ignition ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2173 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–3

Diagnostic Aids .......................................... 6E-139

Diagnostic Trouble Code (DTC) P0118 Engine Coolant Temperature Sensor High

Input ......................................................... 6E-140

DIAGNOSTIC TROUBLE CODE (DTC) P0122 THROTTLE POSITION SENSOR LOW

INPUT ......................................................... 6E-143

Circuit Description ..................................... 6E-143

Diagnostic Aids .......................................... 6E-143

Diagnostic Trouble Code (DTC) P0122 Throttle Position Sensor Low Input ....................... 6E-144

DIAGNOSTIC TROUBLE CODE (DTC) P0123 THROTTLE POSITION SENSOR HIGH

INPUT ...................................................... 6E-147

Circuit Description ..................................... 6E-147

Diagnostic Aids .......................................... 6E-147

Diagnostic Trouble Code (DTC) P0123 Throttle Position Sensor High Input ...................... 6E-148

DIAGNOSTIC TROUBLE CODE (DTC) P0131 O

2 SENSOR CIRCUIT LOW VOLTAGE

(BANK 1 SENSOR 1) ................................. 6E-150

Circuit Description ..................................... 6E-150

Diagnostic Aids .......................................... 6E-150

Diagnostic Trouble Code (DTC) P0131 O

2 Sensor Circuit Low Voltage (Bank 1 Sensor 1)

6E-160

DIAGNOSTIC TROUBLE CODE (DTC) P0132 O

2

SENSOR CIRCUIT HIGH VOLTAGE (BANK 1

SENSOR 1) ................................................ 6E-155

Circuit Description ..................................... 6E-155

Diagnostic Aids .......................................... 6E-155

Diagnostic Trouble Code (DTC) P0132 O

2 Sensor Circuit High Voltage

(Bank 1 Sensor 1) .................................... 6E-156

DIAGNOSTIC TROUBLE CODE (DTC) P0134 O

2 SENSOR NO ACTIVITY DEFECTED

(BANK 1 SENSOR 1) ................................. 6E-159

Circuit Description ..................................... 6E-159

Diagnostic Aids .......................................... 6E-160

Diagnostic Trouble Code (DTC) P0134 O

2 Sensor Circuit No Activity Detected

(Bank 1 Sensor 1) .................................... 6E-160

DIAGNOSTIC TROUBLE CODE (DTC) P0135 O

2 SENSOR HEATER CIRCUIT

(BANK 1 SENSOR 1) ................................. 6E-163

Circuit Description ..................................... 6E-163

Diagnostic Aids .......................................... 6E-164

Diagnostic Trouble Code (DTC) P0135 O

2 Sensor Heater Circuit (Bank 1 Sensor 1) 6E-164

DIAGNOSTIC TROUBLE CODE (DTC) P0201 INJECTOR 1 CONTROL CIRCUIT ............. 6E-167

DIAGNOSTIC TROUBLE CODE (DTC) P0202 INJECTOR 2 CONTROL CIRCUIT ............. 6E-167

DIAGNOSTIC TROUBLE CODE (DTC) P0203 INJECTOR 3 CONTROL CIRCUIT ............. 6E-167

DIAGNOSTIC TROUBLE CODE (DTC) P0204 INJECTOR 4 CONTROL CIRCUIT ............. 6E-167

Circuit Description ...................................... 6E-167

Diagnostic Aids .......................................... 6E-168

Diagnostic Trouble Code (DTC) P0201 Injector 1 Control Circuit .......................... 6E-168

Diagnostic Trouble Code (DTC) P0202 Injector 2 Control Circuit .......................... 6E-168

Diagnostic Trouble Code (DTC) P0203 Injector 3 Control Circuit .......................... 6E-168

Diagnostic Trouble Code (DTC) P0204 Injector 4 Control Circuit .......................... 6E-168

DIAGNOSTIC TROUBLE CODE (DTC) P0325 KNOCK SENSOR (KS) MODULE CIRCUIT 6E-174

Circuit Description ...................................... 6E-174

Diagnostic Aids .......................................... 6E-174

Diagnostic Trouble Code (DTC) P0325 Knock

Sensor Module Circuit ............................. 6E-174

DIAGNOSTIC TROUBLE CODE (DTC) P0327 KNOCK SENSOR (KS) CIRCUIT ............... 6E-177

Circuit Description ...................................... 6E-177

Diagnostic Aids .......................................... 6E-177

Diagnostic Trouble Code (DTC) P0327 Knock Sensor Circuit ............................... 6E-178

DIAGNOSTIC TROUBLE CODE (DTC) P0336 CRANKSHAFT POSITION (CKP) SENSOR

CIRCUIT RANGE/PERFORMANCE (58X) . 6E-180

DIAGNOSTIC TROUBLE CODE (DTC) P0337 CRANKSHAFT POSITION (CKP) SENSOR

CIRCUIT LOW INPUT (58X) ...................... 6E-180

Circuit Description ...................................... 6E-180

Diagnostic Aids .......................................... 6E-181

Diagnostic Trouble Code (DTC) P0336 Crankshaft Position Sensor Circuit

Range/performance (58x) ........................ 6E-181

Diagnostic Trouble Code (DTC) P0337 Crankshaft Position Sensor Circuit Low

Input (58x) ............................................... 6E-181

DIAGNOSTIC TROUBLE CODE (DTC) P0351 IGNITION 1 CONTROL CIRCUIT ............... 6E-186

DIAGNOSTIC TROUBLE CODE (DTC) P0352 IGNITION 2 CONTROL CIRCUIT ............... 6E-186

Circuit Description ...................................... 6E-186

Diagnostic Aids .......................................... 6E-186

Diagnostic Trouble Code (DTC) P0351 Ignition 1 Control Circuit .......................... 6E-187

Diagnostic Trouble Code (DTC) P0352 Ignition 2 Control Circuit .......................... 6E-187

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2175 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–5

ENGINE CRANKS BUT WILL NOT RUN ..... 6E-233

HARD START SYMPTOM ............................ 6E-236

ROUGH, UNSTABLE, OR INCORRECT IDLE, STALLING SYMPTOM ............................... 6E-239

SURGES AND/OR CHUGS SYMPTOM ...... 6E-242

HESITATION, SAG, STUMBLE SYMPTOM 6E-245

CUTS OUT, MISSES SYMPTOM ................. 6E-248

LACK OF POWER, SLUGGISH OR SPONGY SYMPTOM ................................................. 6E-251

DETONATION/SPARK KNOCK SYMPTOM 6E-254

POOR FUEL ECONOMY SYMPTOM .......... 6E-256

EXCESSIVE EXHAUST EMISSIONS OR ODORS SYMPTOM ................................... 6E-258

DIESELING, RUN-ON SYMPTOM ............... 6E-261

BACKFIRE SYMPTOM ................................. 6E-262

ON-VEHICLE SERVICE PROCEDURE ....... 6E-264

ENGINE CONTROL MODULE (ECM) .......... 6E-264

CRANKSHAFT POSITION (CKP) SENSOR 6E-264

ENGINE COOLANT TEMPERATURE (ECT) SENSOR .................................................... 6E-265

INTAKE AIR TEMPERATURE (IAT) SENSOR 6E-265

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR .................................................... 6E-266

THROTTLE POSITION SENSOR (TPS) ...... 6E-266

IDLE AIR CONTROL (IAC) VALVE .............. 6E-267

KNOCK SENSOR ......................................... 6E-268

POWER STEERING PRESSURE (PSP) SWITCH ..................................................... 6E-268

HEATED OXYGEN SENSOR (HO2S) ......... 6E-269

EVAP CANISTER PURGE VALVE SOLENOID 6E-269

FUEL PRESSURE RELIEF .......................... 6E-270

FUEL RAIL ASSEMBLY ............................... 6E-270

FUEL INJECTOR .......................................... 6E-271

FUEL PRESSURE REGULATOR ................ 6E-273

IGNITION COIL ............................................ 6E-275

SPARK PLUGS ............................................ 6E-275

SPARK PLUG CABLES ................................ 6E-277

EMISSION CONTROL ; *CO ADJUSTER (W/O

CATALYSTIC CONVERTER) .................. 6E-277

SPECIAL SERVICE TOOLS ......................... 6E-279

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2176 of 6020

6E–6 ENGINE DRIVEABILITY AND EMISSIONS

ABBREVIATIONS CHARTS

AbbreviationsAppellation

A/C Air Conditioner

A/T Automatic Transmission

ACC Accessory

BLK Black

BLU Blue

BRN Brown

CEL Check Engine Lamp

CKP Crankshaft Position

DLC Data Link Connector

DTC Diagnostic Trouble Code

DVM Digital Volt Meter

ECM Engine Control Module

ECT Engine Coolant Temperature

EEPROM Electrically Erasable & Programmable Read Only Memory

EVAP Evaporative Emission

EVRV Electric Vacuum Regulating Valve

EXH Exhaust

FT Fuel Temperature

GND Ground

GRY Gray

HOS2 Heated Oxygen Sensor

IAC Idel Air Control

IAT Intake Air Temperature

IG Ignition

ITP Intake Throttle Position

KS Knock Sensor

M/T Manual Transmission

MAP Manifold Absolute Pressure

MIL Malfunction Indicator Lamp

OBD On-Board Diagnostic

ORN Orange

OT Oil Temperature

PNK Pink

RED Red

SW Switch

TB Throttle Body

TEMP Temperature

TP Throttle Position

VCC Voltage Constant Control

VSS Vehicle Speed Sensor

WHT White

YEL Yellow

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2178 of 6020

6E–8 ENGINE DRIVEABILITY AND EMISSIONS

1234

(1)

(2) Injector #1 Cylinder

Injector #2 Cylinder (3)

(4) Injector #3 Cylinder

Injector #4 Cylinder (Under the ECM)

(1) Ignition Coil Module Assembly

(1) Heated Oxygen Sensor (HO2S)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2198 of 6020

6E–28 ENGINE DRIVEABILITY AND EMISSIONS

CONNECTOR LIST

No.Connector face No.Connector face

B-24

Green Meter-B C-122

CO Adjuster

B-58

Black Check connector E-6

Fuel injector

B-62

White Ignition switch (IGSUB : G1) E-7

Fuel injector

B-63

White Ignition switch (IGSUB : G2) E-8

Fuel injector

B-68

Immobilizer E-9

Fuel injector

C-2

Silver Engine room-RH ground E-18

Ignition coil

C-56

ECM E-60

ECM

C-107

White J/B E2 E-72

Engine earth-A

C-108

White J/B E1 E-74

Engine earth-B

C-121

IAT sensor E-77

O

2 sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2214 of 6020

6E–44 ENGINE DRIVEABILITY AND EMISSIONS

Connector J2 Port: View Looking Into ECM Case

1

17 16

32

PIN32

PIN1

PIN17

PIN16

Pin

No. B/

Box No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

J2-1 J2-1 Intake Air Temp. (IAT) Sensor Ground GRN Continuity

with

ground -

- - Disconnect ΩJ2-1 GND

J2-2 J2-2 Battery Power Supply RED/ WHT10-14V

Connect DC V J2-2 GND

J2-3 J2-3 Ignition Power Supply BLU/ YELLess than

1V 10-14V

Connect DC V J2-3 GND

J2-4 J2-4 To Data Link Connector No. 6 BLU -

-- - -- - -

J2-5 J2-5 No Connection -- - - - -- - -

J2-6 J2-6 Oxygen Sensor (Ground) PNK Continuity

with

ground -

- - Connect ΩJ2-6 GND

J2-7 J2-7 No Connection -- - - - -- - -

J2-8 J2-8 No Connection -- - - - -- - -

J2-9 J2-9 No Connection -- - - - -- - -

J2-10 J2-10 CO Adjust Signal (W/O Catalystic

Converter) YEL -

-- - -- - -

J2-11 J2-11 Fuel Pump Relay GRN/ WHT10-14V

While relay

is activated; 10-14V

Relay is not

activated;

Less than 1V10-14V Connect DC V J2-11 GND

J2-12 J2-12 No Connection -- - - - -- - -

J2-13 J2-13 A/C Compressor Relay GRY/

RED Less than

1V A/C comp. is operated: Less than 1V

A/C comp. is not operated: 10-14V Connect DC V J2-13 GND

J2-14 J2-14 No Connection -- - - - -- - -

J2-15 J2-15 No Connection -- - - - -- - -

J2-16 J2-16 No Connection -- - - - -- - -

J2-17 J2-17 CO Adjust (W/O Catalystic Converter) RED -

-- - -- - -

J2-18 J2-18 Battery Power Supply RED/ WHT10-14V

Connect DC V J2-18 GND

J2-19 J2-19 No Connection -- - - - -- - -

J2-20 J2-20 Power Steering Pressure Switch GRN/

YEL Less than

1V

Pressure switch is turned on: Less than 1VPressure switch is turned off: 10-14VConnect DC V J2-20 GND

J2-21 J2-21 Oxygen Sensor BLU Less than 1VApprox.

0.4V Wave form D or 0.1 -

0.9V Connect DC V J2-21 J2-6

J2-22 J2-22 Intake Air Temp. (IAT) Sensor (Signal) YEL/

GRN Less than

1V

20℃: Approx. 2.9V / 40 ℃: Approx. 1.8V V

/ 60 ℃: Approx. 1.1V / 80 ℃: Approx. 0.6VConnect DC V J2-22 33

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2216 of 6020

6E–46 ENGINE DRIVEABILITY AND EMISSIONS

Reference Wave Form

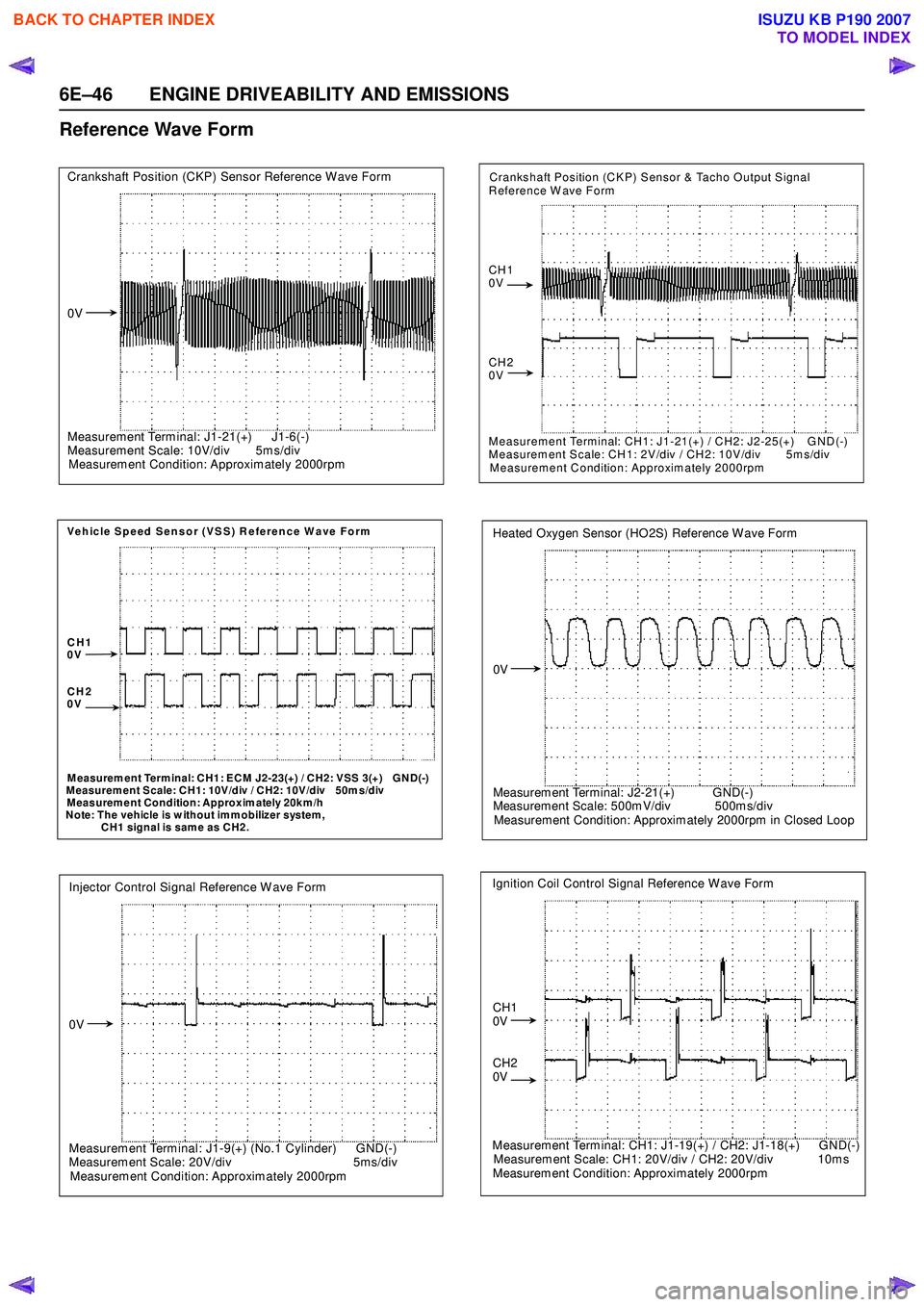

Crankshaft Position (CKP) Sensor Reference W ave Form

0V

Measurem ent Term inal: J1-21(+) J1-6(-)

Measurem ent Scale: 10V/div 5m s/div

Measurem ent Condition: Approxim ately 2000rpm

Vehicle Speed Sensor (VSS) Reference Wave Form

CH1

0V

CH2

0V

M easurem ent Term inal: CH1: ECM J2-23(+) / CH2: VSS 3(+) GND(-)

M easurem ent Scale: CH1: 10V/div / CH2: 10V/div 50m s/div

Measurem ent Condition: Approxim ately 20km /h

Note: The vehicle is w ithout imm obilizer system,

CH1 signal is same as CH2.

Injector Control Signal Reference W ave Form

0V

Measurem ent Term inal: J1-9(+) (No.1 Cylinder) GND(-)

Measurement Scale: 20V/div 5ms/div

Measurem ent Condition: Approximately 2000rpm

Crankshaft Position (CKP) Sensor & Tacho Output Signal

Reference W ave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: J1-21(+) / CH2: J2-25(+) GND(-)

Measurement Scale: CH1: 2V/div / CH2: 10V/div 5ms/div

Measurement Condition: Approximately 2000rpm

Heated Oxygen Sensor (HO2S) Reference Wave Form

0V

Measurem ent Terminal: J2-21(+) GND(-)

Measurem ent Scale: 500m V/div 500m s/div

Measurement Condition: Approxim ately 2000rpm in Closed Loop

Ignition Coil Control Signal Reference Wave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: J1-19(+) / CH2: J1-18(+) GND(-)

Measurem ent Scale: CH1: 20V/div / CH2: 20V/div 10m s

Measurement Condition: Approximately 2000rpm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2218 of 6020

6E–48 ENGINE DRIVEABILITY AND EMISSIONS

GENERAL DESCRIPTION FOR ECM AND

SENSORS

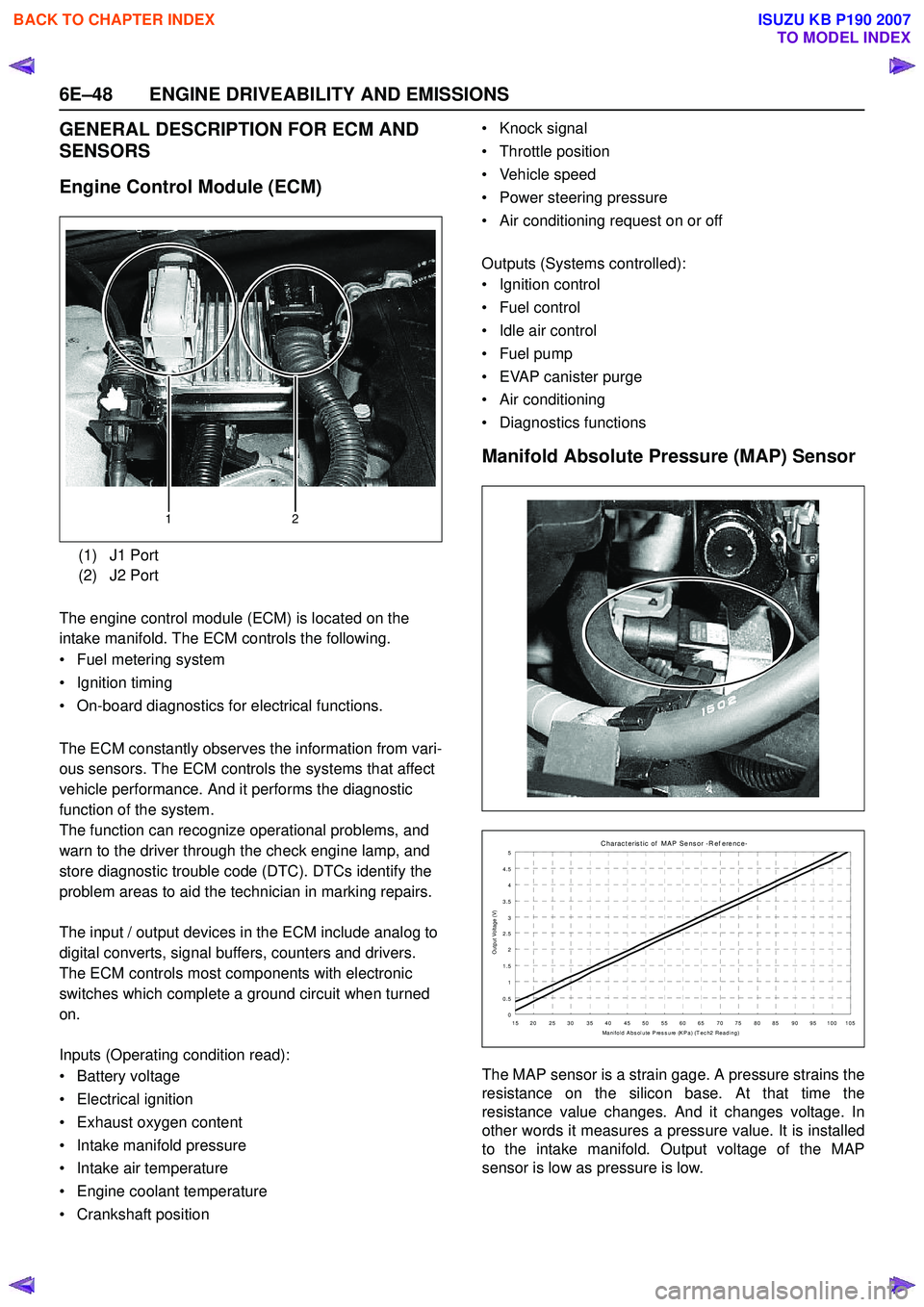

Engine Control Module (ECM)

The engine control module (ECM) is located on the

intake manifold. The ECM controls the following.

• Fuel metering system

• Ignition timing

• On-board diagnostics for electrical functions.

The ECM constantly observes the information from vari-

ous sensors. The ECM controls the systems that affect

vehicle performance. And it performs the diagnostic

function of the system.

The function can recognize operational problems, and

warn to the driver through the check engine lamp, and

store diagnostic trouble code (DTC). DTCs identify the

problem areas to aid the technician in marking repairs.

The input / output devices in the ECM include analog to

digital converts, signal buffers, counters and drivers.

The ECM controls most components with electronic

switches which complete a ground circuit when turned

on.

Inputs (Operating condition read):

• Battery voltage

• Electrical ignition

• Exhaust oxygen content

• Intake manifold pressure

• Intake air temperature

• Engine coolant temperature

• Crankshaft position • Knock signal

• Throttle position

• Vehicle speed

• Power steering pressure

• Air conditioning request on or off

Outputs (Systems controlled):

• Ignition control

• Fuel control

• Idle air control

• Fuel pump

• EVAP canister purge

• Air conditioning

• Diagnostics functions

Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is a strain gage. A pressure strains the

resistance on the silicon base. At that time the

resistance value changes. And it changes voltage. In

other words it measures a pressure value. It is installed

to the intake manifold. Output voltage of the MAP

sensor is low as pressure is low.

(1) J1 Port

(2) J2 Port

12

C harac t eris t ic of MAP Sens or -R ef erenc e-

0

0.5 1

1.5 2

2.5

3

3.5 4

4.5 5

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 Manifold Abs olute Press ure (KPa) (T ec h2 Reading)

Output Voltage (V)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2219 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–49

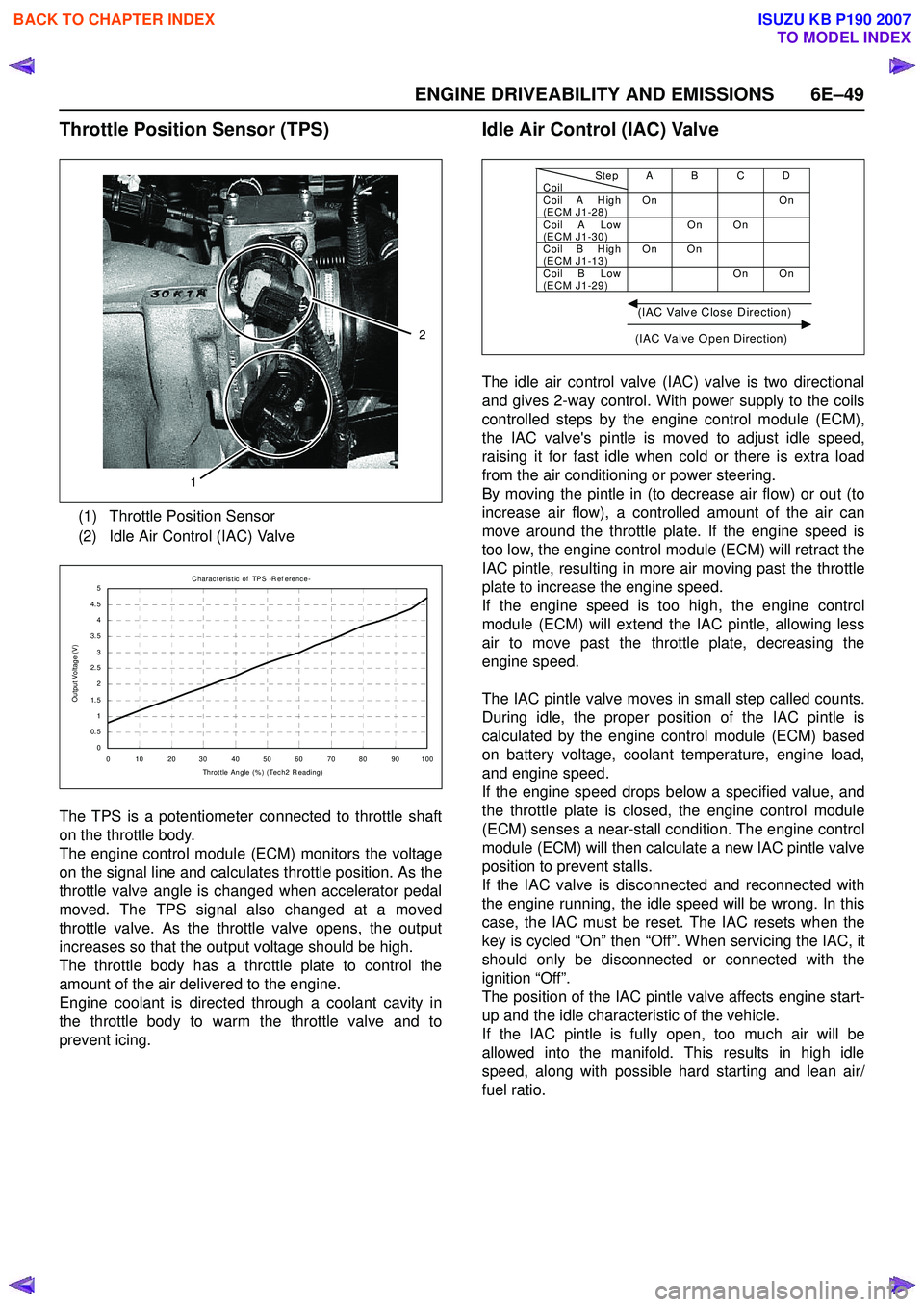

Throttle Position Sensor (TPS)

The TPS is a potentiometer connected to throttle shaft

on the throttle body.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position. As the

throttle valve angle is changed when accelerator pedal

moved. The TPS signal also changed at a moved

throttle valve. As the throttle valve opens, the output

increases so that the output voltage should be high.

The throttle body has a throttle plate to control the

amount of the air delivered to the engine.

Engine coolant is directed through a coolant cavity in

the throttle body to warm the throttle valve and to

prevent icing.

Idle Air Control (IAC) Valve

The idle air control valve (IAC) valve is two directional

and gives 2-way control. With power supply to the coils

controlled steps by the engine control module (ECM),

the IAC valve's pintle is moved to adjust idle speed,

raising it for fast idle when cold or there is extra load

from the air conditioning or power steering.

By moving the pintle in (to decrease air flow) or out (to

increase air flow), a controlled amount of the air can

move around the throttle plate. If the engine speed is

too low, the engine control module (ECM) will retract the

IAC pintle, resulting in more air moving past the throttle

plate to increase the engine speed.

If the engine speed is too high, the engine control

module (ECM) will extend the IAC pintle, allowing less

air to move past the throttle plate, decreasing the

engine speed.

The IAC pintle valve moves in small step called counts.

During idle, the proper position of the IAC pintle is

calculated by the engine control module (ECM) based

on battery voltage, coolant temperature, engine load,

and engine speed.

If the engine speed drops below a specified value, and

the throttle plate is closed, the engine control module

(ECM) senses a near-stall condition. The engine control

module (ECM) will then calculate a new IAC pintle valve

position to prevent stalls.

If the IAC valve is disconnected and reconnected with

the engine running, the idle speed will be wrong. In this

case, the IAC must be reset. The IAC resets when the

key is cycled “On” then “Off”. When servicing the IAC, it

should only be disconnected or connected with the

ignition “Off”.

The position of the IAC pintle valve affects engine start-

up and the idle characteristic of the vehicle.

If the IAC pintle is fully open, too much air will be

allowed into the manifold. This results in high idle

speed, along with possible hard starting and lean air/

fuel ratio.

(1) Throttle Position Sensor

(2) Idle Air Control (IAC) Valve

1

2

C harac teris t ic of TPS -R ef erenc e-

0

0.5

1

1.5 2

2.5

3

3.5 4

4.5 5

0 10 2030 405060 7080 90100 Throt t le Angle (% ) (Tec h2 R eading)

Output Voltage (V)

StepCoilAB CDCoil A H igh

(ECM J1-28) On On

Coil A Low

(ECM J1-30) On On

Coil B H igh

(ECM J1-13) On On

Coil B Low

(ECM J1-29) On On

(IAC Valve Close Direction)

(IAC Valve Open Direction)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2220 of 6020

6E–50 ENGINE DRIVEABILITY AND EMISSIONS

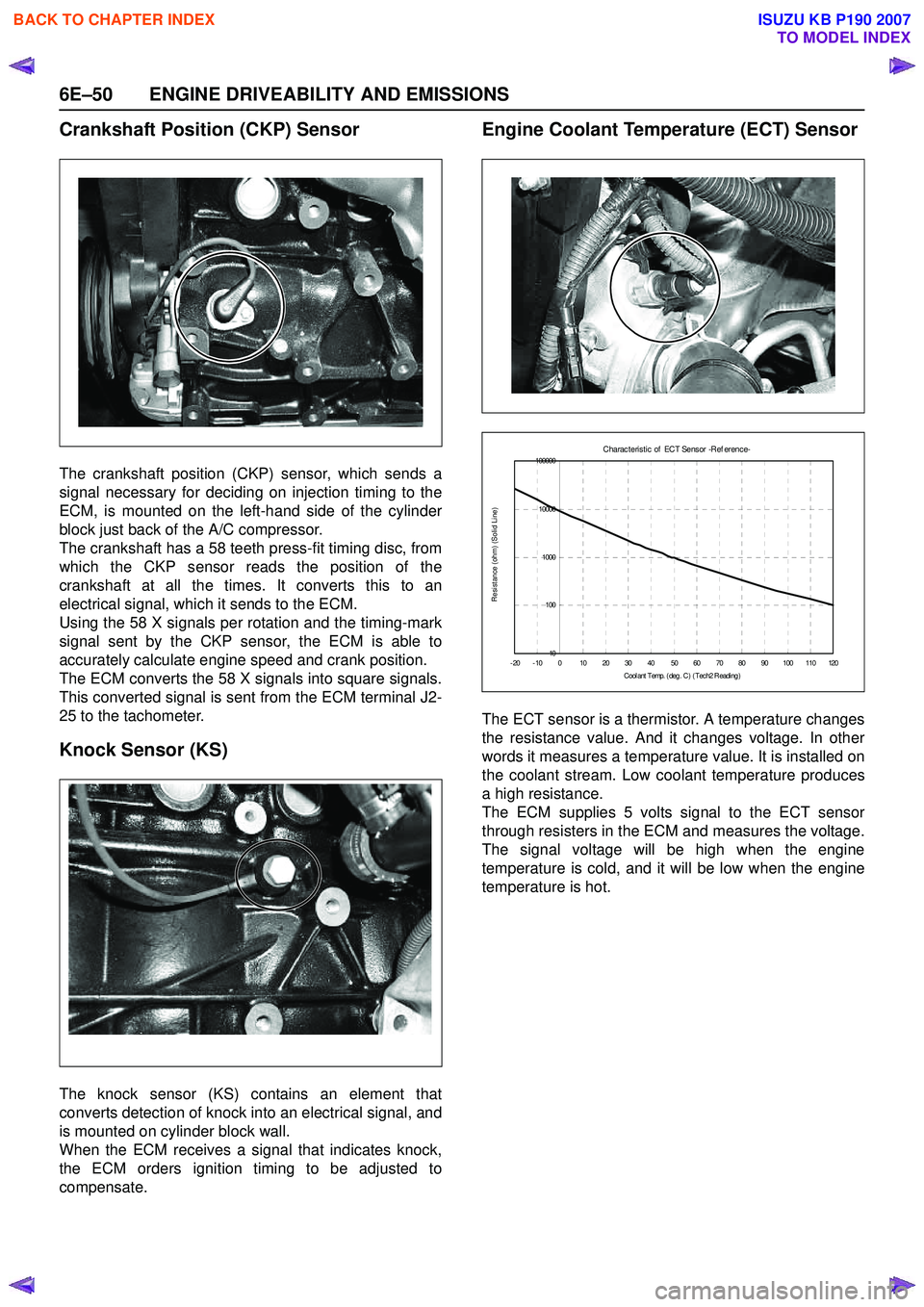

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor, which sends a

signal necessary for deciding on injection timing to the

ECM, is mounted on the left-hand side of the cylinder

block just back of the A/C compressor.

The crankshaft has a 58 teeth press-fit timing disc, from

which the CKP sensor reads the position of the

crankshaft at all the times. It converts this to an

electrical signal, which it sends to the ECM.

Using the 58 X signals per rotation and the timing-mark

signal sent by the CKP sensor, the ECM is able to

accurately calculate engine speed and crank position.

The ECM converts the 58 X signals into square signals.

This converted signal is sent from the ECM terminal J2-

25 to the tachometer.

Knock Sensor (KS)

The knock sensor (KS) contains an element that

converts detection of knock into an electrical signal, and

is mounted on cylinder block wall.

When the ECM receives a signal that indicates knock,

the ECM orders ignition timing to be adjusted to

compensate.

Engine Coolant Temperature (ECT) Sensor

The ECT sensor is a thermistor. A temperature changes

the resistance value. And it changes voltage. In other

words it measures a temperature value. It is installed on

the coolant stream. Low coolant temperature produces

a high resistance.

The ECM supplies 5 volts signal to the ECT sensor

through resisters in the ECM and measures the voltage.

The signal voltage will be high when the engine

temperature is cold, and it will be low when the engine

temperature is hot.

C harac t eris t ic of ECT Sens or -R ef erenc e-

10

100

1000

10000

100000

-20-100 10203040 5060708090100110120 C ool ant T emp. ( deg . C ) ( Tec h2 R eadi ng )

Resistance (ohm) (Solid Line)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007