ignition INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1504 of 5598

DEF-12

< SYSTEM DESCRIPTION >

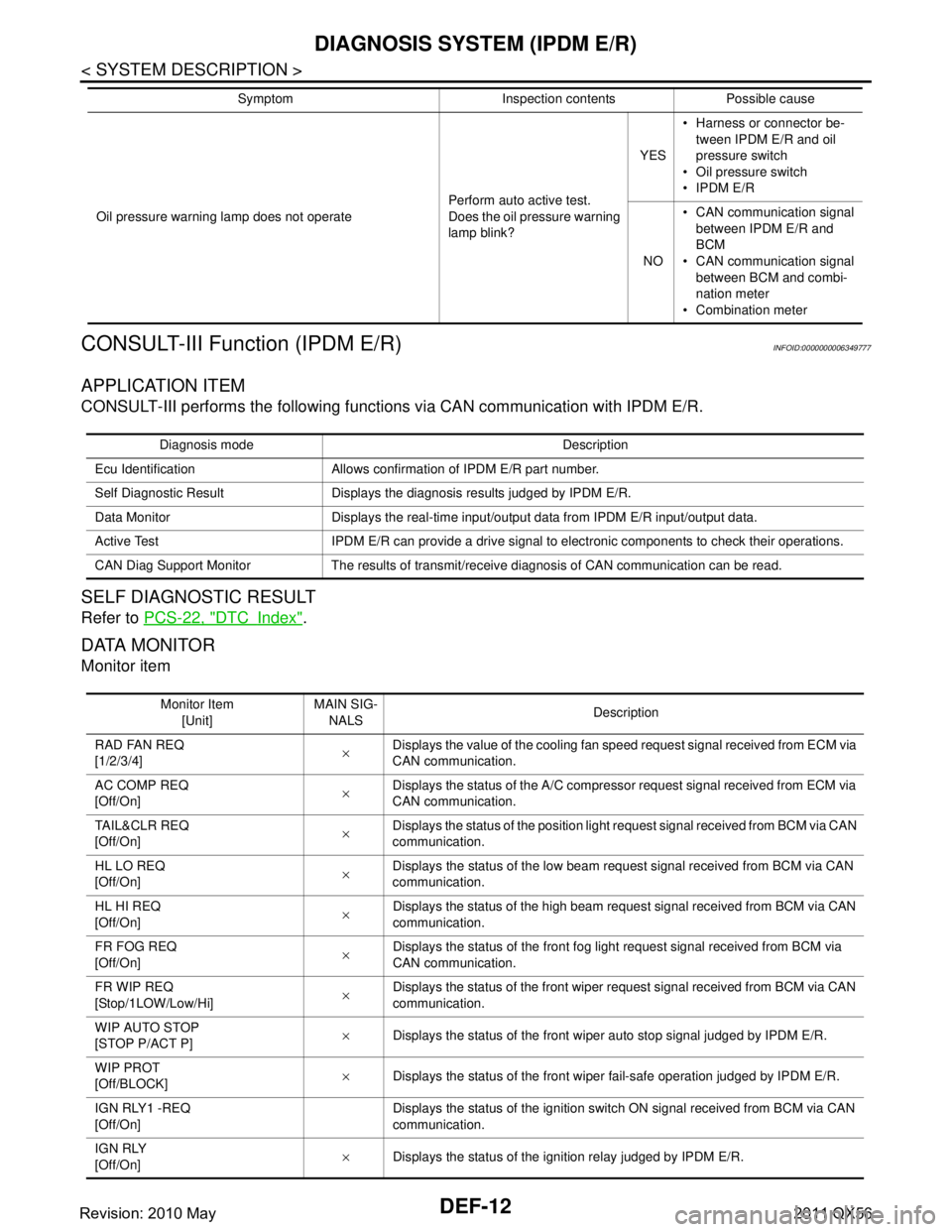

DIAGNOSIS SYSTEM (IPDM E/R)

CONSULT-III Function (IPDM E/R)

INFOID:0000000006349777

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-22, "DTCIndex".

DATA MONITOR

Monitor item

Oil pressure warning lamp does not operate Perform auto active test.

Does the oil pressure warning

lamp blink?YES

Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Symptom Inspection contents Possible cause

Diagnosis mode Description

Ecu Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item [Unit] MAIN SIG-

NALS Description

RAD FAN REQ

[1/2/3/4] ×Displays the value of the cooling fan speed request signal received from ECM via

CAN communication.

AC COMP REQ

[Off/On] ×Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TA I L & C L R R E Q

[Off/On] ×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On] ×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On] ×Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi] ×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY1 -REQ

[Off/On] Displays the status of the ignition switch ON signal received from BCM via CAN

communication.

IGN RLY

[Off/On] ×

Displays the status of the ignition relay judged by IPDM E/R.

Revision: 2010 May2011 QX56

Page 1505 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (IPDM E/R)DEF-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On] Displays the status of the push-button ignition switch judged by INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (IPDM E/R)DEF-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On] Displays the status of the push-button ignition switch judged by](/img/42/57033/w960_57033-1504.png)

DIAGNOSIS SYSTEM (IPDM E/R)DEF-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On] Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP SW

[Off/On] Displays the status of the shift position judged by IPDM E/R.

ST RLY CONT

[Off/On] Displays the status of the starter relay status signal received from BCM via CAN

communication.

IHBT RLY -REQ

[Off/On] Displays the status of the starter control relay signal received from BCM via CAN

communication.

ST/INHI RLY

[Off/ ST ON/INHI ON/UNKWN] Displays the status of the starter relay and starter control relay judged by IPDM

E/R.

DETENT SW

[Off/On] Displays the status of the A/T shift selector (detention switch) judged by IPDM E/

R.

S/L RLY -REQ

[Off/On] Displays the status of the steering lock relay signal received from BCM via CAN

communication.

S/L STATE

[LOCK/UNLK/UNKWN] Displays the status of the steering lock judged by IPDM E/R.

OIL P SW

[Open/Close] Displays the status of the oil pressure switch judged by IPDM E/R.

HOOD SW

[Off/On] Displays the status of the hood switch judged by IPDM E/R.

HL WASHER REQ

[Off/On] Displays the status of the headlamp washer request signal received from BCM via

CAN communication.

THFT HRN REQ

[Off/On] Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[Off/On] Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

Monitor Item

[Unit] MAIN SIG-

NALS Description

Test item Operation Description

CORNERING LAMP LH

NOTE:

This item is indicated, but cannot be tested.

RH

HORN On Operates horn relay for 20 ms.

REAR DEFOGGER Off OFF

On Operates the rear window defogger relay.

FRONT WIPER Off OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

MOTOR FAN* 1OFF

2 Transmits 50% pulse duty signal (PWM signal) to the cooling fan control module.

3 Transmits 75% pulse duty signal (PWM signal) to the cooling fan control module.

4

Transmits 100% pulse duty signal (PWM signal) to the cooling fan control mod-

ule.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 second.

Revision: 2010 May2011 QX56

Page 1518 of 5598

DEF-26

< DTC/CIRCUIT DIAGNOSIS >

REAR WINDOW DEFOGGER RELAY

REAR WINDOW DEFOGGER RELAY

DescriptionINFOID:0000000006299436

The rear window defogger is operated by turning the rear window defogger switch ON.

Component Function CheckINFOID:0000000006299437

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the rear window heating wire is getting warmer.

Is the inspection result normal?

YES >> Rear window defogger relay function is OK.

NO >> Refer to DEF-26, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299438

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check the 15A fuse (No. 41, 42 located in IPDM E/R).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK IPDM E/R OUTPUT SIGNAL

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace IPDM E/R. Refer to PCS-32, "

Removal and Installation".

(+)

(− ) CONSULT-III Active Test condition Voltage (V)

(Approx.)

IPDM E/R

Connector Terminal

E11 14 Ground REAR DEFOGGER ON Battery voltage

OFF 0

Revision: 2010 May2011 QX56

Page 1519 of 5598

REAR WINDOW DEFOGGERDEF-27

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

REAR WINDOW DEFOGGER

DescriptionINFOID:0000000006299439

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window

from fogging up.

Component Function CheckINFOID:0000000006299440

1.CHECK FUNCTION

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the rear window heating wire is getting warmer.

Is the inspection result normal?

YES >> Rear window defogger relay function is OK.

NO >> Refer to DEF-26, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299441

1.CHECK REAR WINDOW DEFOGG ER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger connector.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK REAR WINDOW DE FOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK FILAMENT

Refer to DEF-43, "

Inspection and Repair".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair filament.

4.CHECK REAR WINDOW DEFOGG ER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and rear window defogger harness connector.

(+)

(− ) Condition Voltage (V)

(Approx.)

Rear window defogger

Connector Terminal

D103 1 Ground Rear window defogger switch ON Battery voltage

OFF 0

Rear window defogger GroundContinuity

Connector Terminal

D104 2 Existed

Revision: 2010 May2011 QX56

Page 1521 of 5598

DOOR MIRROR DEFOGGERDEF-29

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000006299442

Heats the heating wire with the power supply from t he rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000006299443

1.CHECK DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that both side door mirror glasses are getting warmer.

Is the inspection result normal?

YES >> Door mirror defogger is OK.

NO >> Refer to DEF-29, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299444

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuse [No.80, loca ted in fuse block (J/B)].

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK DOOR MIRROR DEFOGGER CIRCUIT

1. Disconnect IPDM E/R connector and door mirror (both sides) connector.

2. Check continuity between IPDM E/R harness connec tor and door mirror (driver side) harness connector.

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

IPDM E/R Door mirro r (driver side)

Continuity

Connector Terminal Connector Terminal

E11 14 D3 7 Existed

IPDM E/R GroundContinuity

Connector Terminal

E11 14 Not existed

Revision: 2010 May2011 QX56

Page 1522 of 5598

DEF-30

< DTC/CIRCUIT DIAGNOSIS >

DRIVER SIDE DOOR MIRROR DEFOGGER

DRIVER SIDE DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000006299445

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000006299446

1.CHECK DRIVER SIDE DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the driver side door mirror glass is getting warmer.

Is the inspection result normal?

YES >> Driver side door mirror defogger is OK.

NO >> Refer to DEF-30, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299447

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door mirror (driver side) connector.

3. Turn ignition switch ON.

4. Check voltage between door mirror (driver side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror (driver side) harness connector and ground.

Is the inspection result normal?

YES >> Replace door mirror glass (driver side).

NO >> Repair or replace harness.

(+)

(–) Condition Voltage (V)

(Approx.)

Door mirror (driver side)

Connector Terminal

D3 7 Ground Rear window defogger

switchON Battery voltage

OFF 0

Door mirror (driver side)

GroundContinuity

Connector Terminal

D3 19 Existed

Revision: 2010 May2011 QX56

Page 1523 of 5598

PASSENGER SIDE DOOR MIRROR DEFOGGERDEF-31

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PASSENGER SIDE DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000006299448

Heats the heating wire with the power supply from t he rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000006299449

1.CHECK PASSENGER SIDE DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that the passenger side door mirror glass is getting warmer.

Is the inspection result normal?

YES >> Passenger side door mirror defogger is OK.

NO >> Refer to DEF-31, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299450

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door mirror (passenger side) connector.

3. Turn ignition switch ON.

4. Check voltage between door mirror (passenger side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror (passenger side) harness connector and ground.

Is the inspection result normal?

YES >> Replace door mirror glass (passenger side).

NO >> Repair or replace harness.

(+)

(–) Condition Voltage (V)

(Approx.)

Door mirror (passenger side)

Connector Terminal

D23 7 Ground Rear window defogger

switchON Battery voltage

OFF 0

Door mirror (passenger side)

GroundContinuity

Connector Terminal

D23 19 Existed

Revision: 2010 May2011 QX56

Page 1524 of 5598

DEF-32

< DTC/CIRCUIT DIAGNOSIS >

WIPER DEICER RELAY

WIPER DEICER RELAY

Component Function CheckINFOID:0000000006299451

1.CHECK WIPER DEICER RELAY POWER SUPPLY CIRCUIT

1. Select Active Test (“REAR DEFOGGER”) mode of “BCM” using CONSULT-III.

2. Touch “ON”.

3. Check that the front window heating wire is getting warmer.

Is the inspection result normal?

YES >> Wiper deicer relay power supply circuit function is OK.

NO >> Refer to DEF-32, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006299452

1.CHECK WIPER DEICER CIRCUIT 1

1. Turn ignition switch ON.

2. Check voltage between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK WIPER DEICER CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay and IPDM E/R connector.

3. Check continuity between wiper deicer relay terminal connector and IPDM E/R harness connector.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace harness.

3.CHECK WIPER DEICER CIRCUIT 3

Check voltage between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK WIPER DEICER RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay connector.

3. Check continuity between wiper deicer relay terminal connector and ground.

(+)

(–) Condition Voltage (V)

(Approx.)

Wiper deicer relay

Connector Terminal

E23 1 Ground Rear window defogger switch: ON Battery voltage

Rear window defogger switch: OFF 0

Wiper deicer relay IPDM E/R

Continuity

Connector Terminal Connector Terminal

E23 1 E11 14 Existed

(+) (–)Voltage (V)

(Approx.)

Wiper deicer relay

Connector Terminal E23 3 Ground Battery voltage

Revision: 2010 May2011 QX56

Page 1525 of 5598

WIPER DEICER RELAYDEF-33

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness.

5.CHECK WIPER DEICER RELAY

Check wiper deicer relay.

Refer to DEF-33, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace wiper deicer relay.

6.CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006299453

1.CHECK WIPER DEICER RELAY

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay.

3. Check wiper deicer relay.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace wiper deicer relay.

Wiper deicer relay

GroundContinuity

Connector Terminal

E23 2 Existed

Wiper deicer relay Condition Continuity

Te r m i n a l

35 12 V direct current supply between termi-

nals 1 and 2

Existed

No current supply Not existed

SEF497Y

Revision: 2010 May2011 QX56

Page 1526 of 5598

DEF-34

< DTC/CIRCUIT DIAGNOSIS >

WIPER DEICER

WIPER DEICER

Component Function CheckINFOID:0000000006299454

1.CHECK WIPER DEICER

1. Select Active Test (“REAR DEFOGGER”) mode of “BCM” using CONSULT-III.

2. Touch “ON”.

3. Check that the front window heating wire is getting warmer.

Is the inspection result normal?

YES >> Wiper deicer is OK.

NO >> Refer to DEF-34, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299455

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 15 A fuse [No.75, located in fuse block (J/B)]

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between wiper deicer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 4.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer connector.

3. Check continuity between wiper deicer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness between rear window defogger and ground.

4.CHECK WIPER DEICER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay connector and wiper deicer connector.

3. Check continuity between wiper deicer relay harness connector and wiper deicer harness connector.

(+)

(–) Condition Voltage (V)

(Approx.)

Wiper deicer

Connector Terminal

E40 1 Ground Rear window defogger switch: ON Battery voltage

Rear window defogger switch: OFF 0

Wiper deicer

GroundContinuity

Connector Terminal

E40 2 Existed

Revision: 2010 May2011 QX56