AUX ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2141 of 6020

6D1-4 ENGINE ELECTRICAL

Battery Charging

Observe the following safety precautions when charging the

battery:

1. Never attempt to charge the battery when the fluid level is

below the lower level line on the side of the battery. In this

case, the battery must be replaced.

2. Pay close attention to the battery during charging procedure.

Battery charging should be discontinued or the rate o

f

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate o

f

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on batter

y

charging capacity.

5. The sealed battery used on this vehicle may be either quick charged or slow charged in the same manner as othe

r

batteries.

W hichever method you decide to use, be sure that you completely charge the battery. Never partially charge the

battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an attempt to

start it. Serious damage to the emission system as well as

other vehicle parts will result.

Treat both the discharged battery and the booster battery

with great care when using jumper cables.

Carefully follow the jump starting procedure, being careful

at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE JUMP

STARTING PROCEDURE COULD RESULT IN THE

FOLLOWING:

1. Serous personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery acid, o

r

an electrical fire.

3. Damage to the electronic components of one or both vehicles particularly.

Never expose the battery to an open flame or electrical spark.

Gas generated by the battery may catch fire or explode.

Remove any rings, watches, or other jewelry before working

around the battery. Protect your eyes by wearing an approved

set of goggles.

Never allow battery fluid to come in contact with your eyes or

skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3198 of 6020

Engine Cooling – V6 Engine Page 6B1–63

4.5 Problems Not Requiring Disassembly of

Cooling System

1 Large obstructions blocking radiator or condenser airflow.

• Auxiliary oil coolers

• License plate

• Obstruction of radiator grille, for example, driving lights or mud

2 Loose, damaged or missing air chute side panels.

3 Missing or damaged air baffle.

4 Cracked or loose coolant recovery system hose.

5 Leaking heater component such as the heater core or water valve.

4.6 Problems Requiring Disassembly of Cooling System

1 Damaged cooling fan or faulty motor operation.

2 Pressure test cooling system.

3 Defective coolant pump.

• Eroded or broken impeller vanes

• Failed bearing or seal – check for shaft or bearing end play

4 Internally blocked radiator core.

5 Obstruction of coolant recovery system.

6 Internal system leaks.

• Head gaskets

• Cracked cylinder block

• Engine front cover

• Intake manifold gaskets

7 Blocked coolant passages in cylinder heads or block – remove cylinder heads and check.

4.7 Black Light and Dye Leak Diagnosis Method

It is strongly recommended that this diagnostic method be used to diagnose fluid leaks. This method is a proven and

reliable method that identifies the specific leak source.

The black light kit can be used for the leak detection of a number of fluids, when used with the appropriate tracer dye.

Examples are: Coolant, Engine Oil, Automatic Transmission Fluid and Air Conditioning Refrigerant (R134A).

The following is a summary of the steps involved in detecting a cooling system fluid leak using black light and dye:

1 Pour specified amount of dye into the cooling system via the coolant filler cap on the outlet housing. Refer 3.1 Service Notes in this Section.

2 Road test the vehicle under normal operating conditions.

3 Direct the light towards the suspect area. The fluid leak will appear as a brightly coloured path leading from the source.

4 Repair fluid leak and recheck to ensure that leak has been rectified.

5 Refer to the manufacturer’s directions when using this method.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3630 of 6020

Starting System – V6 Page 6D1-2–22

4.3 Starter Motor Bench Tests

Preliminary Checks

1 Check the drive assembly is fully retracted.

2 Check the drive assembly pinion turns freely on the planetary drive shaft.

3 Perform the No Load Test (as outlined in this Section) if the drive assembly is not fully retracted.

4 Disassemble and service the starter motor if it fails the No Load test, refer to 4.4 Starter Motor Disassemble and

Reassemble in this Section.

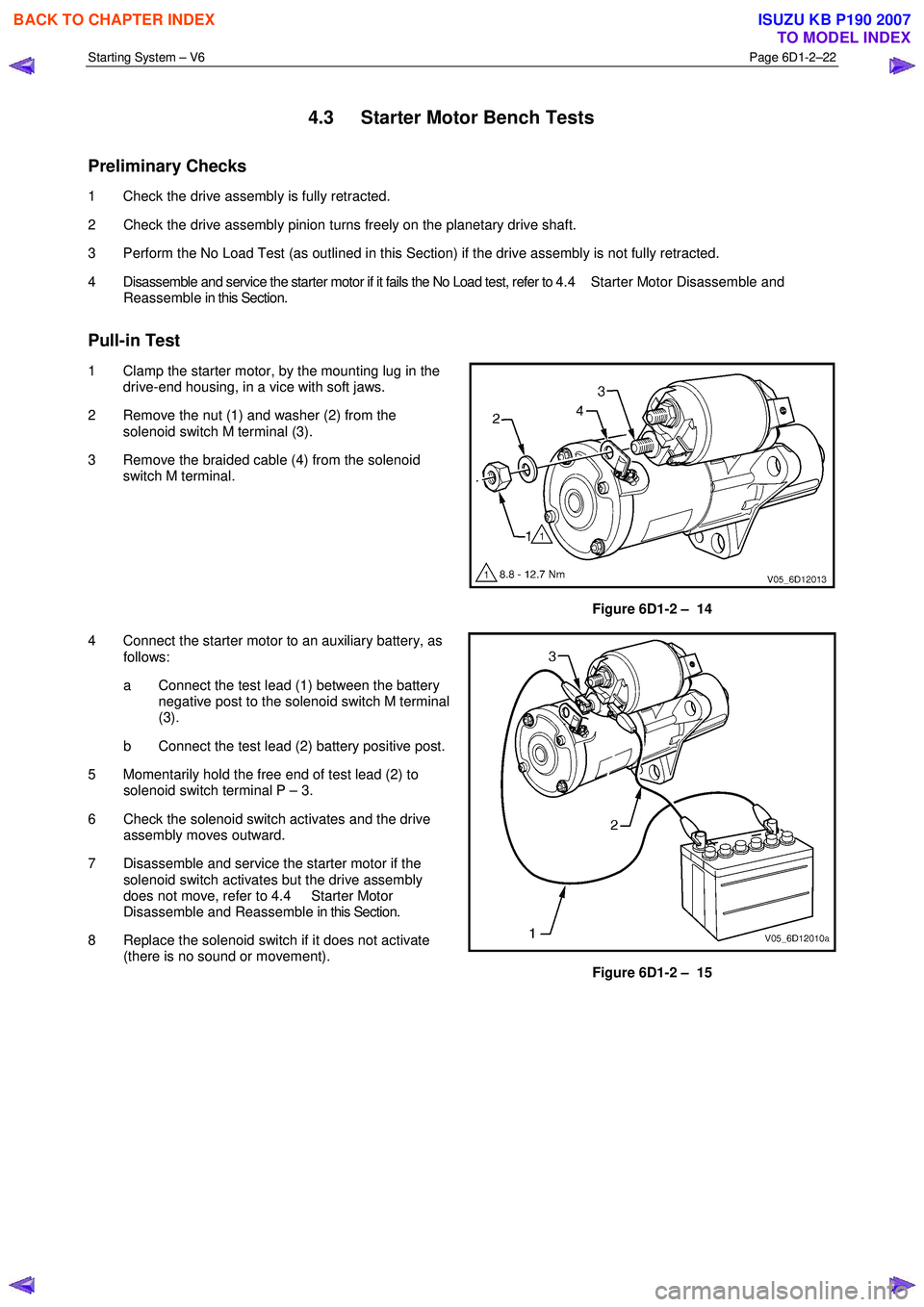

Pull-in Test

1 Clamp the starter motor, by the mounting lug in the drive-end housing, in a vice with soft jaws.

2 Remove the nut (1) and washer (2) from the solenoid switch M terminal (3).

3 Remove the braided cable (4) from the solenoid switch M terminal.

Figure 6D1-2 – 14

4 Connect the starter motor to an auxiliary battery, as follows:

a Connect the test lead (1) between the battery negative post to the solenoid switch M terminal

(3).

b Connect the test lead (2) battery positive post.

5 Momentarily hold the free end of test lead (2) to solenoid switch terminal P – 3.

6 Check the solenoid switch activates and the drive assembly moves outward.

7 Disassemble and service the starter motor if the solenoid switch activates but the drive assembly

does not move, refer to 4.4 Starter Motor

Disassemble and Reassemble in this Section.

8 Replace the solenoid switch if it does not activate (there is no sound or movement).

Figure 6D1-2 – 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3631 of 6020

Starting System – V6 Page 6D1-2–23

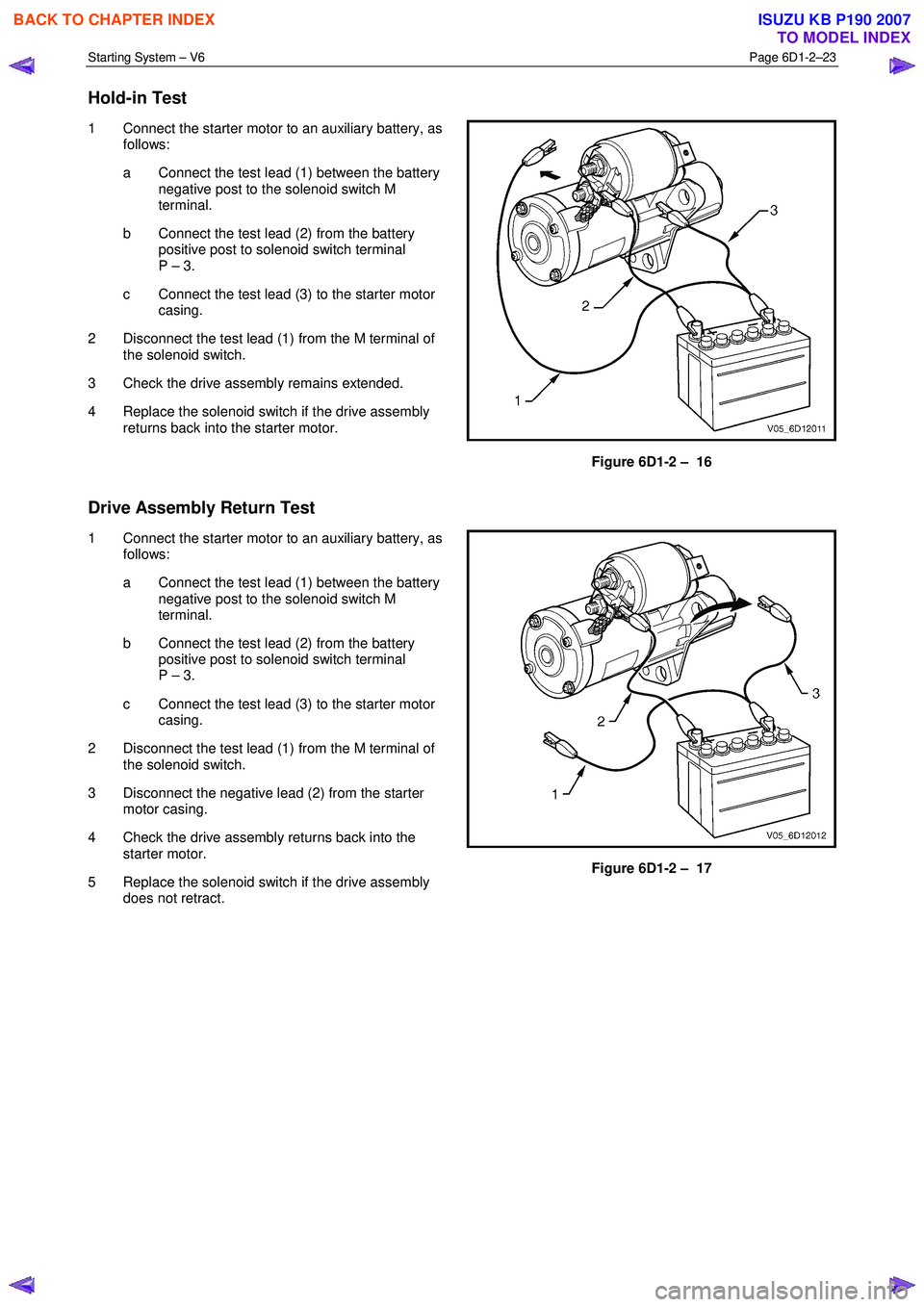

Hold-in Test

1 Connect the starter motor to an auxiliary battery, as

follows:

a Connect the test lead (1) between the battery negative post to the solenoid switch M

terminal.

b Connect the test lead (2) from the battery positive post to solenoid switch terminal

P – 3.

c Connect the test lead (3) to the starter motor casing.

2 Disconnect the test lead (1) from the M terminal of the solenoid switch.

3 Check the drive assembly remains extended.

4 Replace the solenoid switch if the drive assembly returns back into the starter motor.

Figure 6D1-2 – 16

Drive Assembly Return Test

1 Connect the starter motor to an auxiliary battery, as follows:

a Connect the test lead (1) between the battery negative post to the solenoid switch M

terminal.

b Connect the test lead (2) from the battery positive post to solenoid switch terminal

P – 3.

c Connect the test lead (3) to the starter motor casing.

2 Disconnect the test lead (1) from the M terminal of the solenoid switch.

3 Disconnect the negative lead (2) from the starter motor casing.

4 Check the drive assembly returns back into the starter motor.

5 Replace the solenoid switch if the drive assembly does not retract.

Figure 6D1-2 – 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3819 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–33

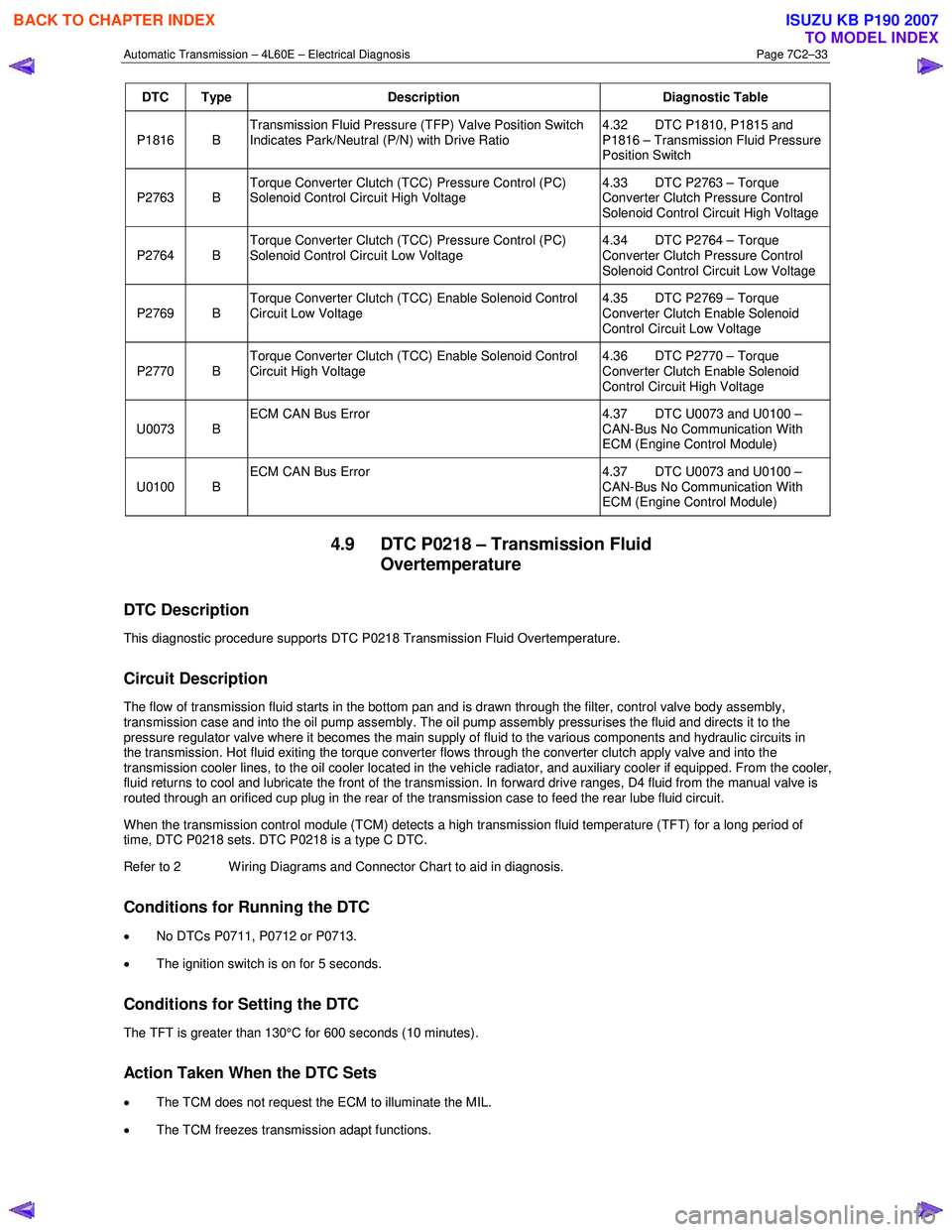

DTC Type Description Diagnostic Table

P1816 B Transmission Fluid Pressure (TFP) Valve Position Switch

Indicates Park/Neutral (P/N) with Drive Ratio 4.32 DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

P2763 B Torque Converter Clutch (TCC) Pressure Control (PC)

Solenoid Control Circuit High Voltage 4.33 DTC P2763 – Torque

Converter Clutch Pressure Control

Solenoid Control Circuit High Voltage

P2764 B Torque Converter Clutch (TCC) Pressure Control (PC)

Solenoid Control Circuit Low Voltage 4.34 DTC P2764 – Torque

Converter Clutch Pressure Control

Solenoid Control Circuit Low Voltage

P2769 B Torque Converter Clutch (TCC) Enable Solenoid Control

Circuit Low Voltage 4.35 DTC P2769 – Torque

Converter Clutch Enable Solenoid

Control Circuit Low Voltage

P2770 B Torque Converter Clutch (TCC) Enable Solenoid Control

Circuit High Voltage 4.36 DTC P2770 – Torque

Converter Clutch Enable Solenoid

Control Circuit High Voltage

U0073 B ECM CAN Bus Error

4.37 DTC U0073 and U0100 –

CAN-Bus No Communication With

ECM (Engine Control Module)

U0100 B ECM CAN Bus Error

4.37 DTC U0073 and U0100 –

CAN-Bus No Communication With

ECM (Engine Control Module)

4.9 DTC P0218 – Transmission Fluid Overtemperature

DTC Description

This diagnostic procedure supports DTC P0218 Transmission Fluid Overtemperature.

Circuit Description

The flow of transmission fluid starts in the bottom pan and is drawn through the filter, control valve body assembly,

transmission case and into the oil pump assembly. The oil pump assembly pressurises the fluid and directs it to the

pressure regulator valve where it becomes the main supply of fluid to the various components and hydraulic circuits in

the transmission. Hot fluid exiting the torque converter flows through the converter clutch apply valve and into the

transmission cooler lines, to the oil cooler located in the vehicle radiator, and auxiliary cooler if equipped. From the cooler ,

fluid returns to cool and lubricate the front of the transmission. In forward drive ranges, D4 fluid from the manual valve is

routed through an orificed cup plug in the rear of the transmission case to feed the rear lube fluid circuit.

When the transmission control module (TCM) detects a high transmission fluid temperature (TFT) for a long period of

time, DTC P0218 sets. DTC P0218 is a type C DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• No DTCs P0711, P0712 or P0713.

• The ignition switch is on for 5 seconds.

Conditions for Setting the DTC

The TFT is greater than 130°C for 600 seconds (10 minutes).

Action Taken When the DTC Sets

•

The TCM does not request the ECM to illuminate the MIL.

• The TCM freezes transmission adapt functions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4878 of 6020

7D1-4 TRANSFER CONTROL SYSTEM

Summary of transfer control system

The transfer control system switches between the 2-wheel

drive (2H), 4-wheel drive high-speed (4H), 4-wheel drive low-

speed (4L), and neutral positions electrically when the driver

operates the switches.

This system has following functions.

1. Connection or disconnection of drive force distribution to the

front wheel front shaft (axle shaft). (The drive force

distribution to the front propeller is connected o

r

disconnected with the motor actuator.)

2. Try to repeat the connection or disconnection of the front wheel drive function as described above.

3. Option: Shift on the fly type only.

Instruction of connection or disconnection of the drive force transmission between the front wheel axle (axle shaft) and

front wheel. (The motor actuator connects or disconnects

the left front wheel and front wheel axle (axle shaft).)

4. Shifting of auxiliary transmission gears, connection o

r

disconnection of wheel and engine drive force (4H, 4L,

neutral).

5. Operation of the indicator on the instrument panel.

6. Transmission of the position signal to other controllers.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007