reset ISUZU KB P190 2007 Workshop Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3451 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–173

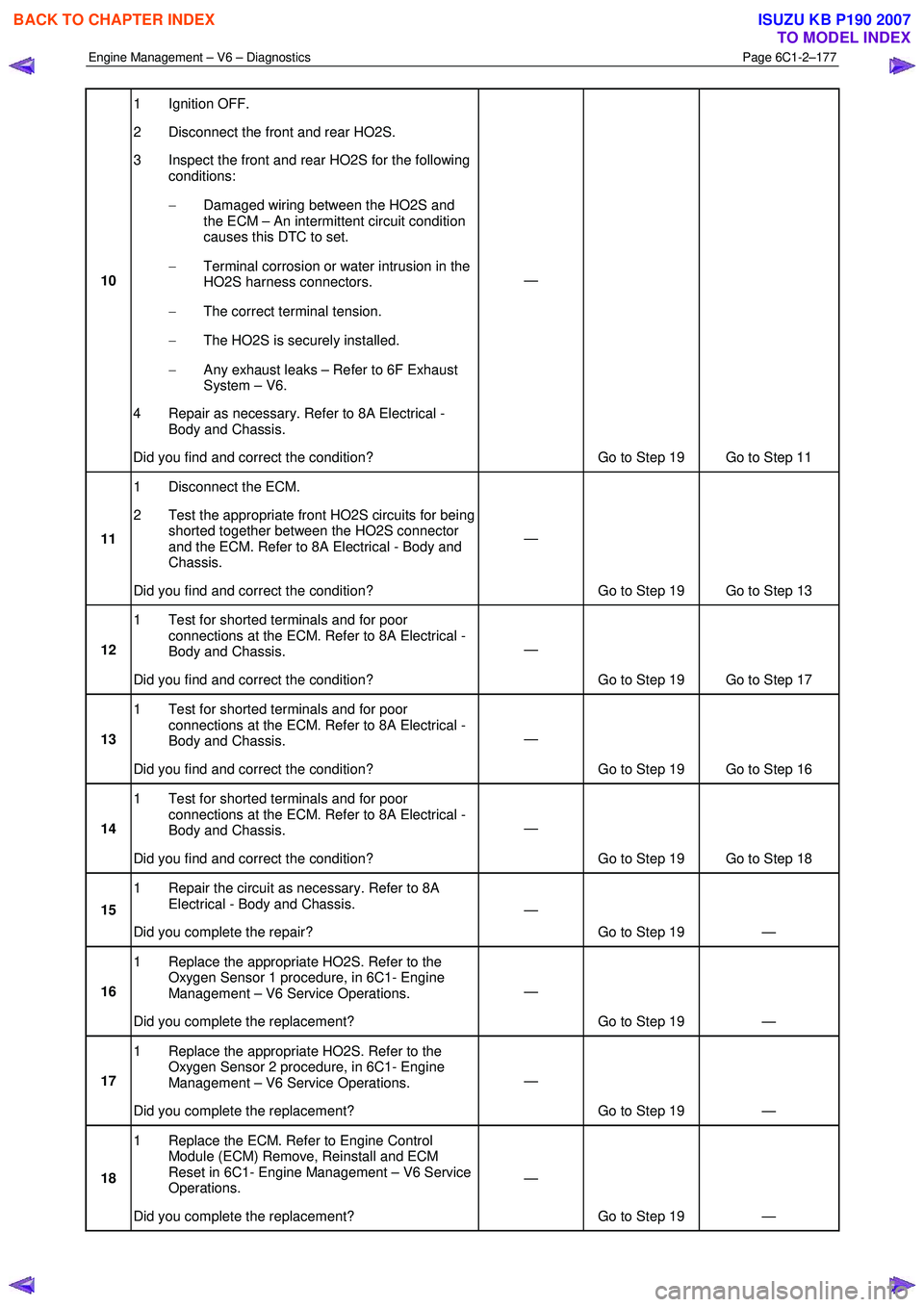

10 1 Ignition OFF.

2 Disconnect the front and rear HO2S.

3 Inspect the front and rear HO2S for the following conditions:

− Damaged wiring between the HO2S and

the ECM – An intermittent circuit condition

causes this DTC to set.

− Terminal corrosion or water intrusion in the

HO2S harness connectors.

− The correct terminal tension.

− The HO2S is securely installed.

− Any exhaust leaks – Refer to 6F Exhaust

System – V6.

4 Repair as necessary. Refer to 8A Electrical - Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 11

11 1 Disconnect the ECM.

2 Test the appropriate front HO2S circuits for being shorted together between the HO2S connector

and the ECM. Refer to 8A Electrical - Body and

Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 13

12 1 Test for shorted terminals and for poor

connections at the HO2S. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 17

13 1 Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 16

14 1 Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

15 1 Repair the circuit as necessary. Refer to 8A

Electrical - Body and Chassis.

Did you complete the repair? —

Go to Step 19 —

16 1 Replace the appropriate HO2S. Refer to the

Oxygen Sensor 1 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement? —

Go to Step 19 —

17 1 Replace the appropriate HO2S. Refer to the

Oxygen Sensor 2 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement? —

Go to Step 19 —

18 1 Replace the ECM. Refer to Engine Control

Module (ECM) Remove, Reinstall and ECM

Reset in 6C1- Engine Management – V6 Service

Operations.

Did you complete the replacement? —

Go to Step 19 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3455 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–177

10 1 Ignition OFF.

2 Disconnect the front and rear HO2S.

3 Inspect the front and rear HO2S for the following conditions:

− Damaged wiring between the HO2S and

the ECM – An intermittent circuit condition

causes this DTC to set.

− Terminal corrosion or water intrusion in the

HO2S harness connectors.

− The correct terminal tension.

− The HO2S is securely installed.

− Any exhaust leaks – Refer to 6F Exhaust

System – V6.

4 Repair as necessary. Refer to 8A Electrical - Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 11

11 1 Disconnect the ECM.

2 Test the appropriate front HO2S circuits for being shorted together between the HO2S connector

and the ECM. Refer to 8A Electrical - Body and

Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 13

12 1 Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 17

13 1 Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 16

14 1 Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

15 1 Repair the circuit as necessary. Refer to 8A

Electrical - Body and Chassis.

Did you complete the repair? —

Go to Step 19 —

16 1 Replace the appropriate HO2S. Refer to the

Oxygen Sensor 1 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement? —

Go to Step 19 —

17 1 Replace the appropriate HO2S. Refer to the

Oxygen Sensor 2 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement? —

Go to Step 19 —

18 1 Replace the ECM. Refer to Engine Control

Module (ECM) Remove, Reinstall and ECM

Reset in 6C1- Engine Management – V6 Service

Operations.

Did you complete the replacement? —

Go to Step 19 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3468 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–190

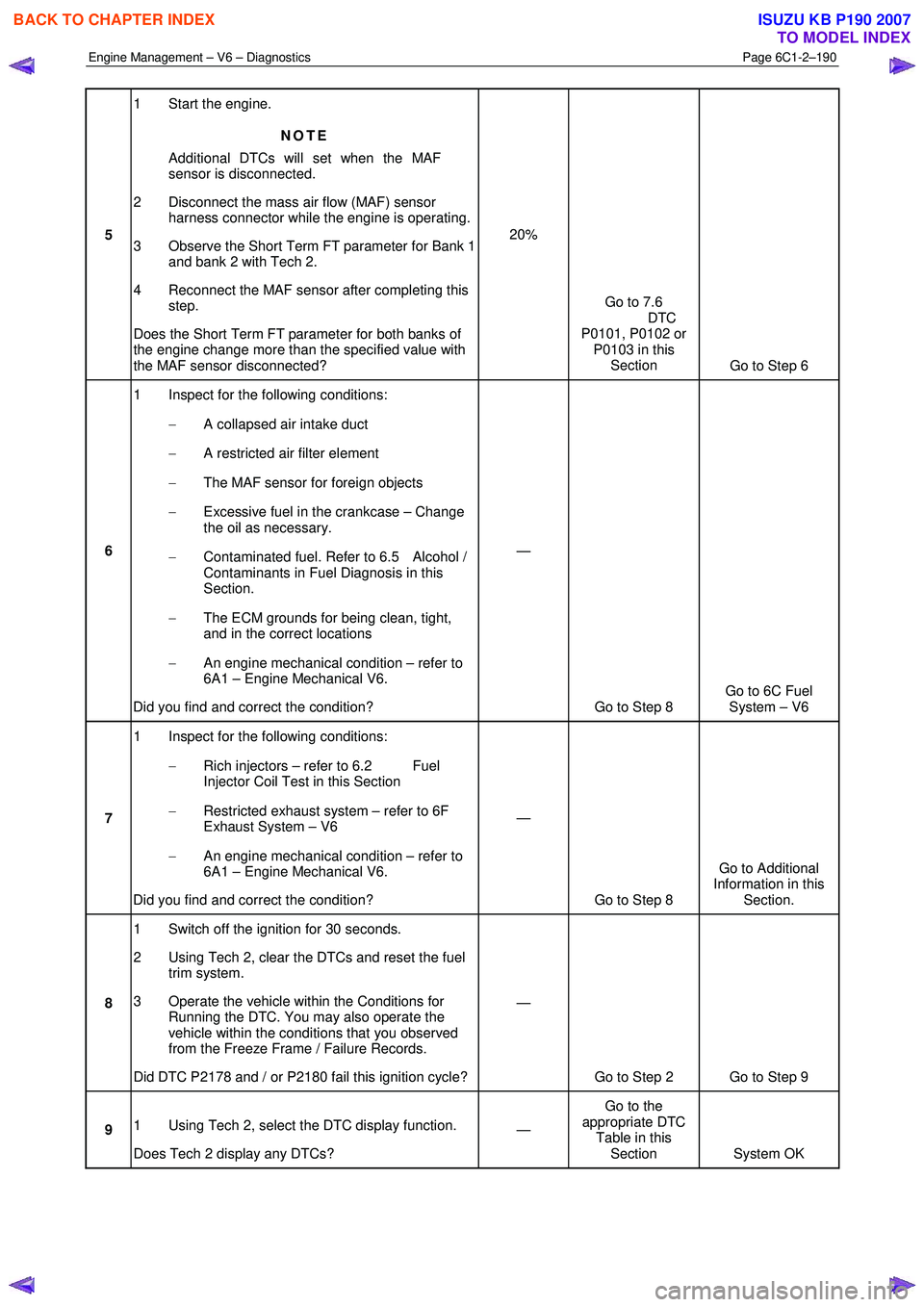

5 1 Start the engine.

NOTE

Additional DTCs will set when the MAF

sensor is disconnected.

2 Disconnect the mass air flow (MAF) sensor harness connector while the engine is operating.

3 Observe the Short Term FT parameter for Bank 1 and bank 2 with Tech 2.

4 Reconnect the MAF sensor after completing this step.

Does the Short Term FT parameter for both banks of

the engine change more than the specified value with

the MAF sensor disconnected? 20%

Go to 7.6

DTC

P0101, P0102 or P0103 in this Section Go to Step 6

6 1 Inspect for the following conditions:

− A collapsed air intake duct

− A restricted air filter element

− The MAF sensor for foreign objects

− Excessive fuel in the crankcase – Change

the oil as necessary.

− Contaminated fuel. Refer to 6.5 Alcohol /

Contaminants in Fuel Diagnosis in this

Section.

− The ECM grounds for being clean, tight,

and in the correct locations

− An engine mechanical condition – refer to

6A1 – Engine Mechanical V6.

Did you find and correct the condition? —

Go to Step 8 Go to 6C Fuel

System – V6

7 1 Inspect for the following conditions:

− Rich injectors – refer to 6.2 Fuel

Injector Coil Test in this Section

− Restricted exhaust system – refer to 6F

Exhaust System – V6

− An engine mechanical condition – refer to

6A1 – Engine Mechanical V6.

Did you find and correct the condition? —

Go to Step 8 Go to Additional

Information in this Section.

8 1 Switch off the ignition for 30 seconds.

2 Using Tech 2, clear the DTCs and reset the fuel trim system.

3 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame / Failure Records.

Did DTC P2178 and / or P2180 fail this ignition cycle? —

Go to Step 2 Go to Step 9

9 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? —

Go to the

appropriate DTC Table in this Section System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3475 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–197

8 1 Turn OFF the ignition for 30 seconds.

2 Using Tech 2, clear the DTCs and reset the fuel trim system.

3 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame / Failure Records.

Did DTC P2188 and / or P2190 fail this ignition cycle? —

Go to Step 2 Go to Step 9

9 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? —

Go to the

appropriate DTC Table in this Section System OK

7.55 DTC P2195 or P2197

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P2195 – B1S1 O2 Sensor – System Too Lean (Bank 1 Sensor 1)

• DTC P2197 – B2S1 O2 Sensor – System Too Lean (Bank 2 Sensor 1)

Circuit Description

The wide band heated oxygen sensor 1 (HO2S1) measures the amount of oxygen in the exhaust system and provides

more information than the switching style HO2S2. The wide band sensor consists of an oxygen sensing cell, an oxygen

pumping cell, and a heater. The exhaust gas sample passes through a diffusion gap between the sensing cell and the

pumping cell. The engine control module (ECM) supplies a voltage to the HO2S and uses this voltage as a reference to

the amount of oxygen in the exhaust system. An electronic circuit within the ECM controls the pump current through the

oxygen pumping cell, maintaining a constant voltage in the oxygen sensing cell.

The ECM monitors the voltage variation in the sensing cell and attempts to keep the voltage constant by increasing or

decreasing the amount of current flow, or oxygen ion flow, to the pumping cell. By measuring the amount of current

required to maintain the voltage in the sensing cell, the ECM can determine the concentration of oxygen in the exhaust.

The HO2S voltage is displayed as a lambda value. A lambda value of 1 is equal to a stoichiometric air fuel ratio of

14.7:1.

Under normal operating conditions, the lambda value will remain around 1. W hen the fuel system is lean, the oxygen

level will be high and the lambda signal will be high or more than 1. W hen the fuel system is rich, the oxygen level will

be low, and the lambda signal will be low or less than 1. The ECM uses this information to maintain the correct air / fuel

ratio.

Conditions for Running the DTC

• Before the ECM can report DTC P2195 or P2197 failed, DTCs P0137, P0138, P0140, P0141, P0157, P0158,

P0160, P0161, P2270, P2271, P2272, and P2273 must run and pass.

• The front and rear heated oxygen sensors are at operating temperature.

• The rear HO2S voltage signal is more than 850 mV.

• The front HO2S is more than 1.08 lambda.

• The Loop Status for both the front and rear sensors is Closed Loop.

• DTCs P2195 and P2197 run continuously once the above conditions are met.

Conditions for Setting the DTC

Condition 1

• The ECM detects that the front HO2S is operating too lean while the rear HO2S is operating too rich and the ECM

detects that the fuel trim is at maximum control,

OR

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3479 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–201

18 1 Replace the ECM. Refer to Engine Control

Module (ECM) Remove, Reinstall and ECM

Reset in 6C1- Engine Management – V6 Service

Operations.

Did you complete the replacement? —

Go to Step 19 —

19 1 Clear the DTCs, using Tech 2.

2 Turn OFF the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P2195 or P2197 fail this ignition cycle? —

Go to Step 2 Go to Step 20

20 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTC? —

Go to the

appropriate DTC Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.56 P2196 or P2198

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P2196 – B1S1 O2 Sensor – System Too Rich (Bank 1 Sensor 1)

• DTC P2198 – B2S1 O2 Sensor – System Too Rich (Bank 2 Sensor 1)

Circuit Description

The wide band heated oxygen sensor 1 (HO2S1) measures the amount of oxygen in the exhaust system and provides

more information than the switching style HO2S2. The wide band sensor consists of an oxygen sensing cell, an oxygen

pumping cell, and a heater. The exhaust gas sample passes through a diffusion gap between the sensing cell and the

pumping cell. The engine control module (ECM) supplies a voltage to the HO2S and uses this voltage as a reference to

the amount of oxygen in the exhaust system. An electronic circuit within the ECM controls the pump current through the

oxygen pumping cell, maintaining a constant voltage in the oxygen sensing cell.

The ECM monitors the voltage variation in the sensing cell and attempts to keep the voltage constant by increasing or

decreasing the amount of current flow, or oxygen ion flow, to the pumping cell. By measuring the amount of current

required to maintain the voltage in the sensing cell, the ECM can determine the concentration of oxygen in the exhaust.

The HO2S voltage is displayed as a lambda value. A lambda value of 1 is equal to a stoichiometric air fuel ratio of

14.7:1.

Under normal operating conditions, the lambda value will remain around 1. W hen the fuel system is lean, the oxygen

level will be high and the lambda signal will be high or more than 1. W hen the fuel system is rich, the oxygen level will

be low, and the lambda signal will be low or less than 1. The ECM uses this information to maintain the correct air / fuel

ratio.

Conditions for Running the DTC

• Before the ECM can report DTC P2196 or P2198 failed, DTCs P0137, P0138, P0140, P0141, P0157, P0158,

P0160, P0161, P2270, P2271, P2272, and P2273 must run and pass.

• The front and rear heated oxygen sensors are at operating temperature.

• The rear HO2S voltage signal is more than 150 mV.

• The front HO2S is more than 0.92 lambda.

• The Loop Status for both the front and rear sensors is Closed Loop.

• DTCs P2196 and P2198 run continuously once the above conditions are met.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3483 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–205

17 1 Replace the HO2S 2. Refer to the Oxygen

Sensor 2 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement? —

Go to Step 19 —

18 1 Replace the ECM. Refer to Engine Control

Module (ECM) Remove, Reinstall and ECM

Reset in 6C1- Engine Management – V6 Service

Operations.

Did you complete the replacement? —

Go to Step 19 —

19 1 Clear the DTCs, using Tech 2.

2 Turn OFF the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P2196 or P2198 fail this ignition cycle? —

Go to Step 2 Go to Step 20

20 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTC? —

Go to the

appropriate DTC Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.57 DTC P2227, P2228 or P2229

DTC Descriptor

This diagnostic procedure supports the following DTCs:

• DTC P2227 – Barometric Pressure Sensor Circuit Range / Performance

• DTC P2228 – Barometric Pressure Sensor Voltage Low

• DTC P2229 – Barometric Pressure Sensor Voltage High

Circuit Description

The ECM applies a positive 5 V reference voltage to the barometric pressure (BARO) sensor through the 5 V reference

circuit and the ground through the low reference circuit.

The BARO sensor provides signal voltage to the ECM that is proportional to the atmospheric pressure changes through

the signal circuit. The ECM uses the BARO signal voltage to maintain the correct fuel delivery at different altitudes.

The ECM monitors and compares the BARO sensor signal voltage against a specified range. A BARO pressure sensor

circuit DTC sets if the ECM detects the BARO sensor signal voltage is outside the specified range.

Conditions for Running the DTC

DTC P2227

Runs continuously once the following conditions are met for 3 seconds:

• DTCs P0121, P0122, P0123, P0221, P0222 or P0223 are not set.

• The engine is running.

DTC P2228 and P2229

Runs continuously once the following conditions are met for 3 seconds:

• DTCs P0101, P0102 or P0103 are not set.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3503 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–225

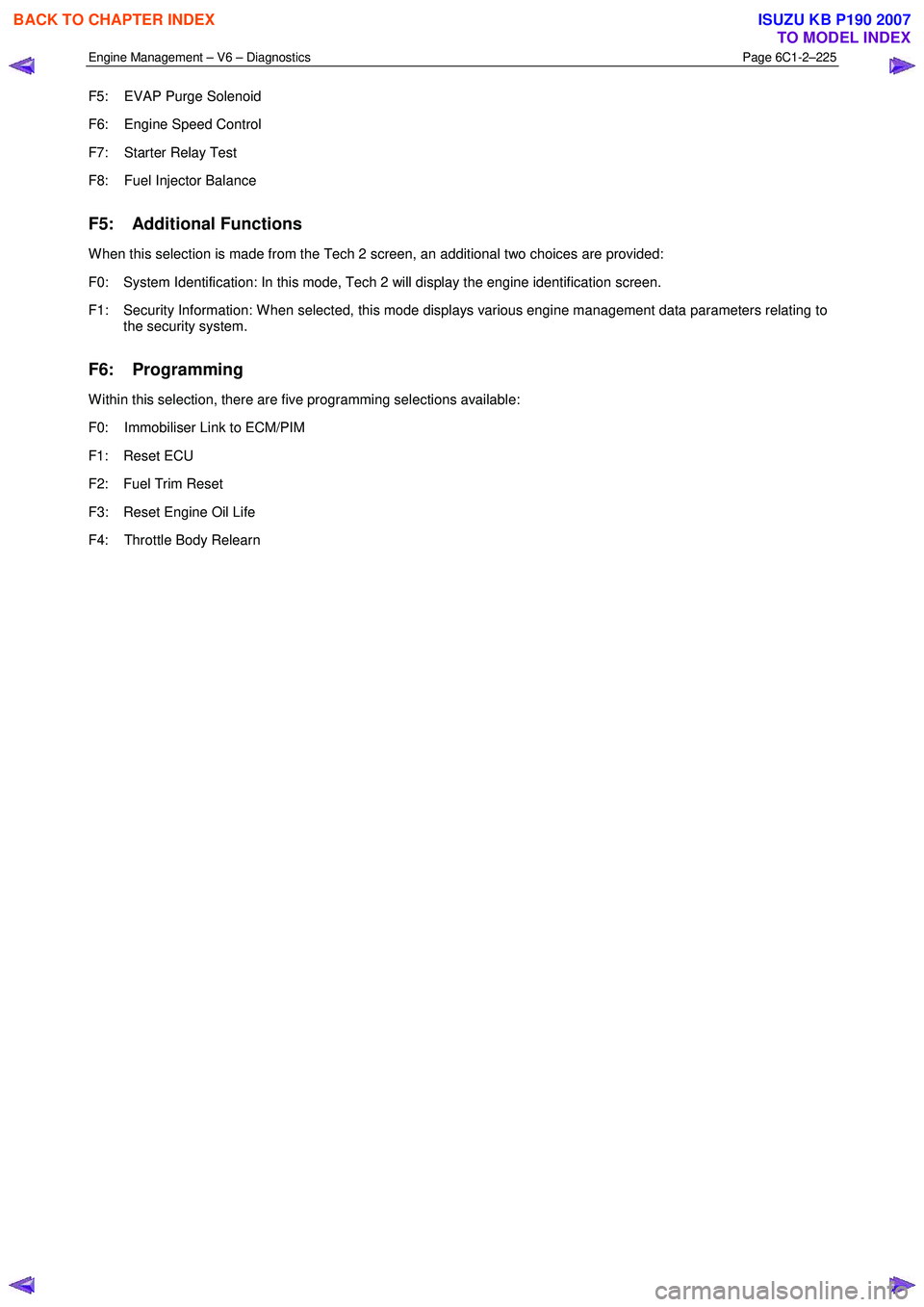

F5: EVAP Purge Solenoid

F6: Engine Speed Control

F7: Starter Relay Test

F8: Fuel Injector Balance

F5: Additional Functions

W hen this selection is made from the Tech 2 screen, an additional two choices are provided:

F0: System Identification: In this mode, Tech 2 will display the engine identification screen.

F1: Security Information: W hen selected, this mode displays various engine management data parameters relating to the security system.

F6: Programming

W ithin this selection, there are five programming selections available:

F0: Immobiliser Link to ECM/PIM

F1: Reset ECU

F2: Fuel Trim Reset

F3: Reset Engine Oil Life

F4: Throttle Body Relearn

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3518 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–240

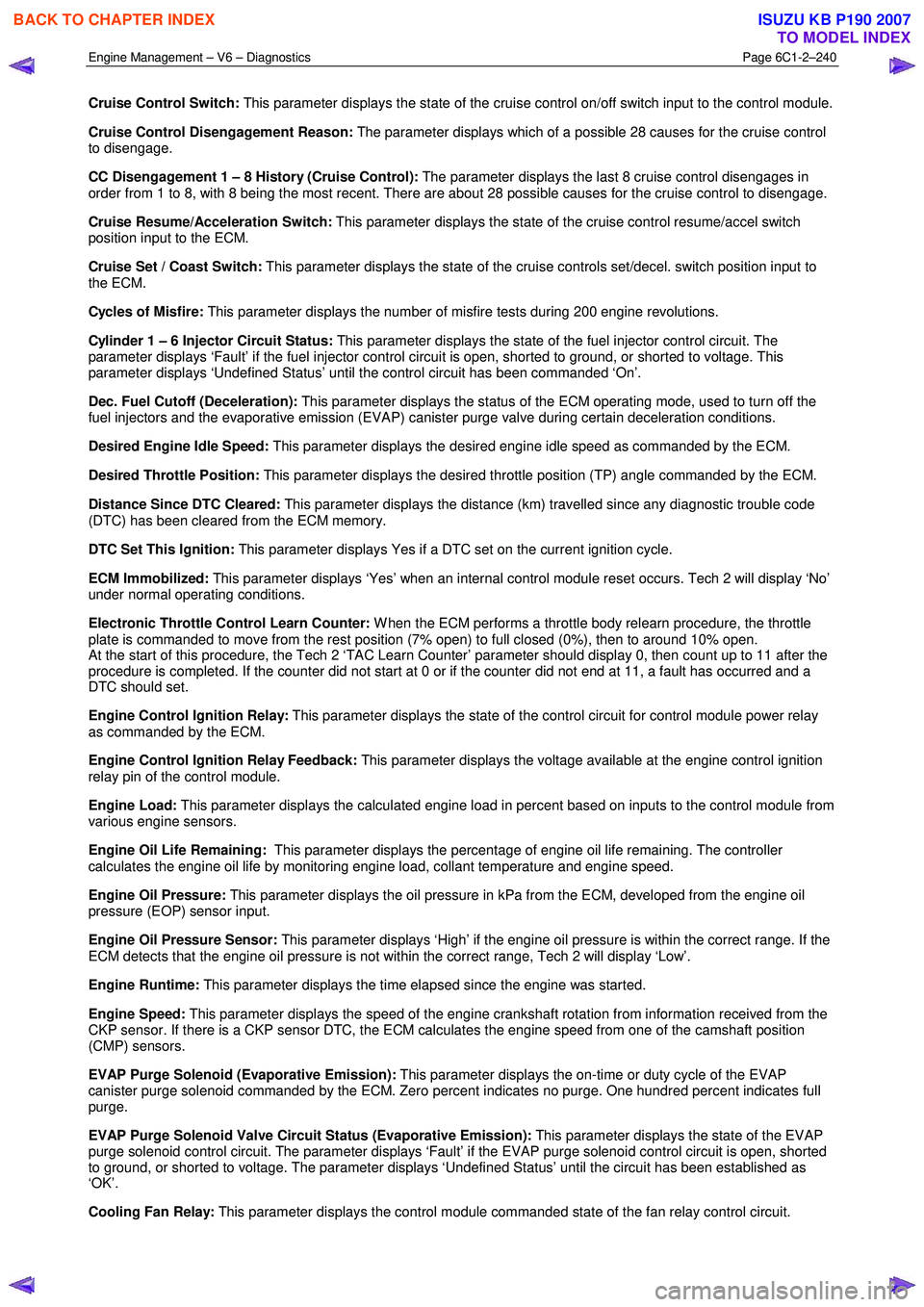

Cruise Control Switch: This parameter displays the state of the cruise control on/off switch input to the control module.

Cruise Control Disengagement Reason: The parameter displays which of a possible 28 causes for the cruise control

to disengage.

CC Disengagement 1 – 8 History (Cruise Control): The parameter displays the last 8 cruise control disengages in

order from 1 to 8, with 8 being the most recent. There are about 28 possible causes for the cruise control to disengage.

Cruise Resume/Acceleration Switch: This parameter displays the state of the cruise control resume/accel switch

position input to the ECM.

Cruise Set / Coast Switch: This parameter displays the state of the cruise controls set/decel. switch position input to

the ECM.

Cycles of Misfire: This parameter displays the number of misfire tests during 200 engine revolutions.

Cylinder 1 – 6 Injector Circuit Status: This parameter displays the state of the fuel injector control circuit. The

parameter displays ‘Fault’ if the fuel injector control circuit is open, shorted to ground, or shorted to voltage. This

parameter displays ‘Undefined Status’ until the control circuit has been commanded ‘On’.

Dec. Fuel Cutoff (Deceleration): This parameter displays the status of the ECM operating mode, used to turn off the

fuel injectors and the evaporative emission (EVAP) canister purge valve during certain deceleration conditions.

Desired Engine Idle Speed: This parameter displays the desired engine idle speed as commanded by the ECM.

Desired Throttle Position: This parameter displays the desired throttle position (TP) angle commanded by the ECM.

Distance Since DTC Cleared: This parameter displays the distance (km) travelled since any diagnostic trouble code

(DTC) has been cleared from the ECM memory.

DTC Set This Ignition: This parameter displays Yes if a DTC set on the current ignition cycle.

ECM Immobilized: This parameter displays ‘Yes’ when an internal control module reset occurs. Tech 2 will display ‘No’

under normal operating conditions.

Electronic Throttle Control Learn Counter: W hen the ECM performs a throttle body relearn procedure, the throttle

plate is commanded to move from the rest position (7% open) to full closed (0%), then to around 10% open.

At the start of this procedure, the Tech 2 ‘TAC Learn Counter’ parameter should display 0, then count up to 11 after the

procedure is completed. If the counter did not start at 0 or if the counter did not end at 11, a fault has occurred and a

DTC should set.

Engine Control Ignition Relay: This parameter displays the state of the control circuit for control module power relay

as commanded by the ECM.

Engine Control Ignition Relay Feedback: This parameter displays the voltage available at the engine control ignition

relay pin of the control module.

Engine Load: This parameter displays the calculated engine load in percent based on inputs to the control module from

various engine sensors.

Engine Oil Life Remaining: This parameter displays the percentage of engine oil life remaining. The controller

calculates the engine oil life by monitoring engine load, collant temperature and engine speed.

Engine Oil Pressure: This parameter displays the oil pressure in kPa from the ECM, developed from the engine oil

pressure (EOP) sensor input.

Engine Oil Pressure Sensor: This parameter displays ‘High’ if the engine oil pressure is within the correct range. If the

ECM detects that the engine oil pressure is not within the correct range, Tech 2 will display ‘Low’.

Engine Runtime: This parameter displays the time elapsed since the engine was started.

Engine Speed: This parameter displays the speed of the engine crankshaft rotation from information received from the

CKP sensor. If there is a CKP sensor DTC, the ECM calculates the engine speed from one of the camshaft position

(CMP) sensors.

EVAP Purge Solenoid (Evaporative Emission): This parameter displays the on-time or duty cycle of the EVAP

canister purge solenoid commanded by the ECM. Zero percent indicates no purge. One hundred percent indicates full

purge.

EVAP Purge Solenoid Valve Circuit Status (Evaporative Emission): This parameter displays the state of the EVAP

purge solenoid control circuit. The parameter displays ‘Fault’ if the EVAP purge solenoid control circuit is open, shorted

to ground, or shorted to voltage. The parameter displays ‘Undefined Status’ until the circuit has been established as

‘OK’.

Cooling Fan Relay: This parameter displays the control module commanded state of the fan relay control circuit.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3519 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–241

Cooling Fan Relay Circuit Status: This parameter displays the state of the fan relay control circuit. The parameter

displays ‘Fault’ if the fan relay control circuit is open, shorted to ground, or shorted to voltage. The parameter displays

‘Undefined’ until the relay control circuit has been determined as being ‘OK’.

Fuel Level: This parameter displays the amount of fuel in the fuel tank in litres, as calculated by the ECM from data

received from the fuel level sensor.

Fuel Level Sensor: This parameter displays the voltage received from the fuel level sensor in the fuel tank, by the ECM.

Fuel Pump Relay Circuit Status: This parameter displays the state of the fuel pump relay control circuit. The

parameter displays ‘Fault’ if the fuel pump relay control circuit is open, shorted to ground, or shorted to voltage. The

parameter displays ‘Undefined’ until the relay control circuit has been determined as being ‘OK’.

Fuel Pump Relay: This parameter displays the ECM commanded state of the fuel pump relay control circuit.

Fuel Trim Learn: This parameter displays ‘Enabled’ when conditions are appropriate for enabling long term fuel trim

corrections. This indicates that the long term fuel trim is adapting continuing amounts of short term fuel trim. If Tech 2

displays ‘Disabled’, then long term fuel trim will not respond to changes in short term fuel trim.

Ignition Accessory Signal: This parameter displays ‘On’ when the control module detects a voltage at the

ignition ‘ACC’ terminal, X1-4 of the ignition switch.

Ignition On Signal: This parameter displays ‘On’ when the control module detects a voltage at the ignition ‘IGN’

terminal X1-3 of the ignition switch.

Initial Brake Apply Signal: This parameter displays the status of the brake lamp switch. Before the cruise control can

be activated, this switch contact must be open circuit when the brake pedal is pressed.

Injection Time Cylinder 1 – 6: This parameter displays the amount of fuel injector On-time or pulse width as

commanded by the ECM.

Intake Air Temperature: This parameter displays the temperature of the air entering the air induction system based on

input to the ECM from the intake air temperature (IAT) sensor.

Knock Sensor Signal (Bank 1 or Bank 2): This parameters displays the voltage input to the control module from the

knock sensor (KS).

Knock Retard: This parameter indicates the amount of spark advance in crankshaft degrees, that the ECM removes

from the ignition control (IC) spark advance in response to the signal from the knock sensors.

Knock Retard Cylinder 1 – 6: This parameter displays the knock retard as commanded by the ECM for cylinders 1-6.

Each cylinder is controlled individually based on both knock sensor signal inputs.

Loop Status B1S1 / B2S1 (Bank 1 or Bank 2 Sensor 1): This parameter displays the state of the fuel control system

as commanded by the ECM. ‘Closed’ Loop operation indicates that the ECM is controlling the fuel delivery based on the

oxygen sensors input signal. In ‘Open’ Loop operation the ECM ignores the oxygen sensor input signal and bases the

amount of fuel to be delivered on other sensor inputs.

LTFT Idle/Deceleration (Bank 1 or Bank 2) (Long Term Fuel Trim): This parameter displays the commanded Long

Term Fuel Trim correction by the ECM for bank 1 or bank 2 for idle and deceleration conditions.

LTFT Cruise/Acceleration (Bank 1 or Bank 2) (Long Term Fuel Trim): This parameter displays the commanded Long

Term Fuel Trim correction by the ECM for bank 1 or bank 2 for cruise and acceleration conditions.

Malfunction Indicator (MI): This parameter displays the commanded (‘On, ‘Off’ or ‘Flashing’) state of the malfunction

indicator lamp (MIL) control circuit by the ECM.

Malfunction Indicator (MI) Circuit Status: This parameter displays the state of the MIL control circuit. The parameter

displays ‘Fault’ if the MIL control circuit is open, shorted to ground, or shorted to voltage. This parameter displays

‘Undefined Status’ until the circuit has been determined as being ‘OK’.

Mass Air Flow: This parameter displays the measured quantity (g/s) of air flowing into the engine during all operating

conditions.

Mass Air Flow Sensor: This parameter displays the signal voltage from the mass air flow (MAF) sensor to the ECM.

Misfire Current Cyl. #1 – #6: Tech 2 displays a range of 0 – 200 counts. This parameter displays the number of

misfires that have been detected during the last 200 cylinder firing events. The counters may normally display some

activity, but the activity should be nearly equal for all of the cylinders, and in low numbers.

Misfire History Cyl. #1 – #6: Tech 2 displays a range of 0 – 65,535 counts. The misfire history counters display the total

level of misfire that has been detected on each cylinder. The misfire history counters will not update or show any activity

until a misfire DTC P0300 has become active. The misfire history counters will update every 200 cylinder firing events.

Oil Level: W hen the ECM receives information from the engine oil level switch, where the engine oil level is within

preset parameters, Tech 2 will display ‘Normal’. If not within preset parameters, the display will show ‘Low’.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3523 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–245

Starter Motor Relay Test

The engine will crank and start during the

starter relay test.

Allows the Technician to turn the starter relay ‘On’, thereby activating the starter motor and cranking the engine.

Preconditions: Apply park brake, firmly apply foot brake, ignition ‘On’, engine ‘Off’, transmission in Park or Neutral.

Fuel Injector Balance

This test allows the Technician to check the fuel flow through each injector when the engine is not running. The

sequence of events are:

1 Install a fuel pressure gauge to the fuel rail.

2 Select ‘Fuel Injector Balance Test’, from the ‘Actuator Test’ menu on Tech 2

3 Activate the fuel injector balance test with Tech 2. This action activates the fuel pump and stabilises the fuel delivery system fuel pressure. The fuel pump is then turned off.

4 Note the stabilised fuel rail pressure.

5 W hen the pump is turned ‘Off’, the injector is activated for a pre-determined time.

6 The fuel pressure drop is then noted from the fuel pressure gauge.

NOTE

For a detailed procedure and analysis of fuel

injector condition, refer to 5.3 Fuel Injector

Balance Test.

8.7 Programming

F0: ICU Link to ECM/PIM : Should the ECM, PIM or ICU be replaced, the modules must be security linked to

each other. If this linking procedure is not performed, the vehicle will not crank nor run. For additional

information relating to Tech 2 and the linking procedure, refer to 11A – Immobiliser.

NOTE

After an ECU reset, the ignition switch must be

turned Off for at least 10 seconds and then

turned On for at least one minute, before

attempting communication between Tech 2 and

the ECU.

Preconditions: TIS approval (TIS 2000 Security Access) must be obtained, the four digit security number

entered into Tech 2 and the theft deterrent system disarmed. Then the ignition must be turned ‘On’, using a

programmed remote coded key.

F1: Reset ECU : This function erases the security link between the Engine Control Module (ECM) and the

Powertrain Interface Modules (PIM). If this procedure is performed, the engine will not crank nor run. A ICU

Link to ECM/PIM procedure will need to be performed. For additional information relating to the ICU Link to

ECM/PIM procedure, refer to 11A – Immobiliser.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007