INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5011 of 5598

ST-24

< SYMPTOM DIAGNOSIS >

HEATED STEERING WHEEL SYSTEM DOES NOT ACTIVATE

5. Check continuity between heated steering wheel relay harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK HEATED STEERING WHEEL RELAY

Check heated steering wheel relay. Refer to ST-19, "

Component Inspection (Heated Steering Wheel Relay)".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace heated steering wheel relay. Refer to ST-7, "

Component Parts Location (Heated Steering

Wheel)".

6.DETECT MALFUNCTIONING ITEM

Check the following.

Battery

Harness for short or open between bat tery and IPDM E/R. Refer to PG-11, "

Wiring Diagram - BATTERY

POWER SUPPLY -".

10A fuse (No.76, located in the IPDM E/R). Refer to PG-143, "

Fuse, Connector and Terminal Arrangement".

IPDM E/R

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace damaged parts.

7.CHECK GROUND CIRCUIT

Check continuity between heated steering wheel switch harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair or replace damaged parts.

8.CHECK HARNESS BETWEEN HEATED STEERING WHEEL RELAY AND HEATED STEERING WHEEL

SWITCH

1. Check continuity between heated steering wheel relay harness connector terminal and heated steering

wheel switch harness connector terminal.

2. Check continuity between heated steering w heel relay harness connector terminal and ground.

Heated steering wheel relay Heated steering wheel

Continuity

Connector Terminal Connector Terminal

E90 5 M303 1 Existed

Heated steering wheel relay GroundContinuity

Connector Terminal

E90 5 Not existed

Heated steering wheel switch GroundContinuity

Connector Terminal

M52 6 Existed

Heated steering wheel relay Heated steering wheel switch Continuity

Connector Terminal Connector Terminal

E90 2 M52 2 Existed

Heated steering wheel relay GroundContinuity

Connector Terminal

E90 2 Not existed

Revision: 2010 May2011 QX56

Page 5012 of 5598

HEATED STEERING WHEEL SYSTEM DOES NOT ACTIVATE

ST-25

< SYMPTOM DIAGNOSIS >

C

D E

F

H I

J

K L

M A

B

ST

N

O P

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace damaged parts.

9.CHECK HARNESS BETWEEN FUSE BLOCK (J/B) AND HEATED STEERING WHEEL SWITCH

1. Check continuity between fuse block (J/B) connec tor terminal and heated steering wheel switch harness

connector terminal.

2. Check continuity between fuse block (J/B) harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Repair or replace damaged parts.

10.DETECT MALFUNCTIONING ITEM

Check the following.

Ignition switch

Harness for short or open between ignition s witch and fuse block (J/B). Refer to PG-11, "

Wiring Diagram -

BATTERY POWER SUPPLY -".

10A fuse [No.3, located in the fuse block (J/B)]. Refer to PG-143, "

Fuse, Connector and Terminal Arrange-

ment".

Fuse block (J/B)

Is the inspection result normal?

YES >> Replace heated steering wheel switch. Refer to ST-56, "Removal and Installation".

NO >> Repair or replace damaged parts.

Fuse block (J/B) Heated steering wheel switch Continuity

Connector Terminal Connector Terminal

M1 2A M52 1 Existed

Fuse block (J/B) GroundContinuity

Connector Terminal

M1 2A Not existed

Revision: 2010 May2011 QX56

Page 5013 of 5598

ST-26

< SYMPTOM DIAGNOSIS >

HEATED STEERING WHEEL SWITCH INDICATOR LAMP DOES NOT TURN ON

HEATED STEERING WHEEL SWITCH INDICATOR LAMP DOES NOT

TURN ON

Description INFOID:0000000006225594

Heated steering wheel switch indicator lamp does not turn on the lamp.

Heated steering wheel switch indicator lamp does not turn off the lamp.

Diagnosis ProcedureINFOID:0000000006225595

1.CHECK POWER SOURCE AND GROUND CIRCUIT

1. Turn ignition switch ON. CAUTION:

Never start the engine.

2. Turn heated steering wheel switch ON.

3. Check voltage between heated steering wheel switch harness connector terminals.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 2.

2.CHECK GROUND CIRCUIT

Check continuity between heated steering wheel switch harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK HARNESS BETWEEN HEATED STEERING WHEEL RELAY AND HEATED STEERING WHEEL

SWITCH

1. Turn ignition switch OFF.

2. Disconnect heated steering wheel relay connector. Refer to ST-7, "

Component Parts Location (Heated

Steering Wheel)".

3. Disconnect heated steering wheel switch connector. Refer to ST-56, "

Removal and Installation".

4. Check continuity between heated steering wheel relay harness connector terminal and heated steering

wheel switch harness connector terminal.

5. Check continuity between heated steering w heel relay harness connector terminal and ground.

Heated steering wheel

Condition Voltage (Approx.)

Connector Terminal

M52 5 − 6 Within 30 minutes after

turning ON the heated

steering switch.

Battery voltage

Other conditions. 0 V

Heated steering wheel switch GroundContinuity

Connector Terminal

M52 6 Existed

Heated steering wheel relay Heated steering wheel switch Continuity

Connector Terminal Connector Terminal

E90 5 M52 5 Existed

Heated steering wheel relay GroundContinuity

Connector Terminal

E90 5 Not existed

Revision: 2010 May2011 QX56

Page 5014 of 5598

HEATED STEERING WHEEL SWITCH INDICATOR LAMP DOES NOT TURN ON

ST-27

< SYMPTOM DIAGNOSIS >

C

D E

F

H I

J

K L

M A

B

ST

N

O P

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK HEATED STEERING WHEEL RELAY

Check heated steering wheel relay. Refer to ST-22, "

Component Inspection (Heated Steering Wheel Relay)".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace heated steering wheel relay. Refer to ST-7, "

Component Parts Location (Heated Steering

Wheel)".

5.CHECK HARNESS BETWEEN HEATED STEERING WHEEL RELAY AND HEATED STEERING WHEEL

SWITCH

1. Check continuity between heated steering wheel relay harness connector terminal and heated steering

wheel switch harness connector terminal.

2. Check continuity between heated steering w heel relay harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace damaged parts.

6.CHECK HARNESS BETWEEN FUSE BLOCK (J/B) AND HEATED STEERING WHEEL SWITCH

1. Check continuity between fuse block (J/B) connec tor terminal and heated steering wheel switch harness

connector terminal.

2. Check continuity between fuse block (J/B) harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace damaged parts.

7.DETECT MALFUNCTIONING ITEM

Check the following.

Ignition switch

Harness for short or open between ignition s witch and fuse block (J/B). Refer to PG-11, "

Wiring Diagram -

BATTERY POWER SUPPLY -".

10A fuse [No.3, located in the fuse block (J/B)]. Refer to PG-143, "

Fuse, Connector and Terminal Arrange-

ment".

Fuse block (J/B)

Is the inspection result normal?

YES >> Replace heated steering wheel switch. Refer to ST-56, "Removal and Installation".

Heated steering wheel relay Heated steering wheel switch

Continuity

Connector Terminal Connector Terminal

E90 2 M52 2 Existed

Heated steering wheel relay GroundContinuity

Connector Terminal

E90 2 Not existed

Fuse block (J/B) Heated steering wheel switch Continuity

Connector Terminal Connector Terminal

M1 2A M52 1 Existed

Fuse block (J/B) GroundContinuity

Connector Terminal

M1 2A Not existed

Revision: 2010 May2011 QX56

Page 5015 of 5598

ST-28

< SYMPTOM DIAGNOSIS >

HEATED STEERING WHEEL SWITCH INDICATOR LAMP DOES NOT TURN ON

NO >> Repair or replace damaged parts.

Revision: 2010 May2011 QX56

Page 5016 of 5598

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGST-29

< SYMPTOM DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

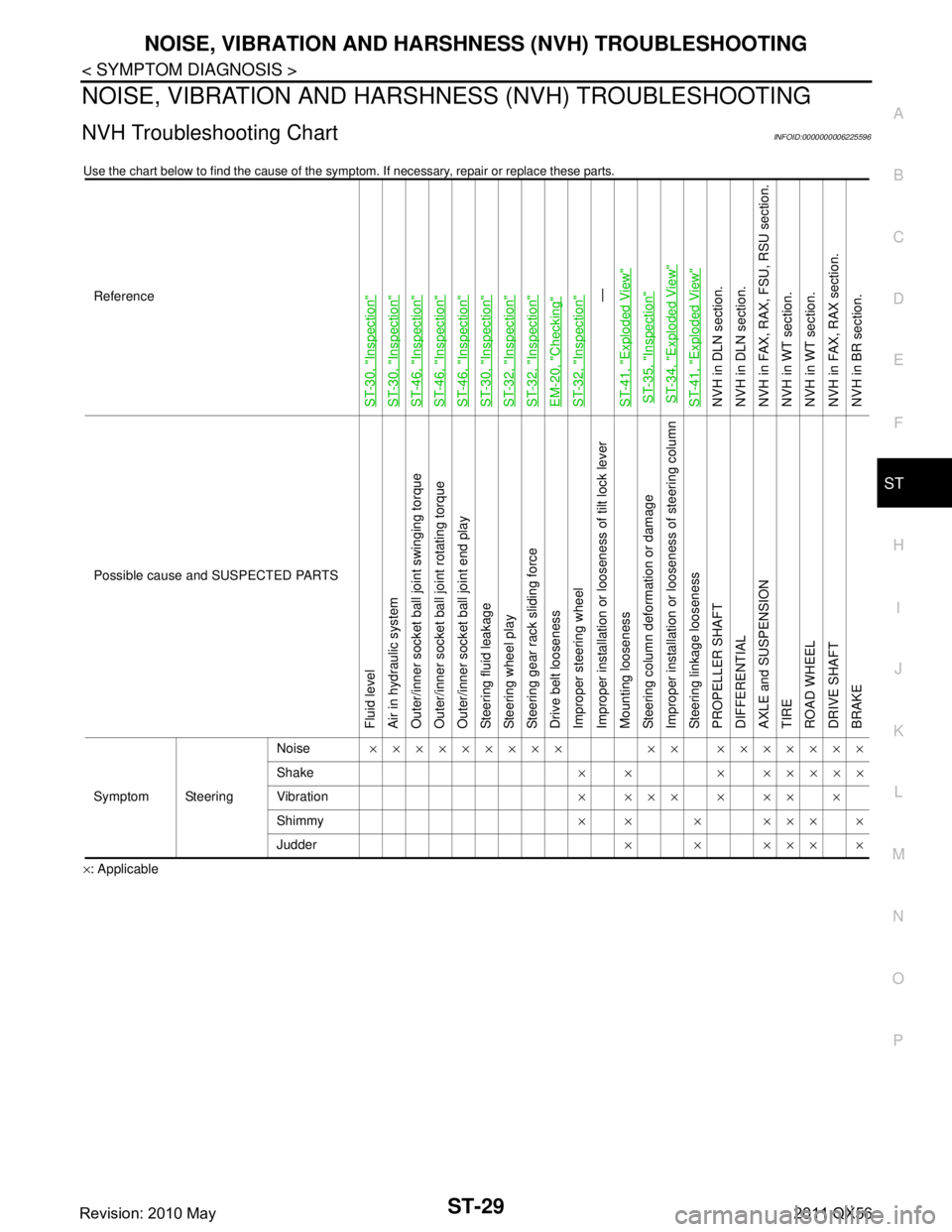

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000006225596

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference

ST-30, "

Inspection

"

ST-30, "

Inspection

"

ST-46, "

Inspection

"

ST-46, "

Inspection

"

ST-46, "

Inspection

"

ST-30, "

Inspection

"

ST-32, "

Inspection

"

ST-32, "

Inspection

"

EM-20, "

Checking

"

ST-32, "

Inspection

"—

ST-41, "

Exploded View

"

ST-35, "

Inspection

"

ST-34, "

Exploded View

"

ST-41, "

Exploded View

"

NVH in DLN section.

NVH in DLN section.

NVH in FAX, RAX, FSU, RSU section.

NVH in WT section.

NVH in WT section.

NVH in FAX, RAX section.

NVH in BR section.

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer/inner socket ball joint swinging torque

Outer/inner socket ball joint rotating torque

Outer/inner socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting looseness

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

Symptom Steering Noise

××××××××× ×× ×××××××

Shake × × × ×××××

Vibration ××××××××

Shimmy ×× × ××××

Judder ××××××

Revision: 2010 May2011 QX56

Page 5017 of 5598

ST-30

< PERIODIC MAINTENANCE >

POWER STEERING FLUID

PERIODIC MAINTENANCE

POWER STEERING FLUID

InspectionINFOID:0000000006225597

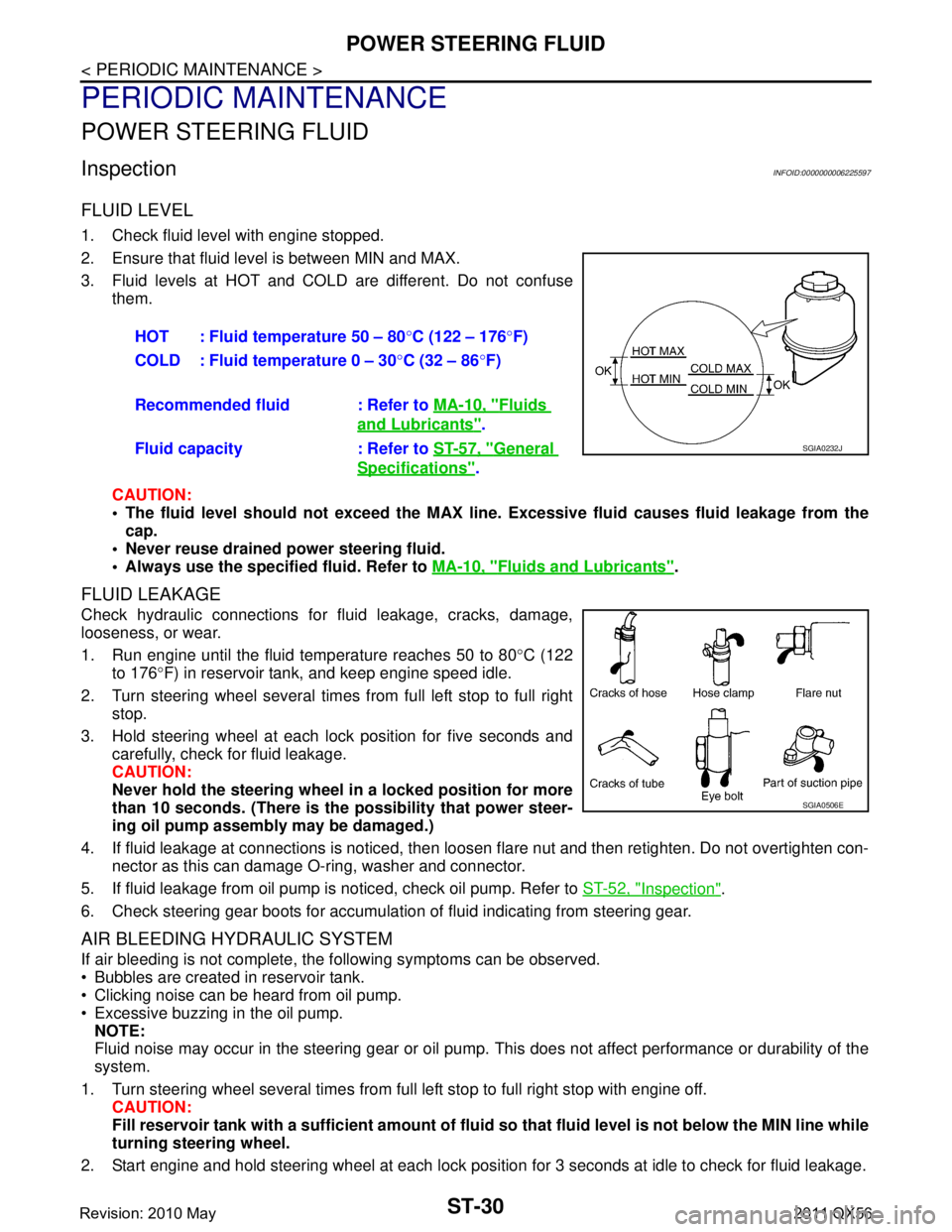

FLUID LEVEL

1. Check fluid level with engine stopped.

2. Ensure that fluid level is between MIN and MAX.

3. Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive flui d causes fluid leakage from the

cap.

Never reuse drained power steering fluid.

Always use the specified fluid. Refer to MA-10, "

Fluids and Lubricants".

FLUID LEAKAGE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80 °C (122

to 176 °F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right stop.

3. Hold steering wheel at each lock position for five seconds and carefully, check for fluid leakage.

CAUTION:

Never hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that power steer-

ing oil pump assembly may be damaged.)

4. If fluid leakage at connections is noticed, then loos en flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-52, "

Inspection".

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

AIR BLEEDING HYDRAULIC SYSTEM

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump. NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of the

system.

1. Turn steering wheel several times from full left stop to full right stop with engine off. CAUTION:

Fill reservoir tank with a sufficien t amount of fluid so that fluid level is not below the MIN line while

turning steering wheel.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

HOT : Fluid temperature 50 – 80

°C (122 – 176 °F)

COLD : Fluid temperature 0 – 30 °C (32 – 86 °F)

Recommended fluid : Refer to MA-10, "

Fluids

and Lubricants".

Fluid capacity : Refer to ST-57, "

General

Specifications".

SGIA0232J

SGIA0506E

Revision: 2010 May2011 QX56

Page 5018 of 5598

POWER STEERING FLUIDST-31

< PERIODIC MAINTENANCE >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

3. Repeat step 2 above several times at approximately 3 seconds intervals. CAUTION:

Never hold the steering wheel in a locked positio n for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.

5. Stop engine if bubbles and white contamination do not drain out. Perform step 2 and 3 above after waiting

until bubbles and white contamination drain out.

6. Stop the engine, and then check fluid level.

Revision: 2010 May2011 QX56

Page 5019 of 5598

ST-32

< PERIODIC MAINTENANCE >

STEERING WHEEL

STEERING WHEEL

InspectionINFOID:0000000006225598

STEERING WHEEL AXIAL END PLAY

1. Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

2. Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial direction.

3. Check the following items when steering w heel axial end play is out of the standard.

Check the steering column assembly mounting condition. Refer to ST-34, "

Exploded View".

Check steering gear assembly mounting condition for looseness. Refer to ST-41, "

Exploded View".

STEERING WHEEL PLAY

1. Turn steering wheel so that front wheels come to the straight-ahead position.

2. Start engine and lightly turn steering wheel to the left and right until front wheels start to move.

3. Measure steering wheel movement on the outer circumference.

4. Check the following items when steeri ng wheel play is out of the standard.

Check backlash for each joint of steering column assembly.

Check installation condition of steering gear assembly. Steering wheel axial end play : Refer to

ST-57, "

Steering Wheel Axial End Play and Play".

Steering wheel play : Refer to ST-57, "

Steering Wheel Axial End Play and Play".

Revision: 2010 May2011 QX56

Page 5020 of 5598

STEERING WHEELST-33

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

REMOVAL AND INSTALLATION

STEERING WHEEL

Exploded ViewINFOID:0000000006225599

Removal and InstallationINFOID:0000000006225600

REMOVAL

NOTE:

When reconnecting spiral cable, fix cable with a tape so that fixing case and rotating part keep aligned. This

will omit neutral position alignment procedure during spiral cable installation.

1. Set vehicle to the straight-ahead position.

2. Remove driver air bag module. Refer to SR-11, "

Removal and Installation".

3. Remove steering wheel lock nut after steering is locked.

4. Remove steering wheel with the steering wheel puller (A) [SST: ST27180001 (J-25726-A)].

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never twist spiral cable freely on excessively after it becomes tight (doing so may cause the cable to

tear off).

NOTE:

Check the spiral cable neutral position after r eplacing or rotating spiral cable. Refer to SR-14, "

Removal and

Installation".

1. Steering wheel

Refer to GI-4, "

Components" for symbols in the figure.

JSGIA0704GB

JSGIA0711ZZ

Revision: 2010 May2011 QX56