INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5021 of 5598

ST-34

< REMOVAL AND INSTALLATION >

STEERING COLUMN

STEERING COLUMN

Exploded ViewINFOID:0000000006225601

Removal and InstallationINFOID:0000000006225602

REMOVAL

CAUTION:

Never give axial impact to steering column assembly during removal.

Never move steering gear assembly when removing steering column assembly.

Never rotate the steering shaft when removing steering column assembly.

1. Set the vehicle to the straight-ahead position.

2. Place the tilt to the highest level. Place the telescopic to the longest level.

3. Remove driver air bag module. Refer to SR-11, "

Removal and Installation".

4. Remove steering wheel. Refer to ST-33, "

Removal and Installation".

5. Remove instrument lower panel LH. Refer to IP-14, "

Removal and Installation".

6. Remove the steering column cover. Refer to IP-14, "

Removal and Installation".

7. Remove spiral cable. Refer to SR-14, "

Removal and Installation".

8. Remove combination switch. Refer to BCS-82, "

Removal and Installation".

9. Disconnect each switch harness connectors installed to steering column assembly.

10. Remove the upper joint mounting bolt and separate the joint from upper joint.

11. Remove steering column assembly.

1. Bracket 2. Steering column mounting bracket 3. Upper joint

4. Telescopic motor 5. Tilt motor 6. Steering column assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPGIA0066GB

Revision: 2010 May2011 QX56

Page 5022 of 5598

STEERING COLUMNST-35

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

If necessary, remove telescopic motor, tilt motor, and brackets.

12. Perform inspection after removal. Refer to ST-35, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

To install the slide plate (1), create clearance (L) in the steering col-

umn assembly mounting area (2) as follows.

Tighten the mounting bolts and nuts in the order shown in the fig- ure when installing the steering column assembly.

Be careful of the following points when installing the steering col- umn assembly.

CAUTION:

Never give axial impact to steering column assembly during installation.

Never move steering gear assembly.

Perform inspection after installation. Refer to ST-35, "

Inspection".

InspectionINFOID:0000000006225603

INSPECTION AFTER REMOVAL

Check each part of steering column assembly for damage or other malfunctions. Replace if necessary.

Measure steering column assembly rotating torque using a preload gauge [SST: ST3127S000 (J-25765-A)]. Replace steering column assembly if outside the standard.

Measure the length (L) as shown, if vehicle has been involved in a minor collision. Replace steering column assembly if out side the

standard. L : 2.0 mm (0.079 in)

JSGIA0315ZZ

JPGIA0026ZZ

Rotating torque : Refer to

ST-57, "Steering Column Operating Range".

L : Refer to ST-57, "

Steering Column Length".

JSGIA0797ZZ

Revision: 2010 May2011 QX56

Page 5023 of 5598

ST-36

< REMOVAL AND INSTALLATION >

STEERING COLUMN

Install the bracket and steering column housing so that the clear-ance (A) is within the specified range as described below. Replace

steering column assembly if out side the standard.

INSPECTION AFTER INSTALLATION

Check each part of steering column assembly for damage or other malfunctions. Replace if necessary.

Check the steering wheel play, neutral position steeri ng wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-32, "

Inspection".

Check tilt and telescopic mechanism operating range tilt operating

range (T), telescopic operating range (L) as shown in the figure.

Adjust neutral position of steering angle sensor. Refer to BRC-64,

"Work Procedure".

A : Refer to

ST-57, "

Steering Column Mounting Di-

mensions".

JSGIA0795ZZ

T : Refer to ST-57, "Steering Column Operating

Range".

L : Refer to ST-57, "

Steering Column Operating

Range".

JSGIA0798ZZ

Revision: 2010 May2011 QX56

Page 5024 of 5598

STEERING SHAFTST-37

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

STEERING SHAFT

Exploded ViewINFOID:0000000006225604

Removal and InstallationINFOID:0000000006225605

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Fix the steering wheel.

3. Remove steering shaft fixing bolt and nut (lower joint side). CAUTION:

The steering shaft bellows are easily bent. N ever press the bellows too much with a tool.

4. Remove lower joint fixing bolt (steering gear side).

5. Remove lower joint from steering shaft and steering gear assembly. CAUTION:

When removing lower joint, n ever insert a tool, such as a screw driver, into the yoke groove to

pull out the lower joint. In case of the violation of the above, replace lower joint with a new one.

Spiral cable may be cut if steering wheel tu rns while separating steering column assembly and

steering gear assembly. Be sure to secure st eering wheel using string to avoid turning.

6. Turn carpet and remove the hole cover mounting nuts.

7. Remove the upper joint fixing bolt and nut (steering shaft side).

1. Lower joint 2. Steering shaft 3. Hole cover*

4. Clamp* 5. Hole cover seal 6. Collar

7. Upper joint

*: Replace “3” and “4” as a set.

Refer to GI-4, "

Components" for symbols in the figure.

JPGIA0067GB

Revision: 2010 May2011 QX56

Page 5025 of 5598

ST-38

< REMOVAL AND INSTALLATION >

STEERING SHAFT

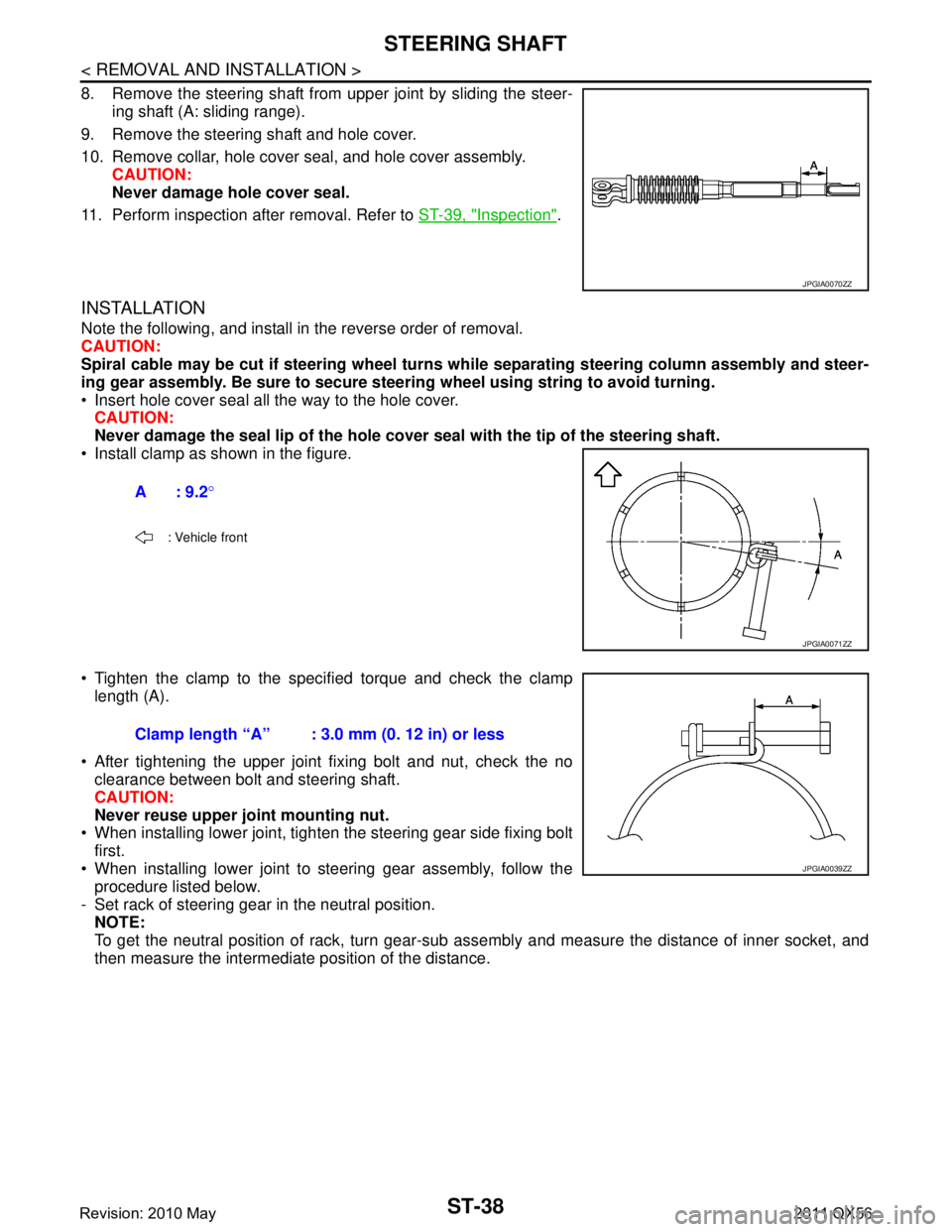

8. Remove the steering shaft from upper joint by sliding the steer-ing shaft (A: sliding range).

9. Remove the steering shaft and hole cover.

10. Remove collar, hole cover seal, and hole cover assembly. CAUTION:

Never damage hole cover seal.

11. Perform inspection after removal. Refer to ST-39, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steer ing wheel using string to avoid turning.

Insert hole cover seal all the way to the hole cover. CAUTION:

Never damage the seal lip of the hole cover seal with the tip of the steering shaft.

Install clamp as shown in the figure.

Tighten the clamp to the spec ified torque and check the clamp

length (A).

After tightening the upper joint fixing bolt and nut, check the no clearance between bolt and steering shaft.

CAUTION:

Never reuse upper joint mounting nut.

When installing lower joint, tighten the steering gear side fixing bolt

first.

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position. NOTE:

To get the neutral position of rack, turn gear-sub as sembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

JPGIA0070ZZ

A: 9.2 °

: Vehicle front

JPGIA0071ZZ

Clamp length “A” : 3.0 mm (0. 12 in) or less

JPGIA0039ZZ

Revision: 2010 May2011 QX56

Page 5026 of 5598

STEERING SHAFTST-39

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

When installing lower joint (1) to steering shaft (2), check the fixing length (A).

Perform inspection after installation. Refer to ST-39, "

Inspection".

InspectionINFOID:0000000006225606

INSPECTION AFTER REMOVAL

Lower Joint

Check dust boot clamp (looseness and disconnection) and dust boot (scratches, cracks, and holes).

Replace the lower joint, as necessary.

Check each part of lower joint for damage and other malfunctions. Replace if there is a malfunction.

Steering Shaft

Check steering shaft and hole cover seal for scratches, cracks, and holes. Replace the stee\

ring shaft or hole

cover seal, as necessary.

Check the sliding range of the steering shaft.

CAUTION:

Check the sliding range (A) (b etween the extended position

and the contracted position) of the steering shaft.

Check the length (L) (extended posit ion) of the steering shaft.

: Bolt

JPGIA0038ZZ

A : 15.3 mm (0.602 in)

JPGIA0068ZZ

A : Refer to ST-58, "Steering Shaft Sliding Range".

JPGIA0070ZZ

L : Refer to ST-58, "Steering Shaft Sliding Range".

JPGIA0069ZZ

Revision: 2010 May2011 QX56

Page 5027 of 5598

ST-40

< REMOVAL AND INSTALLATION >

STEERING SHAFT

Rotate the steering shaft to check runout of the steering shaft atthe runout measuring point ( ) by using dial indicator and V-block.

Check each part of steering shaft for damage and other malfunc- tions. Replace if there is a malfunction.

INSPECTION AFTER INSTALLATION

Check dust boot bellows (deformation, such as dent s). Manually rework the bellows, as necessary.

Check if steering wheel turns smoothly when it is tur ned several times fully to the end of the left and right.

Check the steering wheel play, neutral position steeri ng wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-32, "

Inspection".

Adjust neutral position of steering angle sensor. Refer to BRC-64, "

Work Procedure".

Runout : Refer to

ST-58, "

Steering Shaft Sliding

Range".

A : 120 mm (4.72 in)

B : 240 mm (9.45 in)

JPGIA0075ZZ

Revision: 2010 May2011 QX56

Page 5028 of 5598

STEERING GEAR AND LINKAGEST-41

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

STEERING GEAR AND LINKAGE

Exploded ViewINFOID:0000000006225607

REMOVAL

DISASSEMBLY

Engine speed sensitive type

1. Steering gear assembly 2. Cotter pin

Refer to GI-4, "

Components" for symbols in the figure.

JPGIA0072GB

JPGIA0095GB

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Adjusting screw 8. Adjusting screw lock nut 9. Spring

Revision: 2010 May2011 QX56

Page 5029 of 5598

ST-42

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

Vehicle speed sensitive type

Removal and InstallationINFOID:0000000006225608

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove tires.

3. Remove front final drive assembly. Refer to DLN-162, "

Removal and Installation".

10. Retainer 11. O-ring 12. Low pressure piping

13. Gear-sub assembly 14. Rear cover cap 15. Cylinder tubes

: Apply power steering fluid.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t . : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPGIA0073GB

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Adjusting screw 8. Adjusting screw lock nut 9. Spring

10. Retainer 11. O-ring 12. Low pressure piping

13. Power steering solenoid valve 14. Gear-sub assembly 15. Rear cover cap

16. Cylinder tubes

: Apply power steering fluid.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t . : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

Revision: 2010 May2011 QX56

Page 5030 of 5598

STEERING GEAR AND LINKAGEST-43

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

4. Remove cotter pin (1), and then loosen the nut.

5. Remove steering outer socket (2) from steering knuckle (3) so as not to damage ball joint boot (4) using suitable ball joint

remover (commercial service tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

6. Remove high pressure piping and low pressure piping of hydraulic piping, and then drain power steering fluid.

7. Remove power steering solenoid valve harness connector.

8. Remove lower joint fixing bolt (steering gear side).

9. Separate the lower joint from the steering gear assembly. Refer to ST-37, "

Exploded View".

CAUTION:

When removing lower joint, n ever insert a tool, such as a screw driver, into the yoke groove to

pull out the lower joint. In case of the violation of the above, replace lower joint with a new one.

Spiral cable may be cut if steering wheel tu rns while separating steering column assembly and

steering gear assembly. Be sure to secure st eering wheel using string to avoid turning.

10. Remove steering gear assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steer ing wheel using string to avoid turning.

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub a ssembly and measure the distance of inner socket, and

then measure the intermediat e position of the distance.

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

Never reuse cotter pin and steering gear mounting nut.

Perform inspection after installation. Refer to ST-46, "

Inspection".

Disassembly and AssemblyINFOID:0000000006225609

DISASSEMBLY

CAUTION:

Disassemble and assemble steering gear assembly by fixing the mounting area with a vise using

copper plates.

Clean steering gear assembly with kerosene before disassembling. Be careful to avoid splashing or

applying any kerosene over connector of discharge port or return port.

1. Remove cylinder tubes from gear housing assembly.

2. Remove rear cover cap from gear-sub assembly.

PGIA0063E

: Bolt

JPGIA0038ZZ

Revision: 2010 May2011 QX56