cooling ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1302 of 6020

6E-268 Engine Control System (4JH1)

Checks Action

Engine Mechanical Check Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Inspect for poor cylinder compression. Proper compression is more than 2100 kPa

(309 psi).

• Improper mechanical timing

• Improper valve gap

• Broken or weak valve springs

• W orn camshaft lobes

Additional Checks •

Inspect the generator output voltage. Repair if less than 9 volts or more than 16

volts.

• Inspect the EGR system operating correctly.

• Inspect the engine overheat condition. Refer to the Engine Cooling section.

• Inspect the A/C operation.

• Inspect the torque converter clutch (TCC) operation (A/T only).

Hesitation, Sag, Stumble

Checks Action

DEFINITION:The vehicle has a momentary lack of response when pushing down on the accelerator. The condition can occur

at any vehicle speed. The condition is usually most severe when trying to make the vehicle move from a stop. If severe

enough, the condition may cause the engine to stall.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Compare the vehicle with a similar unit. Ensure the vehicle has an actual problem.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect for a proper transmission shift pattern and down shift operation.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Inspect the scan tool Data List in this section.

• Inspect the engine control module (ECM) and fuel injection pump control unit (PCU)

grounds for being clean, tight, and in their proper locations.

• Inspect the Service Bulletins for ECM software updates.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the scan tool

Data List in this section.

• Use the scan tool to compare the Engine Coolant Temperature (ECT) with the Intake

Air Temperature (IAT) and Fuel Temperature (FT) on a cold engine condition. If the

difference among temperature reading is more than 5°C (9°F) on a cold engine,

check for high resistance on the low reference circuit and signal circuit or for a

skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT sensor may

indicate a higher than normal intake air temperature if the ignition switch is being ON.

FT sensor is internal to the PCU and it is part of the fuel injection pump assembly.

• Use the scan tool to compare the MAF Sensor parameter with the Desired MAF

parameter. Start the engine and warm up (allow engine coolant temperature to reach

at least 60°C [140°F]). The MAF Sensor parameter must follow the Desired MAF

parameter within 100 mg/strk. If not, inspect the air intake system, EGR system

components and contaminated, skewed or slow MAF sensor.

• Use the scan tool to observe the Accelerator Pedal Position Accelerator Pedal

Position. Accelerator Pedal Position parameter should change linearly from 0% to

100% according to the accelerator pedal operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1305 of 6020

Engine Control System (4JH1) 6E-271

Checks Action

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Inspect for poor cylinder compression. Proper compression is more than 2100 kPa

(309 psi).

• Inspect for incorrect basic engine parts such as camshaft, cylinder head, pistons,

etc.

• Inspect for any excessive oil entering combustion chamber.

Additional Checks •

Inspect the EGR system operating correctly.

• Inspect other possible causes that can make similar noise such as loose component

parts, bracket, mount and weak clutch damper spring.

Poor Fuel Economy

Checks Action

DEFINITION:Fuel economy, as measured by actual road tests and several tanks of fuel, is noticeably lower than expected.

Also, the economy is noticeably lower than it was on this vehicle at one time, as previously shown by actual road tests.

Preliminary Checks • Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect the driving habits of the owner.

• Is the A/C ON full time, defroster mode ON?

• Are the tires at the correct pressure?

• Are the tire sizes changed?

• Are excessively heavy loads being carried?

• Is the acceleration too much, too often?

• Inspect for clutch slip.

• Inspect brake drag.

• Inspect dive belt tension.

• Inspect for a proper transmission shift pattern and down shift operation (A/T only).

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Suggest to the owner to fill the fuel tank and recheck the fuel economy.

• Suggest to the driver to read the Important Facts on Fuel Economy in the Owner

Manual.

• Inspect the odometer is correctly operated.

• Inspect the Service Bulletins for ECM software updates.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the scan tool

Data List in this section.

• Use the scan tool to compare the Engine Coolant Temperature (ECT) with the Intake

Air Temperature (IAT) and Fuel Temperature (FT) on a cold engine condition. If the

difference among temperature reading is more than 5°C (9°F) on a cold engine,

check for high resistance on the low reference circuit and signal circuit or for a

skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT sensor may

indicate a higher than normal intake air temperature if the ignition switch is being ON.

FT sensor is internal to the PCU and it is part of the fuel injection pump assembly.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Inspect the fuel type and quality.

• Check fuel leak.

Cooling System Checks Inspect the cooling system for the following conditions. Refer to the Cooling System

Section.

• Inspect the engine coolant level.

• Inspect the engine thermostat for always being open or for the wrong heat range.

• Inspect the engine cooling fan for always being ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1325 of 6020

Engine Control System (4JH1) 6E-291

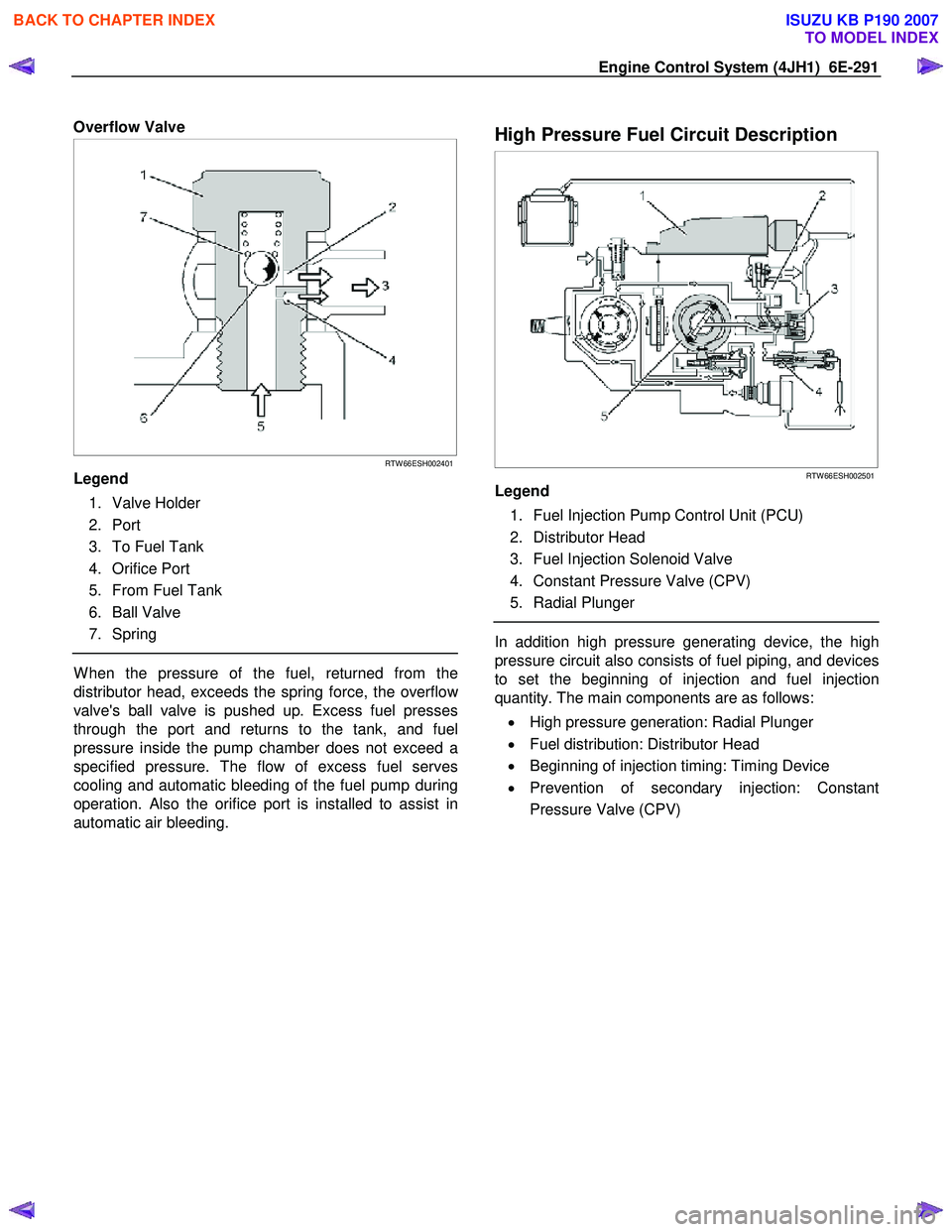

Overflow Valve

RTW 66ESH002401

Legend

1. Valve Holder

2. Port

3. To Fuel Tank

4. Orifice Port

5. From Fuel Tank

6. Ball Valve

7. Spring

W hen the pressure of the fuel, returned from the

distributor head, exceeds the spring force, the overflo

w

valve's ball valve is pushed up. Excess fuel presses

through the port and returns to the tank, and fuel

pressure inside the pump chamber does not exceed a

specified pressure. The flow of excess fuel serves

cooling and automatic bleeding of the fuel pump during

operation. Also the orifice port is installed to assist in

automatic air bleeding.

High Pressure Fuel Circuit Description

RTW 66ESH002501

Legend

1. Fuel Injection Pump Control Unit (PCU)

2. Distributor Head

3. Fuel Injection Solenoid Valve

4. Constant Pressure Valve (CPV)

5. Radial Plunger

In addition high pressure generating device, the high

pressure circuit also consists of fuel piping, and devices

to set the beginning of injection and fuel injection

quantity. The main components are as follows:

• High pressure generation: Radial Plunger

• Fuel distribution: Distributor Head

• Beginning of injection timing: Timing Device

• Prevention of secondary injection: Constant

Pressure Valve (CPV)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1332 of 6020

6E-298 Engine Control System (4JH1)

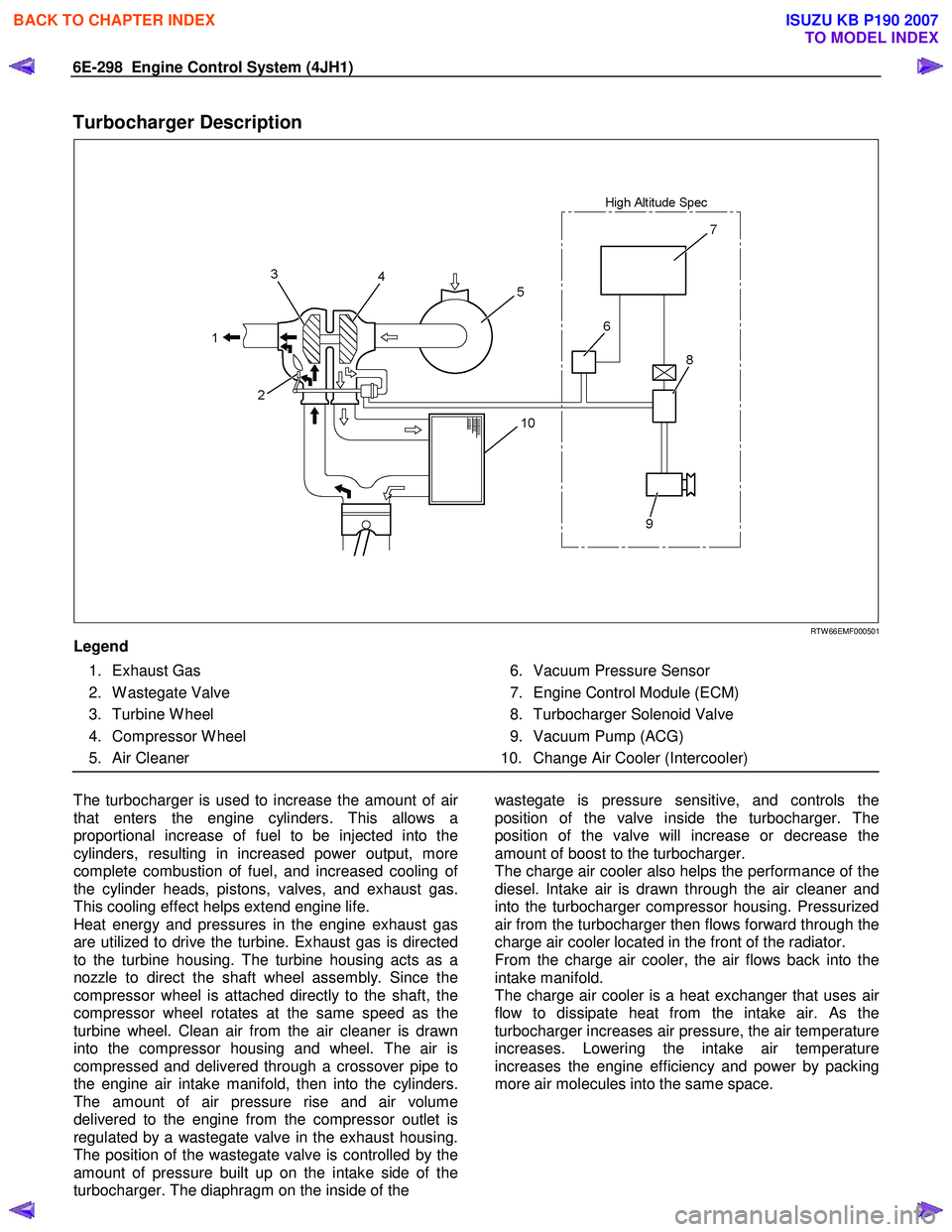

Turbocharger Description

RTW 66EMF000501

Legend

1. Exhaust Gas

2. W astegate Valve

3. Turbine W heel

4. Compressor W heel

5. Air Cleaner

6. Vacuum Pressure Sensor

7. Engine Control Module (ECM)

8. Turbocharger Solenoid Valve

9. Vacuum Pump (ACG)

10. Change Air Cooler (Intercooler)

The turbocharger is used to increase the amount of ai

r

that enters the engine cylinders. This allows a

proportional increase of fuel to be injected into the

cylinders, resulting in increased power output, more

complete combustion of fuel, and increased cooling o

f

the cylinder heads, pistons, valves, and exhaust gas.

This cooling effect helps extend engine life.

Heat energy and pressures in the engine exhaust gas

are utilized to drive the turbine. Exhaust gas is directed

to the turbine housing. The turbine housing acts as a

nozzle to direct the shaft wheel assembly. Since the

compressor wheel is attached directly to the shaft, the

compressor wheel rotates at the same speed as the

turbine wheel. Clean air from the air cleaner is drawn

into the compressor housing and wheel. The air is

compressed and delivered through a crossover pipe to

the engine air intake manifold, then into the cylinders.

The amount of air pressure rise and air volume

delivered to the engine from the compressor outlet is

regulated by a wastegate valve in the exhaust housing.

The position of the wastegate valve is controlled by the

amount of pressure built up on the intake side of the

turbocharger. The diaphragm on the inside of the

wastegate is pressure sensitive, and controls the

position of the valve inside the turbocharger. The

position of the valve will increase or decrease the

amount of boost to the turbocharger.

The charge air cooler also helps the performance of the

diesel. Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressurized

air from the turbocharger then flows forward through the

charge air cooler located in the front of the radiator.

From the charge air cooler, the air flows back into the

intake manifold.

The charge air cooler is a heat exchanger that uses ai

r

flow to dissipate heat from the intake air. As the

turbocharger increases air pressure, the air temperature

increases. Lowering the intake air temperature

increases the engine efficiency and power by packing

more air molecules into the same space.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1360 of 6020

PAGE

Section 6A Engine Mechanical .................................................................................... 1361

Section 6B Engine Cooling .......................................................................................... 1524

Section 6C Fuel System ............................................................................................... 1542

Section 6D Engine Electrical ....................................................................................... 1589

Section 6E Engine Control System ............................................................................ 1618

Section 6F Exhaust System ........................................................................................ 1986

Section 6H Engine Speed Control System ................................................................ 1998

SECTION 6

ENGINE

TA BLE OF CONTENTS

ENGINE 6

4JK

1/4J J1 MODELS

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1372 of 6020

6A-12 ENGINE MECHANICAL (4JK1/4JJ1)

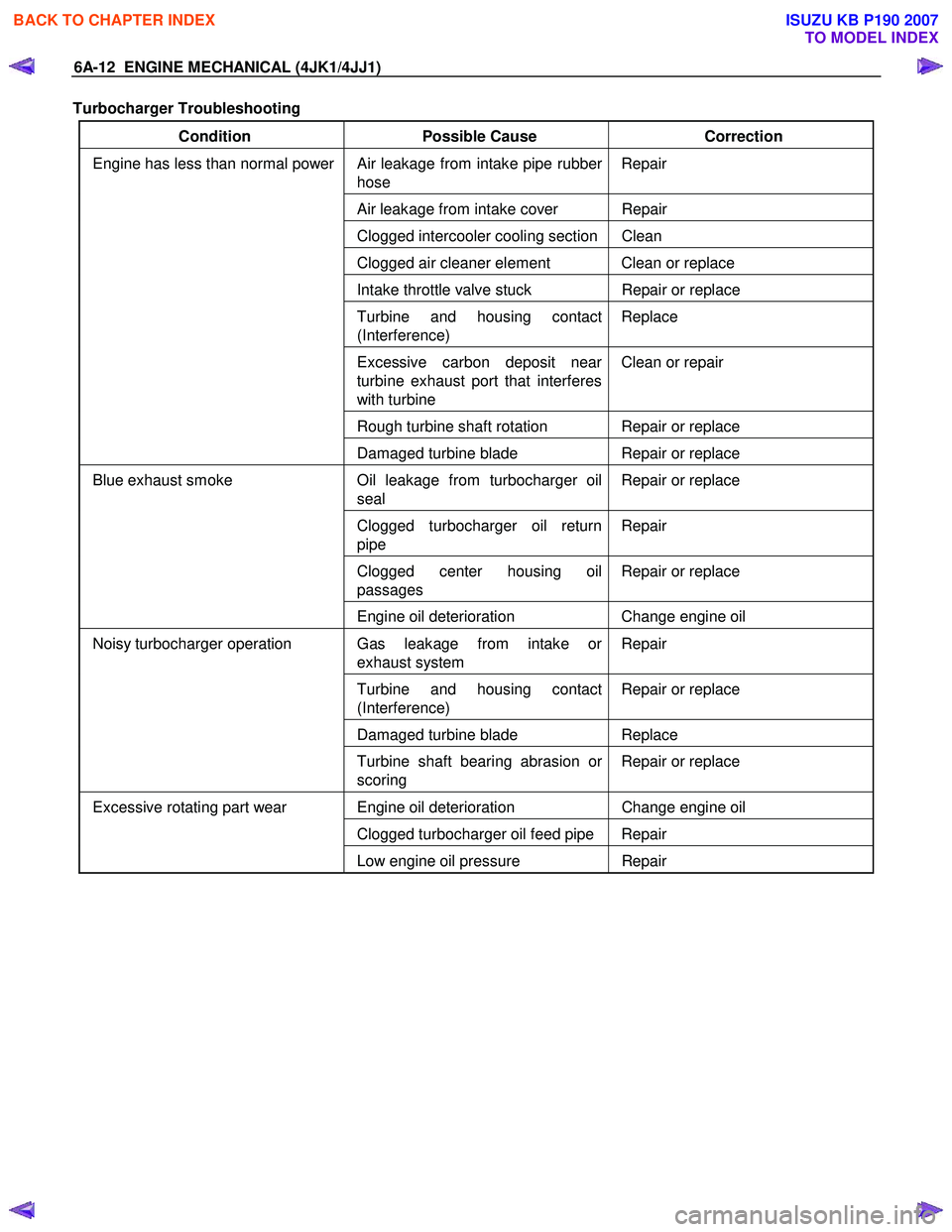

Turbocharger Troubleshooting

Condition Possible Cause Correction

Air leakage from intake pipe rubber

hose Repair

Air leakage from intake cover Repair

Clogged intercooler cooling section Clean

Clogged air cleaner element Clean or replace

Intake throttle valve stuck

Repair or replace

Turbine and housing contact

(Interference) Replace

Excessive carbon deposit near

turbine exhaust port that interferes

with turbine Clean or repair

Rough turbine shaft rotation Repair or replace

Engine has less than normal power

Damaged turbine blade Repair or replace

Oil leakage from turbocharger oil

seal Repair or replace

Clogged turbocharger oil return

pipe Repair

Clogged center housing oil

passages Repair or replace

Blue exhaust smoke

Engine oil deterioration Change engine oil

Gas leakage from intake or

exhaust system Repair

Turbine and housing contact

(Interference) Repair or replace

Damaged turbine blade

Replace

Noisy turbocharger operation

Turbine shaft bearing abrasion or

scoring Repair or replace

Engine oil deterioration

Change engine oil

Clogged turbocharger oil feed pipe Repair

Excessive rotating part wear

Low engine oil pressure Repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1373 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-13

Main Data and specifications

Item Engine model 4JK1 Engine model 4JJ1

Type Diesel/4-cycle/water cooling-type in-line DOHC

Combustion chamber type Direct injection type

Cylinder liner type Liner less

Number of cylinders -cylinder

bore × strokes mm (in) 4-95.4 (3.76) × 87.4 (3.44) 4-95.4(3.76) × 104.9(4.13)

Displacement

cc (cu.in) 2499 (152) 2999 (183)

Compression ratio 18.3 17.5

Compression pressure MPa (psi)/rpm 3 (435)/200

Idling speed rpm 700 ± 25

Valve clearance Intake 0.15 (0.006) (cold)

mm (in) Exhaust 0.15 (0.006) (cold)

Ignition type Compressed ignition

Injection order 1 - 3 - 4 - 2

Lubricating system

Lubricating type Pressure delivery type

Oil pump type Gear type

Volume of lubricating oil L (qts) 8.0 (8.5)

Oil filter type Full flow filter (cartridge type)

Oil cooling type Built-in-type, water cooling

Cooling system

Cooling type W ater cooling type

Radiator type Corrugated fin (pressure type)

W ater pump type Centrifugal, belt drive type

Thermostat type W ax-type units

Thermostat valve-opening temperature °C ( °F) 85 (185)

Volume of coolant L (qts) M/T8.7 (9.2) A/T 8.6 (9.1) (incl. radiator)

Fuel system

Injection pump type Fuel supply pump fuel rail type

Fuel injector type Electronic control injector

6-hole

Fuel pump type Into the fuel tank type

Charging system

Generator type AC type

Power output V-A 12 - 90

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1411 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-51

Removal

1. Partially drain the engine coolant.

2. Remove the radiator upper hose.

RTW 56FSH000101

3. Remove the fan guide.

RTW 46BSH000101

Legend

1. Fan Guide

2. Clips

3. Lower Fan Guide

4. Fan Shroud

4. Remove the cooling fan and fan pulley.

RTW 56ASH025401

5. Remove the A/C compressor drive belt and fan

belt.

6. Remove the crank pulley.

7. Remove the power steering pump with hose.

RTW 56ASH021101

Legend

1. Power Steering Pump

2. Nut

• Disconnect the bracket (1) of power steering oil

hose.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1417 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-57

6. Remove the M6 bolt from the idle gear A.

7. Install the gear case cover. • Apply the liquid gasket (ThreeBond TB-1207B

or equivalent).

RTW 56ASH020101

Legend

1. Apply the liquid gasket

• Install the gasket in slot of the gear case cover.

• Tighten the bolts to the specified torque.

Tightening torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

RTW 56ASH012101

8. Install the vacuum pump.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Install the oil pipe (feed side and return side) o

f

vacuum pump.

• Install the vacuum pipe bracket and vacuum

pipe.

9. Install the power steering pump. • Tighten the nuts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Connect the bracket (1) of power steering oil

hose.

LTW 56ASH000101

10. Install the crank pulley.

Tightening torque: 294 N ⋅

⋅⋅

⋅

m (30.0 kg ⋅

⋅⋅

⋅

m / 217 lb ft)

11. Install the A/C compressor drive belt and fan belt.

Refer to drive belt tension check procedure fo

r

Heating and air conditioning and Engine cooling in

this manual.

12. Install the cooling fan.

13. Install the fan guide.

14. Install the radiator upper hose.

15. Replenish the engine coolant.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1433 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-73

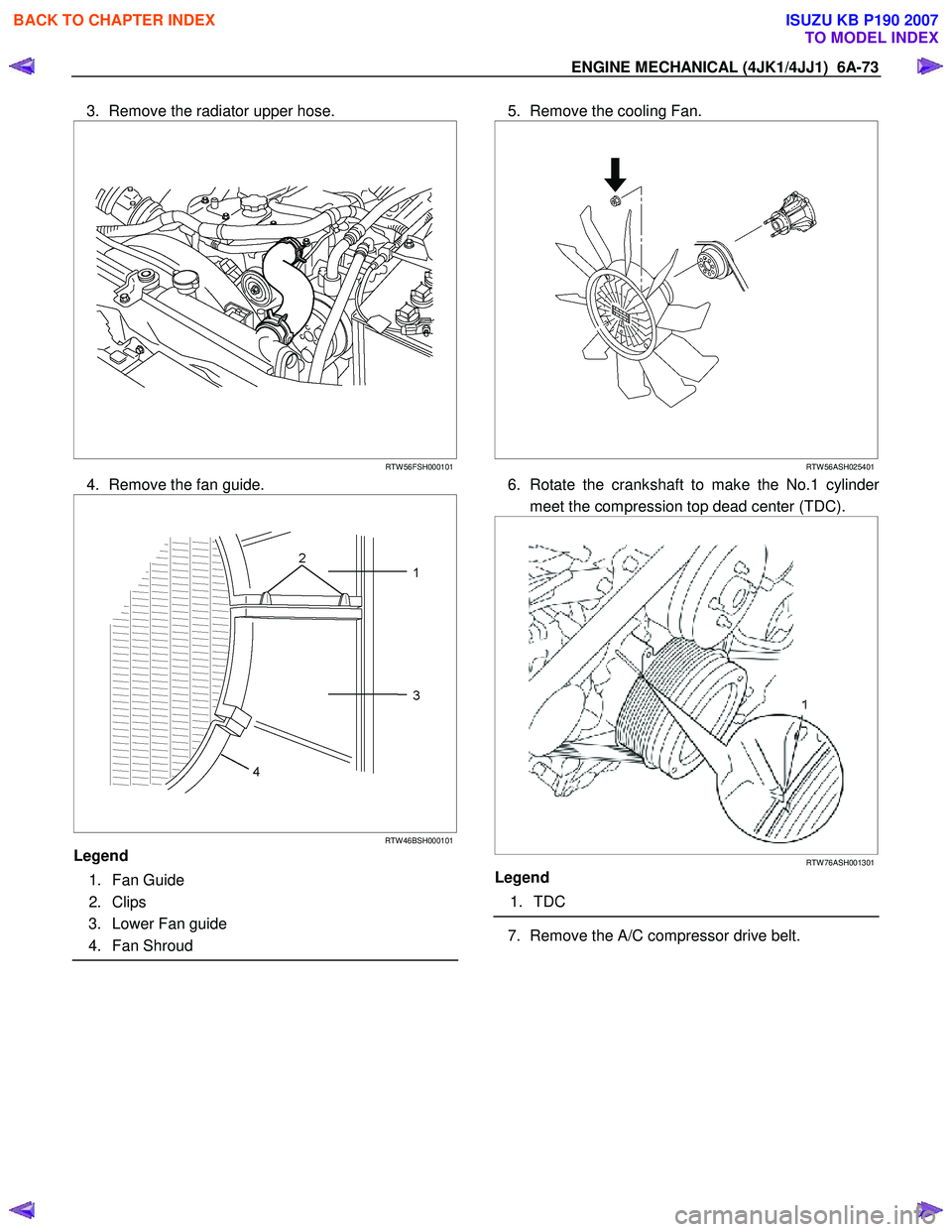

3. Remove the radiator upper hose.

RTW 56FSH000101

4. Remove the fan guide.

RTW 46BSH000101

Legend

1. Fan Guide

2. Clips

3. Lower Fan guide

4. Fan Shroud

5. Remove the cooling Fan.

RTW 56ASH025401

6. Rotate the crankshaft to make the No.1 cylinder

meet the compression top dead center (TDC).

RTW 76ASH001301

Legend

1. TDC

7. Remove the A/C compressor drive belt.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007