checking oil ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3867 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–81

Action Taken When the DTC Sets

• The TCM requests the ECM to illuminate the MIL during the second consecutive trip in which the conditions for

setting the DTC are met.

• The TCM commands maximum line pressure.

• The TCM freezes transmission adaptive functions.

• The TCM inhibits TCC.

• The TCM inhibits 4th gear if in hot mode.

• At the time of the first failure, the TCM records the operating conditions when the conditions for setting the DTC are

met. The TCM stores this information as a Failure Record.

• At the time of the second failure, the ECM records the operating conditions when the conditions for setting the DTC

are met. The ECM stores this information as a Freeze Frame.

• The TCM stores DTC P0894 in TCM history during the second consecutive trip in which the conditions for setting

the DTC are met.

Conditions for Clearing the DTC

• The ECM turns off the MIL after the fourth consecutive drive trip in which the TCM does not send a MIL illumination

request.

• Tech 2 can clear the DTC.

• The TCM clears the DTC from TCM history if the vehicle completes 40 warm-up cycles without a non-emission

related diagnostic fault occurring.

• The TCM cancels the DTC default actions when the ignition is off long enough to power down the TCM.

Diagnostic Aids

•

Bronze material found in the transmission oil pan may indicate stator shaft bushing wear. If bushing wear is

suspected, inspect the stator shaft and the input, turbine, shaft for damage.

• Perform the Torque Converter Diagnosis Procedure, refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and

Mechanical Diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 Checks the torque converter for slippage while in a commanded lock-up state.

4-12 Checks the mechanical components that cause the DTC and their state.

13 W hen the TAP cells are cleared the TCM needs to relearn the TAP cells for the transmission. As such, when the vehicle is first driven, the shifts may be harsh. The transmission shifts should become smoother the more the

vehicle is driven until the TCM has relearned all TAP cells.

DTC P0894 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.7 Diagnostic System Check

2 Inspect for correct transmission fluid level, refer to 7C4 Automatic

Transmission – 4L60E – On-vehicle Servicing.

Did you perform the fluid checking procedure?

Go to Step 3 Check the

transmission fluid level, refer to

7C4 Automatic

Transmission –

4L60E – On-vehicle Servicing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4016 of 6020

7A2-50 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Action Taken When The DTC Sets

• Control at A/T oil temperature 80 °C (176 °F).

• No squat control.

• No slope control.

• No 3rd start mode.

• No line pressure reduction at gear change.

• No coast control.

• No line pressure reduction control at garage.

• No shift solenoid functional failure detection.

• No L-up solenoid functional failure detection.

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

•

Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

• Check oil temperature sensor for proper mounting and adjustment.

Circuit/System Testing DTC P0712

Step Action Value(s) YES NO

1

W as the On-Board Diagnostic (OBD) System Check

performed? — Go to

Step 2 Go to OBD

System Check

2 Perform the transmission fluid checking procedure. Refer to checking Transmission Fluid level and

Condition in Automatic Transmission 7A section.

W as the fluid checking procedure performed? — Go to

Step 3 Refer to

Checking

Transmission

Fluid level and Condition in Automatic

Transmission

(AW 30-40LE) section

3 1. Lift the driving wheels.

2. Start the engine and place the select lever in D

position.

3. W ait for 5 minutes.

Does a scan tool indicate DTC P0712? — Go to

Step 4 Refer to

Diagnostic Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4019 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-53

• No L-up solenoid functional failure detection.

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

•

Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

• Check oil temperature sensor for proper mounting

and adjustment.

Circuit/System Testing DTC P0713

Step Action Value(s) YES NO

1

W as the On-Board Diagnostic (OBD) System Check

performed ? — Go to

Step 2 Go to OBD

System check

2 Perform the transmission fluid checking procedure. Refer to Checking Transmission Fluid Level and

condition Automatic Transmission 7A section.

W as the fluid checking procedure performed? — Go to

Step 3 Refer to

checking

Transmission

Fluid Level and Condition

Automatic

Transmission

(AW 30-40LE) section

3 1. Lift the driving wheels.

2. Start the engine and place the select lever in D

position.

3. W ait for 15 minutes.

Does a scan tool indicate DTC P0713? — Go to

Step 4 Refer to

Diagnostic Aids

4 Observe the voltage of the oil temperature sensor on the Tech 2 data.

1. Turn “OFF” the ignition.

2. Disconnect the oil temperature sensor connector

E-83

3. Install a fused jumper wire from terminal E83-2 to E83-1 on the transmission harness.

4. Turn “ON” the ignition.

Does a scan tool indicate specified value? About 0V Go to

Step 5 Go to Step 6

5 Replace the transmission fluid temperature sensor.

If the action complete? — Go to

Step 9 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4311 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-27

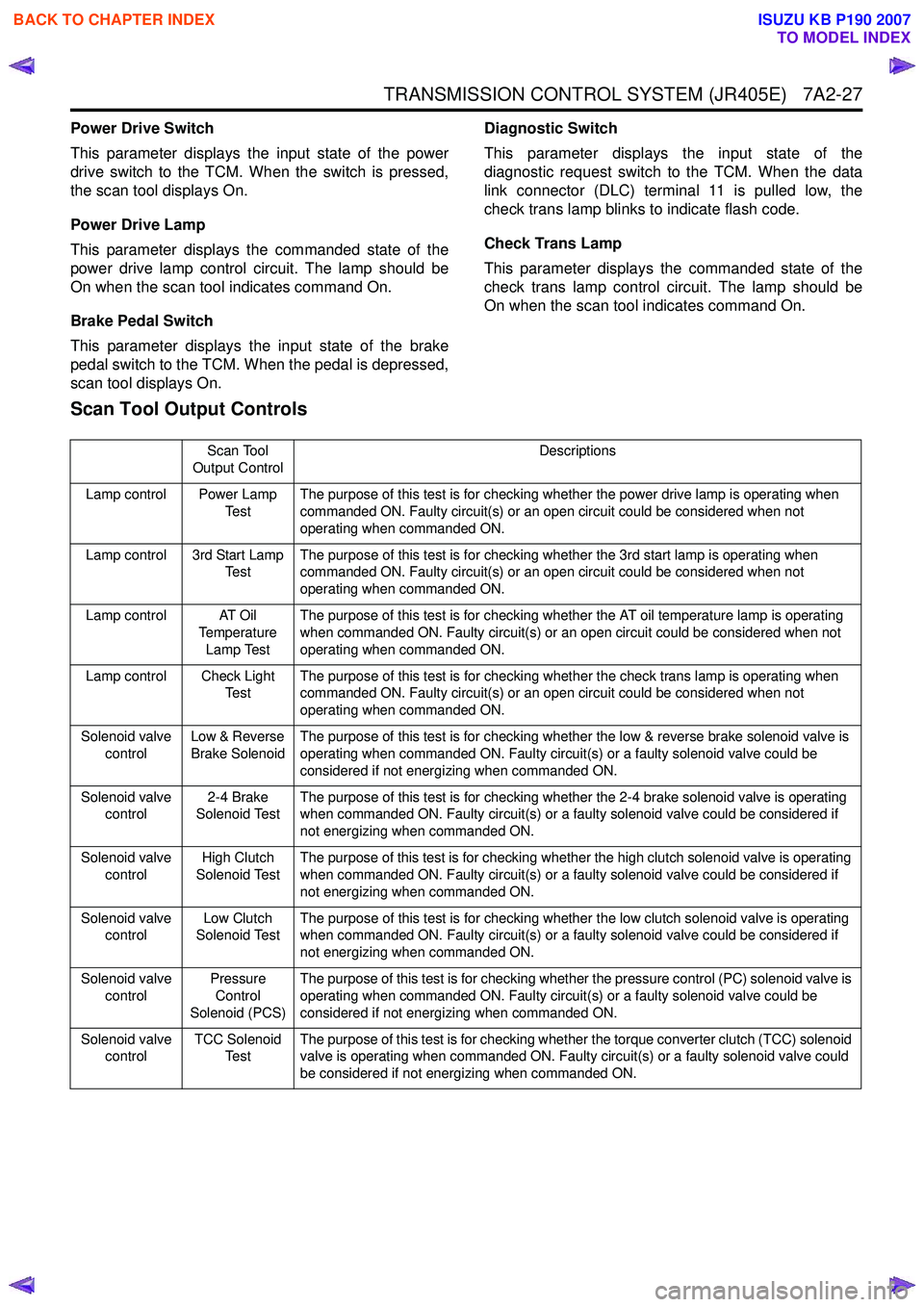

Power Drive Switch

This parameter displays the input state of the power

drive switch to the TCM. When the switch is pressed,

the scan tool displays On.

Power Drive Lamp

This parameter displays the commanded state of the

power drive lamp control circuit. The lamp should be

On when the scan tool indicates command On.

Brake Pedal Switch

This parameter displays the input state of the brake

pedal switch to the TCM. When the pedal is depressed,

scan tool displays On. Diagnostic Switch

This parameter displays the input state of the

diagnostic request switch to the TCM. When the data

link connector (DLC) terminal 11 is pulled low, the

check trans lamp blinks to indicate flash code.

Check Trans Lamp

This parameter displays the commanded state of the

check trans lamp control circuit. The lamp should be

On when the scan tool indicates command On.

Scan Tool Output Controls

Scan Tool

Output Control Descriptions

Lamp control Power Lamp Te s tThe purpose of this test is for checking whether the power drive lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Lamp control 3rd Start Lamp Te s t The purpose of this test is for checking whether the 3rd start lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Lamp control AT Oil Temperature

Lamp Test The purpose of this test is for checking whether the AT oil temperature lamp is operating

when commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Lamp control Check Light Te s t The purpose of this test is for checking whether the check trans lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Solenoid valve control Low & Reverse

Brake Solenoid The purpose of this test is for checking whether the low & reverse brake solenoid valve is

operating when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be

considered if not energizing when commanded ON.

Solenoid valve control 2-4 Brake

Solenoid Test The purpose of this test is for checking whether the 2-4 brake solenoid valve is operating

when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be considered if

not energizing when commanded ON.

Solenoid valve control High Clutch

Solenoid Test The purpose of this test is for checking whether the high clutch solenoid valve is operating

when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be considered if

not energizing when commanded ON.

Solenoid valve control Low Clutch

Solenoid Test The purpose of this test is for checking whether the low clutch solenoid valve is operating

when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be considered if

not energizing when commanded ON.

Solenoid valve control Pressure

Control

Solenoid (PCS) The purpose of this test is for checking whether the pressure control (PC) solenoid valve is

operating when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be

considered if not energizing when commanded ON.

Solenoid valve control TCC Solenoid

Te s t The purpose of this test is for checking whether the torque converter clutch (TCC) solenoid

valve is operating when commanded ON. Faulty circuit(s) or a faulty solenoid valve could

be considered if not energizing when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4336 of 6020

7A2-52 TRANSMISSION CONTROL SYSTEM (JR405E)

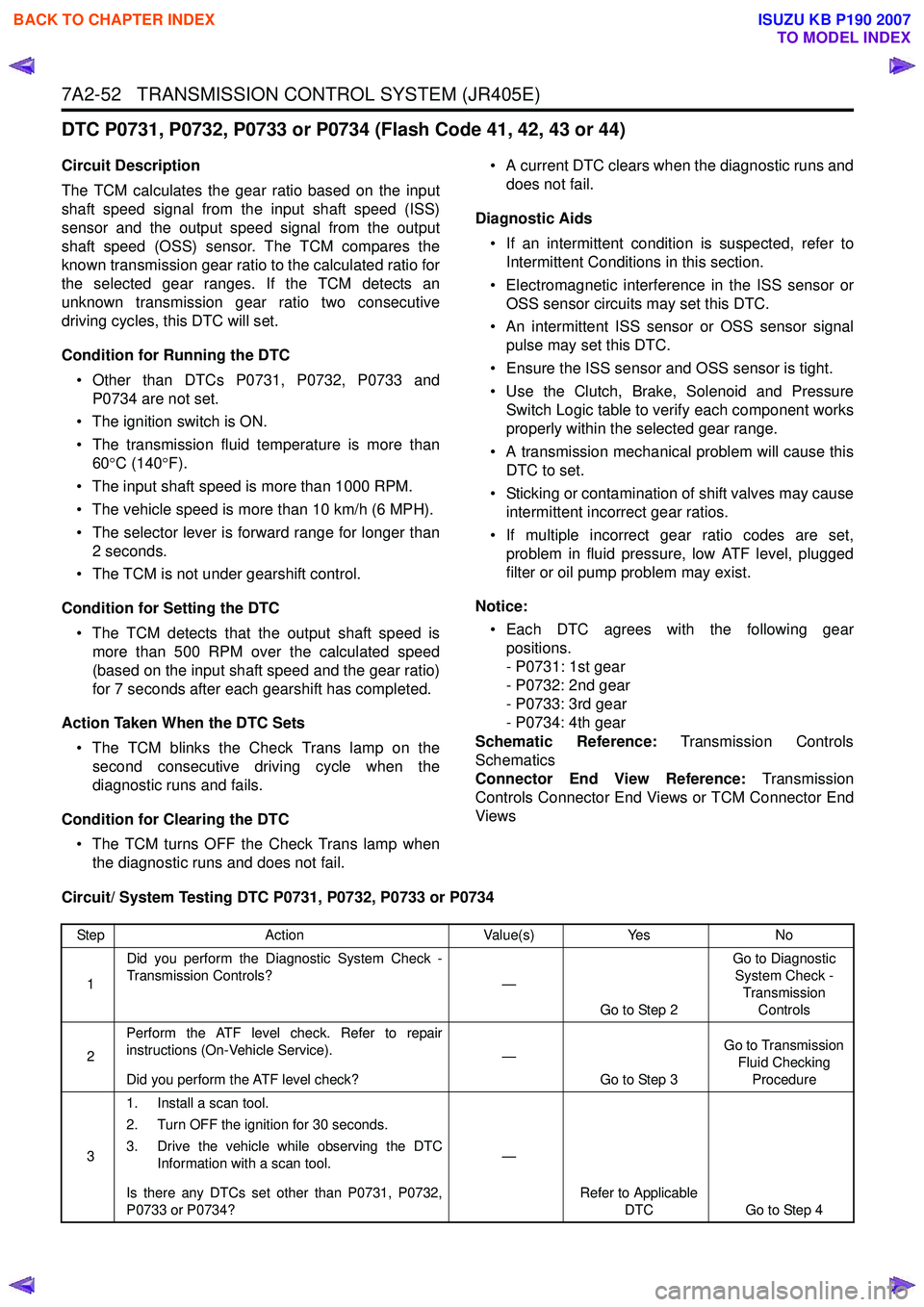

DTC P0731, P0732, P0733 or P0734 (Flash Code 41, 42, 43 or 44)

Circuit Description

The TCM calculates the gear ratio based on the input

shaft speed signal from the input shaft speed (ISS)

sensor and the output speed signal from the output

shaft speed (OSS) sensor. The TCM compares the

known transmission gear ratio to the calculated ratio for

the selected gear ranges. If the TCM detects an

unknown transmission gear ratio two consecutive

driving cycles, this DTC will set.

Condition for Running the DTC • Other than DTCs P0731, P0732, P0733 and P0734 are not set.

• The ignition switch is ON.

• The transmission fluid temperature is more than 60 °C (140 °F).

• The input shaft speed is more than 1000 RPM.

• The vehicle speed is more than 10 km/h (6 MPH).

• The selector lever is forward range for longer than 2 seconds.

• The TCM is not under gearshift control.

Condition for Setting the DTC • The TCM detects that the output shaft speed is more than 500 RPM over the calculated speed

(based on the input shaft speed and the gear ratio)

for 7 seconds after each gearshift has completed.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp on the second consecutive driving cycle when the

diagnostic runs and fails.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail. • A current DTC clears when the diagnostic runs and

does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the ISS sensor or OSS sensor circuits may set this DTC.

• An intermittent ISS sensor or OSS sensor signal pulse may set this DTC.

• Ensure the ISS sensor and OSS sensor is tight.

• Use the Clutch, Brake, Solenoid and Pressure Switch Logic table to verify each component works

properly within the selected gear range.

• A transmission mechanical problem will cause this DTC to set.

• Sticking or contamination of shift valves may cause intermittent incorrect gear ratios.

• If multiple incorrect gear ratio codes are set, problem in fluid pressure, low ATF level, plugged

filter or oil pump problem may exist.

Notice: • Each DTC agrees with the following gear positions.

- P0731: 1st gear

- P0732: 2nd gear

- P0733: 3rd gear

- P0734: 4th gear

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0731, P0732, P0733 or P0734

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 Perform the ATF level check. Refer to repair

instructions (On-Vehicle Service).

Did you perform the ATF level check? —

Go to Step 3 Go to Transmission

Fluid Checking Procedure

3 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Drive the vehicle while observing the DTC Information with a scan tool.

Is there any DTCs set other than P0731, P0732,

P0733 or P0734? —

Refer to Applicable DTC Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4401 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-117

H1: Judder Occurs at Lock Up

H2: Large Shock at Lock Up

H3: Lock Up Point is High or Low

I1: No Lock Up

Diagnosis Hints • Causes such as the solenoid operating sound or a faulty oil pump are

suspected.

• Distinguishing is possible by stopping the solenoid operation temporarily, checking the correlation for the former case and, changing

the line pressure and confirming the correlation with noise.

• As a matter of course, noise other than the transmission may be generated around the engine, and should be checked carefully.

Notice: When the noise is generated only at the time of a gear shift, it may

be the sound of transmission fluid flowing or gear noise. If the sound varies

depending on the gear speed to be shifted, it may be the gear noise

generated from the planetary gear and its components. If the sound varies

depending on the vehicle speed, it may be the gear noise of the output

system, or the gear noise of the input system or a faulty torque converter.

Checks

Action

Checks Action

Definition:

Judder occurs when lock up area.

Diagnosis Hints Slip due to burning of the torque converter clutch (TCC) facing or insufficient

engagement due to dropped working pressure are suspected. Refer to

category No. “l1: No Lock Up “.

Notice: When the TCC facing has burnt, foreign material mixed in the oil

cooler is suspected. In such a case, inspect the oil cooler circuit for clogging

of the oil cooler.

Checks Action

Definition: • A large shock is felt at lock up.

• Lock up point is excessively high or low.

Diagnosis Hints Incorrect input signals or faulty operation of torque converter clutch (TCC) is

suspected. Refer to category No. “I1: No Lock Up”.

Checks Action

Definition:

Lock up is not performed even though lock up control conditions being satisfied.

Diagnosis Hints • Monitor the signal to the torque converter clutch (TCC) solenoid valve

while carrying out a running test.

• When the transmission fluid temperature is lower than 20 °C (68 °F),

lock up control is inhibited.

• When the output signal to the TCC solenoid valve is sent correctly, causing no lock up, clogged hydraulic circuits or malfunction of the TCC

piston may be suspected.

• Even with the lock up area, the output signal to the TCC solenoid valve is not sent, a fault of the transmission fluid temperature (TFT) sensor

controlling the lock up may be suspected.

Notice: When the TCC facing has burnt, foreign material mixed in the oil

cooler is suspected. In such a case, inspect the oil cooler circuit for clogging

of the oil cooler.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5712 of 6020

9A1-30 RESTRAINT CONTROL SYSTEM

Step Action Yes No

4

1. Disconnect and inspect the SRS coil assembly yellow

connector located at the base of the steering column.

2. If ok, reconnect the SRS coil assembly yellow connector.

3. Ignition switch is “ON”.

Is DTC B0021 current? Go to Step 5 Go to Step 8

5

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and the passenger air bag assembly,

yellow 2–pin connector located at the base of the steering

column and behind the glove box assembly.

3. Connect the SRS driver / passenger load tool 5-8840-2421-0

and appropriate adapter to the SRS coil and the passenger

air bag assembly harness connectors.

4. Ignition switch is “ON”.

Is DTC B0021 current? Go to Step 6 Go to Step 7

6

1. Ignition switch is at “LOCK“.

2. There has been an increase in the total circuit resistance of

the driver deployment loop.

3. Use the high resolution ohmmeter mode of the DMM while

checking circuits “Driver Bag High” and “Driver Bag Low”, and

the SRS control unit connector terminal “14” and “13” to

locate the root cause.

W as a fault found? Replace SRS

harness.

Go to Step 8 Go to Chart A

7

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS driver / passenger load tool from the

SRS coil assembly harness connector.

3. Connect the SRS driver / passenger load tool 5-8840-2421-0 on the top of the steering column.

4. Reconnect the SRS coil assembly harness connector at the

base of the steering column.

5. Ignition switch is “ON”.

Is DTC B0021 current? Ignition switch

“LOCK”.

Replace SRS coil assembly.

Go to Step 8 Ignition switch

“LOCK”.

Replace driver air bag assembly. Go to Step 8

8

1. Reconnect all components and ensure all components are

properly mounted.

2. Clear the diagnostic trouble codes.

Is this step finished? Repeat the “SRS

Diagnostic System Check” ―

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5715 of 6020

RESTRAINT CONTROL SYSTEM 9A1-33

Step Action Yes No

5 1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and passenger air bag assembly, yellow connector located at the base of the steering column

and behind the glove box assembly.

3. Connect the SRS driver / passenger load tool 5-8840-2421-0 and appropriate adapter to the SRS coil and passenger air

bag assembly harness connectors.

4. Ignition switch is “ON”.

Is DTC B0022 current? Go to Step 6 Go to Step 7

6

1. Ignition switch to “LOCK”.

2. There has been a decrease in the total circuit resistance of

the driver deployment loop.

3. Use the high resolution ohmmeter mode of the DMM while

checking circuits “Driver Bag High” and “Driver Bag Low”, and

the SRS control unit connector terminal “14” and “13” to

locate the root cause.

W as a fault found? Replace SRS

harness.

Go to Step 8 Go to Chart A

7

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS driver / passenger load tool from the

driver air bag assembly harness connector.

3. Connect the SRS driver / passenger load tool 5-8840-2421-0 to the top of the steering column connector.

4. Reconnect the SRS coil assembly harness connector at the

base of the steering column.

5. Ignition switch is “ON”.

Is DTC B0022 current? Ignition switch

“LOCK”.

Replace SRS coil assembly.

Go to Step 8 Ignition switch

“LOCK”.

Replace driver air bag assembly. Go to Step 8

8

1. Reconnect all components and ensure all components are

properly mounted.

2. Clear the diagnostic trouble codes.

Is this step finished? Go to the “SRS

Diagnostic System Check” ―

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5727 of 6020

RESTRAINT CONTROL SYSTEM 9A1-45

DTC B0031 (Flash Code 31) Passenger Pretensioner Squib Circuit Low Resistance

Step Action Yes No

1 W as the “SRS Diagnostic System Check” performed?

Go to Step 2 Repeat the “SRS

Diagnostic System Check”

2

1. Check the passenger pretensioner squib circuit for short to

valtage or short to ground.

2. If the broblem found, repair as necessary.

W as a problem found? Verify repair Go to Step 3

3

1. Ignition switch is at “LOCK”.

2. Make sure the passenger air bag assembly yellow connector

located at the base of the passenger seat.

Is the yellow connector connected properly? Go to Step 4 Seat passenger

pretensioner

assembly yellow connector properly.

Go to Step 7

4

1. Disconnect and inspect the passenger air bag assembly

yellow connector located at the base of the passenger seat.

2. If ok, reconnect the passenger air bag assembly connector.

3. Ignition switch is at “ON”.

Is DTC B0031 Current? Go to Step 5 Go to Step 7

5

1. Ignition switch is at “LOCK”.

2. Disconnect SRS coil and passenger pretensioner assembly,

yellow connector located at the base of the passenger seat.

3. Connect 5-8840-2421-0 SRS driver/passenger load tool and

appropriate adapters to passenger pretensioner assembly

harness connectors.

4. Ignition switch is at “ON”.

Is DTC B0031 current? Go to Step 6 Ignition switch is at

“OFF”.

Replace the passenger

pretensioner assembly.

Go to Step 7

6

1. Ignition switch is at “LOCK”.

2. There has been a decrease in the total circuit resistance of

the passenger inflator deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while checking circuits “Passenger pretensioner High” and

“Passenger Pretensioner Low”, and SRS control unit

connector terminal “11” and “10” to locate the root cause.

W as a fault found? Replace SRS

harness or repair chassis harness. Go to Step 7 Go to Chart A

7

1. Reconnect all components, ensure all component are

properly mounted.

2. Clear diagnostic trouble codes.

W as this step finished? Repeat the “SRS

Diagnostic System Check” ―

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5735 of 6020

RESTRAINT CONTROL SYSTEM 9A1-53

Step Action Yes No

4

1. Disconnect and inspect the pretensioner yellow connector

located base of the driver seat.

2. If ok, reconnect the Pretensioner assembly yellow connector.

3. Ignition switch “ON.”

Is DTC B0041 current? Go to Step 5 Go to Step 8

5

1. Ignition switch is at “LOCK”.

2. Disconnect deive pretensioner assembly, yellow connector

located at the base of the driver seat.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to drive pretensioner assembly harness

connectors.

4. Ignition switch “ON”.

Is DTC B0041 current? Go to Step 6 Go to Step 7

6

1. Ignition switch is at “LOCK”.

2. There has been a decrease in the total circuit resistance of

the driver deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking circuits “Driver Pretensioner High” and “Driver

Pretensioner Low”, and SRS control unit connector terminal

“8” and “7” to locate the root cause.

W as a fault found? Replace SRS

harness or repair chassis harness. Go to Step 8 Go to Chart A

7

1. Ignition switch is at “LOCK”.

2. Disconnect SRS driver / passenger load tool from driver

pretensioner assembly harness connector.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 to the top of steering column connector.

4. Reconnect pretensioner harness connector as the base of the

driver seat.

5. Ignition switch is at “ON”.

Is DTC B0041 current? Ignition switch is at

“OFF”.

Replace SRS coil assembly.

Go to Step 8 Ignition switch is at

“LOCK”.

Replace driver pretensioner assembly.

Go to Step 8

8

1. Reconnect all components, ensure all component are

properly mounted.

2. Clear diagnostic trouble codes.

W as this step finished? Go to the “SRS

Diagnostic System Check” ―

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007