wheel INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4989 of 5598

ST-2

STEERING WHEEL ...........................................33

Exploded View ..................................................... ...33

Removal and Installation ........................................33

STEERING COLUMN ........................................34

Exploded View ..................................................... ...34

Removal and Installation ........................................34

Inspection ...............................................................35

STEERING SHAFT ............................................37

Exploded View ..................................................... ...37

Removal and Installation ........................................37

Inspection ...............................................................39

STEERING GEAR AND LINKAGE ....................41

Exploded View ..................................................... ...41

Removal and Installation ........................................42

Disassembly and Assembly ....................................43

Inspection ...............................................................46

POWER STEERING OIL PUMP ........................48

Exploded View ..................................................... ...48

Removal and Installation ........................................49

Disassembly and Assembly ....................................50

Inspection ...............................................................52

HYDRAULIC LINE .......................................... ...54

Exploded View ..................................................... ...54

HEATED STEERING WHEEL SWITCH ............56

Exploded View ..................................................... ...56

Removal and Installation .........................................56

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

57

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

57

General Specifications ......................................... ...57

Steering Wheel Axial End Play and Play ................57

Steering Wheel Turning Force ................................57

Steering Angle ........................................................57

Steering Column Length .........................................57

Steering Column Mounting Dimensions ..................57

Steering Column Operating Range .........................57

Steering Shaft Sliding Range ..................................58

Rack Sliding Force ..................................................58

Rack Stroke ............................................................58

Socket Swing Force and Rotating Torque ..............58

Socket Axial End Play .............................................58

Inner Socket Length ................................................58

Relief Oil Pressure ..................................................58

Revision: 2010 May2011 QX56

Page 4990 of 5598

PRECAUTIONSST-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006272045

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006272046

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 4991 of 5598

ST-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for Steering SystemINFOID:0000000006225573

In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehicle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

- Never reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

Revision: 2010 May2011 QX56

Page 4992 of 5598

PREPARATIONST-5

< PREPARATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PREPARATION

PREPARATION

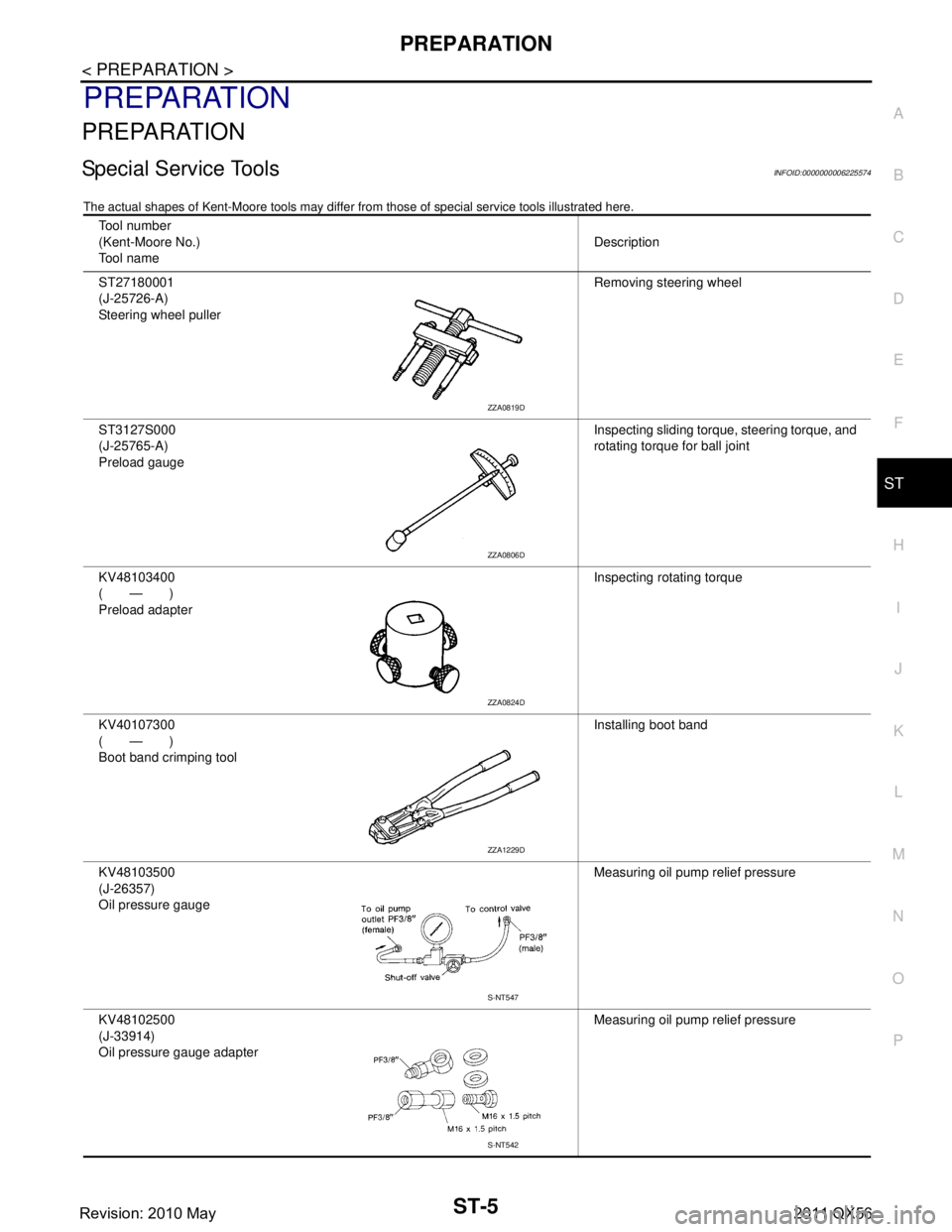

Special Service ToolsINFOID:0000000006225574

The actual shapes of Kent-Moore t ools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

ST27180001

(J-25726-A)

Steering wheel puller Removing steering wheel

ST3127S000

(J-25765-A)

Preload gauge Inspecting sliding torque, steering torque, and

rotating torque for ball joint

KV48103400

(—)

Preload adapter Inspecting rotating torque

KV40107300

(—)

Boot band crimping tool Installing boot band

KV48103500

(J-26357)

Oil pressure gauge Measuring oil pump relief pressure

KV48102500

(J-33914)

Oil pressure gauge adapter Measuring oil pump relief pressure

ZZA0819D

ZZA0806D

ZZA0824D

ZZA1229D

S-NT547

S-NT542

Revision: 2010 May2011 QX56

Page 4994 of 5598

COMPONENT PARTSST-7

< SYSTEM DESCRIPTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts Locatio n (Heated Steering Wheel)INFOID:0000000006225576

Component Description (Heated Steering Wheel)INFOID:0000000006225577

Heated Steering WheelINFOID:0000000006225578

The heated steering wheel is activated by the pow er supply from the heated steering wheel relay.

1. Heated steering wheel relay 2. Heated steering wheel switch 3. Heated steering wheel

A. Engine room right side

JSGIA0824ZZ

Part name Reference/Function

Heated steering wheel Heating element Refer to ST-7, "

Heated Steering Wheel".

Thermostat

Heated steering wheel relay Refer to ST-8, "

Heated Steering Wheel Relay".

Heated steering wheel switch Timer Refer to ST-8, "

Heated Steering Wheel Switch".

Revision: 2010 May2011 QX56

Page 4995 of 5598

ST-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

Furthermore, the heated steering wheel incorporates a heating element and a thermostat to control heated

steering wheel temperatures.

Heating element: Heat is generated by the passage of an electric current.

Thermostat: ON/OFF operation of power supply at a certain temperature.

Heated Steering Wheel SwitchINFOID:0000000006225579

Controls the heated steering wheel relay and operates the heated steering wheel system.

The heated steering wheel switch incorporates a ti mer and turns OFF the heated steering wheel relay when

operating time reaches a certain time.

- Timer: ON/OFF operation of the heated st eering wheel relay at a certain time.

Turns the indicator lamp ON when the system is activated.

Heated Steering Wheel RelayINFOID:0000000006225580

Operates the heated steering system with the control signal from the heated steering wheel switch.

Revision: 2010 May2011 QX56

Page 4996 of 5598

SYSTEMST-9

< SYSTEM DESCRIPTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

SYSTEM

System Description (Heated Steering Wheel)INFOID:0000000006225581

The heated steering wheel switch controls the heated steering wheel relay. When the heated steering wheel

switch is turned on, the heated steering wheel relay is energized and the heated steering wheel system will

operate. The heated steering wheel system will turn of f when the heated steering wheel temperature reaches

approximately 30 °C (86 °F). Heated steering wheel system operati on can also be canceled by pressing the

heated steering wheel switch again. In addition, the heat ed steering wheel switch incorporates a timer and

turns OFF the heated steering wheel relay to exit the heated steering wheel system when the operating time

reaches a certain time.

NOTE:

If the surface temperature of the steering wheel is below 20 °C (68 °F), the system will heat the steering wheel

and cycle off and on to maintain a temperature above 20 °C (68 °F). The indicator light will remain on as long as

the system is on. Push the switch again to turn t he heated steering wheel system off manually. The indicator

light will go off.

SYSTEM DIAGRAM

JSGIA0826GB

Revision: 2010 May2011 QX56

Page 4997 of 5598

ST-10

< WIRING DIAGRAM >

HEATED STEERING WHEEL

WIRING DIAGRAM

HEATED STEERING WHEEL

Wiring DiagramINFOID:0000000006225582

JCGWM0373GB

Revision: 2010 May2011 QX56

Page 4998 of 5598

HEATED STEERING WHEELST-11

< WIRING DIAGRAM >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

JCGWM0390GB

Revision: 2010 May2011 QX56

Page 4999 of 5598

ST-12

< WIRING DIAGRAM >

HEATED STEERING WHEEL

JCGWM0391GB

Revision: 2010 May2011 QX56