stop start ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4379 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-95

Vehicle Does Not Run

Trouble at Starting

Faulty Gearshift

Faulty Shift Pattern

No or Error Gearshift

Faulty Operation During Running

Faulty Operation in Stopping

Faulty Lock Up

No Lock Up

Transmission Fluid Leak

Others

Diagnostic CategoryCategory No.

This table consists of diagnostic categories that are located in the left column. Using this column, choose the appropriate

category based on the operating conditions of the vehicle or transmission. After selecting a category, use the right column to

locate the specific symptom diagnostic information.

Vehicle Does Not Run Vehicle does not run in D, 3, 2, L & L range A1

Vehicle does not run in R range A2

Vehicle does not run in D, 3, 2 and L range A3

Trouble at Starting Vehicle runs in N range B1

Poor acceleration at starting B2

Engine races up during starting (slip) B3

Large shock when selector lever is changed from N to D range or N to R

range B4

Engine stalls when selector lever is changed from N to R, D, 3, 2 or L

range B5

Engine does not crank in P or N range B6

Engine cranks in other than P or N range B7

Extended time lag when selector lever is changed from N to D B8

Extended time lag when selector lever is changed from N to R B9

Brake is applied in R range B10

Insufficient starting or shaking in D range B11

Noise or vibration occurs at starting B12

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4381 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-97

Faulty Operation in Stopping Vehicle moves in P range or parking is not disengaged in other than Prange G1

Large creeping force G2

Small creeping force G3

Large noise during idle with vehicle stop G4

Faulty Lock Up Judder Occurs at Lock Up H1

Large Shock at Lock Up H2

Lock Up Point is High or Low H3

No Lock Up No Lock Up I1

Transmission Fluid Leak Transmission fluid leaks from breather J1

Transmission fluid leaks between engine and converter housing J2

Transmission fluid leaks between converter housing and transmission

case J3

Transmission fluid leaks between transmission case and extension

housing J4

Transmission fluid leaks from oil pan J5

Transmission fluid leaks from manual shaft oil seal J6

Transmission fluid leaks from oil cooler pipe joint J7

Others Transmission overheat Z1

Mode lamp (power drive or 3rd start) does not turn On Z2

Mode lamp (power drive or 3rd start) does not turn Off Z3

A/T oil temperature lamp turns On Z4

Selector lever feeling is faulty Z5

Poor fuel consumption Z6

Shift indicator is faulty Z7

Abnormal smell Z8

Transmission fluid quantity is low or high Z9

Transmission fluid quantity is low or high Z10

Abnormal transmission fluid pressure Z11

Diagnostic Category

Category No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4383 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-99

C1

Engine race up (slipping) when gearshift is

up from 1st to 2nd

C2

Engine race up (slipping) when gearshift is

up from 2nd to 3rd

C3

Engine race up (slipping) when gearshift is

up from 3rd to 4th

C4

Engine race up (slipping) when gearshift is

down from 4th to 3rd

C5

Engine race up (slipping) when gearshift is

down (or kick-down) from 4th to 2nd

C6

Engine race up (slipping) when gearshift is

down (or kick-down) from 3rd to 2nd

C7

Engine race up (slipping) when gearshift is

down (or kick-down) from 4th or 3rd to 2nd

C8 Engine race up (slipping) othersC9

Braking feel when gearshift is up from 1st to

2nd

C10

Braking feel when gearshift is up from 2nd to

3rd

C11

Braking feel when gearshift is up from 3rd to

4th

C12

Large shock when gearshift from 1st to 2nd

or 2nd to 1st

C13

Large shock when gearshift from 2nd to 3rd

or 3rd to 2nd

C14

Large shock when gearshift from 3rd to 4th

or 4th to 3rd

C15 Large shock when kick-downC16

Large shock when accelerator pedal is

stepped ON or OFF without gearshift

C17

Large shock when gearshift from 2nd to 1st

in L range

C18 Large shock othersC19

Large shock when vehicle speed is reduced

by no accelerator pedal or vehicle is stopped

C20 Large shock at lock upC21

Shift down or engine overrun when

accelerator pedal is stepped ON in 4th gear

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Out of standard value

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Slip

Seizure

Faulty operation

Separation

Faulty operation

Engine speed signal

Accelerator pedal position signal

Input shaft speed sensor

Output shaft speed sensor

Power drive or 3rd start switch

Transmission range switch

TCM power or ground

Transmission fluid temperature sensor

Pressure control solenoid

Torque converter clutch solenoid

Low & reverse brake solenoid

2-4 brake solenoid

High clutch solenoid

Low clutch solenoid

Ground return circuit

Low & reverse brake fluid pressure switch

2-4 brake fluid pressure switch

High clutch fluid pressure switch

Transmission fluid quantity

Control spool valve

High clutch solenoid accumulator

Low clutch solenoid accumulator

Low & reverse brake solenoid accumulator

2-4 brake solenoid accumulator

High clutch accumulator

2-4 brake accumulator

Pressure control solenoid hydraulic circuit

Torque converter clutch hydraulic circuit

High clutch solenoid hydraulic circuit

Low clutch solenoid hydraulic circuit

Low & reverse brake solenoid hydraulic circuit

2-4 brake solenoid hydraulic circuit

Oil cooler

Torque converter

Clutch (brake)

Torque converter clutch piston

Hydraulic control

Powertrain

Diagnostic category

Possible causes

Electrical

Disordered selector lever cable

Disordered transmission range switch

Faulty line pressure

Faulty engine idle speed

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4384 of 6020

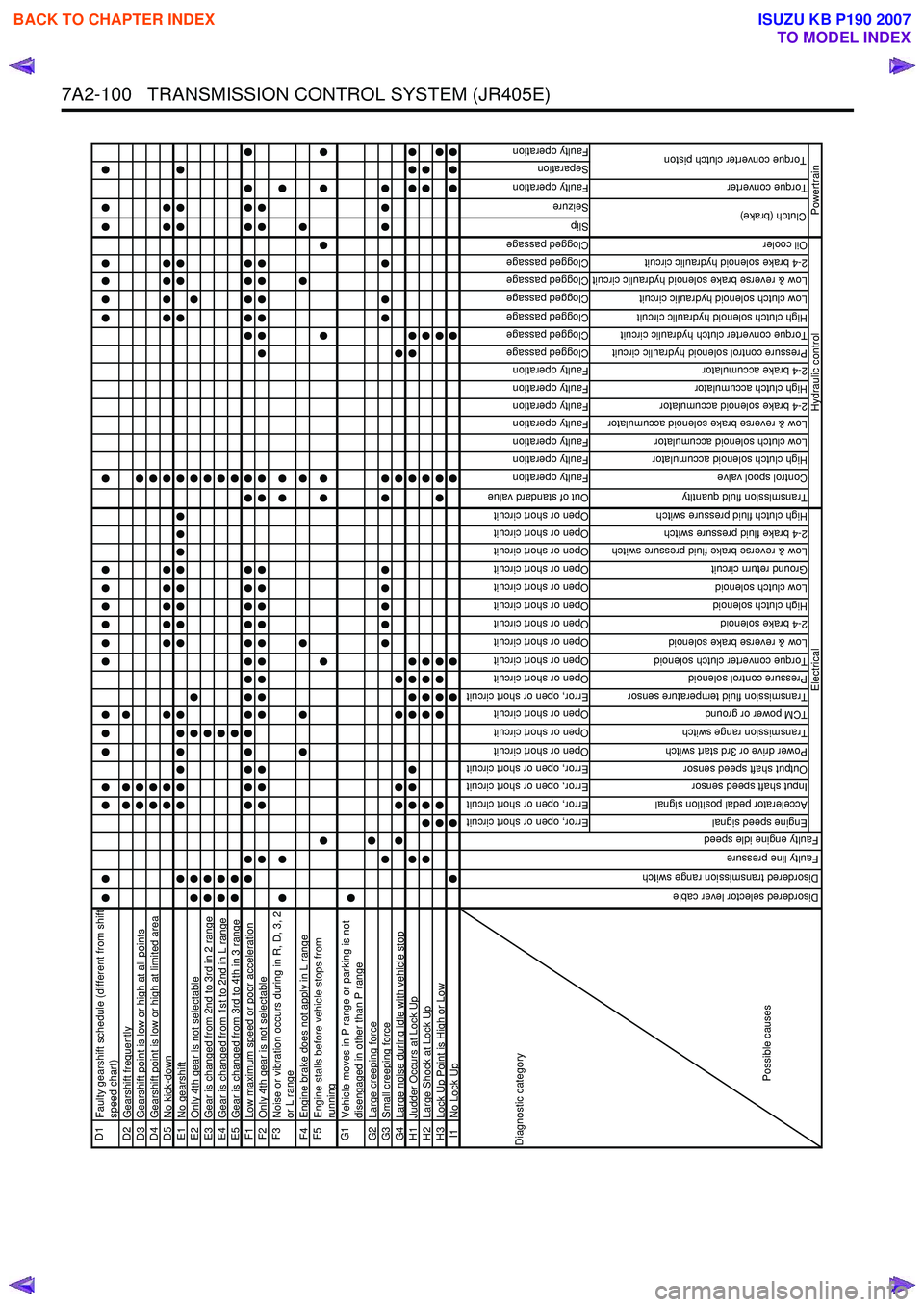

7A2-100 TRANSMISSION CONTROL SYSTEM (JR405E)

D1

Faulty gearshift schedule (different from shift

speed chart)

D2 Gearshift frequentlyD3Gearshift point is low or high at all pointsD4Gearshift point is low or high at limited areaD5No kick-downE1No gearshiftE2Only 4th gear is not selectableE3Gear is changed from 2nd to 3rd in 2 rangeE4Gear is changed from 1st to 2nd in L rangeE5Gear is changed from 3rd to 4th in 3 rangeF1Low maximum speed or poor accelerationF2Only 4th gear is not selectableF3

Noise or vibration occurs during in R, D, 3, 2

or L range

F4 Engine brake does not apply in L rangeF5

Engine stalls before vehicle stops from

running

G1

Vehicle moves in P range or parking is not

disengaged in other than P range

G2 Large creeping forceG3Small creeping forceG4Large noise during idle with vehicle stopH1Judder Occurs at Lock UpH2Large Shock at Lock UpH3Lock Up Point is High or LowI1No Lock Up

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Out of standard value

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Slip

Seizure

Faulty operation

Separation

Faulty operation

Engine speed signal

Accelerator pedal position signal

Input shaft speed sensor

Output shaft speed sensor

Power drive or 3rd start switch

Transmission range switch

TCM power or ground

Transmission fluid temperature sensor

Pressure control solenoid

Torque converter clutch solenoid

Low & reverse brake solenoid

2-4 brake solenoid

High clutch solenoid

Low clutch solenoid

Ground return circuit

Low & reverse brake fluid pressure switch

2-4 brake fluid pressure switch

High clutch fluid pressure switch

Transmission fluid quantity

Control spool valve

High clutch solenoid accumulator

Low clutch solenoid accumulator

Low & reverse brake solenoid accumulator

2-4 brake solenoid accumulator

High clutch accumulator

2-4 brake accumulator

Pressure control solenoid hydraulic circuit

Torque converter clutch hydraulic circuit

High clutch solenoid hydraulic circuit

Low clutch solenoid hydraulic circuit

Low & reverse brake solenoid hydraulic circuit

2-4 brake solenoid hydraulic circuit

Oil cooler

Torque converter

Diagnostic category

Possible causes

Electrical

Disordered selector lever cable

Disordered transmission range switch

Faulty line pressure

Faulty engine idle speed

Clutch (brake)

Torque converter clutch piston

Hydraulic control

Powertrain

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4457 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-3

Cold Level

The vehicle must not have been driven so that the

temperature reaches around 20 °C (68 °F) before the

cold level check is made.

1. Park the vehicle on a level surface.

2. Apply the parking brake firmly.

3. Start the engine and allow it to warm up.

The engine coolant temperature gauge needle should be midway between the “C” mark and “H”

mark.

4. Let the engine run at idle.

Move the select lever slowly through all the gea

r

ranges.

Stop in each range just long enough for the transmission to engage.

5. Return the select lever either “P” or “N”.

6. Remove the ATF level dipstick.

7. W ipe the dipstick clean with a paper towel.

8. Reinsert the dipstick and wait several seconds.

9. Remove the dipstick.

The ATF level should be inside the “C” range on the dipstick.

If the ATF level is below the “C” range, ATF must be added.

242R300002

ATF CHANGE

1. Park the vehicle on level ground and block the rear

wheels.

2. Start the engine and allow it to idle until the ATF reaches a temperature of 40-50 °C (104-122 °F).

3. Stop the engine.

4. Raise the front to the vehicle and support with suitable safety stands.

5. Remove the drain plug from the oil pan and drain the ATF (approximately 6 liters).

6. Remove the oil pan.

7. Inspect the oil pan (details written below).

8. Install the oil pan.

Note:

Use a new gasket. Clean the oil pan and magnet.

Oil pan bolt torque : 8 N ⋅m (0.8 kgf ⋅m/69 lb ⋅in)

9. Replace the gasket and install the drain plug.

Drain plug torque : 35 N ⋅m (3.6 kgf ⋅m/26 lb ⋅ft)

Note:

Do not reuse the old washer (gasket).

Clean the drain plug (especially the threaded section).

10.Remove the safety stands and wheel blocks.

11.Pour about 5 liters of new ATF.

12. Start the engine. W ith your foot on the brake, move the shift lever through each gear range, and shift to

“P” range.

13.Check the ATF level. Add more ATF carefully as necessary using the dipstick. Refer to “ATF LEVEL”

preciously in this section.

Note:

Keep the engine idle (do not stop it) during the ATF level

adjustment.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4921 of 6020

TRANSFER CONTROL SYSTEM 7D1-47

3. Shifting from 4H to 4L

3-1 When the 4L indicator flashes at 2Hz

W hen shifting from 4H to 4L, the 4L indicator continues flashing at 2Hz until shifting in the transfer case is

completed. The phases of the engaged splines may sometimes deviate preventing completion of shifting. By

correcting the deviation of phases, shifting is completed.

Step 3-1:

(In case of AT): Set the select bar of the transmission to the D position.

(In case of MT): Set the lever of the transmission to a position allowing running and engage the clutch gently.

At this time, some rotating force acts on the engaged splines, phase is corrected and the engagement is

completed.

3-2 When the 4L indicator flashes at 2Hz for 10 seconds and then keeps ON again (AT vehicle)

This condition occurs when torsional torque has been generated between the transmission and road surface

and the transfer standby mechanism cannot absorb it completely.

Step 3-2:

Set the select lever of the transmission to the N position. (Stepping on the brake pedal is effective at

this time.)

3-3 When the 4L indicator flashes at a frequency of 4Hz

Shifting from 4H to 4L is restricted.

W hen the vehicle is running, the transmission lever is at the running range and the engine speed is high (L4:

3000rpm or more V6: 2000rpm), the transfer cannot be shifted from 4H to 4L (restriction on operation).

Restriction on operation (Except 4JA1-T)

The 4H, neutral and 4L shifting mechanism has no synchronization function. Therefore, if relative rotations in the

mechanism become excessive, shifting exerts adverse influence on the internal mechanism of the transfer. To

avoid such a trouble, vehicle condition is detected to restrict the operation (vehicle speed, engine speed and TM

position).

Requirement to restrict the speed: Vehicle should be in stop. Due to the detection logic, time to wait for start of operation may be required.

A/T: If the vehicle is in stop for a long time at the TM running range (D, 1, 2) before operating the AT, waiting

time becomes longer (from 1 second to 3 minutes at the maximum).

M/T: If the vehicle is at stop with the clutch stepped on at the T/M running position (1 – R), the time to wait

becomes longer.

W aiting time means the time commencing from when other requirements (engine speed and T/M position) are

met to permission of the speed restriction. Operation during the waiting time is not permissible.

The waiting time is 1 second at the minimum and increases up to 5 seconds if the above condition continues for

3 minutes. After that, the waiting time increases up to 3 minutes in 2 minute intervals.

W hen it is clear that the above condition has continued and reduction of waiting time is required, turn on or off

the ignition or start and stop the vehicle several meters.

Requirements for permission of restriction on engine speed: Engine speed should be decreased.

The engine speed of 3000rpm (V6: 2000rpm) or below is advisable.

Requirements for permission of restriction on T/M position restriction:

(AT) N range is recommended

(MT) should be at the neutral.

These requirements for permission should all be met before the switch is operated. If the requirements are met

after operation, operation is not automatically effected but re-operation is required after permission is given.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4923 of 6020

TRANSFER CONTROL SYSTEM 7D1-49

Step 4-3: (Same procedure as the step 3-3)

Stop the vehicle (close the accelerator and decrease the engine speed to L4: 3000rpm V6: 2000rpm or below).

(In case of AT): Set the transmission select lever to the N position.

(In case of MT): Set the transmission lever to the neutral position (stepping on the clutch lever is recommended).

Push the 4H button.

If shifting is not complete (indicator flashes at 2Hz), go to step 4-1.

5. When shifting from 4H or 4L to neutral

(Same procedure is required when shifting from 2H but in such a case, requirements for shifting from

2H to 4H are also applied.)

5-1 Neutral indicator continues flashing at 2Hz The neutral indicator continues flashing at 2Hz until 4H (4L) is completely separated in the transfer. If torsional

torque has accumulated between the transmission and road surface, separation may be difficult.

Step 5-1:

If the operation is not complete, execute step 7 for confirmation.

(In case of AT): Set the transmission select lever to the D position. After confirming that the gears are at the neutral position, return the lever to the N

position.

(In case of MT): Set the transmission lever to a vehicle running position and engage the clutch gently. After confirming that the gears are at the neutral position, return the lever to the

neutral position

5-2 When the neutral indicator flashes at 4Hz

As in the case of shifting from 4L to 4H, restriction is imposed to the operation from 4L or 4H (including 2H). If

the transmission lever is at a running range and engine speed is high (L4: 3000rpm, V6: 2000rpm or more)

while the vehicle is running, operation from the 4L or 4H (including 2H) of the transfer to the neutral is

impossible (restriction on operation).

Step 5-2:

Stop the vehicle.

(In case of AT): Set the transmission select lever to the N (or P) position.

(In case of MT): Set the transmission lever to the neutral position (at this time, stepping on the clutch is recommended).

Keep pushing the 2H and 4L button for 10 seconds.

Follow the start procedure for confirmation. (Confirmation of drive force is not transferred; same as in

step 5-1)

After the confirmation, set the transmission to the neutral position in the case of MT or to the neutral

position in the case of AT.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4935 of 6020

TRANSFER CONTROL SYSTEM 7D1-61

From 4H to 4L; Even after the correction step 3-3(*), 4Lo indicator blinks at 4Hz

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once.

Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start

the engine.

Has the valve check for 2

seconds been completed

normally? Go to step 3.

Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H.

After taking the remedy, trace this

chart from the beginning.

3 Shift to 2H.

Can be shifted to 2H and then to

4H? Go to step 4.

Refer to the paragraph about

shifting from 2H to 4H.

In particular, check if not at the

Check4W D condition, return to

this chart and trace it from the

beginning.

4 Set to N position in case of AT

and set to the neutral position in

case of MT and check if the

lamp blinks at 4Hz after

operation.

Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning. Shift back to 4H and go to step 5.

5

Start the engine and use the

vehicle.

Does the speedometer run at

this time? Go to step 6.

Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the

transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble detected? Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.) Go to step 7.

7

Run the vehicle for several

meters, stop it, meet the

permission requirements for

operation limits.

Did you wait for several seconds

after the requirements were

met? Failed controller.

Replace the controller and trace

this chart from the beginning. You did not wait for enough time.

Optimum waiting time is 1 second

or maximum 3 minutes,

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining a trouble (Non-trouble mode)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4936 of 6020

7D1-62 TRANSFER CONTROL SYSTEM

From 4L to 4H: After the correction step 4-3(*), 4Lo indicator blinks at 4H.

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once.

Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start

the engine.

Has the valve check for 2

seconds been completed

normally? Go to step 3.

Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H.

After taking the remedy, trace this

chart from the beginning.

3 Can be shifted to 2H and then to

4L? Go to step 4.

(Impossible usually.)

Failed controller In case of Check 4W D, shifting to

2H is possible.

Returning to 4L is impossible.

Refer to the paragraph about

Check4W D.

4 Set to N position in case of AT

and set to the neutral position in

case of MT and check if the

lamp blinks at 4Hz after

operation.

Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning. Press the operation switch of 4L

and go to step 5.

5 Start the engine and use the

vehicle.

Does the speedometer run at

this time? Go to step 6.

Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the

transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble detected? Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.) Go to step 7.

7

Run the vehicle for several

meters, stop it, meet the

permission requirements for

operation limits.

Did you wait for several seconds

after the requirements were

met? Failed transfer controller.

Replace the controller and trace

this chart from the beginning. You did not wait for enough time.

Optimum waiting time is 1 second

or maximum 3 minutes,

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining a trouble (Non-trouble mode)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4937 of 6020

TRANSFER CONTROL SYSTEM 7D1-63

To neutral: After the correction step 5-2(*), neutral indicator blinks at 4Hz.

Check the function between H and L according to the chart for 4L to 4H instead of check

for the requirements of neutral.

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once. Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start the

engine.

Has the valve check for 2

seconds been completed

normally? Go to step 3.

Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H (7D1-

37).

After taking the remedy, trace this

chart from the beginning.

3 Can be shifted to 2H and then to 4L? Go to step 4.

(Impossible usually.)

Failed controller Refer to the paragraph about

shifting from 2H to 4H.

In particular, check if not at the

Check4W D condition, return to

this chart and trace it from the

beginning.

In case of Check4W D, shifting to

2H is possible.

Returning to 4H is impossible.

Refer to the paragraph about

Check4W D.

4 Set to N position in case of AT and set to the neutral position in

case of MT and check if the lamp

blinks at 4Hz after operation. Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning. Shift back to 4H and go to step 5.

5 Start the engine and use the

vehicle.

Does the speedometer run at this

time? Go to step 6.

Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble noticed? Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.) Go to step 7.

7 Run the vehicle for several

meters, stop it, meet the

permission requirements for

operation limits.

Did you wait for several seconds

after the requirements were met? Failed controller.

Replace the controller and trace

this chart from the beginning. You did not wait for enough time.

Optimum waiting time is 1 second

or maximum 3 minutes,

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining a trouble (Non-trouble mode)

For shifting to neutral, 2H and 4L switches should be pressed at the same time for 10 seconds.

For shifting from neutral to other position, 2H, 4H or 4L switch should be pressed for 10 seconds.

W hen shifting from neutral to other position, the lamp blinking at 2Hz indicates active condition.

W hen the lamp keeps blinking at 2Hz, follow the step for the case when the lamp keeps blinking at 2Hz when

shifting between positions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007