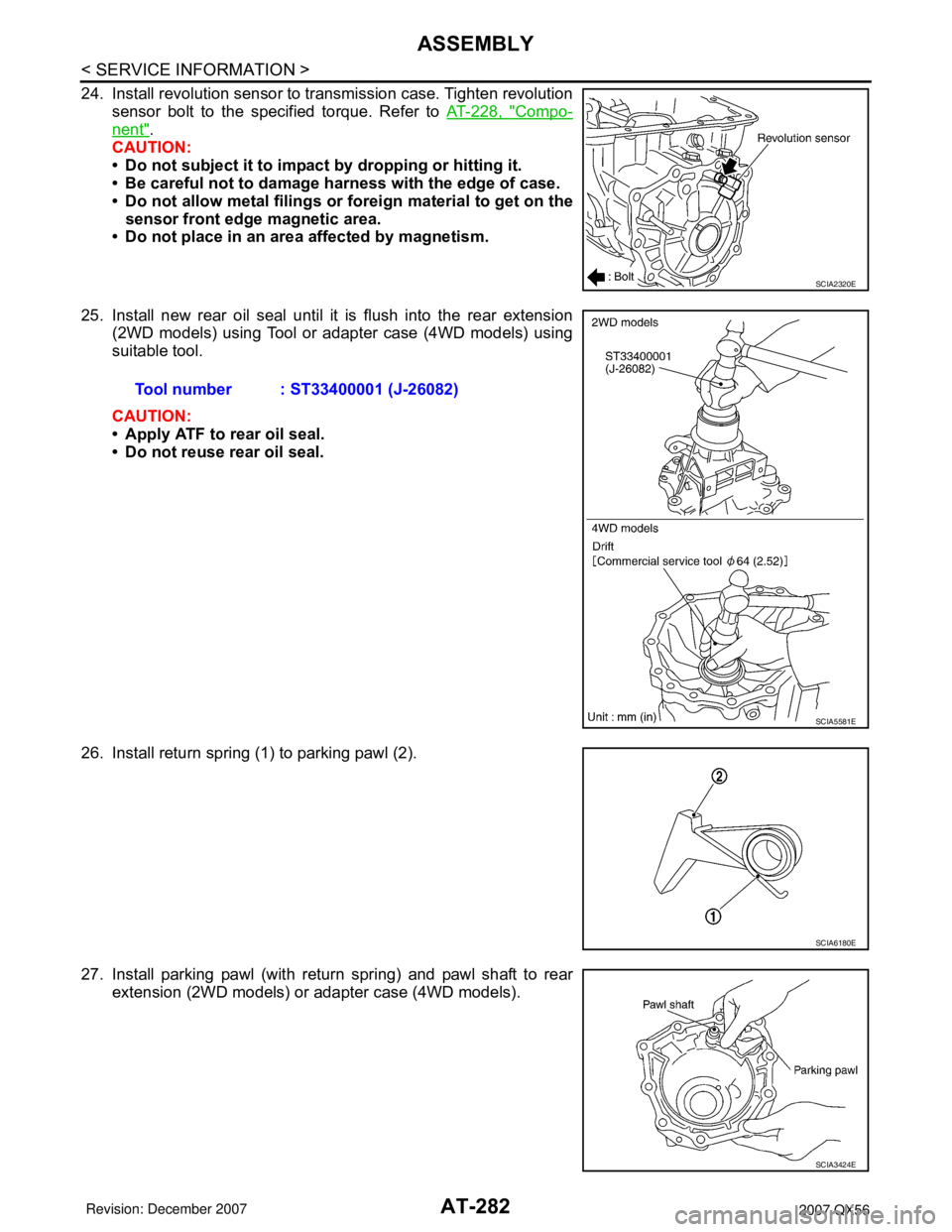

24. Install revolution sensor to transmission case. Tighten revolution

sensor bolt to the specified torque. Refer to AT-228, "

Compo-

nent".

CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Be careful not to damage harness with the edge of case.

• Do not allow metal filings or foreign material to get on the

sensor front edge magnetic area.

• Do not place in an area affected by magnetism.

25. Install new rear oil seal until it is flush into the rear extension

(2WD models) using Tool or adapter case (4WD models) using

suitable tool.

CAUTION:

• Apply ATF to rear oil seal.

• Do not reuse rear oil seal.

26. Install return spring (1) to parking pawl (2).

27. Install parking pawl (with return spring) and pawl shaft to rear

extension (2WD models) or adapter case (4WD models).

SCIA2320E

Tool number : ST33400001 (J-26082)

SCIA5581E

SCIA6180E

SCIA3424E

Page 353 of 3061

ASSEMBLY

AT-283

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

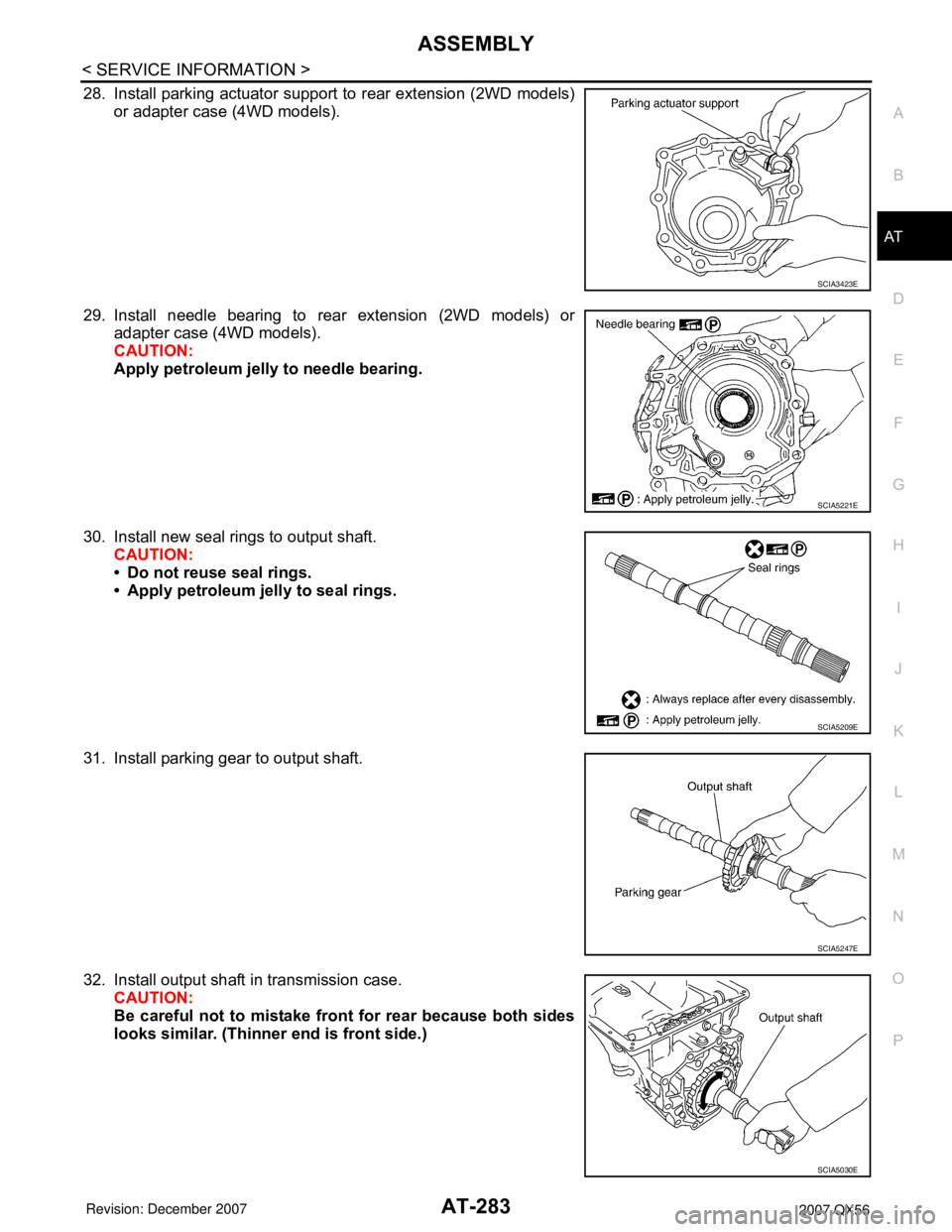

28. Install parking actuator support to rear extension (2WD models)

or adapter case (4WD models).

29. Install needle bearing to rear extension (2WD models) or

adapter case (4WD models).

CAUTION:

Apply petroleum jelly to needle bearing.

30. Install new seal rings to output shaft.

CAUTION:

• Do not reuse seal rings.

• Apply petroleum jelly to seal rings.

31. Install parking gear to output shaft.

32. Install output shaft in transmission case.

CAUTION:

Be careful not to mistake front for rear because both sides

looks similar. (Thinner end is front side.)

SCIA3423E

SCIA5221E

SCIA5209E

SCIA5247E

SCIA5030E

Page 354 of 3061

AT-284

< SERVICE INFORMATION >

ASSEMBLY

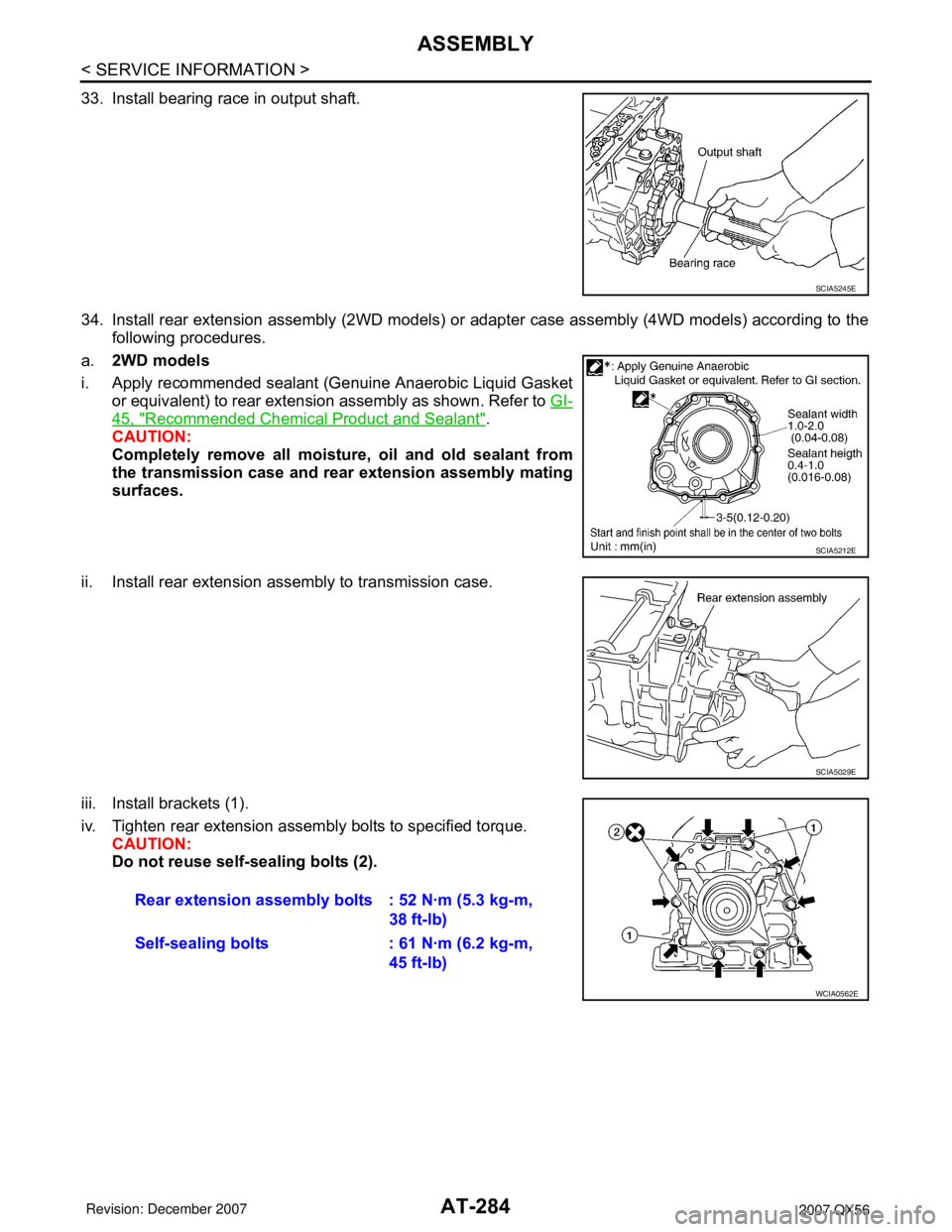

33. Install bearing race in output shaft.

34. Install rear extension assembly (2WD models) or adapter case assembly (4WD models) according to the

following procedures.

a.2WD models

i. Apply recommended sealant (Genuine Anaerobic Liquid Gasket

or equivalent) to rear extension assembly as shown. Refer to GI-

45, "Recommended Chemical Product and Sealant".

CAUTION:

Completely remove all moisture, oil and old sealant from

the transmission case and rear extension assembly mating

surfaces.

ii. Install rear extension assembly to transmission case.

iii. Install brackets (1).

iv. Tighten rear extension assembly bolts to specified torque.

CAUTION:

Do not reuse self-sealing bolts (2).

SCIA5245E

SCIA5212E

SCIA5029E

Rear extension assembly bolts : 52 N·m (5.3 kg-m,

38 ft-lb)

Self-sealing bolts : 61 N·m (6.2 kg-m,

45 ft-lb)

WCIA0562E

Page 355 of 3061

ASSEMBLY

AT-285

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

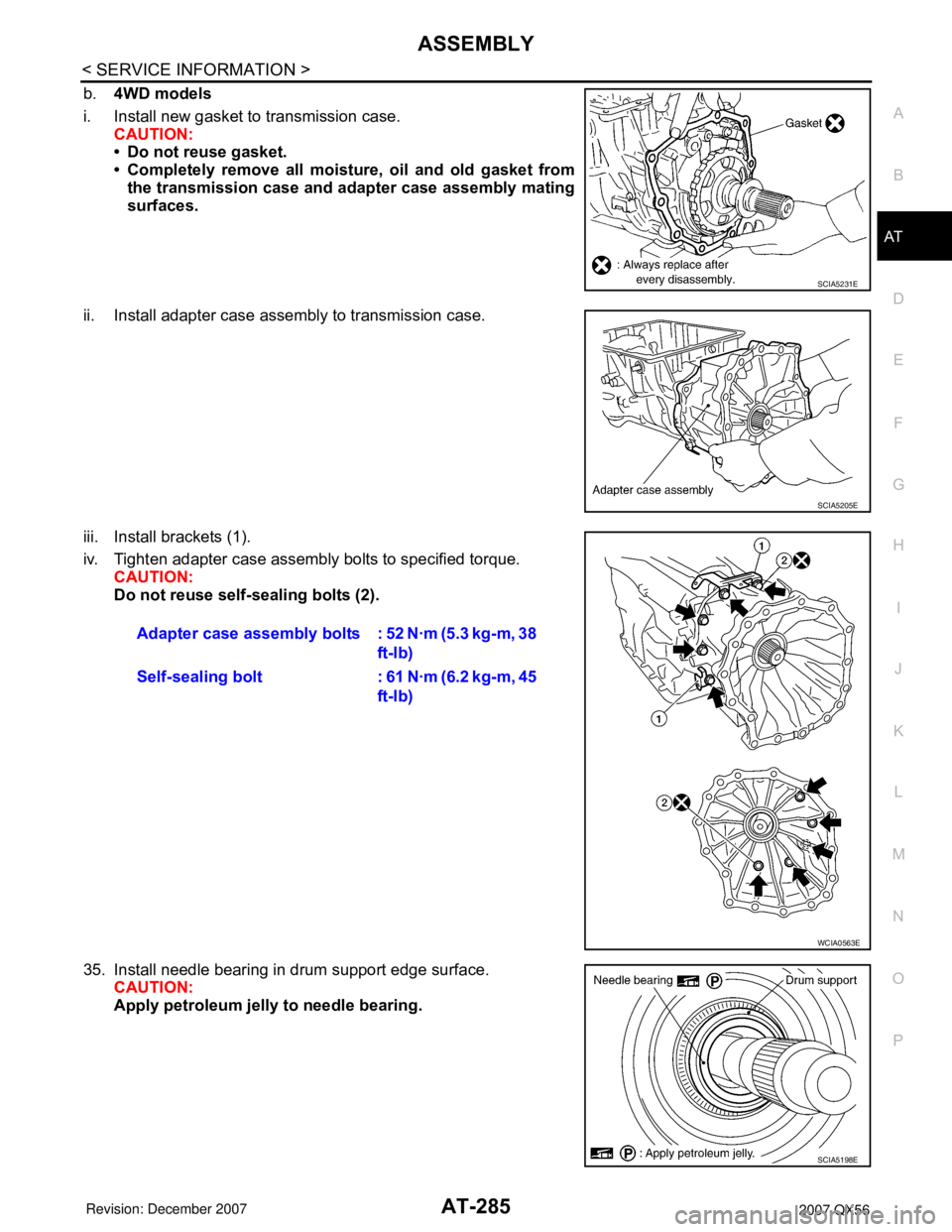

b.4WD models

i. Install new gasket to transmission case.

CAUTION:

• Do not reuse gasket.

• Completely remove all moisture, oil and old gasket from

the transmission case and adapter case assembly mating

surfaces.

ii. Install adapter case assembly to transmission case.

iii. Install brackets (1).

iv. Tighten adapter case assembly bolts to specified torque.

CAUTION:

Do not reuse self-sealing bolts (2).

35. Install needle bearing in drum support edge surface.

CAUTION:

Apply petroleum jelly to needle bearing.

SCIA5231E

SCIA5205E

Adapter case assembly bolts : 52 N·m (5.3 kg-m, 38

ft-lb)

Self-sealing bolt : 61 N·m (6.2 kg-m, 45

ft-lb)

WCIA0563E

SCIA5198E

Page 359 of 3061

ASSEMBLY

AT-289

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

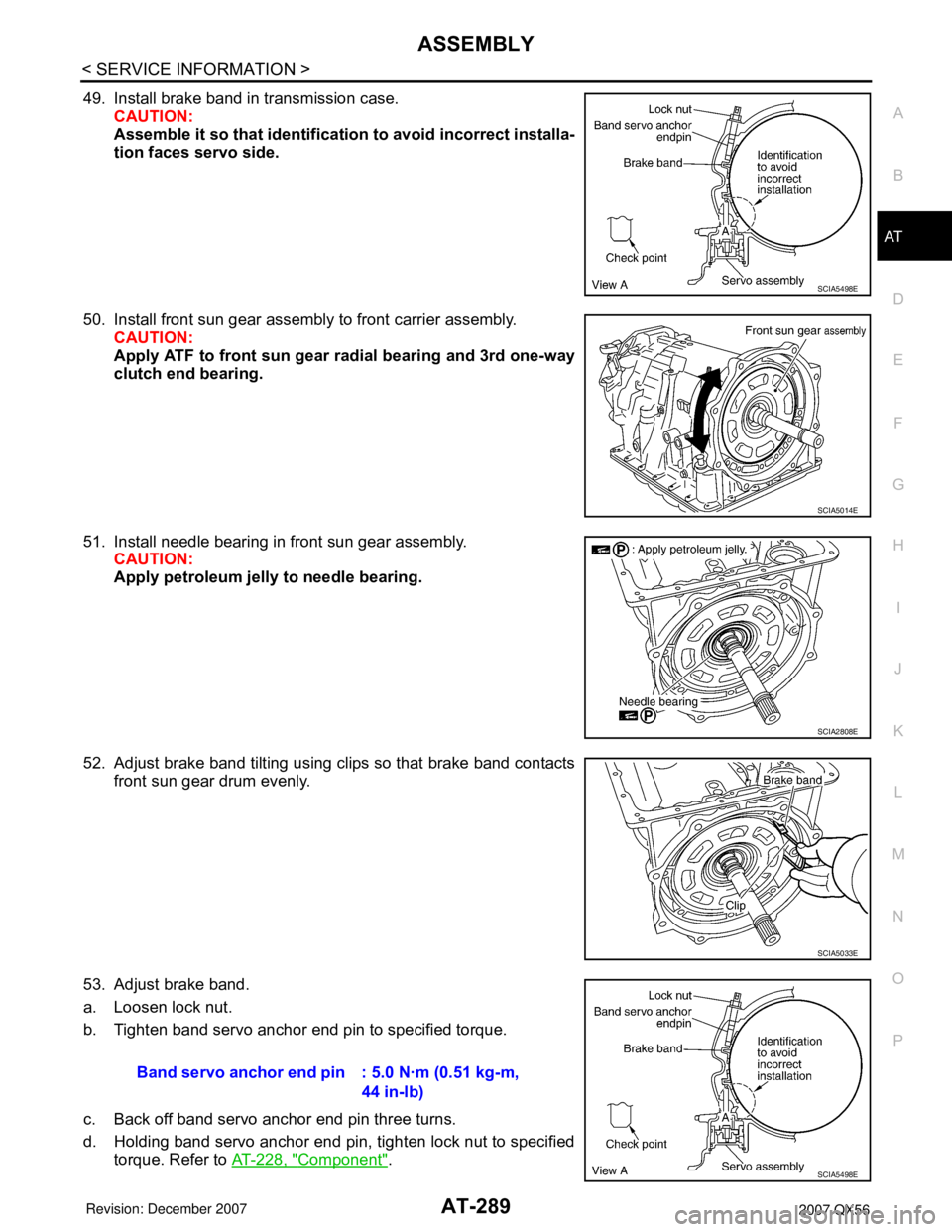

49. Install brake band in transmission case.

CAUTION:

Assemble it so that identification to avoid incorrect installa-

tion faces servo side.

50. Install front sun gear assembly to front carrier assembly.

CAUTION:

Apply ATF to front sun gear radial bearing and 3rd one-way

clutch end bearing.

51. Install needle bearing in front sun gear assembly.

CAUTION:

Apply petroleum jelly to needle bearing.

52. Adjust brake band tilting using clips so that brake band contacts

front sun gear drum evenly.

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to specified torque.

c. Back off band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to specified

torque. Refer to AT-228, "

Component".

SCIA5498E

SCIA5014E

SCIA2808E

SCIA5033E

Band servo anchor end pin : 5.0 N·m (0.51 kg-m,

44 in-lb)

SCIA5498E

Page 360 of 3061

AT-290

< SERVICE INFORMATION >

ASSEMBLY

Adjustment

INFOID:0000000003532494

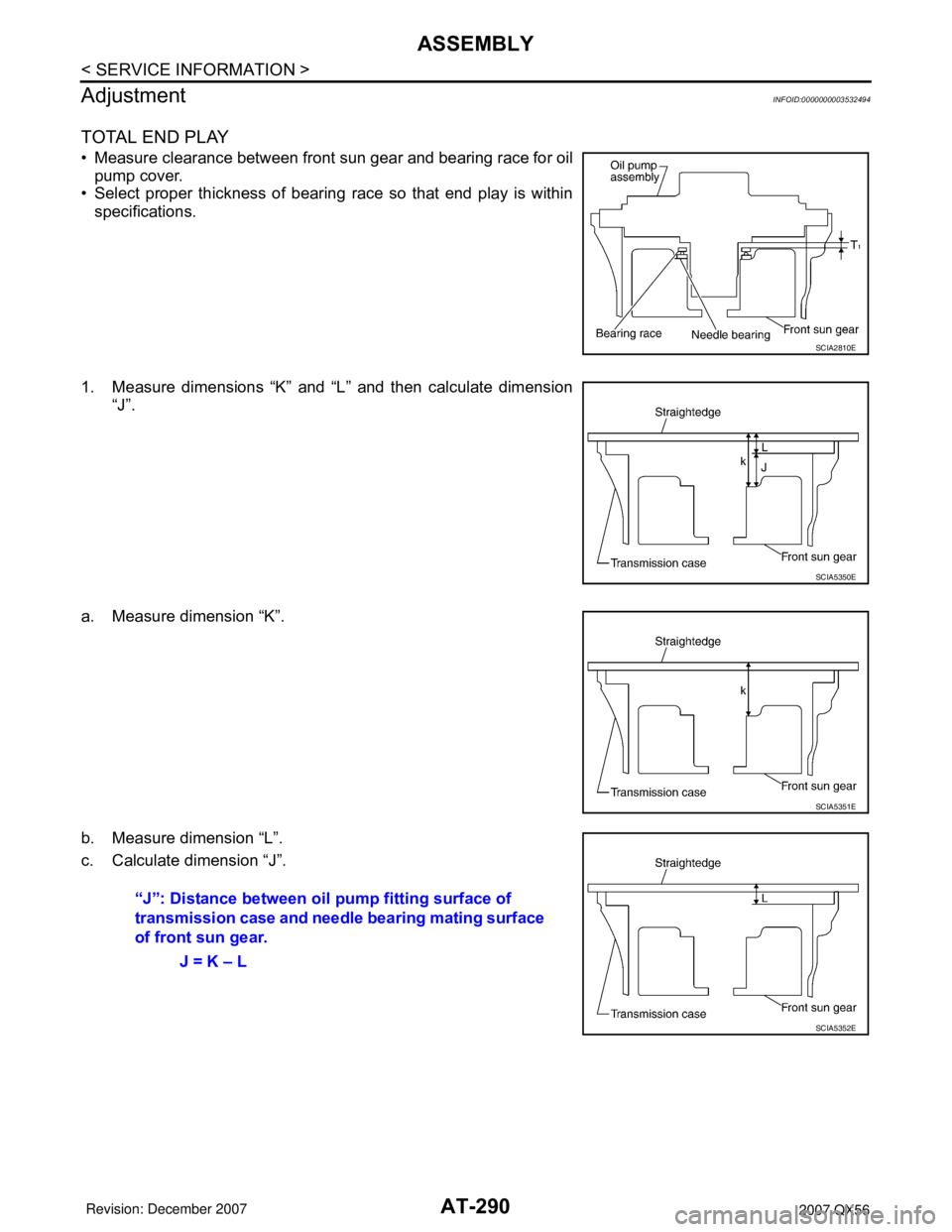

TOTAL END PLAY

• Measure clearance between front sun gear and bearing race for oil

pump cover.

• Select proper thickness of bearing race so that end play is within

specifications.

1. Measure dimensions “K” and “L” and then calculate dimension

“J”.

a. Measure dimension “K”.

b. Measure dimension “L”.

c. Calculate dimension “J”.

SCIA2810E

SCIA5350E

SCIA5351E

“J”: Distance between oil pump fitting surface of

transmission case and needle bearing mating surface

of front sun gear.

J = K – L

SCIA5352E