cooling ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1535 of 6020

6B-12 ENGINE COOLING (4JK1/4JJ1)

MFW 41CSH001401

Legend

1. W ooden Piece

2. Agitating Rod

Installation

1. Thermostat

Install the thermostat.

Mount the jiggle valve with the valve facing engine front.

RTW 56BSH000101

Legend

1. Front

2. Thermostat

3. Jiggle Valve

2. W ater Outlet Pipe.

a. Install the water outlet pipe with new gasket to the thermostat housing.

b. Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

c. Connect the turbocharger-cooling pipe to outlet pipe.

d. Install the engine harness clip.

3. Radiator Upper Hose.

RTW 56FSH000101

a. Connect the radiator upper hose to the water

outlet pipe.

b. The knob of the clamp should be directed to the horizontal side.

c. Replenish the engine coolant.

4. Install the engine cover.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1536 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-13

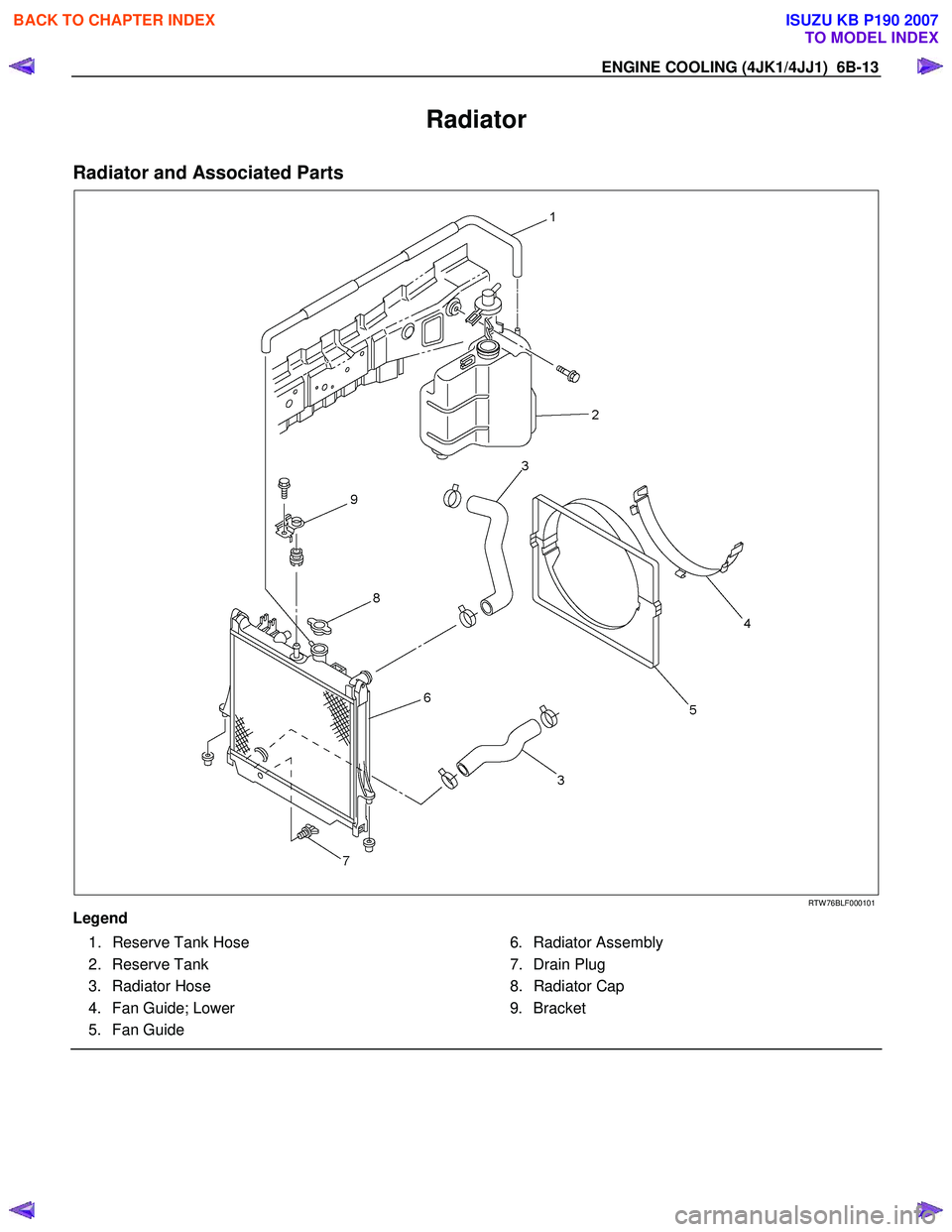

Radiator

Radiator and Associated Parts

RTW 76BLF000101

Legend

1. Reserve Tank Hose

2. Reserve Tank

3. Radiator Hose

4. Fan Guide; Lower

5. Fan Guide

6. Radiator Assembly

7. Drain Plug

8. Radiator Cap

9. Bracket

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1537 of 6020

6B-14 ENGINE COOLING (4JK1/4JJ1)

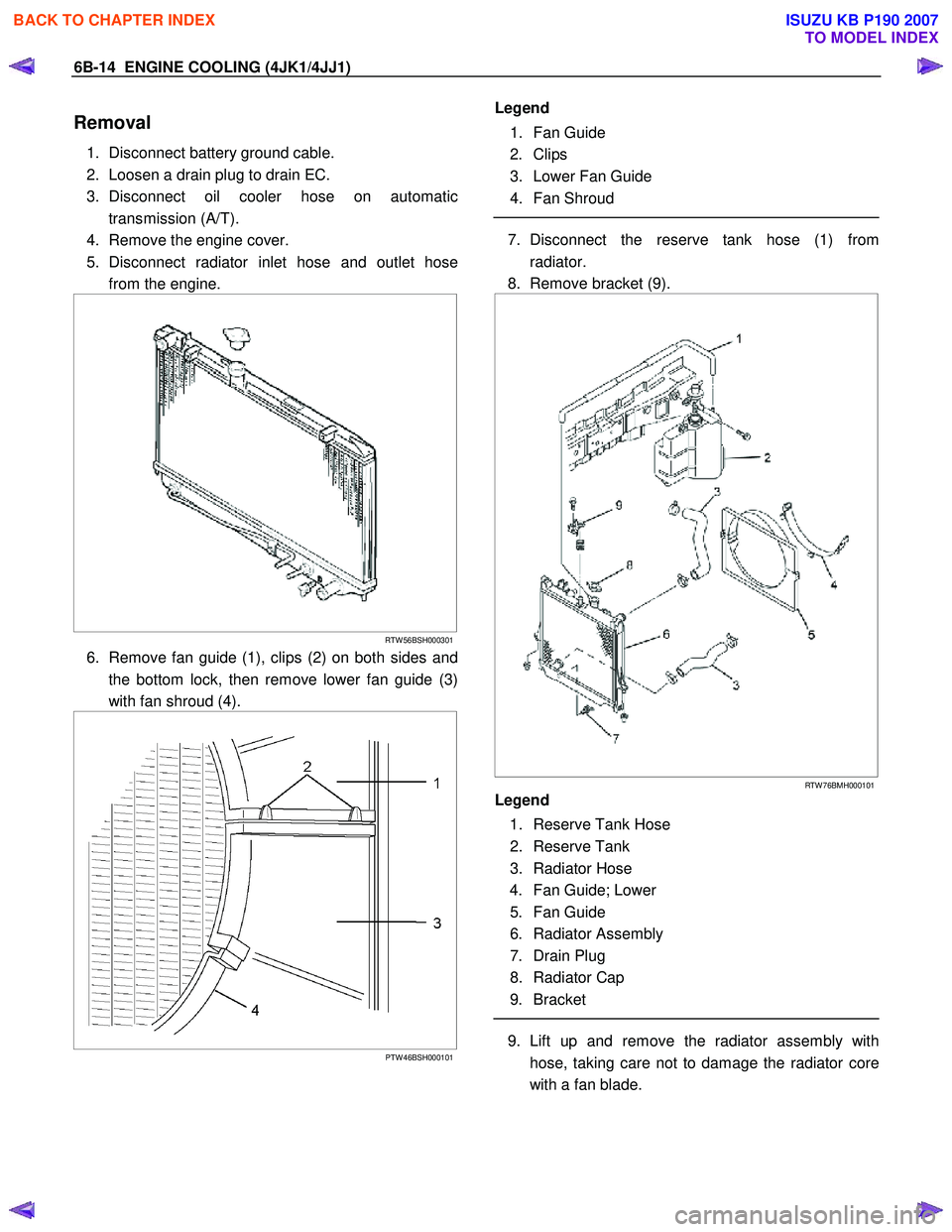

Removal

1. Disconnect battery ground cable.

2. Loosen a drain plug to drain EC.

3. Disconnect oil cooler hose on automatic transmission (A/T).

4. Remove the engine cover.

5. Disconnect radiator inlet hose and outlet hose from the engine.

RTW 56BSH000301

6. Remove fan guide (1), clips (2) on both sides and

the bottom lock, then remove lower fan guide (3)

with fan shroud (4).

PTW 46BSH000101

Legend

1. Fan Guide

2. Clips

3. Lower Fan Guide

4. Fan Shroud

7. Disconnect the reserve tank hose (1) from

radiator.

8. Remove bracket (9).

RTW 76BMH000101

Legend

1. Reserve Tank Hose

2. Reserve Tank

3. Radiator Hose

4. Fan Guide; Lower

5. Fan Guide

6. Radiator Assembly

7. Drain Plug

8. Radiator Cap

9. Bracket

9. Lift up and remove the radiator assembly with

hose, taking care not to damage the radiator core

with a fan blade.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1538 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-15

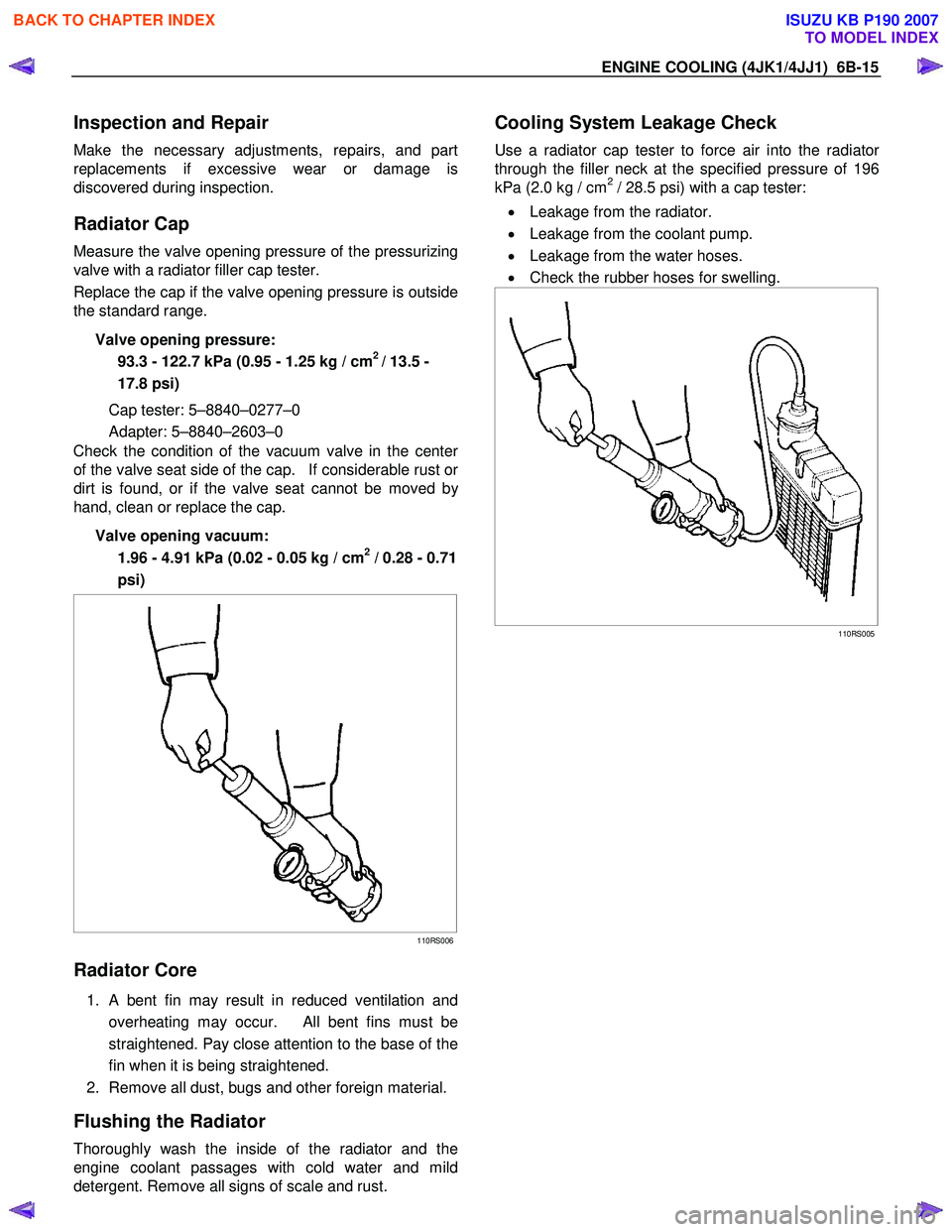

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure: 93.3 - 122.7 kPa (0.95 - 1.25 kg / cm

2 / 13.5 -

17.8 psi)

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the cente

r

of the valve seat side of the cap. If considerable rust or

dirt is found, or if the valve seat cannot be moved by

hand, clean or replace the cap.

Valve opening vacuum: 1.96 - 4.91 kPa (0.02 - 0.05 kg / cm

2 / 0.28 - 0.71

psi)

110RS006

Radiator Core

1. A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the

fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the

engine coolant passages with cold water and mild

detergent. Remove all signs of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196

kPa (2.0 kg / cm2 / 28.5 psi) with a cap tester:

• Leakage from the radiator.

• Leakage from the coolant pump.

• Leakage from the water hoses.

• Check the rubber hoses for swelling.

110RS005

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1539 of 6020

6B-16 ENGINE COOLING (4JK1/4JJ1)

Installation

1. Install radiator assembly (6) with hose, taking care

not to damage the radiator core with a fan blade.

2. Support the radiator upper tank with the bracket (9) and secure the radiator.

3. Connect reserve tank hose (1).

4. Install lower fan guide (4).

5. Connect radiator inlet hose and outlet hose (3) to the engine.

6. Install the engine cover.

7. Connect oil cooler hose to automatic transmission.

8. Connect battery ground cable.

RTW 76BMH000101

Legend

1. Reserve Tank Hose

2. Reserve Tank

3. Radiator Hose

4. Fan Guide; Lower

5. Fan Guide

6. Radiator Assembly

7. Drain Plug

8. Radiator Cap

9. Bracket

9. Pour engine coolant up to filler neck of radiator,

and up to MAX mark of reserve tank.

Important operation (in case of 100% engine coolant change) procedure for filling with engine

coolant.

RTW 76BSH000101

Engine coolant change

Refer to change procedure for Draining and Refilling

Cooling System in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1540 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-17

Fan Clutch with Cooling Fan

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage or any other abnormal conditions are

found through inspection.

Visually inspect for damage, leak (silicon grease) o

r

other abnormal conditions.

1. Inspection (on-vehicle) a) Turn the fan clutch by hand when in a lo

w

temperature condition before starting the

engine, and confirm that it can be turned

readily.

b) Start the engine to warm it up until the temperature at the fan clutch portion gets to

around 85°C (185°F). Then stop the engine and

confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned

by hand.

If the fan clutch rotates more readily, however, this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

RTW 56ASH025401

2. Inspection (in unit)

W arm up the bimetal of the fan clutch by using the heat gun until the temperature gets to about 85°C

when measured with the thermistor. Then confirm

that the fan clutch can be turned with considerable

effort (clutch torque).

If the fan clutch rotates more readily at this time, this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

033RY00011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1541 of 6020

6B-18 ENGINE COOLING (4JK1/4JJ1)

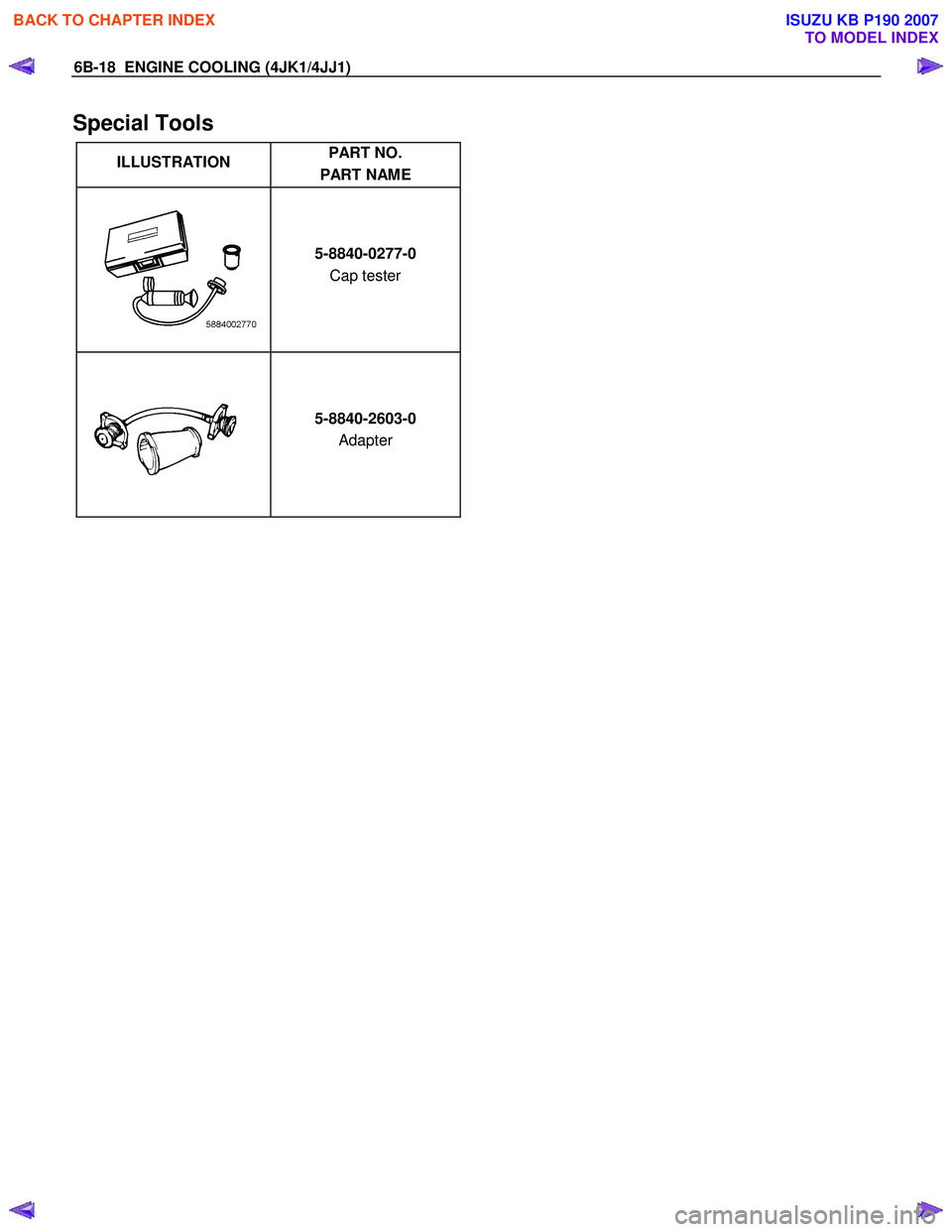

Special Tools

ILLUSTRATION PART NO.

PART NAME

5-8840-0277-0

Cap tester

5-8840-2603-0

Adapter

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1569 of 6020

6C-28 FUEL SYSTEM (4JK1/4JJ1)

Removal

1. Partially drain the engine coolant.

Refer to drain procedure for engine cooling in this manual.

2. Remove the radiator upper hose.

RTW 56FSH000101

3. Remove the fan guide.

RTW 46BSH000101

Legend

1. Fan Guide

2. Clips

3. Lower Fan Guide

4. Fan Shroud

4. Remove the cooling Fan.

RTW 56ASH025401

5. Remove the A/C compressor drive belt.

6. Remove the A/C compressor adjust pulley.

RTW 56ASH010601

Legend

1. Bolt

2. Nut

7. Remove the battery.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1578 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-37

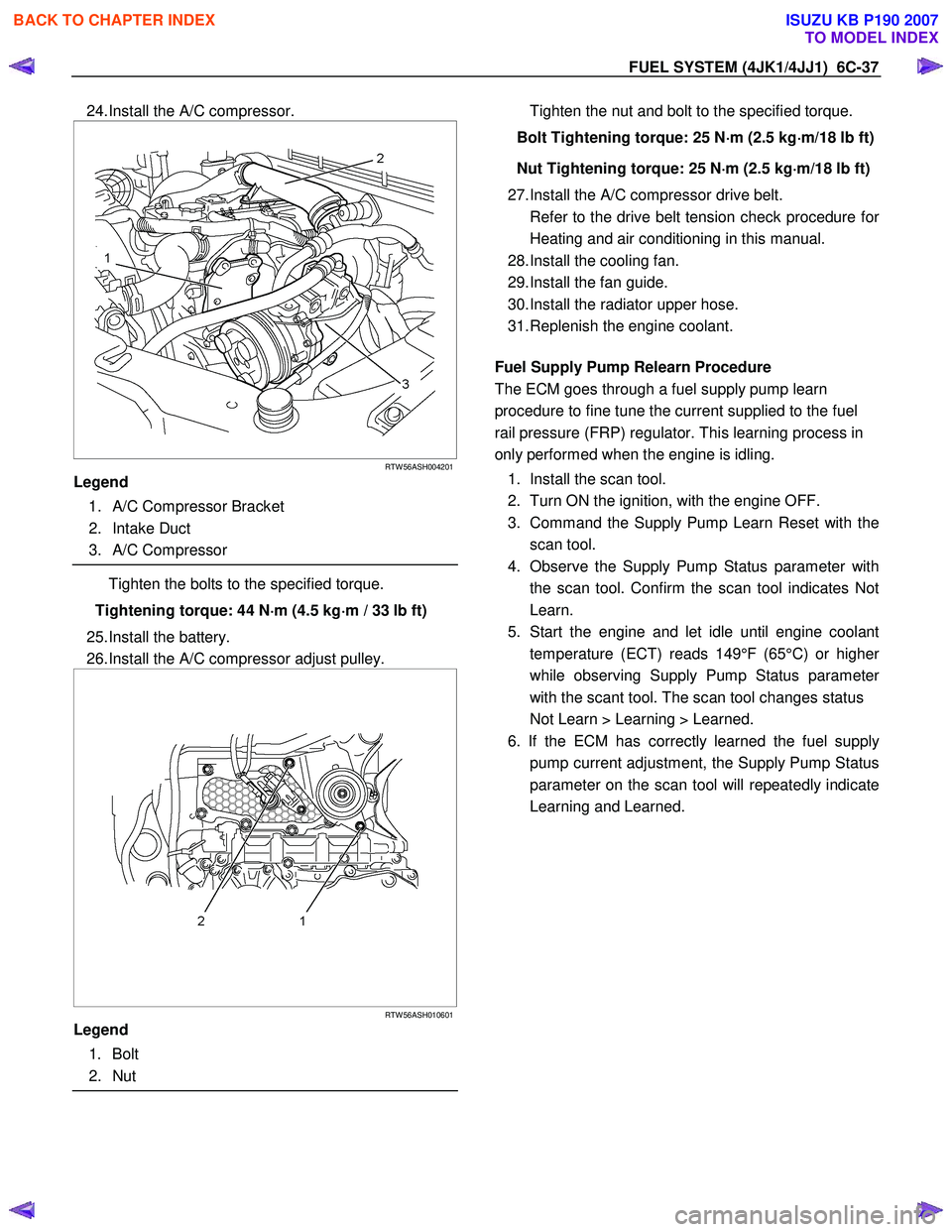

24. Install the A/C compressor.

RTW 56ASH004201

Legend

1. A/C Compressor Bracket

2. Intake Duct

3. A/C Compressor

Tighten the bolts to the specified torque.

Tightening torque: 44 N ⋅

⋅⋅

⋅

m (4.5 kg ⋅

⋅⋅

⋅

m / 33 lb ft)

25. Install the battery.

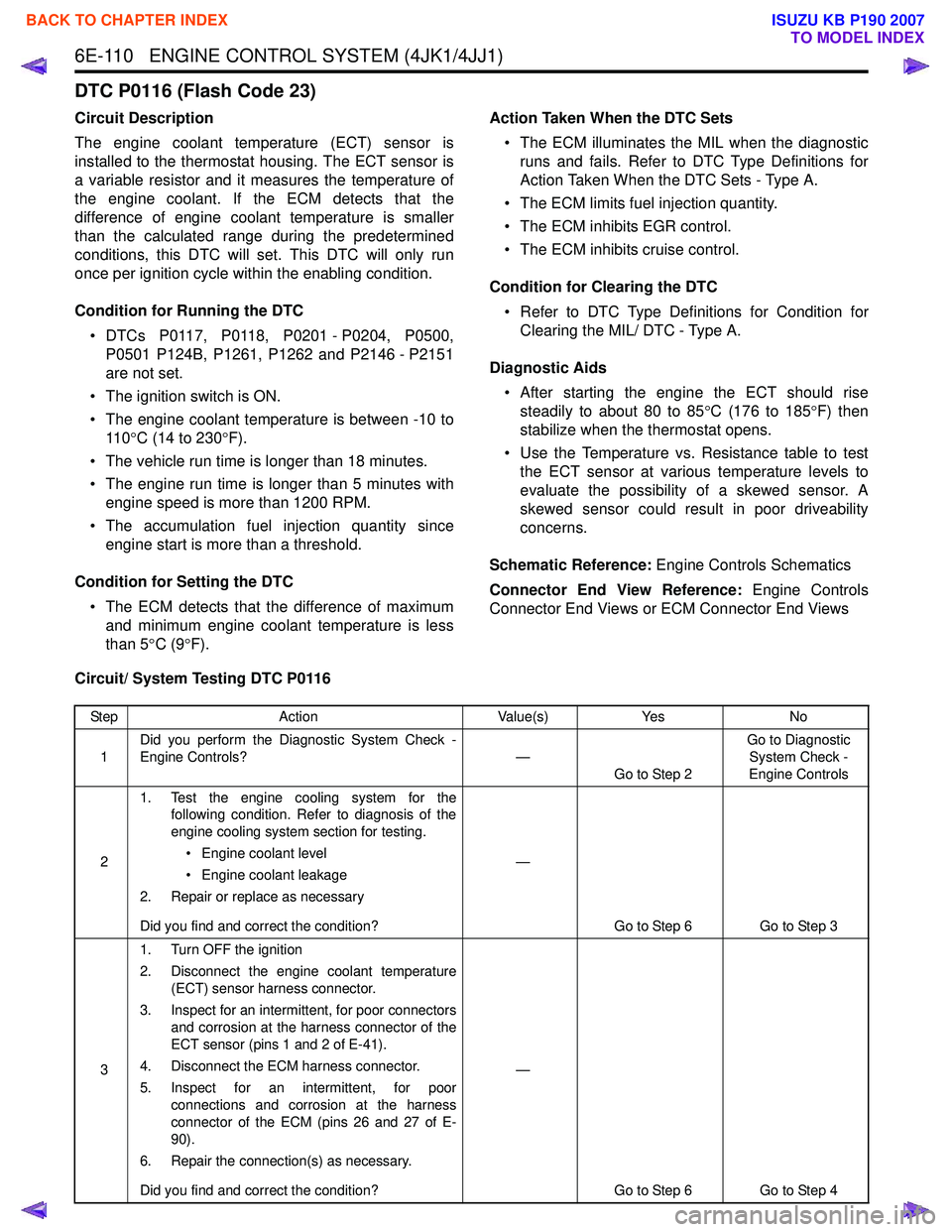

26. Install the A/C compressor adjust pulley.

RTW 56ASH010601

Legend

1. Bolt

2. Nut

Tighten the nut and bolt to the specified torque.

Bolt Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

Nut Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

27. Install the A/C compressor drive belt.

Refer to the drive belt tension check procedure fo

r

Heating and air conditioning in this manual.

28. Install the cooling fan.

29. Install the fan guide.

30. Install the radiator upper hose.

31. Replenish the engine coolant.

Fuel Supply Pump Relearn Procedure

The ECM goes through a fuel supply pump learn

procedure to fine tune the current supplied to the fuel

rail pressure (FRP) regulator. This learning process in

only performed when the engine is idling.

1. Install the scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Command the Supply Pump Learn Reset with the scan tool.

4. Observe the Supply Pump Status parameter with the scan tool. Confirm the scan tool indicates Not

Learn.

5. Start the engine and let idle until engine coolant temperature (ECT) reads 149°F (65°C) or highe

r

while observing Supply Pump Status parameter

with the scant tool. The scan tool changes status

Not Learn > Learning > Learned.

6. If the ECM has correctly learned the fuel supply pump current adjustment, the Supply Pump Status

parameter on the scan tool will repeatedly indicate

Learning and Learned.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1727 of 6020

6E-110 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0116 (Flash Code 23)

Circuit Description

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor and it measures the temperature of

the engine coolant. If the ECM detects that the

difference of engine coolant temperature is smaller

than the calculated range during the predetermined

conditions, this DTC will set. This DTC will only run

once per ignition cycle within the enabling condition.

Condition for Running the DTC • DTCs P0117, P0118, P0201 - P0204, P0500, P0501 P124B, P1261, P1262 and P2146 - P2151

are not set.

• The ignition switch is ON.

• The engine coolant temperature is between -10 to 11 0 °C (14 to 230 °F).

• The vehicle run time is longer than 18 minutes.

• The engine run time is longer than 5 minutes with engine speed is more than 1200 RPM.

• The accumulation fuel injection quantity since engine start is more than a threshold.

Condition for Setting the DTC • The ECM detects that the difference of maximum and minimum engine coolant temperature is less

than 5 °C (9 °F). Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • After starting the engine the ECT should rise steadily to about 80 to 85 °C (176 to 185 °F) then

stabilize when the thermostat opens.

• Use the Temperature vs. Resistance table to test the ECT sensor at various temperature levels to

evaluate the possibility of a skewed sensor. A

skewed sensor could result in poor driveability

concerns.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0116

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Test the engine cooling system for the

following condition. Refer to diagnosis of the

engine cooling system section for testing.

• Engine coolant level

• Engine coolant leakage

2. Repair or replace as necessary

Did you find and correct the condition? —

Go to Step 6 Go to Step 3

3 1. Turn OFF the ignition

2. Disconnect the engine coolant temperature (ECT) sensor harness connector.

3. Inspect for an intermittent, for poor connectors and corrosion at the harness connector of the

ECT sensor (pins 1 and 2 of E-41).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 26 and 27 of E-

90).

6. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007