reset ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2246 of 6020

6E–76 ENGINE DRIVEABILITY AND EMISSIONS

MISCELLANEOUS TEST

The state of each circuit can be tested by using

miscellaneous test menus. Especially when DTC

cannot be detected, a faulty circuit can be diagnosed by

testing each circuit by means of these menus.

Even DTC has been detected, the circuit tests using

these menus could help discriminate between a

mechanical trouble and an electrical trouble.

Connect Tech 2 and select “Powertrain”, “2.XL L4

HV240” & “Miscellaneous Test”.

F0: Lamps

F0: Malfunction Indicator Lamp

When the Tech 2 is operated, “Malfunction Indicator

Lamp (Check Engine Lamp)” is turned on or off.

The circuit is normal if the “Malfunction Indicator Lamp

(Check Engine Lamp)” in the instrument panel is turned

on or off in accordance with this operation.

F1: Relays

F0: Fuel Pump Relay

When the Tech 2 is operated, fuel pump relay signal

turns ON or OFF.

The circuit is normal if fuel pump sound is generated in

accordance with this operation when key switch is

turned ON.

F1: A/C Clutch Relay

When the Tech 2 is operated, A/C clutch relay signal

turns ON or OFF.

The circuit is normal if A/C compressor clutch is

energized in accordance with this operation when the

engine is running.

F2: EVAP

F0: Purge Solenoid

When the Tech 2 is operated, duty ratio of EVAP purge

solenoid is changed 10%-by-10%.

• Press “Increase” key. Then, EVAP Purge Solenoid is increases 10%-by-

10%.

• Press “Quit” Key. F3: IAC System

F0: IAC Control

When the Tech 2 is operated, “Idle Air Control”

increases or decreases 5steps-by-5steps up to

150steps.

The circuit is normal if idle engine speed is changed in

accordance with this operation.

• Press “Increase” key. Then, Idle Air Control is increases 1osteps-by-

10steps up to 160steps. Engine speed is also

changed by this operation.

• Press “Quit” Key.

F1: IAC Reset

When the Tech 2 is operated, “Idle Air Control” resets.

The circuit is normal if idle engine speed is droped in

accordance with this operation.

• Press “Increase” key. Then, Desired Idle speed is increases 50rpm-by-

50rpm up to 1550rpm. Engine speed is also changed

by this operation.

• Press “Quit” Key.

Purge Solenoid

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80 °C

Start Up ECT 50 °C

Intake Air Temperature 30 °C

Start Up IAT 25 °C

Manifold Absolute Pressure 35kPa

EVAP Purge Solenoid 30%

IAC Control

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80 °C

Sta rt U p E C T 50 °C

Intake Air Temperature 30 °C

Start Up IAT25 °C

Manifold Absolute Pressure 35kPa

Idle Air Control 30 Steps

IAC Reset

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80 °C

Sta rt U p E C T 50 °C

Intake Air Temperature 30 °C

Start Up IAT 25 °C

Manifold Absolute Pressure 35kPa

Idle Air Control 30 Steps

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2288 of 6020

6E–118 ENGINE DRIVEABILITY AND EMISSIONSP1167 D Fuel Supply System Rich During

Deceleration Fuel Cutoff 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. O

2 sensor bank 1 output voltage is more

than 550mV in deceleration fuel cutoff

mode. No fail-safe function.

O

2 sensor output voltage is below 550mV. 1. Sensor harness open or short to ground

circuit.

2. O

2 sensor malfunction.

3. MAF sensor output is incorrect.

4. Air intake line malfunction.

5. IAC valve malfunction.

6. Low fuel pressure.

7. Injector malfunction.

8. EVAP purge solenoid valve malfunction.

9. Ignition system malfunction.

10. Spark plug malfunction. 11. ECM malfunction. J2-6/

J2-21

P1171 D Fuel Supply System Lean During Power Enrichment 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60deg. C.

3. Mass air flow is below 13.5m/s.

4. O

2 sensor bank 1 output voltage is below

350mV in power enrichment mode. No fail-safe function.

O

2 sensor output voltage is more than

350mV. 1. Sensor harness open or short to ground

circuit.

2. O

2 sensor malfunction.

3. MAF sensor output is incorrect.

4. Air intake line malfunction.

5. IAC valve malfunction.

6. Low fuel pressure.

7. Injector malfunction.

8. ECM malfunction. J2-6/

J2-21

P1625 B ECM System Reset ECM reset has occurred other than “On ”. Engine control disabled. Memory are is OK. 1. Electrical interference.

2. Magnetic interference.

3. ECM malfunction. -

P1626 - Immobilizer No Signal No response from immobilizer control unit. 1. Engine does not start.

2. Check engine lamp flash.No recovery.

1. ECM and immobilizer control unit

communication circuit open circuit, short to

ground circuit or short to voltage circuit.

2. ECM malfunction.

3. Immobilizer control unit malfunction.

4. Transponder key malfunction. J2-23/

J2-32

P1631 - Immobilizer Wrong Signal Received response is not correct. 1. ECM malfunction.

2. Immobilizer control unit malfunction.

3. Transponder key malfunction. -

P1648 - Wrong Security Code Entered Received incorrect security code. 1. ECM malfunction.

2. Immobilizer control unit malfunction.

3. Transponder key malfunction. -

P1649 - Immobilizer Function Not Programmed Immobilizer function is not programmed in the ECM. ECM malfunction.

-

P1693 B Tachometer Output Low Voltage Tacho output circuit short to ground circuit. No fail-safe function. Tacho output circuit is correct condition. 1. Tacho output circuit short to ground circuit.

2. Poor connector connection.

3. ECM malfunction. J2-25

Code Type

DTC Name DTC Setting Condition Fail-Safe (Back Up)Recovery Condition Related Failure PartsRelated

ECM

Pin No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2387 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–217

DIAGNOSTIC TROUBLE CODE (DTC) P1625 ECM SYSTEM RESET

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) monitors unexpected

ECM reset. This will not turn on MIL light on, only

records code DTC P1625.

Diagnostic Aids

Check for the follwing conditions:

• P1625 alone stored does not need diagnosis. Clear DTC code.

NOTE: DTC P1625 is a DTC to record a ECM reset

history. If DTC P1625 is not reset and no engine

abnormality occurs after learing the DTC, no farther

diagnostic procedures are required.

Diagnostic Trouble Code (DTC) P1625 ECM System Reset

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P1625 B ECM System Reset ECM reset has occurred other than “On”. Engine control disabled.

StepAction Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P1625 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P1625 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Is the Immobilizer function programmed in the ECM? — Verify repair Go to Step 5

5 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 6

6 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2573 of 6020

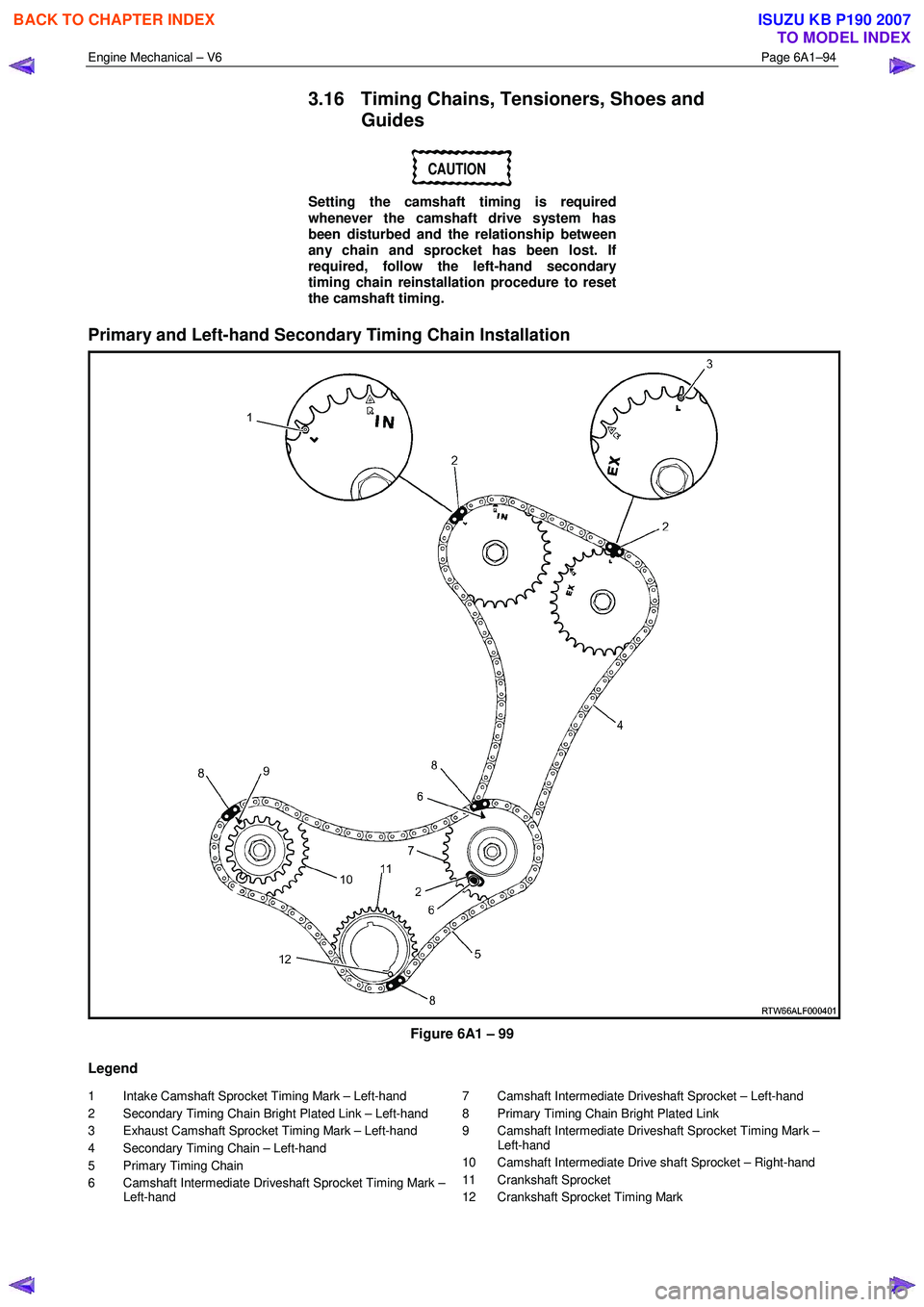

Engine Mechanical – V6 Page 6A1–94

3.16 Timing Chains, Tensioners, Shoes and

Guides

CAUTION

Setting the camshaft timing is required

whenever the camshaft drive system has

been disturbed and the relationship between

any chain and sprocket has been lost. If

required, follow the left-hand secondary

timing chain reinstallation procedure to reset

the camshaft timing.

Primary and Left-hand Secondary Timing Chain Installation

Figure 6A1 – 99

Legend

1 Intake Camshaft Sprocket Timing Mark – Left-hand

2 Secondary Timing Chain Bright Plated Link – Left-hand

3 Exhaust Camshaft Sprocket Timing Mark – Left-hand

4 Secondary Timing Chain – Left-hand

5 Primary Timing Chain

6 Camshaft Intermediate Driveshaft Sprocket Timing Mark – Left-hand 7 Camshaft Intermediate Driveshaft Sprocket – Left-hand

8 Primary Timing Chain Bright Plated Link

9 Camshaft Intermediate Driveshaft Sprocket Timing Mark – Left-hand

10 Camshaft Intermediate Drive shaft Sprocket – Right-hand

11 Crankshaft Sprocket

12 Crankshaft Sprocket Timing Mark

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2587 of 6020

Engine Mechanical – V6 Page 6A1–108

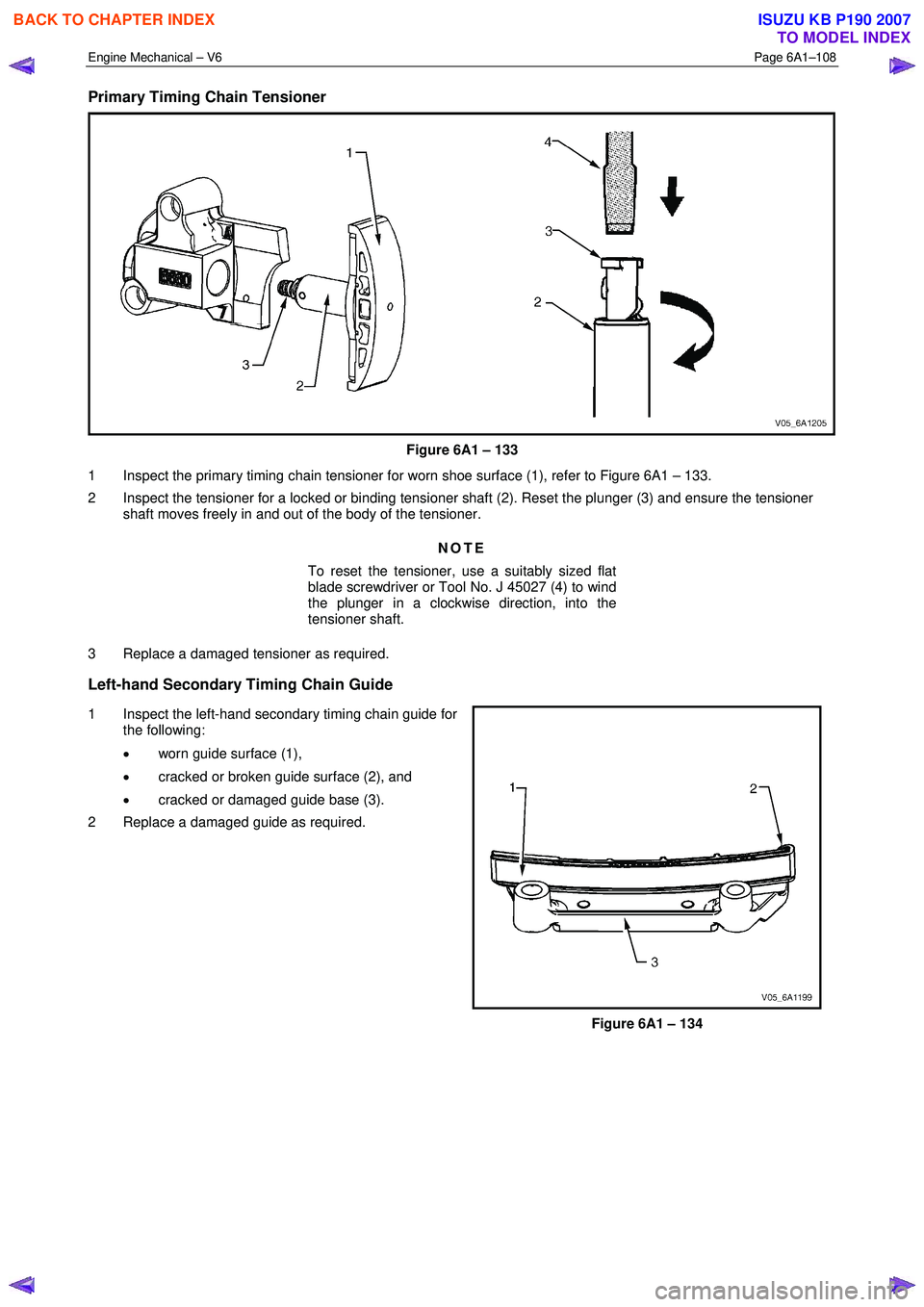

Primary Timing Chain Tensioner

Figure 6A1 – 133

1 Inspect the primary timing chain tensioner for worn shoe surface (1), refer to Figure 6A1 – 133.

2 Inspect the tensioner for a locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner shaft moves freely in and out of the body of the tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

3 Replace a damaged tensioner as required.

Left-hand Secondary Timing Chain Guide

1 Inspect the left-hand secondary timing chain guide for the following:

• worn guide surface (1),

• cracked or broken guide surface (2), and

• cracked or damaged guide base (3).

2 Replace a damaged guide as required.

Figure 6A1 – 134

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2589 of 6020

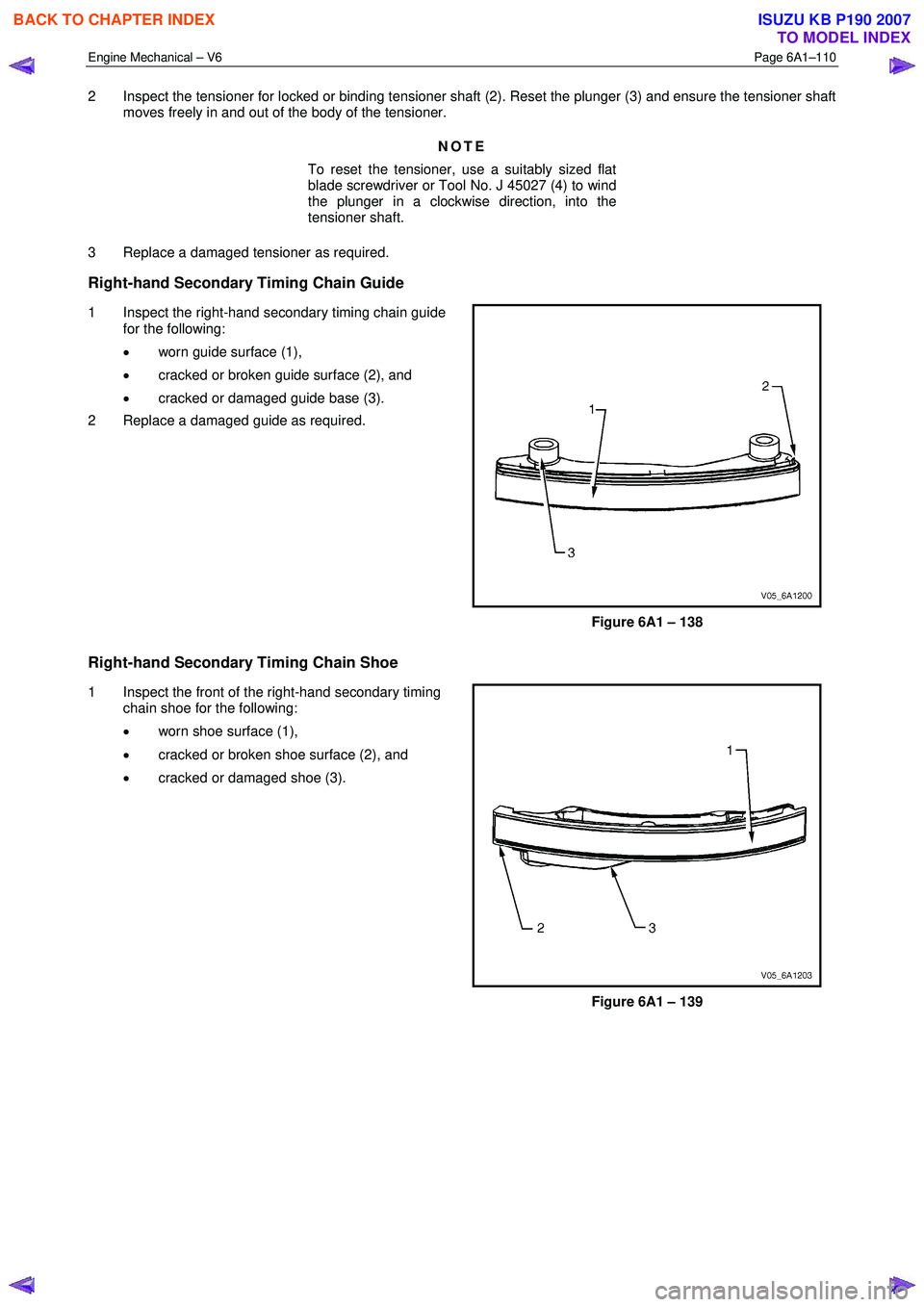

Engine Mechanical – V6 Page 6A1–110

2 Inspect the tensioner for locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner shaft

moves freely in and out of the body of the tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

3 Replace a damaged tensioner as required.

Right-hand Secondary Timing Chain Guide

1 Inspect the right-hand secondary timing chain guide for the following:

• worn guide surface (1),

• cracked or broken guide surface (2), and

• cracked or damaged guide base (3).

2 Replace a damaged guide as required.

Figure 6A1 – 138

Right-hand Secondary Timing Chain Shoe

1 Inspect the front of the right-hand secondary timing chain shoe for the following:

• worn shoe surface (1),

• cracked or broken shoe surface (2), and

• cracked or damaged shoe (3).

Figure 6A1 – 139

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

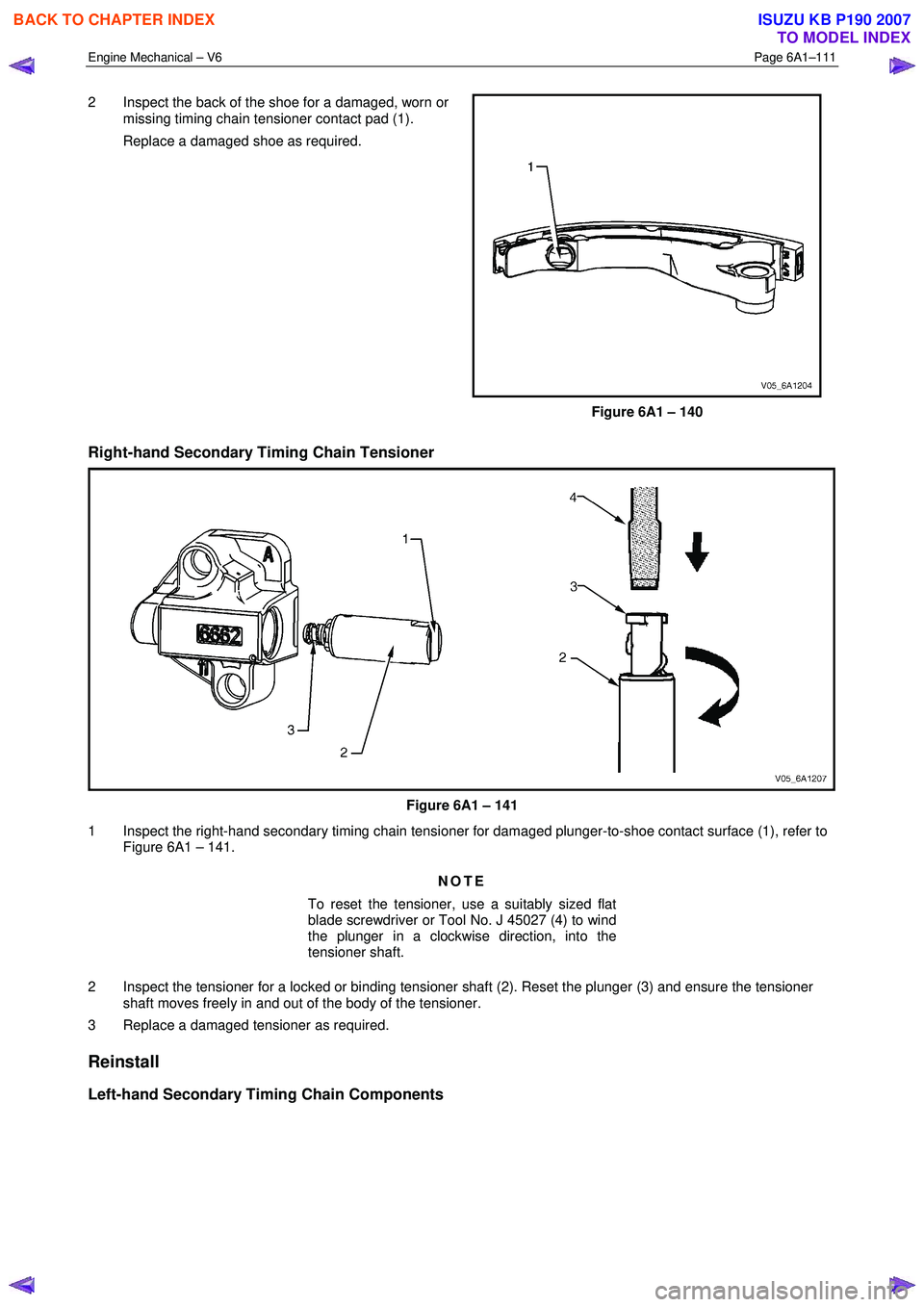

Page 2590 of 6020

Engine Mechanical – V6 Page 6A1–111

2 Inspect the back of the shoe for a damaged, worn or

missing timing chain tensioner contact pad (1).

Replace a damaged shoe as required.

Figure 6A1 – 140

Right-hand Secondary Timing Chain Tensioner

Figure 6A1 – 141

1 Inspect the right-hand secondary timing chain tensioner for damaged plunger-to-shoe contact surface (1), refer to Figure 6A1 – 141.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

2 Inspect the tensioner for a locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner shaft moves freely in and out of the body of the tensioner.

3 Replace a damaged tensioner as required.

Reinstall

Left-hand Secondary Timing Chain Components

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2597 of 6020

Engine Mechanical – V6 Page 6A1–118

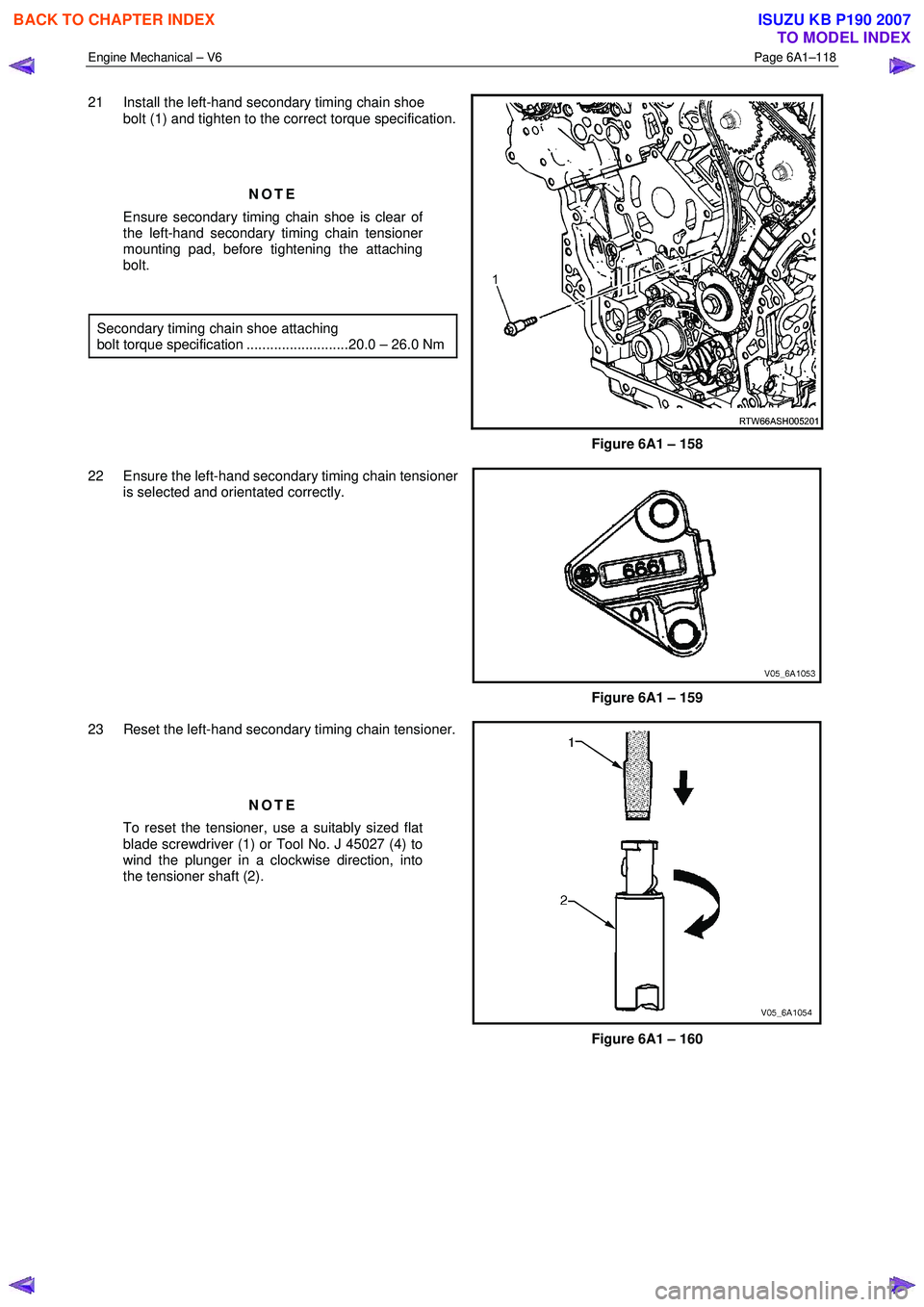

21 Install the left-hand secondary timing chain shoe

bolt (1) and tighten to the correct torque specification.

NOTE

Ensure secondary timing chain shoe is clear of

the left-hand secondary timing chain tensioner

mounting pad, before tightening the attaching

bolt.

Secondary timing chain shoe attaching

bolt torque specification ..........................20.0 – 26.0 Nm

Figure 6A1 – 158

22 Ensure the left-hand secondary timing chain tensioner is selected and orientated correctly.

Figure 6A1 – 159

23 Reset the left-hand secondary timing chain tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver (1) or Tool No. J 45027 (4) to

wind the plunger in a clockwise direction, into

the tensioner shaft (2).

Figure 6A1 – 160

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2604 of 6020

Engine Mechanical – V6 Page 6A1–125

13 Install the primary timing chain upper guide (1).

14 Install the primary timing chain upper guide bolts (2) and tighten to the correct torque specification.

Primary timing chain upper guide

attaching bolt torque specification ...........20.0 – 26.0 Nm

Figure 6A1 – 179

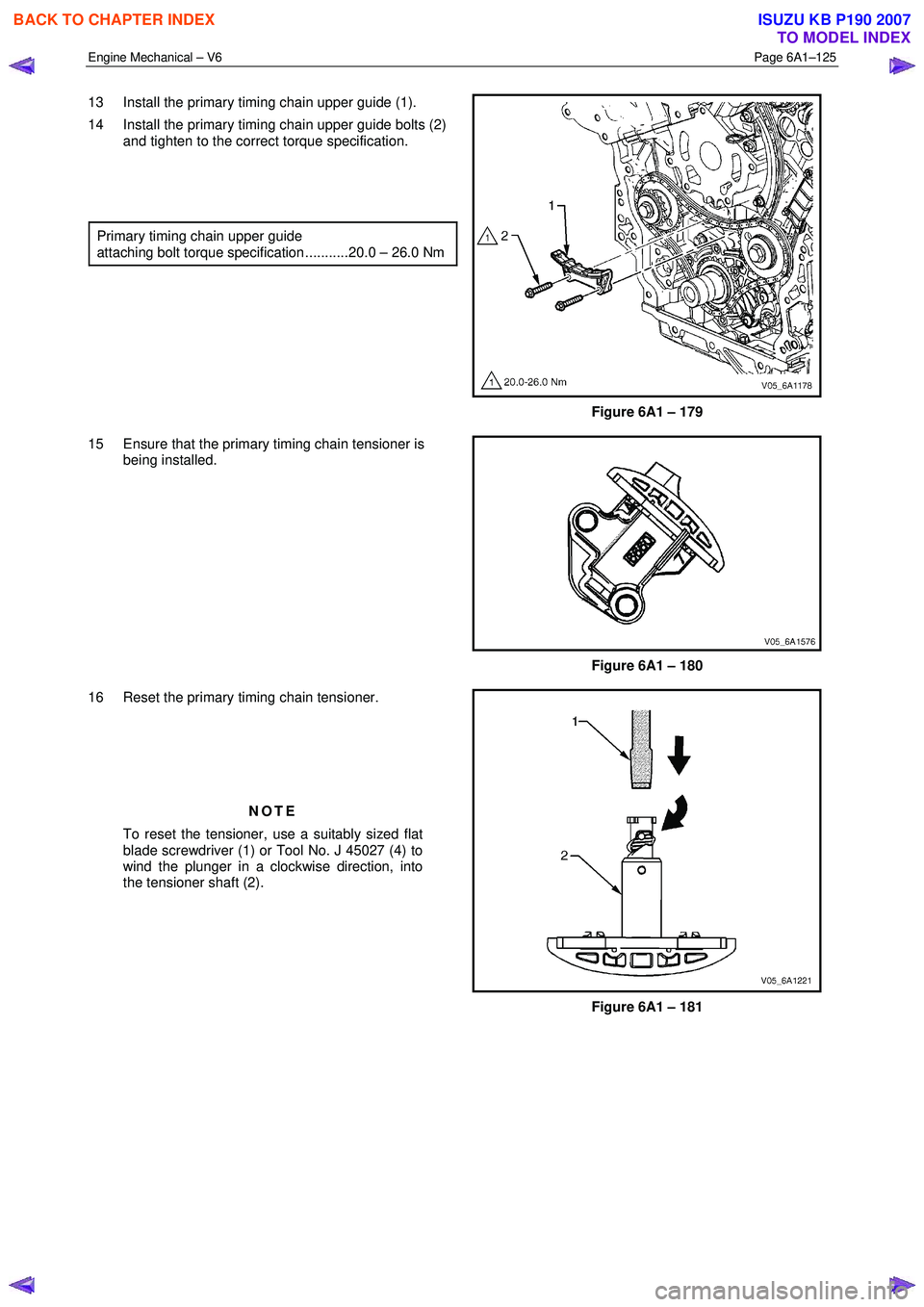

15 Ensure that the primary timing chain tensioner is being installed.

Figure 6A1 – 180

16 Reset the primary timing chain tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver (1) or Tool No. J 45027 (4) to

wind the plunger in a clockwise direction, into

the tensioner shaft (2).

Figure 6A1 – 181

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2612 of 6020

Engine Mechanical – V6 Page 6A1–133

15 Install the secondary timing chain shoe bolt (1) and

tighten to the correct torque specification.

Secondary timing chain shoe

attaching bolt torque specification ...........20.0 – 26.0 Nm

Figure 6A1 – 202

16 Ensure the right-hand secondary timing chain tensioner is selected and orientated correctly.

Figure 6A1 – 203

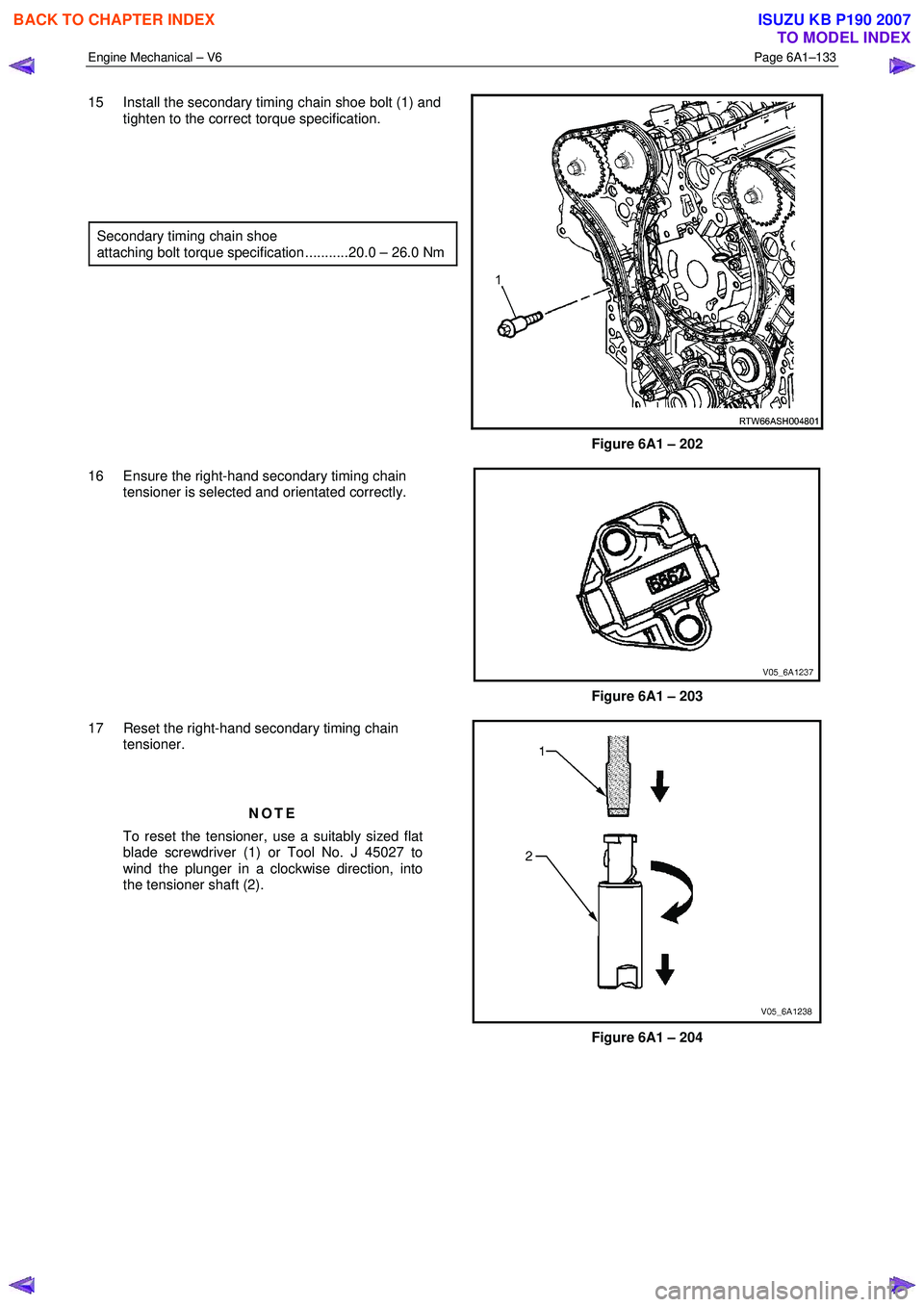

17 Reset the right-hand secondary timing chain tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver (1) or Tool No. J 45027 to

wind the plunger in a clockwise direction, into

the tensioner shaft (2).

Figure 6A1 – 204

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007